1. Introduction

Bunkering, the fuel supply to ships, is one of the most important activities in the maritime shipping industry. Although bunkering fuel is sometimes supplied from land-based supply depots or trucks, most bunkering fuel is supplied by bunker barges on a ship-to-ship (STS) basis in the port area [

1]. The timing of bunkering varies depending on the port, type of vessel, and situations, for example, whether the bunker barge is laid alongside on the opposite side of the quay when cargo is loaded or discharged at the quay or anchored together when the vessels are anchored offshore. Moreover, each vessel does not always fill up with a full load of fuel at each port call. A vessel may limit the refueling amount to the minimum necessary in ports with relatively high prices, whereas a vessel may stop over the ports only for refueling. Therefore, competition among neighboring ports to provide better bunkering services is sometimes observed.

In recent years, in response to growing global environmental awareness, the maritime sector has faced replacing fuel oil with other fuels for ships as part of efforts to build a decarbonized society [

2]. In Japan, the large LNG-fueled car carrier SAKURA LEADER was completed in October 2020, and the LNG bunker barge KAGUYA, which is used to supply LNG fuel, has begun operations [

3]. In addition, alternative fuels such as ammonia, hydrogen fuel cells, and carbon-recycled methane are expected to emerge and spread in the future, and the supply methods and systems for each type of fuel are being studied [

4].

Based on the competitive situation among ports in bunkering, the bunkering strategy of each port should be considered in the context of a global bunkering network with the service level of each port. Since bunkering demand is low in the early stages of the prevalence of new fuels, it is essential to consider the situation of other ports. However, at present, few statistics or pieces of literature comprehensively organize the actual situation of bunkering in each port, making it difficult to compare the bunkering service level among ports.

Although some studies on bunkering, such as comparisons of port competitiveness and the determinants of competitiveness, take qualitative approaches based on questionnaire surveys, few quantitative analyses have been conducted mainly because of the difficulty of collecting data, as will be described in

Section 2. Therefore, this study uses a vessel’s automatic identification system (AIS) data for quantitatively evaluating vessel movements, including bunkering. This study aims to develop an algorithm to extract bunkering operations based on AIS data and to understand and compare the characteristics of bunkering operations, such as distributions of bunkering service times and starting times of bunkering operations by size and type of bunkered vessels and bunker barges in several Asian port areas (Tokyo Bay, Busan Port, and Singapore Port) and their differences, including locations and number of bunkering during refueling.

The remainder of this paper is organized as follows.

Section 2 summarizes the literature review and positions this study.

Section 3 states the data used in this study, and

Section 4 describes the methodology and algorithm used to extract bunkering operations and validates them.

Section 5 shows the characteristics of bunkering operations in three port areas and discusses their difference by size and type of bunkered vessels. A summary of the study is presented in

Section 6.

2. Literature Review

Most studies on bunkering operations have taken a qualitative approach, and few have taken a quantitative approach. Acosta et al. [

5] analyzed the factors determining the competitiveness of bunkering in each port in the Strait of Gibraltar from the port operator’s perspective. They found that fuel prices and geographic advantage were the two main factors influencing shipping companies’ choice of bunkering port, followed by cost and service quality, such as port tariffs and waiting times. Aronietis et al. [

6] interviewed shipping companies in the port of Antwerp to investigate the decision-making factors in bunkering port selection. They concluded that cost, including fuel prices, was the main factor, while the quantity and quality of fuel and service reliability were also important. Lam et al. [

7] developed a framework and methodology for assessing the competitiveness of ports as bunkering hubs and conducted empirical studies on Singapore and Shanghai Ports. Yao et al. [

8] proposed an optimization model that determines the optimal bunkering port, bunkering volume, and ship speed to minimize the total bunker fuel-related costs for a single liner service. Wang et al. [

9] used the Fuzzy Delphi–TOPSIS procedure to develop a benchmarking framework for liner shipping companies to evaluate the performance of bunkering ports. Ghosh et al. [

10] developed a dynamic programming model of bunkering decisions for a liner service to minimize total bunkering cost with uncertainty on fuel consumption using Monte Carlo simulation, and Aydin et al. [

11] also proposed a dynamic programming model to optimize the vessel speed, bunkering ports, and bunkering amounts of a liner service with uncertain service times and time windows at ports. De et al. [

12] focused on the problem of bunker fuel management for liner shipping networks under different fuel pricing scenarios with mixed integer non-linear programming to minimize the total expected cost, considering the fluctuation of fuel prices at various ports. Meanwhile, Meng et al. [

13] dealt with a practical tramp ship routing problem to maximize the total profit with different bunker prices at different ports using an integer linear programming model.

Regarding LNG bunkering, Peng et al. [

14] summarized the research on port LNG bunkering stations, including fuel demand forecast, bunkering method selection, and LNG bunkering network planning. For example, Tam [

15] studied the compatibility of shore-to-ship and STS operations for LNG bunkering and showed bunker barge specifications and operational requirements to ensure compatibility of the two approaches. Chae et al. [

16] forecasted the LNG bunkering demand by country with meta-analysis and several machine learning techniques, while Kim et al. [

17] and Ha et al. [

18] examined the decision-making factors for LNG bunkering selection and found that safety and security issues, bunkering prices, port service charges, and vessel turnaround time were the main factors, as with heavy oil. Aymelek et al. [

19] proposed an optimal liner shipping network model considering the bunkering of LNG fuel, and Ursavas et al. [

20] proposed a Lagrangian relaxation heuristic algorithm on LNG bunkering network design and applied it to the West European river network. Liu et al. [

21] proposed a heuristic algorithm for solving the LNG bunkering problem, including decisions to assign ships to tanks, manage the inventory of the tanks, and schedule LNG trucks for bunkering ships and replenishing tanks. Moreover, Yang and Lam [

22] developed a simulation model of the bunker supply chain and evaluated the impact of ammonia bunkering, another alternative fuel other than LNG.

Meanwhile, AIS data allow for quantitative analysis of vessel behavior [

23,

24,

25]. Mou et al. [

26] conducted a quantitative analysis of vessels involved in collisions using AIS data for the Port of Rotterdam. Dobrkovic et al. [

27] showed how to apply a genetic algorithm to clustering ship waypoints and used it to create a directed graph representing maritime routes. Zhang et al. [

28] presented an analytical approach based on AIS data to analyze vessel traffic demand and the spatio-temporal dynamics of vessel traffic in port waters for Singapore Port. Nguyen et al. [

29] introduced a deep learning framework for detecting anomalous vessel behavior using AIS data. Han et al. [

30] proposed a clustering method for AIS data by combining DBSCAN with the Mahalabinos distance metric. Murray and Perera [

31] introduced a deep learning framework that uses AIS data to support regional vessel behavior prediction. Liu et al. [

32] proposed a framework for extracting global maritime shipping traffic networks using AIS data based on DBSCAN.

Regarding an algorithm for extracting bunkering operations based on AIS data, Aarsnes [

33] proposed a method based on certainty assessment using vessel length and heading. Fuentes [

34] proposed a method for identifying ship anchoring patterns and extracting bunkering operations using the DBSCAN algorithm. In his method, the trajectory of anchored vessels was extracted using DBSCAN, and if a tanker stayed continuously around the trajectory, it was recognized as a rendezvous for bunkering. These studies used only the proximity of the bunker barge to the vessel as a criterion and did not reflect the navigation history of the bunker barge, leaving much for improvement in computational complexity and accuracy. In addition, Market Intelligence Network (MINT) [

35], an AIS data service provided by S&P Global, lists bunkering activities based on AIS data. MINT has its own list of bunker barges and detects bunkering operations if the high proximity of a barge in the list to another vessel is observed; however, it does not cover bunkering at quays, and its algorithm is unclear. Therefore, this study aims to develop a more sophisticated bunkering operation extraction algorithm that considers the behavior of bunker barges. Specifically, the proposed method uses AIS data to extract characteristic behaviors of bunkering vessels, such as refueling at refineries and anchoring at bases, filters the data accordingly, and uses a combination of Aarsnes’s [

33] and Fuentes’s [

34] methods to extract bunkering operations.

