The Structure Features and Improvement of Concrete Properties with Dead Jellyfish Mass

Abstract

:1. Introduction

- −

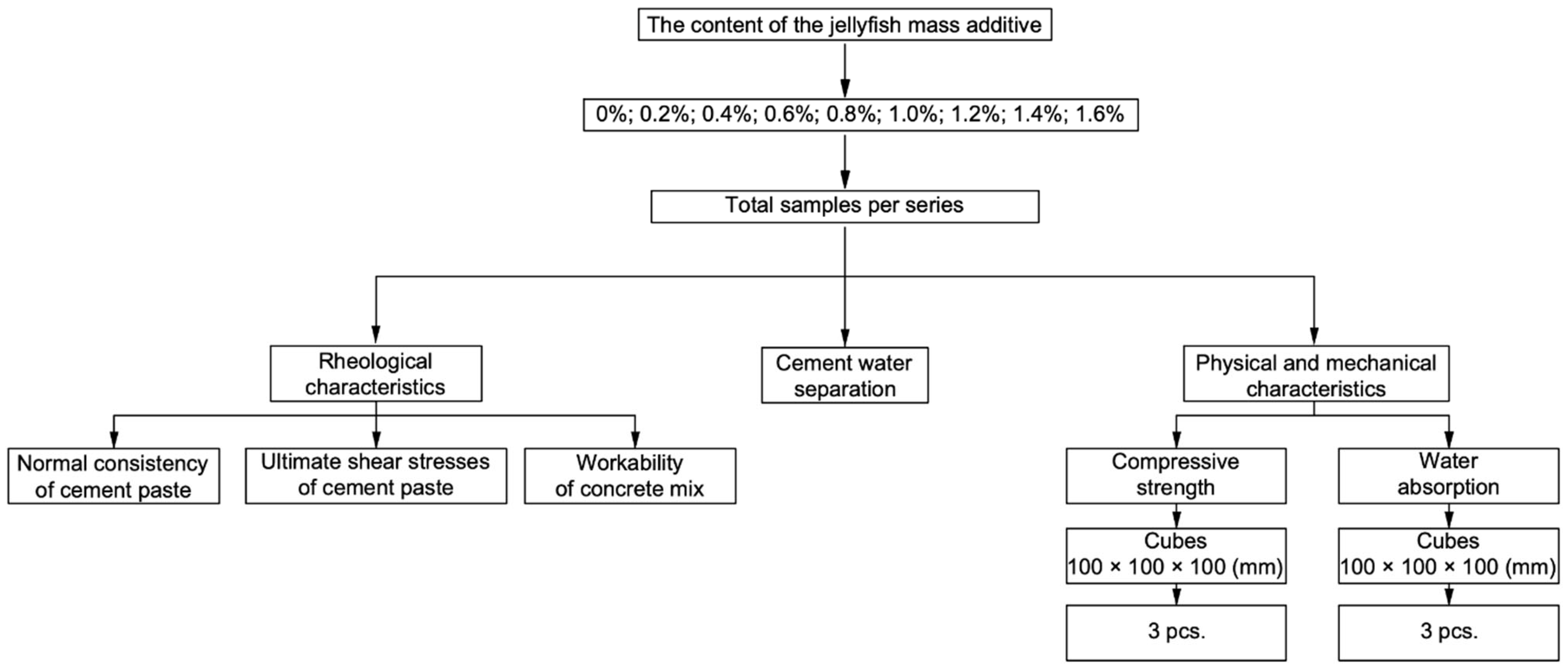

- Conducting experimental studies with a preliminary determination of the initial factors and parameters influencing the recipe and technological effectiveness of the proposed methods;

- −

- An analysis of the results obtained and a comparison of these results with the results obtained by other additives, similar in effect and mechanism of action but having a different nature of origin;

- −

- Determining the possibility and feasibility of such a use of dead jellyfish mass and clarifying specific recommendations for the applied industry, as well as a conclusion about the effectiveness of using such environmentally and cost-effective methods.

2. Materials and Methods

- −

- Portland cement CEM I 52.5N (PC) (Sebryakovcement, Volgograd, Russia);

- −

- Crushed sandstone (CS) (RostMed, Kamensk, Russia);

- −

- Quartz sand (S) (RostStroyMix, Rostov-on-Don, Russia)

- −

- The collection of dead jellyfish mass washed ashore and in the coastal zone;

- −

- The transportation of dead jellyfish mass in closed containers with a small amount of sea water to the laboratory;

- −

- Cleansing the collected dead jellyfish mass by washing it under running water;

- −

- Bringing the cleaned dead jellyfish mass to a gel-like state by cutting with a knife and squeezing with a pestle in a porcelain mortar;

- −

- The mandatory conservation of dead jellyfish mass;

- −

- The storage of preserved dead jellyfish mass.

