Abstract

The increasing consumption of plastics has necessitated the need to find a sustainable solution to reuse PET within common building materials. Recycled PET reinforcement would reduce plastic waste that is difficult to dispose of and CO2 emissions, representing a sustainable solution for generating lighter building materials. The goal of this work was to define a new cementitious mixture design and to study the mechanical and thermal behavior of three typologies of screeds with fine recycled polyethylene terephthalate (PET) aggregates. A weight percentage of PET of 1%, 2%, and 3% was used. The test results for sustainable screeds (S-Screeds) with waste PET were compared with a reference screed without the addition of plastic. In the fresh state, the workability and the air content were measured, while in the hardened state, the density, thermal conductivity, and compressive and flexural strength were investigated. These properties showed improvement for some tested S-Screeds after the introduction of fine (a few millimeters in size) and irregularly shaped waste plastic aggregates. Scanning electron microscopy (SEM) analysis showed the presence of a release surface between the cementitious mixtures and the plastic material, even if the mechanical interaction between the matrix and PET still existed.

1. Introduction

The escalating global consumption of plastic has resulted in a notable surge in plastic waste, creating a critical environmental and health hazard [1]. Polyethylene terephthalate (PET) has gained widespread usage among various plastic polymers [2], considering its exceptional attributes such as robust strength, thermal stability, and chemical resistance. Nevertheless, PET’s limited biodegradability has led to its accumulation in landfills and marine environments, emphasizing the pressing need for immediate measures to ensure efficient management and sustainable utilization of PET waste [3]. In the field of structural engineering, one of the most interesting approaches to reusing PET waste, thereby reducing the amount of plastic entering landfills, is to incorporate it within building materials such as screeds [4]. The use of PET in cementitious mixtures offers a sustainable solution to several environmental issues associated with cement production and use. It contributes to the recycling of plastic bottles and the reduction in waste and CO2 emissions associated with the production of traditional materials. The lightweight nature of PET reduces the density of the mixture, decreasing overall material use and transportation costs. In addition, the improved durability of concrete with added PET can extend the useful life of structures, reducing the need for frequent repairs [5]. Therefore, the use of PET in cement mixtures on the one hand has positive aspects related to mitigating the environmental impact of disposing of excessive amounts of plastic in landfills [6,7]. On the other hand, it has other positive effects related to the improvement in the mechanical and physical performance of reinforced composites [8].

Screeds, as well as all cementitious mixtures, are materials that possess good compressive strength but low tensile strength. The use of plastic materials produced by recycling waste PET bottles could be an effective solution for overcoming this deficit in screeds. In fact, PET has an approximately 30-times greater tensile strength than ordinary construction screeds [9]. Therefore, the use of PET fibers could increase the flexural strength of cementitious mixtures by producing a material that better resists cracking [10]. As demonstrated by scientific literature, the stitching effect exhibited by these fibers can restrain the opening of cracks [11,12] by delaying the achievement of the ultimate deformation and increasing ductility and toughness [13]. Asdollah-Tabar et al. [14] discovered that the fracture toughness increased by up to 8.5% and 16.3% when a percentage of 4% in weight of fine and coarse PET aggregates was added, respectively. The benefit of the use of coarse aggregates was more significant than that of the fine ones due to the resistance conferred by the larger size of the aggregates. PET fibers can also be combined with other fibers or reinforcing materials that together improve the characteristics of cementitious mixtures. For example, by combining PET, polyethylene (PE), and polypropylene (PP), the mortar strength values that are affected are mainly those after the first crack. In other words, until the first cracking of the cementitious mixture, the strength is not influenced by the fiber reinforcement but depends almost exclusively on the characteristics of the mortar [15]. In [1], Arulrajah carried out a characterization of cementitious mixtures used for pavement construction reinforced with 3% and 5% PET by mass. The use of both the plastic aggregate and that from recycled concrete verified that there was a reduction in the resistant moduli. However, the 5% PET mixtures with RCA and CB, stabilized with cement, exhibited physical and strength characteristics that met the specifications set by road authorities for the construction of pavement base and subbase. Fraternali et al. [16] tested the mechanical properties of fiber-reinforced concrete and its durability in an aggressive marine environment. The experimental results showed that the curing condition in seawater slightly modified the first-crack strength and reduced the toughness of fiber-reinforced concrete. Several studies [17,18,19,20] have shown that waste PET reinforcement can limit drying shrinkage, increasing the compactness of the cementitious mixture. Fibers with a higher aspect ratio (AR) are usually more effective at controlling cracking [11,12]. In [21], a significant reduction in the plastic shrinkage cracking of the mortar was observed due to the increase in the volume fraction of the PET fibers in a range between 1.0% and 1.50% for a PET fiber length of 50 mm. Instead, the plastic shrinkage cracks completely disappeared at a fiber volume fraction equal to 1.5% and fiber length of 50 mm. Screeds with greater resistance to cracking have greater durability and save material through reduced casting thickness [7]. The use of PET aggregates also confers a reduction in the thickness of screeds considering the decrease in weight due to the lightness of this composite material. For this reason, screeds with PET aggregates could be cast with minor thicknesses compared to the conventional ones with the same flexural strength. Reis et al. [22] showed that the density of polymer mortars with binders, epoxy, and unsaturated polyester was reduced by about 23% on average with the incorporation of 20% shredded PET by weight. The way in which PET can be introduced into screeds can be different; the reinforcement can be in the form of aggregate or fiber [23,24,25,26]. In the first case, the application of regular, circular-shaped particles [8,27,28,29] leads to an increase in compressive strength reducing air content [30]. In the second case, PET fibers assume the same role that reinforcing steel bars have within the concrete [31]. The most distinguishing aspect of the effectiveness of these PET reinforcements within cementitious mixtures is their geometry. In fact, having fibers that have a high aspect ratio (AR) with proper dosing and small equivalent diameters ensures better mechanical performance [32].