4. Methods

4.1. Bunkering Operation and Estimation Framework

In a bunkering operation, the shipowner or shipping company orders a bunkering supplier, specifying the type and quantity of fuel. Once the contract for an STS bunkering is signed and a time and location for bunkering are specified, the vessel to be bunkered usually anchors and waits for the bunker barge. During the operation, the vessels are secured to each other with ropes, and oil is pumped using hoses. Bunkering is operated with great care to prevent oil leakage at sea. Since the performance of fuel tanks of a bunkered vessel limits the speed and pressure at which oil can be delivered, a bunker barge does not necessarily speed up the operation for its high performance. After the operation, the client signs a document indicating that the operation has been conducted under an agreement, and the bunker barge leaves.

Bunker barges must also be preloaded with sufficient fuel to supply the operation by refueling at the refinery. In Tokyo Bay, for example, bunker barges are generally refueled at refineries in Chiba, Kawasaki, Yokohama, and other cities the day before operations, dock at night at their bases, and move to the bunker barges the next morning to supply fuel.

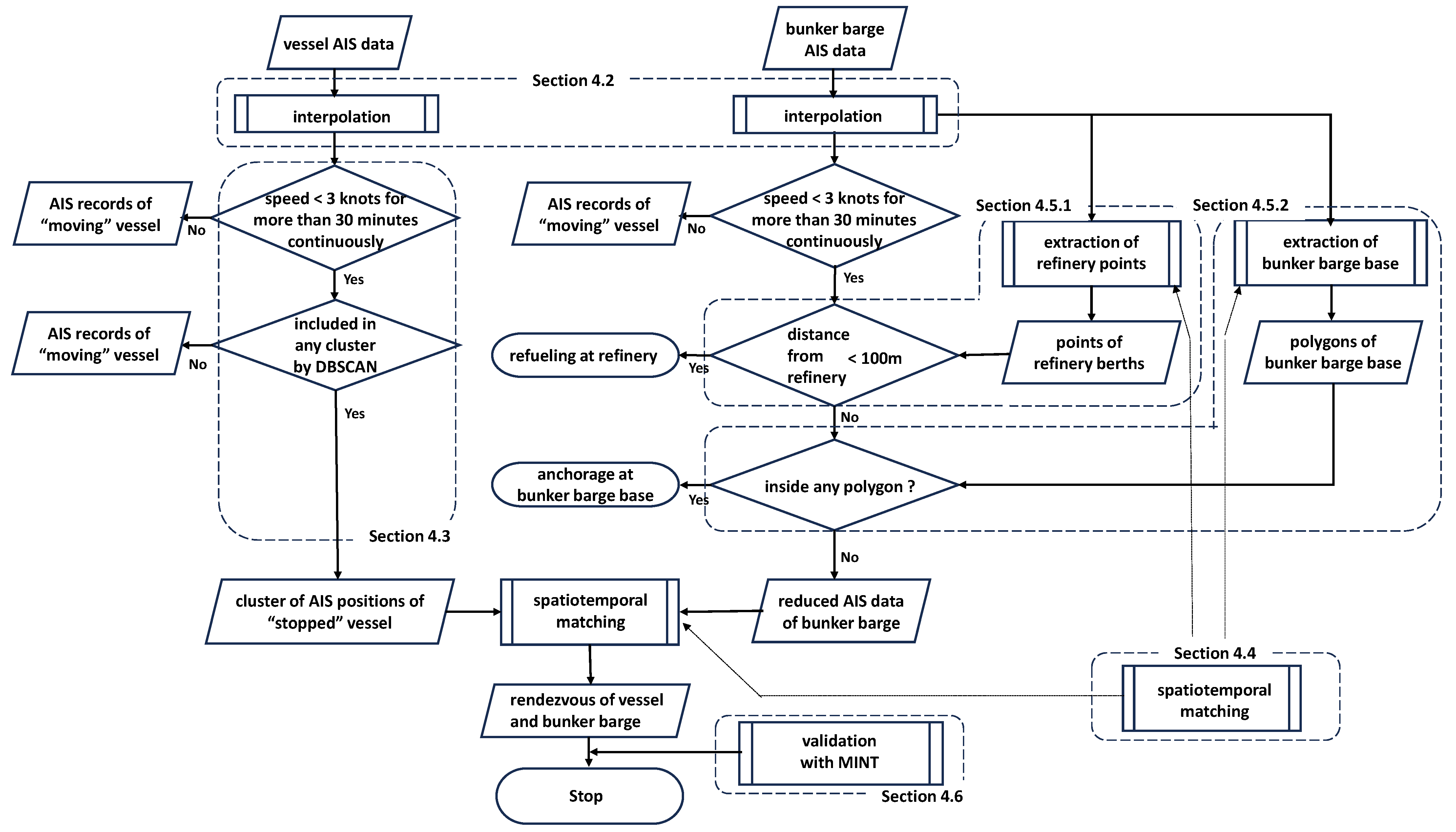

Based on such bunkering operation flow, this study develops a bunkering operation extraction algorithm that considers the behavior of bunker barges, as shown in

Figure 2. The basic concept of bunkering operation extraction in this study is to detect rendezvous between bunker barges and anchored vessels by estimating the proximity of both vessels from the time stamps and latitude/longitude information in the AIS data. However, the vessels listed in bunker barges are also included in the anchored vessels to be refueled because they may be engaged in transporting liquid cargo, as mentioned in

Section 3.2. In other words, two vessels listed in bunker barges may sometimes match each other. Therefore, after interpolating AIS data in

Section 4.2, while anchored vessels are extracted using a clustering method (

Section 4.3), the behavior of bunker barges is reflected in the data based on the history of port calls to refineries and bunker bases (

Section 4.5). Finally, we match bunker barges with bunkered vessels spatio-temporally (

Section 4.4).

4.2. Interpolating AIS Data

Although AIS data contain information such as latitude/longitude and ship speed at each time stamp, the time interval is not always uniform. The larger the interval, the more difficult it would be to obtain sufficient information on vessel movements. Therefore, data interpolation is necessary to obtain reliable results in our algorithm to spatio-temporally match the trajectories of bunker barges and anchored vessels during operations.

This study uses linear interpolation for latitude and longitude information of AIS data, as with several previous studies [

28,

37], with time intervals between 10 min and 2 h so that the data interval becomes within 5 min, based on the assumption that the distance traveled by vessels during bunkering operations is small. Notably, if a data interval is over 2 h, we remove it as discontinuous, unreliable data. In addition, vessel speed is also interpolated based on the distance traveled.

Specifically, the latitude

, longitude

, and ship speed

at time

are interpolated as described in Equations (1)–(3).

where

is the distance traveled by the vessel from time

to

In addition, AIS data, in which the ship’s speed in the target water areas is less than 3 knots for more than 30 consecutive minutes, are extracted to reduce the computational complexity.

4.3. Extracting Anchored Vessels

In extracting bunkering operations, only AIS data that satisfy the speed and trajectory suitable for bunkering for both bunker barges and bunkered vessels should be examined. However, the speed over ground in the AIS data is not always zero when the vessel stops; in particular, a vessel may move to some extent under the influence of wind and currents in operations in offshore bunkering.