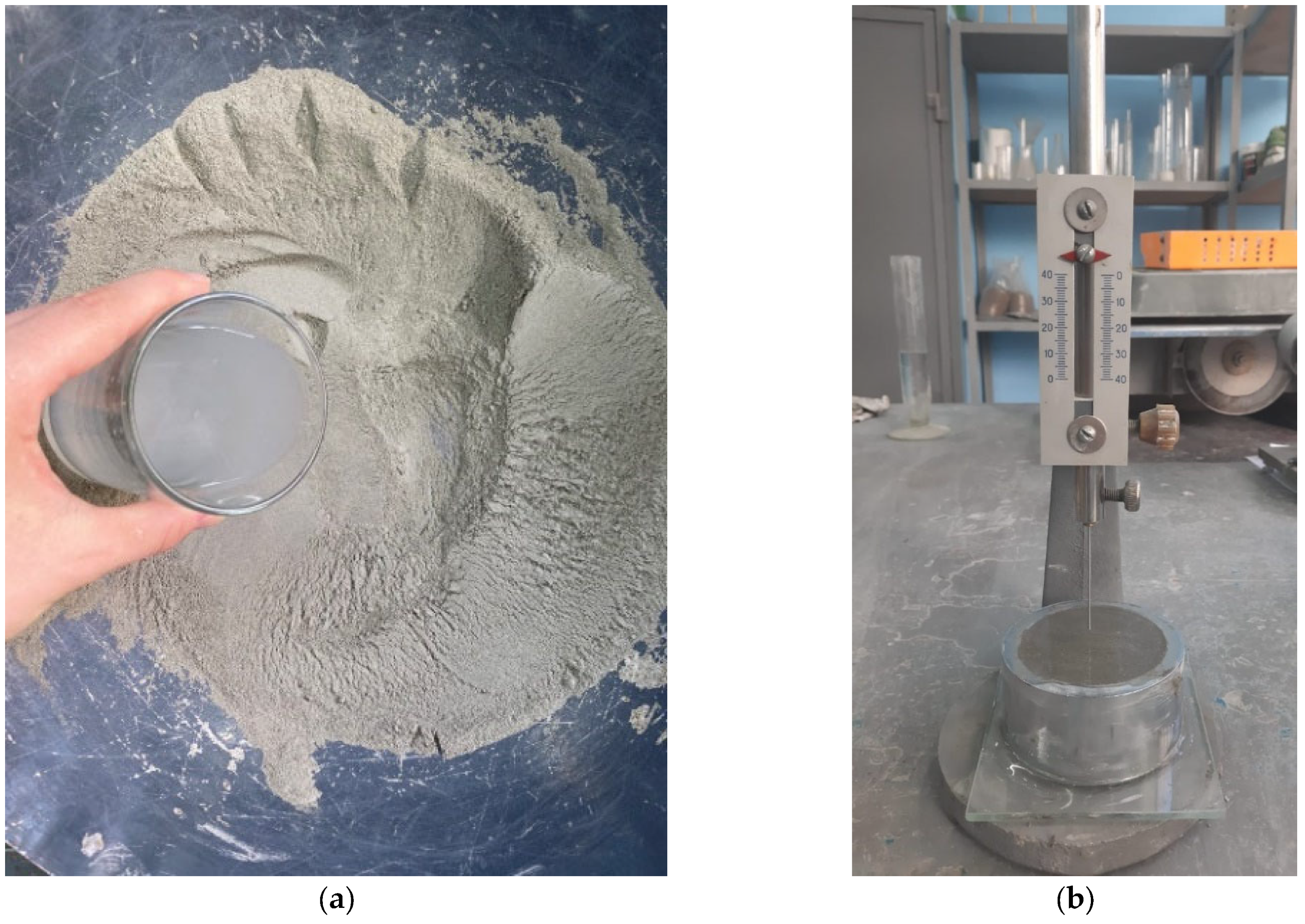

Methods

- F—breaking load (N);

- A—working section area of the sample (mm2);

- α—the scale factor for reducing the strength of concrete to the strength of concrete in samples of basic size, with the shape measured at 0.95.

- mw—the mass of the water-saturated sample (g);

- md—dry sample weight (g).

- −

- Laboratory concrete mixer BL-10 (ZZBO, Zlatoust, Russia);

- −

- Laboratory scales HT-5000 (NPP Gosmetr, St. Petersburg, Russia);

- −

- Cube shapes 2FK-100 (RNPO “RusPribor”, St. Petersburg, Russia);

- −

- Normal curing chamber KNT-1 (RNPO RusPribor, St. Petersburg, Russia);

- −

- Laboratory vibration platform (IMash, Armavir, Russia).

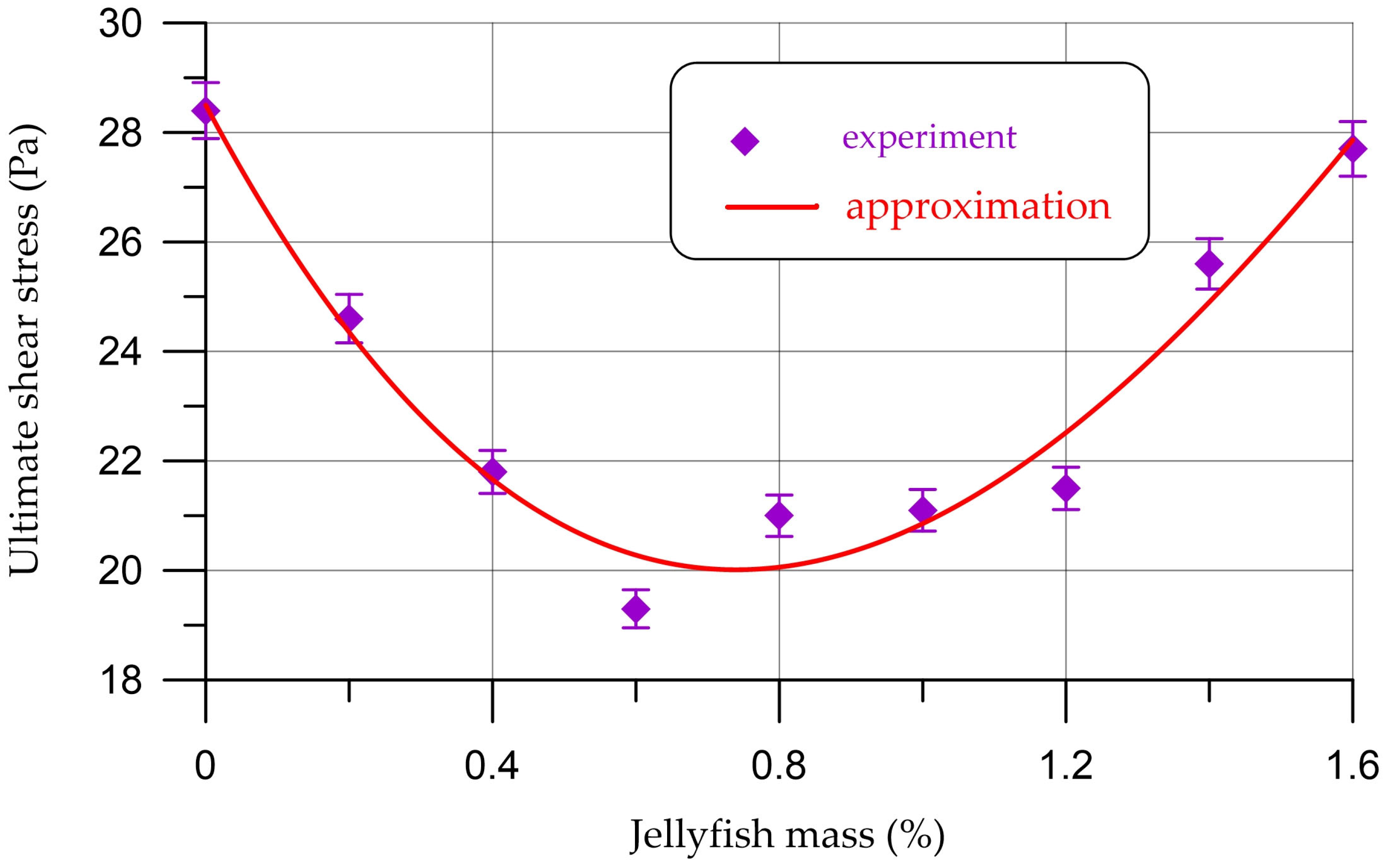

3. Results and Discussion

4. Conclusions

- (1)

- Dead jellyfish mass is a natural complex additive based on surfactants. The surface-active properties of the additive and its hydrophilicity were due to the presence of organic substances in the composition—protein and glycogen.

