Mechanical Properties and Flexural Response of Palm Shell Aggregate Lightweight Reinforced Concrete Beam

Abstract

:1. Introduction

2. Materials and Methods

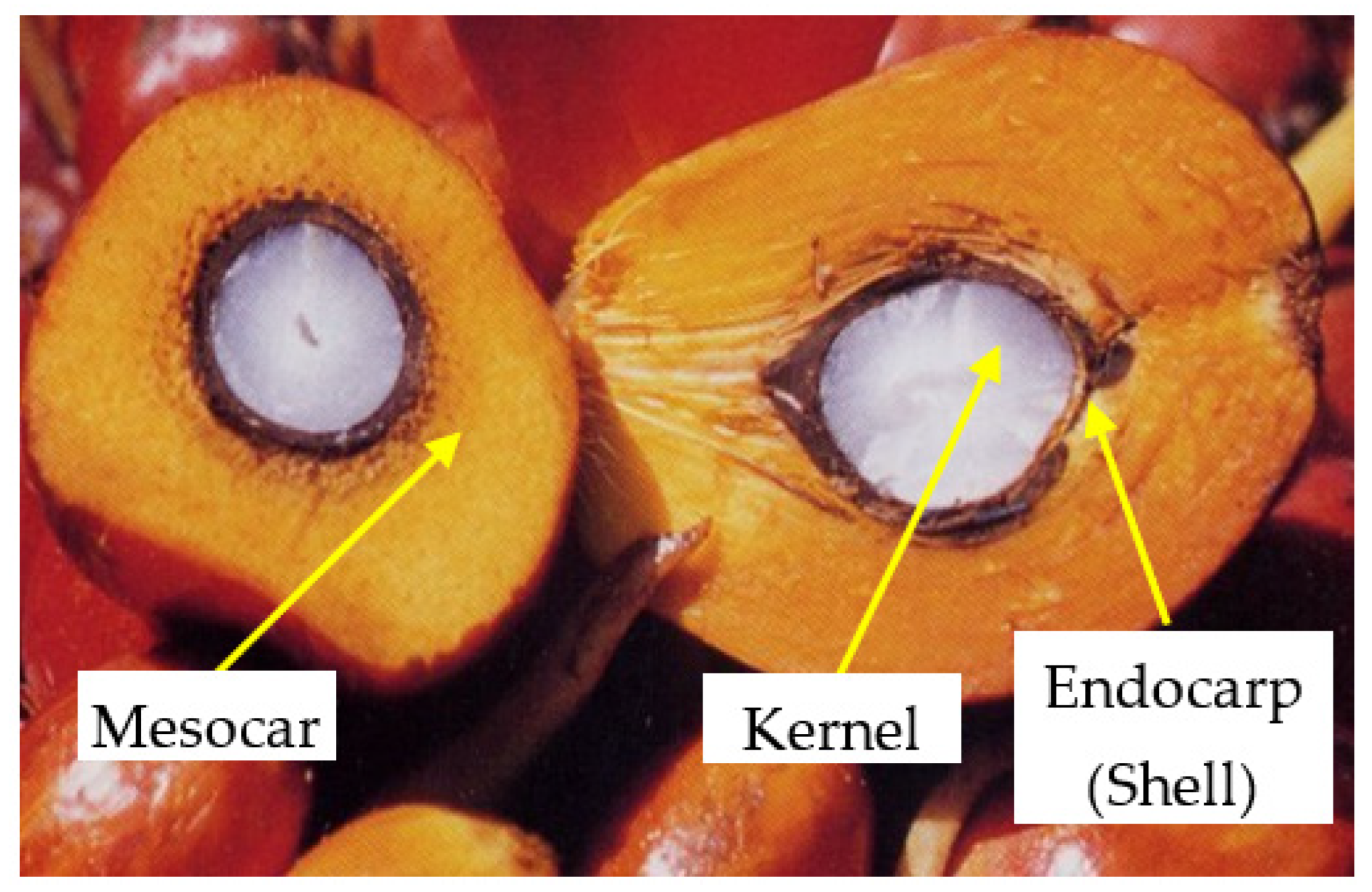

2.1. Materials Selection and Mix Composition

2.2. Specimen Configuration, Preparation, and Curing

2.3. Instrumentation and Testing Procedure

2.3.1. Fresh Properties

2.3.2. Mechanical Properties

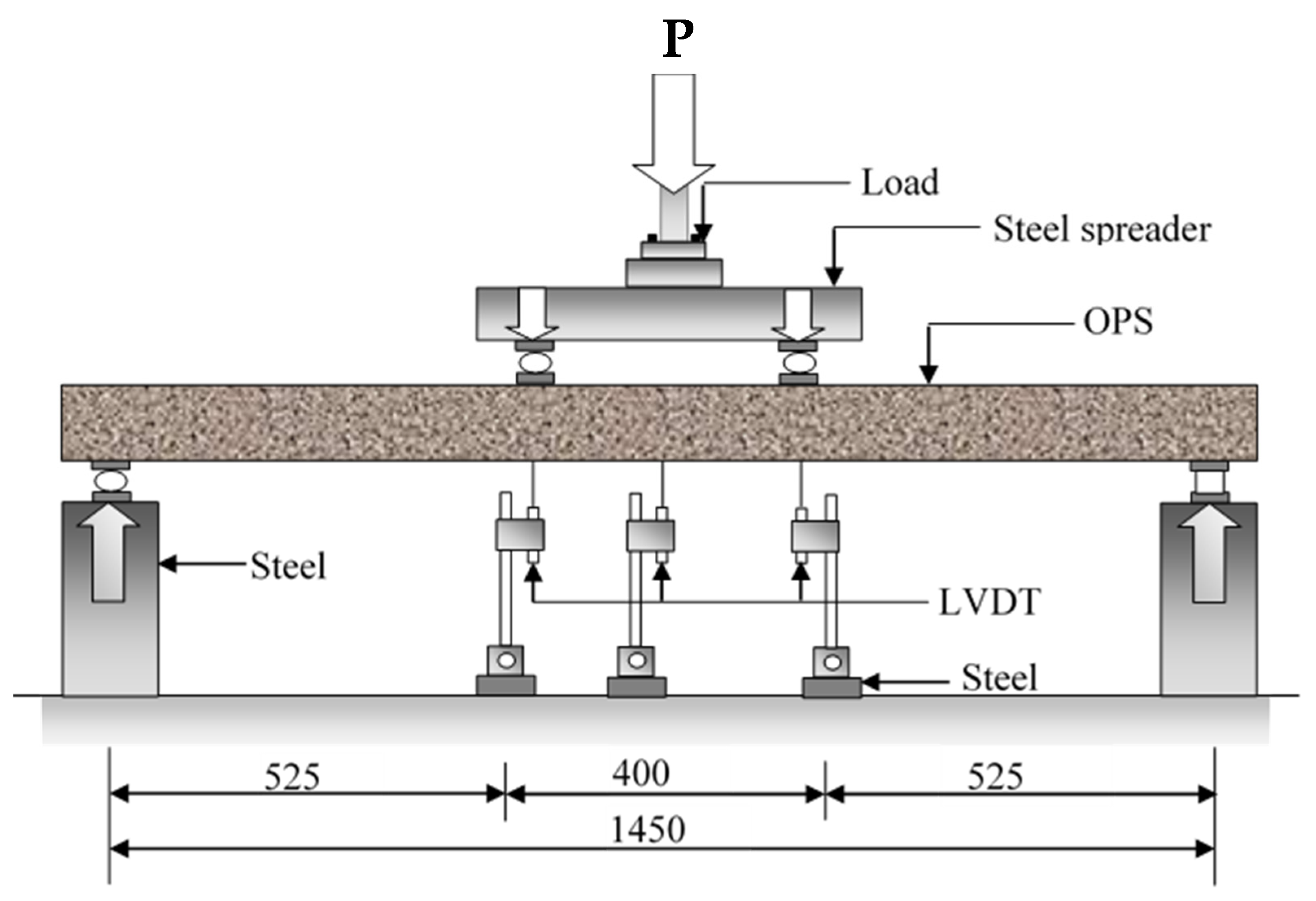

2.3.3. Flexural Testing of Beam

2.4. Analytical Methods

