Abstract

This paper presents a two-stage mathematical model aimed at enhancing supply chain efficiency by evaluating multiple sourcing strategies and optimizing extra procurement. In the first stage, the model minimizes the gap between Sales and Operation Planning (SOP) and maximum product quantity achievable with current inventory levels, setting the foundation for understanding resource requirements. The second stage focuses on extra procurement strategy optimization, considering lead times, cost-effectiveness. We analyze the trade-offs between multiple sourcing and single vendor approaches, providing valuable insights for supply chain decision-makers. This research offers a practical framework to improve supply chain efficiency, reduce gaps, and enhance customer satisfaction while strengthening supply chain resilience in the face of unforeseen challenges, as demonstrated by the lessons from the COVID-19 pandemics.

1. Introduction

Electronic manufacturing is a dynamic and highly competitive sector characterized by its relentless pace of technological advancement, product diversification, and rapidly shifting market demands. This industry plays a pivotal role in powering modern life, as it produces a wide range of electronic devices, parts, and systems, from smartphones and laptops to medical devices and automotive electronics. As consumers and businesses increasingly rely on electronic products, manufacturers face a growing need to optimize their production processes and supply chains to meet evolving expectations efficiently.

The onset of the COVID-19 pandemic in early 2020 introduced unprecedented challenges to the electronic manufacturing landscape. The pandemic disrupted global supply chains, causing shortages in critical electronic parts, raw materials, and skilled labor. Lockdowns, travel restrictions, and factory closures further exacerbated these issues, making resource constraints even more pronounced and unpredictable. Manufacturers had to adapt rapidly to this new reality, reevaluate their production strategies, and find innovative ways to mitigate the impact of these disruptions. According to the report by Ernst and Young [1], automotive and the vast majority (97%) of industrial products companies have reported experiencing adverse impacts due to the pandemic. Furthermore, 47% of all organizations indicated that the pandemic had disrupted their workforce.

Such kind of supply chain disruptions are more observed in the electronic manufacturing industries (Cai and Luo [2]). To understand the situation, it is necessary to understand the overall characteristics of the concomitant industry. One of the distinctive features of electronic manufacturing is the constant need for innovation. Electronic devices are subject to rapid obsolescence due to continuous advancements in technology, design, and functionality. Consequently, manufacturers must continuously adapt their product offerings to incorporate the latest technological breakthroughs and stay ahead of the competition. This frequent product turnover creates an inherent complexity in production planning, as it demands not only the efficient production of existing product lines but also the rapid introduction of new products and variants (Choi et al. [3]).

Resource constraints, intensified by the challenges brought about by the pandemic, are a perennial challenge in electronic manufacturing (Montoya-Torres et al. [4]). These constraints manifest in various forms, including limited production capacity, finite availability of critical parts, skilled labor shortages, and finite floor space. Such constraints can disrupt production schedules, delay product launches, and impact the overall profitability of electronic manufacturers. Consequently, effective resource management becomes paramount to ensure that production capabilities are optimized and aligned with business goals (Moosavi et al. [5]).

To meet the Sales and Operations Plan (SOP), electronic manufacturing companies often need to employ sophisticated procurement practices. This includes strategically sourcing critical parts and materials, either through traditional suppliers or by exploring alternative supply chain channels. The procurement process must be agile and responsive to market dynamics, ensuring that the necessary materials are available when needed to support the production plan. In the face of resource constraints and the unpredictability brought about by the pandemic, procurement practices become essential in bridging the gap between supply and demand and achieving the goals outlined in the SOP (Agarkov et al. [6]).

Moreover, electronic manufacturing frequently involves the production of products with multiple sourcing strategies (Kotula et al. [7]), allowing for the selection of different vendors and the comparison of these strategies against single sourcing approaches. This multi-sourcing strategy condition stems from the inherent complexity of electronic products, which often comprise numerous parts, sub-assemblies, and variants. Each sourcing strategy may have different part requirements, lead times, costs, and associated risks. Managing and optimizing production across these various sourcing strategies requires sophisticated decision-making processes to balance efficiency, cost-effectiveness, and product quality (Zhu [8]).

The ability to adapt to unexpected disruptions, such as those seen during the COVID-19 pandemic (Basit et al. [9]), highlights the crucial role of supply chain resilience in electronic manufacturing (Ye and Lau [10]). Specifically, vast amount of literature studied and reviewed the supply chain resilience in various perspective (Rajesh [11]; Soni et al. [12]; Hosseini et al. [13]). Resilience refers to an organization’s capacity to absorb shocks, recover quickly from disruptions, and adapt to changing circumstances. In this context, multiple sourcing strategies and agile procurement practices are vital elements of supply chain resilience. By diversifying sourcing options and being responsive to market dynamics, electronic manufacturing companies can enhance their resilience to unforeseen challenges, ensuring a more robust and flexible supply chain. Especially, under the situation where the U.S.–China trade war is combined, firms were motivated to shift to a “China plus one” strategy of spreading production between China and a Southeast Asian country (Harvard Business Review [14]).

In this intricate landscape, SOP serves as a cornerstone for effective electronic manufacturing management. SOP is a strategic process that aligns production plans with demand forecasts, sales targets, and overall business objectives. Achieving harmony between production planning and SOP is essential to ensure that customer demand is met promptly, inventory levels are optimized, and production resources are utilized efficiently. Any misalignment between production planning and SOP can lead to sub-optimal resource utilization, excess inventory, or customer service disruptions, all of which can have significant financial repercussions.

Hence, this study addresses the challenges of resource constraints, supply chain resilience, and effective procurement practices to provide a holistic approach to optimizing electronic manufacturing operations. Specifically, we address two-stage decision framework to handle the concomitant problem, each of which are modeled as a mixed-integer linear programming. In the first phase, the initial model calculates the maximum production quantity that can be assembled under the consideration of current inventory level and target quantity, namely SOP. Next, after noticing the inevitable gap between SOP and calculated quantity, the model seeks to consider resource procurement considering two procurement methods with lead time. In this paper, we name the framework as a Resource-Constrained Multi-Phased Procurement Optimization Model, or RCMPO in short.

This paper is organized as follows. In Section 2, we present the related literature to explain the basic ideas of the proposed problem. Next, we formally define the problem in mathematical form, together with two-stage mixed-integer linear programming which are explained in detail. In Section 4, we use the dataset provided by the global leading electronic manufacturing company to computationally compare the effectiveness and efficiency of the proposed math model. Taking a deeper step, we test two scenarios to observe the solution behavior with regard to parameter changes. Lastly, we conclude this paper and suggests the future possible research directions.