- (2)

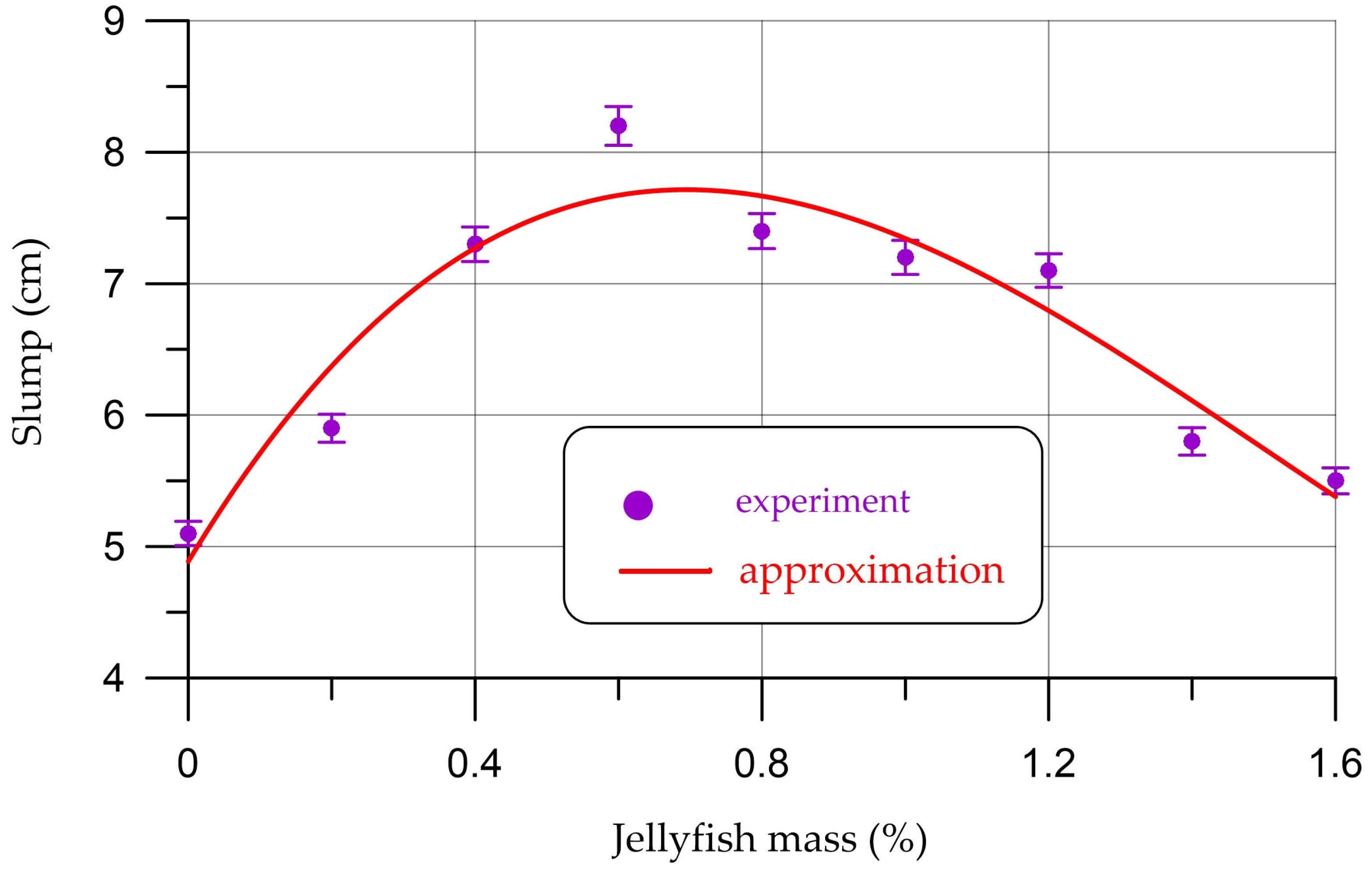

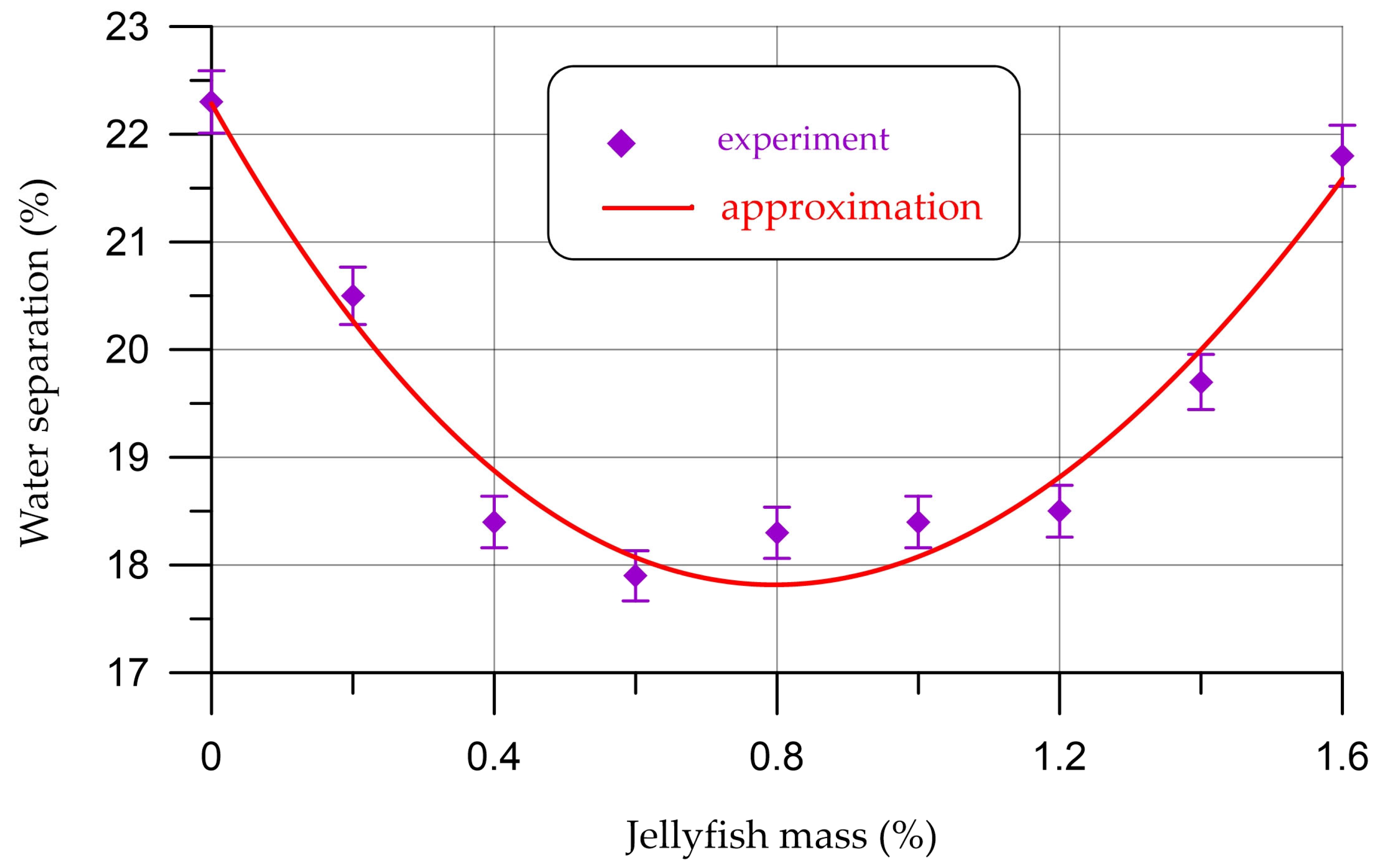

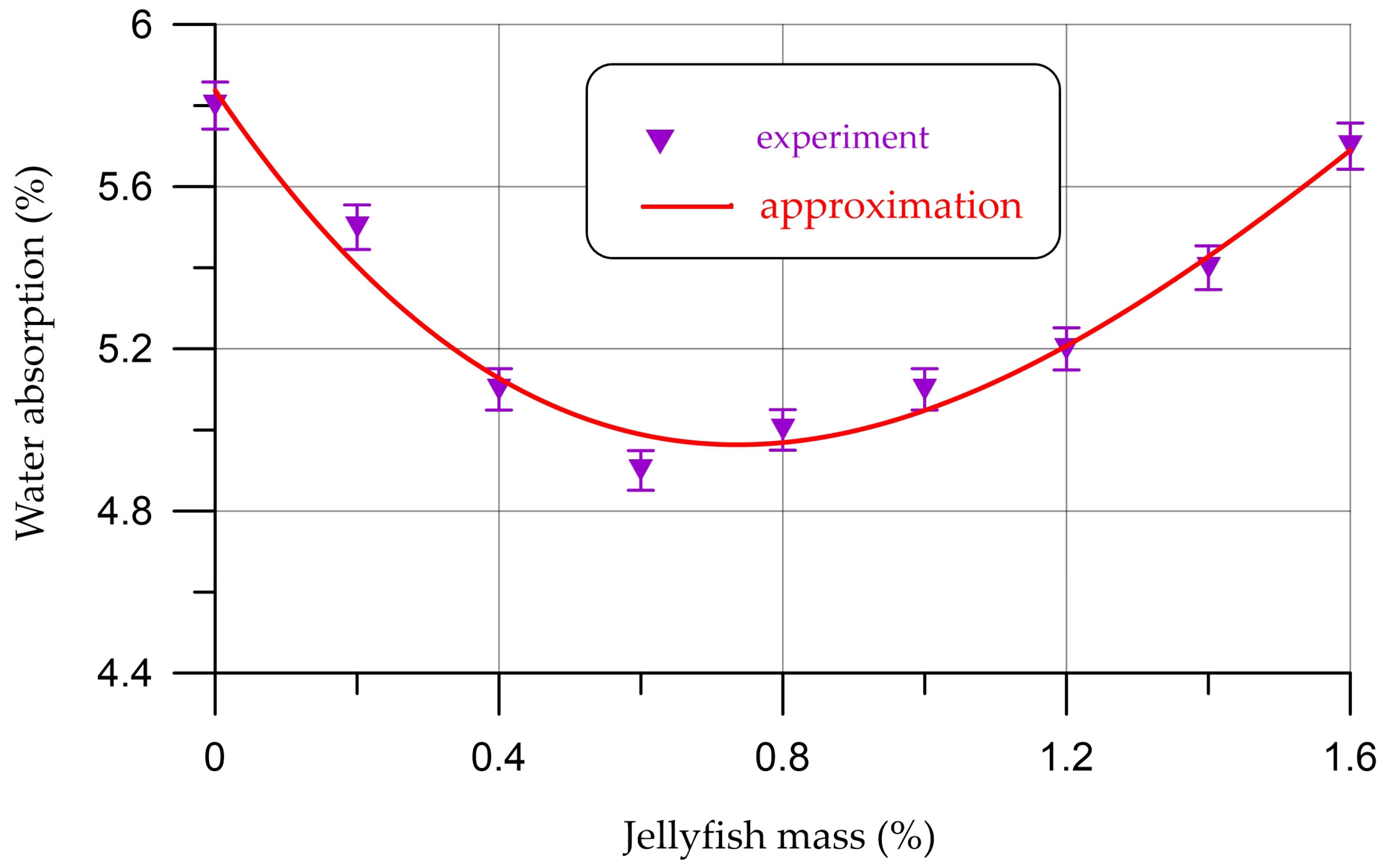

- Based on the results of the experimental studies, the optimal range for using the dead jellyfish mass additive in concrete was established, which varied from 0.2% to 1.2% by weight of cement. The greatest effectiveness was shown by the addition of dead jellyfish mass in an amount of 0.6%.

- (3)

- DJM improved the rheological characteristics of the cement paste. At 0.6% DJM, the normal consistency of the cement paste was reduced by 16.3%, and the ultimate shear stress was reduced by 32% compared to the control composition; the workability of the concrete mixture, expressed in its slump, improved by 60.8%; the water separation of the cement was reduced by 19.7%.

- (4)

- The strength of concrete with 0.6% DJM increased by 10.6%, and water absorption decreased by 15.5% compared to the control samples.

- (5)