In the present study, the results of an experimental campaign conducted on three different types of screeds, with increasing amounts of fine PET aggregates, are presented. The results of this research aim to find new benefits for the use of PET as a fine aggregate researching the tradeoff solution for the improvement of the mechanical and thermal performance. The simultaneous enhancement of different physical characteristics of screeds would make these materials useful in multiple areas of the construction industry. This offers advantages in optimizing resources, simplifying logistics, and reducing material use with a view to sustainability.

2. Materials and Methods

2.1. Materials

2.1.1. Screeds and PET

The screeds tested in this experimental campaign were the following:

- MT99, which is a traditional indoor and outdoor screed (TS) made of Portland cement clinker 42.5R, sand aggregates (from 0.15–0.6 mm to 3 mm), and superplasticizer,

- MF21, which is a self-leveling underlayment screed for interiors (IS) made of natural gypsum binder and sand aggregates (from 0.15–0.6 mm to 1.3–3 mm),

- AR97, which is a self-levelling screed particularly suitable for underfloor heating systems (HS) made of Portland cement clinker 42.5R and sand aggregates (from 0.15–0.6 mm to 3 mm).

In each of the three tested screeds, an increasing percentage of fine PET aggregates was introduced.

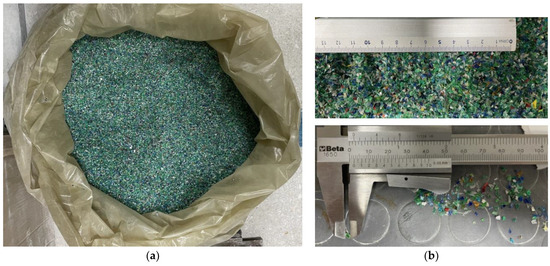

The PET type identification code used to perform this research was 01. The PET waste plastic material had the size of chopped particles with a flaky and irregular shape (Figure 1a). Specifically, the size of the fine PET particles ranged in length and width between 1 mm and 5 mm with a thickness of about 0.5 mm (Figure 1b). These plastic aggregates were produced by shredding through industrial machines for processing and recycling waste PET bottles. In particular, the first selection of the material to process was made through a screening and metal detector system. The bottle label was removed with hot water, and during the cutting phase, the material was gradually washed. The bottles were shredded inside a blade mill, then a hopper conveyed the PET flakes to a conveyor belt. From it, the plastic particles were led inside a flotation cell where the cap was separated from the remaining part of the bottle.

Figure 1.

Fine PET aggregates used in the experimental study: (a) top view of the particle size obtained by shredding recycled plastic bottles; (b) measurements with a ruler (above) and a caliper (below) of the size of the plastic aggregates.

2.1.2. Sustainable Screed (S-Screed) Mixtures

The percentages in weight of PET used in this study were 0%, 1%, 2%, and 3%. Table 1 shows the mixtures tested.

Table 1.

Design of the S-screeds analyzed in the study.

The mixing procedure followed EN 13892-1 [33] and UNI EN 196-1 [34], which, in Section 4, regulates the equipment to be used for manufacturing and packaging of the specimens. Specifically, for each mixture, cementitious matrix and plastic aggregate were combined in a bowl containing water in the percentages prescribed in Table 1. Then, a paddle was rotated at a constant speed of 140 rpm for a mixing time of 90 s, for a total of 210 rotations.

2.2. Methods

After the blending process, the mixture at fresh state was tested to evaluate its properties. Subsequently, the fluid mixture was cast into three prismatic and three cylindrical molds to perform, respectively, mechanical strength tests and thermal tests after 28 days. The mixing, casting, curing, and testing phases were carried out under controlled conditions of temperature and pressure of 25 °C and 1 atm, respectively. All the properties observed in both the fresh and hardened states of the three S-screeds were compared with those without reinforcement. In particular, the workability, air content, density, thermal conductivity, and compressive and flexural strength were analyzed in accordance with the relevant European UNI EN standards. Finally, scanning electron microscopy (SEM) and optical microscopy analyses were conducted along the fracture surfaces in order to investigate the existing interaction between PET and the cementitious screed.

2.2.1. Workability

The workability of the mixture was measured using the flow table equipment UTCM-0660E. To perform this test, the UNI EN 1015-3 standard [35] was followed, according to which the mixture to be tested was cast inside a truncated-cone or cylindrical mold placed on a rigid disc plate and compacted with a pestle. With a 15% water content, the IS mixture had a high workability, so the flow table test was performed by pouring the fresh mixture into a cylindrical mold with a smaller diameter. After lifting the mold in a vertical direction, the diameter value of the S-screed deposited on the rigid plate was measured. Due to the self-levelling features of mixtures IS and HS, it was not necessary to carry out the 15 strokes prescribed by the flow table test standard. These mixtures, only under their own weight, were deposited on the surface immediately after removing the mold. The workability of each mixture was measured with a standard ruler with an accuracy of 1 mm. Spreading of the mixture deposited on the plate was measured in two mutually orthogonal directions, and then the arithmetic mean of the two values was calculated.

2.2.2. Air Content

This test was performed in accordance with UNI EN 1015-7 [36], which concerns test methods for fresh mortars. The method used to determine the air content was the “pressure method”, for which a volume of the S-screed was placed inside a specific measuring vessel. Then, water was poured onto the top surface of the mixture, and by the application of compressed air, the water was forced inside the S-screed, and the air was removed from the inner pores. The pressure drop in the air chamber reflects the air content of the S-screed specimen and was read by the indicator on the pressure gauge.

2.2.3. Thermal Conductivity

The thermal conductivity and mechanical performance of the mixtures were measured at 28 days after casting in the hardened state. Thermal conductivity tests were performed at the Technical Physics Laboratory, while mechanical strength tests were carried out at the M. Salvati Laboratory of Polytechnic University of Bari.