2. Literature Review

This literature review thoroughly reviews the two foundational aspects in contemporary supply chain management together with a brief summary of conventional inventory management literature: the multiple sourcing strategy and procurement strategy optimization. These elements serve as essential pillars upon which resilient and efficient manufacturing organizations are erected. Amid the intricate dynamics of modern markets and supply chain uncertainties, these interrelated strategies offer the potential for heightened adaptability, robustness, and cost-efficiency. Our inquiry is devoted to navigating the extensive research landscape surrounding these critical elements, elucidating the methodologies, empirical insights, and findings that guide strategic decisions within manufacturing firms striving for supply chain excellence.

2.1. Inventory Management and Post-Pandemics

Inventory management is a critical component of supply chain and operations management, encompassing the planning, control, and optimization of the various components that make up an organization’s inventory. A thorough review of the inventory management in operations research perspective is well explained in the work of Silver [15].

One of the central themes in inventory management is the trade-off between carrying costs and ordering costs. Harris [16] introduced the economic order quantity (EOQ) model and it remains a foundational framework for balancing these costs. The EOQ model provides a framework for determining the optimal order quantity that minimizes the total inventory costs, considering ordering costs and holding costs.

Researchers have developed several extensions and variations to the EOQ model to account for complexities in real-world scenarios. The Economic Production Quantity (EPQ) model extends EOQ model by considering production constraints. EPQ enables organizations to determine the optimal production quantity minimizing their production, ordering, and holding costs simultaneously (Harris [17]).

The COVID-19 pandemic has forced the industry to change the conventional practices, requiring innovative practices for any kind of industry fields. For example, tourism (Sousa et al. [18] and Sousa et al. [19]), business management (Illiashenko et al. [20]), or education sector (Shen and Guo [21]) have searched for novel breakthroughs to overcome pandemic situations. For the case of supply chain management, Ali et al. [22] has thoroughly reviewed the main drivers for Internet of Things (IoT) adoption in the post-pandemic situations. Discrete event simulation has been used to deal with the strategy to safely exit the post-pandemic situation, where post-disruption recovery is the main consideration (Ivanov [23]). However, to the best of our knowledge, no studies have investigated or suggested the compact decision framework to consider production with multiple sourcing and extra consideration of the use of procurement strategies.

2.2. Multiple Sourcing Strategy

Supplier selection and sourcing strategies play a pivotal role in the success of manufacturing organizations. The decision to choose suppliers is a multifaceted process, encompassing considerations such as cost, quality, reliability, and capacity (Weber [24]; Hassanzadeh [25]). Traditionally, companies relied on single-sourcing strategies, where one primary supplier provided essential elements. However, with the increasing complexity and globalization of supply chains, manufacturing firms have shifted towards multiple-sourcing strategies, diversifying their supplier base across several providers (Burke [26]).

The adoption of multiple sourcing brings several advantages, including decreased supply chain risk, enhanced quality, and cost-efficiency (Burke [26]; Yohanes [27]). When confronted with high demand uncertainty, dual or multiple sourcing often emerges as the preferred strategy (Burke [26]). Nevertheless, this approach also introduces challenges, such as heightened coordination complexities and increased costs (Yohanes [27]). The optimal sourcing strategy hinges on factors like product attributes, supplier characteristics, and the priorities of the company (Agarwal [28]).

Various methodologies have been devised for a comprehensive, multi-criteria evaluation, and selection of suppliers. The Analytic Hierarchy Process (AHP) stands out as a favored approach, as it takes into account both qualitative and quantitative criteria to determine the most suitable set of suppliers (Sharma and Dubey [29]). Additionally, mathematical programming models, including Linear Programming (LP) and Integer Programming (IP), have been applied to optimize supplier selection while considering cost and capacity constraints (Hassanzadeh [25]). Data Envelopment Analysis (DEA), employing linear programming techniques, evaluates supplier efficiency by identifying those capable of meeting buyer requirements at the lowest cost (Hassanzadeh [25]).

In conclusion, the existing body of literature suggests that, in uncertain manufacturing environments, multiple-sourcing strategies are often the preferred choice. Numerous multi-criteria decision-making methods exist to assess suppliers based on diverse criteria. The ultimate sourcing strategy and supplier selection method should be tailored to the unique priorities and constraints of each manufacturing firm.

2.3. Procurement Strategy Optimization

This papers explore various strategies for optimizing resource usage and supply chain management in manufacturing, especially electronics manufacturing. Sen [30] proposes evaluating and optimizing integrated supply chain demand response strategies (SCDRS) like make-to-stock, make-to-order, and assemble-to-order. Migalska [31] develops an integer linear programming model to optimize finished goods allocation to customers and raw materials to products under constraints like parts shortage. This approach enables quick response to supply challenges and systematic supply chain decision making. Ștefea [32] highlights ways to optimize resource consumption of direct materials, labor, and overhead to increase manufacturing efficiency. Rao [33] reviews current supply chain strategies and suggests improvements like increasing flexibility and agility to ensure customers get the right products on time. Hammer [34] proposes leveraging lean, green, and constraint management approaches with an integrated loss bridge to reduce waste and costs. Ghani [35] proposes a conceptual approach to minimize energy consumption in production with an integrated monitoring system to help sustainable resource use. Tian [36] develops a graph-based cost model to optimize manufacturing supply chain network configuration for reconfiguration decisions considering outsourcing and risks. The model minimizes total cost including operating and reconfiguration cost. The graph-based model relates supply chain network graphical similarity to reconfiguration cost. In summary, the papers propose various optimization models and strategies to improve resource usage, supply chain management, and responsiveness in manufacturing. Integrating lean, green, and constraint management and optimizing supply chain demand response and network configuration can help minimize costs, reduce waste, ensure customer satisfaction, and promote sustainability.

2.4. Research Gap

As reviewed, the existing literature on supply chain optimization predominantly focuses on either various sourcing methods to meet the SOP or procurement strategies independently. However, there is a notable research gap concerning the integration of these two critical aspects of supply chain management into a cohesive, two-stage mathematical model. Specifically, there is limited research that systematically minimizes the gap between SOP and maximum product quantity achievable with current inventory levels and subsequently optimizes extra procurement strategies, taking into account factors such as lead times and cost effectiveness. Furthermore, the literature lacks a comprehensive analysis of the trade-offs between multiple sourcing and single vendor approaches within this integrated framework. Addressing this research gap is essential for providing supply chain decision-makers with a holistic and practical approach to enhance supply chain efficiency and resilience, especially in the situation where supply chain is disrupted, as demonstrated during the COVID-19 pandemic.

3. Problem Description and Mathematical Model

In this section, we explain the proposed problem. We consider the situation where each product has several possible sourcing strategy with various costs that can be chosen upon. In such condition, we aim to create an optimal production plan to meet the given SOP as much as possible, which in turn can be rephrased as minimizing the gap between the SOP and production plan. In this study, we employ the Mixed-Integer Linear Program (MILP) to obtain the optimal solutions, a methodology commonly utilized for SOP optimization (Pereira, Oliveira, and Carravilla [37]).