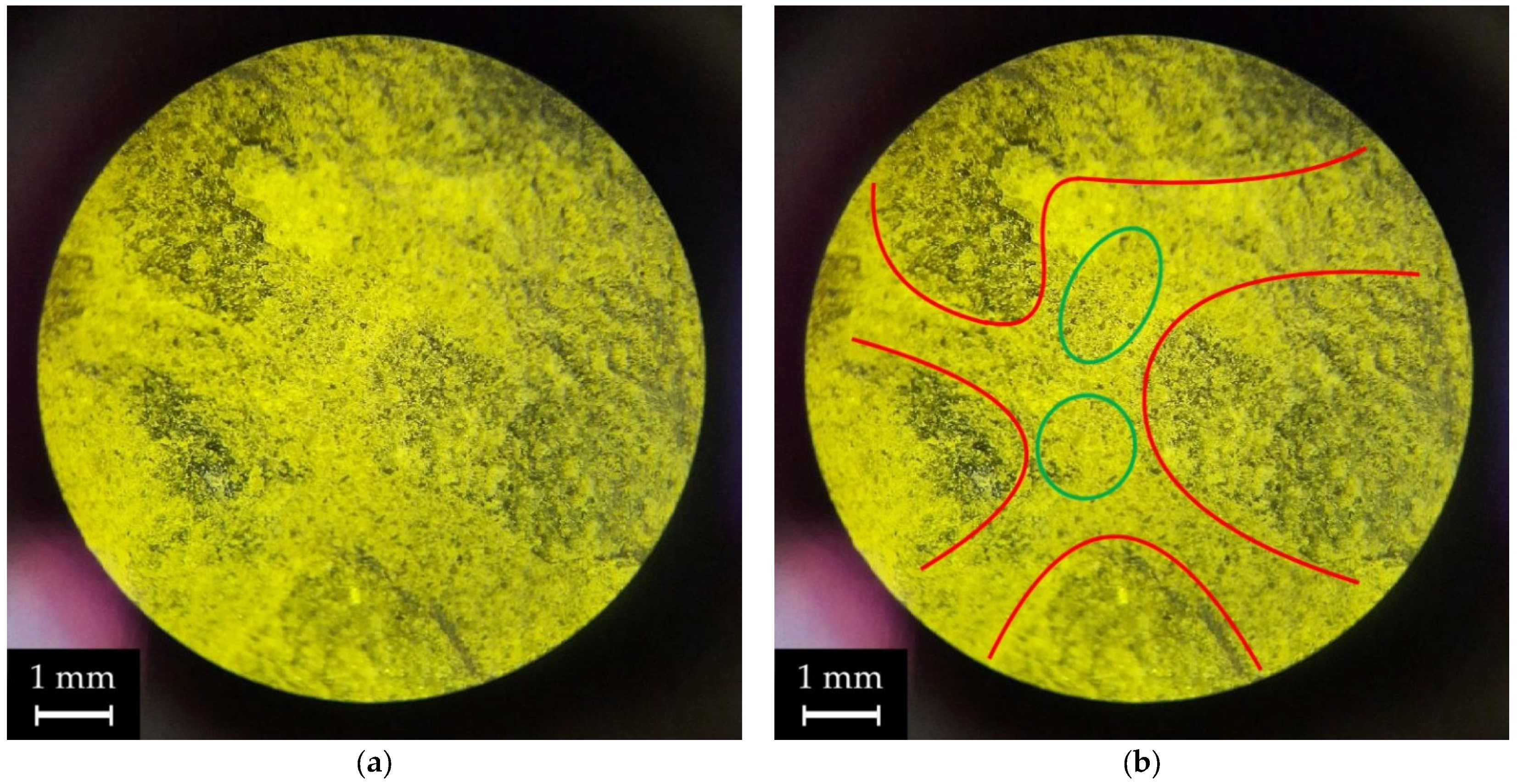

- The modification of the concrete structure with dead jellyfish mass reduced the overall porosity and made the structure denser.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, Y.; Shao, S.; Fang, B.; Shi, T.; Zhang, B.; Wang, X.; Zhao, X. Chloride ion penetration resistance of matrix and interfacial transition zone of multi-walled carbon nanotube-reinforced concrete. J. Build. Eng. 2023, 72, 106587. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, J.; Shao, X.; Li, L.; Sun, J.; Wang, X. The feasibility of using ultra-high performance concrete (UHPC) to strengthen RC beams in torsion. J. Mater. Res. Technol. 2023, 24, 9961–9983. [Google Scholar] [CrossRef]

- Li, Y.; Pei, J.; Zhang, F. Comprehensive Ecological Planning and Evaluation of Towns from the Perspective of Sustainable Development. Sustainability 2023, 15, 11153. [Google Scholar] [CrossRef]

- Wang, W.; Wei, W.; Gao, S.; Chen, G.; Yuan, J.; Li, Y. Agricultural and Aquaculture Wastes as Concrete Components: A Review. Front. Mater. Sci. 2021, 8, 762568. [Google Scholar] [CrossRef]

- Tang, Y.; Wang, Y.; Wu, D.; Chen, M.; Pang, L.; Sun, J.; Feng, W.; Wang, X. Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis. Rev. Adv. Mater. Sci. 2023, 62, 20230347. [Google Scholar] [CrossRef]

- Chen, L.; Chen, Z.; Xie, Z.; Wei, L.; Hua, J.; Huang, L.; Yap, P.-S. Recent developments on natural fiber concrete: A review of properties, sustainability, applications, barriers, and opportunities. Dev. Built Environ. 2023, 16, 100255. [Google Scholar] [CrossRef]

- Shetty, P.P.; Rao, A.U.; Pai, B.H.V.; Kamath, M.V. Performance of High-Strength Concrete with the Effects of Seashell Powder as Binder Replacement and Waste Glass Powder as Fine Aggregate. J. Compos. Sci. 2023, 7, 92. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; Dotsenko, N.; Kotenko, M. Nanomodified Concrete with Enhanced Characteristics Based on River Snail Shell Powder. Appl. Sci. 2022, 12, 7839. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Tashpulatov, S.S.; Chernil’nik, A.; Shcherban’, N.; Tyutina, A. Composition, Technological, and Microstructural Aspects of Concrete Modified with Finely Ground Mussel Shell Powder. Materials 2023, 16, 82. [Google Scholar] [CrossRef]

- Sukhinov, A.I.; Belova, Y.V.; Nikitina, A.V.; Atayan, A.M. Modeling biogeochemical processes in the Azov Sea using statistically processed data on river flow. Adv. Eng. Res. 2020, 20, 437–445. [Google Scholar] [CrossRef]

- Radulescu, V. Environmental Conditions and the Fish Stocks Situation in the Black Sea, between Climate Change, War, and Pollution. Water 2023, 15, 1012. [Google Scholar] [CrossRef]

- Cadar, E.; Pesterau, A.-M.; Sirbu, R.; Negreanu-Pirjol, B.S.; Tomescu, C.L. Jellyfishes—Significant Marine Resources with Potential in the Wound-Healing Process: A Review. Mar. Drugs 2023, 21, 201. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, Z.; Powell, L.C.; Matin, N.; Mearns-Spragg, A.; Thornton, C.A.; Khan, I.M.; Francis, L.W. Jellyfish Collagen: A Biocompatible Collagen Source for 3D Scaffold Fabrication and Enhanced Chondrogenicity. Mar. Drugs 2021, 19, 405. [Google Scholar] [CrossRef] [PubMed]

- Zhandarova, A.A.; Denisenko, E.V. Use of modern materials in biodirectional architecture. Constr. Mater. Prod. 2022, 5, 59–69. [Google Scholar] [CrossRef]

- Kovalenko, L.V. Improving the Properties of Cement Concrete by Adding Jellyfish Mass; RISI: Rostov-on-Don, Russia, 1985; 166p. [Google Scholar]

- Pivnenko, T.N.; Pozdnyakova, Y.M.; Kovalev, A.N. Research of methods of preparation of low-molecular collagen from jelly-fish rhopilema asamushi. Sci. Work. Dalrybvtuz 2017, 4, 43. [Google Scholar]

- Esparza-Espinoza, D.M.; del Carmen Santacruz-Ortega, H.; Plascencia-Jatomea, M.; Aubourg, S.P.; Salazar-Leyva, J.A.; Rodríguez-Felix, F.; Ezquerra-Brauer, J.M. Chemical-Structural Identification of Crude Gelatin from Jellyfish (Stomolophus meleagris) and Evaluation of Its Potential Biological Activity. Fishes 2023, 8, 246. [Google Scholar] [CrossRef]