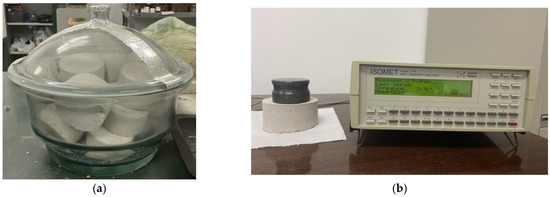

Thermal conductivity values were obtained through the dynamic method with a transient plane source apparatus. Using the ISOMET 2104 analyzer (Applied Precision Ltd., Rača, Slovakia) (Figure 2b), for each mixture, three cylindrical specimens with a dimeter equal to 100 mm and a height equal to 50 mm were tested, for a total of 36 specimens. The measurement involved applying a probe equipped with a thermocouple to the smooth surface of the cylindrical specimen after recording a stable temperature. The specimen surface was made flat with sandpaper by removing all asperities that may alter the measurements. To record the correct values of the conductivity for each cementitious mixture, the specimens were first placed in an oven at 105 °C for at least one day and then dried in silica gel desiccators (Figure 2a) for about half a day. Through the values of temperature and thermal conductivity, the machine also measured the parameters of thermal diffusivity and volume heat capacity for each mixture tested. The thermal conductivity of each mixture was assumed by considering the average value among those of each specimen. Values too far from the arithmetic mean were discarded because they were caused by an irregularity in the surface of the tested specimen. The roughness on which the probe is placed is a source of error because air voids, by their nature, alter the value of the final thermal conductivity.

Figure 2.

Specimens inside the silica gel dryer (a); set up of the measurement of thermal properties with the analyzer ISOMET 2104 (b).

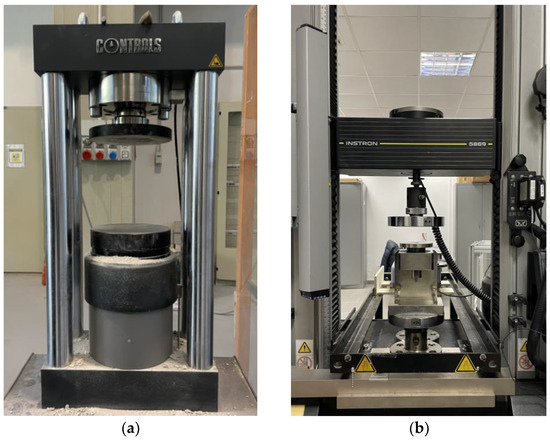

2.2.4. Flexural Strength

The mechanical strength of the screed mixtures was measured through compression and flexural tests described in EN 196-1 and EN 13892-2. The mixtures were cast in metal molds with dimensions of 40 mm × 40 mm × 160 mm. The flexural strength tests were performed using an Instron 5869 machine (Norwood, MA, USA) (Figure 3b). This equipment lifts a displacement-controlled plate until the flexural strength of the individual beam is reached. The machine’s points of contact with the specimen consist of one central upper roller and two lateral lower rollers (three-point flexural test). One of the support rollers and the loading roller must be able to tilt slightly to allow an even load distribution across the width of the specimen without subjecting it to torsional stress.

Figure 3.

Strength-testing equipment: (a) Controls C300; (b) Instron 5869.

The flexural strength, Rf, was calculated in MPa using the following equation:

where Fl is the breaking load applied to the center of the prism, l is the distance between the cylindrical supports in mm, and b is the side of the square section of the prism in mm.

2.2.5. Compressive Strength

The compressive strength tests were carried out using the Controls MCCC66 machine with a C300 frame (Controls Group, Liscate, Milano) (Figure 3a) with a loading rate equal to 150 N/s. Specifically, the compression tests were performed on the two parts resulting from the flexural failure of the beam; of the six values of compressive strength measured on each part of the beam, the average was calculated.

The compressive strength, Rc, was calculated as the maximum load Fc carried by the specimen divided by the cross-sectional area A of the specimen in contact with the bearing plate:

During the flexural and compressive strength tests, measurements from damaged specimens were discarded. As with the thermal conductivity test, the average values of the three specimens (for the flexural test) and six specimens (for the compressive test) tested for each mixture were considered. Since the data did not deviate much from the mean, it was not considered necessary to do specific statistical analyses other than those prescribed by the standard.

2.2.6. OM and SEM Analysis

The observation of the specimens by optical microscopy (OM) was performed using the Leica EZ4 HD (Leica Microsystems, Heerbrugg, Schweiz). During this test the morphology of the fracture surfaces produced by the flexural failure of the specimens was observed. Before the investigation, the flexural broken specimens were brought to the laboratory and cleaned by removing any residual dust. To have a stable support surface to fix the movements of the specimen during the investigation, each specimen was tested on a container with silica gel. The objective lens was centered on a more linear and less jagged area of the fracture surface so that all points were in more uniform focus. Finally, the focus stacking images captured by OM were combined together and focused through the CombineZP v1.0.0 software. To obtain a higher degree of detail on the existing interaction between the constituent materials of the tested mixtures, SEM EVO-50XVP (LEO) (Carl Zeiss AG, Oberkochen, Germany) was used. The SEM was equipped with an Oxford Instruments AZTEC EDS microanalysis system with SD X-MaxN detector (80 mm2). A scanning electron microscope is an instrument that uses an electron beam with a wavelength shorter than that of light to obtain micrographs with a scale magnification level of 10−1 to 10−5. Therefore, through this equipment, the specimen was investigated at a higher magnification.