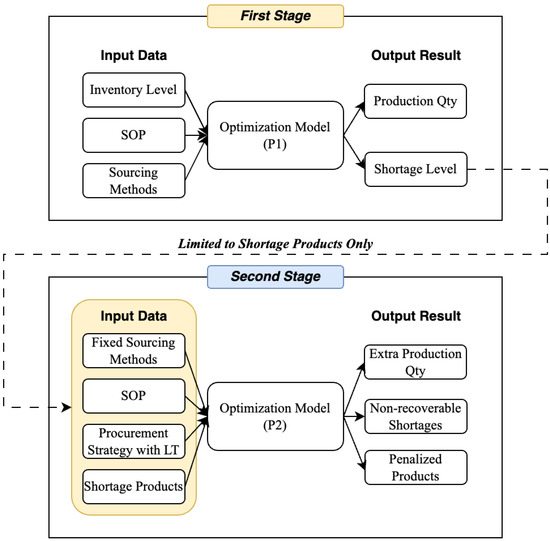

Given the condition, we divide the decision steps into two-stages. In the first stage, the model calculates the production quantity under current inventory level. Explicitly, the model does not consider the extra resource procurement in this step. The intention behind this is to give the planner an idea of the current best production plan under the given resource level. Next, the second stage is executed where the model search for a possible objective value enhancement with resource procurement. In this step, we decide whether to additionally procure resources to meet the SOP level under profit and lead time consideration. Specifically, two procurement methods exist: (1) Normal Procurement Strategy and (2) Express Procurement Strategy. The normal procurement strategy corresponds to moderate time-required delivery with moderate cost, for example truck delivery or vessel shipping. On the other hand, the express procurement strategy provides faster delivery with higher cost compared to the normal procurement strategy.

Figure 1 shows the concomitant structure of the overall framework with two-stages. As shown in the figure, the first stage calculates the production quantity and shortage quantity considering three data: Inventory Level, SOP and Sourcing Methods. In the second stage, the model optimizes the procurement strategy under the consideration of the shortage products only.

Figure 1.

The overall framework of RCMPO. Note that the results of the first stage are used as inputs in the second stage.

3.1. Assumptions and Preliminaries

Now, we address the assumptions that our problem holds.

- We assume a fictional electronics manufacturing company where multiple sourcing is in consideration compared to single sourcing strategy.

- The SOP level and current inventory level are given, where the SOP quantities for each product strictly exceed the possible production quantities using current inventory level.

- The product can be produced with various parts sourced from multiple vendors.

- We do not allow additional resource procurement in the first stage, rather consider in the second stage so as to provide the maximum production quantity possible at the current stage to the planner.

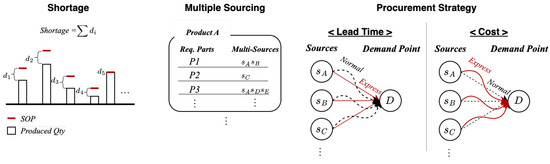

Under such assumptions, we explain some important concept that we utilize in this paper (See Figure 2 for illustrated version). First, we explain Shortage that represents the gap between SOP level and calculated production quantity. The minimization of this shortage is the main objective of the Stage 1. When minimizing the shortage, the model also has to consider the cost of the production. Such consideration is dealt with multiple sourcing strategy optimization. The multiple sourcing strategy is common strategy in manufacturing industries, where the resources are provided from multiple vendors with different costs. For example, as illustrated in Figure 2, the part P1 can be sourced from source A or B, while some parts are solely sourced from a single vendor. Lastly, the procurement strategy used in the Stage 2 can be described in a multi-arc graph as shown in Figure 2. Specifically, we assume that there are two ways to procure the parts, each of which are normal and express. The normal procurement strategy requires a longer lead time with less cost, where the express procurement strategy requires a higher cost but provides faster shipping.

Figure 2.

The illustration of the three important concepts: shortage, multiple sourcing and procurement strategy.

3.2. Stage 1: Production Planning under Resource Constraints

Stage 1 forms the foundational core of our comprehensive decision framework for electronic manufacturing. In this initial phase, we adeptly balance resource constraints—ranging from limited production capacities to the complexities of multiple sourcing strategies—with the imperative of aligning production plans with the SOP. Our mathematical model is precisely harnessed to minimize discrepancies between the SOP and the maximum feasible production quantity while judiciously managing available resources. Against the backdrop of global disruptions, such as those witnessed during the COVID-19 pandemic, Stage 1 emerges as the essential starting point on the path toward operational excellence in this dynamic industry. Here, theoretical models are pragmatically transformed into adaptable solutions, establishing the groundwork for effective production planning. Subsequent sections of this paper will provide in-depth insights into the mathematical formulations and computational methodologies that underpin Stage 1, offering a comprehensive guide for electronic manufacturing companies navigating the intricate terrain of production planning.

3.2.1. Preliminaries: Sets and Variables

Now, we define sets and necessary variables to solve the Stage 1 problem. First, we define a set P that refers to the set of product SOP requires. Then, we can define a set B consisted of a subset , such that represents a set of configuration b for product . Let I be an auxiliary set to indicate the index of a part that are scattered across the various configurations. Now, we define a set R which indicates the branches of a single configuration from the root node. Then, we can explicitly create an ordered set | i elements that are only in configuration b, Branch r}, where . Creating this set is very critical, and thus will be explained in detail at the next subsection. The SOP quantity of each product p is given as a set . Table 1 formally explains the sets and parameters.

Table 1.

Sets and Parameters—Stage 1.

Let be a decision variable to indicate the production quantity of a product p by configuration . Given the quantity of a resource required to create a product p with a designated configuration as , the decision variable is a non-negative continuous variable indicating the actual total quantity used to create the product p. See Table 2 for a detailed explanation.

Table 2.

Decision Variables—Stage 1.

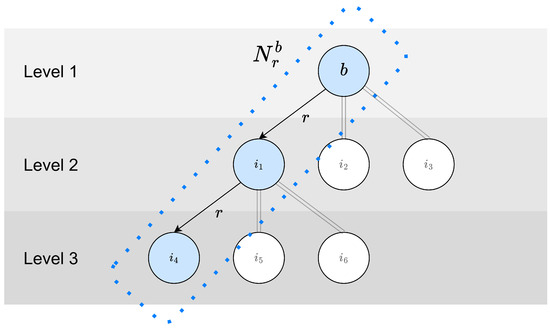

3.2.2. Sourcing Strategy Set Creation

In Section 3.2.1, we outlined the need to construct an ordered set, , to address the Stage 1 problem. As detailed in the prior section, each element within a configuration b exhibits a hierarchical level. Higher-level elements are systematically assembled from those of the subsequent level, signifying a transformation from raw materials to semi-finished goods. To produce a specific configuration, one might utilize solely raw materials, exclusively semi-finished goods immediately preceding the final product, or even a combination of elements across all levels. Given this complexity, it’s imperative to establish a set comprising all hierarchically related elements. To achieve this, we employ the Depth First Search (DFS) algorithm. This method delves downwards until encountering an element without a lower hierarchical counterpart, at which point a branch r is formed. The constituent part j within this branch then populate the set . Graphical illustration of the set creation is shown in Figure 3.

