Effective Ti-6Al-4V Powder Recycling in LPBF Additive Manufacturing Considering Powder History

Abstract

:1. Introduction

2. Methods

2.1. System and Powder

2.2. Characterization and Testing

2.3. Quantifying Powder Recycling

3. Results and Discussion

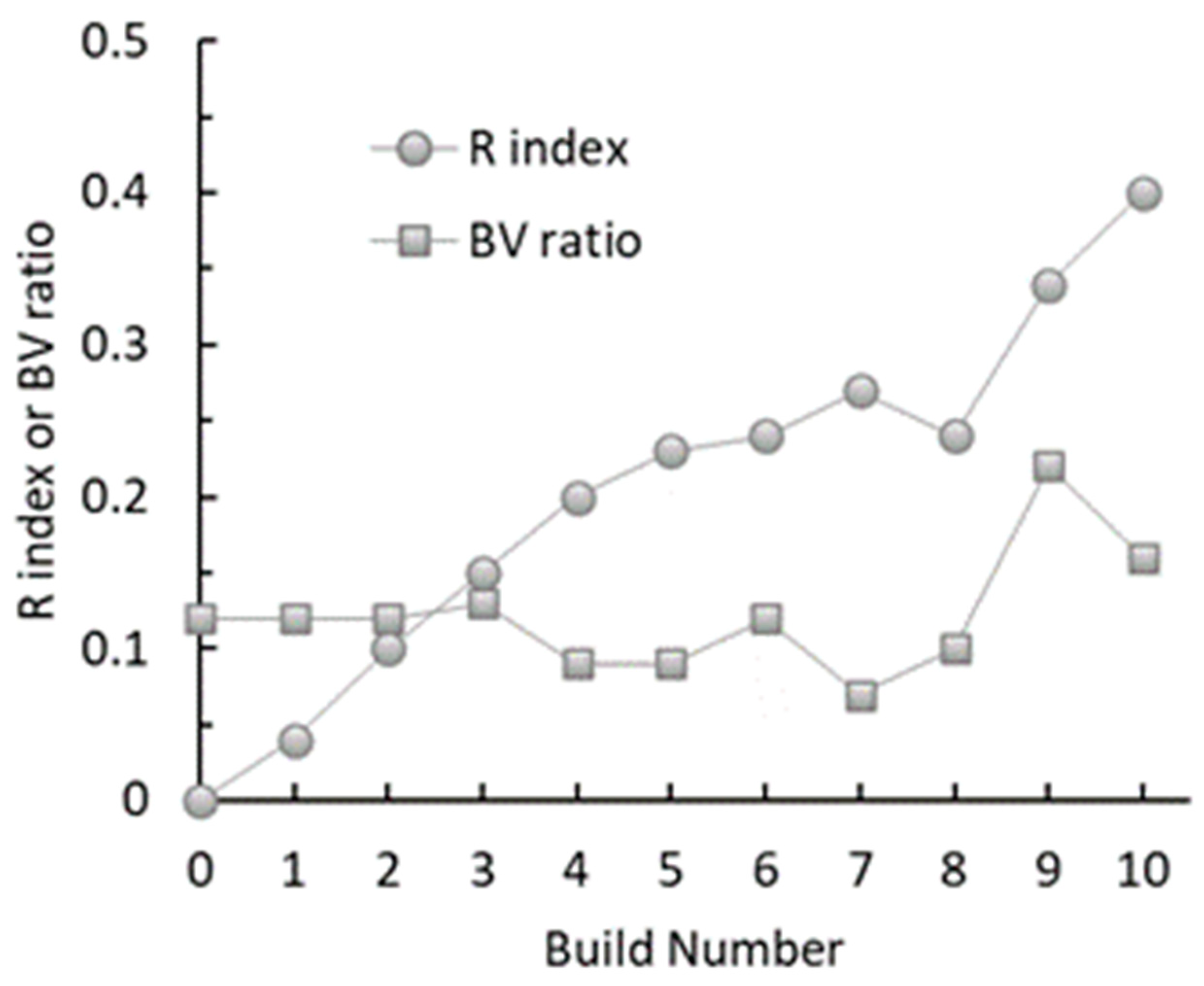

3.1. Quantifying Powder Recycling

3.1.1. Morphology

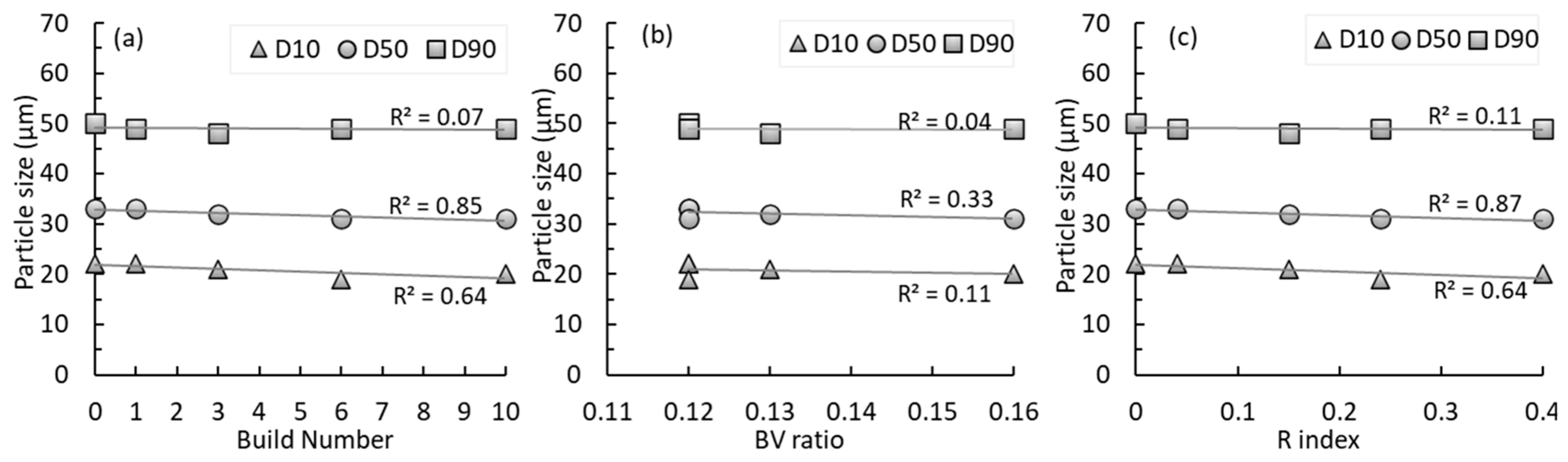

3.1.2. Particle Size Distribution

3.1.3. Flowability

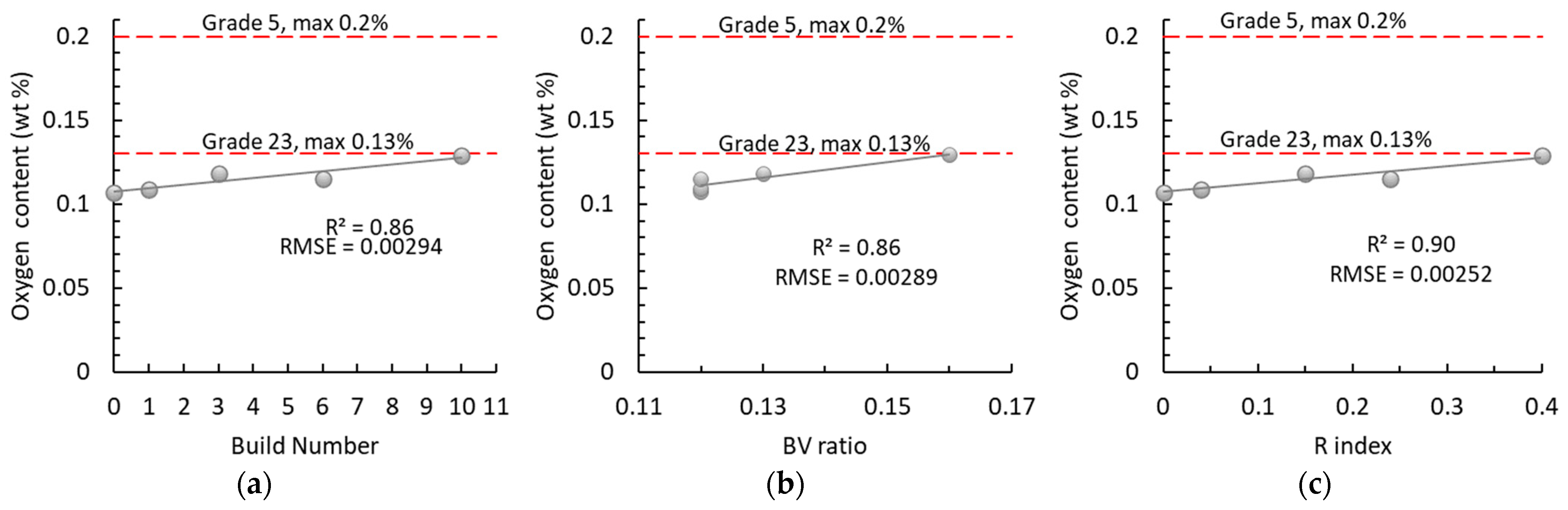

3.1.4. Powder Chemistry