3. Results and Discussion

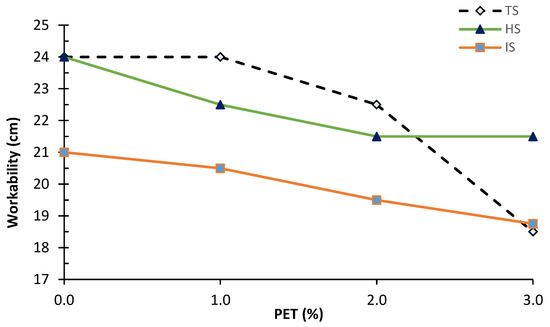

3.1. Workability

The workability results presented in Figure 4 show that as the amount of PET in each mixture increased, the values of this property gradually decreased. Similar trends in workability were also found in [37]. The HS and TS mixtures exhibited greater workability than the IS mixture; the decrease in HS was less pronounced with 3% PET. The TS mixture with 3% PET showed a sharp decrease in consistency with smaller values than the other mixtures. The general behavior of reduced workability in each mixture was justified by the fact that the fine PET aggregate had a very small size with irregular shape and rough edges. The presence of edges and rough surfaces contributed to the increased friction existing between the aggregates by reducing their movement within the cement matrix. In this way, the aggregates had limited possibility of movement resulting in less workability of the entire mixture.

Figure 4.

Experimental measurements of the workability.

3.2. Density

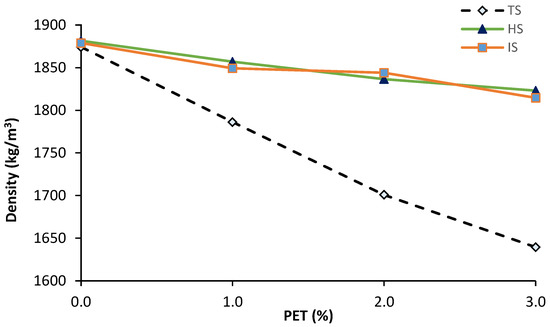

The density values of each mixture are presented in Figure 5.

Figure 5.

Results of S-screed densities.

Generally [4], the use of the plastic aggregate tended to produce a reduction in the density of the mixture, considering that this type of aggregate has a lower weight than natural ones. Therefore, the results showed that the HS and IS mixtures exhibited a slight density reduction with an increase in the weight of the fine PET aggregates from 0% to 3%. The TS mixture had a different density reduction curve from the other two; in fact, the inclusion of plastic aggregates produced a progressive density reduction of about 5% for each increasing weight percentage of PET.

3.3. Air Content

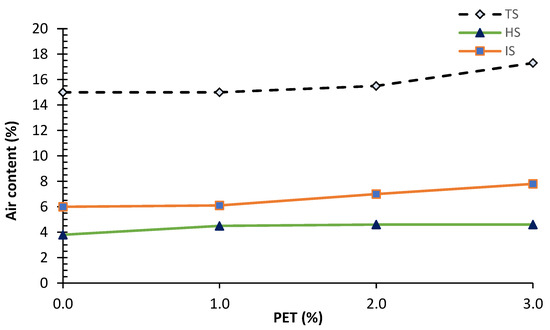

The fresh-state tests that were performed to evaluate the consistency of the mixtures studied included one to determine the air content. Figure 6 shows the results of the air content of different tested screed mixtures.

Figure 6.

Air content results.

Figure 6 shows that there was a corresponding increase between the percentage of PET and the air content of the mixtures. This direct proportionality between the air content and the amount of PET was also observed in [38,39]. The IS and HS mixtures had approximately similar air content. Differently, the TS mixture had an air content that was approximately two to four times higher than that of the other mixtures. It is interesting to note that this trend in air content of the TS mixture was also related to that of the density and workability for each percentage of PET. In fact, if the air content is higher, the density is lower since there are more voids within the mixture. And further, the air content affects the workability because a lower compactness of the particles pulls them away, making the mixture disaggregated. The reason for this result is that the chemical adhesion between plastic and cement is less than that between natural fine aggregate (like sand) and cement. This reduced adhesion contributes to the development of air bubbles during the mixing phase. Thus, afterwards, during the curing phase, this layer of air localized along the contact surface between the PET and cement matrix. The concentration of air was greater in mixtures with plastic aggregates having an angular and slightly rounded shape.

3.4. Thermal Behavior

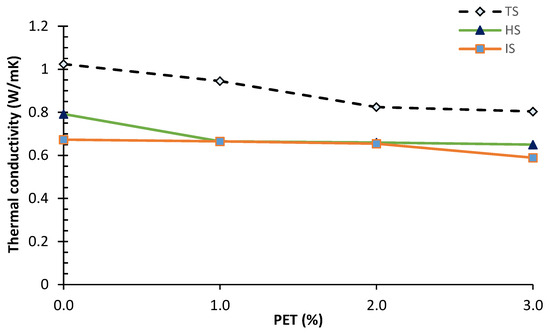

Thermal conductivity is the ability of a body to transfer heat. A screed with higher thermal conductivity will be able to insulate a room less by allowing heat to pass through. This property typically depends on the internal structure of the material and on the different bonding strength between the components of a mixture. Two materials spaced between them by layers of air hinders the transfer of heat from one material to the other by reducing conductivity. This is the reason why, as shown in Figure 7, the thermal conductivity in the three mixtures tested decreases as the amount of PET increases. The IS and HS mixtures show the same value of the thermal conductivity at 1% and 2% PET. However, the thermal performance of the IS mixture is not much affected by the addition of PET; in fact, the trend is stable up to 2%. For the TS mixture, on the other hand, the range from 2% to 3% PET produces a slight variation in the property studied. Another reason for the reduction in thermal conductivity when cement mixtures are reinforced with PET is that PET that has a lower thermal conductivity than cement, ranging between 0.15 W/(mK) and 0.24 W/(mK).

Figure 7.

Experimental values of the thermal conductivity.