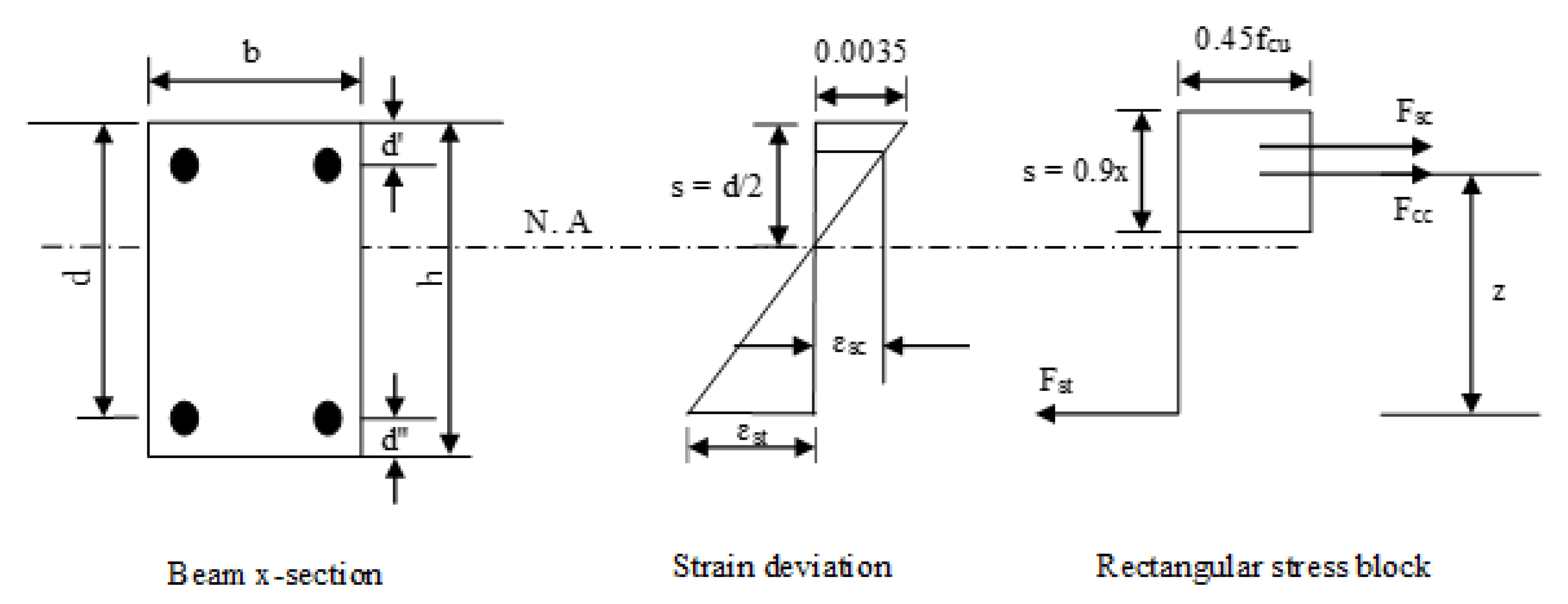

2.4.1. Flexural Response of RC Beam

2.4.2. Ductility Index

3. Results and Discussion

3.1. Properties of Fresh Concrete

3.2. Mechanical Characteristics of Concrete

3.2.1. Compressive Strength

3.2.2. Splitting Tensile Strength

3.2.3. Modulus of Rupture Strength

3.2.4. Modulus of Elasticity

3.3. Comparison between Experimental Results and Theoretical Prediction

3.4. Flexural Response of OPS Beams

3.4.1. Load vs. Deflection Behaviors

3.4.2. Ductility Behaviors

3.4.3. First Cracking and Ultimate Loading

3.4.4. Failure Modes

4. Conclusions

- All the mixes had satisfactory slump, density, and air content values that indicated the concrete medium workability and satisfied the lightweight concrete requirement. In addition, the higher concentration of OPS in the concrete mixes has decreased the slump and density values, albeit the air content of OPS concrete increased subsequently. In the slump test, the value lessened at about 27.42%, 37.10%, 43.55%, and 53.23% as compared to the control mix.

