1. Introduction

The development of energy storage is crucial to solve the problems of supply and demand matching and volatility in the new power system. Currently, the improvement of energy storage system economy is the key to the medium- to long-term large-scale development of energy storage [

1]. Compressed air energy storage (CAES) system is considered one of the most promising energy storage technologies, which can be applied in fields such as power grid “peak shaving and valley filling”, renewable energy grid connected power generation, and distributed energy supply [

2]. The compressor/expander is one of the key components of the compressed air energy storage system, and its characteristics directly determine the overall performance and economy of the energy storage system. He et al. [

3] introduced the latest review of CAES technology, as well as methods for modeling and selecting CAES system extenders, and discussed suggestions and guidance for selecting suitable expanders.

The main components of a compressed air energy storage system include compressors, expanders, gas storage equipment, and heat storage systems [

4]. The performance of compressors has the most significant impact on the overall performance of the system, and its energy conversion efficiency directly determines the overall efficiency and economy of the system [

5,

6,

7]. Compressors can generally be divided into reciprocating compressors, centrifugal compressor, and scroll compressors. Leszczyński et al. [

8] introduced the unique design of a micro CAES device with efficient total energy conversion for generating, storing, and transmitting electrical energy. The mathematical model was compared with the experimental data of a single-drive air expander, and the reliability of the model was demonstrated qualitatively and quantitatively. The results indicate that the maximum total energy conversion efficiency is 81%. Chen et al. [

9] proposed a modeling method for developing models of CAES systems. The designed experimental device has an efficiency range of 13 to 25% under different conditions, and the optimal system efficiency can be increased to 60%. Mendoza et al. [

10] designed and tested a compressor and expander that can serve as CAES systems and experimented at a wide range of rotational speeds, different water injection flows, and different nominal side clearances. The results showed that the maximum power output and overall isothermal efficiency are 1.74 kW and 34%. Heidari et al. [

11] introduced the macroscopic representation of energy as a method for dynamic nonlinear modeling of reciprocating air compressors and developing models for different subsystems to consider the wall thermistor and capacitance effects using the thermoelectric analogy method. Khaljani et al. [

12] developed a new reversible liquid piston gas compressor and expander for small-scale near isothermal CAES systems. Through a combination of experiments, thermodynamics, technical economy, and environmental analysis, the economic and environmental characteristics of these small-scale CAES systems were evaluated. Heidari et al. [

13] experimentally tested a new type of finned piston compressor, which increased the heat transfer area and coefficient, presented simulation results and verified it on an experimental test bench. The results showed that the volumetric efficiency of the compressor decreased by 8% and the exergy efficiency increased by 23.3%. Ma et al. [

14] established a one-dimensional loss model for multi-stage centrifugal compressors for an adiabatic CAES system to design the compression process and to analyze the energy loss distribution of each representative single stage. Gao et al. [

15] proposed an adiabatic CAES system using one ejector alongside final stage compression and developed a thermodynamic model to alleviate the choke through numerical study.

Scroll compressors have the advantages of simple structure, small volume, lower cost, and easier control, making them more suitable for micro CAES systems [

16]. Emhardt et al. [

17] investigated the effects of different scroll geometric parameters on the performance of a constant wall thickness scroll expander, considering the use of variable wall thickness and its impact on performance. Liu et al. [

18] conducted numerical research on the flow field of a scroll compressor working with air to investigate the characteristics of tangential leakage flow under different radial clearances and analyzed the field distribution and the influence of radial clearances on the time-averaged performance and aerodynamic forces in all directions of a scroll compressor. Zhao et al. [

19] established a three-dimensional unsteady computational fluid dynamics model and validated it, studying the impact of exhaust port design on the transient performance and flow mechanism of a scroll compressor. Luo et al. [

20] proposed a new hybrid pneumatic system that will recover energy from exhaust compressed air through a scroll expander, derived a mathematical model of the entire system, and provided simulation results. A test bench was built to verify the feasibility of the proposed system structure. The simulation and test results show that the scheme has good real-time performance and effectiveness. Rak et al. [

21] proposed a two-dimensional unsteady flow numerical model containing leakage between working chambers and a special numerical mesh deformation process, analyzing the effects of specific parameters such as blade shape, exhaust pressure, and rotational speed of a scroll compressor on the thermal balance inside the chamber under tangential leakage conditions. Wang et al. [

22] prepared aluminum alloy scroll parts using the semi-solid squeeze casting process and investigated the effects of process parameters such as pouring temperature, mold temperature, and extrusion speed on the filling and solidification behavior of the alloy based on a power law cutoff material model. Ma et al. [

23] proposed a dynamic modeling and simulation method for scroll expanders in small power generation systems. The modeling of a scroll expander was completed by establishing a geometric model of the scroll, combining the valve model, heat transfer equation, internal leakage model, energy balance equation, and motion equation.