- Ren, Y.; Liu, L.; Xiong, X.; Krastev, R.; Smeets, R.; Rimashevskiy, D.; Schnettler, R.; Alkildani, S.; Emmert, S.; Jung, O.; et al. Suitability of R. pulmo Jellyfish-Collagen-Coated Well Plates for Cytocompatibility Analyses of Biomaterials. Int. J. Mol. Sci. 2023, 24, 3007. [Google Scholar] [CrossRef]

- D’Ambra, I.; Merquiol, L. Jellyfish from Fisheries By-Catches as a Sustainable Source of High-Value Compounds with Biotechnological Applications. Mar. Drugs 2022, 20, 266. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, J.; Zhu, J.; Yang, Y.; Zhou, D.; Wang, T.; Shu, X.; Qiao, M. Advances in Organic Rheology-Modifiers (Chemical Admixtures) and Their Effects on the Rheological Properties of Cement-Based Materials. Materials 2022, 15, 8730. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; Zherebtsov, Y. Development of High-Tech Self-Compacting Concrete Mixtures Based on Nano-Modifiers of Various Types. Materials 2022, 15, 2739. [Google Scholar] [CrossRef]

- Qian, Y.; Lesage, K.; El Cheikh, K.; De Schutter, G. Effect of polycarboxylate ether superplasticizer (PCE) on dynamic yield stress, thixotropy and flocculation state of fresh cement pastes in consideration of the Critical Micelle Concentration (CMC). Cem. Concr. Res. 2018, 107, 75–84. [Google Scholar] [CrossRef]

- Mukhametrakhimov, R.K. Investigation of plasticizing additives based on polycarboxylate esters on the properties of concretes formed by 3D printing. Constr. Mater. Prod. 2022, 5, 42–58. [Google Scholar] [CrossRef]

- Lei, L.; Hirata, T.; Plank, J. 40 years of PCE superplasticizers—History, current state-of-the-art and an outlook. Cem. Concr. Res. 2022, 157, 106826. [Google Scholar] [CrossRef]

- Karakuzu, K.; Kobya, V.; Mardani-Aghabaglou, A.; Felekoğlu, B.; Ramyar, K. Adsorption properties of polycarboxylate ether-based high range water reducing admixture on cementitious systems: A review. Constr. Build. Mater. 2021, 312, 125366. [Google Scholar] [CrossRef]

- Sha, S.; Wang, M.; Shi, C.; Xiao, Y. Influence of the structures of polycarboxylate superplasticizer on its performance in cement-based materials-A review. Constr. Build. Mater. 2020, 233, 117257. [Google Scholar] [CrossRef]

- Plank, J.; Pöllmann, K.; Zouaoui, N.; Andres, P.R.; Schaefer, C. Synthesis and performance of methacrylic ester based polycarboxylate superplasticizers possessing hydroxy terminated poly(ethylene glycol) side chains. Cem. Concr. Res. 2008, 38, 1210–1216. [Google Scholar] [CrossRef]

- Guoxin, L.; Tingshu, H.; Dawei, H.; Chen, S. Effects of two retarders on the fluidity of pastes plasticized with aminosulfonic acid-based superplasticizers. Constr. Build. Mater. 2012, 26, 72–78. [Google Scholar] [CrossRef]

- Tian, Z.; Ren, J.; Li, H.; Wang, X.; Feng, Y.; Xiong, W.; Yang, J.; Xu, S.; Ren, Z. Synergistic Effect of Polycarboxylate Superplasticiser and Protein Retarders in Cementitious Materials Containing Na- Montmorillonite: Effect of Addition Methods. Materials 2022, 15, 6614. [Google Scholar] [CrossRef]

- Kong, T.-W.; Yang, H.-M.; Lee, H.-S.; Yoon, C.-B. Evaluations of All-in-One, Polycarboxylate-Based Superplasticizer with Viscosity Modifying Agents for the Application of Normal-Strength, High-Fluidity Concrete. Appl. Sci. 2021, 11, 11141. [Google Scholar] [CrossRef]

- El Bitouri, Y.; Azéma, N.; Le Saoût, G.; Lauten, R.A.; De Weerdt, K. Effect of Plasticizer on Hydration and Rheological Behavior of Cement Pastes. CivilEng 2022, 3, 748–759. [Google Scholar] [CrossRef]

- Magina, S.; Barros-Timmons, A.; Evtuguin, D.V. Synthesis of Lignosulfonate-Based Dispersants for Application in Concrete Formulations. Materials 2021, 14, 7388. [Google Scholar] [CrossRef] [PubMed]

- Danner, T.; Justnes, H.; Geiker, M.; Lauten, R.A. Phase changes during the early hydration of Portland cement with Ca-lignosulfonates. Cem. Concr. Res. 2015, 69, 50–60. [Google Scholar] [CrossRef]

- Colombo, A.; Geiker, M.; Justnes, H.; Lauten, R.A.; De Weerdt, K. The effect of calcium lignosulfonate on ettringite formation in cement paste. Cem. Concr. Res. 2018, 107, 188–205. [Google Scholar] [CrossRef]

- Stabili, L.; Rizzo, L.; Caprioli, R.; Leone, A.; Piraino, S. Jellyfish Bioprospecting in the Mediterranean Sea: Antioxidant and Lysozyme-Like Activities from Aurelia coerulea (Cnidaria, Scyphozoa) Extracts. Mar. Drugs 2021, 19, 619. [Google Scholar] [CrossRef] [PubMed]

- Turk, V.; Fortič, A.; Kos Kramar, M.; Tušek Žnidarič, M.; Štrus, J.; Kostanjšek, R.; Malej, A. Observations on the Surface Structure of Aurelia solida (Scyphozoa) Polyps and Medusae. Diversity 2021, 13, 244. [Google Scholar] [CrossRef]

- Garić, R.; Batistić, M. Description of Aurelia pseudosolida sp. nov. (Scyphozoa, Ulmaridae) from the Adriatic Sea. Water 2022, 14, 135. [Google Scholar] [CrossRef]

- GOST 310.3-76; Cements. Methods for Determination of Standard Consistency, Times of Setting and Soundness. Gost Standard: Moscow, Russia, 2003. Available online: https://docs.cntd.ru/document/871001226 (accessed on 6 October 2023).

- GOST 23789-2018; Gypsum Binders. Test Methods. Gost Standard: Moscow, Russia, 2018. Available online: https://docs.cntd.ru/document/1200160549 (accessed on 9 November 2023).

- GOST 33697-2015 (ISO 10414-2:2011); Oil-Based Drilling Fluids. Field Testing of Fluids Characteristics. Gost Standard: Moscow, Russia, 2016. Available online: https://docs.cntd.ru/document/1200136902 (accessed on 9 November 2023).

- GOST R 57809-2017/EN 12350-2:2009; Testing Fresh Concrete. Part 2. Slump Test. Gost Standard: Moscow, Russia, 2019. Available online: https://docs.cntd.ru/document/1200157288 (accessed on 6 October 2023).