3.5. Compressive Strength

Table 2 shows the results of the compression tests.

Table 2.

Compressive strength values (in MPa) of S-screeds with increasing quantities of PET.

From the values in Table 2, as the weight percentage of PET increases, in each mixture, the compressive strength does not significantly change. In fact, the values are near to that of the corresponding reference material in which there is not any plastic aggregate. Other previous studies [40,41] have also stated how the use of PET in cementitious mixtures does not produce large changes in their mechanical performance. In this study, the analyzed mixtures exhibited different compressive behaviors with increasing PET aggregate quantities. It is interesting to note that the relationship between the compressive strengths among the different mixtures is incremental. Specifically, the compressive strengths of HS and IS, for each ratio of PET, were about two and three times higher than those of TS, respectively. The mechanical parameters decreased in all mixtures except for TS and IS 2P where there was a slight increase in strength values. It is not possible to describe with a mathematical law the trend of resistance as a function of PET percentage. The use of fine plastic aggregates produced from recycled plastic bottles did not always cause an enhancement in compressive strength because the shape of the aggregates was not very regular. Smaller PET aggregates generally exhibited better behavior than larger aggregates in terms of compressive strength of the cementitious mixture.

3.6. Flexural Strength

The results of flexural failure tests are shown in Table 3.

Table 3.

Flexural strength values (in MPa) of S-screeds with increasing quantities of PET.

The trend curves of the flexural strengths of each mixture are similar to those of the compressive strength. In fact, in each mixture there is a drop in mechanical performance with 1% PET and then a positive trend. As the percentage by weight of PET increases, the S-screeds undergo a reduction in flexural strength that is very pronounced with 1% by weight of PET. This happened because the geometry of the plastic aggregates was highly irregular with a completely random aspect ratio (AR). Therefore, the introduced PET was unable to hold together the parts of the specimen that split because of reaching the tensile strength of the mixture. The reduction in resistance occurred for each increasing percentage of PET except for IS_2P where a slight increase was achieved.

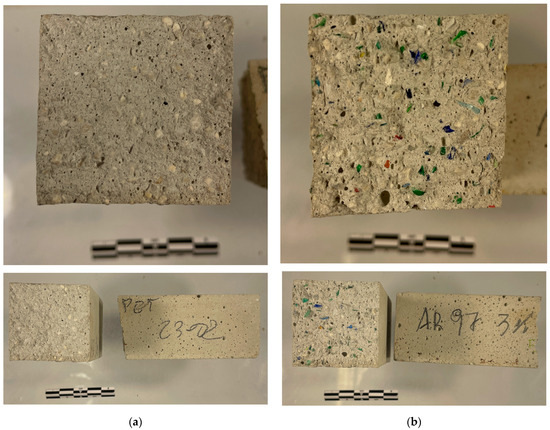

Figure 8 shows the flexural failure patterns of the control (0% PET) and 3P (3% PET) specimens of the HS mixture.

Figure 8.

A view of the HS specimens after flexural failure: (a) 0% wt. of PET; (b) 3% wt. of PET.

3.7. OM and SEM Analysis

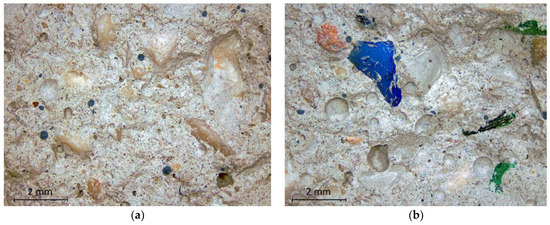

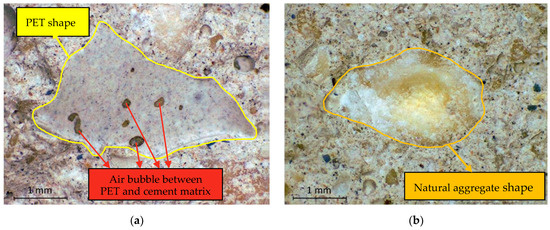

Optical microscopy (OM) analysis allowed the comparison of the pattern of roughness between the two separating parts of the beam with 0% and 3% PET, respectively. By analyzing the shape and size of the cavities generated along the fracture surfaces, it was possible to assess the existing interaction between plastic material and cement matrix. Figure 9 shows the fracture surfaces of the HS specimen in a way that is also representative of the other TS and IS mixtures.

Figure 9.

HS fracture surface scanned by the OM: (a) Specimen with 0% PET; (b) Specimen with 3% PET.

Figure 8b and Figure 9b show that the introduction of fine PET aggregates produced an increase in the porosity of the original cementitious material. In fact, the increase in weight of PET from 0% to 3% enhanced both the number of cavities and their diameters. The presence of these internal micro-porosities also produced a reduction in the compressive strength of the S-screed. The use of very small plastic particles did not ensure stress transfer of the mix into a larger volume of material. The material with PET presented a reduction in mechanical strength because in areas where voids were present, stress transfer did not occur along adjacent fibers. So generated points of weakness decreased the overall strength of the entire mix.

Figure 10 shows the detail of the enlargements of some pores present along the fractured surfaces of the specimens broken by flexural stress. It can be observed that when the conglomerate was brought to failure, the separation of the aggregate in PET occurred (Figure 10a). On the other hand, when only natural aggregates were used, the fracture surface divided the aggregate into two parts (Figure 10b). Therefore, the natural aggregate remained integral to the cement matrix even when the ultimate strength was reached. Instead, the plastic aggregate separated from the matrix; it represents a point of weakness. In Figure 10a, it is possible to distinguish circular and regular pores, which were caused by imperfections during the mixing stage, from angular and irregular pores that were caused by the separation of the plastic PET aggregate. However, it is interesting to observe that these circular mixing porosities generated exactly along the contact surface between PET aggregates and the cement matrix. This suggests that already during the mixing stage, waste plastic could not easily bond with cement. From this stage until the end of curing, there were void areas between the PET and cement matrix.

