Assessment of Construction Competitiveness through Knowledge Management Process Implementation

Abstract

1. Introduction

- To examine key KMP factors affecting the CC in construction companies.

- To explore interrelationships between key KMP factors and CC.

- To develop a self-assessment form of KMP implementation for construction companies to assess their current KM implementation and suggest plans to improve KMP and enhance CC in the long term.

2. Literature Review

2.1. KMP Factors in the Construction Industry

2.1.1. Knowledge Acquisition Factor

- The acquisition of knowledge from clients (KA1) item: Yusof and Bakar [47] mentioned that knowledge can be acquired from clients through their feedback on services. ElFar et al. [32] stated that construction companies can acquire knowledge from customer relations to catch their needs and intentions.

- The acquisition of knowledge from competitors (KA2) item: Alrubaiee et al. [40] mentioned that construction companies could acquire knowledge from competitors through their strategies and processes. Valdez-Juárez et al. [33] added that companies should acquire knowledge from competitors to update their business strategies.

- The acquisition of knowledge through the employee’s KPI processes (KA3) item: Liao and Wu [48] mentioned that the acquisition knowledge process affected employees through activities (i.e., identifying best practices, exchanging experiences, and competing performance between individuals). Bing Chong et al. [49] mentioned that knowledge could be extracted from workers through mapping knowledge.

- The acquisition of knowledge through the financial reporting systems (KA4) item: Ahmad and An [39] mentioned that data (e.g., financial data, cost, and profit) may be used to improve the body of knowledge in companies. Akram et al. [50] stated that a good KA should have a financial reporting system that is well-developed to manage financial activities and support managers in decision-making.

- The acquisition of knowledge through market research (KA5) item: Parker [51] mentioned that construction companies could extend their knowledge through markets. Jayasingam et al. [46] stated that practices associated with the acquisition of ideas and solutions could come from real market needs. Abu Bakar et al. [31] mentioned that acquisition refers to activities conducted to obtain knowledge from the business environment.

- The acquisition of knowledge through previous project experiences (KA6) item: Gonzalez and Martins [29] stated that previous experiences should be acquired to update and improve project performance. Kale and Karaman [52] mentioned that companies can acquire knowledge from defects, design changes, and planning to improve subsequent projects.

2.1.2. Knowledge Dissemination Factor

- The dissemination of hard copies to stakeholders (KD1) item: Mohamad and Mat Zin [2] mentioned that disseminating knowledge to stakeholders through hard copies (e.g., reports, newsletters, policy, and procedure manuals) improves competitiveness in construction companies. Chen and Fong [13] added that disseminating hard copies to stakeholders helps update project information and improve knowledge in construction companies.

- The dissemination of knowledge through staff mentoring (KD2) item: Chen and Fong [37] mentioned that staff mentoring could disseminate knowledge among members to maintain interactive themes for KD in companies. Ulhaq et al. [56] stated that transferring the captured knowledge to employees through mentoring and coaching can support the individual’s decision-making.

- The dissemination of knowledge of products and processes within the company using updated technology (KD3) item: Almomani et al. [35] mentioned that knowledge of products and processes disseminated using the technology will enhance the marketing innovation of companies. Allameh and Abbas [57] recommended that companies should use technology to disseminate business process knowledge to improve innovation and performance.

- The dissemination of market trends and developments among internal departments (KD4) item: Hassan and Raziq [30] mentioned that market information should be freely disseminated in companies. Lo et al. [58] added that disseminating market trends to all employees improves KD, leading to improved organizational effectiveness.

- The dissemination of knowledge by encouraging two-way communication (KD5) item: Jayasingam et al. [46] mentioned that knowledge is disseminated among people throughout the organization through meetings between departments, managers, and employees. Wibowo et al. [43] mentioned that KD should be performed to ensure that the organizational knowledge is received by all members.

2.1.3. Knowledge Responsiveness Factor

- The response to changes in client needs (KR1) item: Saini et al. [12] mentioned that responsiveness to client demand improves agility, which is the ability to adapt to continual changes in companies. Wibowo et al. [43] stated that the KR involves activities carried out as a response to clients to improve the success of projects.

- The response to the client’s reactions to technological changes (KR2) item: Akram et al. [50] stated that responding to technological changes helps companies take the best ideas from disparate functions. Yousaf and Ali [34] stated that the ability to respond to technological changes on clients improves operational effectiveness.

- The response to competitor strategies (KR3) item: Hassan and Raziq [30] mentioned that the competitors’ strategies reflect the current state of the market. Darroch [38] added that responding to competitor strategies helps firms gain more information about market trends and update their strategies proactively and effectively.

- The response to employee needs (KR4) item: Wibowo et al. [43] mentioned that responding to employees’ needs helps the company make adjustments in management. This also motivates employees to participate in KM activities.

- The response to market changes in the market plan (KR5) item: Dang et al. [4] mentioned that the model of KM capability (i.e., infrastructure and process) that responds to market changes is crucial to improving market performance. Mohamad and Mat Zin [2] stated that reacting to changes in the market helps companies improve innovation in products and processes.

2.1.4. Knowledge Storage Factor

- The authorization of accessible permission into the database (KS1) item: Albooyeh and Yaghmaie [24] mentioned that the successful implementation of a data storage system requires user participation through the use and updating of new knowledge. Allowing employees to access data at the appropriate level of responsibility is essential for the implementation of KS.

- The data screening before saving them into the database (KS2) item: Alrubaiee et al. [40] mentioned that data screening is a necessary step to ensure the reliability of data. It is a critical step in providing reliable analysis results for managers when making decisions. Tennakoon et al. [59] stated that construction project activities are driven by knowledge, and this knowledge can be stored in databases called knowledge management systems once subject experts have validated it.

- The storage of knowledge using the data warehousing technology (KS3) item: Novák [41] mentioned that the use of data storage technology is an essential part of KM. Suresh et al. [44] stated that centralized data storage provides connectivity in information management. This helps improve project management and reduce project costs.

- The storage of knowledge in hard copies (KS4) item: Fong and Choi [21] mentioned that storing data in hard copy (i.e., reports, newsletters, policy, and procedure manuals) is a traditional method in the construction industry. It is widely used in the management of construction sites in the form of drawings, acceptance records, and progress reports. Shahzad et al. [60] mentioned that hard copy, an explicit type of knowledge, requires amplification mechanisms such as procedures, IT systems, and cultural work to maximize the benefits of the combination stage of the KM process.

- The storage of lessons learned in a database (KS5) item: Park et al. [61] mentioned that the knowledge of employees needs to be stored in a knowledge storage system so that it can be easily queried and analyzed to support decision-making.

- The procedures for knowledge storage (KS6) item: Wang and Meng [14] mentioned that to collect data effectively, construction companies need to establish data collection procedures and disseminate them to all departments. This helps improve the consistency and efficiency of data collection and storage.

2.1.5. Knowledge Utilization Factor

- The use of existing knowledge to improve company business processes (KU1) item: Mohamad and Mat Zin [2] mentioned that construction companies can use the knowledge gained from their operations to improve business processes by reusing experiences from similar projects. This depends on the level of knowledge that the company possesses and the level of KM maturity.

- The use of knowledge to deal with competitive conditions (KU2) item: ElFar et al. [32] commented that knowledge is used to deal with changes in the business environment. It helps companies adapt to a dynamic market (i.e., new materials and new technologies). Egbu [62] mentioned that KM is a critical enabler for innovation to deal with competitive conditions.

- The use of knowledge to adapt strategic directions (KU3) item: Dang et al. [7] mentioned that the development of construction companies is affected by their ability to adapt to the market. The use of knowledge to build plans and strategies to create appropriate products and services will help businesses increase the efficiency of market development.

- The use of accumulated knowledge to solve problems (KU4) item: Garcia and Mollaoglu [18] mentioned that the knowledge used by individuals to solve problems reflects their ability to apply knowledge. Chen and Fong [13] stated that the knowledge accumulated by employees increases their problem-solving ability, leading to improved efficiency of the companies.

- The use of new knowledge to improve company business processes (KU5) item: Wibowo et al. [43] mentioned that the use of knowledge will create new knowledge to improve the company’s performance. It also increases the innovation of the business through the creation of improvements (i.e., using information systems for estimating and quoting instead of using experience).

2.2. Construction Competitiveness in the Construction Industry

2.3. Conceptual Model of KMP and CC Factors

- H1: Knowledge storage positively affects knowledge acquisition. Gonzalez and Martins [29] mentioned that the data warehousing of previous projects could create the appropriate conditions for organizational learning that help companies enhance knowledge acquisition from their information stored. Novák [41] stated that acquired knowledge can be maintained and transferred to other explicit things such as written documents, electronic databases, codified human knowledge, and documented organizational procedures and processes. The transformation of knowledge type between explicit and tacit knowledge creates new knowledge that extends and updates existing knowledge in companies [81].