- GOST 310.6-2020; Cements. Method for Determination of Water Separator. Gost Standard: Moscow, Russia, 2020. Available online: https://docs.cntd.ru/document/1200174649 (accessed on 6 October 2023).

- EN 12390-1:2021; Testing Hardened Concrete—Part 1: Shape, Dimensions and Other Requirements of Specimens and Moulds. iTeh Standards: Etobicoke, ON, Canada, 2021. Available online: https://standards.iteh.ai/catalog/standards/cen/d1c9ccee-2e5a-425e-a964-961da95d2f99/en-12390-1-2021 (accessed on 6 October 2023).

- EN 12390-2:2019; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/ae7e6a86-1cbc-455e-8b2a-8964be9087f9/en-12390-2-2019 (accessed on 6 October 2023).

- EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/7eb738ef-44af-436c-ab8e-e6561571302c/en-12390-3-2019 (accessed on 6 October 2023).

- BS 1881-122:2011+A1:2020; Testing Concrete Method for Determination of Water Absorption. European Standards: Plzen, Czech Republic, 2020. Available online: https://www.en-standard.eu/bs-1881-122-2011-a1-2020-testing-concrete-method-for-determination-of-water-absorption/ (accessed on 6 October 2023).

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; El’shaeva, D. Influence of the Chemical Activation of Aggregates on the Properties of Lightweight Vibro-Centrifuged Fiber-Reinforced Concrete. J. Compos. Sci. 2022, 6, 273. [Google Scholar] [CrossRef]

- Sritam Swapnadarshi, S.; Indu Siva Ranjani, G. Studies on influence of characteristics of surfactant and foam on foam concrete behaviour. J. Build. Eng. 2021, 40, 102333. [Google Scholar] [CrossRef]

- Lokesha, G.; Nantha Kumar, P.; Aishwarya, N.; Parthiban, P.; Ponshanmugaumar, A. Experimental study of the effect of water reducing admixtures on concrete. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Shana, G.; Zhao, S.; Qiao, M.; Gao, N.; Chen, J.; Ran, Q. Synergism effects of coconut diethanol amide and anionic surfactants for entraining stable air bubbles into concrete. Constr. Build. Mater. 2020, 237, 117625. [Google Scholar] [CrossRef]

- Dong, D.; Wang, Y.; Huang, Y.; Han, H.; Zhu, J.; Zhang, X.; Li, J.; Zhao, P.; Hou, P.; Lu, L. Effect of surfactants on the viscosity and hydration of magnesium ammonium phosphate cement. J. Build. Eng. 2023, 65, 105743. [Google Scholar] [CrossRef]

- Stepanov, S.V.; Morozov, N.M.; Khozin, V.G. Investigation of the phase composition of hydrated cement with a complex hardening accelerator. Proc. Kazan State Univ. Archit. Civ. Eng. 2015, 1, 31. [Google Scholar]

- Jin, W.; Yang, X.; Shang, W.; Wu, Y.; Guo, C.; Huang, W.; Deng, Q.; Peng, D. Assembled structure and interfacial properties of oleosome-associated proteins from Camellia oleifera as natural surface-active agents. LWT 2023, 173, 114318. [Google Scholar] [CrossRef]

- Mirpoor, S.F.; Ibáñez-Ibáñez, P.F.; Giosafatto, C.V.L.; Castillo-Santaella, T.; Rodríguez-Valverde, M.A.; Maldonado-Valderrama, J. Surface activity of protein extracts from seed oil by-products and wettability of developed bioplastics. Food Hydrocoll. 2023, 145, 109091. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; El’shaeva, D.; Kotenko, M. The Investigation of Compacting Cement Systems for Studying the Fundamental Process of Cement Gel Formation. Gels 2022, 8, 530. [Google Scholar] [CrossRef] [PubMed]

- Sybis, M.; Konował, E.; Prochaska, K. Dextrins as Green and Biodegradable Modifiers of Physicochemical Properties of Cement Composites. Energies 2022, 15, 4115. [Google Scholar] [CrossRef]

- Pourcheza, J.; Ruot, B.; Debayle, J.; Pourchez, E.; Grosseau, P. Some aspects of cellulose ethers influence on water transport and porous structure of cement-based materials. Cem. Concr. Res. 2010, 40, 242–252. [Google Scholar] [CrossRef]

- Akindahunsi, A.A. Investigation into the use of extracted starch from cassava and maize as admixture on the creep of concrete. Constr. Build. Mater. 2019, 214, 659–667. [Google Scholar] [CrossRef]

- Vieira, M.C.; Klemm, D.; Einfeldt, L.; Albrecht, G. Dispersing agents for cement based on modified polysaccharides. Cem. Concr. Res. 2005, 35, 883–890. [Google Scholar] [CrossRef]

- Gaidzhurov, P.P.; Volodin, V.A. Strength Calculation of the Coupling of the Floor Slab and the Monolithic Reinforced Concrete Frame Column by the Finite Element Method. Adv. Eng. Res. 2022, 22, 306–314. [Google Scholar] [CrossRef]