- Mix with varying concentrations of OPS replacement has shown a decreasing trend on compressive strength, splitting tensile, modulus of rupture strength, and modulus of elasticity of OPS concrete. It has been demonstrated that the compressive strength decreased 44.73%, 50.83%, 53.33%, and 57.22% at 28 days as compared to the control mix of 10%, 15%, 20%, and 50% replacement of PSC. The decrease in the splitting tensile strength of OPS concrete when increasing the concentration of OPS in the mixes is relatively smaller compared to the properties of modulus of rupture strength, modulus of elasticity, and compressive strength with respect to the conventional coarse aggregate concrete mixes.

- Analytical prediction of varying codes of practice provides a good estimation of the mechanical properties of OPS concrete in this study. In contrast, few codes of practice demonstrated a scatter prediction with the experimental results. Moreover, the analytical prediction suggests that one can easily quantify any properties from others without conducting the test. It will ultimately decrease the cost of experimentation, time, labor, and equipment utilization in the laboratory.

- The flexural responses of the OPS lightweight concrete beam resemble the behavior of the NCA concrete beam. It was obtained that although every OPS lightweight concrete beam revealed less ultimate capacity than the NCA beam, considering the material economy, the OPS lightweight concrete beams have great potential to be used in local building industries.

- The beam made with OPS aggregate concrete demonstrated a higher ductile response than the NCA concrete beam. All the OPS lightweight concrete beams showed a considerable degree of deflection, which indicated ample warning of the imminence of final failure.

- The theoretical result of varying percentages of OPS lightweight concrete beams shows close agreement with the experimental investigation. In general, it provides a good estimation of the first cracking and ultimate load-carrying capacity of palm shell aggregate lightweight concrete beams.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kushairi, A.; Loh, S.K.; Azman, I.; Hishamuddin, E.; Ong-Abdullah, M.; Izuddin, Z.; Razmah, G.; Sundram, S.; Parveez, G.K.A. Oil palm economic performance in Malaysia and R&D progress in 2017. J. Oil Palm Res. 2018, 30, 163–195. [Google Scholar]

- Muda, K.; Ezechi, E.H. Overview of trends in crude palm oil production and economic impact in Malaysia. Sriwij. J. Environ. 2019, 4, 19–26. [Google Scholar]

- Gao, S.; Zhao, G.; Guo, L.; Zhou, L.; Yuan, K. Utilization of coal gangue as coarse aggregates in structural concrete. Constr. Build. Mater. 2021, 268, 121212. [Google Scholar] [CrossRef]

- Sukiran, M.A.; Abnisa, F.; Wan Daud, W.M.A.; Abu Bakar, N.; Loh, S.K. A review of torrefaction of oil palm solid wastes for biofuel production. Energy Convers. Manag. 2017, 149, 101–120. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Kumar, P.S.; Lakshmipathy, M. Mechanical and bond properties of coconut shell concrete. Constr. Build. Mater. 2011, 25, 92–98. [Google Scholar] [CrossRef]

- Mustafa, M.A.-T.; Hanafi, I.; Mahmoud, R.; Tayeh, B.A. Effect of partial replacement of sand by plastic waste on impact resistance of concrete: Experiment and simulation. Structures 2019, 20, 519–526. [Google Scholar] [CrossRef]

- Valizadeh, A.; Hamidi, F.; Aslani, F.; Shaikh, F.U.A. The effect of specimen geometry on the compressive and tensile strengths of self-compacting rubberised concrete containing waste rubber granules. Structures 2020, 27, 1646–1659. [Google Scholar] [CrossRef]

- Tobbala, D.E.; Rashed, A.S.; Salama, R.S.; Ahmed, T.I. Performance enhancement of reinforced concrete exposed to electrochemical magnesium chloride using nano-ferrite zinc-rich epoxy. J. Build. Eng. 2022, 57, 104869. [Google Scholar] [CrossRef]