- H2: Knowledge storage positively affects the knowledge dissemination. Al-Qubaisi et al. [36] mentioned that adopting IT in distributing knowledge could help companies increase the effectiveness of knowledge dissemination. Wang and Meng [14] mentioned that stored information tools (e.g., building information modeling) can provide a convenient way to manage information across different project phases, enable knowledge exchange between departments, and define relationships between current and previous construction activities to integrate relevant knowledge. Singh and Mirzaeifar [82] proposed a framework based on memory systems to assess the transactions of distributed content knowledge resources in modern construction projects. This helps increase the effectiveness of knowledge dissemination for project management.

- H3: Knowledge acquisition positively affects the knowledge dissemination. Chen and Fong [13] mentioned that the new knowledge acquired should be disseminated to all departments to adapt to new ideas and situations. Lessons learned from previous projects and clients can be shared through effective communication among team members to retain new knowledge and enhance work practices [34]. Teerajetgul et al. [83] mentioned that knowledge acquisition and sharing by employees consist of work trust, collaboration, and individual competency influencing onsite construction works. New knowledge acquired from markets and projects is also distributed through updated processes, guidelines, and manuals, resulting in increasing intensive activities of knowledge dissemination [13,38].

- H4: Knowledge responsiveness positively affects knowledge acquisition. Yousaf and Ali [34] mentioned that acquiring quality and quantity of information from clients is assisted by achieving effective responses to clients. To deal with new changes in the market, knowledge acquisition activities get knowledge from the market that updates and extends the existing knowledge [37]. The higher the intensity of the knowledge responsiveness, the higher the interaction with the knowledge source, and the higher the intensity of knowledge acquisition [13].

- H5: Knowledge dissemination positively affects knowledge utilization. Alashwal et al. [84] mentioned that distributing knowledge to stakeholders increases coordination and effective decision-making when dealing with project changes. Sharing knowledge among members of the project team increases the effectiveness of using knowledge to reduce mistakes and improve productivity [85,86]. The higher the intensity of knowledge dissemination, the more activities using knowledge [13].

- H6: Knowledge utilization positively affects knowledge responsiveness. Mohamad and Mat Zin [2] mentioned that data should be used and analyzed before responding to clients and competitors to demonstrate how companies transform their data and knowledge into projects and business practices. Using knowledge in production and business activities creates new knowledge, which can be used to respond to market changes [37]. Therefore, use knowledge as a trigger to increase interaction with the market by responding to changes in customers and competitors [16].

- H7: Construction competitiveness positively affects knowledge storage. Novák [41] mentioned that organizational databases and expert experiences influence organizational performance in financial, innovational, growth, and operation performance. Tennakoon et al. [59] mentioned that information on projects is stored in the systems (e.g., BIM), which helps companies manage all phases of projects effectively, resulting in a satisfaction increase in owners and stakeholders. To improve the project’s success, the information demand of management increases to tackle the risks and the changes in projects [87]. The growing market share when companies get more competitive requires more information and data for marketing activities [88]. These information demands of companies lead to a higher intensity of knowledge storage.

- H8: Construction competitiveness positively affects knowledge acquisition. Jayasingam et al. [46] stated that KA significantly affects strategic and process improvement by acquiring market, client, and employee ideas and solutions. Pietersen [89] mentioned that performance outcomes represent new knowledge that reveals the competitive position of the company, resulting in the intensity of knowledge acquisition. The demand for the management of data and information is higher when construction competitiveness increases, resulting in a higher intensity of activities of knowledge acquisition [29].

- H9: Knowledge dissemination positively affects construction competitiveness. Ren et al. [8] stated that strategies, including standardizing project management, using information and post-project evaluation systems, and encouraging a shared culture to enhance inter-project communication and transfer intention, provide superior advantages for construction companies. Arif et al. [90] mentioned that sharing knowledge improves the productivity of construction projects and affects the strategy and operation of companies. Teerajetgul and Chareonngam [91] mentioned that tacit knowledge is disseminated and re-combined based on networks among individuals in projects, facilitating a steady evolution of best practices. The higher the intensity of knowledge dissemination, the higher the construction competitiveness.

- H10: Knowledge responsiveness positively affects construction competitiveness. KR enhances the interaction between the company and its client to update information, adapt work practices following client comments, and enhance work innovation [38]. Hassan and Raziq [30] stated that knowledge responsiveness helps companies be proactive to changes and more innovative when they interact with clients and competitors. Butnariu and Luca [92] mentioned that the development of trust-based relationships depends on relational marketing with stakeholders in order to bring added value to the involved parties of projects. The higher the intensity of the knowledge responsiveness, the more construction competitiveness.

- H11: Knowledge utilization positively affects construction competitiveness. Chen and Fong [13] mentioned that effective use of knowledge may enhance business performance in terms of finance, client, process, and learning and growth [13]. Construction companies could use experiences and knowledge from previous projects to enhance performance [84]. Using KM could also help construction project managers control cost-effectively, resulting in construction competitiveness [44]. The higher the intensity of knowledge utilization the more CC improvement.

