Sustainable Material Selection Framework: Taxonomy and Systematisation of Design Approaches to Sustainable Material Selection

Abstract

:1. Introduction

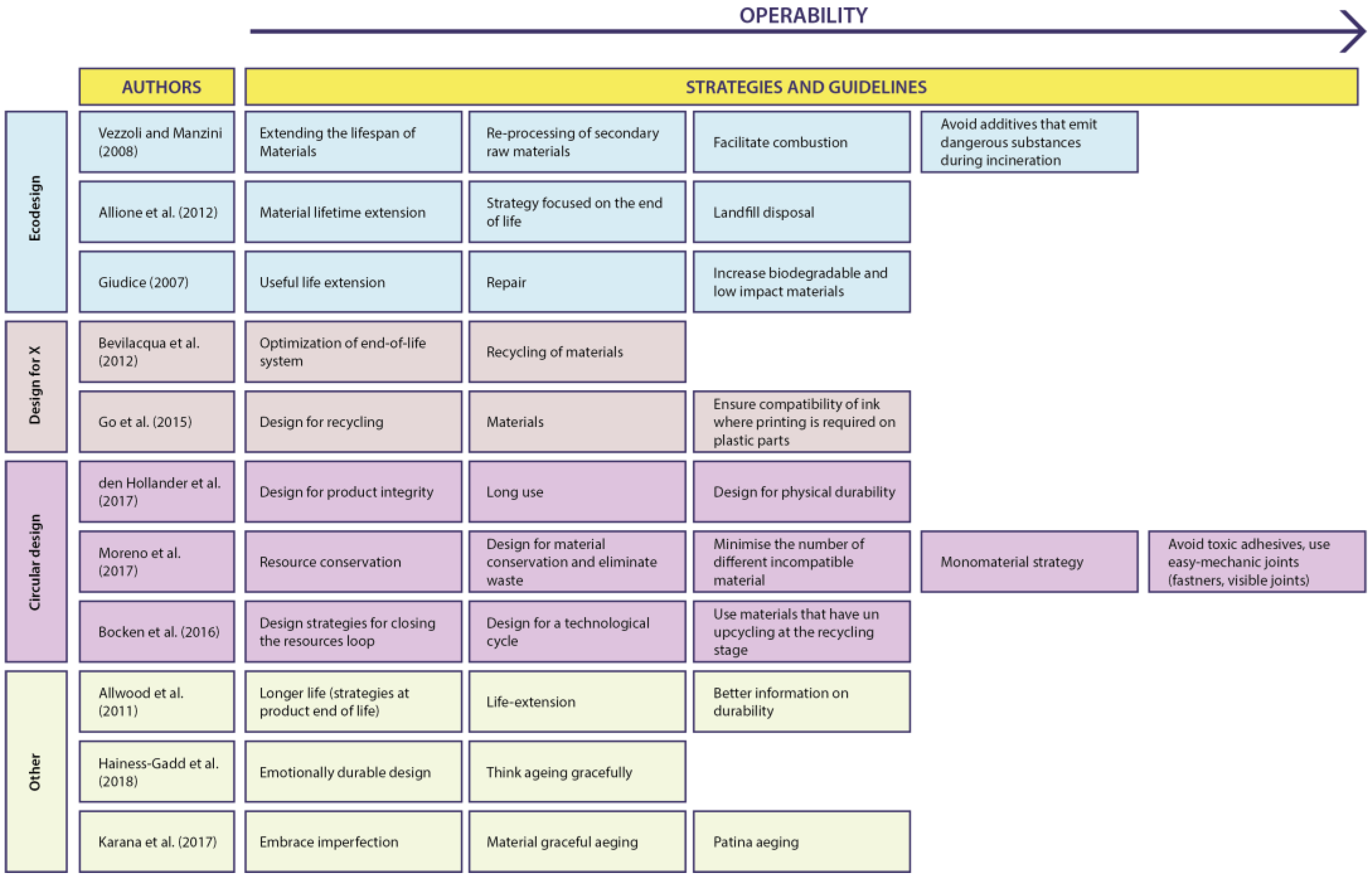

1.1. Ecodesign Strategies and Guidelines

1.2. Design for Environment/Design for Sustainability Strategies and Guidelines

1.3. Circular Design Strategies and Guidelines

1.4. Other Perspectives

1.5. Research Gap and Objective