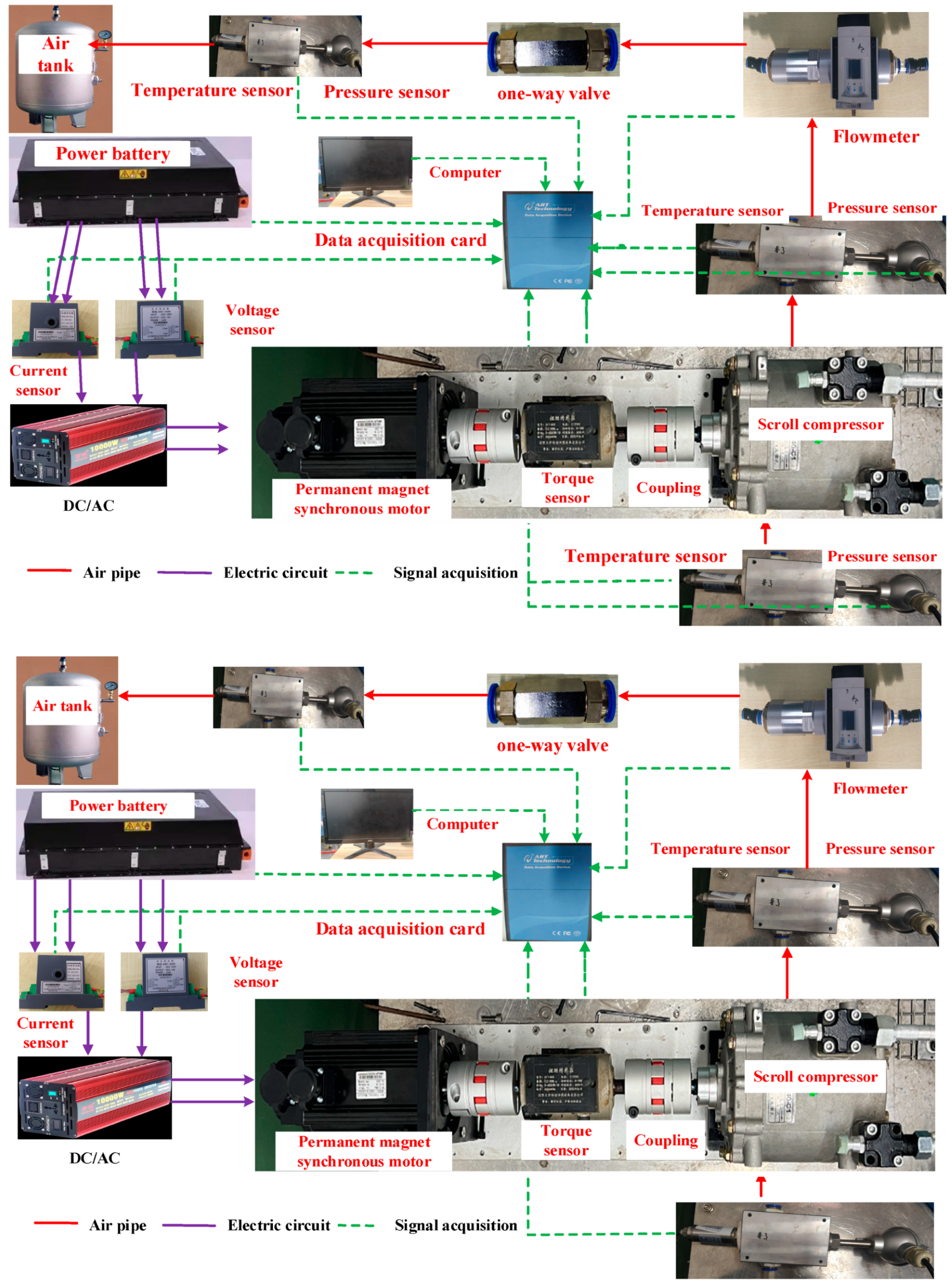

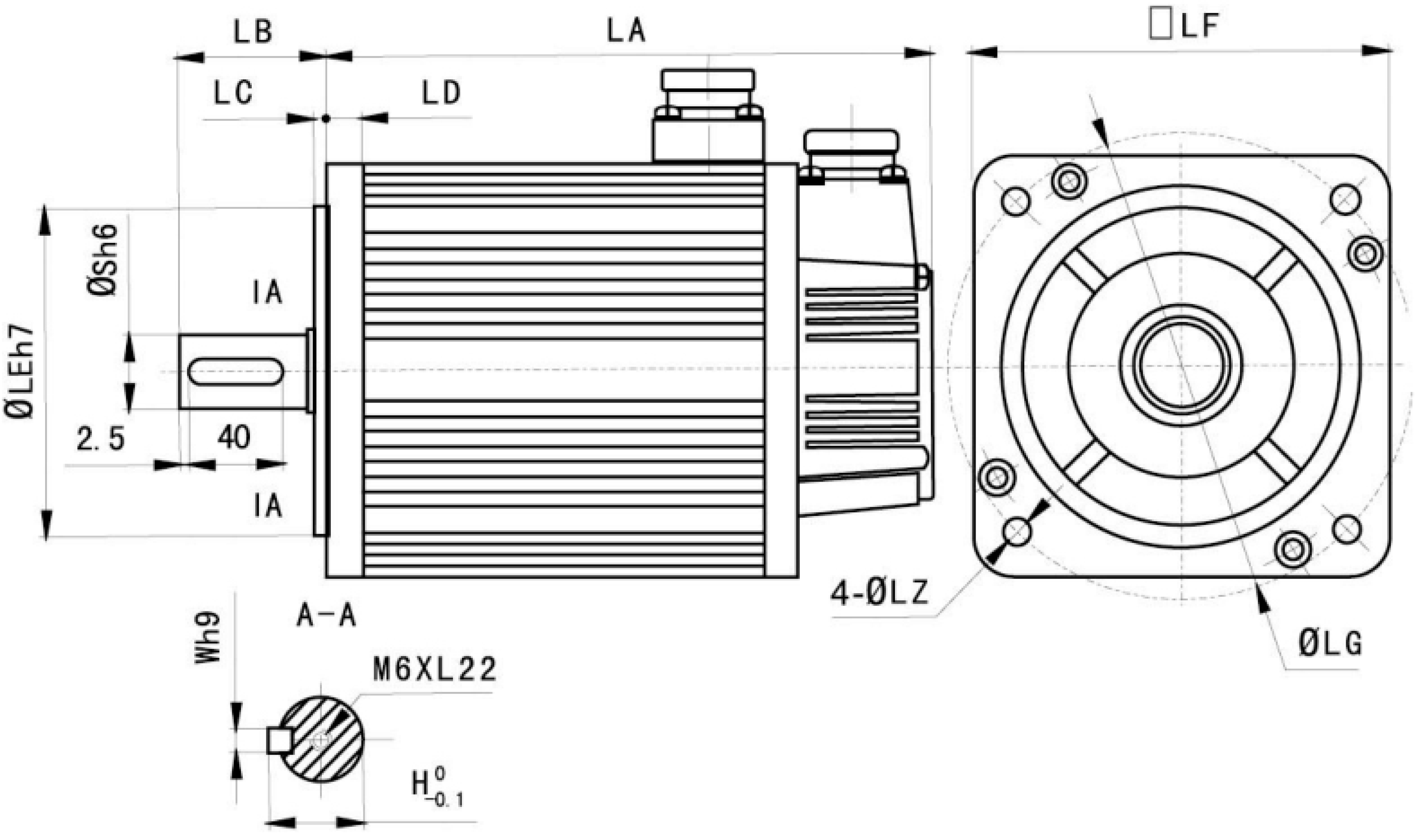

As mentioned in the above literature, compressors and expanders, as core equipment for compression energy storage and expansion energy release, have significant impact on the performance and energy conversion efficiency of micro compressed air energy storage systems. At present, the compressor and expander in the compressed air energy storage system work separately, which has problems such as large unit volume, multiple equipment, and low efficiency. This article proposes a compression and expansion composite machine that integrates compression and expansion functions. The scroll composite machine is connected to the fan impeller and generator through a mechanical coupling device, forming a micro compressed air energy storage system based on scroll expansion/compression integration. The scroll compressor utilizes the rotating belt of the main shaft to move and rotate statically, achieving the compression of gas. The scroll expander uses high-pressure gas expansion to conduct work, driving the rotating and stationary disks to rotate, thereby driving the main shaft to rotate. The forward and reverse rotation of the spindle are utilized to achieve compression and expansion functions, respectively. However, due to the progress of the experiment, in this study, a micro-scale CAES system based on a scroll compressor is constructed, mainly investigating the output performance