Figure 3.

Within configuration b, each element is characterized by a hierarchical level. We utilize a depth first search to generate a branch r. The elements found within this branch then compose the set .

3.2.3. Mathematical Model

Using the sets, variables, and properly defined sets, we formally define the mathematical model (P1) as follows.

The objective function (1) aims to maximize the production quantity possible, which equals to minimizing the shortage. Constraint (2) calculates the production quantity by dividing the decided usage quantity of a part j () by usage rate required to make a single product (). Constraint (3) limits the usage of each part i to the current stock level for each part. Constraint (4) ensures the production quantity to stay below the SOP level. Constraints (5) and (6) declare the conditions for each variables.

3.3. Stage 2: Procurement Strategy Optimization Considering Profit and Lead Time

In the dynamic realm of electronic manufacturing, Stage 2 of our decision framework takes another key stage, serving as the pivotal phase where precision meets agility. After Stage 1’s evaluation of resource constraints and alignment with the SOP, Stage 2 emerges as the focal point. Here, we execute a procurement optimization, emphasizing two distinct procurement strategies and addressing resource scarcity, lead times, and profit maximization.

The overarching goal in Stage 2 is to strategically acquire materials, optimizing the balance between production quantity, lead times, and costs. It’s a delicate balancing act, ensuring resource efficiency while safeguarding profitability. Stage 2 translates mathematical models into actionable procurement plans, responding dynamically to the evolving landscape of electronic manufacturing.

In this exploration of Stage 2, we unravel the intricacies of procurement optimization, providing electronic manufacturing companies with a road-map to navigate this complex terrain with precision.

3.3.1. Preliminaries: Sets and Variables

The sets and variables in Stage 2 share many similarities with those in Stage 1. Additional sets and variables are defined to account for lead times and time limits for materials. Subsets containing only the products, configurations, and materials that were included in the Stage 1 solution are used in Stage 2. These sets are distinguished from the sets in Stage 1 by adding a bar symbol (e.g., , , , , , ). The newly added set denotes the index of the part’s procurement method.

Let represent the selling price of the product p, and let indicate the purchase price of part i when procured in m way. refers to the time limit for all parts and is lead time of part j procured by m method. The is the cost incurred due to procuring materials past the . Lastly, M represents a sufficiently large number (See Table 3 for a detailed explanation).

Table 3.

Sets and Parameters–Stage 2.

The decision variables are identical to those in Stage 1, with additional variables included to account for the time limit (refer to Table 4). Considering the index of a part , product , configuration , Branch , , is a binary decision variable that equals 1 if part j in branch r procured by method m is delivered after the time limit, else 0. With the same indices, , are non-negative continuous variables that represent the number of parts exceeded the time limit, and the number of parts shipped before the time limit, respectively.

Table 4.

Decision Variables—Stage 2.

3.3.2. Mathematical Model

Now, we introduce the mathematical model (P2) for Stage 2 using the newly defined sets, variables, and the result from the Stage 1.

The objective function (7) seeks to maximize the profit of all additionally produced products while subtracting the cost incurred from purchasing additional parts and the penalty for delayed part arrivals. This objective function allows consideration of the trade-off between profit and lead time penalty, based on the procurement method. Constraints (8) and (9) are the same as constraints (2) and (4), except for the sets used. Constraint (10) states that the value of equals the sum of and values procured through each method. This approach guarantees the total usage of material j is equivalent to the amount of material j procured before and after the time limit in the normal and the express way. Constraints (11) and (12) utilize to properly adjust the values of and , each of which corresponds to the quantity that are procured after the and before the for all part j and procurement method m. Constraints (13) and (14) ensure to be 0 if part j procured by method m arrives within the time limit, 1 otherwise. Constraints (15)–(17) state the conditions for each variable.

4. Computational Experiments

In this section, we compare the results between RCMPO and baseline algorithm. Specifically, we compare the result between the baseline and Stage 1, which corresponds to comparing the single-sourcing method and multi-sourcing method. Next, we report the objective value between the results of Stage 1 and Stage 2. This comparison corresponds to the effectiveness of extra procurement, especially choosing among the procurement strategies.

4.1. Data and Environment

Throughout this whole section, a case study of a global electronics product manufacturing company headquartered in Korea is conducted to showcase the optimization results of the previously proposed RCMPO. We tested five dataset, which corresponds to five sessions of production plans that are required to be established. These results are then compared to a rule-based heuristic algorithm, or baseline algorithm that will be explained in the next subsection, to validate its effectiveness.

Utilizing the available dataset, we executed two-stage optimization models on a desktop system featuring an AMD Ryzen 9 5900X 12-Core 3.70 GHz processor paired with 64 gigabytes of random access memory. The optimization task was resolved employing the open-source tool Google OR Tools, version 9.4.1874 developed by Google AI [38]. Implementation of the algorithms was carried out in Python 3.8.11, without the application of any acceleration techniques.

4.2. Baseline Algorithm

In this subsection, we introduce a rule-based heuristic algorithm tailored for benchmarking. Recognizing the intricacies of real-life scenarios, we underscore that often, due to the challenges of multi-sourcing, a single configuration is chosen for each product, typically determined by external sources like SCM or operations teams. Given a list of product SOPs and their pre-determined configurations, we systematically devise a production plan for each product. Our procedure commences by accepting the externally-determined configuration for the current product. Using the mathematical model detailed in the previous section—but modified to accommodate only one configuration—we ascertain the feasible production volume for this configuration. Once the potential production quantity is identified, we proceed to produce up to this limit. After production, we adjust the inventory and employ this newly updated information for the subsequent product, iterating until every product is evaluated. Algorithm 1 presents the pseudocode of the baseline algorithm.

| Algorithm 1 Baseline Algorithm. |

Require: List of product SOPs with their externally determined configurations

|

4.3. Results

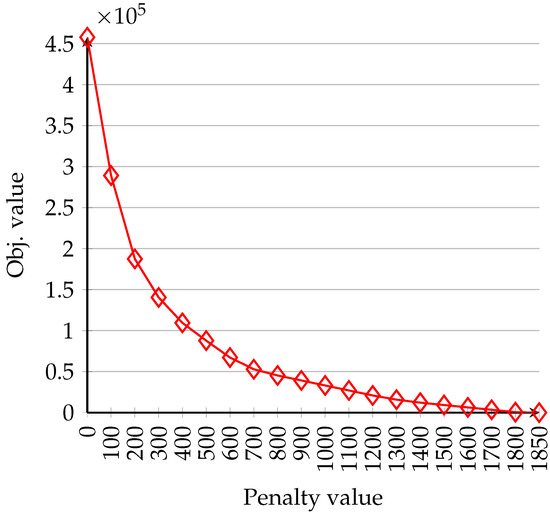

This subsection describes the results of numerical experiments. Total of two experiments were conducted, where the first experiment aims to quantitatively analyze the benefits of multiple sourcing, whereas the second experiment aims to figure out the best procurement method and quantity considering the extra profit. The parameters used in the experiments are Penalty set to 50 and Time limit (TL) set to 14 days (2 weeks). Selecting the appropriate penalty value is very intricate work, as it directly affects the solution behavior. Therefore, we have executed the extra experiment postulating the objective value behavior with regard to the penalty value changes in Figure A1. As depicted in the figure, the objective value decreases in a curved pattern, showing that the effect of the penalty increase is dominant in the early stages.

