Impact of Mealworm Powder (Tenebrio molitor) Fortification on Ice Cream Quality

Abstract

:1. Introduction

2. Materials and Methods

2.1. Insect Processing and Ice Cream Manufacturing

2.2. Nutrient, Mineral and Fatty Acid Composition

2.3. Ice Cream Overrun

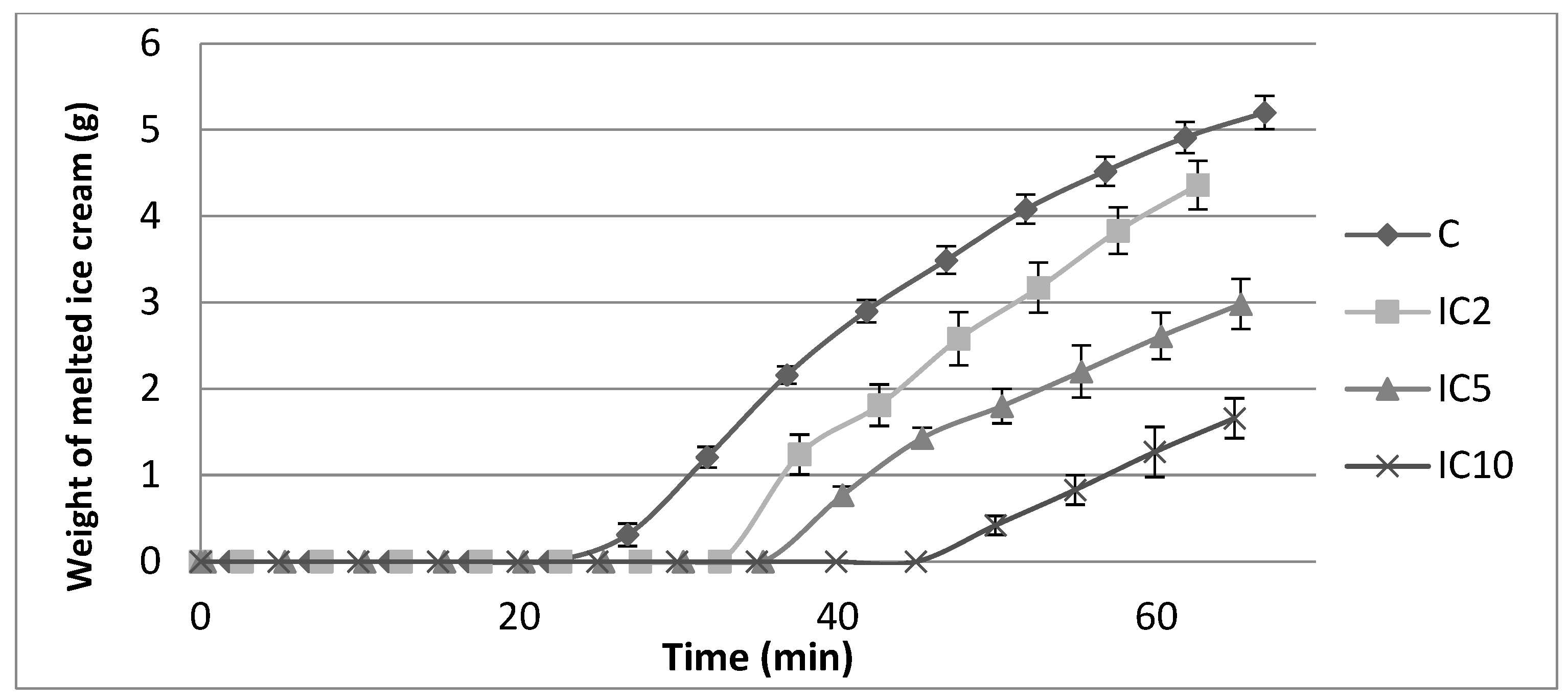

2.4. Melting Properties

2.5. Color Measurements

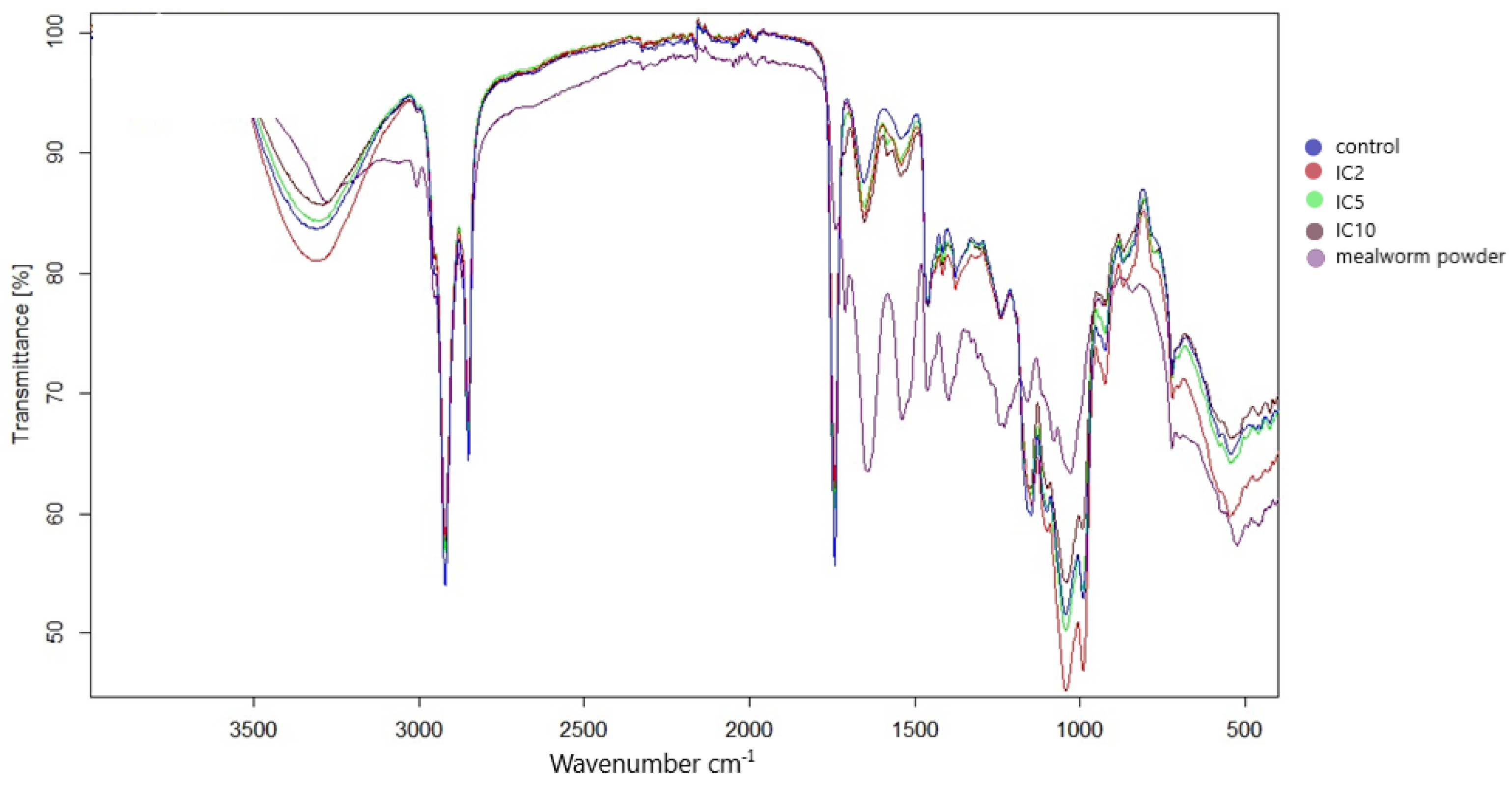

2.6. Fourier-Transform–Infrared (FT-IR) Spectroscopy

2.7. Antioxidant Properties of Ice Creams

2.7.1. Extraction of Bioactive Compounds

2.7.2. Antiradical Activity

2.8. Statistical Analysis

3. Results and Discussion

3.1. Nutrient Composition

3.2. Mineral Content

3.3. Fatty Acid Profile

3.4. Melting Time and Resistance

3.5. Overrun

3.6. Color

3.7. Antioxidant Properties

3.8. FT-IR

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rumpold, B.A.; Schlüter, O.K. Nutritional composition and safety aspects of edible insects. Mol. Nutr. Food Res. 2013, 57, 802–823. [Google Scholar] [CrossRef]

- Finke, M.D.; Oonincx, D. Insects as Food for Insectivores; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 9780123914538. [Google Scholar]

- Kouřimská, L.; Adámková, A. Nutritional and sensory quality of edible insects. NFS J. 2016, 4, 22–26. [Google Scholar] [CrossRef]