To consider these conditions and reduce the computational complexity of the matching algorithm, a density-based spatial clustering of applications with noise (DBSCAN) is used to extract the anchored vessels’ data based on the location information. The DBSCAN parameter ϵ is defined in Equation (4) based on Fuentes [

34], allowing for some movement of anchored vessels. This equation assumes that the distance traveled in a short time can be approximated based on the Euclidean distance calculated from the latitude and longitude.

The movement of up to 200 m in 10 min is caused by external forces such as wind and currents; thus, the conditions for forming clusters are set as

(equivalent to 200 m) and

[

34].

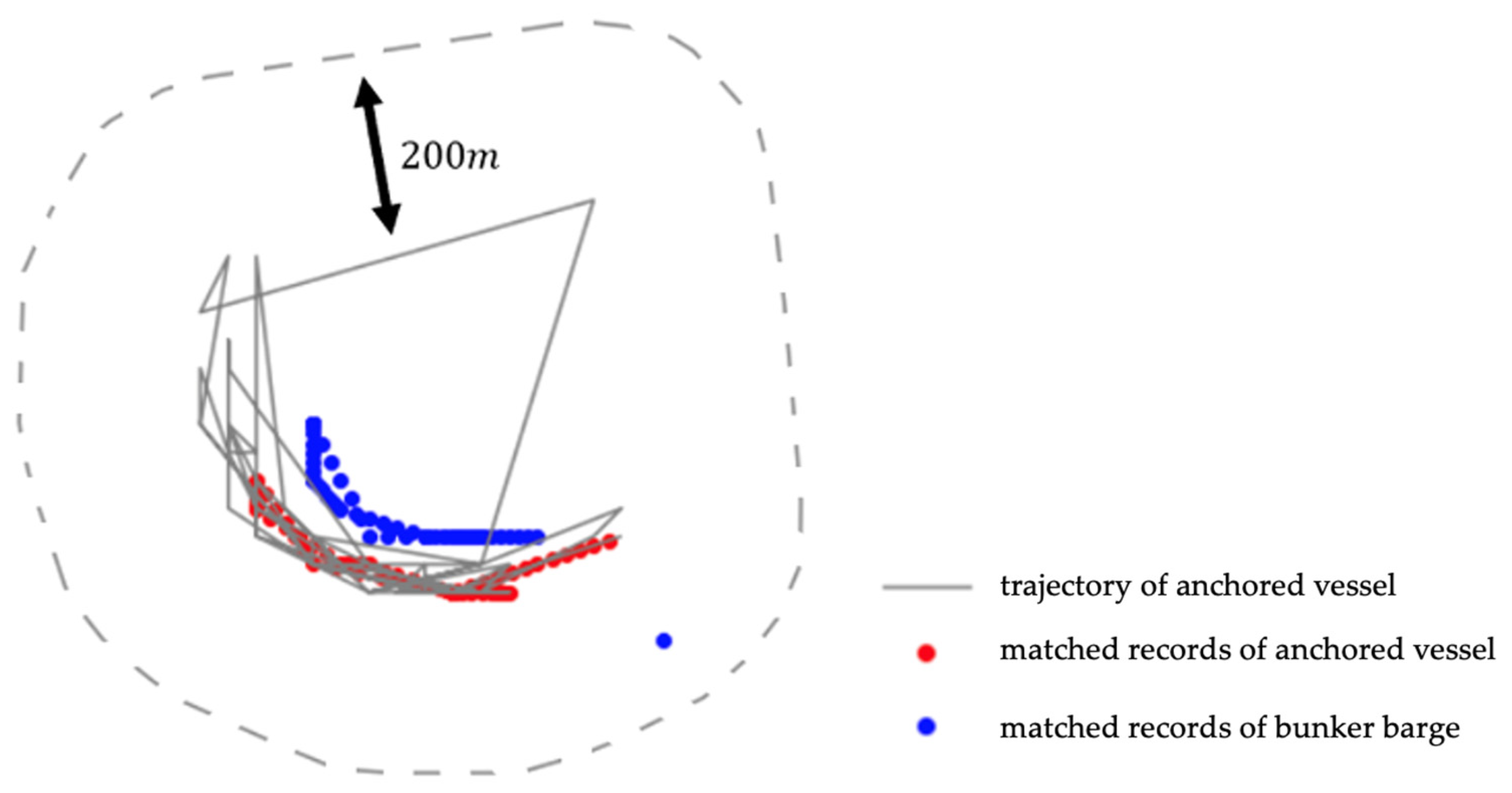

4.4. Spatio-Temporal Matching of Anchored Vessels and Bunker Barges

The anchored vessels extracted as described in

Section 4.3 and bunker barges are matched spatio-temporally to detect rendezvousing vessels, as shown in

Figure 3. Notably, this method considers bunkering with multiple bunker barges attached to one bunkered vessel because such operations are sometimes observed, especially in refueling with large quantities. The procedure is as follows.

- (1)

Create a trajectory of the anchored vessel.

- (2)

Extract bunker barges located within 200 m of the above trajectory according to the start and end times of anchored vessels. In addition, to avoid detecting bunker barges that simply cross the trajectory and pass by, we impose a condition that the bunker barges should remain within the area for at least 30 min.

- (3)

Match the coordinates of each anchored vessel with the coordinates of each bunker barge in space and time. The data of bunker barges whose differences in time stamps are within 10 min of each anchored vessel’s coordinates and whose distance is less than 150 m are extracted.

The larger the vessel, the larger the distance between the rendezvousing vessels, whose locations are represented by the AIS antenna equipped in each vessel, because each vessel carries it in a different position. Moreover, GPS errors may sometimes occur. However, the larger the vessel distance threshold for detecting a rendezvous, the more likely a bunker barge will be matched with unrelated anchored vessels, especially in a crowded port such as Singapore. Thus, this study set 150 m as the threshold of the rendezvous at distances between vessels in bunkering operations. Although we adopt the same threshold (150 m) in all ports for consistency, a detailed determination of the optimum threshold or other detailed considerations, such as the directions between vessels [

33], is one of the future issues.

4.5. Considering Bunker Barges’ Behavior

As mentioned in

Section 4.1, bunker barges stop not only during bunkering but also during refueling and at their base. Meanwhile, multiple barges are considered to anchor in the refueling area and at their base, and they are also matched by the method presented in

Section 4.4. Thus, the following data processing must be additionally conducted to distinguish between bunkering and other operations.