3. Research Methodology

3.1. Research Framework

3.2. Questionnaire Survey Development and Pilot Test

3.3. The Exploratory Factor Analysis and the Reliability Test

3.4. The Structural Equation Modeling Approach

4. Analyses Results

4.1. Data Collection and Data Screening Results

4.2. EFA Results

4.3. SEM Results

4.3.1. Measurement Model Results

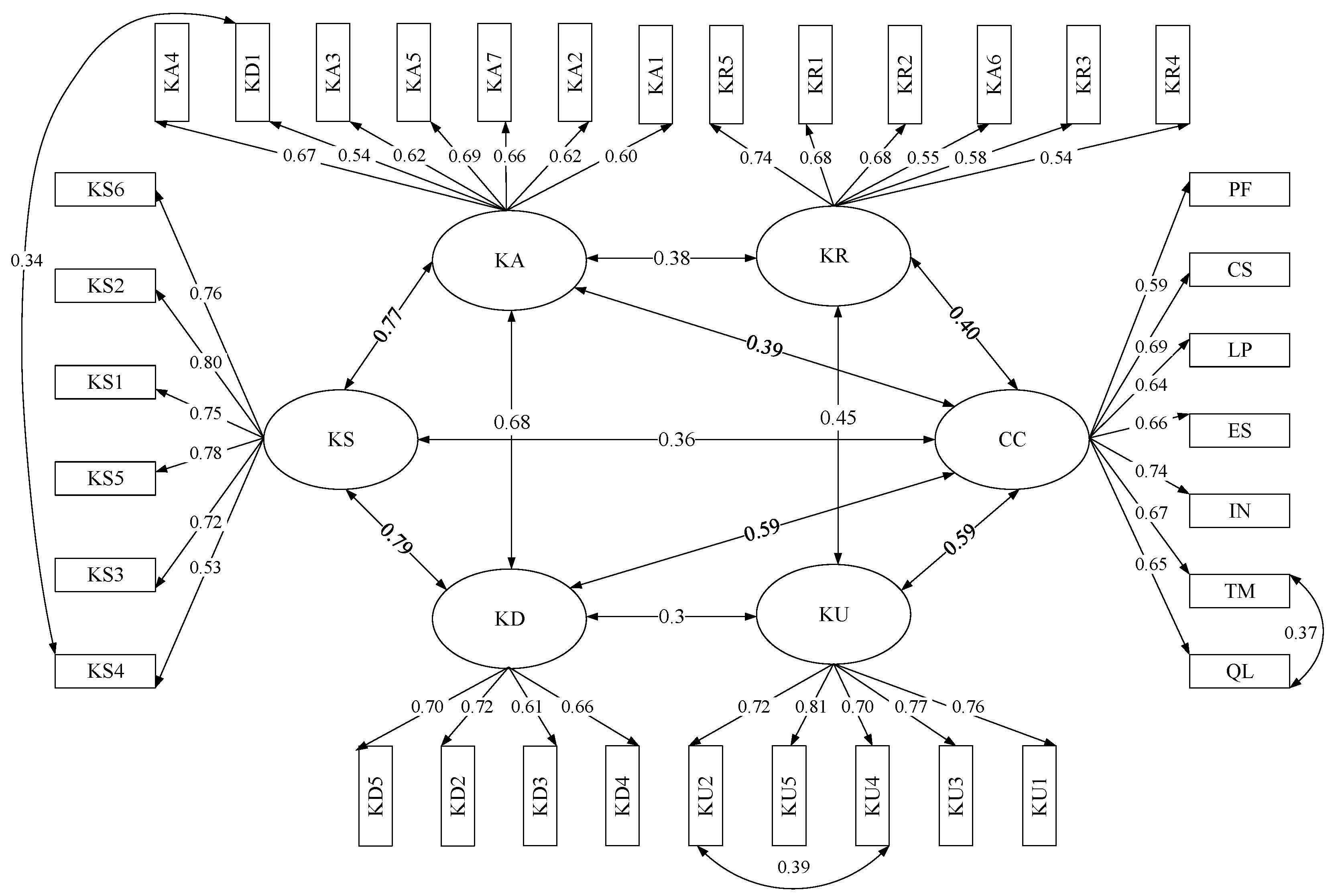

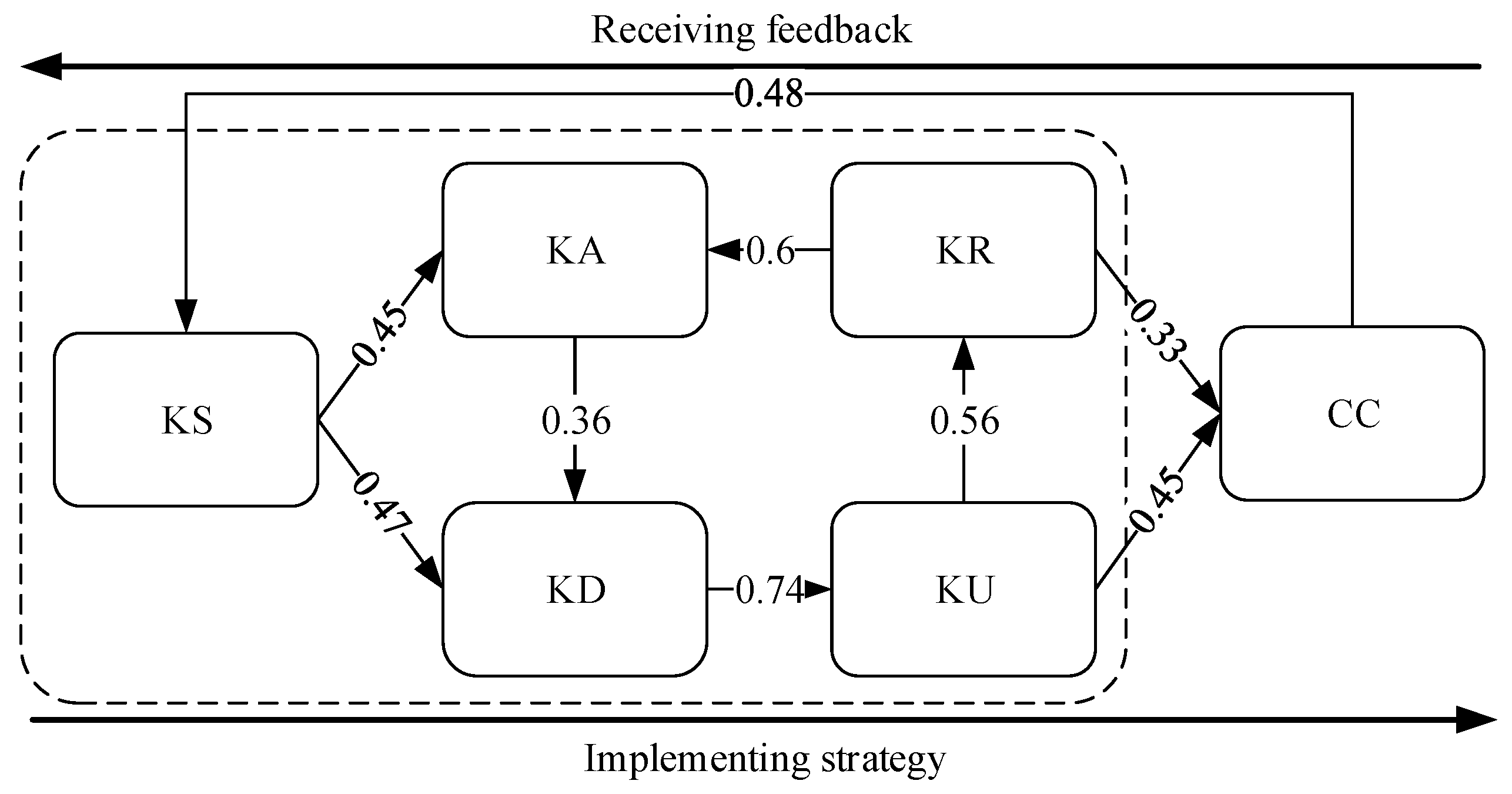

4.3.2. Structural Model Results

5. Discussion of Results

6. Self-Assessment Form of CC through KMP Implementation

- 1—No KMP in place: KMP activities are performed randomly, and CC is achieved without KMP implementation.

- 2—Beginner level: KMP activities are recognized but not performed regularly. No standard practices are conducted.

- 3—Medium level: KMP activities are performed under a standard process. The KMP practices are assessed on a regular basis.

- 4—High level: KMP activities are acknowledged as a tool to enhance the CC and are well-managed with supporting tools.

- 5—Excellent level: KMP activities are comprehensively and continuously improved and performed in an optimized manner. A long-term KMP improvement plan is established, implemented, and regularly updated to enhance CC.

- Step 1: Each item of KMP and CC factors is assessed using a 5-point scale. The assessment score of each item is multiplied by its importance weight, and all items’ scores are summed to achieve the total score of each KMP and CC factor, (see Table 7). Please note that the assessment scores used in Table 11 are the assumed scores and do not reflect the actual status of the Vietnamese construction industry. They are used as examples for the calculation steps only. The total score of the KS factor (KSs) is (0.79 × 3) + (0.79 × 3) + (0.77 × 3) + (0.74 × 4) + (0.71 × 4) + (0.52 × 2) = 13.89 points (see Table 11). The total score is then adjusted to a maximum adjusted score of 5 points. For example, the maximum total score of the KS factor is (0.79 + 0.79 + 0.77 + 0.74 + 0.71 + 0.52) × 5 = 21.6 points when all six KS items receive 5 points in the assessment. The adjusted score of the KS factor (KSa) is then 13.89 × 5/21.6 = 3.22 points (see Table 11).

- Step 2: The influences the five KMP factors have on CC are reflected by the influential score of KMP factors on CC (KMPf). It is calculated by multiplying the adjusted scores of five KMP factors by their influential weights (see Table 10). It is summed to achieve a maximum influential score of 8.55 points (i.e., when five KMP factors receive the adjusted scores of 5 points). For example, the total effect the KS factor has on CC is 0.16 (see Table 10); this results in the influential score of the KS factor on CC of 0.16 × 3.22 = 0.52 (when the adjusted score of the KS factor is 3.22), see Table 11.

- Step 3: The final score of CC through KMP implementation (CCKMP) is finally calculated by summing the adjusted score of CC (CCa) with the influential score of KMP factors on CC (KMPf). It is then adjusted to a maximum score of 5 points by multiplying by 5 and dividing by 13.55 (which is the maximum score of CCa and KMPf, i.e., 5 + 8.55 = 13.55 points). In Table 11, the CCKMP is (3.28 + 5.09) × 5/13.55 = 3.09.

7. Implications for the Construction Industry

- In the short term, project managers may organize a weekly meeting on sites to discuss problems and challenges with workers. Workers with good examples are invited to give a short talk on their performance, and their stories are posted on the company website. Social communication channels are encouraged to promptly manage and solve problems on sites. The new technology as building information modeling (BIM) and 3D model, is utilized in client discussions, and the discussion summaries are recorded for future reference.

- In the long term, the company should invest in data warehousing to effectively record, analyze, and use the data to minimize possible human errors. Skill training in data warehousing is required for effective utilization. The BIM is encouraged to be used to closely monitor the work progress, manage problems, and record solutions for future uses.

8. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anumba, C.J.; Egbu, C.; Carrillo, P. Knowledge Management in Construction; John Wiley & Sons: New York, NY, USA, 2008. [Google Scholar]

- Mohamad, M.R.; Mat Zin, N. Knowledge management and the competitiveness of small construction firms: Innovation as mediator. Compet. Rev. 2019, 29, 534–550. [Google Scholar] [CrossRef]

- Chen, L.; Mohamed, S. Impact of the internal business environment on knowledge management within construction organisations. Constr. Innov. 2008, 8, 61–81. [Google Scholar] [CrossRef]

- Dang, C.N.; Le-Hoai, L.; Kim, S.Y. Impact of knowledge enabling factors on organizational effectiveness in construction companies. J. Knowl. Manag. 2018, 22, 759–780. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Toh, H.M. Investigating the principal factors impacting knowledge management implementation in construction organisations. J. Eng. Des. Technol. 2020, 18, 55–69. [Google Scholar] [CrossRef]

- Chen, L.; Mohamed, S. The strategic importance of tacit knowledge management activities in construction. Constr. Innov. 2010, 10, 138–163. [Google Scholar] [CrossRef]

- Dang, C.N.; Chih, Y.Y.; Le-Hoai, L.; Nguyen, L.D. Project-based A/E/C firms’ knowledge management capability and market development performance: Does firm size matter. J. Constr. Eng. Manag. 2020, 146, 04020127. [Google Scholar] [CrossRef]

- Ren, X.; Deng, X.; Liang, L. Knowledge transfer between projects within project-based organizations: The project nature perspective. J. Knowl. Manag. 2018, 22, 1082–1103. [Google Scholar] [CrossRef]

- Thukral, E. COVID-19: Small and medium enterprises challenges and responses with creativity, innovation, and entrepreneurship. Strateg. Change 2021, 30, 153–158. [Google Scholar] [CrossRef]

- Le-Hoai, L.; Lee, Y.D.; Lee, J.Y. Delay and cost overruns in Vietnam large construction projects: A comparison with other selected countries. KSCE J. Civ. Eng. 2008, 12, 367–377. [Google Scholar] [CrossRef]

- Zhang, L.; He, J. Critical Factors Affecting Tacit-Knowledge Sharing within the Integrated Project Team. J. Manag. Eng. 2016, 32, 04015045. [Google Scholar] [CrossRef]

- Saini, M.; Arif, M.; Kulonda, D.J. Critical factors for transferring and sharing tacit knowledge within lean and agile construction processes. Constr. Innov. 2017, 18, 64–89. [Google Scholar] [CrossRef]

- Chen, L.; Fong, P.S.W. Evaluation of knowledge management performance: An organic approach. Inf. Manag. 2015, 52, 431–453. [Google Scholar] [CrossRef]

- Wang, H.; Meng, X. BIM-based knowledge management in construction projects. Int. J. Inf. Technol. Proj. Manag. 2018, 9, 20–37. [Google Scholar] [CrossRef]

- Yu, D.; Yang, J. Knowledge Management Research in the Construction Industry: A Review. J. Knowl. Econ. 2018, 9, 782–803. [Google Scholar] [CrossRef]

- Andreeva, T.; Kianto, A. Does knowledge management really matter? Linking knowledge management practices, competitiveness and economic performance. J. Knowl. Manag. 2012, 16, 617–636. [Google Scholar] [CrossRef]

- Le, P.T.; Kirytopoulos, K.; Chileshe, N.; Rameezdeen, R. Taxonomy of risks in PPP transportation projects: A systematic literature review. Int. J. Constr. Manag. 2022, 22, 166–181. [Google Scholar] [CrossRef]

- Garcia, A.J.; Mollaoglu, S. Measuring Key Knowledge-Related Factors for Individuals in AEC Project Teams. J. Constr. Eng. Manag. 2020, 146, 04020063. [Google Scholar] [CrossRef]

- Joseph Garcia, A.; Mollaoglu, S. Individuals’ Capacities to Apply Transferred Knowledge in AEC Project Teams. J. Constr. Eng. Manag. 2020, 146, 04020016. [Google Scholar] [CrossRef]

- Oti, A.H.; Tah, J.H.M.; Abanda, F.H. Integration of Lessons Learned Knowledge in Building Information Modeling. J. Constr. Eng. Manag. 2018, 144, 04018081. [Google Scholar] [CrossRef]

- Fong, P.S.W.; Choi, S.K.Y. The processes of knowledge management in professional services firms in the construction industry: A critical assessment of both theory and practice. J. Knowl. Manag. 2009, 13, 110–126. [Google Scholar] [CrossRef]

- Rezgui, Y.; Zarli, A. Paving the Way to the Vision of Digital Construction: A Strategic Roadmap. J. Constr. Eng. Manag. 2006, 132, 767–776. [Google Scholar] [CrossRef]

- Liu, K.; Su, Y.; Pollack, J.; Liang, H.; Zhang, S. Explaining the Formation Mechanism of Intrateam Knowledge Exchange Network in Offsite Construction Projects: A Social Cognitive Perspective. J. Constr. Eng. Manag. 2022, 148, 04021192. [Google Scholar] [CrossRef]

- Albooyeh, S.; Yaghmaie, F. Evaluation of knowledge management model in construction companies using the fuzzy AHP and fuzzy TOPSIS. Int. J. Bus. Excell. 2019, 18, 64–97. [Google Scholar] [CrossRef]

- Gunasekera, V.S.; Chong, S.C. Knowledge management critical success factors and project management performance outcomes in major construction organisations in Sri Lanka: A case study. VINE J. Inform. Knowl. Manag. 2018, 48, 537–558. [Google Scholar] [CrossRef]

- Núñez, D.; Ferrada, X.; Neyem, A.; Serpell, A.; Sepúlveda, M. A user-centered mobile cloud computing platform for improving knowledge management in small-to-medium enterprises in the Chilean construction industry. Appl. Sci. 2018, 8, 516. [Google Scholar] [CrossRef]

- Zhang, L.; He, J.; Zhou, S. Sharing tacit knowledge for integrated project team flexibility: Case study of integrated project delivery. J. Constr. Eng. Manag. 2013, 139, 795–804. [Google Scholar] [CrossRef]

- Gold, A.H.; Malhotra, A.; Segars, A.H. Knowledge management: An organizational capabilities perspective. J. Manag. Inf. Syst. 2001, 18, 185–214. [Google Scholar] [CrossRef]

- Gonzalez, R.; Martins, M.F. Knowledge Management Process: A theoretical-conceptual research. Gestão Produção 2017, 24, 248–265. [Google Scholar] [CrossRef]

- Hassan, N.; Raziq, A. Effects of knowledge management practices on innovation in SMEs. Manag. Sci. Lett. 2019, 9, 997–1008. [Google Scholar] [CrossRef]

- Abu Bakar, A.H.; Yusof, M.N.; Tufail, M.A.; Virgiyanti, W. Effect of knowledge management on growth performance in construction industry. Manag. Decis. 2016, 54, 735–749. [Google Scholar] [CrossRef]

- ElFar, A.; Elsaid, A.M.; Elsaid, E. How knowledge management implementation affects the performance of Egyptian construction companies. J. Appl. Bus. Res. 2017, 33, 409–438. [Google Scholar] [CrossRef]

- Valdez-Juárez, L.E.; De Lema, D.G.P.; Maldonado-Guzmán, G. Management of knowledge, innovation and performance in SMEs. Interdiscip. J. Inf. Knowl. Manag. 2016, 11, 141–176. [Google Scholar] [CrossRef]

- Yousaf, M.J.; Ali, Q. Impact of knowledge management on innovation: Evidence from a South Asian country. J. Inf. Knowl. Manag. 2018, 17, 1850035. [Google Scholar] [CrossRef]

- Almomani, R.Z.Q.; Al-Abbadi, L.H.M.; Rumman, A.R.A.A.A.; Abu-Rumman, A.; Banyhamdan, K. Organizational memory, knowledge management, marketing innovation and cost of quality: Empirical effects from construction industry in Jordan. Acad. Entrep. J. 2019, 25, 1–3. [Google Scholar]

- Al-Qubaisi, S.S.; Ajmal, M.M.; Khan, M. Impact of knowledge management and ICT on operational efficiency: An empirical study. Int. J. Knowl. Based Dev. 2018, 9, 174–202. [Google Scholar] [CrossRef]

- Chen, L.; Fong, P.S.W. Visualizing evolution of knowledge management capability in construction firms. J. Constr. Eng. Manag. 2013, 139, 839–851. [Google Scholar] [CrossRef]

- Darroch, J. Knowledge management, innovation and firm performance. J. Knowl. Manag. 2005, 9, 101–115. [Google Scholar] [CrossRef]

- Ahmad, H.S.; An, M. Knowledge management implementation in construction projects: A KM model for Knowledge Creation, Collection and Updating (KCCU). Int. J. Proj. Organ. Manag. 2008, 1, 133–166. [Google Scholar] [CrossRef]

- Alrubaiee, L.; Alzubi, H.M.; Hanandeh, R.E.; Al Ali, R. Investigating the relationship between knowledge management processes and organizational performance the mediating effect of organizational innovation. Int. Rev. Manag. Bus. Res. 2015, 4, 989–1009. [Google Scholar]