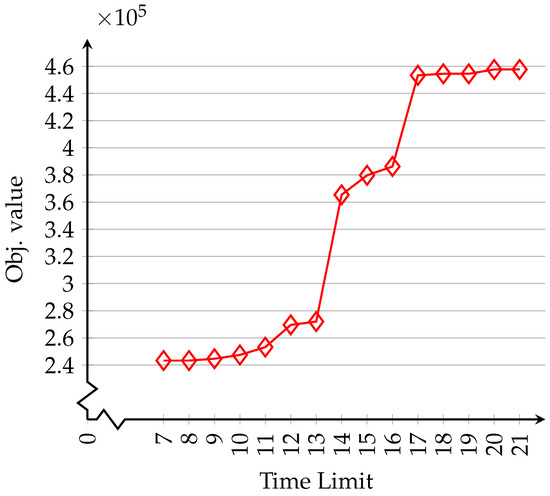

For the TL being set as 14, we referred to the literature of Sahin, Narayanan, and Robinson [39], which in practice the TL is composed of the first week fixed plan and another week with the part of rolling horizon. Although the results in this section has been derived with the TL being 14, we also postulated various TL values shown in Figure A2.

4.3.1. Comparison 1: Single Sourcing vs. Multiple Sourcing

In Stage 1, two experiments were conducted to compare the results of single sourcing and multiple sourcing. Each experiment compared (1) the SOP achievement rate and the inventory usage rate, and (2) the number of configurations used and the SOP shortage units, depending on the sourcing method.

Table 5 shows the experimental results comparing the SOP achievement rate and stock-out rate by sourcing method. In each SOP achievement rate and Inventory Usage Rate, the values for single sourcing and multiple sourcing are compared. Especially, we have added the “Gap (%)” column to show the effectiveness of usage of the multiple sourcing. The column “Gap (%)” is calculated by using the Equation (18).

Table 5.

SOP achievement rate and Inventory usage rate for single sourcing and multiple sourcing strategy.

It can be seen that the multiple sourcing method provides better solutions in terms of SOP achievement rate and stock-out rate than the single sourcing method. The largest increase in SOP achievement rate was 16.02% for Data C. The largest increase in stock-out rate was 4.34% for Data B.

Table 6 presents a comparison between the number of configurations utilized and the number of SOP shortages based on different sourcing methods. Similar to the findings in Table 5, it is evident that employing multiple sourcing strategies leads to superior outcomes compared to single sourcing. For Data A and B, multiple sourcing utilizes two configurations. The experimental results unequivocally demonstrate that the multiple sourcing approach consistently produces superior results than the single sourcing method, even when only a single configuration is used. This implies that proposed method chooses the best configuration among all possible configurations even in the case that a single configuration is chosen as a result. Notably, in the case of Data C, there is a reduction of approximately 44% in terms of SOP shortages for the multiple sourcing method, which corresponds to almost the half of the single sourcing method.

Table 6.

The number of used configurations and SOP Shortage by sourcing method.

4.3.2. Comparison 2: Effectiveness of Extra Procurement

The experiment in Stage 2 is designed to determine the effect of additional procurement which is postulated in this comparison section. It examines the number of SOP shortages reduced by additional procurement, gross profit, revenue from the sale of additional production, the cost of purchasing additional parts, the penalty for parts arriving after the time limit, and the ratio of normal and express procurement.

Table 7 presents the results of additional procurement within the context of the solution generated through multiple sourcing in Stage 2. The column labeled “Reduced SOP Shortage (ea)” quantifies the reduction in shortages resulting from the implementation of extra procurement. Meanwhile, the “Extra Profit ($)” column represents the objective value of (P2), which encompasses the values found in the columns “Production Sale Revenue ($)”, “Part Purchase Cost ($)”, and “Penalty for late delivery ($)”. Notably, the “Extra Profit ($)” column consistently displays positive values, indicating that the adoption of extra procurement has led to an increase in company profits.

Table 7.

The result of the Stage 2. The result shows the effective planning of choosing the extra procurement strategies considering the penalty.

It is worth noting that Data C exhibits marginal improvements in comparison to other datasets. This observation suggests that in the case of Data C, the utilization of multiple sourcing in Stage 1 already effectively satisfies SOP requirements, as evident from the highest SOP achievement rate in Table 5 and the substantial reduction in SOP shortages in Table 6 due to multiple sourcing.

Across all scenarios, both normal and express procurement methods were consistently chosen, with no distinct preference except in the case of Data B. This phenomenon can be attributed to the consideration of a trade-off between lead time and cost when selecting the most suitable procurement method, further highlighting the nuanced decision-making process within this context.

4.4. Scenario Test

In this subsection, we postulate two scenarios regarding the COVID-19 situation. During pandemic recession, the supply chains have been critically disrupted in worldwide scale in terms of costs (Helper and Soltas [40], Sun et al. [41]). Additionally, the timely delivery of the ordered parts were not executed, which in turn resulted as a delay of the sourcing (Paul and Chowdhury [42]). Therefore, we utilized two scenarios, where the first scenario applied a surcharge of between 100–140% for normal procurement and between 200–240% for express procurement, using a uniform distribution. In the second scenario, a 50% additional delay in the delivery lead time was introduced.

4.4.1. Scenario 1: Cost Disruption

Table 8 is the result of the scenario test. In this test, as mentioned earlier, the procurement costs are increased by more than 2 times in the case of Normal and 3 times in the case of Express procurement method. Consequently, compared to the pre-COVID situation in Table 7, the part purchasing cost has increased and the total profit has decreased. With the exception of Data A and C, we noticed alterations in SOP shortage values, as well as profits and other related factors. This outcome signifies that even when procurement costs fluctuate, our model still identifies values that keep the SOP shortage stable, thereby fostering stability within the overall supply chain. Moreover, in other datasets where profits and shortage quantities decreased, our model suggested a profitable extra production amount by adjusting how we procure extra components.