of the scroll compressor. The impact of key parameters such as rotating speed, torque, current, and air tank pressure on the pressure ratio, power consumption, and efficiency of the scroll compressor is investigated. In this paper, we mainly investigated the performance of scroll compressors. In future work, we will investigate the performance of scroll expanders and then achieve the composite machine that integrates compression and expansion functions.

3. Result and Discussion

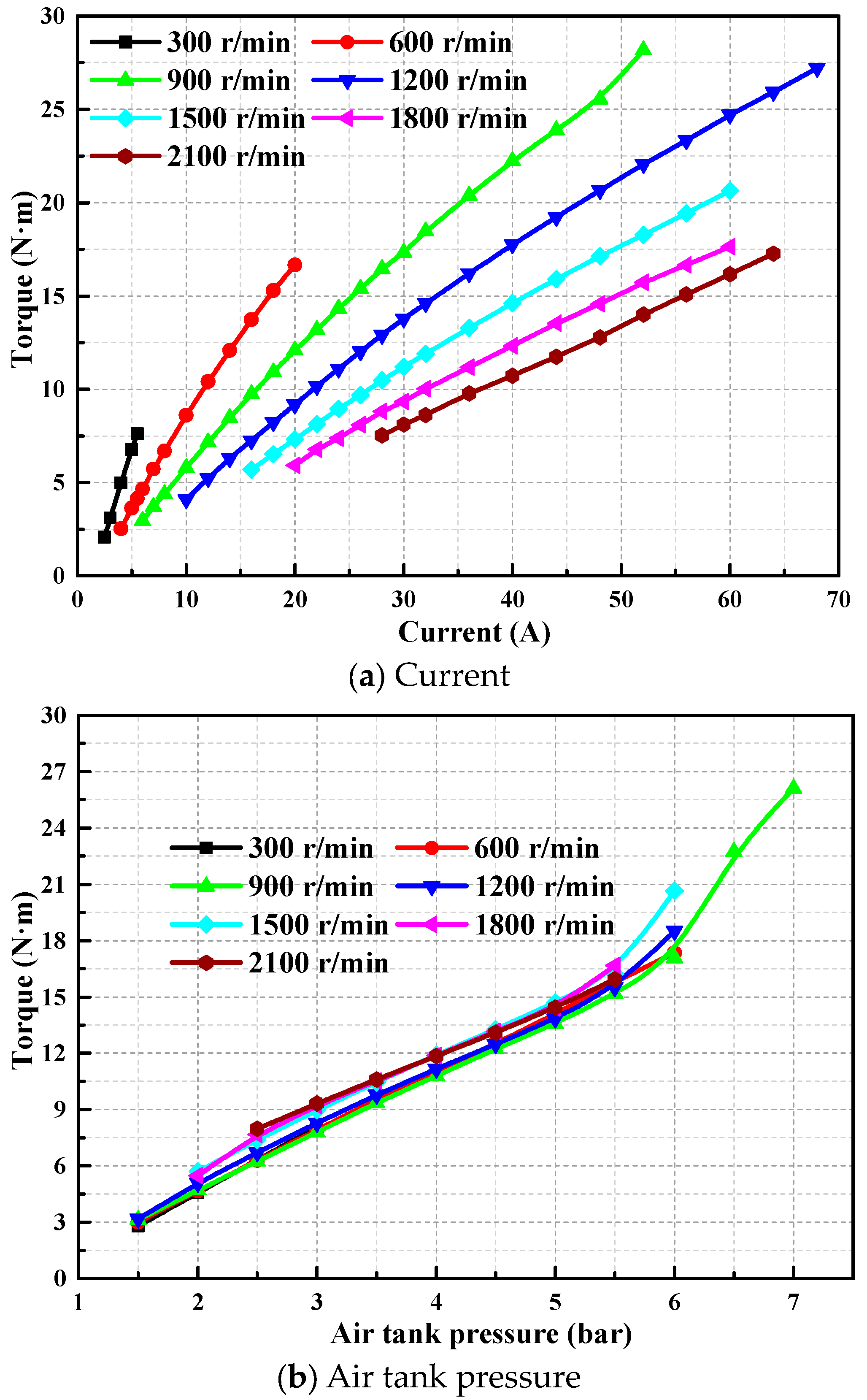

Figure 5a shows the torque of the scroll compressor as a function of the current. Overall, the torque of the scroll compressor shows an increasing trend with the increase in current. As the rotating speed increases, the torque of the scroll compressor shows a decreasing trend with the increase in current. When the current is the same, the torque of the scroll compressor shows a decreasing trend as the rotating speed increases. When the rotating speed is 900 r/min and the current is 52 A, the maximum torque of the scroll compressor is about 28 N·m.

Figure 5b shows the variation in torque with the air tank pressure. Overall, the torque shows an increasing trend as the air tank pressure increases. At different rotating speeds, the torque value basically coincides with the change trend of the air tank pressure. When the rotating speed is 900 r/min and the air tank pressure is 7 bar, the maximum torque reaches approximately 26 N m.