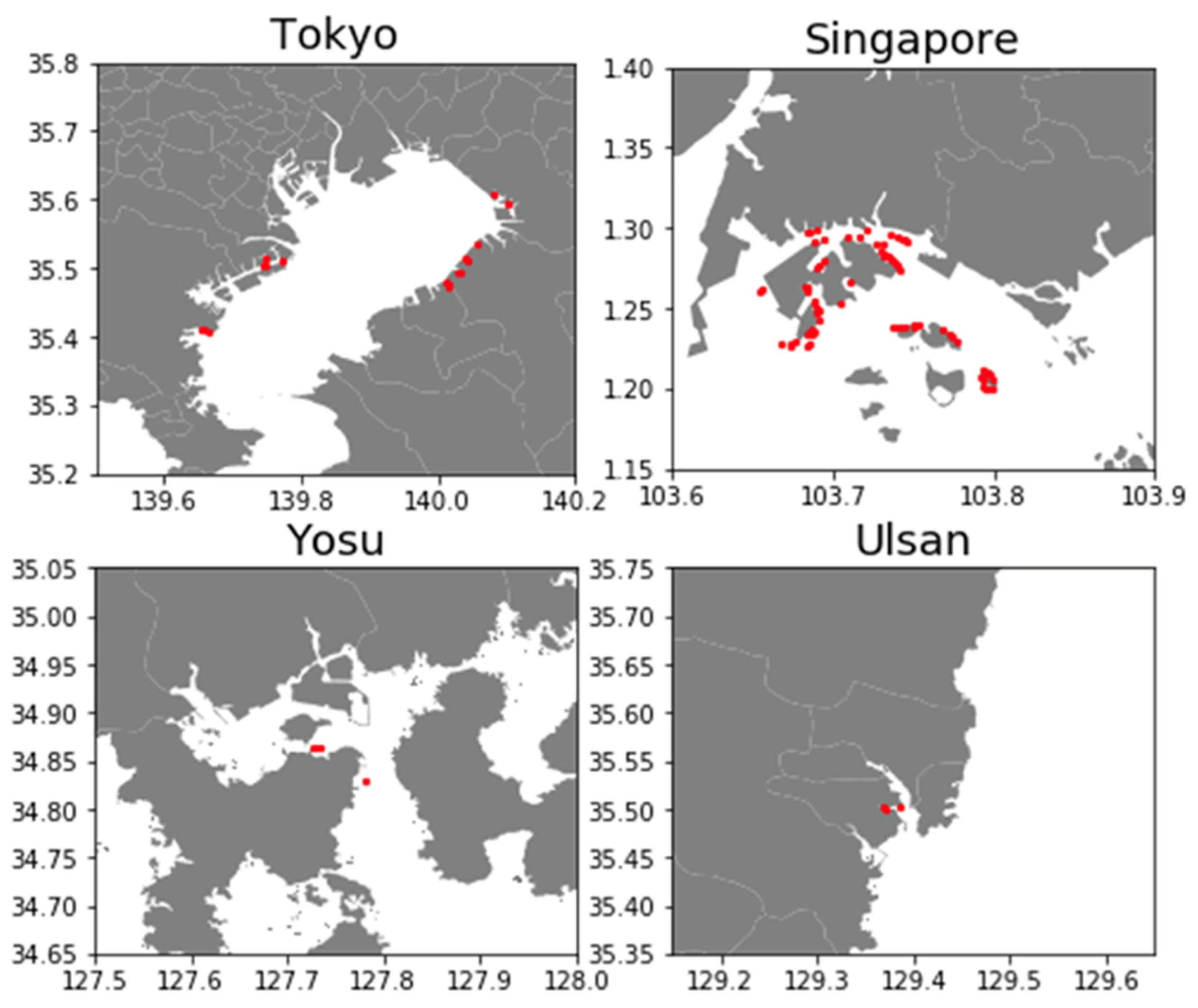

4.5.1. Refueling at Refineries

As mentioned in

Section 4.1, refueling at refineries is a typical activity other than bunkering for bunker barges. This study focuses on changes in the draft of barges to identify the anchorage points instead of individually investigating the location of refineries and refueling berths and obtaining their coordinates. The refinery locations are efficiently identified by specifying the points where the draft of bunker barges has increased according to the following steps.

- (1)

Considering that refueling to the bunker barge is performed while the bunker barge is at anchor, the location data for the vessels whose draft has increased compared to the previous time are extracted.

- (2)

The location data acquired in the previous step are clustered by applying DBSCAN with є = 0.009 (equivalent to 100 m) and minPts = 1.

- (3)

The center of gravity (average of latitude and longitude) of the points included in each cluster is used as the representative point. These points are confirmed with satellite images whether or not they are refueling berths at the refineries.

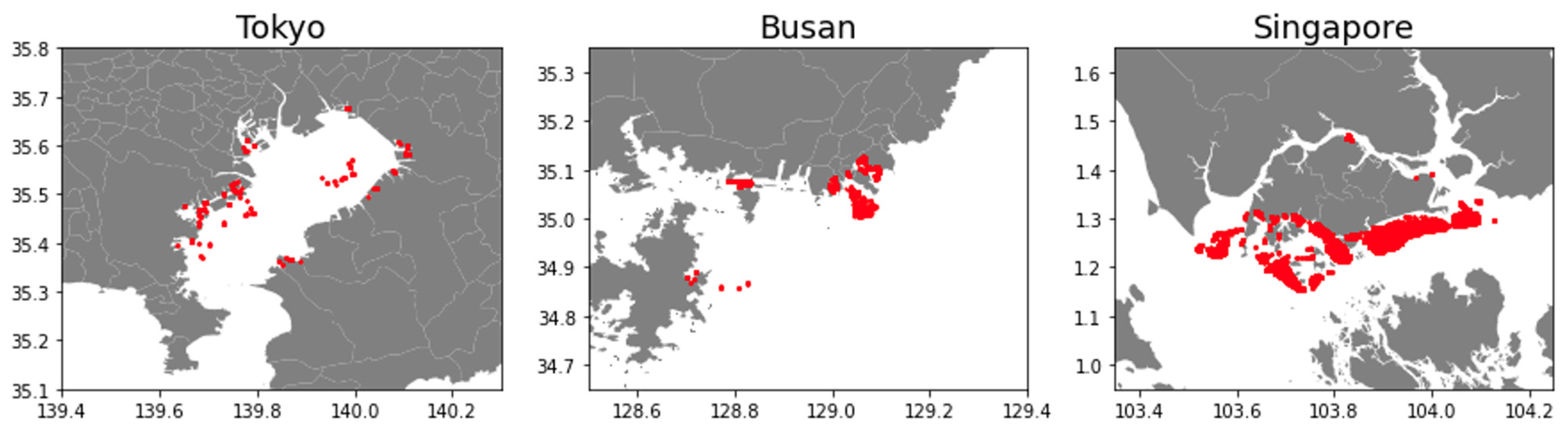

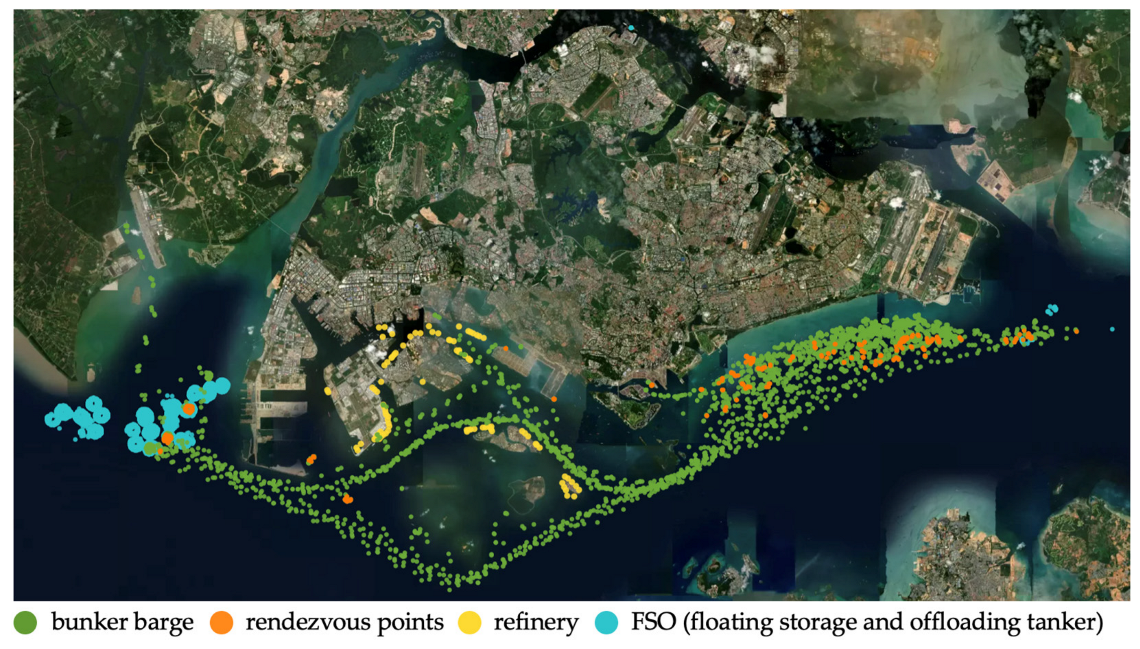

Figure 4 shows the possible refinery berths in the three water areas (Tokyo Bay, Busan Port, and Singapore Port). Since no refineries are found in the Busan Port area, refineries in the nearby ports of Yeosu and Ulsan are extracted based on the bunker barge activity range.