Figure 10.

Details of the fracture surface scanned by OM: (a) PET aggregate shape separated from the cement matrix and voids along the PET surface; (b) natural aggregate cut into two parts that remain bonded to the cement mixture.

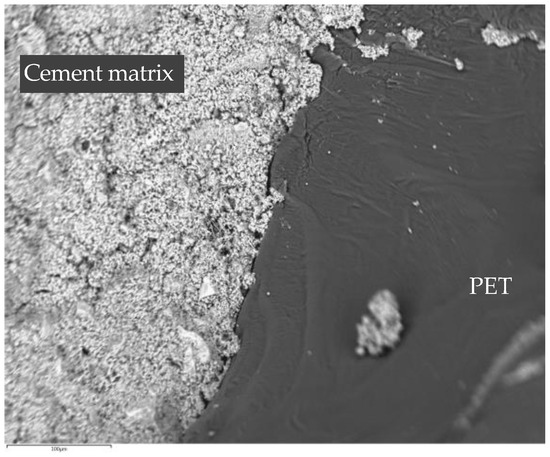

Through SEM investigations, chemical and internal porosity analysis could be carried out. Figure 11 shows the micrographs obtained from SEM investigations. This image shows that the cement matrix (on the left) and the PET aggregate (on the right) remained two elements separated from each other by a detachment surface.

Figure 11.

SEM micrograph of the contact surface between the PET and cement matrix.

Among the tested mixtures, TS was found to be the most sensitive to plastic aggregate reinforcement. Its performance for each property studied showed different trends than those of the other mixtures. As the results showed, the use of fine PET aggregates had the great advantage of lightening the slabs on which the S-screed was cast. In addition, although the workability was reduced, the more durable the plastic was, the more it increased the service life of the cementitious materials. Thus, it is possible to use new screeds in the construction world that manage to mitigate the problem of environmental impact related to plastic disposal. Recovering some PET waste to construct new sustainable buildings would reduce the need for natural aggregates and therefore the associated CO2 emissions for their production.

4. Conclusions and Future Research

This research investigated the effects produced by using fine recycled PET aggregates within common construction screeds. The properties in the fresh state and hardened state of three different screed typologies were tested. Finally, through a series of micrographs obtained from light microscopy and SEM investigations, the existing interaction between the materials was analyzed. In accordance with the results, the conclusions can be summarized as follows:

- The resistance of the frictional force existing between the plastic aggregates prevents them from moving and floating freely during casting, to the detriment of workability. To increase this property, PET aggregates with smooth, circular, and regular shapes should be used. Only in this way can the friction forces existing between particles be reduced.

- Increasing the amount of PET within a screed produces a progressive reduction in the overall density of the mixture. This is caused by the low specific gravity that the plastic material possesses compared to natural aggregates. Therefore, the introduction of PET within common construction screeds produces a beneficial effect in terms of weight reduction by lightening structural elements.

- The hydrophobicity of PET makes it a material that binds poorly with the cement matrix. This facilitates the segregation of plastic aggregates from the mix and produces an enhancement of existing voids along the contact surfaces between cement matrix plastic aggregates at the disadvantage of air content. For future developments, it would be more interesting to adopt plastic aggregates that have a regular shape and a larger contact surface with the cement paste. In this way through friction and mechanical interaction, the two materials would remain bonded by forming fewer air bubbles.

- The addition of PET produces a reduction in thermal conductivity because the thermal conductivity is directly proportional to density and PET produces a reduction in the density in the mixture. The increase in air content further creates air bubbles that represent additional obstacles to the passage of heat. In fact, the latter will be forced to take a longer and more irregular path to transfer from one surface to the next.

- The increase in the PET aggregate amount leads to a slight enhancement in compressive strength of TS and IS with 2% PET (2P). Instead, the other PET ratios show a worst compressive behavior due to the poor mechanical interaction existing between small, irregularly shaped particles and cement paste. For future developments to increase compressive strength in all the mixtures, circular plastic aggregates should be used.

- Cementitious mixtures, as well as screeds, have reduced flexural strength due to their low tensile strength. The use of PET waste plastic material that possesses higher tensile strength may contribute to the increase in tensile and flexural strength of the entire cementitious mixture. Usually, by increasing the AR of PET particles, they would assume the function of reinforcing fibers that hold together the fracture surfaces generated due to the achievement of ultimate tensile strength. PET fibers would be able to sew together the two parts of the cement paste that separate, delaying flexural failure and increasing the strength value. Although the aggregates used in this research did not have a fibrous geometry with high AR, the introduction of 2% PET in IS produced a slight improvement in flexural strength. Hence, in the mixtures with gypsum (IS), a better interaction occurred between plastic aggregates and binder.

In conclusion, the S-screed that exhibited better mechanical behavior resulted in the IS mixture. Increasing thermal insulation, coupled with a reduction in the weight of common building screeds, is a big advantage in construction. In fact, with the same strengths, it would be possible to save material by lightening structures and maintaining a high level of thermal insulation. Through experimental results, this study aimed to show how, in order to encourage a circular economy, one solution may be to reinforce cementitious screeds using recycled PET. This solution would not only contribute to the reduction in the ever-increasing amount of waste plastic disposed of in landfills but also improve the mechanical and thermal properties of common building materials.

Future research can be carried out using fibers or aggregates produced from recycled PET bottles by adopting more regular shapes and sizes or by increasing the amount by weight or volume of the reinforcing plastic waste. In addition, to evaluate the long-term durability of these screeds, it might be useful to study mechanical and physical properties using an accelerated ageing test in a further experimental campaign.