- Novák, A. Knowledge management and organizational performance–literature review. In Proceedings of the MakeLearn and TIIM International Conference, Lublin, Poland, 17–19 May 2017; pp. 433–440. [Google Scholar]

- Fong, P.S.; Chen, L. Governance of learning mechanisms: Evidence from construction firms. J. Constr. Eng. Manag. 2012, 138, 1053–1064. [Google Scholar] [CrossRef]

- Wibowo, M.A.; Waluyo, R.; Zhabrinna, Z. Investigation of the relationship between the knowledge management process and performance of a construction company: An empirical study. Interdiscip. J. Inf. Knowl. Manag. 2018, 13, 417–435. [Google Scholar] [CrossRef]

- Suresh, S.; Olayinka, R.; Chinyio, E.; Renukappa, S. Impact of knowledge management on construction projects. Proc. Inst. Civ. Eng. Manag. Proc. Law. 2017, 170, 27–43. [Google Scholar] [CrossRef]

- Darroch, J.; McNaughton, R. Beyond market orientation: Knowledge management and the innovativeness of New Zealand firms. Eur. J. Mark. 2003, 37, 572–593. [Google Scholar] [CrossRef]

- Jayasingam, S.; Ansari, M.A.; Ramayah, T.; Jantan, M. Knowledge management practices and performance: Are they truly linked? Knowl. Manag. Res. Pract. 2013, 11, 255–264. [Google Scholar] [CrossRef]

- Yusof, M.N.; Bakar, A.H.A. Knowledge Management and Growth Performance in Construction Companies: A Framework. Procedia Soc. Behav. Sci. 2012, 62, 128–134. [Google Scholar] [CrossRef][Green Version]

- Liao, S.H.; Wu, C.C. Knowledge management and innovation: The mediating effects of organizational learning. In Proceedings of the 2009 IEEE International Conference on Industrial Engineering and Engineering Management, Hong Kong, China, 8–11 December 2009; pp. 1850–1854. [Google Scholar]

- Bing Chong, N.; Uden, L.; Naaranoja, M. Knowledge management system for construction projects in Finland. Int. J. Knowl. Manag. Stud. 2007, 1, 240–260. [Google Scholar] [CrossRef]

- Akram, M.U.; Chauhan, C.; Ghosh, K.; Singh, A. Knowledge management, sustainable business performance and empowering leadership: A firm-level approach. Int. J. Knowl. Manag. 2019, 15, 20–35. [Google Scholar] [CrossRef]

- Parker, H. Knowledge acquisition and leakage in inter-firm relationships involving new technology-based firms. Manag. Decis. 2012, 50, 1618–1633. [Google Scholar] [CrossRef]

- Kale, S.; Karaman, E.A. A diagnostic model for assessing the knowledge management practices of construction firms. KSCE J. Civ. Eng. 2012, 16, 526–537. [Google Scholar] [CrossRef]

- Niu, K.H. Organizational trust and knowledge obtaining in industrial clusters. J. Knowl. Manag. 2010, 14, 141–155. [Google Scholar] [CrossRef]

- Virgiyanti, W.; Tufail, M.A.; Bakar, A.H.A. Intervention of organizational culture in achieving competitive advantage through knowledge management in Malaysian construction companies. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 204–214. [Google Scholar]

- Etemadi, R.; Hon, C.K.H.; Murphy, G.; Manley, K. The use of social media for work-related knowledge sharing by construction professionals. Arch. Eng. Des. 2020, 16, 426–440. [Google Scholar] [CrossRef]

- Ulhaq, I.; Khalfan, M.M.A.; Maqsood, T.; Le, T. Development of a conceptual framework for knowledge management within construction project supply chain. Int. J. Knowl. Manag. Stud. 2017, 8, 191–209. [Google Scholar] [CrossRef]

- Allameh, S.M.; Abbas, S.K. The relationship between knowledge management practices and innovation level in organizations: Case study of sub-companies of selected corporations in the city of Esfahan. J. Bus. Case Stud. 2010, 6. [Google Scholar] [CrossRef][Green Version]

- Lo, M.-C.; Mohamad, A.A.; Ramayah, T.; Abdullah, M.A.; Lim, M.-C. The role of knowledge management on organisational effectiveness: Organisational culture as the moderator. Int. J. Bus. Soc. 2017, 18, 808–818. [Google Scholar]

- Tennakoon, T.M.M.P.; Kulatunga, U.; Jayasena, H.S. Influence of organisational culture on knowledge management in BIM-enabled construction environments. VINE J. Inform. Knowl. Manag. 2022, 52, 224–242. [Google Scholar] [CrossRef]

- Shahzad, K.; Bajwa, S.U.; Siddiqi, A.F.I.; Ahmid, F.; Raza Sultani, A. Integrating knowledge management (KM) strategies and processes to enhance organizational creativity and performance. J. Model. Manag. 2016, 11, 154–179. [Google Scholar] [CrossRef]

- Park, M.; Jang, Y.; Lee, H.S.; Ahn, C.; Yoon, Y.S. Application of knowledge management technologies in Korean small and medium-sized construction companies. KSCE J. Civ. Eng. 2013, 17, 22–32. [Google Scholar] [CrossRef]

- Egbu, C.O. Managing knowledge and intellectual capital for improved organizational innovations in the construction industry: An examination of critical success factors. Eng. Constr. Archit. Manag. 2004, 11, 301–315. [Google Scholar] [CrossRef]

- Shen, L.-Y.; Lu, W.-S.; Yam, M.C. Contractor key competitiveness indicators: A China study. J. Constr. Eng. Manag. 2006, 132, 416–424. [Google Scholar] [CrossRef]

- Soewin, E.; Chinda, T. Factors affecting construction performance: Exploratory factor analysis. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP: London, UK, 2018; p. 012102. [Google Scholar]

- Othman, A.; Ismail, S.; Yahya, K.; Ahmad, M.H. Critical success factors in implementing knowledge management in consultant firms for Malaysian construction industry. Manag. Sci. Lett. 2018, 8, 305–316. [Google Scholar] [CrossRef]

- Hussinki, H.; Ritala, P.; Vanhala, M.; Kianto, A. Intellectual capital, knowledge management practices and firm performance. J. Intellect. Cap. 2017, 18, 904–922. [Google Scholar] [CrossRef]

- Gholami, M.H.; Asli, M.N.; Nazari-Shirkouhi, S.; Noruzy, A. Investigating the influence of knowledge management practices on organizational performance: An empirical study. Acta Polytech. 2013, 10, 205–216. [Google Scholar] [CrossRef]

- Chen, D.-N.; Liang, T.-P. Knowledge evolution strategies and organizational performance: A strategic fit analysis. Electron. Commer. Res. Appl. 2011, 10, 75–84. [Google Scholar] [CrossRef]

- Duodu, B.; Rowlinson, S. Intellectual Capital, Innovation, and Performance in Construction Contracting Firms. J. Manag. Eng. 2021, 37, 04020097. [Google Scholar] [CrossRef]

- Kim, S.B. Impacts of knowledge management on the organizationlal success. KSCE J. Civ. Eng. 2014, 18, 1609–1617. [Google Scholar] [CrossRef]

- Lielgaidina, L.; Geipele, I. Theoretical aspects of competitiveness in construction enterprises. Bus. Manag. Econ. Eng. 2011, 9, 67–80. [Google Scholar] [CrossRef]

- Chan, T.K. Measuring performance of the Malaysian construction industry. Constr. Manag. Econ. 2009, 27, 1231–1244. [Google Scholar] [CrossRef]

- Chen, C.-J.; Huang, J.-W. Strategic human resource practices and innovation performance—The mediating role of knowledge management capacity. J. Bus. Res. 2009, 62, 104–114. [Google Scholar] [CrossRef]

- Cheung, S.O.; Qi, X. Managing for innovation developments in construction organisations. Int. J. Proj. Organ. Manag. 2017, 9, 249–273. [Google Scholar] [CrossRef]

- Darroch, J.; McNaughton, R. Examining the link between knowledge management practices and types of innovation. J. Intellect. Cap. 2002, 3, 210–222. [Google Scholar] [CrossRef]

- Deng, F.; Smyth, H. Contingency-based approach to firm performance in construction: Critical review of empirical research. J. Constr. Eng. Manag. 2013, 139, 04013004. [Google Scholar] [CrossRef]

- Enshassi, A.; Mohamed, S.; Abushaban, S. Factors affecting the performance of construction projects in the Gaza strip. J. Civ. Eng. Manag. 2009, 15, 269–280. [Google Scholar] [CrossRef]

- Graham, B.; Thomas, K. An emerging grounded theory of knowledge management in the leading Irish construction organisations. In Proceedings of the 9th European Conference on Knowledge Management, Southampton, UK, 4–5 September 2008; pp. 225–232. [Google Scholar]