| Characteristics | Actual Value |

|---|---|

| Specific surface area (m2/kg) | 341 |

| Soundness (mm) | 0.5 |

| Fineness, passage through a sieve No 008 (%) | 98.3 |

| Setting times (min): | |

| - start | 180 |

| - end | 250 |

| Compressive strength (MPa): | |

| - 2 days | 26.8 |

| - 28 days | 58.5 |

| SiO2 (%) | 17.6 |

| Al2O3 (%) | 5.3 |

| Fe2O3 (%) | 4.7 |

| CaO (%) | 65.7 |

| MgO (%) | 1.5 |

| Alkali oxides in terms of | |

| (Na2O + 0.658 K2O) (%) | 0.5 |

| Insoluble residue (%) | 0.3 |

| SO3 (%) | 3.4 |

| Cl− (%) | 0.006 |

| Loss on Ignition (%) | 0.994 |

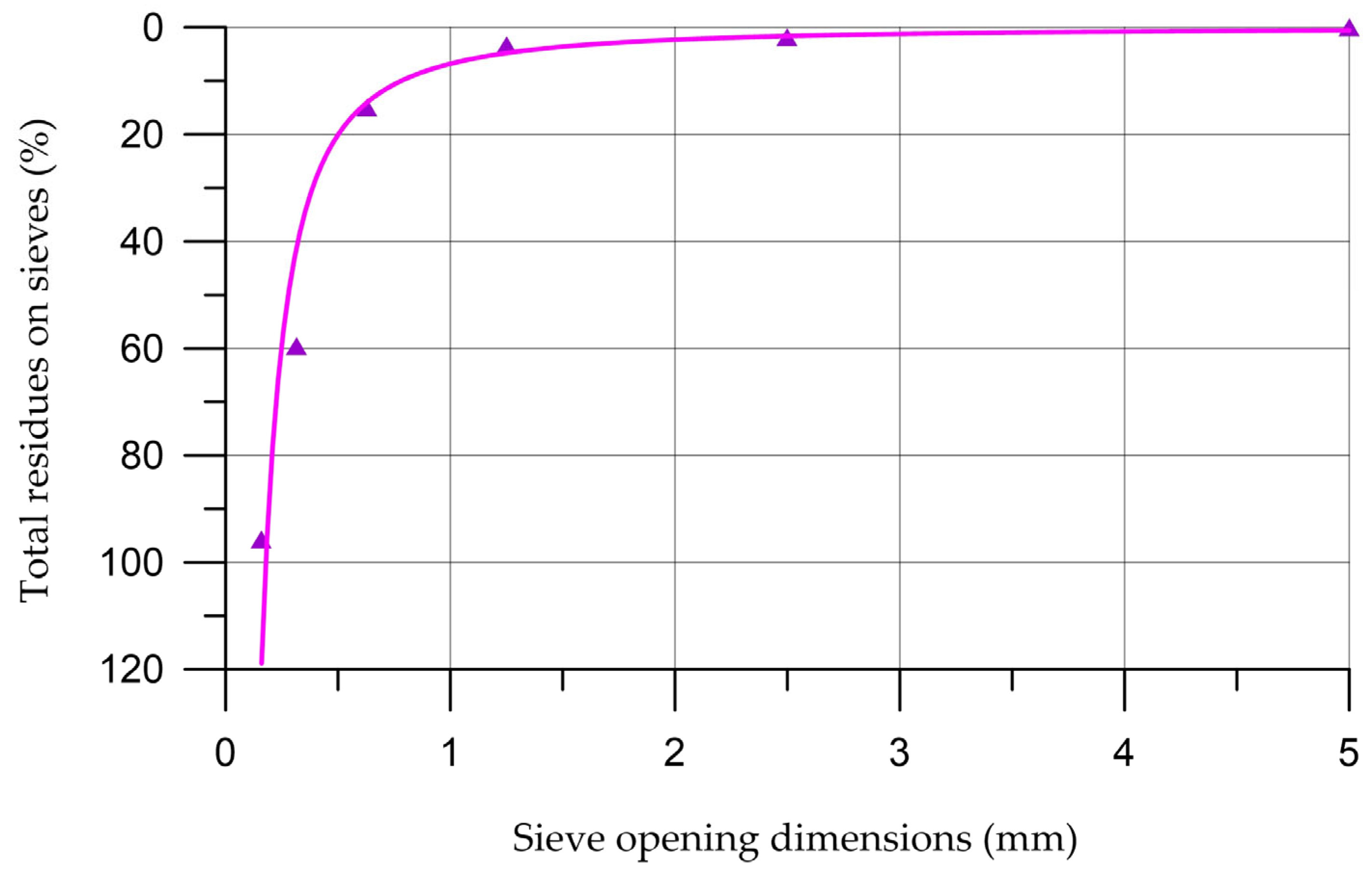

| Characteristics | Actual Value | |||||

|---|---|---|---|---|---|---|

| Bulk density (kg/m3) | 1341 | |||||

| The content of dust and clay particles (%) | 0.07 | |||||

| Content of clay in lumps (%) | 0.11 | |||||

| Organic and contaminant content | No | |||||

| Particle distribution | ||||||

| Sieve opening dimensions (mm) | Content (% by weight) of grains with a particle size of less than 0.16 mm | Fineness modulus | ||||

| Partial residues on sieves (%) | ||||||

| Total residues on sieves (%) | ||||||

| 2.5 | 1.25 | 0.63 | 0.315 | 0.16 | ||

| 1.9 | 1.4 | 11.7 | 44.6 | 36.1 | 4.7 | 1.76 |

| 1.9 | 3.3 | 15.0 | 59.6 | 95.7 | ||

| Characteristics | Actual Value |

|---|---|

| Particle size (mm) | 5–20 |

| Bulk density (kg/m3) | 1415 |

| Apparent density (kg/m3) | 2567 |

| Resistance to fragmentation (wt %) | 11.4 |

| The content of lamellar and acicular grains (wt %) | 8.3 |

| Name of Substance | Content (% by Raw Jellyfish Mass) |

|---|---|

| Water | 95.5 ± 1.5 |

| Protein | 0.56 ± 0.12 |

| Fat | 0.02 ± 0.002 |

| Glycogen | 1.55 ± 0.34 |

| Ash residue | 2.37 ± 0.48 |

| Name of Chemical Element | Content in g/kg of Jellyfish Mass |

|---|---|

| Ca | 12.1 |

| P | 0.61 |

| Na | 3.93 |

| Cl | 6.07 |

| Composition Type | Concrete Mixture Proportion per 1 m3 | ||||

|---|---|---|---|---|---|

| PC (kg/m3) | W (l/m3) | CS (kg/m3) | S (kg/m3) | Dead Jellyfish Mass (% by Weight of Cement) | |

| C | 361 | 205 | 985 | 738 | 0 |

| DJM0.2 | 361 | 205 | 985 | 738 | 0.2 |

| DJM0.4 | 361 | 205 | 985 | 738 | 0.4 |

| DJM0.6 | 361 | 205 | 985 | 738 | 0.6 |

| DJM0.8 | 361 | 205 | 985 | 738 | 0.8 |

| DJM1.0 | 361 | 205 | 985 | 738 | 1.0 |

| DJM1.2 | 361 | 205 | 985 | 738 | 1.2 |

| DJM1.4 | 361 | 205 | 985 | 738 | 1.4 |

| DJM1.6 | 361 | 205 | 985 | 738 | 1.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Tyutina, A.; Chernil’nik, A.; El’shaeva, D. The Structure Features and Improvement of Concrete Properties with Dead Jellyfish Mass. Sustainability 2023, 15, 16617. https://doi.org/10.3390/su152416617

Beskopylny AN, Stel’makh SA, Shcherban’ EM, Mailyan LR, Meskhi B, Tyutina A, Chernil’nik A, El’shaeva D. The Structure Features and Improvement of Concrete Properties with Dead Jellyfish Mass. Sustainability. 2023; 15(24):16617. https://doi.org/10.3390/su152416617

Chicago/Turabian StyleBeskopylny, Alexey N., Sergey A. Stel’makh, Evgenii M. Shcherban’, Levon R. Mailyan, Besarion Meskhi, Anastasia Tyutina, Andrei Chernil’nik, and Diana El’shaeva. 2023. "The Structure Features and Improvement of Concrete Properties with Dead Jellyfish Mass" Sustainability 15, no. 24: 16617. https://doi.org/10.3390/su152416617

APA StyleBeskopylny, A. N., Stel’makh, S. A., Shcherban’, E. M., Mailyan, L. R., Meskhi, B., Tyutina, A., Chernil’nik, A., & El’shaeva, D. (2023). The Structure Features and Improvement of Concrete Properties with Dead Jellyfish Mass. Sustainability, 15(24), 16617. https://doi.org/10.3390/su152416617