- Aditto, F.S.; Sobuz, M.H.R.; Saha, A.; Jabin, J.A.; Kabbo, M.K.I.; Hasan, N.M.S.; Islam, S. Fresh, mechanical and microstructural behaviour of high-strength self-compacting concrete using supplementary cementitious materials. Case Stud. Constr. Mater. 2023, 19, e02395. [Google Scholar] [CrossRef]

- Wang, W.; Wei, W.; Gao, S.; Chen, G.; Yuan, J.; Li, Y. Agricultural and aquaculture wastes as concrete components: A Review. Front. Mater. 2021, 8, 762568. [Google Scholar] [CrossRef]

- Teo, D.C.L.; Mannan, M.A.; Kurian, J.V. Flexural behaviour of reinforced lightweight concrete beams made with oil palm shell (OPS). J. Adv. Concr. Technol. 2006, 4, 459–468. [Google Scholar] [CrossRef]

- Mannan, M.A.; Alexander, J.; Ganapathy, C.; Teo, D.C.L. Quality improvement of oil palm shell (OPS) as coarse aggregate in lightweight concrete. Build. Environ. 2006, 41, 1239–1242. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Jumaat, M.Z.; Mahmud, H. Ductility behaviour of reinforced palm kernel shell concrete beams. Eur. J. Sci. Res. 2008, 23, 406–420. [Google Scholar]

- Olanipekun, E.A.; Olusola, K.O.; Ata, O. A comparative study of concrete properties using coconut shell and palm kernel shell as coarse aggregates. Build. Environ. 2006, 41, 297–301. [Google Scholar] [CrossRef]

- Hamada, H.M.; Thomas, B.S.; Tayeh, B.; Yahaya, F.M.; Muthusamy, K.; Yang, J. Use of oil palm shell as an aggregate in cement concrete: A review. Constr. Build. Mater. 2020, 265, 120357. [Google Scholar] [CrossRef]

- Datta, S.D.; Sobuz, M.H.R.; Akid, A.S.M.; Islam, S. Influence of coarse aggregate size and content on the properties of recycled aggregate concrete using non-destructive testing methods. J. Build. Eng. 2022, 61, 105249. [Google Scholar] [CrossRef]

- ASTM C330/C330M-17; Standard Specification for Lightweight Aggregates for Structural Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- Maghfouri, M.; Shafigh, P.; Aslam, M. Optimum oil palm shell content as coarse aggregate in concrete based on mechanical and durability properties. Adv. Mater. Sci. Eng. 2018, 2018, 4271497. [Google Scholar] [CrossRef]

- Teo, D.C.L.; Mannan, M.A.; Kurian, V.J. Structural concrete using oil palm shell (OPS) as lightweight aggregate. Turk. J. Eng. Environ. Sci. 2006, 30, 251–257. [Google Scholar]

- Mannan, M.A.; Ganapathy, C. Engineering properties of concrete with oil palm shell as coarse aggregate. Constr. Build. Mater. 2002, 16, 29–34. [Google Scholar] [CrossRef]

- Mannan, M.A.; Ganapathy, C. Concrete from an agricultural waste-oil palm shell (OPS). Build. Environ. 2004, 39, 441–448. [Google Scholar] [CrossRef]

- Teo, D.C.L.; Mannan, M.A.; Kurian, V.J.; Ganapathy, C. Lightweight concrete made from oil palm shell (OPS): Structural bond and durability properties. Build. Environ. 2007, 42, 2614–2621. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Mahmud, H.; Jumaat, M.Z. Comparison of mechanical and bond properties of oil palm kernel shell concrete with normal weight concrete. Int. J. Phys. Sci. 2010, 5, 1231–1239. [Google Scholar]

- Md Sadiqul Hasan, N.; Rahman Sobuz, H.; Sharif Auwalu, A.; Tamanna, N. Investigation into the suitability of kenaf fiber to produce structural concrete. Adv. Mater. Lett. 2015, 6, 731–737. [Google Scholar] [CrossRef]

- Adin, M.Ş. A parametric study on the mechanical properties of MIG and TIG welded dissimilar steel joints. J. Adhes. Sci. Technol. 2023, 1–24. [Google Scholar] [CrossRef]