- Payne, C.L.R.; Scarborough, P.; Rayner, M.; Nonaka, K. A systematic review of nutrient composition data available for twelve commercially available edible insects, and comparison with reference values. Trends Food Sci. Technol. 2016, 47, 69–77. [Google Scholar] [CrossRef]

- Köhler, R.; Kariuki, L.; Lambert, C.; Biesalski, H.K. Protein, amino acid and mineral composition of some edible insects from Thailand. J. Asia Pac. Entomol. 2019, 22, 372–378. [Google Scholar] [CrossRef]

- Mlcek, J.; Rop, O.; Borkovcova, M.; Bednarova, M. A Comprehensive Look at the Possibilities of Edible Insects as Food in Europe—A Review. Pol. J. Food Nutr. Sci. 2014, 64, 147–157. [Google Scholar] [CrossRef]

- German, J.B.; Dillard, C.J. Saturated fats: A perspective from lactation and milk composition. Lipids 2010, 45, 915–923. [Google Scholar] [CrossRef]

- Michas, G.; Micha, R.; Zampelas, A. Dietary fats and cardiovascular disease: Putting together the pieces of a complicated puzzle. Atherosclerosis 2014, 234, 320–328. [Google Scholar] [CrossRef]

- de Castro, R.J.S.; Ohara, A.; Aguilar, J.G.d.S.; Domingues, M.A.F. Nutritional, functional and biological properties of insect proteins: Processes for obtaining, consumption and future challenges. Trends Food Sci. Technol. 2018, 76, 82–89. [Google Scholar] [CrossRef]

- Evans, J.; Alemu, M.H.; Flore, R.; Frøst, M.B.; Halloran, A.; Jensen, A.B.; Maciel-Vergara, G.; Meyer-Rochow, V.B.; Münke-Svendsen, C.; Olsen, S.B.; et al. “Entomophagy”: An evolving terminology in need of review. J. Insects Food Feed 2015, 1, 293–305. [Google Scholar] [CrossRef]

- Kowalczewski, P.Ł.; Walkowiak, K.; Masewicz, Ł.; Bartczak, O.; Lewandowicz, J.; Kubiak, P.; Baranowska, H.M. Gluten-free bread with cricket powder—Mechanical properties and molecular water dynamics in dough and ready product. Foods 2019, 8, 240. [Google Scholar] [CrossRef]

- Adámek, M.; Adámková, A.; Mlček, J.; Borkovcová, M.; Bednářová, M. Acceptability and sensory evaluation of energy bars and protein bars enriched with edible insect. Potravin. Slovak J. Food Sci. 2018, 12, 431–437. [Google Scholar] [CrossRef]

- Ribeiro, J.C.; Lima, R.C.; Maia, M.R.G.; Almeida, A.A.; Fonseca, A.J.M.; Cabrita, A.R.J.; Cunha, L.M. Impact of defatting freeze-dried edible crickets (Acheta domesticus and Gryllodes sigillatus) on the nutritive value, overall liking and sensory profile of cereal bars. LWT 2019, 113, 108335. [Google Scholar] [CrossRef]

- Zielińska, E.; Pankiewicz, U. Nutritional, Physiochemical, and Antioxidative Characteristics of Shortcake Biscuits Enriched with Tenebrio molitor Flour. Molecules 2020, 25, 5629. [Google Scholar] [CrossRef] [PubMed]

- Smarzyński, K.; Sarbak, P.; Kowalczewski, P.Ł.; Różańska, M.B.; Rybicka, I.; Polanowska, K.; Fedko, M.; Kmiecik, D.; Masewicz, Ł.; Nowicki, M.; et al. Low-Field NMR Study of Shortcake Biscuits with Cricket Powder, and Their Nutritional and Physical Characteristics. Molecules 2021, 26, 5417. [Google Scholar] [CrossRef] [PubMed]

- Djouadi, A.; Sales, J.R.; Carvalho, M.O.; Raymundo, A. Development of Healthy Protein-Rich Crackers Using Tenebrio molitor Flour. Foods 2022, 11, 702. [Google Scholar] [CrossRef]

- Per Capita Sales of Ice Cream in Europe in 2020, by Country. Available online: https://www.statista.com/statistics/596114/per-capita-consumption-of-ice-cream-in-europe-by-country/ (accessed on 20 August 2023).