Author Contributions

Conceptualization, C.G.C. and P.L.; Methodology, C.G.C. and P.L.; Validation, C.G.C.; Formal analysis, C.G.C.; Investigation, C.G.C.; Resources, C.G.C.; Data curation, C.G.C.; Writing—original draft, C.G.C.; Writing—review & editing, C.G.C., P.L., M.F.S. and D.F.; Visualization, C.G.C.; Supervision, P.L. and D.F.; Project administration, D.F.; Funding acquisition, D.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been supported by the Company CAV Srl (Trani, Italy).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The authors thank “CAV Srl (Trani, Italy)” and, in particular, Vitantonio Contento, for providing pre-mixed materials.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Arulrajah, A.; Perera, S.; Wong, Y.C.; Horpibulsuk, S.; Maghool, F. Stiffness and Flexural Strength Evaluation of Cement Stabilized PET Blends with Demolition Wastes. Constr. Build. Mater. 2020, 239, 117819. [Google Scholar] [CrossRef]

- Foti, D. Recycled Waste PET for Sustainable Fiber-Reinforced Concrete. In Use of Recycled Plastics in Eco-Efficient Concrete; Elsevier: Amsterdam, The Netherlands, 2018; pp. 387–410. ISBN 9780081026762. [Google Scholar]

- Foti, D.; Lerna, M. New Mortar Mixes with Chemically Depolymerized Waste PET Aggregates. Adv. Mater. Sci. Eng. 2020, 2020, 8424936. [Google Scholar] [CrossRef]

- Lerna, M.; Foti, D.; Petrella, A.; Sabbà, M.F.; Mansour, S. Effect of the Chemical and Mechanical Recycling of PET on the Thermal and Mechanical Response of Mortars and Premixed Screeds. Materials 2023, 16, 3155. [Google Scholar] [CrossRef] [PubMed]

- Alani, A.H.; Bunnori, N.M.; Noaman, A.T.; Majid, T.A. Durability Performance of a Novel Ultra-High-Performance PET Green Concrete (UHPPGC). Constr. Build. Mater. 2019, 209, 395–405. [Google Scholar] [CrossRef]

- Mendes, R.F.; Narciso, C.R.P.; Mendes, J.F.; Viana, Q.S.; Eugênio, T.M.C.; Vilela, A.P. Study of New Reinforcing Materials for Cementitious Panel Production. Environ. Sci. Pollut. Res. 2021, 28, 37217–37230. [Google Scholar] [CrossRef] [PubMed]

- Tanzadeh, R.; Tanzadeh, J.; Hosseini, M.H.; Mirsepahi, M. Performance Evaluation of Reinforced Roller Compacted Concrete Pavement with Basalt Fibers and Recycled Polyethylene in Warm Regions of Iran. In Proceedings of the International Conference on Transportation and Development 2016, Houston, TX, USA, 26–29 June 2016; pp. 1122–1131. [Google Scholar]

- Umasabor, R.I.; Daniel, S.C. The Effect of Using Polyethylene Terephthalate as an Additive on the Flexural and Compressive Strength of Concrete. Heliyon 2020, 6, e04700. [Google Scholar] [CrossRef] [PubMed]

- Tapia-Picazo, J.C.; Luna-Bárcenas, J.G.; García-Chávez, A.; Gonzalez-Nuñez, R.; Bonilla-Petriciolet, A.; Alvarez-Castillo, A. Polyester Fiber Production Using Virgin and Recycled PET. Fibers Polym. 2014, 15, 547–552. [Google Scholar] [CrossRef]

- Waysal, S.; Patil, Y.; Dholakiya, B.K. Effect of PET Resin as Cement Substitute on Properties of Cement Mortar Subjected to Different During Conditions. U. Porto J. Eng. 2023, 9, 16–27. [Google Scholar] [CrossRef]

- Najm, H.; Balaguru, P. Effect of Large-Diameter Polymeric Fibers on Shrinkage Cracking of Cement Composites. Mater. J. 2002, 99, 345–351. [Google Scholar]

- Banthia, N.; Yan, C. Shrinkage Cracking in Polyolefin Fiber-Reinforced Concrete. Mater. J. 2000, 97, 432–437. [Google Scholar]

- Da Silva Magalhãesand, M.; Fernandes, M.S.V. Bending Behaviour of Recycled PET Fiber Reinforced Cement-Based Composite. Int. J. Eng. Technol. 2015, 7, 282. [Google Scholar] [CrossRef]

- Asdollah-Tabar, M.; Heidari-Rarani, M.; Aliha, M.R.M. The Effect of Recycled PET Bottles on the Fracture Toughness of Polymer Concrete. Compos. Commun. 2021, 25, 100684. [Google Scholar] [CrossRef]

- Signorini, C.; Volpini, V. Mechanical Performance of Fiber Reinforced Cement Composites Including Fully-Recycled Plastic Fibers. Fibers 2021, 9, 16. [Google Scholar] [CrossRef]

- Fraternali, F.; Spadea, S.; Berardi, V.P. Effects of Recycled PET Fibres on the Mechanical Properties and Seawater Curing of Portland Cement-Based Concretes. Constr. Build. Mater. 2014, 61, 293–302. [Google Scholar] [CrossRef]

- Chinchillas-Chinchillas, M.J.; Gaxiola, A.; Alvarado-Beltrán, C.G.; Orozco-Carmona, V.M.; Pellegrini-Cervantes, M.J.; Rodríguez-Rodríguez, M.; Castro-Beltrán, A. A New Application of Recycled-PET/PAN Composite Nanofibers to Cement–Based Materials. J. Clean Prod. 2020, 252, 119827. [Google Scholar] [CrossRef]