Figure 6a shows the temperature difference of compressed air at the inlet and outlet of the scroll compressor as a function of the current. Overall, the temperature difference shows an increasing trend with the increase in current. When the rotating speed is 1200 r/min and the current is 64 A, the maximum temperature difference at the inlet and outlet of the scroll compressor is approximately 45 °C. During the air compression process, the air pressure increases while the temperature increases, which is caused by the conversion of compression work into heat. Because when air is compressed, it is equivalent to work being conducted by the outside world on this mass of air. According to the law of conservation of energy, the work conducted by the outside world on it is converted into internal energy of the air, so the temperature of the air will increase.

Figure 6b shows the temperature difference between the inlet and outlet of a scroll compressor as a function of torque. Overall, the temperature difference between the inlet and outlet of the scroll compressor shows an increasing trend with the increase in torque. At the same torque value, the temperature difference increases as the rotating speed increases. When the torque value is 28 N m and the rotating speed is 1200 r/min, the maximum temperature difference between the inlet and outlet of the scroll compressor is about 45 °C.

Figure 6c shows the temperature difference between the inlet and outlet of the scroll compressor as a function of the air tank pressure. Overall, the temperature difference between the inlet and outlet of the scroll compressor increases with the increase in the air tank pressure. When the air tank pressure is the same, the temperature difference between the inlet and outlet of the scroll compressor increases with the increase in the rotating speed. When the air tank pressure is 6 bar and the rotating speed is 1200 r/min, the maximum temperature difference between the inlet and outlet of the scroll compressor is about 42 °C.

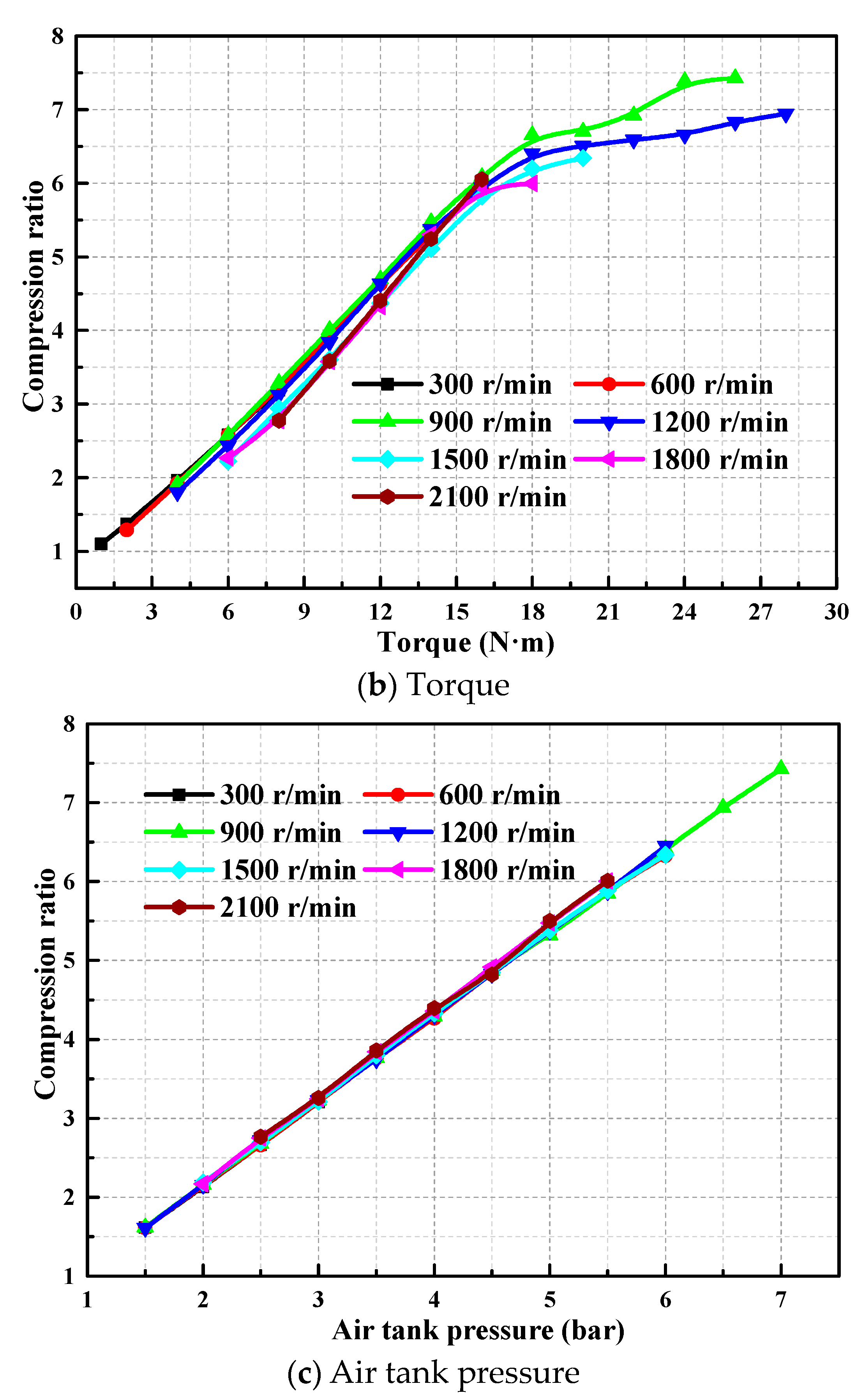

Figure 7a shows the variation in compression ratio with current. Overall, the compression ratio shows an increasing trend with the increase in current, and the rate of increase in compression ratio decreases with the increase in rotating speed. At the same current, the compression ratio shows a decreasing trend as the speed increases. The higher the pressure ratio of the compressor, the higher the efficiency of the compressor. The higher the pressure ratio, the greater the compression work completed by the compressor in each cycle, which can provide higher compression power under the same exhaust volume. The compressor pressure ratio is an important indicator for evaluating compressor efficiency, and its size is influenced by various factors. When the speed of rotation is 900 r/min and the current is 48 A, the compression ratio reaches its maximum value of approximately 7.4.

Figure 7b shows the pressure ratio of a scroll compressor as a function of torque. Overall, the pressure ratio of a scroll compressor shows a trend of first increasing, then tending to flatten, and finally reaching its maximum value as the torque increases. When the torque is less than 14 N m, the curve of pressure ratio changing with torque at different speeds basically coincides. When the torque value is 26 N m and the rotating speed is 900 r/min, the maximum pressure ratio of the scroll compressor is about 7.4.