- Ramos-Elorduy, J.; Pino, J.M.M.; Escamilla, E.P.; Alvarado, M.P.; Lagunez, J.O.; Ladron, O.d.G. Nutritional value of edible insects from the state of oaxaca, mexico. J. Food Compos. Anal. 1997, 10, 142–157. [Google Scholar] [CrossRef]

- Mishyna, M.; Chen, J.; Benjamin, O. Sensory attributes of edible insects and insect-based foods—Future outlooks for enhancing consumer appeal. Trends Food Sci. Technol. 2020, 95, 141–148. [Google Scholar] [CrossRef]

- Roncolini, A.; Milanović, V.; Cardinali, F.; Osimani Id, A.; Garofalo, C.; Sabbatini, R.; Clementi, F.; Pasquini, M.; Mozzon, M.; Foligni, R.; et al. Protein fortification with mealworm (Tenebrio molitor L.) powder: Effect on textural, microbiological, nutritional and sensory features of bread. PLoS ONE 2019, 14, e0211747. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International 962.09; AOAC: Rockville, MD, USA, 2010; pp. 2–4. [Google Scholar]

- Jorhem, L.; Engman, J.; Arvidsson, B.-M.; Åsman, B.; Åstrand, C.; Gjerstad, K.O.; Haugsnes, J.; Heldal, V.; Holm, K.; Jensen, A.M.; et al. Determination of Lead, Cadmium, Zinc, Copper, and Iron in Foods by Atomic Absorption Spectrometry after Microwave Digestion: NMKL1 Collaborative Study. J. AOAC Int. 2000, 83, 1189–1203. [Google Scholar] [CrossRef] [PubMed]

- Ismail, E.; Al-Saleh, A.; Metwalli, A. Inulin Supplementation on Rheological Properties of Low-Fat Ice Cream. Life Sci. J. 2013, 10, 1097–8135. [Google Scholar]

- Góral, M.; Kozłowicz, K.; Pankiewicz, U.; Góral, D.; Kluza, F.; Wójtowicz, A. Impact of stabilizers on the freezing process, and physicochemical and organoleptic properties of coconut milk-based ice cream. LWT 2018, 92, 516–522. [Google Scholar] [CrossRef]

- Silva Junior, D.E.; Lannes, S.C.D.S. Effect of different sweetener blends and fat types on ice cream properties. Food Sci. Technol. 2011, 31, 217–220. [Google Scholar] [CrossRef]

- Koxholt, M.M.R.; Eisenmann, B.; Hinrichs, J. Effect of the Fat Globule Sizes on the Meltdown of Ice Cream. J. Dairy Sci. 2001, 84, 31–37. [Google Scholar] [CrossRef]

- Szmejda, K.; Duliński, R.; Byczyński, Ł.; Karbowski, A.; Florczak, T.; Żyła, K. Analysis of the selected antioxidant compounds in ice cream supplemented with Spirulina (Arthrospira platensis) extract. Biotechnol. Food Sci. 2018, 82, 41–48. [Google Scholar]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef] [PubMed]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- European Commission. COMMISSION IMPLEMENTING REGULATION (EU) 2021/1975 of 12 November 2021 authorising the placing on the market of frozen, dried and powder forms of Locusta migratoria as a novel food under Regulation (EU) 2015/2283 of the European Parliament and of the Council and amending Commission Implementing Regulation (EU) 2017/2470. Off. J. Eur. Union 2021, 1975, 10. [Google Scholar]

- European Commission. COMMISSION IMPLEMENTING REGULATION (EU) 2022/169 of 8 February 2022 authorising the placing on the market of frozen, dried and powder forms of yellow mealworm (Tenebrio molitor larva) as a novel food under Regulation (EU) 2015/2283 of the European Parliam. Off. J. Eur. Union 2022, 2016, 48–119. [Google Scholar]

- European Commission. COMMISSION IMPLEMENTING REGULATION (EU) 2023/5 of 3 January 2023 authorising the placing on the market of Acheta domesticus (house cricket) partially defatted powder as a novel food. Off. J. Eur. Union 2023, L2, 48–119. [Google Scholar]

- European Commission. COMMISSION IMPLEMENTING REGULATION (EU) 2023/58 of 5 January 2023 authorising the placing on the market of the frozen, paste, dried and powder forms of Alphitobius diaperinus larvae (lesser mealworm) as a novel food and amending Implementing Regulation (EU) 2017/2470. Off. J. Eur. Union 2023, 58, 10–15. [Google Scholar]