As described above, we assume bunker barges stay within a radius of 100 m from each berth to be refueling activities at the refineries. In matching anchored vessels and bunker barges described in

Section 4.4, data matched in the vicinity of the refinery are removed because the two bunker barges might be individually refueled there.

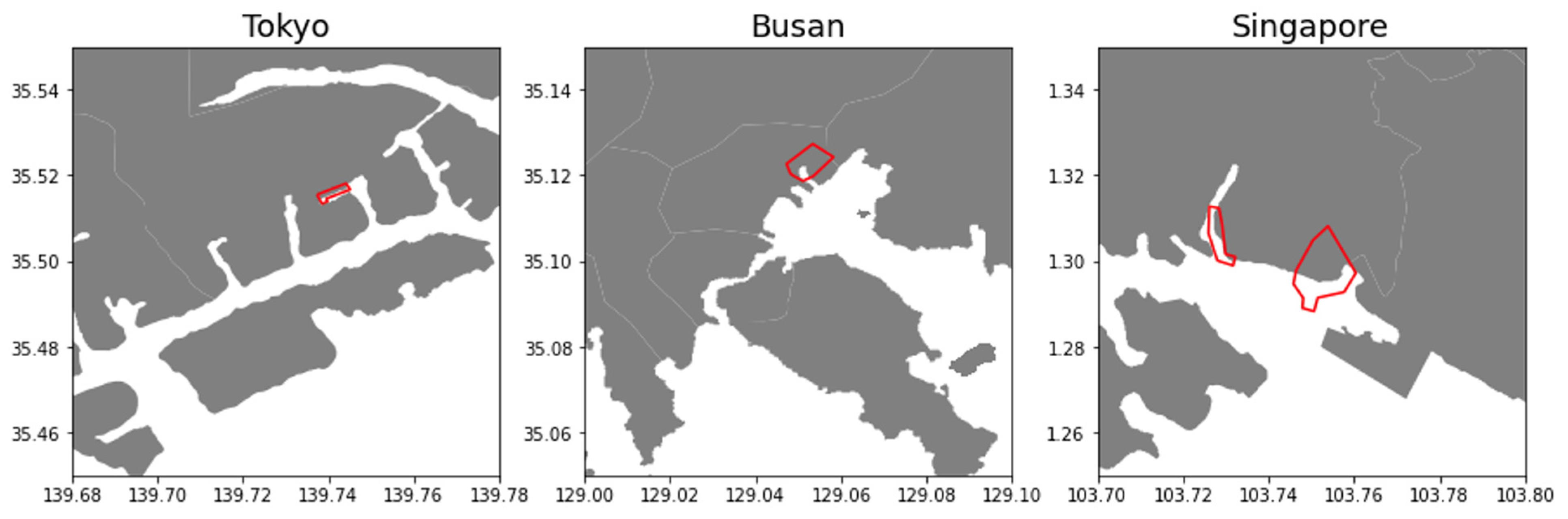

4.5.2. Anchorage at the Bunker Barge Base

Since bunker barges sometimes berth at their bases, as with oil refineries, vessels berthing at the base may be matched as rendezvous because of their proximity. By observing the obtained coordinates where bunker barges are matched using the matching method described in

Section 4.4 with satellite images, the locations of the bunker barge bases are identified, as shown in

Figure 5. The matching data in these bases are removed from bunkering operation points.

In addition, anchored vessels that are matched with bunker barges more than ten times during the period are excluded from the analysis because these vessels are considered rendezvous for other purposes (see

Section 5.5).

4.6. Validation of the Proposed Method

The estimated matching points for bunker barges are shown in

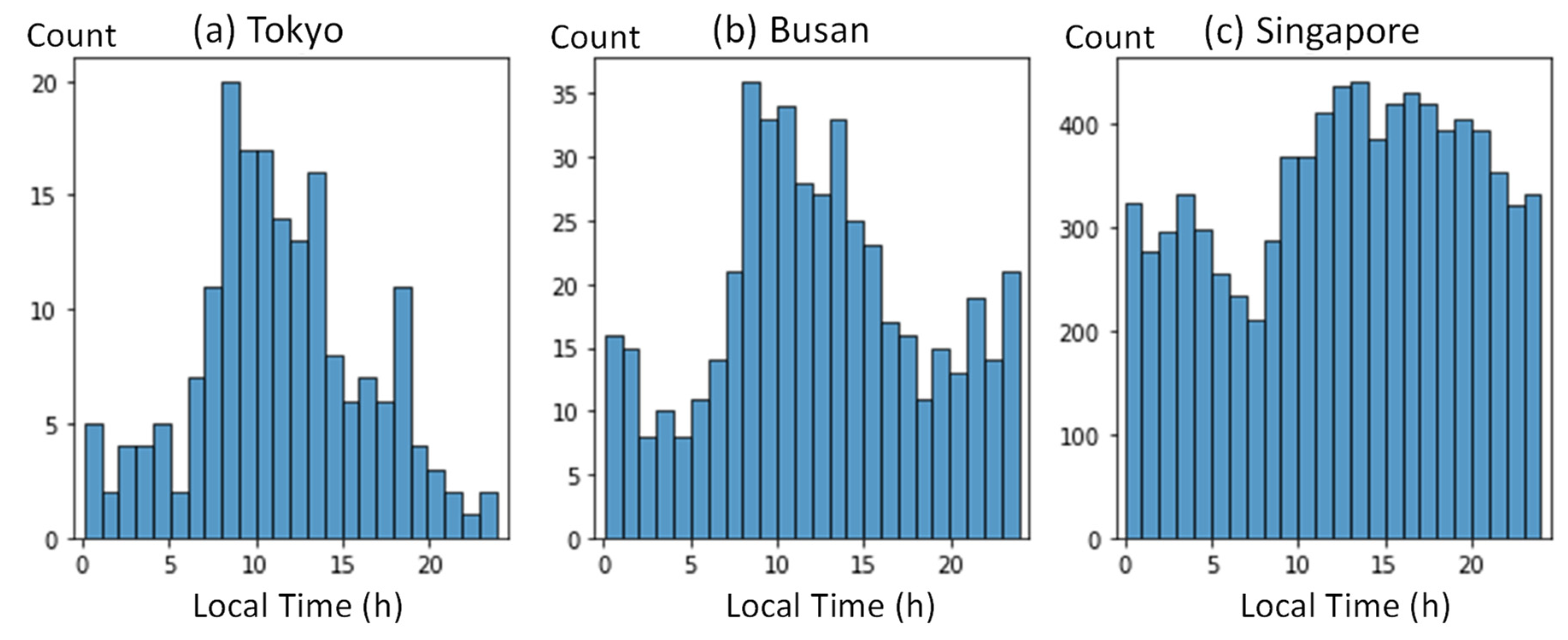

Figure 6. In Tokyo Bay, most bunkering operations occur at quays, while offshore operations are limited to two major areas. Many bunkering operations at quays also characterize Busan Port, and offshore operations are limited to the south of the port. In Singapore Port, operations are observed regardless of offshore anchorage or quay.