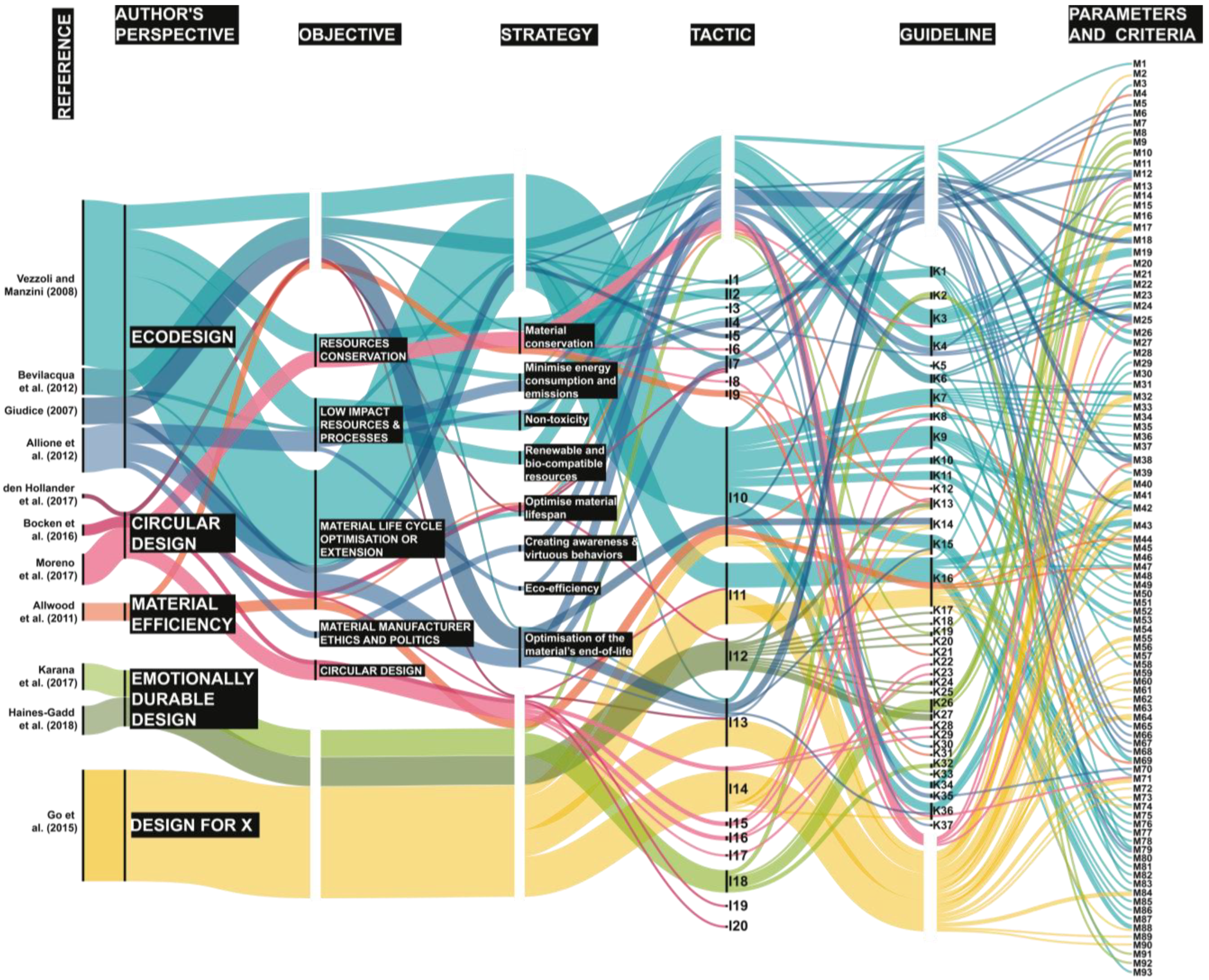

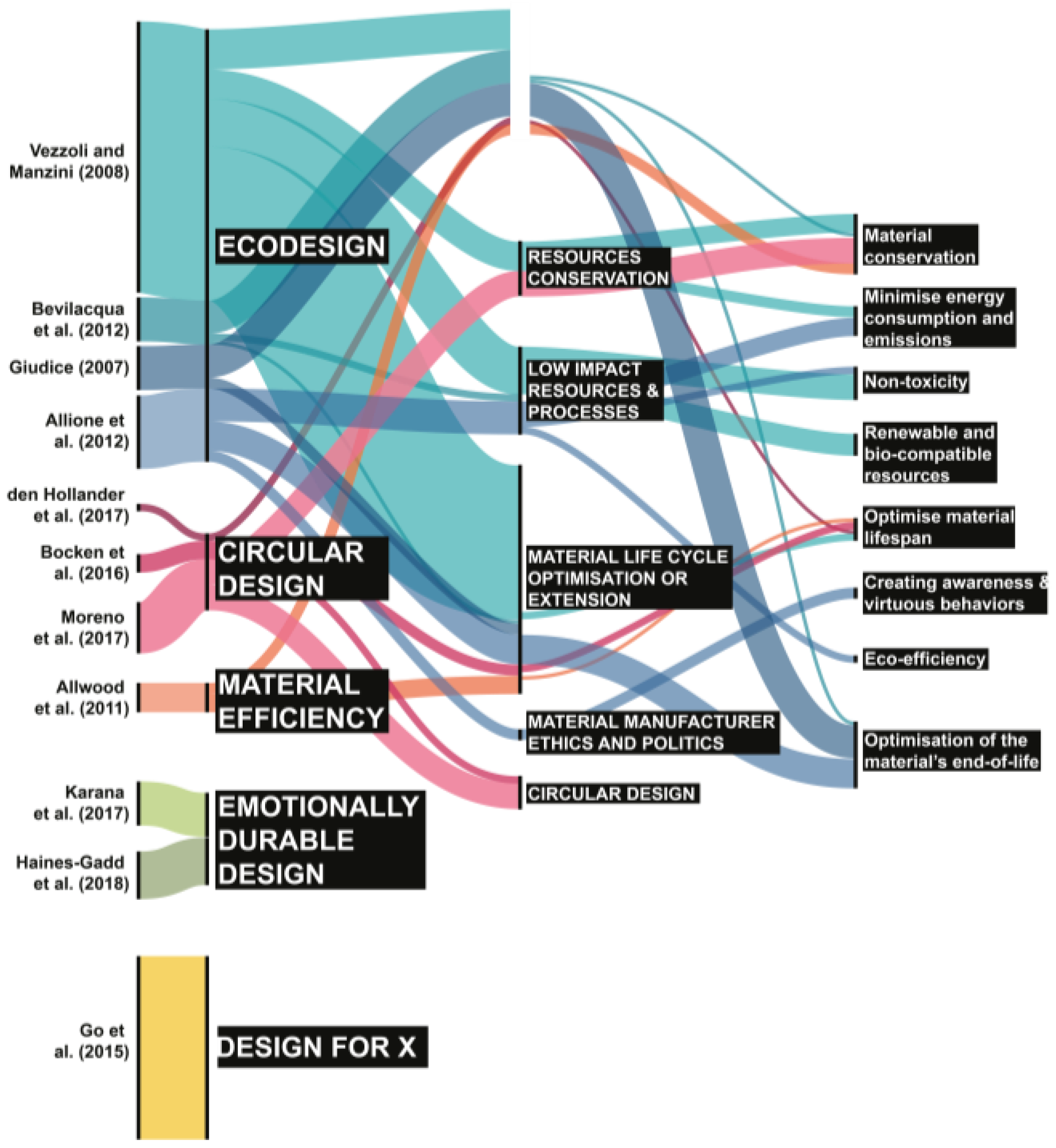

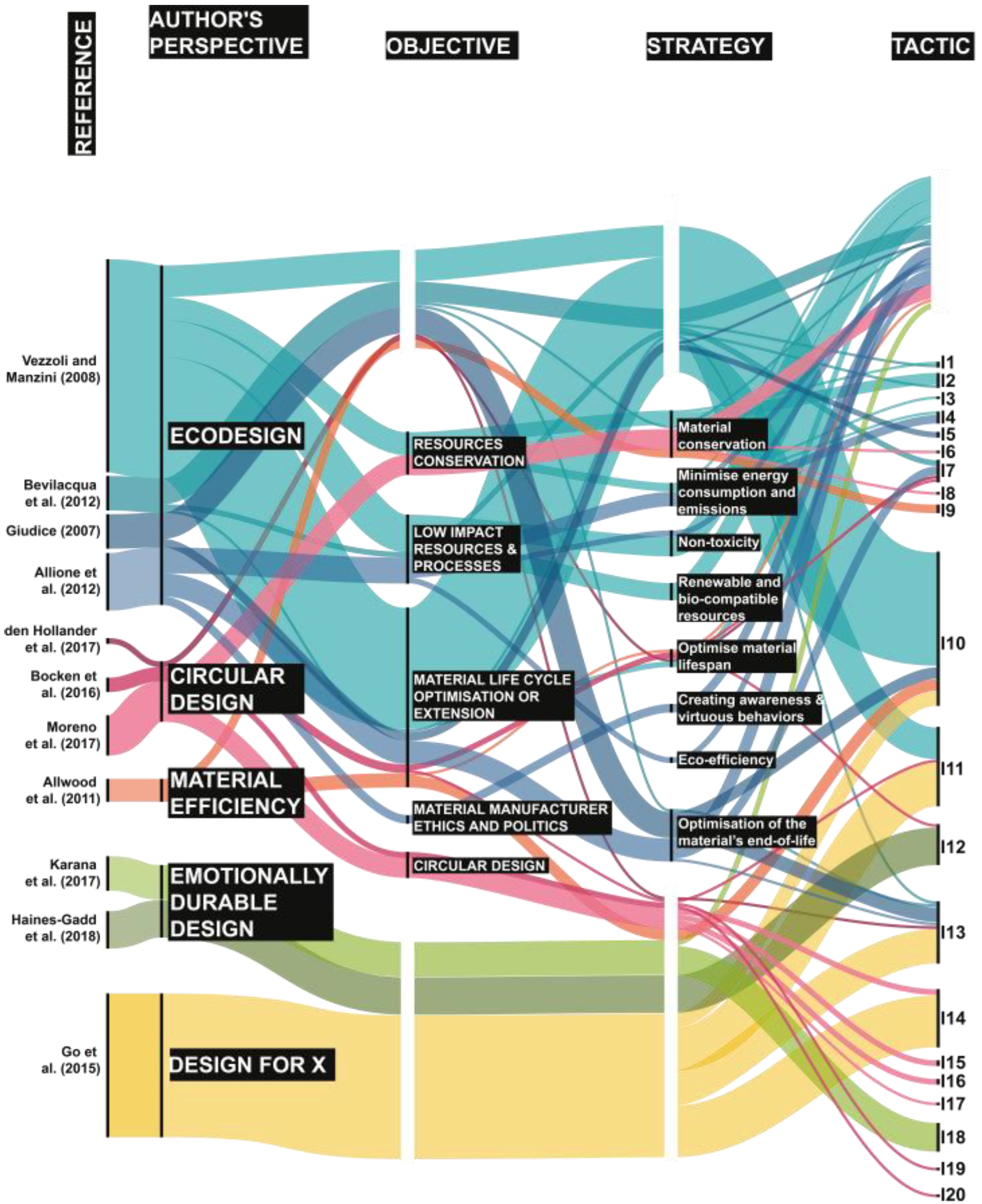

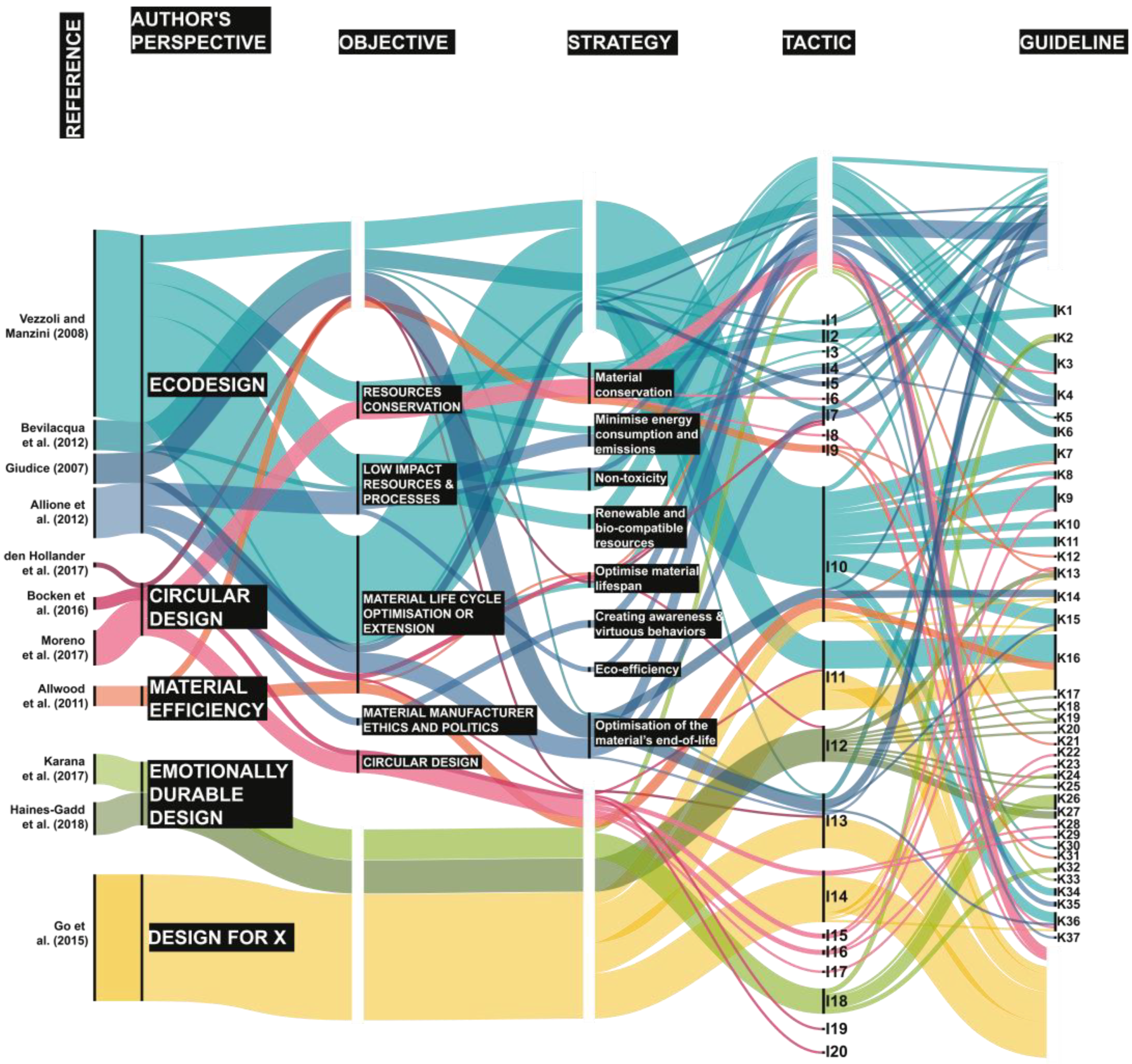

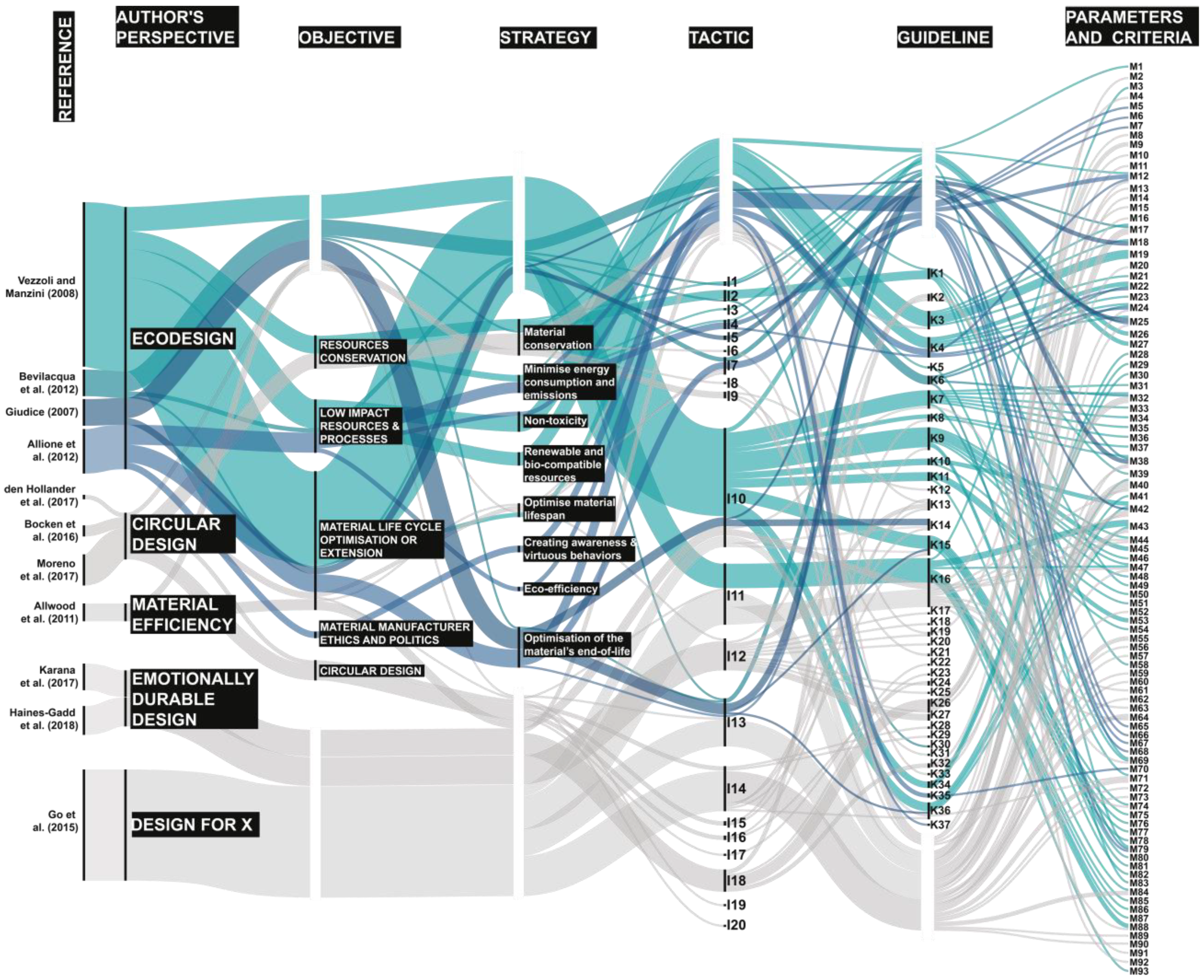

2. Methodology

- Author’s perspective: An umbrella term for the many design approaches for sustainability;

- Objective: The purpose toward which the design effort is directed and which it seeks to achieve: the aim, goal, or end of action;

- Strategy: The act of devising plans which represent the best possible way to deal with a design challenge and have the best possible sustainability benefit;

- Tactic: The particular methods, actions, and themes used to achieve a sustainable design objective;

- Guidelines: A rule, instruction, or information that guides the designer on how something should be carried out or how something should be. In this case, indication or outline to apply in design activities to foster materials selection;

- Parameters and criteria: Standard or sharp information (unambiguous, testable, or measurable) that indicates fixed limits on how something should be, which guide the decision-making process. In this case, limit, indication, or physical properties necessary for materials selection.