- Pečová, M.; Pospiech, M.; Javůrková, Z.; Ljasovská, S.; Dobšíková, R.; Tremlová, B. Influence of feed on anti-inflammatory and antioxidant effects of Zophobas morio. J. Asia. Pac. Entomol. 2022, 25, 102010. [Google Scholar] [CrossRef]

- Finke, M. Estimate of chitin in raw whole insects. Zoo Biol. 2007, 26, 105–115. [Google Scholar] [CrossRef]

- Genovese, A.; Balivo, A.; Salvati, A.; Sacchi, R. Functional ice cream health benefits and sensory implications. Food Res. Int. 2022, 161, 111858. [Google Scholar] [CrossRef]

- Akbari, M.; Eskandari, M.H.; Davoudi, Z. Application and functions of fat replacers in low-fat ice cream: A review. Trends Food Sci. Technol. 2019, 86, 34–40. [Google Scholar] [CrossRef]

- Mwangi, M.N.; Oonincx, D.G.A.B.; Stouten, T.; Veenenbos, M.; Melse-Boonstra, A.; Dicke, M.; van Loon, J.J.A. Insects as sources of iron and zinc in human nutrition. Nutr. Res. Rev. 2018, 31, 248–255. [Google Scholar] [CrossRef]

- Zielińska, E.; Baraniak, B.; Karaś, M.; Rybczyńska, K.; Jakubczyk, A. Selected species of edible insects as a source of nutrient composition. Food Res. Int. 2015, 77, 460–466. [Google Scholar] [CrossRef]

- Hernández Toxqui, A.G.; Ramírez Ramírez, J.; Pino Moreno, J.M.; Talamantes Gómez, J.M.; Angeles Campos, S.C.; Ramírez Orejel, J.C. Development of Nutraceutical Ice Creams Using Flour Yellow Worm Larvae (Tenebrio molitor), Chia (Salvia hispanica), and Quinoa (Chenopodium quinoa). Front. Vet. Sci. 2021, 8, 629180. [Google Scholar] [CrossRef] [PubMed]

- De Smet, J.; Lenaerts, S.; Borremans, A.; Scholliers, J.; Van Der Borght, M.; Van Campenhout, L. Stability assessment and laboratory scale fermentation of pastes produced on a pilot scale from mealworms (Tenebrio molitor). LWT 2019, 102, 113–121. [Google Scholar] [CrossRef]

- Fontaneto, D.; Tommaseo-Ponzetta, M.; Galli, C.; Risé, P.; Glew, R.H.; Paoletti, M.G. Differences in Fatty Acid Composition between Aquatic and Terrestrial Insects Used as Food in Human Nutrition. Ecol. Food Nutr. 2011, 50, 351–367. [Google Scholar] [CrossRef]

- Daw, E.; Hartel, R.W. Fat destabilization and melt-down of ice creams with increased protein content. Int. Dairy J. 2015, 43, 33–41. [Google Scholar] [CrossRef]

- Ye, A. Functional properties of milk protein concentrates: Emulsifying properties, adsorption and stability of emulsions. Int. Dairy J. 2011, 21, 14–20. [Google Scholar] [CrossRef]

- Segall, K.I.; Goff, H.D. A modified ice cream processing routine that promotes fat destabilization in the absence of added emulsifier. Int. Dairy J. 2002, 12, 1013–1018. [Google Scholar] [CrossRef]

- Gould, J.; Wolf, B. Interfacial and emulsifying properties of mealworm protein at the oil/water interface. Food Hydrocoll. 2018, 77, 57–65. [Google Scholar] [CrossRef]

- David-Birman, T.; Romano, A.; Aga, A.; Pascoviche, D.; Davidovich-Pinhas, M.; Lesmes, U. Impact of silkworm pupae (Bombyx mori) powder on cream foaming, ice cream properties and palatability. Innov. Food Sci. Emerg. Technol. 2022, 75, 102874. [Google Scholar] [CrossRef]

- Warren, M.M.; Hartel, R.W. Effects of Emulsifier, Overrun and Dasher Speed on Ice Cream Microstructure and Melting Properties. J. Food Sci. 2018, 83, 639–647. [Google Scholar] [CrossRef] [PubMed]

- Kurt, A.; Atalar, I. Effects of quince seed on the rheological, structural and sensory characteristics of ice cream. Food Hydrocoll. 2018, 82, 186–195. [Google Scholar] [CrossRef]