- Shafigh, P.; Mahmud, H.B.; Jumaat, M.Z. Oil palm shell lightweight concrete as a ductile material. Mater. Des. (1980–2015) 2012, 36, 650–654. [Google Scholar] [CrossRef]

- Altun, F.; Aktaş, B. Investigation of reinforced concrete beams behavior of steel fiber added lightweight concrete. Constr. Build. Mater. 2013, 38, 575–581. [Google Scholar] [CrossRef]

- Vakili, S.E.; Homami, P.; Esfahani, M.R. Effect of fibers and hybrid fibers on the shear strength of lightweight concrete beams reinforced with GFRP bars. Structures 2019, 20, 290–297. [Google Scholar] [CrossRef]

- Deifalla, A. Torsion design of lightweight concrete beams without or with fibers: A comparative study and a refined cracking torque formula. Structures 2020, 28, 786–802. [Google Scholar] [CrossRef]

- Olanitori, L.M.; Okusami, J.I. Effect of Shear Reinforcement on Flexural Strengths of Normal Weight and Palm-Kernel Shell Reinforced Concrete Beams. Eur. J. Sustain. Dev. 2019, 8, 279. [Google Scholar] [CrossRef]

- Yap, S.P.; Alengaram, U.J.; Mo, K.H.; Jumaat, M.Z. Ductility behaviours of oil palm shell steel fibre-reinforced concrete beams under flexural loading. Eur. J. Environ. Civ. Eng. 2019, 23, 866–878. [Google Scholar] [CrossRef]

- ASTM C143/C143M-20; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2009.

- BS EN 12350-6:2009; Testing Fresh Concrete Density. British Standards Institution: London, UK, 2009.

- BS EN 12390-3:2002; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. British Standards Institution: London, UK, 2002.

- ASTM C496/C496M-17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C78/C78M-18; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2002; pp. 1–3.

- ASTM C469/C469M-14; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2014.

- BS 8110-1:1997; Structural Use of Concrete: Code of Practice for Design and Construction—Part 1. British Standards Institution: London, UK, 1997.

- Leite, M.B.; Santana, V.M. Evaluation of an experimental mix proportion study and production of concrete using fine recycled aggregate. J. Build. Eng. 2019, 21, 243–253. [Google Scholar] [CrossRef]

- Zhao, Z.; Courard, L.; Michel, F.; Remond, S.; Damidot, D. Influence of granular fraction and origin of recycled concrete aggregates on their properties. Eur. J. Environ. Civ. Eng. 2018, 22, 1457–1467. [Google Scholar] [CrossRef]

- Thomas, J.; Thaickavil, N.N.; Wilson, P.M. Strength and durability of concrete containing recycled concrete aggregates. J. Build. Eng. 2018, 19, 349–365. [Google Scholar] [CrossRef]

- Shafigh, P.; Salleh, S.; Ghafari, H.; Bin Mahmud, H. Oil palm shell as an agricultural solid waste in artificial lightweight aggregate concrete. Eur. J. Environ. Civ. Eng. 2018, 22, 165–180. [Google Scholar] [CrossRef]

- Graybeal, B.; Lwin, M.M. Lightweight concrete in highway infrastructure. ASPIRE Spring 2013, 3, 44–45. [Google Scholar]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z.; Yap, S.P. Feasibility study of high volume slag as cement replacement for sustainable structural lightweight oil palm shell concrete. J. Clean. Prod. 2015, 91, 297–304. [Google Scholar] [CrossRef]

- Islam, M.M.U.; Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z. Mechanical and fresh properties of sustainable oil palm shell lightweight concrete incorporating palm oil fuel ash. J. Clean. Prod. 2016, 115, 307–314. [Google Scholar] [CrossRef]

- Khankhaje, E.; Rafieizonooz, M.; Salim, M.R.; Mirza, J.; Hussin, M.W. Comparing the effects of oil palm kernel shell and cockle shell on properties of pervious concrete pavement. Int. J. Pavement Res. Technol. 2017, 10, 383–392. [Google Scholar] [CrossRef]