Figure 7c shows the variation in pressure ratio with the air tank pressure. From the graph, it can be observed that the pressure ratio shows a linear increasing trend as the air tank pressure increases. At different rotating speeds, the pressure ratio of the scroll compressor coincides with the change curve of the air tank pressure, which also indicates good consistency of experimental data.

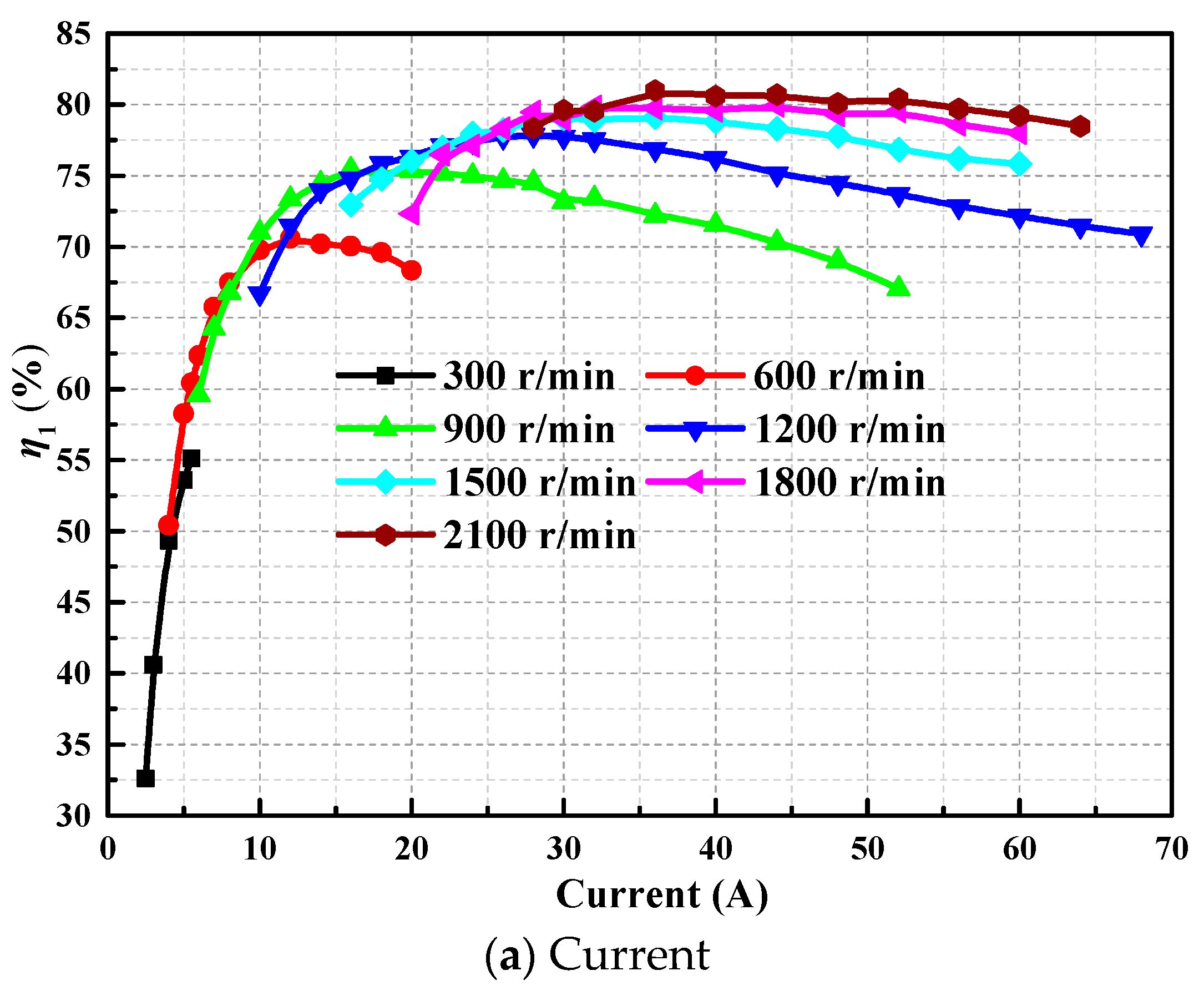

Figure 8a shows the variation in the power consumption of the scroll compressor with the current. The power consumption of the scroll compressor shows a linear increasing trend with the increase in current. When the current is less than 30 A, the power consumption curves of the scroll compressor basically overlap at different rotating speeds. When the current is greater than 30 A and the current is the same, the power consumption of the scroll compressor increases with the increase in rotating speed. Increasing the rotating speed of the scroll compressor appropriately can change the power consumption. When the rotating speed is 2100 r/min and the current is 64 A, the maximum power consumption of the scroll compressor is approximately 3427 W.

Figure 8b shows the power consumption of a scroll compressor as a function of torque. Overall, the power consumption of the scroll compressor shows an increasing trend with the increase in torque, and, with the increase in rotating speed, the power consumption of the scroll compressor increases more significantly with the increase in torque. When the torque value is the same, the power consumption of the scroll compressor increases with the increase in rotating speed. When the rotating speed is 1200/r/min and the torque is 28 N m, the maximum power consumption of the scroll compressor is about 3366 W.

Figure 8c shows the variation in power consumption of a scroll compressor with the air tank pressure. Overall, the power consumption of the scroll compressor shows an increasing trend with the increase in the air tank pressure. Under the same air tank pressure, the power consumption of the scroll compressor increases with the increase in rotating speed.