- Hwang, S.-Y.; Choi, S.-K. Quality Characteristics of Muffins Containing Mealworm(Tenebrio molitor). Korean J. Culin. Res. 2015, 21, 104–115. [Google Scholar]

- Zielińska, E.; Pankiewicz, U.; Sujka, M. Nutritional, Physiochemical, and Biological Value of Muffins Enriched with Edible Insects Flour. Antioxidants 2021, 10, 1122. [Google Scholar] [CrossRef]

- Min, K.-T.; Kang, M.-S.; Kim, M.-J.; Lee, S.-H.; Han, J.-S.; Kim, A.-J. Manufacture and Quality Evaluation of Cookies prepared with Mealworm (Tenebrio molitor) Powder. Korean J. Food Nutr. 2016, 29, 12–18. [Google Scholar] [CrossRef]

- Gantner, M.; Król, K.; Piotrowska, A.; Sionek, B.; Sadowska, A.; Kulik, K.; Wiącek, M. Adding Mealworm (Tenebrio molitor L.) Powder to Wheat Bread: Effects on Physicochemical, Sensory and Microbiological Qualities of the End-Product. Molecules 2022, 27, 6155. [Google Scholar] [CrossRef] [PubMed]

- Oh, E.; Park, W.J.; Kim, Y. Effects of Tenebrio molitor larvae and its protein derivatives on the antioxidant and anti-inflammatory capacities of tofu. Food Biosci. 2022, 50, 102105. [Google Scholar] [CrossRef]

- Nongonierma, A.B.; FitzGerald, R.J. Unlocking the biological potential of proteins from edible insects through enzymatic hydrolysis: A review. Innov. Food Sci. Emerg. Technol. 2017, 43, 239–252. [Google Scholar] [CrossRef]

- Di Mattia, C.; Battista, N.; Sacchetti, G.; Serafini, M. Antioxidant activities in vitro of water and liposoluble extracts obtained by different species of edible insects and invertebrates. Front. Nutr. 2019, 6, 106. [Google Scholar] [CrossRef] [PubMed]

- Hall, F.; Johnson, P.E.; Liceaga, A. Effect of enzymatic hydrolysis on bioactive properties and allergenicity of cricket (Gryllodes sigillatus) protein. Food Chem. 2018, 262, 39–47. [Google Scholar] [CrossRef]

- Kurt, A.; Kahyaoglu, T. Rheological properties and structural characterization of salep improved by ethanol treatment. Carbohydr. Polym. 2015, 133, 654–661. [Google Scholar] [CrossRef] [PubMed]

- Chua, M.; Chan, K.; Hocking, T.J.; Williams, P.A.; Perry, C.J.; Baldwin, T.C. Methodologies for the extraction and analysis of konjac glucomannan from corms of Amorphophallus konjac K. Koch. Carbohydr. Polym. 2012, 87, 2202–2210. [Google Scholar] [CrossRef]

| Sample | Protein (%) | Fat (%) | Carbohydrate (%) | Ash (%) | Moisture (%) | Energy Value (kcal) |

|---|---|---|---|---|---|---|

| C | 1.48 ± 0.13 d | 19.40 ± 1.61 a | 14.26 ± 1.12 a | 0.57 ± 0.05 b | 64.29 ± 1.74 a | 238 ± 18 a |

| IC2 | 1.85 ± 0.09 c | 19.82 ± 1.11 a | 14.43 ± 1.05 a | 0.60 ± 0.05 b | 63.30 ± 1.83 a | 244 ± 15 a |

| IC5 | 2.32 ± 0.03 b | 19.86 ± 0.17 a | 14.03 ± 0.85 a | 0.63 ± 0.02 b | 63.16 ± 1.15 a | 244 ± 5 a |

| IC10 | 3.08 ± 0.22 a | 18.33 ± 0.64 a | 14.92 ± 0.96 a | 0.73 ± 0.02 a | 62.94 ± 1.57 a | 237 ± 9 a |

| MP | 52.12 ± 0.29 | 34.28 ± 0.27 | 2.77 ± 0.24 | 4.85 ± 0.04 | 5.98 ± 0.77 | 528 ± 5 |

| Sample | Ca | Mg | K | Na | Fe | Zn |

|---|---|---|---|---|---|---|

| C | 94.86 ± 5.25 a | 7.84 ± 1.39 c | 128.43 ± 11.64 ab | 29.70 ± 1.41 a | 0.23 ± 0.09 b | 0.41 ± 0.04 b |