- Sweis, R.J.; Ogla, K.; Abdallat, Y.; Sweis, G.J.; Suifan, T.; Saleh, R. The impact of human resource management practices on organisational performance in construction companies in Jordan. Int. J. Bus. Innov. Res. 2020, 23, 515–539. [Google Scholar] [CrossRef]

- Lin, H.F. The effects of knowledge management capabilities and partnership attributes on the stage-based e-business diffusion. Internet Res. 2013, 23, 439–464. [Google Scholar] [CrossRef]

- Nonaka, I.; Takeuchi, H. The Knowledge-Creating Company: How Japanese Companies Create the Dynamics of Innovation; Oxford University Press: New York, NY, USA, 2009. [Google Scholar]

- Singh, V.; Mirzaeifar, S. Assessing transactions of distributed knowledge resources in modern construction projects–A transactive memory approach. Autom. Constr. 2020, 120, 103386. [Google Scholar] [CrossRef]

- Teerajetgul, W.; Chareonngam, C.; Wethyavivorn, P. Key knowledge factors in Thai construction practice. Int. J. Proj. Manag. 2009, 27, 833–839. [Google Scholar] [CrossRef]

- Alashwal, A.M.; Abdul-Rahman, H.; Radzi, J. Knowledge Utilization Process in Highway Construction Projects. J. Manag. Eng. 2016, 32, 05016006. [Google Scholar] [CrossRef]

- Kiomjian, D.; Srour, I.; Srour, F.J. Knowledge Sharing and Productivity Improvement: An Agent-Based Modeling Approach. J. Constr. Eng. Manag. 2020, 146, 04020076. [Google Scholar] [CrossRef]

- Wen, Q.; Qiang, M. Coordination and Knowledge Sharing in Construction Project-Based Organization: A Longitudinal Structural Equation Model Analysis. Autom. Constr. 2016, 72, 309–320. [Google Scholar] [CrossRef]

- Yan, M.R. Project-based market competition and policy implications for sustainable developments in building and construction sectors. Sustainability 2015, 7, 15423–15448. [Google Scholar] [CrossRef]

- Malesev, S.; Cherry, M. Digital and social media marketing-growing market share for construction SMEs. Constr. Econ. Build. 2021, 21, 65–82. [Google Scholar] [CrossRef]

- Pietersen, W. Strategic Learning: How To Be Smarter than Your Competition and Turn Key Insights into Competitive Advantage; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Arif, M.; Al Zubi, M.; Gupta, A.D.; Egbu, C.; Walton, R.O.; Islam, R. Knowledge sharing maturity model for Jordanian construction sector. Eng. Constr. Archit. Manag. 2017, 24, 170–188. [Google Scholar] [CrossRef]

- Teerajetgul, W.; Chareonngam, C. Tacit knowledge utilization in Thai construction projects. J. Knowl. Manag. 2008, 12, 164–174. [Google Scholar] [CrossRef]

- Butnariu, A.-M.; Luca, F.-A. The Role Of Marketing Activities In Reducing Risk For Construction Companies. SEA-Pract. Appl. Sci. 2020, 24, 369–375. [Google Scholar]

- Deepak, M.D.; Mahesh, G. Developing a knowledge-based safety culture instrument for construction industry: Reliability and validity assessment in Indian context. Eng. Constr. Archit. Manag. 2019, 26, 2597–2613. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R. Multivariate Data Analysis, 7th ed.; Pearson: London, UK, 2009. [Google Scholar]

- Babic, V.; Zaric, S. The impact of knowledge management on wage growth in the construction sector: The case of medium-sized and large companies in the republic of serbia. Econ. Horiz. 2020, 22, 55–66. [Google Scholar] [CrossRef]

- Vitharana, V.H.P.; Chinda, T. Structural equation modelling of lower back pain due to whole-body vibration exposure in the construction industry. Int. J.Occup. Saf. Ergon. 2019, 25, 257–267. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Abdul-Rahman, H.; Wang, C. Preventive Mitigation of Overruns with Project Communication Management and Continuous Learning: PLS-SEM Approach. J. Constr. Eng. Manag. 2018, 144, 04018025. [Google Scholar] [CrossRef]

- Pal, R.; Wang, P.; Liang, X. The critical factors in managing relationships in international engineering, procurement, and construction (IEPC) projects of Chinese organizations. Int. J. Proj. Manag. 2017, 35, 1225–1237. [Google Scholar] [CrossRef]

- Lau, E.; Rowlinson, S. Trust relations in the construction industry. Int. J. Manag. Proj. Bus. 2010, 3, 693–704. [Google Scholar] [CrossRef]

- Chinda, T.; Mohamed, S. Structural equation model of construction safety culture. Eng. Constr. Archit. Manag. 2008, 15, 114–131. [Google Scholar] [CrossRef]

- Lee, K.W.; Wu, K.L.; Kuo, H.P.; Yuan, P.L. Design and validation of a knowledge map system—The case of construction industry in Taiwan. Hum. Factors Ergon. Manuf. Serv. Ind. 2017, 27, 30–44. [Google Scholar] [CrossRef]

- Rajesh, R. Flexible business strategies to enhance resilience in manufacturing supply chains: An empirical study. J. Manuf. Syst. 2021, 60, 903–919. [Google Scholar] [CrossRef]

- Sun, J.; Ren, X.; Anumba, C.J. Analysis of Knowledge-Transfer Mechanisms in Construction Project Cooperation Networks. J. Manag. Eng. 2019, 35, 04018061. [Google Scholar] [CrossRef]

- Nguyen, N.H.; Chinda, T. Interrelationships among key profit factors of vietnamese residential projects using structural equation modeling. Songklanakarin J. Sci. Technol. 2018, 40, 467–474. [Google Scholar] [CrossRef]

- Fuller, C.M.; Simmering, M.J.; Atinc, G.; Atinc, Y.; Babin, B.J. Common methods variance detection in business research. J. Bus. Res. 2016, 69, 3192–3198. [Google Scholar] [CrossRef]

- Rodríguez-Ardura, I.; Meseguer-Artola, A. Editorial: How to Prevent, Detect and Control Common Method Variance in Electronic Commerce Research. J. Theor. Appl. Electron. Commer. Res. 2020, 15, 1–5. [Google Scholar] [CrossRef]

- Upstill-Goddard, J.; Glass, J.; Dainty, A.; Nicholson, I. Implementing sustainability in small and medium-sized construction firms. Eng. Constr. Archit. Manag. 2016, 23, 407–427. [Google Scholar] [CrossRef]

- Chinda, T. Structural equation modeling of productivity enhancement. Suranaree J. Sci. Technol. 2010, 17, 259–276. [Google Scholar]

- Gaski, J.F. The Theory of Power and Conflict in Channels of Distribution. J. Mark. 1984, 48, 9–29. [Google Scholar] [CrossRef]

- Ping Tserng, H.; Lin, Y.-C. Developing an activity-based knowledge management system for contractors. Autom. Constr. 2004, 13, 781–802. [Google Scholar] [CrossRef]

- Vaz-Serra, P.; Edwards, P. Addressing the knowledge management “nightmare” for construction companies. Constr. Innov. 2020, 21, 300–320. [Google Scholar] [CrossRef]

- Suhr, D. Step your way through path analysis. In Proceedings of the Western Users of SAS Software; University of Northern Colorado: Greeley, CO, USA, 2008; pp. 1–10. [Google Scholar]

- Sang, L.; Xia, D.; Ni, G.; Cui, Q.; Wang, J.; Wang, W. Influence mechanism of job satisfaction and positive affect on knowledge sharing among project members: Moderator role of organizational commitment. Eng. Constr. Archit. Manag. 2019, 27, 245–269. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Shavarebi, K. Enhancing project delivery performances in construction through experiential learning and personal constructs: Competency development. Int. J. Constr. Manag. 2022, 3, 436–452. [Google Scholar] [CrossRef]

- Zhang, X.; Mao, X.; AbouRizk, S.M. Developing a knowledge management system for improved value engineering practices in the construction industry. Autom. Constr. 2009, 18, 777–789. [Google Scholar] [CrossRef]

- Jallow, H.; Renukappa, S.; Suresh, S.; Alneyadi, A. Strategies for knowledge management in the UK construction industry: Benefits and challenges. In Proceedings of the 20th European Conference on Knowledge Management, ECKM, Lisbon, Portugal, 5–6 September 2019; pp. 550–555. [Google Scholar]

- Pryke, S.; Badi, S.; Bygballe, L. Editorial for the special issue on social networks in construction. Constr. Manag. Econ. 2017, 35, 445–454. [Google Scholar] [CrossRef]