3. Results

3.1. Objectives

- Resource conservation: reflects upon how to manage natural resources without compromising the ecosystem;

- Low-impact resources and processes: focuses on reducing emissions and compromising effect on production processes and energy consumption;

- Material life cycle optimisation and/or extension: characterised by improved LCA efficiency directly in the definition of sustainable material selection activity strategies and guidelines;

- Material manufacturer ethics and politics: focusing on the importance and relevance of creating awareness of the consequences of material manufacturing;

- Circular design: guidelines and strategies explicitly referring to circular economy principles.

3.2. Strategies

3.3. Tactics

3.4. Guidelines, Parameters, and Criteria

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Cambridge (https://dictionary.cambridge.org/dictionary/english/ accessed on 5 December 2023) | Oxford (https://www.oxfordlearnersdictionaries.com/ accessed on 5 December 2023) | Merriam-Webster (https://www.merriam-webster.com/ accessed on 5 December 2023) | Collins (https://www.collinsdictionary.com/it/ accessed on 5 December 2023) | |

| Objective | Something that you plan to do or achieve. | Something that you are trying to achieve. | Something toward which effort is directed: an aim, goal, or end of action. A strategic position to be attended or a purpose to be achieved by a military operation. | Your objective is what you are trying to achieve. The object of one’s endeavors, goal, or aim. |

| Strategy | A way of doing something or dealing with something. A long-range plan for achieving something or reaching a goal, or the skill of making such plans. | A plan that is intended to achieve a particular purpose. Strategy to do/for doing something. The process of planning something or putting a plan into creation. | A careful plan or method: a clever stratagem. The art of devising or employing plans or stratagems toward a goal. | A strategy is a general plan or set of plans intended to achieve something, especially over a long period. Strategy is the art of planning the best way to gain an advantage or achieve success, especially in war. |

| Tactic | A planned way of doing something. A specific action intended to achieve a particular result. | The particular method you use to achieve something. | A device for accomplishing an end. Of, relating to, or having (such) an arrangement or pattern. | Tactics are the methods that you choose to use in order to achieve what you want in a particular situation. Having a specified kind of pattern or arrangement or having an orientation determined by a specified force. |

| Guideline | Information intended to advise people on how something should be carried out or what something should be. A piece of information that suggest how something should be done. | A set of rules or instruction that are given by an official organization telling you how to do something, especially something difficult. Something that can be used to help you make a decision or form an opinion. | A line by which one is guided such as:

| If an organization issues guidelines on something, it issues official advice about how to do it. A guideline is something that can be used to help you plan your actions or to form an opinion about something. |

| Parameter | A set of facts or a fixed limit that establishes or limits how something can or must happen or be done. A set of facts which describes and puts limits on how something should happen or be done. | Something that decide or limits the way in which something can be done. | An arbitrary constant whose value characterizes a member of a system (such as a family of curves). Any of a set of physical properties whose values determine the characteristics or behavior of something. Something represented by a parameter: a characteristic element. Limit or boundary. | Parameters are factors or limits which affect the way that something can be carried out or made. |

| Criteria | A standard by which you judge, decide about, or deal with something. A condition or a fact used as a standard by which something can be judged or considered. | A standard or principle by which something is judged, or with the help of which a decision is made. | A standard on which a judgment or decision may be based. A characterizing mark or trait. | A criterion is a factor on which you judge or decide something. |

Appendix B

| Code | Tactic |

|---|---|

| I1 | Minimising scraps and discards |

| I2 | Minimising resources and materials consumption during usage |

| I3 | Minimising energy consumption and emission during pre-production and production |

| I4 | Short distribution chain: minimising energy consumption and emissions during transportation and storage |

| I5 | Design for repair |

| I6 | Minimise the number of different incompatible materials |

| I7 | Design for physical reliability and durability |

| I8 | Consider a healthy material flow |

| I9 | Material upgrade |

| I10 | Design for re-manufacturing and re-use |

| I11 | Design for dis- and re-assembly |

| I12 | Design for emotional durability |

| I13 | Design for recycling |

| I14 | Design for environment |

| I15 | Design for multiple life cycles |

| I16 | Design for users |

| I17 | Design for the present towards the future |

| I18 | Design for embracing material imperfection |

| I19 | Design for the technological cycle |

| I20 | Design for the biological cycle |

Appendix C

| Code | Guideline |

|---|---|

| K1 | Select more consumption-efficient systems |

| K2 | Graceful ageing |

| K3 | Non-toxic/non-harmful/non-restricted materials |

| K4 | Renewable and biocompatible materials |

| K5 | Select renewable and biocompatible energy resources |

| K6 | Select low-impact materials |

| K7 | Select materials with the most efficient recycling technologies |

| K8 | Facilitate end-of-life collection and transportation |

| K9 | Facilitate cleaning |

| K10 | Facilitate composting |

| K11 | Facilitate combustion |

| K12 | Improve processes |

| K13 | Optimise material durability |

| K14 | Optimize performance, resistance, and reliability |

| K15 | Identify materials |

| K16 | Reduce and facilitate operations of disassembly and separation |

| K17 | Create a sense of nostalgia |

| K18 | Use artefacts with existing stories |

| K19 | Elicit a sense of ambiguity, curiosity, and surprise |

| K20 | Create a little magic |

| K21 | Local properties control |

| K22 | Select innovative materials |

| K23 | Select materials based on their timeless aesthetics |

| K24 | Celebrate imperfection |

| K25 | Engage the senses |

| K26 | Make it unique |

| K27 | Consider materials’ responses to environmental conditions/human interaction over time |

| K28 | Create regenerative systems (biomimicry) |

| K29 | Care about social impact |

| K30 | No energy/auxiliary material use |

| K31 | Material substitution (changing material) |

| K32 | Generate a deeper and enduring relationship with the product through the material |

| K33 | Materials supporting multi-functional products |

| K34 | Engage a cascade approach |

| K35 | Consider landfill typology |

| K36 | Reduce material variety |

| K37 | Gas or energy recovery |

Appendix D

| Code | Parameters and Criteria |

|---|---|

| M1 | Processes to reduce scraps |

| M2 | Mark all plastic and similar parts for ease of identification |

| M3 | Employ joining elements that can be chemically or physically destroyed |

| M4 | Avoid welding |

| M5 | Total quality management (TQM certification) |

| M6 | Environmental management system EMS declaration |

| M7 | Eco label product certification |

| M8 | Prefer unprocessed, natural, and raw materials to emphasize their uniqueness (emotional bond) |