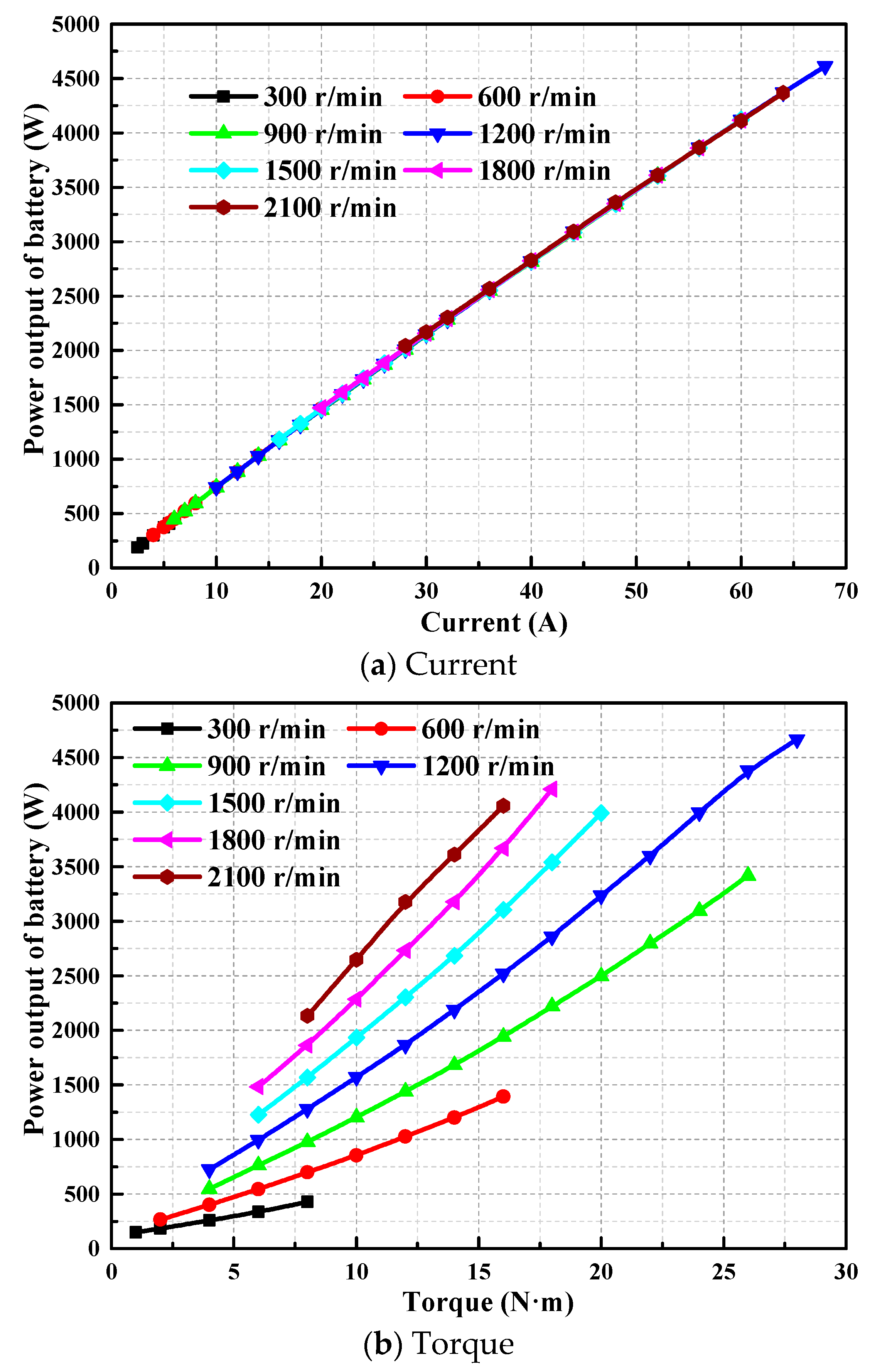

Figure 9a shows the variation in the power output of the power battery with the current. From the graph, it can be seen that the power output of the power battery exhibits a linear relationship with the current. At different rotating speeds, the power output curves of the power battery overlap, which also indicates good consistency of the experimental data. When the current is 68 A, the maximum power output of the power battery is approximately 4613 W.

Figure 9b shows the variation in the power output of the power battery with torque. From the overall trend, the power output of the battery and the power output of the scroll compressor have a consistent trend with the variation in torque. When the rotating speed is 1200/r/min and the torque is 28 N m, the maximum power consumption of the scroll compressor is about 4665 W.

Figure 9c shows the variation in the power output of the power battery with the air tank pressure. The power output of the power battery changes with the air tank pressure, and the trend of the scroll compressor changes with the air tank pressure is basically the same. When the air tank pressure is 6 bar and the rotating speed is 1500 r/min, the maximum power output of the battery is about 4100 W.