- Polat, G.; Donmez, U. Marketing management functions of construction companies: Evidence from Turkish contractors. J. Civ. Eng. Manag. 2010, 16, 267–277. [Google Scholar] [CrossRef]

- Ammarapala, V.; Chinda, T.; Pongsayaporn, P.; Ratanachot, W.; Punthutaecha, K.; Janmonta, K. Cross-border shipment route selection utilizing analytic hierarchy process (AHP) method. Songklanakarin J. Sci. Technol. 2018, 40, 31–37. [Google Scholar] [CrossRef]

| Construct | Item | Description | Reference |

|---|---|---|---|

| KA | KA1 | Acquiring knowledge from clients | [21,29,31,32,33,34] |

| KA2 | Acquiring knowledge from competitors | ||

| KA3 | Acquiring knowledge through the employee’s KPI processes | ||

| KA4 | Acquiring knowledge through financial reporting systems | ||

| KA5 | Acquiring knowledge through market research | ||

| KA6 | Acquiring knowledge through previous project experiences | ||

| KA7 | Acquiring knowledge from the standard benchmarking systems | ||

| KD | KD1 | Disseminating hard copies (e.g., reports, newsletters, policy, and procedure manuals) to stakeholders | [2,13,30,34,35,36] |

| KD2 | Disseminating knowledge through staff mentoring | ||

| KD3 | Disseminating knowledge of products and processes within the company using updated technology | ||

| KD4 | Disseminating market trends and developments among internal departments | ||

| KD5 | Disseminating knowledge using encouraging two-way communication | ||

| KR | KR1 | Responding positively to changes in client needs | [2,4,30,34,37,38] |

| KR2 | Responding to the client’s reactions to technological changes | ||

| KR3 | Responding to competitor strategies | ||

| KR4 | Responding to employee needs | ||

| KR5 | Responding to market changes in the market plan | ||

| KS | KS1 | Authorizing the accessible permission into the database | [14,21,24,39,40,41] |

| KS2 | Conducting data screening before saving them into the database | ||

| KS3 | Storing knowledge using the data warehousing technology | ||

| KS4 | Storing knowledge in hard copies (e.g., reports, newsletters, policy, and procedure manuals) | ||

| KS5 | Storing lessons learned into the database (knowledge storage system) | ||

| KS6 | Having procedures for knowledge storage | ||

| KU | KU1 | Using existing knowledge to improve company business processes | [2,13,42,43] |

| KU2 | Using knowledge to deal with competitive conditions | ||

| KU3 | Using knowledge to adapt strategic directions | ||

| KU4 | Using accumulated knowledge to solve problems | ||

| KU5 | Using new knowledge to improve company business processes |

| Reference | Profit (PF) | Client Satisfaction (CS) | Labor Productivity (LP) | Innovative Work Process (IN) | Timely Project Completion (TM) | Project Quality (QL) |

|---|---|---|---|---|---|---|

| Abu Bakar et al. [31] | x | x | ||||

| Alrubaiee et al. [40] | x | x | ||||

| Chan [72] | x | x | x | x | x | x |

| Chen and Fong [13] | x | x | x | x | x | |

| Chen and Fong [37] | x | x | x | x | x | |

| Chen and Huang [73] | x | |||||

| Chen and Liang [68] | x | x | x | |||

| Chen and Mohamed [3] | x | x | x | x | x | |

| Cheung and Qi [74] | x | |||||

| Dang et al. [4] | x | |||||

| Dang et al. [7] | x | |||||

| Darroch [38] | x | x | ||||

| Darroch and McNaughton [75] | x | x | ||||

| Deng and Smyth [76] | x | x | x | x | x | |

| Duodu and Rowlinson [69] | x | x | x | x | ||

| ElFar et al. [32] | x | x | x | |||

| Enshassi et al. [77] | x | x | x | x | x | x |

| Fong and Chen [42] | x | x | x | x | x | |

| Gholami et al. [67] | x | x | ||||

| Gold et al. [28] | x | |||||

| Graham and Thomas [78] | x | x | ||||

| Gunasekera and Chong [25] | x | x | x | |||

| Hassan and Raziq [30] | x | |||||

| Hussinki et al. [66] | x | x | ||||

| Jayasingam et al. [46] | x | |||||

| Mohamad and Mat Zin [2] | x | x | ||||

| Soewin and Chinda [64] | x | x | x | x | x | x |

| Sweis et al. [79] | x | x | x | |||

| Yousaf and Ali [34] | x |

| Information | Percentage |

|---|---|

| Experience | |

| Up to 5 years | 29.8 |

| 6–10 years | 30.9 |

| 11–15 years | 30.1 |

| >15 years | 9.2 |

| Position | |

| Project engineer | 27.2 |

| Project manager | 19.1 |

| Officer | 18.8 |

| Team leader/Site manager | 14.7 |

| Division manager | 10.7 |

| Others | 9.5 |

| Job title | |

| Project & construction management | 34.9 |

| Technical supervision/construction | 21.7 |

| Management/administration | 13.6 |

| Structural design | 11.0 |

| Planning | 4.0 |

| Others | 14.8 |

| Type of company | |

| Private company | 73.2 |

| Public Company | 17.3 |

| Foreign direct investment | 9.5 |

| Number of employees | |

| <100 employees | 31.7 |

| 100–199 employees | 27.9 |

| ≥200 employees | 40.4 |

| Item | Mean | Standard Deviation |

|---|---|---|

| KA1 | 3.95 | 0.79 |

| KA2 | 4.05 | 0.86 |

| KA3 | 3.86 | 0.84 |

| KA4 | 3.75 | 0.83 |

| KA5 | 4.03 | 0.84 |

| KA6 | 4.31 | 0.77 |

| KA7 | 3.97 | 0.86 |

| KD1 | 3.60 | 0.93 |

| KD2 | 3.97 | 0.83 |

| KD3 | 4.13 | 0.82 |

| KD4 | 3.99 | 0.73 |

| KD5 | 4.14 | 0.73 |

| KR1 | 4.22 | 0.78 |

| KR2 | 4.01 | 0.80 |

| KR3 | 3.74 | 0.91 |

| KR4 | 3.90 | 0.90 |

| KR5 | 4.16 | 0.79 |

| KS1 | 3.79 | 0.87 |

| KS2 | 3.93 | 0.80 |

| KS3 | 3.93 | 0.89 |

| KS4 | 3.37 | 1.03 |

| KS5 | 3.98 | 0.76 |

| KS6 | 3.98 | 0.77 |

| KU1 | 3.91 | 0.83 |

| KU2 | 3.97 | 0.78 |

| KU3 | 4.05 | 0.78 |

| KU4 | 4.01 | 0.80 |

| KU5 | 4.18 | 0.75 |

| IN | 4.08 | 0.80 |

| TM | 3.97 | 0.84 |

| CS | 4.01 | 0.75 |

| QL | 4.07 | 0.78 |

| ES | 3.91 | 0.81 |

| LP | 4.03 | 0.75 |

| PF | 3.94 | 0.87 |

| Item | Factor Extracted | α Value | |||||

|---|---|---|---|---|---|---|---|

| KA | KD | KR | KS | KU | CC | ||

| KA4 | 0.643 | 0.852 | |||||

| KD1 | 0.596 | ||||||

| KA3 | 0.393 | ||||||

| KA5 | 0.378 | ||||||

| KA7 | 0.324 | ||||||

| KA2 | 0.303 | ||||||

| KA1 | 0.302 | ||||||

| KD5 | 0.521 | 0.798 | |||||

| KD2 | 0.387 | ||||||

| KD3 | 0.367 | ||||||

| KD4 | 0.318 | ||||||

| KR5 | 0.747 | 0.812 | |||||

| KR1 | 0.684 | ||||||

| KR2 | 0.565 | ||||||

| KA6 | 0.522 | ||||||

| KR3 | 0.402 | ||||||

| KR4 | 0.353 | ||||||

| KS6 | 0.710 | 0.858 | |||||

| KS2 | 0.607 | ||||||

| KS1 | 0.587 | ||||||

| KS5 | 0.516 | ||||||

| KS3 | 0.423 | ||||||

| KS4 | 0.315 | ||||||

| KU2 | 0.725 | 0.883 | |||||

| KU5 | 0.703 | ||||||

| KU4 | 0.688 | ||||||

| KU3 | 0.659 | ||||||

| KU1 | 0.649 | ||||||

| IN | 0.781 | 0.887 | |||||

| TM | 0.757 | ||||||

| CS | 0.743 | ||||||

| QL | 0.743 | ||||||

| ES | 0.733 | ||||||

| LP | 0.700 | ||||||

| PF | 0.641 | ||||||

| Variable | KA | KD | KR | KS | KU | CC |

|---|---|---|---|---|---|---|

| KA | 1 | |||||

| KD | 0.713 ** | 1 | ||||

| KR | 0.766 ** | 0.630 ** | 1 | |||

| KS | 0.741 ** | 0.700 ** | 0.611 ** | 1 | ||

| KU | 0.662 ** | 0.719 ** | 0.574 ** | 0.605 ** | 1 | |

| CC | 0.629 ** | 0.687 ** | 0.602 ** | 0.584 ** | 0.680 ** | 1 |

| Fit Index | Recommended Value | Baseline Model | Best-Fit Measurement | Best-Fit Structural |