| M9 | Use recycled materials (from food waste, re-used materials, and discarded objects) for their unique textural and visual experience |

| M10 | Designing with anomalies and effects inherent to the materials through manufacturing processes |

| M11 | Designing with anomalies and effects inherent to the materials through unique handmade objects |

| M12 | Select local material and energy sources |

| M13 | Envelop and normalise scratches, color changes, wear, and tear |

| M14 | Design with and for imperfection, visible human traces |

| M15 | DIY manual labour and craftsmanship to relate with products |

| M16 | Select multi-situated and ambiguous materials: ability to support a variety of different functions |

| M17 | Avoid toxic, regulated, restricted, or harmful materials for product components |

| M18 | Minimise the hazard of toxic and harmful materials |

| M19 | Avoid materials that emit toxic or harmful substances during life cycle |

| M20 | Avoid toxic adhesives, use easy-mechanic joints (fasteners and visible joints) |

| M21 | Avoid toxic or harmful surface treatments |

| M22 | Use of renewable/non-exhaustible materials |

| M23 | Use residual materials from production processes |

| M24 | Use recycled materials, alone or combined with primary materials |

| M25 | Use biodegradable materials |

| M26 | Select materials with durability according to the product performance and lifespan |

| M27 | Design for excessive use of materials in places more subject to deterioration |

| M28 | Arrange and facilitate recycling of materials in components with lower mechanical requirements |

| M29 | Arrange and facilitate recycling of materials in components with lower aesthetical requirements |

| M30 | Arrange and facilitate energy recovery from materials throughout combustion |

| M31 | Select materials that easily recover after recycling the original performance characteristics |

| M32 | Use recyclable materials |

| M33 | Engage geometrical solutions like ribbing to increase polymer stiffness instead of reinforcing fibres |

| M34 | Prefer thermoplastic polymers to thermosetting |

| M35 | Prefer heat-proof thermoplastic polymers to fireproof additives |

| M36 | Design taking into consideration the secondary use of the materials once recycled |

| M37 | Design in compliance with a product retrieval system |

| M38 | Reduce/minimise material weight |

| M39 | Design for the efficient consumption of operational materials |

| M40 | Monomaterial product or sub-assembly |

| M41 | Use only one material, but process in sandwich structures |

| M42 | Use compatible materials (that can be recycled/composted together) within the product or sub-assembly |

| M43 | For joining, use the same or compatible materials as in the components (to be joined, including fasteners, screws, rivets, staples, etc.) |

| M44 | Avoid unnecessary/secondary coatings procedures (paintings, coatings, platings, etc.) |

| M45 | Avoiding irremovable coating materials/facilitate coatings removal |

| M46 | Use coating procedures in compliance with coated materials |

| M47 | Avoid adhesives or choose in compliance with materials to be recycled |

| M48 | Prefer dyeing internal polymers, rather than surface painting |

| M49 | Design for the more efficient supply of raw materials |

| M50 | Avoid using additional materials for marking or codification |

| M51 | Eliminate incompatible paints on parts e use label imprints or even inserts |

| M52 | Select materials that degrade in the expected end-of-life environment |

| M53 | Avoid materials and additives that emit dangerous substances during incineration |

| M54 | Select high-energy materials for products that are going to be incinerated |

| M55 | Ensure compatibility of ink where printing is required on plastic parts |

| M56 | Use high strength-to-weight materials on moving parts |

| M57 | Use low-alloy metals which are more recyclable than high-alloy ones |

| M58 | Design for the more efficient use of maintenance materials |

| M59 | Use unplated metals which are more recyclable than plated |

| M60 | Increase corrosion resistance of fasteners |

| M61 | Group harmful materials in sub-assemblies |

| M62 | Avoid the combination of ageing and corrosive materials |

| M63 | Avoid parts and materials likely to damage machinery (shredder) |

| M64 | Avoid moulded-in metal inserts or reinforcements in plastic parts |

| M65 | Select materials with low-C02-equivalent emission |

| M66 | Provide material maintenance procedure |

| M67 | Select materials according to their contextual wear resistance |

| M68 | Use compostable materials |

| M69 | Design for the cascading of recycling systems |

| M70 | Provide indication on landfill typology (inert, hazardous, or non-hazardous) |

| M71 | Avoid composite materials |

| M72 | Eliminate incompatible labels on plastic parts |

| M73 | Standardise and use common parts and materials |

| M74 | Codify different materials to facilitate their identification/separation |

| M75 | Provide additional information about the material’s age, number of times recycled, and additives used |

| M76 | Use standardised materials identification systems |

| M77 | Arrange codifications in easily visible places |

| M78 | Avoid codifying after component production stages |

| M79 | Select materials with low embodied energy |

| M80 | Mark and codify materials during moulding |

| M81 | Codify polymers with a laser |

| M82 | Facilitate the separation of materials that might compromise the efficiency of combustion (with a low energy value) |

| M83 | Use highly caulked materials and technical components |

| M84 | Hazardous parts should be clearly marked and easily removed |

| M85 | Avoid additional materials while welding |

| M86 | Weld with compatible materials |

| M87 | Prefer ultrasonic and vibration welding with polymers |

| M88 | Provide easy access to harmful, valuable, or reusable parts |

| M89 | Minimise fragile parts |

| M90 | Protect subassemblies against soiling and corrosion |

| M91 | Prefer natural materials due to their graceful ageing (e.g., maturity of natural materials) |

| M92 | Select materials in prevision of their patina ageing |

| M93 | Employ easily removable adhesives |

References

- OECD. Global Material Resources Outlook to 2060: Economic Drivers and Environmental Consequences; OECD: Paris, France, 2019. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials and the Environment: Eco-Informed Material Choice; Butterworth-Heinemann: Oxford, UK, 2009; ISBN 978-0-08-088448-6. [Google Scholar]

- Miller, G.T. Energetics, Kinetics and Life: Ecological Approach; Wadsworth Publishing Co., Inc.: Belmont, CA, USA, 1972; ISBN 978-0-534-00136-0. [Google Scholar]

- Steffen, W.; Broadgate, W.; Deutsch, L.; Gaffney, O.; Ludwig, C. The Trajectory of the Anthropocene: The Great Acceleration. Anthr. Rev. 2015, 2, 81–98. [Google Scholar] [CrossRef]

- United Nations (UN). Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015. [Google Scholar]

- WCED. Our Common Future; UN: New York, NY, USA, 1987.