As described in

Section 2, limited pieces of literature comprehensively summarize the actual bunkering operation in each area.

Table 2 compares the estimated results of this study and the bunkering information provided by MINT. The table shows that our method extracted more operations in Tokyo Bay and Busan Port than MINT. By contrast, MINT extracted more than twice as many operations as our method in Singapore Port. This result is discussed in the following two cases.

- (1)

Operations listed in MINT but not extracted by this method:

One reason our method cannot extract the operations is that MINT uses more detailed AIS data to estimate bunkering, whereas the AIS data used in this study are interpolated from data that had been processed to some extent by the data providers. This raises the possibility that there are not sufficient data for matching.

On the other hand, the MINT estimation may also contain some errors. For example, among the bunkering operations listed by MINT, we found that bunker barge speeds in some records were more than 10 knots, which were likely to be misestimated, at least concerning the timing of bunkering.

- (2)

Operations not listed in MINT but extracted by this method:

Although this study includes rendezvous at the quay in the extraction, they were not included in MINT. Therefore, the number of bunkering operations for containerships, which tend to be bunkered at the quay, may be particularly underestimated in MINT. This is why the number of bunkering operations extracted by our method is much larger in Busan Port. For example, our method observed many bunkering activities at quays in the New Busan Port area, while MINT extracted only one.

6. Conclusions

This paper developed an algorithm to extract rendezvous between bunker barges and other vessels using AIS data. Specifically, anchored vessels were first extracted, and the distance between the coordinates of the anchored vessel and bunker barges was calculated for spatio-temporal matching. By using DBSCAN to extract anchored vessels, vessels drifting during rendezvous, not only stopped vessels, can be extracted. In addition, by considering the matching at the refinery and bunker barge base, the stopping of bunker barges around these places can be subtracted from potential bunker points. Compared with the bunkering information provided by MINT, the accuracy of the extraction results was found to depend on the granularity of AIS data. Meanwhile, our algorithm can detect many operations at quays that MINT does not cover.