|---|---|---|---|---|

| χ2/df | <3 [30] | 3.0 | 2.9 | 2.4 |

| RMSEA | ≤0.08 [101] | 0.09 | 0.08 | 0.07 |

| CFI | >0.8 [86] | 0.8 | 0.8 | 0.9 |

| Hypothesis | Best-Fit Measurement Model Results | Best-Fit Structural Model Results | ||

|---|---|---|---|---|

| Correlation Coefficient | Significance | Path Coefficient | Significance | |

| H1 | 0.77 | Yes | 0.45 *** | Yes |

| H2 | 0.79 | Yes | 0.47 *** | Yes |

| H3 | 0.68 | Yes | 0.36 ** | Yes |

| H4 | 0.38 | Yes | 0.60 *** | Yes |

| H5 | 0.30 | Yes | 0.74 *** | Yes |

| H6 | 0.45 | Yes | 0.56 *** | Yes |

| H7 | 0.36 | Yes | 0.48 *** | Yes |

| H8 | 0.39 | Yes | 0.09 | No |

| H9 | 0.59 | Yes | 0.01 | No |

| H10 | 0.40 | Yes | 0.33 *** | Yes |

| H11 | 0.59 | Yes | 0.45 *** | Yes |

| KD | KU | KA | KR | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Direct | Indirect | Total | Direct | Indirect | Total | Direct | Indirect | Total | Direct | Indirect | Total | |

| KS | 0.47 | (0.45 × 0.16) = 0.16 | 0.63 | - | (0.45 × 0.36 × 0.47) + (0.47 × 0.74) = 0.47 | 0.47 | 0.45 | (0.47 × 0.74 × 0.56 × 0.6) = 0.12 | 0.57 | - | (0.47 × 0.74 × 0.56) = 0.19 | 0.19 |

| KD | - | - | - | 0.74 | - | 0.74 | - | (0.74 × 0.56 × 0.6) = 0.25 | 0.25 | - | (0.74 × 0.56) = 0.41 | 0.41 |

| KU | - | (0.56 × 0.6 × 0.36) = 0.12 | 0.12 | - | - | - | - | (0.56 × 0.6) = 0.34 | 0.34 | 0.56 | - | 0.56 |

| KA | 0.36 | - | 0.36 | - | (0.36 × 0.74) = 0.27 | 0.27 | - | - | - | - | (0.36 × 0.74 × 0.56) = 0.15 | 0.15 |

| KR | - | (0.6 × 0.36) = 0.22 | 0.22 | - | (0.6 × 0.36 × 0.74) = 0.16 | 0.16 | 0.6 | - | 0.6 | - | - | - |

| Factor | Direct Effect | Indirect Path | Indirect Effect | Total Effect |

|---|---|---|---|---|

| KU | 0.45 | KU-KR-CC | 0.56 × 0.33 = 0.18 | 0.63 |

| KD | - | KD-KU-CC | 0.74 × 0.45 = 0.33 | 0.47 |

| KD-KU-KR-CC | 0.74 × 0.56 × 0.33 = 0.14 | |||

| KR | 0.33 | - | - | 0.33 |

| KS | - | KS-KD-KU-CC | 0.47 × 0.74 × 0.45 = 0.16 | 0.16 |

| KA | - | KA-KD-KU-CC | 0.36 × 0.74 × 0.45 = 0.12 | 0.12 |

| Sum | 0.78 | 0.93 | 1.71 |

| Factor | Items | Important Weight | Assessment Score * | Calculated Score |

|---|---|---|---|---|

| KS | KS2 | 0.79 | 3 | 2.37 |

| KS5 | 0.79 | 3 | 2.37 | |

| KS6 | 0.77 | 3 | 2.31 | |

| KS1 | 0.74 | 4 | 2.96 | |

| KS3 | 0.71 | 4 | 2.84 | |

| KS4 | 0.52 | 2 | 1.04 | |

| Total score of KS | 13.89 | |||

| Adjusted score (KSa) = 13.89 × 5/21.60 = 3.22 | ||||

| KA | KA5 | 0.72 | 3 | 2.16 |

| KA4 | 0.69 | 3 | 2.07 | |

| KA7 | 0.69 | 2 | 1.38 | |

| KA3 | 0.66 | 3 | 1.98 | |

| KA2 | 0.66 | 4 | 2.64 | |

| KA1 | 0.66 | 3 | 1.98 | |

| KD1 | 0.56 | 2 | 1.12 | |

| Total score of KA (KAs) | 13.33 | |||

| Adjusted score (KAa) = 13.33 × 5/23.20 = 2.87 | ||||

| KD | KD4 | 0.72 | 3 | 2.16 |

| KD3 | 0.70 | 2 | 1.40 | |

| KD2 | 0.69 | 4 | 2.76 | |

| KD5 | 0.68 | 4 | 2.72 | |

| Total score of KD (KDs) | 9.04 | |||

| Adjusted score (KDa) = 9.04 × 5/13.95 = 3.24 | ||||

| KR | KR5 | 0.73 | 3 | 2.19 |

| KR2 | 0.69 | 4 | 2.76 | |

| KR1 | 0.68 | 2 | 1.36 | |

| KR3 | 0.61 | 2 | 1.22 | |

| KA6 | 0.60 | 3 | 1.80 | |

| KR4 | 0.60 | 3 | 1.80 | |

| Total score of KR (KRs) | 11.13 | |||

| Adjusted score (KRa) = 11.13 × 5/19.55 = 2.85 | ||||

| KU | KU5 | 0.80 | 3 | 2.40 |

| KU3 | 0.77 | 3 | 2.31 | |

| KU1 | 0.77 | 3 | 2.31 | |

| KU2 | 0.74 | 2 | 1.48 | |

| KU4 | 0.73 | 3 | 2.19 | |

| Total score of KU (KUs) | 10.69 | |||

| Adjusted score (KUa) = 10.69 × 5/19.05 = 2.81 | ||||

| CC | IN | 0.79 | 3 | 2.37 |

| CS | 0.75 | 3 | 2.25 | |

| TM | 0.73 | 3 | 2.19 | |

| ES | 0.72 | 3 | 2.16 | |

| QL | 0.71 | 4 | 2.84 | |

| LP | 0.70 | 4 | 2.80 | |

| PF | 0.65 | 3 | 1.95 | |

| Total score of CC (CCs) | 16.56 | |||

| Adjusted score (CCa) = 16.56 × 5/25.25 = 3.28 | ||||

| KMP factor | Total effect | Adjusted score | Influential score | |

| The influences of KMP factors on CC | KS | 0.16 | 3.22 | 0.52 |

| KA | 0.12 | 2.87 | 0.34 | |

| KD | 0.47 | 3.24 | 1.52 | |

| KR | 0.33 | 2.85 | 0.94 | |

| KU | 0.63 | 2.81 | 1.77 | |

| Influential score of KMP factors on CC (KMPf) = 0.52 + 0.34 + 1.52 + 0.94 + 1.77 = 5.09 | ||||

| Final score of CC through KMP implementation (CCKMP) = (CCa + KMPf) × 5/13.55 = (3.28 + 5.09) × 5/13.55 = 3.09 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khoa, V.D.; Chinda, T. Assessment of Construction Competitiveness through Knowledge Management Process Implementation. Sustainability 2023, 15, 15897. https://doi.org/10.3390/su152215897

Khoa VD, Chinda T. Assessment of Construction Competitiveness through Knowledge Management Process Implementation. Sustainability. 2023; 15(22):15897. https://doi.org/10.3390/su152215897

Chicago/Turabian StyleKhoa, Vo Dang, and Thanwadee Chinda. 2023. "Assessment of Construction Competitiveness through Knowledge Management Process Implementation" Sustainability 15, no. 22: 15897. https://doi.org/10.3390/su152215897

APA StyleKhoa, V. D., & Chinda, T. (2023). Assessment of Construction Competitiveness through Knowledge Management Process Implementation. Sustainability, 15(22), 15897. https://doi.org/10.3390/su152215897