- IUCN; UNEP; WWF. Caring for the Earth: A Strategy for Sustainable Living; IUCN/UNEP/WWF: Gland, Switzerland, 1991; ISBN 978-2-8317-0074-8. [Google Scholar]

- Thackara, J. The Bubble: Designing in a Complex World; MIT Press: Cambridge, MA, USA, 2005; ISBN 978-0-262-20157-5. [Google Scholar]

- Ceschin, F.; Gaziulusoy, I.A. Evolution of Design for Sustainability: From Product Design to Design for System Innovations and Transitions. Des. Stud. 2016, 47, 118–163. [Google Scholar] [CrossRef]

- Mendoza, J.M.F.; Sharmina, M.; Gallego-Schmid, A.; Heyes, G.; Azapagic, A. Integrating Backcasting and Eco-Design for the Circular Economy: The BECE Framework. J. Ind. Ecol. 2017, 21, 526–544. [Google Scholar] [CrossRef]

- Vezzoli, C. Design for Environmental Sustainability: Life Cycle Design of Products, 2nd ed.; Springer: London, UK, 2018; ISBN 978-1-4471-7363-2. [Google Scholar]

- European Union. Ecodesign Your Future; Publications Office of the European Union: Luxembourg, 2014.

- Bonilla Hernández, A.E. On How the Selection of Materials Affects Sustainability. Procedia Manuf. 2019, 33, 625–631. [Google Scholar] [CrossRef]

- Bahrudin, F.I.; Aurisicchio, M.; Baxter, W. Sustainable Materials in Design Projects. In Proceedings of the EKSIG 2017: Alive. Active. Adaptive, Rotterdam, The Netherlands, 19–20 June 2017. [Google Scholar]

- Graedel, T.; Barr, R.; Chandler, C.; Chase, T.R.; Choi, J.; Christoffersen, L.; Friedlander, E.; Henly, C.; Jun, C.; Nassar, N.T.; et al. Methodology of Metal Criticality Determination. Environ. Sci. Technol. 2012, 46, 1063–1070. [Google Scholar] [CrossRef] [PubMed]

- Shove, E.; Watson, M.; Hand, M.; Ingram, J. The Design of Everyday Life; Cultures of Consumption Series; Berg Publishers: Oxford, UK, 2007; ISBN 978-1-84520-683-3. [Google Scholar]

- Vezzoli, C.; Manzini, E. Design for Environmental Sustainability; Springer: London, UK, 2008; ISBN 978-1-84800-163-3. [Google Scholar]

- Boks, C. The Soft Side of Ecodesign. J. Clean. Prod. 2006, 14, 1346–1356. [Google Scholar] [CrossRef]

- Leitner, H. Pattern Theory: Introduction and Perspectives on the Tracks of Christopher Alexander; CreateSpace Independent Publishing Platform: Scotts Valley, CA, USA, 2015; ISBN 978-1-5056-3743-4. [Google Scholar]

- Alexander, C.S.; Ishikawa, S.; Silverstein, M.; Jacobson, M.; Fiksdahl-King, I.; Angel, S. A Pattern Language: Towns, Buildings, Construction; Oxford University Press: Cambridge, UK, 1977. [Google Scholar]

- Allione, C.; De Giorgi, C.; Lerma, B.; Petruccelli, L. From Ecodesign Products Guidelines to Materials Guidelines for a Sustainable Product. Qualitative and Quantitative Multicriteria Environmental Profile of a Material. Energy 2012, 39, 90–99. [Google Scholar] [CrossRef]

- Giudice, F. Product Design for the Environment: The Life Cycle Perspective and a Methodological Framework for the Design Process. In Environment Conscious Manufacturing; CRC Press: Boca Raton, FL, USA, 2007; pp. 33–90. ISBN 978-0-429-11797-8. [Google Scholar]

- Bevilacqua, M.; Ciarapica, F.E.; Giacchetta, G. Design for Environment as a Tool for the Development of a Sustainable Supply Chain; Springer Science and Business Media: Berlin/Heidelberg, Germany, 2012; ISBN 978-1-4471-2461-0. [Google Scholar]

- Go, T.F.; Wahab, D.A.; Hishamuddin, H. Multiple Generation Life-Cycles for Product Sustainability: The Way Forward. J. Clean. Prod. 2015, 95, 16–29. [Google Scholar] [CrossRef]

- den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product Design in a Circular Economy: Development of a Typology of Key Concepts and Terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Moreno, M.; De los Rios, C.; Rowe, Z.; Charnley, F. A Conceptual Framework for Circular Design. Sustainability 2016, 8, 937. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; Grinten, B. van der Product Design and Business Model Strategies for a Circular Economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material Efficiency: A White Paper. Resour. Conserv. Recycl. 2011, 55, 362–381. [Google Scholar] [CrossRef]

- Haines-Gadd, M.; Chapman, J.; Lloyd, P.; Mason, J.; Aliakseyeu, D. Emotional Durability Design Nine-A Tool for Product Longevity. Sustainability 2018, 10, 1948. [Google Scholar] [CrossRef]

- Karana, E.; Giaccardi, E.; Rognoli, V. Materially Yours. In Routledge Handbook of Sustainable Product Design; Routledge: London, UK, 2017; pp. 206–221. ISBN 978-1-138-91017-1. [Google Scholar]

- Prendeville, S. Envisioning Ecodesign: Definitions, Case Studies and Best Practices; ENEC: Cardiff, UK, 2014. [Google Scholar]

- Meerkamm, H.; Koch, M.R. Design for X. In Design Process Improvement: A Review of Current Practice; Springer Science and Business Media: Berlin/Heidelberg, Germany, 2005; pp. 306–323. ISBN 978-1-85233-701-8. [Google Scholar]