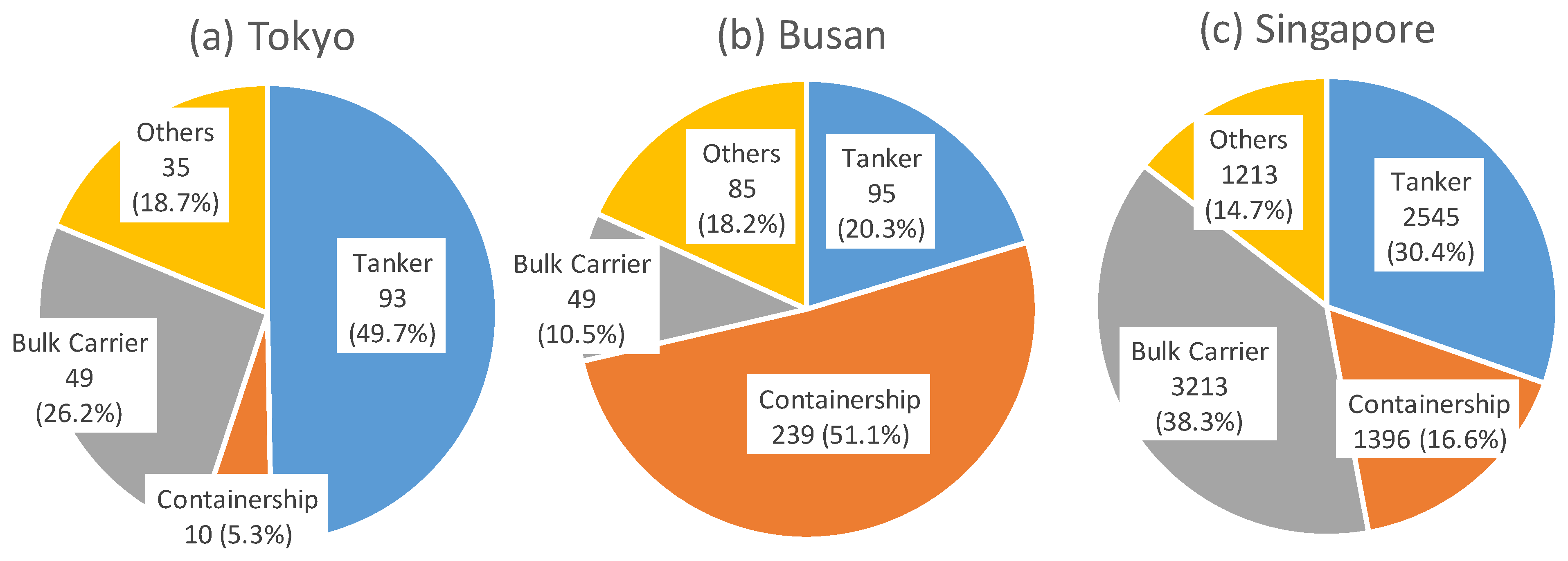

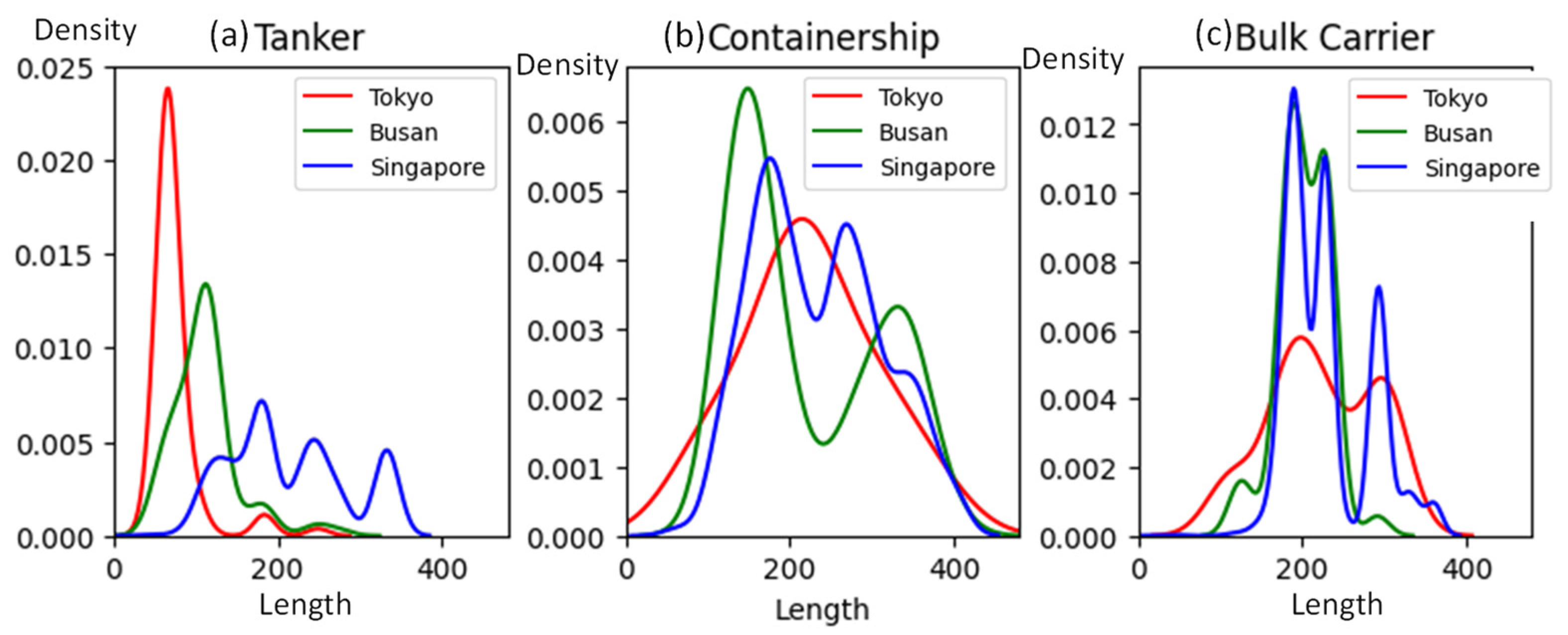

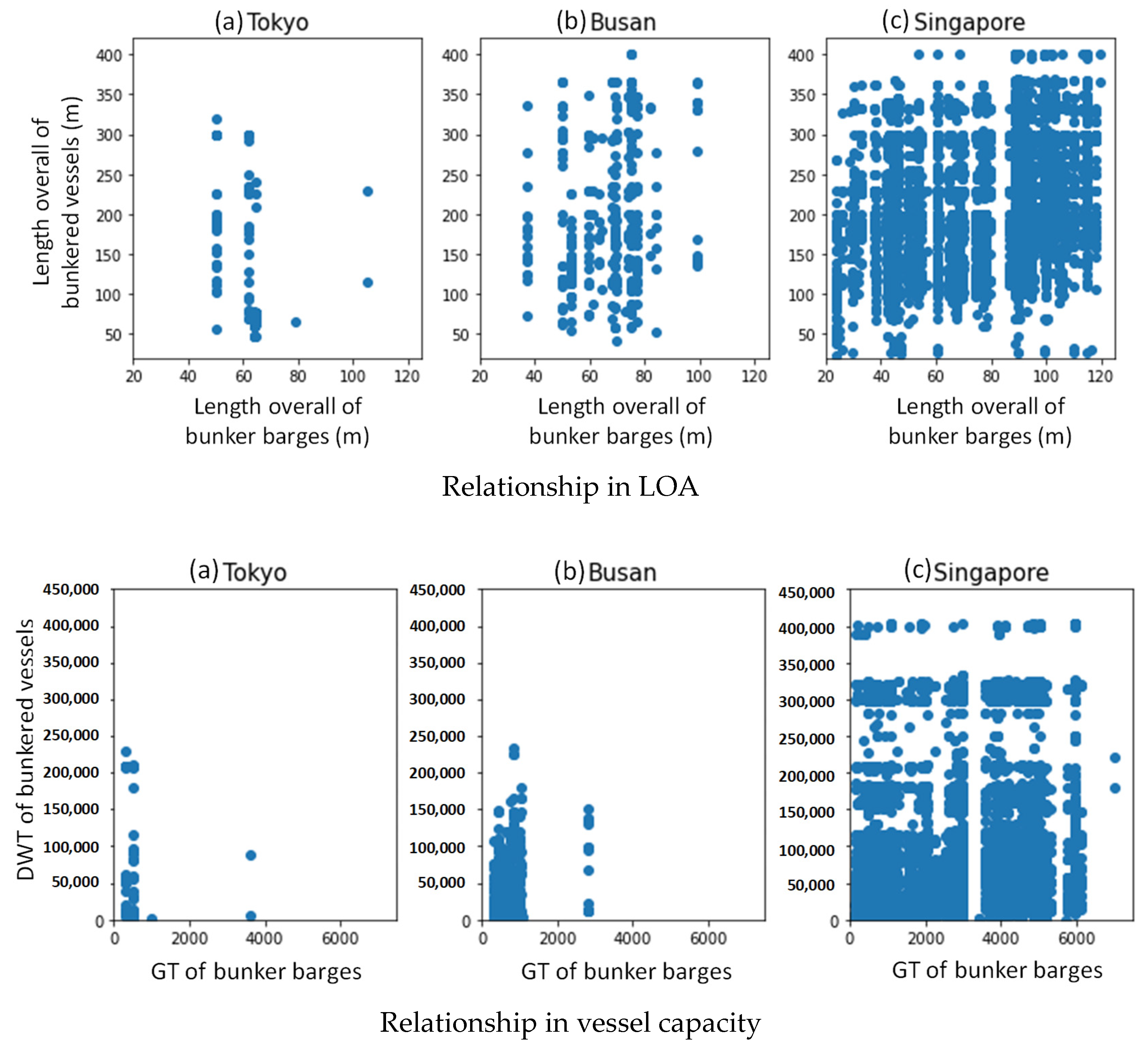

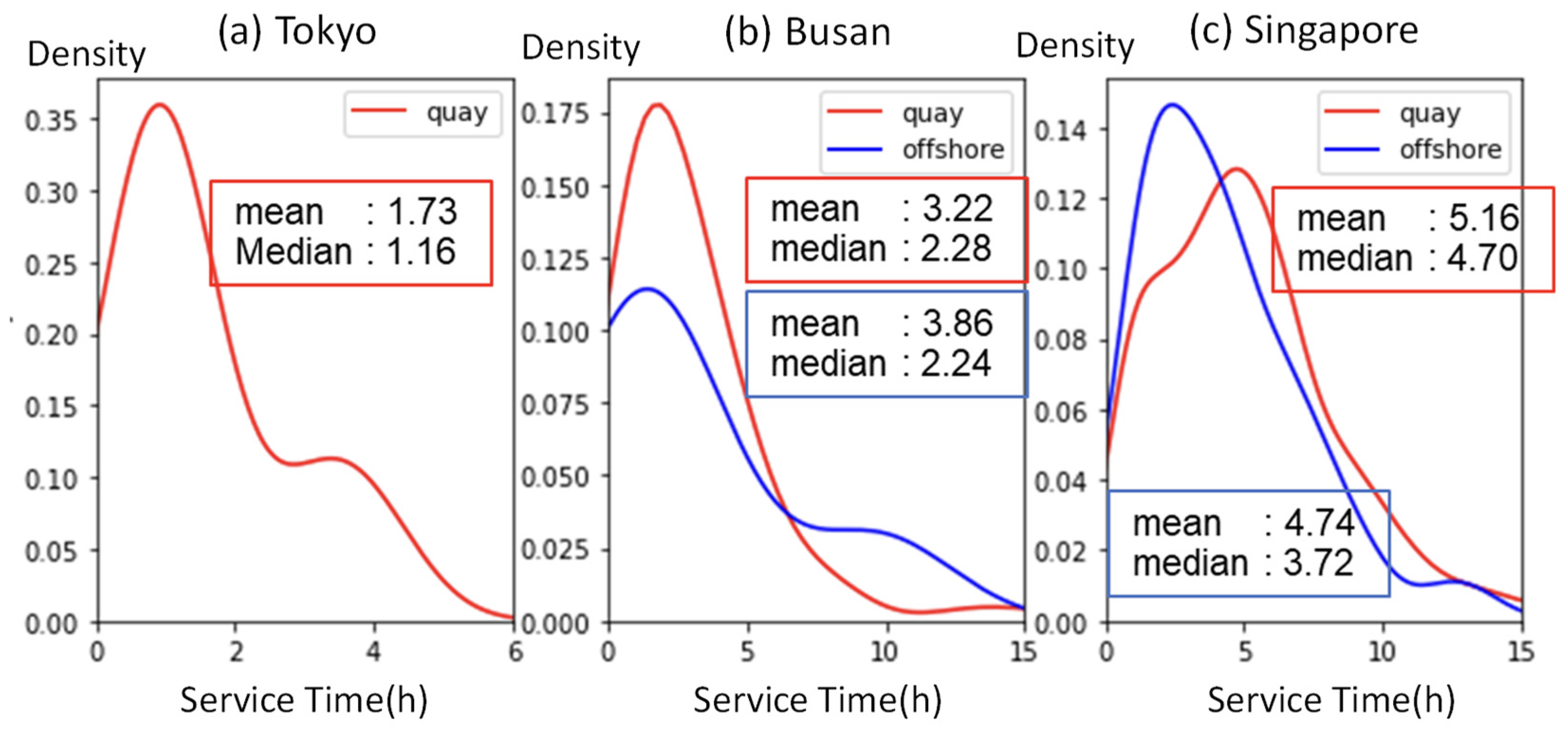

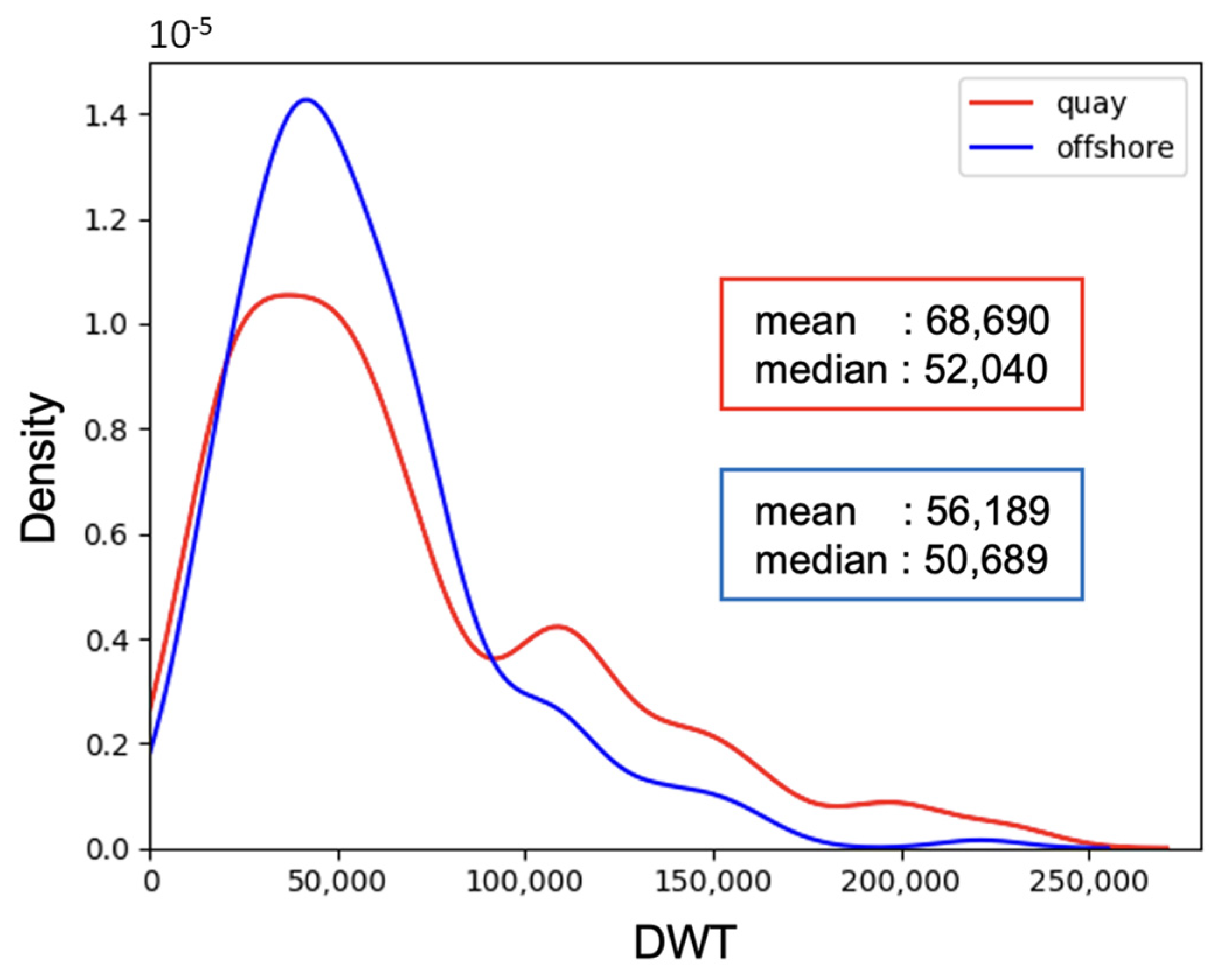

Subsequently, based on the estimated bunkering service data, we examined the characteristics and differences in bunkering service times and starting times of bunkering operations by size and type of bunkered vessels in Tokyo Bay, Busan Port, and Singapore Port. The main findings were as follows. First, the composition of vessel types to be bunkered and the service times of bunkering operations differed among the three port areas. In Tokyo Bay, in particular, service times were shorter for containerships and bulk carriers than the other two ports, suggesting lower order volumes of fuel due to its high prices. Second, no correlation between the size of bunker barges and bunkered vessels was found in all ports, whereas there was a positive correlation between the size of the containerships and the bunkering service times in Singapore Port. Third, regarding the start time of bunkering, most bunkering services started during the daytime in Tokyo Bay, whereas operations in Singapore Port more equally started throughout the day. Fourth, regarding bunkering locations of containerships, most bunkering operations took place at the container terminals in Tokyo Bay and Busan Port, whereas it was common for operations offshore in Singapore Port. This result indicates that most containerships are bunkered at quays while providing their liner service, whereas some containerships are bunkered while anchoring offshore in Singapore Port. Lastly, the number of times bunker barges rendezvoused with other vessels for a single refueling varied by port. This result implies that in the areas where a bunker barge is usually refueled at the refinery for each bunkering operation, such as Tokyo Bay, the accuracy of determining whether a rendezvous is for bunkering or not can be improved from the behavior pattern of bunker barges acquired from AIS data. However, for ports such as Busan and Singapore, where bunkering is performed multiple times per refueling, it is more difficult to determine the purpose of rendezvous.