| IC2 | 85.63 ± 11.97 a | 11.35 ± 1.60 c | 119.15 ± 17.39 b | 26.85 ± 5.37 a | 0.18 ± 0.01 b | 0.57 ± 0.15 b |

| IC5 | 95.26 ± 2.84 a | 17.78 ± 0.08 b | 150.26 ± 4.06 ab | 32.04 ± 0.81 a | 0.35 ± 0.09 b | 0.70 ± 0.04 b |

| IC10 | 96.67 ± 2.14 a | 24.31 ± 0.67 a | 168.93 ± 3.20 a | 34.02 ± 0.91 a | 0.92 ± 0.08 a | 1.14 ± 0.01 a |

| MP | 56.27 ± 2.99 | 293.07 ± 4.36 | 880.76 ± 24.29 | 128.93 ± 0.17 | 4.95 ± 0.15 | 12.99 ± 0.29 |

| Fatty Acid Composition | Studied Ice Cream | |||

|---|---|---|---|---|

| C | IC2 | IC5 | IC10 | |

| C6:0 | 1.01 ± 0.01 a | 1.0 ± 0.01 a | 0.94 ± 0.01 b | 0.92 ± 0.01 b |

| C8:0 | 1.16 ± 0.01 a | 1.13 ± 0.02 a | 1.06 ± 0.01 b | 0.99 ± 0.01 c |

| C10:0 | 3.21 ± 0.02 a | 3.09 ± 0.01 b | 2.95 ± 0.02 c | 2.74 ± 0.01 d |

| C11:0 | 0.07 ± 0.01 a | 0.07 ± 0.01 a | 0.06 ± 0.01 a | 0.05 ± 0.01 a |

| C12:0 | 3.93 ± 0.02 a | 3.81 ± 0.04 b | 3.67 ± 0.04 c | 3.41 ± 0.04 d |

| C13:0 | 0.13 ± 0.01 a | 0.13 ± 0.01 a | 0.12 ± 0.01 a | 0.12 ± 0.01 a |

| C14:0 | 12.74 ± 0.12 a | 12.6 ± 0.1 a | 12.13 ± 0.02 b | 11.52 ± 0.02 c |

| C14:1n5 | 1.12 ± 0.01 a | 1.05 ± 0.01 b | 1.08 ± 0.01 c | 0.99 ± 0.01 d |

| C15:0 | 1.28 ± 0.03 a | 1.27 ± 0.02 a | 1.2 ± 0.01 b | 1.13 ± 0.01 c |

| C16:0 | 34.68 ± 0.65 ab | 34.85 ± 0.5 a | 33.45 ± 0.4 bc | 32.44 ± 0.55 c |

| C16:1n7 | 1.65 ± 0.1 a | 1.62 ± 0.06 a | 1.7 ± 0.02 a | 1.75 ± 0.02 a |

| C17:0 | 0.6 ± 0.01 a | 0.6 ± 0.01 a | 0.57 ± 0.01 b | 0.55 ± 0.01 b |

| C17:1n7 | 0.2 ± 0.01 b | 0.21 ± 0.01 b | 0.3 ± 0.01 a | 0.19 ± 0.01 b |

| C18:0 | 10.67 ± 0.21 ab | 10.72 ± 0.15 a | 10.14 ± 0.6 ab | 9.75 ± 0.3 b |

| C18:1n9c + C18:1n9t | 19.97 ± 0.5 b | 20.14 ± 0.2 b | 21.65 ± 0.84 ab | 22.99 ± 0.82 a |

| C18:2n6c + C18:2n6t | 1.51 ± 0.09 c | 1.53 ± 0.08 c | 2.91 ± 0.07 b | 3.82 ± 0.07 a |

| C18:3n3 (alpha) | 0.19 ± 0.01 b | 0.12 ± 0.01 c | 0.32 ± 0.01 a | 0.3 ± 0.01 a |