- Basri, H.B.; Mannan, M.A.; Zain, M.F.M. Concrete using waste oil palm shells as aggregate. Cem. Concr. Res. 1999, 29, 619–622. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Mahmud, H.; Jumaat, M.Z. Enhancement and prediction of modulus of elasticity of palm kernel shell concrete. Mater. Des. 2011, 32, 2143–2148. [Google Scholar] [CrossRef]

- Rilem, L.C. Functional classification of lightweight concrete. Mater. Struct 1978, 11, 281–283. [Google Scholar]

- Chen, B.; Liu, J. Experimental application of mineral admixtures in lightweight concrete with high strength and workability. Constr. Build. Mater. 2008, 22, 1108–1113. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H.B.; Abd Hamid, N.A. Lightweight concrete made from crushed oil palm shell: Tensile strength and effect of initial curing on compressive strength. Constr. Build. Mater. 2012, 27, 252–258. [Google Scholar] [CrossRef]

- Salam, S.A.; Abdullah Ali, A. Lightweight concrete using oil palm shells as aggregates. In Proceedings of the National Symposium on Oil Palm By-Products for Agro-Based Industries, Kuala Lumpur, Malaysia, 5–6 November 1985; Institut Penyelidikan Minyak Kelapa Sawit Malaysia: Kuala Lumpur, Malaysia, 1987. [Google Scholar]

- Shetty, M.S.; Jain, A.K. Concrete Technology (Theory and Practice), 8th ed.; S. Chand Publishing: New Delhi, India, 2019. [Google Scholar]

- Monteiro, P. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Publishing: New York, NY, USA, 2006. [Google Scholar]

- Alengaram, U.J.; Jumaat, M.Z.; Mahmud, H. Influence of sand content and silica fume on mechanical properties of palm kernel shell concrete. In Proceedings of the International Conference on Construction and Building Technology ICCBT, Kuala Lumpur, Malaysia, 16–20 June 2008. [Google Scholar]

- Campione, G.; Miraglia, N.; Papia, M. Mechanical properties of steel fibre reinforced lightweight concrete with pumice stone or expanded clay aggregates. Mater. Struct. 2001, 34, 201–210. [Google Scholar] [CrossRef]

- AS 3600:2001; Concrete Structures. Standards Australia: Sydney, Australia, 2001.

- ACI Committee. 318-99/318R-99: Building Code Requirements for Structural Concrete & Commentary; American Concrete Institute: Farmington Hills, MI, USA, 1999. [Google Scholar]

- ACI Committee. 363R-92, State-of-the-Art Report on High-Strength Concrete (Reapproved in 1997); American Concrete Institute: Farmington Hills, MI, USA, 1997. [Google Scholar]

- Comité Euro-International du Béton. CEB-FIP Model Code 1990, Final Draft 1991; Bulletin D’information no. 203; Secretariat Permanent: Lausanne, Switzerland, 1991; pp. 1–2. [Google Scholar]

- Alengaram, U.J.; Jumaat, M.Z.; Mahmud, H.; Fayyadh, M.M. Shear behaviour of reinforced palm kernel shell concrete beams. Constr. Build. Mater. 2011, 25, 2918–2927. [Google Scholar] [CrossRef]

- Ahmmad, R.; Jumaat, M.Z.; Bahri, S.; Islam, A.B.M.S. Ductility performance of lightweight concrete element containing massive palm shell clinker. Constr. Build. Mater. 2014, 63, 234–241. [Google Scholar] [CrossRef]

- Yap, S.P.; Bu, C.H.; Alengaram, U.J.; Mo, K.H.; Jumaat, M.Z. Flexural toughness characteristics of steel–polypropylene hybrid fibre-reinforced oil palm shell concrete. Mater. Des. 2014, 57, 652–659. [Google Scholar] [CrossRef]

- Ashour, S.A. Effect of compressive strength and tensile reinforcement ratio on flexural behavior of high-strength concrete beams. Eng. Struct. 2000, 22, 413–423. [Google Scholar] [CrossRef]