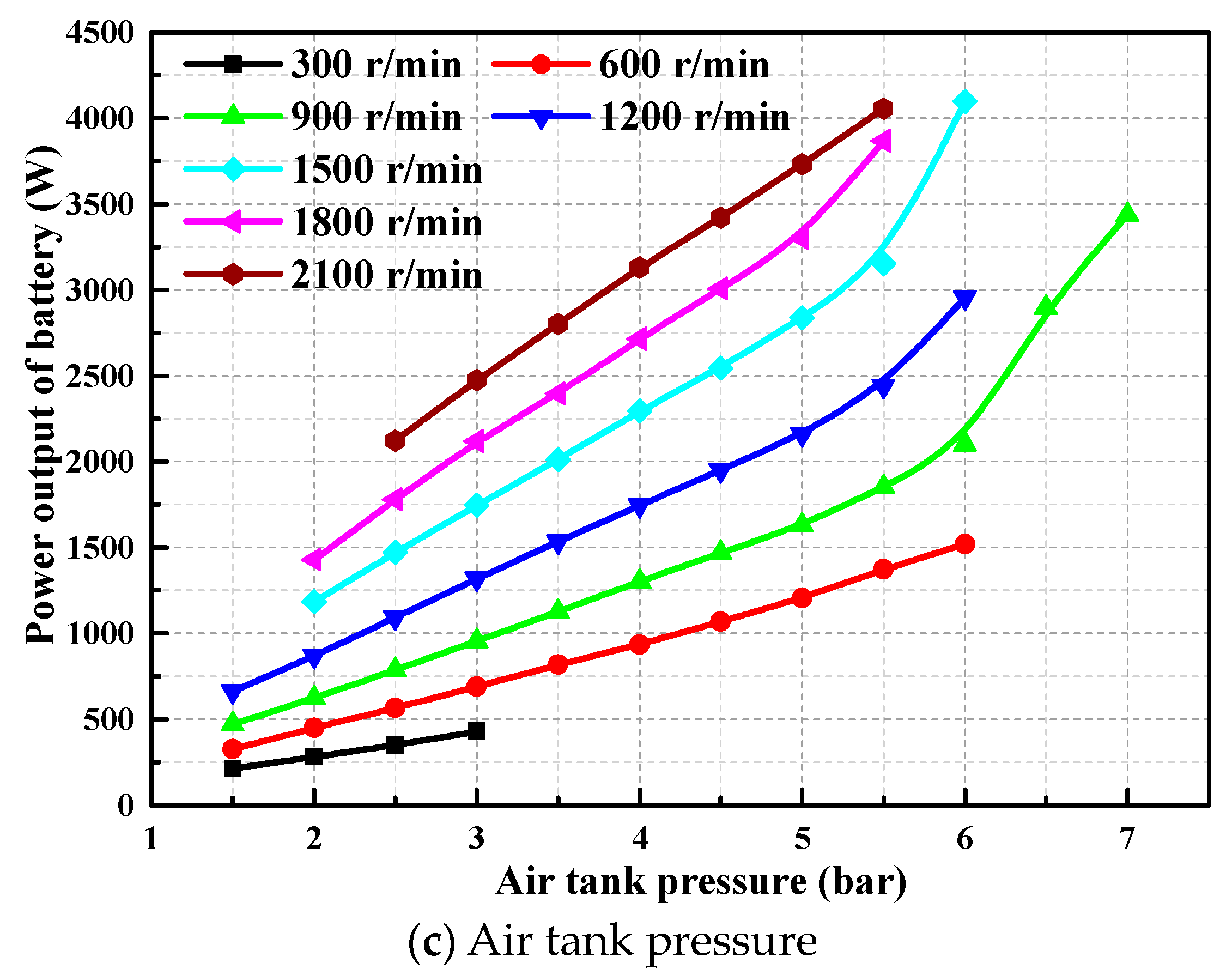

Figure 10a shows the trend of DC/AC conversion efficiency as a function of current. Overall, the conversion efficiency of DC/AC shows an increasing trend with the increase in current. When it reaches its maximum value, it tends to flatten out and finally shows a decreasing trend. When the rotating speed and current are low, the conversion efficiency of DC/AC shows a linear increase trend. When the current value is the same, the conversion efficiency of DC/AC increases with the increase in rotating speed. When the rotating speed is 2100 r/min and the current value is 36 A, the maximum conversion efficiency of DC/AC is about 81%.

Figure 10b shows the conversion efficiency of DC/AC as a function of torque. Overall, the energy conversion efficiency of DC/AC shows a trend of first increasing, then gradually reaching its maximum value, and finally decreasing with the increase in torque. When the torque value is the same, the conversion efficiency of DC/AC increases with the increase in rotating speed. From the graph, it can be seen that the high-efficiency range of DC/AC is mainly concentrated near medium torque. When the torque is 10 N m and the rotating speed is 2100 r/min, the maximum conversion efficiency of DC/AC is about 80%.

Figure 10c shows the conversion efficiency of DC/AC as a function of the air tank pressure. Overall, the conversion efficiency of DC/AC shows a trend of first increasing, then flattening out, and finally decreasing as the air tank pressure increases. When the air tank pressure is the same, the conversion efficiency of DC/AC increases with the increase in rotating speed. The high-efficiency range of DC/AC conversion efficiency is mainly concentrated around the medium pressure range of the air tank pressure. When the rotating speed is 2100 r/min and the air tank pressure is 2.5, 3.0, 3.5, 4.0, and 4.5 bar, the conversion efficiency of DC/AC reaches the maximum value of approximately 80%.