In summary, this study reveals the reality of bunkering, which varies by port because of the differences in market conditions, such as the frequency of bunkering opportunities, bunker prices, and regulations. As a result, similar to Fuentes’s [

34] analysis of Mediterranean ports, this study confirms that service time and bunkering locations (quaysides or offshore) vary depending on ports. In addition, the bunkering service times obtained in this study are, even in Singapore Port, overall shorter than those in Fuentes [

34] because we estimate the rendezvous between bunker barges and bunkered vessels more strictly by spatio-temporally matching individual AIS data before clustering. Furthermore, this study considers the behavior of bunkering barges to circumnavigate not only bunkered vessels but also refineries and bunker barge bases, which were not considered in the existing literature, and clarifies the characteristics of each port from the perspective of bunkering vessel operations.

One of the future issues, other than applying our method to the ports in other regions of the world, is to link the knowledge obtained from the method proposed in this study to forming alternative fuel bunkering bases such as LNG. For example, in the development stage of bunkering bases with few refueling stations, the current situation in Singapore Port, where milk-run operations are a distinctive feature, will be helpful as a reference. Another lesson from Singapore Port, which provides bunkering services day and night, is the possibility of encouraging bunkering operations during nighttime, including formulating regulations and developing bunkering bases to optimize bunkering services. It is also important to model the selection of bunkering ports for each type of cargo vessel and the amount of bunker fuel ordered to predict the future bunkering demand and develop a strategy for bunkering service provision.