- Ahmad, S.H.; Barker, R. Flexural behavior of reinforced high-strength lightweight concrete beams. Struct. J. 1991, 88, 69–77. [Google Scholar]

| Properties | Palm Shell Aggregate | Natural Aggregate |

|---|---|---|

| Bulk density (kg/m3) | 572 | 1445 |

| Water absorption for 24 h (%) | 25.64 | 0.7 |

| Specific gravity | 1.21 | 2.72 |

| Aggregate impact value | 6.65 | 12.32 |

| Los Angeles abrasion value (%) | 5.1 | 24.5 |

| Aggregate crushing value | 6.78 | 17.92 |

| Thickness of shell (mm) | 0.5–4.0 | 5–20 |

| Fineness Modulus | 6.24 | 6.76 |

| Maximum aggregate size (mm) | 12.5 | 20 |

| Rebar Type | Yield Capacity (MPa) | Elastic Modulus (GPa) |

|---|---|---|

| Compression, T10 | 482 | 195 |

| Tension, T10 | 482 | 195 |

| Compression, T6 | 470 | 189 |

| Shear stirrup, R6 | 215 | 200 |

| OPS Replacement Level (%) | 0 | 10 | 15 | 20 | 50 |

|---|---|---|---|---|---|

| Beam Designation | OPSB-0 | OPSB-10 | OPSB-15 | OPSB-20 | OPSB-50 |

| Beam Designation | Experimental Value | Theoretical Value | Failure Mode | First Crack Width (mm) | Ductility Index | ||||

|---|---|---|---|---|---|---|---|---|---|

| Pcr (kN) | Put (kN) | (mm) | (mm) | Pcr (kN) | Pult (kN) | ||||

| PSCB-0 | 7.6 | 37.0 | 10.18 | 14.97 | 8.0 | 38.4 | Flexural | 0.05 | 1.47 |

| PSCB-10 | 6.2 | 35.6 | 10.83 | 16.55 | 6.5 | 37.0 | Shear-tension | 0.04 | 1.53 |

| PSCB-15 | 6.0 | 32.6 | 11.12 | 17.46 | 6.2 | 34.0 | Shear-tension | 0.03 | 1.57 |

| PSCB-20 | 5.8 | 30.3 | 11.41 | 18.36 | 5.9 | 31.8 | Shear-tension | 0.02 | 1.61 |

| PSCB-50 | 7.0 | 28.5 | 10.67 | 18.95 | 7.2 | 29.4 | Shear-tension | 0.01 | 1.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobuz, M.H.R.; Islam, M.S.; Akid, A.S.M.; Datta, S.D.; Alahmari, T.S.; Hasan, N.M.S.; Khondoker, M.T.H.; Aditto, F.S. Mechanical Properties and Flexural Response of Palm Shell Aggregate Lightweight Reinforced Concrete Beam. Sustainability 2023, 15, 15783. https://doi.org/10.3390/su152215783

Sobuz MHR, Islam MS, Akid ASM, Datta SD, Alahmari TS, Hasan NMS, Khondoker MTH, Aditto FS. Mechanical Properties and Flexural Response of Palm Shell Aggregate Lightweight Reinforced Concrete Beam. Sustainability. 2023; 15(22):15783. https://doi.org/10.3390/su152215783

Chicago/Turabian StyleSobuz, Md. Habibur Rahman, Md. Saiful Islam, Abu Sayed Mohammad Akid, Shuvo Dip Datta, Turki S. Alahmari, Noor Md. Sadiqul Hasan, Md. Tareq Hossain Khondoker, and Fahim Shahriyar Aditto. 2023. "Mechanical Properties and Flexural Response of Palm Shell Aggregate Lightweight Reinforced Concrete Beam" Sustainability 15, no. 22: 15783. https://doi.org/10.3390/su152215783

APA StyleSobuz, M. H. R., Islam, M. S., Akid, A. S. M., Datta, S. D., Alahmari, T. S., Hasan, N. M. S., Khondoker, M. T. H., & Aditto, F. S. (2023). Mechanical Properties and Flexural Response of Palm Shell Aggregate Lightweight Reinforced Concrete Beam. Sustainability, 15(22), 15783. https://doi.org/10.3390/su152215783