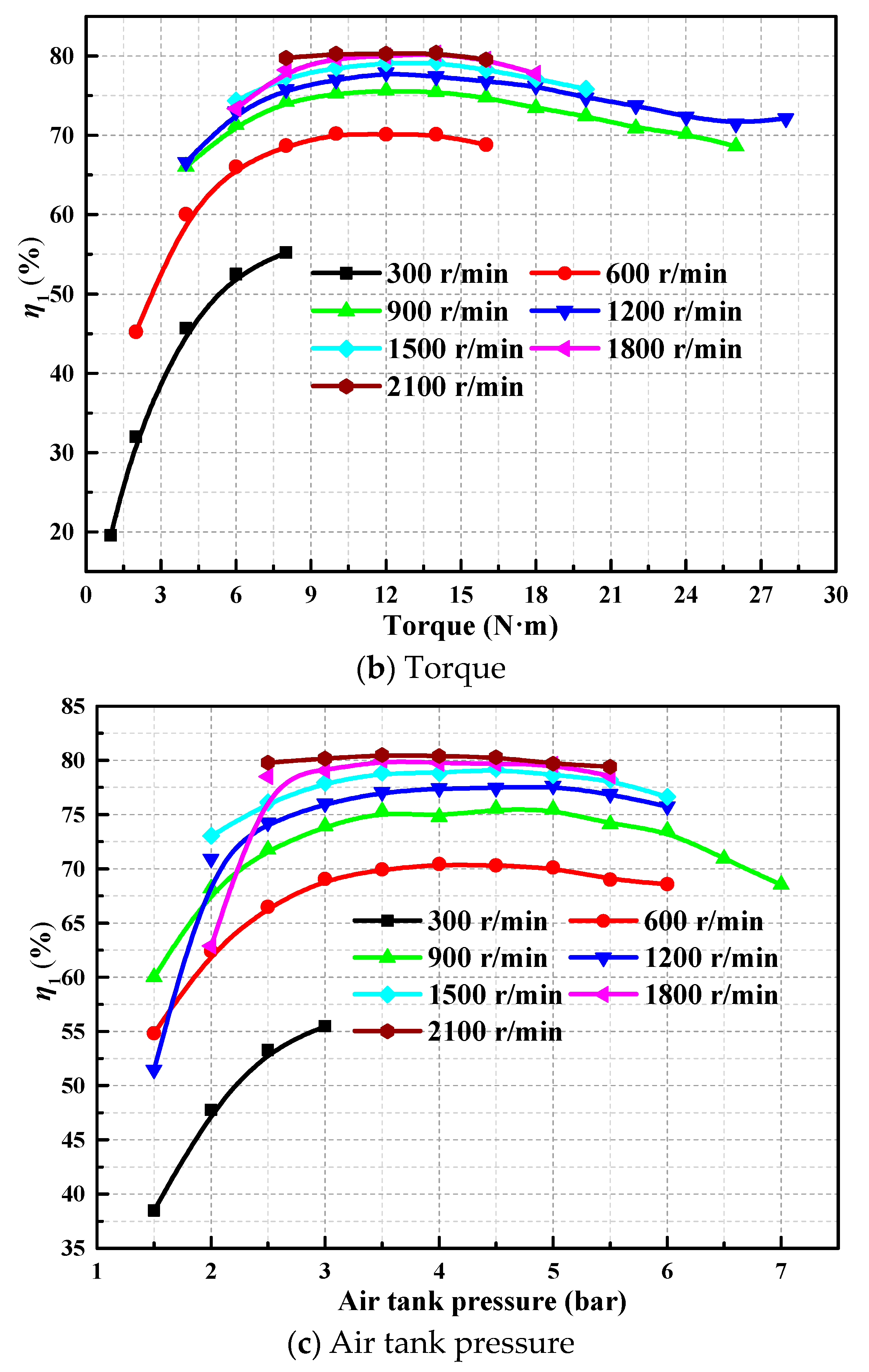

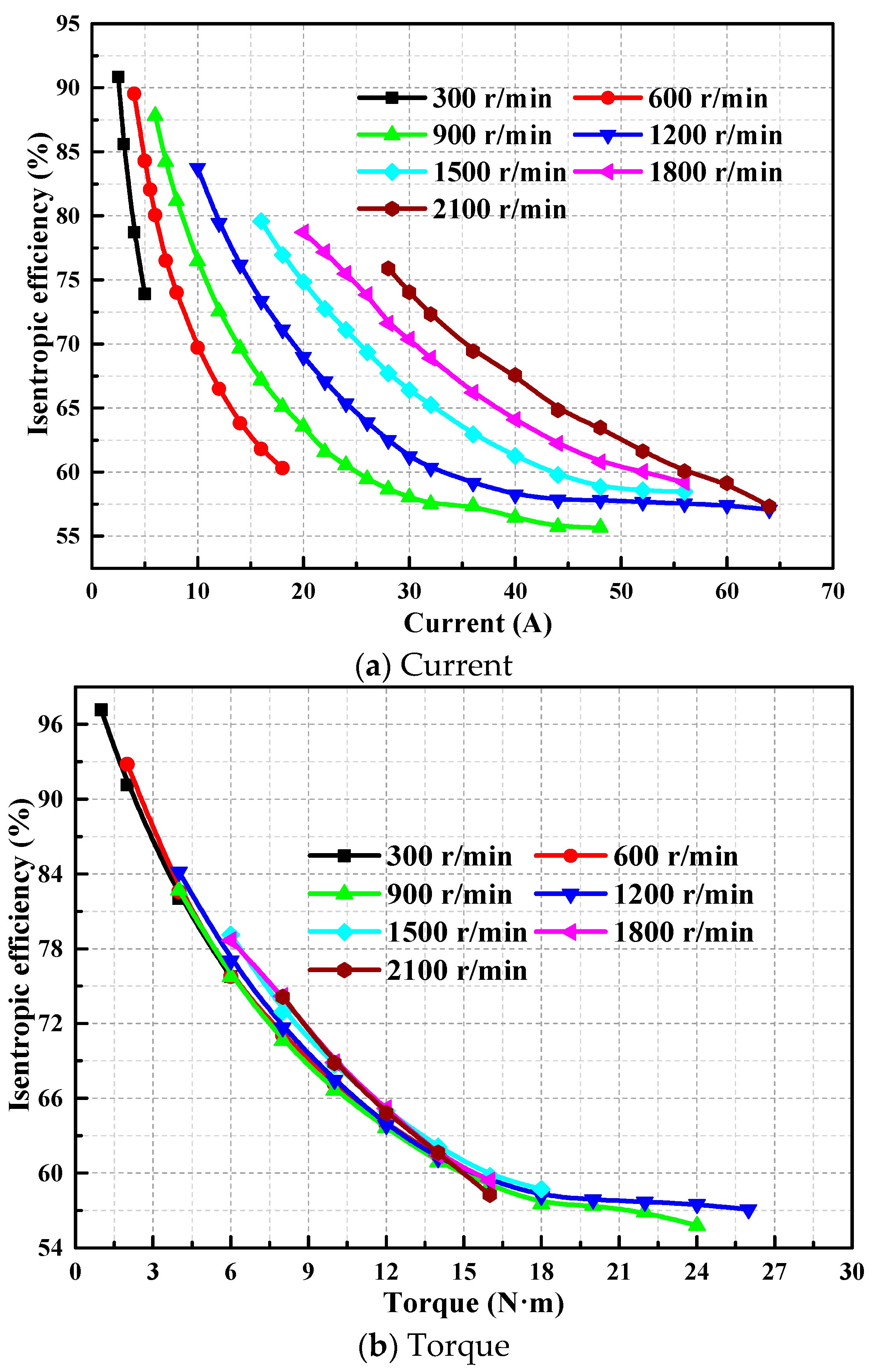

Figure 11a shows the isentropic efficiency of a scroll compressor as a function of current. Overall, the isentropic efficiency of the scroll compressor shows a decreasing trend with the increase in current. When the current value is the same, the isentropic efficiency of the scroll compressor shows an increasing trend with the increase in rotating speed. The higher the isentropic efficiency, the higher the energy utilization efficiency of the scroll compressor and the lower the required power under the same working state. The method of improving isentropic efficiency can effectively reduce energy consumption, improve production efficiency, and save operating costs. When the rotating speed is 300 r/min and the current is 2.5 A, the isentropic efficiency of the scroll compressor reaches its maximum value of approximately 90.8%.

Figure 11b shows the isentropic efficiency of a scroll compressor as a function of torque. From the overall trend, the isentropic efficiency of the scroll compressor shows a decreasing trend as the torque value increases. At different rotating speeds, the isentropic efficiency curve of the scroll compressor basically coincides with the variation in torque. The torque value corresponding to the maximum isentropic efficiency of a scroll compressor increases with the increase in rotating speed.

Figure 11c shows the isentropic efficiency of a scroll compressor as a function of the air tank pressure. Overall, the isentropic efficiency of a scroll compressor shows a decreasing trend as the air tank pressure increases. At different rotating speeds, the isentropic efficiency of the scroll compressor coincides with the variation curve of the air tank pressure. When the air tank pressure is 1.5 bar, the isentropic efficiency of the scroll compressor reaches its maximum value of approximately 87%.