Table 8.

Scenario test about cost change result of 5 datasets.

This outcome underscores that shifts in procurement costs might lead to changes in what and how we purchase the extra parts, resulting in fewer additional products produced. Despite this reduction in procurement quantity, it’s important to note that our two-stage decision framework still managed to find an extra production quantity that can generate profit for the company. In practical terms, this framework serves as an invaluable decision support tool for planners.

4.4.2. Scenario 2: Delivery Lead Time Disruption

Additional case study about lead time change is dealt in this section. As mentioned earlier, the results are based on a 50% increase in lead time. As shown in the Table 9, in all cases the percentage of express procurement decreased and the penalty tended to increase significantly compared to the results in Table 7 under the pre-COVID situation. On the other hand, Product Sales Revenue increased in all cases, and Reduced SOP Shortage increased in Data A, C, and E. However, in the end, due to the increase in penalties, the extra profit from additional procurement decreased in all cases except Data D compared to the results in Table 7. The observed outcomes can be reasonably ascribed to two key factors: the escalation of penalties and alterations in the composition of procured parts. These modifications are likely a consequence of the rising prevalence of cost-effective routine procurement procedures. This shift is particularly pronounced as the overall lead time extends, consequently diminishing the pool of parts that can be feasibly procured within the specified time limit.

Table 9.

Scenario test about lead time change result of 5 datasets.

4.5. Findings

In this section, we briefly explain the main findings in two viewpoints: theoretical and practical perspectives.

4.5.1. Theoretical Perspective

The study’s findings significantly contribute to the discourse on sustainability within supply chain management, expanding the focus beyond the Sustainable Development Goals (SDGs). By optimizing procurement and supply chain efficiency through a two-stage mathematical model, the research offers a fresh perspective on sustainable practices, which has not been dealt actively in the past. It emphasizes the potential for reduced environmental impact by minimizing excess inventory and excess resource consumption. Additionally, the study underscores the benefits of diversified sourcing strategies in enhancing both supply chain resilience and sustainability, reducing risks associated with over-reliance on a single vendor. This research provides a pragmatic framework for aligning supply chain operations with sustainability principles while improving operational efficiency.

4.5.2. Practical Perspective

The study’s practical findings offer actionable guidance for supply chain practitioners. The two-stage mathematical model provides a concrete approach to improve supply chain efficiency and sustainability. As studied in the work of Taşkın et al. [43], the actual practice for SOP optimization is usually executed with ERP systems by experts. Although optimization model for a specific company has been proposed in Taşkın et al. [43], the consideration of multiple sourcing or procurement has not been adopted. Specifically, as shown in the tables in Section 4, the use of multiple sourcing and extra procurement possesses the benefits, compared to the baseline practice. Moreover, by optimizing procurement and supply chain operations, it demonstrates the potential to reduce environmental impact by minimizing excess inventory and resource waste, enhancing supply chain resilience and sustainability in practical terms. These findings equip practitioners to align their operations with sustainability principles while enhancing operational efficiency.

5. Conclusions

In contemporary electronic manufacturing, achieving operational excellence necessitates the orchestration of strategic decisions. Our exploration of this complex landscape has yielded the development of the “Resource-Constrained Multi-Phased Procurement Optimization Model” (RCMPO Model) through rigorous academic inquiry. This model highlights the multifaceted challenges and opportunities that characterise modern supply chain management.

Throughout our examination, we have explored the academic landscape, unearthing valuable insights and methodologies. In this paper, we have dealt various literature and methods to put an emphasis on the crucial importance of utilizing multiple sourcing strategies. These proven methodologies act as a vital defense mechanism against uncertainty, ultimately enhancing product quality whilst providing opportunities for cost savings. Amid the complexities of global supply chains in an era punctuated by volatility and disruptions, as evidenced by the COVID-19 pandemic, the implementation of diversified sourcing strategies has become a strategic necessity.

Simultaneously, our research has focused on the intricacies of optimizing procurement strategies. Guided by mathematical models and decision-making frameworks, this part of supply chain management empowers manufacturing companies to effectively balance cost-effectiveness, resource allocation, and agility. It allows for the strategic deployment of resources while deftly navigating the constraints that arise from resource availability.

The RCMPO Model, resulting from multiple sourcing and procurement strategy optimization, encapsulates our aim for supply chain excellence. It embodies adaptability, resilience and efficiency, offering a guiding framework for manufacturing firms navigating the intricacies of electronic manufacturing. Specifically, the RCMPO model contains two stages, where the first stage optimizes the maximum possible production quantity, and the second stage maximize the profit by selecting the appropriate procurement strategy considering the lead time. The analysis comprises two main parts. Initially, the comparison between single-sourcing and multi-sourcing strategies is presented. The results demonstrate that utilizing multiple sources to maximize production quantity has a significant impact in terms of meeting the required SOP level. Specifically, the result from the experiments show the benefit of the use of multiple sourcing in terms of SOP which corresponds to the resilient operation of the supply chain that this paper targets. Following this, the effectiveness of additional procurement measures is evaluated through a comparison of results from Stages 1 and 2. The findings indicate that a combination of procurement strategies for particular parts can increase company profits, taking into account both lead time and profit. Next, through the scenario test, we explored the scenario of a two to three-fold increase in logistics costs attributed to the COVID-19 situation. While this cost surge did adversely affect our overall profitability, it enabled us to refine our procurement strategy, ultimately aligning it with the evolving cost landscape.

This paper introduces a comprehensive two-stage decision framework aimed at achieving two crucial objectives in supply chain management. The first stage of the framework focuses on maximizing production quantity to meet the required SOP levels, ensuring the efficient fulfillment of orders. In the second stage, the framework shifts its focus to profit maximization by incorporating additional procurement strategies as a post-planning measure. By adopting this two-stage approach, the framework effectively balances the immediate operational needs of meeting SOP with the longer-term goal of profit optimization, providing a holistic solution for manufacturing firms.

Furthermore, the implementation of this framework has broader implications for supply chain resilience and efficiency. It fosters the optimal utilization of existing inventory parts, minimizing waste and redundancies in the supply chain. This, in turn, enhances supply chain resilience by reducing dependencies on single sources and elevates efficiency by streamlining inventory management and procurement strategies. Moreover, choosing the appropriate configuration and procurement strategy enables the lean management and efficient management of the overall supply chain. In sum, the proposed framework not only addresses immediate operational challenges but also contributes to the long-term sustainability and competitiveness of supply chain management practices.