- Benabdellah, A.C.; Bouhaddou, I.; Benghabrit, A.; Benghabrit, O. A Systematic Review of Design for X Techniques from 1980 to 2018: Concepts, Applications, and Perspectives. Int. J. Adv. Manuf. Technol. 2019, 102, 3473–3502. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy: An Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- Moreno, M.; Ponte, O.; Charnley, F. Taxonomy of Design Strategies for a Circular Design Tool. In Proceedings of the 2nd Conference on Product Lifetimes and the Environment (PLATE), Delft, The Netherlands, 8–10 November 2017; IOS Press: Delft, The Netherlands, 2017. [Google Scholar]

- Snyder, H. Literature Review as a Research Methodology: An Overview and Guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Wohlin, C. Guidelines for Snowballing in Systematic Literature Studies and a Replication in Software Engineering. In Proceedings of the 18th International Conference on Evaluation and Assessment in Software Engineering, London, UK, 13–14 May 2014; Association for Computing Machinery: New York, NY, USA, 2014; pp. 1–10. [Google Scholar]

- Mauri, M.; Elli, T.; Caviglia, G.; Uboldi, G.; Azzi, M. RAWGraphs: A Visualisation Platform to Create Open Outputs. In Proceedings of the 12th Biannual Conference on Italian SIGCHI Chapter, Cagliari, Italy, 18–20 September 2017; Association for Computing Machinery: New York, NY, USA; pp. 1–5. [Google Scholar] [CrossRef]

- Costantino, T.E. Constructivism. In The SAGE Encyclopedia of Qualitative Research Methods; Sage Publications: Thousand Oaks, CA, USA, 2008; pp. 116–120. [Google Scholar]

- Faludi, J.; Hoffenson, S.; Kwok, S.; Saidani, M.; Hallstedt, S.I.; Telenko, C.; Martinez, V. A Research Roadmap for Sustainable Design Methods and Tools. Sustainability 2020, 12, 8174. [Google Scholar] [CrossRef]

- Brundiers, K.; Wiek, A. Do We Teach What We Preach? An International Comparison of Problem- and Project-Based Learning Courses in Sustainability. Sustainability 2013, 5, 1725–1746. [Google Scholar] [CrossRef]

- Faludi, J.; Gilbert, C. Best Practices for Teaching Green Invention: Interviews on Design, Engineering, and Business Education. J. Clean. Prod. 2019, 234, 1246–1261. [Google Scholar] [CrossRef]

| Ref. | Authors | Title | Publication Type/Place | Year |

|---|---|---|---|---|

| [17] | Vezzoli, C., and Manzini, E. | Design for Environmental Sustainability | Book. Springer, London | 2008 |

| [23] | Bevilacqua, M., Ciarapica, F. E., and Giacchetta, G. | Design for Environment as a Tool for the Development of a Sustainable Supply Chain | Book (Focus on Chapter 2). Springer Science & Business Media | 2012 |

| [22] | Giudice, F. | Product Design for the Environment: The Life Cycle Perspective and a Methodological Framework for the Design Process | Book Chapter. In Environment Conscious Manufacturing | 2007 |

| [21] | Allione, C., De Giorgi, C., Lerma, B., and Petruccelli, L. | From Ecodesign Products Guidelines to Materials Guidelines for a Sustainable Product. Qualitative and Quantitative Multicriteria Environmental Profile of a Material | Journal article. Energy | 2012 |

| [25] | den Hollander, M. C., Bakker, C. A., and Hultink, E. J. | Product Design in a Circular Economy: Development of a Typology of Key Concepts and Terms | Journal article. Journal of Industrial Ecology | 2017 |

| [27] | Bocken, N. M. P., Pauw, I. de, Bakker, C., and van der Grinten, B. | Product Design and Business Model Strategies for a Circular Economy | Journal article. Journal of Industrial and Production Engineering | 2016 |

| [26] | Moreno, M., Ponte, O., and Charnley, F. | Taxonomy of Design Strategies for a Circular Design Tool | Conference proceedings. Proceedings of the 2nd Conference on Product Lifetimes and the Environment (PLATE) | 2017 |

| [28] | Allwood, J. M., Ashby, M. F., Gutowski, T. G., and Worrell, E. | Material Efficiency: A White Paper | Journal article. Resources, Conservation and Recycling | 2011 |

| [30] | Karana, E., Giaccardi, E., and Rognoli, V | Materially Yours | Book Chapter. In Routledge Handbook of Sustainable Product Design | 2017 |

| [29] | Haines-Gadd, M., Chapman, J., Lloyd, P., Mason, J., and Aliakseyeu, D. | Emotional Durability Design Nine: A Tool for Product Longevity | Journal article. Sustainability | 2018 |

| [24] | Go, T. F., Wahab, D. Abd., and Hishamuddin, H. | Multiple Generation Life-Cycles for Product Sustainability: The Way Forward | Journal article. Journal of Cleaner Production | 2015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Italia, M.; Papile, F.; Santi, R.; Del Curto, B. Sustainable Material Selection Framework: Taxonomy and Systematisation of Design Approaches to Sustainable Material Selection. Sustainability 2023, 15, 16689. https://doi.org/10.3390/su152416689

Italia M, Papile F, Santi R, Del Curto B. Sustainable Material Selection Framework: Taxonomy and Systematisation of Design Approaches to Sustainable Material Selection. Sustainability. 2023; 15(24):16689. https://doi.org/10.3390/su152416689

Chicago/Turabian StyleItalia, Mattia, Flavia Papile, Romina Santi, and Barbara Del Curto. 2023. "Sustainable Material Selection Framework: Taxonomy and Systematisation of Design Approaches to Sustainable Material Selection" Sustainability 15, no. 24: 16689. https://doi.org/10.3390/su152416689

APA StyleItalia, M., Papile, F., Santi, R., & Del Curto, B. (2023). Sustainable Material Selection Framework: Taxonomy and Systematisation of Design Approaches to Sustainable Material Selection. Sustainability, 15(24), 16689. https://doi.org/10.3390/su152416689