| C20:0 | 0.16 ± 0.01 a | 0.17 ± 0.01 a | 0.15 ± 0.01 a | 0.15 ± 0.01 a |

| C20:1n9 | <LOD | <LOD | 0.04 ± 0.01 a | 0.05 ± 0.01 a |

| C20:2n6 | 0.04 ± 0.01 a | <LOD | 0.06 ± 0.01 a | 0.05 ± 0.01 a |

| C21:0 | 0.06 ± 0.01 b | <LOD | 0.1 ± 0.01 a | 0.09 ± 0.01 a |

| C22:0 | 0.03 ± 0.01 | <LOD | <LOD | <LOD |

| C22:1n9 | 0.12 ± 0.01 a | 0.13 ± 0.01 a | 0.12 ± 0.01 a | 0.13 ± 0.1 a |

| C22:2n6 | 0.03 ± 0.01 | <LOD | <LOD | <LOD |

| C23:0 | 0.04 ± 0.01 a | <LOD | 0.04 ± 0.01 a | <LOD |

| SFA | 69.77 | 69.44 | 66.58 | 63.87 |

| MUFA | 23.06 | 23.15 | 24.89 | 26.1 |

| PUFA | 1.84 | 1.71 | 3.35 | 4.22 |

| OMEGA 3 | 0.24 | 0.18 | 0.38 | 0.35 |

| OMEGA 6 | 1.6 | 1.53 | 2.97 | 3.87 |

| OMEGA 9 | 20.09 | 20.27 | 21.81 | 23.17 |

| Sample | Overrun (%) | Melting Rate (g/min) | Melting Start (min) | Maximum Meltdown Rate (g/min) |

|---|---|---|---|---|

| C | 32.58 ± 0.6 a | 0.145 ± 0.02 a | 26.8 ± 2.12 c | 0.248 ± 0.05 a |

| IC2 | 17.69 ± 0.3 b | 0.136 ± 0.02 b | 37.6 ± 0.78 b | 0.19 ± 0.02 bc |

| IC5 | 15.94 ± 0.28 c | 0.099 ± 0.01 c | 40.3 ± 0.1 b | 0.154 ± 0.02 c |

| IC10 | 13.10 ± 0.22 d | 0.094 ± 0.04 c | 49.9 ± 6.5 a | 0.122 ± 0.02 c |

| Sample | L* | a* | b* | ∆E | BI | WI |

|---|---|---|---|---|---|---|

| C | 99.62 ± 0.61 a | −5.12 ± 0.85 c | 5.53 ± 0.96 c | - | −3.71 ± 0.45 c | 93.3 ± 0.12 a |

| IC2 | 89.88 ± 2.37 b | 1.51 ± 0.43 b | 9.76 ± 0.46 b | 13.17 ± 0.23 c | 1.25 ± 0.26 b | 85.68 ± 0.82 b |

| IC5 | 82.99 ± 1.38 c | 3.56 ± 0.57 a | 11.55 ± 0.91 ab | 20.23 ± 0.37 b | 3.54 ± 0.11 a | 79.13 ± 1.99 c |

| IC10 | 77.37 ± 0.85 d | 4.71 ± 0.53 a | 12.69 ± 0.82 a | 25.84 ± 0.75 a | 4.40 ± 0.46 a | 73.62 ± 0.79 d |

| Sample | DPPH (mM TE) | ABTS (mM TE) |

|---|---|---|

| C | 0.04 ± 0.01 c | 0.12 ± 0.01 d |

| IC2 | 0.06 ± 0.01 c | 0.16 ± 0.01 d |

| IC5 | 0.15 ± 0.01 b | 0.24 ± 0.01 c |

| IC10 | 0.20 ± 0.05 b | 0.35 ± 0.02 b |

| MP | 0.71 ± 0.05 a | 0.53 ± 0.02 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zielińska, E.; Pečová, M.; Pankiewicz, U. Impact of Mealworm Powder (Tenebrio molitor) Fortification on Ice Cream Quality. Sustainability 2023, 15, 16041. https://doi.org/10.3390/su152216041

Zielińska E, Pečová M, Pankiewicz U. Impact of Mealworm Powder (Tenebrio molitor) Fortification on Ice Cream Quality. Sustainability. 2023; 15(22):16041. https://doi.org/10.3390/su152216041

Chicago/Turabian StyleZielińska, Ewelina, Martina Pečová, and Urszula Pankiewicz. 2023. "Impact of Mealworm Powder (Tenebrio molitor) Fortification on Ice Cream Quality" Sustainability 15, no. 22: 16041. https://doi.org/10.3390/su152216041

APA StyleZielińska, E., Pečová, M., & Pankiewicz, U. (2023). Impact of Mealworm Powder (Tenebrio molitor) Fortification on Ice Cream Quality. Sustainability, 15(22), 16041. https://doi.org/10.3390/su152216041