This study provides valuable insights into strategies aimed at enhancing supply chain resilience; however, it is imperative to acknowledge certain limitations. One noteworthy constraint is the restriction of our dataset to a single Korean company. The diverse supply chain networks present in different regions, each characterized by distinct procurement methodologies and associated costs, may yield disparate results. Expanding the scope of our research to encompass various supply chain network systems is a promising avenue for future exploration. Furthermore, our utilization of MILP to address the formulated problem, while effective for current datasets, may encounter computational challenges when applied to larger datasets, particularly in terms of computation time. Hence, considering alternative artificial intelligence methodologies, such as Reinforcement Learning, presents a novel approach to addressing the problem at hand. Moreover, the current RCMPO neglects to account for the production line capacity associated with each model. Future research may focus on incorporating considerations related to production sequence and volume, addressing a potential area for further exploration.

Author Contributions

Conceptualization, C.-K.K., C.L., D.K., H.C. and T.C.; methodology, C.-K.K., C.L. and H.C.; software, C.-K.K. and C.L.; validation, D.K. and H.C.; formal analysis, C.L., D.K. and H.C.; investigation, C.L. and D.K.; resources, C.-K.K.; data curation, C.-K.K.; writing—original draft preparation, C.-K.K.; writing—review and editing, H.C. and T.C.; visualization, C.L., D.K. and H.C.; supervision, H.C. and T.C.; project administration, T.C.; funding acquisition, T.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Korea Institute for Advancement of Technology (KIAT) grant funded by the Korea government (MOTIE) (P0020649, The Competency Development Program for Industry Specialist) and the National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (No. NRF-2021R1F1A1059302).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| SOP | Sales and Operation Plan |

| RCMPO | Resource-Constrained Multi-Phased Procurement Optimization |

| DFS | Depth First Search |

| MILP | Mixed Integer Linear Programming |

| LP | Linear Programming |

| IP | Integer Programming |

| DEA | Data Envelopment Analysis |

| AHP | Analytic Hierarchy Process |

Appendix A. Sensitivity Analysis for the Penalty Term and Time Limit Variations

The objective function of the (P2) possesses a penalty term, indicating the penalty of late procurement considering the lead time. The use of penalty term can affect the solution directively if not set properly. Therefore, we have tested wide range of the penalty values so as to see the solution behavior with regard to the various penalty values. Notably, when the penalty value is increased to 1850, the objective value converges to zero, signifying that engaging in extra procurement does not yield any additional profit. In such instances, it becomes evident to the planner that further procurement planning is superfluous and unnecessary.

The variations of the TL also affects the objective values, specifically the constraints through (13) to (14). This in turn affects quantity that disobeys the given time limit, and therefore affects the objective term.

Figure A1.

The objective value changes depending on the penalty values used. As shown in the chart, as the penalty value increases, the objective value decreases in a curved pattern. The results indicate that early-stage penalties have a stronger impact on production quantity and profit compared to later stages. This means decision-makers can consider various options to make more detailed decisions, taking into account the different challenges the company faces.

Figure A2.

As depicted in the chart, the objective value exhibits a distinct stepwise growth as the time limit extends, notably featuring two prominent increments. It can be deduced that these two substantial increments primarily correspond to specific procurement approaches: express and normal. For instance, the significant leap in the objective value at a time limit of 17 primarily results from enabling the timely delivery of parts procured through the normal method.

References

- Harapko, S. How COVID-19 Impacted Supply Chains and What Comes Next|EY—Global. 2023. Available online: https://www.ey.com/en_gl/supply-chain/how-covid-19-impacted-supply-chains-and-what-comes-next (accessed on 8 September 2023).

- Cai, M.; Luo, J. Influence of COVID-19 on manufacturing industry and corresponding countermeasures from supply chain perspective. J. Shanghai Jiaotong Univ. (Sci.) 2020, 25, 409–416. [Google Scholar] [CrossRef]

- Choi, K.; Narasimhan, R.; Kim, S.W. Opening the technological innovation black box: The case of the electronics industry in Korea. Eur. J. Oper. Res. 2016, 250, 192–203. [Google Scholar] [CrossRef]

- Montoya-Torres, J.R.; Muñoz-Villamizar, A.; Mejia-Argueta, C. Mapping research in logistics and supply chain management during COVID-19 pandemic. Int. J. Logist. Res. Appl. 2023, 26, 421–441. [Google Scholar] [CrossRef]

- Moosavi, J.; Fathollahi-Fard, A.M.; Dulebenets, M.A. Supply chain disruption during the COVID-19 pandemic: Recognizing potential disruption management strategies. Int. J. Disaster Risk Reduct. 2022, 75, 102983. [Google Scholar] [CrossRef]

- Agarkov, M.A.; Guskova, M.F.; Korzhin, S.N. An innovative method of procurement management in the electronics industry. In Proceedings of the 2021 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), Moscow, Russia, 26–29 January 2021; pp. 1870–1873. [Google Scholar]

- Kotula, M.; Ho, W.; Dey, P.K.; Lee, C.K.M. Strategic sourcing supplier selection misalignment with critical success factors: Findings from multiple case studies in Germany and the United Kingdom. Int. J. Prod. Econ. 2015, 166, 238–247. [Google Scholar] [CrossRef]

- Zhu, S.X. Analysis of dual sourcing strategies under supply disruptions. Int. J. Prod. Econ. 2015, 170, 191–203. [Google Scholar] [CrossRef]

- Basit, A.; Wang, L.; Nazir, S.; Mehmood, S.; Hussain, I. Managing the COVID-19 Pandemic: Enhancing Sustainable Supply Chain Performance through Management Innovation, Information Processing Capability, Business Model Innovation and Knowledge Management Capability in Pakistan. Sustainability 2023, 15, 13538. [Google Scholar] [CrossRef]

- Ye, Y.; Lau, K.H. Competitive green supply chain transformation with dynamic capabilities—An exploratory case study of Chinese electronics industry. Sustainability 2022, 14, 8640. [Google Scholar] [CrossRef]

- Rajesh, R. Optimal trade-offs in decision-making for sustainability and resilience in manufacturing supply chains. J. Clean. Prod. 2021, 313, 127596. [Google Scholar] [CrossRef]

- Soni, U.; Jain, V.; Kumar, S. Measuring supply chain resilience using a deterministic modeling approach. Comput. Ind. Eng. 2014, 74, 11–25. [Google Scholar] [CrossRef]

- Hosseini, S.; Ivanov, D.; Dolgui, A. Review of quantitative methods for supply chain resilience analysis. Transp. Res. Part E Logist. Transp. Rev. 2019, 125, 285–307. [Google Scholar] [CrossRef]

- Shih, W.C. Global Supply Chains in a Post-Pandemic World. 2020. Available online: https://hbr.org/2020/09/global-supply-chains-in-a-post-pandemic-world (accessed on 8 September 2023).