- Liu, Z. Experimental Research on the Engineering Characteristics of Polyester Fiber–Reinforced Cement-Stabilized Macadam. J. Mater. Civ. Eng. 2015, 27, 04015004. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Durability Performance of Polymeric Scrap Tire Fibers and Its Reinforced Cement Mortar. Mater. Struct. Mater. Constr. 2017, 50, 158. [Google Scholar] [CrossRef]

- Mazzoli, A.; Monosi, S.; Plescia, E.S. Evaluation of the Early-Age-Shrinkage of Fiber Reinforced Concrete (FRC) Using Image Analysis Methods. Constr. Build. Mater. 2015, 101, 596–601. [Google Scholar] [CrossRef]

- Al-Tulaian, B.S.; Al-Shannag, M.J.; Al-Hozaimy, A.R. Recycled Plastic Waste Fibers for Reinforcing Portland Cement Mortar. Constr. Build. Mater. 2016, 127, 102–110. [Google Scholar] [CrossRef]

- Reis, J.M.L.; Carneiro, E.P. Evaluation of PET Waste Aggregates in Polymer Mortars. Constr. Build. Mater. 2012, 27, 107–111. [Google Scholar] [CrossRef]

- Borg, R.P.; Baldacchino, O.; Ferrara, L. Early Age Performance and Mechanical Characteristics of Recycled PET Fibre Reinforced Concrete. Constr. Build. Mater. 2016, 108, 29–47. [Google Scholar] [CrossRef]

- Hidaya, N.; Mutuku, R.N.; Mwero, J.N. Physical and Mechanical Experimental Investigation of Concrete Incorporated with Polyethylene Terephthalate (PET) Fibers. Eur. Int. J. Sci. Technol. 2017, 6. Available online: https://eijst.org.uk/images/frontImages/gallery/Vol._6_No._8/5.31-41.pdf (accessed on 10 August 2023).

- Akçaözoǧlu, S.; Atiş, C.D.; Akçaözoǧlu, K. An Investigation on the Use of Shredded Waste PET Bottles as Aggregate in Lightweight Concrete. Waste Manag. 2010, 30, 285–290. [Google Scholar] [CrossRef] [PubMed]

- Pereira De Oliveira, L.A.; Castro-Gomes, J.P. Physical and Mechanical Behaviour of Recycled PET Fibre Reinforced Mortar. Constr. Build. Mater. 2011, 25, 1712–1717. [Google Scholar] [CrossRef]

- Choi, Y.W.; Moon, D.J.; Chung, J.S.; Cho, S.K. Effects of Waste PET Bottles Aggregate on the Properties of Concrete. Cem. Concr. Res. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- Singh, G.; Kumar, H.; Singh, S. Krispon Mechanical Performance of Red Mud Polymer Concrete Composites Fabricated Using Recycled PET Resin. Abstr. Int. Conf. Meet. AICM 2020, 1, 21. [Google Scholar] [CrossRef]

- Ávila Córdoba, L.; Martínez-Barrera, G.; Barrera Díaz, C.; Ureña Nuñez, F.; Loza Yañez, A. Effects on Mechanical Properties of Recycled PET in Cement-Based Composites. Int. J. Polym. Sci. 2013, 2013, 763276. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Tarverdi, K.; Umoren, A.; Bassey, D.E.; Okorie, U.; Adediran, J. Evaluation of Eco-Friendly Concrete Having Waste PET as Fine Aggregates. Clean. Mater. 2021, 2, 100026. [Google Scholar] [CrossRef]

- Foti, D. Innovative Techniques for Concrete Reinforcement with Polymers. Constr Build Mater 2016, 112, 202–209. [Google Scholar] [CrossRef]

- Pons Ribera, S.; Hamzaoui, R.; Colin, J.; Bessette, L.; Audouin, M. Valorization of Vegetal Fibers (Hemp, Flax, Miscanthus and Bamboo) in a Fiber Reinforced Screed (FRS) Formulation. Materials 2023, 16, 2203. [Google Scholar] [CrossRef]

- EN 13892-1:2002; Methods of Test for Screed Materials—Part 1: Sampling. Making and Curing Specimens for Test. British Standards Institution: London, UK, 2002.

- UNI EN 196-1:2016; Metodi di Prova dei Cementi-Parte 1: Determinazione delle resistenze meccaniche. UNI Ente Itaiano di Normazione: Milano, Italy, 2016.

- EN 1015-3:2007; Methods of Test for Mortar for Masonry—Part 3. British Standards Institution: London, UK, 2007; pp. 79–95.

- EN 1015-7:1998; Methods of Test for Mortar for Masonry—Part 7: Determination of Air Content of Fresh Mortar. British Standards Institution: London, UK, 1998.

- Jacob-Vaillancourt, C.; Sorelli, L. Characterization of Concrete Composites with Recycled Plastic Aggregates from Postconsumer Material Streams. Constr. Build. Mater. 2018, 182, 561–572. [Google Scholar] [CrossRef]

- Guendouz, M.; Debieb, F.; Boukendakdji, O.; Kadri, E.H.; Bentchikou, M.; Soualhi, H. Use of Plastic Waste in Sand Concrete. J. Mater. Environ. Sci. 2016, 7, 382–389. [Google Scholar]

- Akinyele, J.O.; Ajede, A. The Use of Granulated Plastic Waste in Structural Concrete. Afr. J. Sci. Technol. Innov. Dev. 2018, 10, 169–175. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A.; Fini, E.H. Sustainable Construction via Novel Geopolymer Composites Incorporating Waste Plastic of Different Sizes and Shapes. Constr. Build. Mater. 2022, 324, 126697. [Google Scholar] [CrossRef]

- Azhdarpour, A.M.; Nikoudel, M.R.; Taheri, M. The Effect of Using Polyethylene Terephthalate Particles on Physical and Strength-Related Properties of Concrete; A Laboratory Evaluation. Constr. Build. Mater. 2016, 109, 55–62. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).