- Silver, E.A. Operations research in inventory management: A review and critique. Oper. Res. 1981, 29, 628–645. [Google Scholar] [CrossRef]

- Harris, F.W. How many parts to make at once. Oper. Res. 1990, 38, 947–950. [Google Scholar] [CrossRef]

- Harris, F.W. What quantity to make at once. Libr. Fact. Manag. 1915, 5, 47–52. [Google Scholar]

- Sousa, N.; Jorge, F.; Teixeira, M.S.; Losada, N.; Melo, M.; Bessa, M. An Exploratory Study about the Effect of COVID-19 on the Intention to Adopt Virtual Reality in the Tourism Sector. Sustainability 2023, 15, 8725. [Google Scholar] [CrossRef]

- Sousa, N.; Alén, E.; Losada, N.; Melo, M. Virtual Reality in Tourism Promotion: A Research Agenda Based on A Bibliometric Approach. J. Qual. Assur. Hosp. Tour. 2022, 1–30. [Google Scholar] [CrossRef]

- Illiashenko, S.; Bilovodska, O.; Tsalko, T.; Tomchuk, O.; Nevmerzhytska, S.; Buhas, N. Opportunities, threats and risks of implementation the innovative business management technologies in the post-pandemic period COVID-19. WSEAS Trans. Bus. Econ. 2022, 19, 1215–1229. [Google Scholar] [CrossRef]

- Shen, Y.; Guo, H. New breakthroughs and innovation modes in english education in post-pandemic era. Front. Psychol. 2022, 13, 839440. [Google Scholar] [CrossRef]

- Ali, S.M.; Ashraf, M.A.; Taqi, H.M.M.; Ahmed, S.; Rob, S.A.; Kabir, G.; Paul, S.K. Drivers for Internet of Things (IoT) adoption in supply chains: Implications for sustainability in the post-pandemic era. Comput. Ind. Eng. 2023, 183, 109515. [Google Scholar] [CrossRef]

- Ivanov, D. Exiting the COVID-19 pandemic: After-shock risks and avoidance of disruption tails in supply chains. Ann. Oper. Res. 2021, 1–18. [Google Scholar] [CrossRef]

- Weber, C.A.; Current, J.R.; Benton, W. Vendor selection criteria and methods. Eur. J. Oper. Res. 1991, 50, 2–18. [Google Scholar] [CrossRef]

- Hassanzadeh, S.; Cheng, K. Suppliers Selection In Manufacturing Industries And Associated Multi-Objective Desicion Making Methods: Past, Present And The Future. Eur. Sci. J. 2016, 12, 93–113. [Google Scholar] [CrossRef][Green Version]

- Burke, G.J.; Carrillo, J.E.; Vakharia, A.J. Single versus multiple supplier sourcing strategies. Eur. J. Oper. Res. 2007, 182, 95–112. [Google Scholar] [CrossRef]

- Yohanes, K.N. Dual sourcing strategy in mass customized manufacturing. In Proceedings of the 2008 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 8–11 December 2008; pp. 1088–1092. [Google Scholar]

- Agarwal, P.; Sahai, M.; Mishra, V.; Bag, M.; Singh, V. A review of multi-criteria decision making techniques for supplier evaluation and selection. Int. J. Ind. Eng. Comput. 2011, 2, 801–810. [Google Scholar] [CrossRef]

- Sharma, S.; Dubey, D. Multiple sourcing decisions using integrated AHP and knapsack model: A case on carton sourcing. Int. J. Adv. Manuf. Technol. 2010, 51, 1171–1178. [Google Scholar] [CrossRef]

- Sen, W.; Shin, Y.W.; Kumar, A.; Piplani, R. Supply chain demand response strategy evaluation and optimization. In Proceedings of the 2000 IEEE International Conference on Management of Innovation and Technology. ICMIT 2000. ‘Management in the 21st Century’ (Cat. No.00EX457), Singapore, 12–15 November 2000. [Google Scholar]

- Migalska, A.; Pawlus, W. Supply Chain optimization to Mitigate Electronic Components Shortage in Manufacturing of Telecommunications Network Equipment. In Proceedings of the 2020 IEEE 29th International Symposium on Industrial Electronics (ISIE), Delft, The Netherlands, 17–19 June 2020; pp. 474–479. [Google Scholar]

- Stefea, P.; Pelin, A. On the Principles of Resource Consumption Optimization on Microeconomic Level. Entren.-Enterp. Res. Innov. 2015, 1, 376–382. [Google Scholar] [CrossRef]

- Rao, J.J.; Kumara, V. Review of supply chain management in manufacturing systems. In Proceedings of the 2017 International Conference on Innovative Mechanisms for Industry Applications (ICIMIA), Bengaluru, India, 21–23 February 2017; pp. 759–762. [Google Scholar]

- Hammer, M.; Karre, H.; Ramsauer, C. Resource-Productive Operations—How Lean, Green And Constraint Management Approaches Blend Together. Ann. Fac. Eng. Hunedoara—Int. J. Eng. 2018, 16, 87–92. [Google Scholar]

- Ghani, U.; Monfared, R.; Harrison, R. Energy based efficient resources for real time manufacturing systems. In Proceedings of the World Congress on Engineering, London, UK, 6–8 July 2011; Volume 1, p. 802. [Google Scholar]

- Tian, Q.; Guo, W. Reconfiguration of manufacturing supply chains considering outsourcing decisions and supply chain risks. J. Manuf. Syst. 2019, 52, 217–226. [Google Scholar] [CrossRef]

- Pereira, D.F.; Oliveira, J.F.; Carravilla, M.A. Tactical sales and operations planning: A holistic framework and a literature review of decision-making models. Int. J. Prod. Econ. 2020, 228, 107695. [Google Scholar] [CrossRef]

- Google Inc. Google’s Optimization Tools (or-Tools). 2018. Available online: https://www.github.com/google/or-tools (accessed on 15 November 2023).

- Sahin, F.; Narayanan, A.; Robinson, E.P. Rolling horizon planning in supply chains: Review, implications and directions for future research. Int. J. Prod. Res. 2013, 51, 5413–5436. [Google Scholar] [CrossRef]

- Helper, S.; Soltas, E. Why the Pandemic Has Disrupted Supply Chains|CEA|The White House. 2021. Available online: https://www.whitehouse.gov/cea/written-materials/2021/06/17/why-the-pandemic-has-disrupted-supply-chains/ (accessed on 4 October 2023).

- Sun, J.; Lee, H.; Yang, J. The impact of the COVID-19 pandemic on the global value chain of the manufacturing industry. Sustainability 2021, 13, 12370. [Google Scholar] [CrossRef]

- Paul, S.K.; Chowdhury, P. A production recovery plan in manufacturing supply chains for a high-demand item during COVID-19. Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 104–125. [Google Scholar] [CrossRef]

- Taşkın, Z.C.; Ağralı, S.; Ünal, A.T.; Belada, V.; Gökten-Yılmaz, F. Mathematical programming-based sales and operations planning at vestel Electronics. Interfaces 2015, 45, 325–340. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).