3.2. Build Material Characterisation

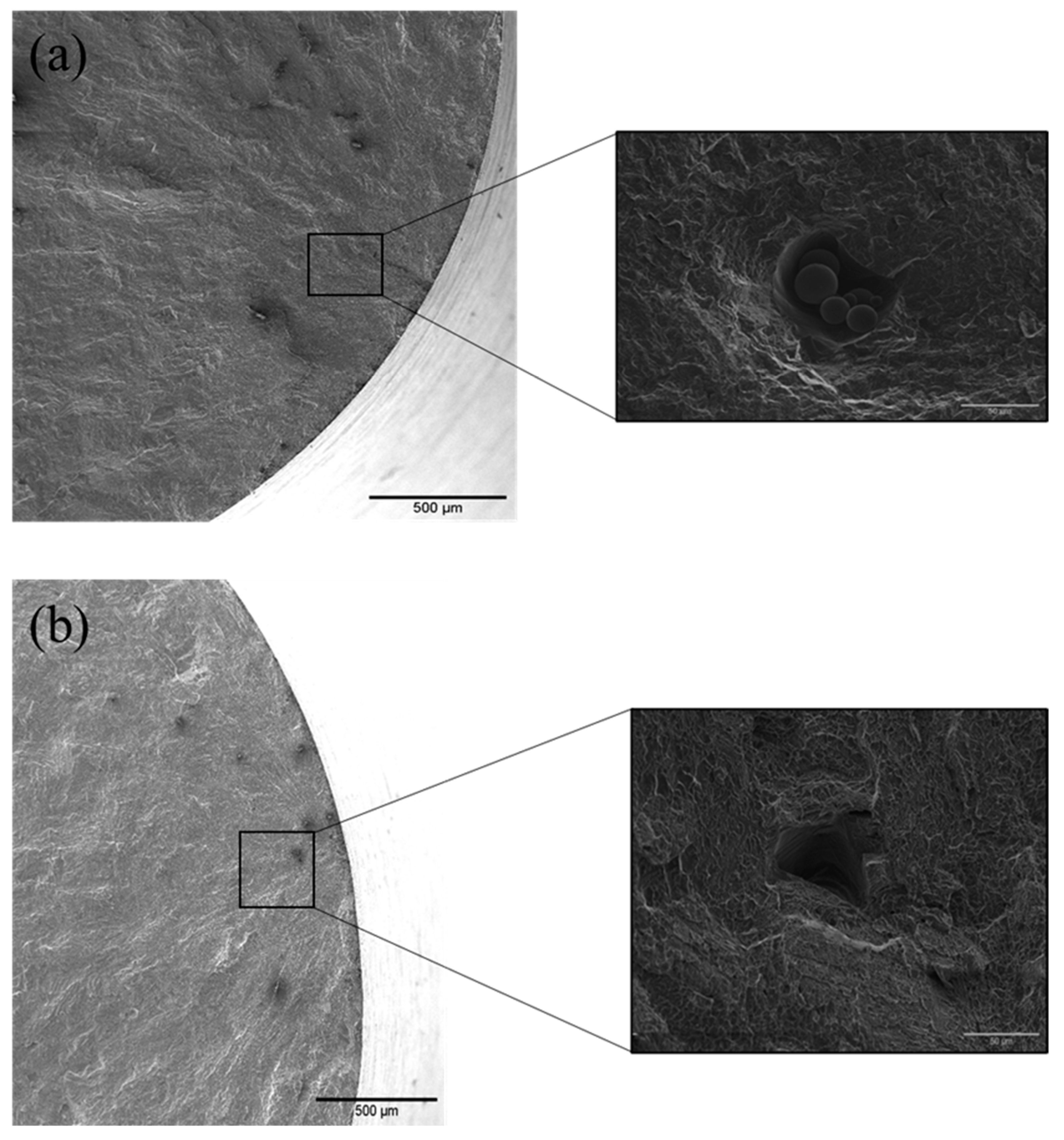

3.2.1. Density and Microstructure

3.2.2. Tensile Performance

| Process Condition | Recycle Method | Recycle Times/BV Ratio/ R Index | Powder/ (Part) Oxygen Content (%) | Mechanical Properties | ||||

|---|---|---|---|---|---|---|---|---|

| YS (MPa) | UTS (MPa) | R.A (%) | ||||||

| Present study | LPBF and heat treated at 800 °C 6 h | Sieving and refreshing | 0/0.12/0 | 0.107 | 948 ± 8 | 1034 ± 5 | 16.0 ± 2.0 | 36 ± 6 |

| 1/0.12/0.04 | 0.109 | 946 ± 14 | 1035 ± 6 | 17.0 ± 1.0 | 38 ± 2 | |||

| 3/0.13/0.15 | 0.118 | 929 ± 23 | 1035 ± 6 | 17.0 ± 1.0 | 38 ± 3 | |||

| 6/0.12/0.24 | 0.115 | 939 ± 27 | 1033 ± 17 | 16.0 ± 1.4 | 37 ± 5 | |||

| 10/0.16/0.40 | 0.129 | 930 ± 28 | 1033 ± 17 | 14.5 ± 1.0 | 40 ± 5 | |||

| [43] | LPBF and heat treated at 650 °C 3 h then 800 °C 2 h | Sieving only | 0 | (0.125) | 933 ± 5 | 1030 ± 4 | 15.7 ± 0.5 | 56 ± 2 |

| 1 | (0.110) | 938 ± 9 | 1027 ± 5 | 17.3 ± 0.4 | 59 ± 1 | |||

| 4 | (0.120) | 947 ± 6 | 1034 ± 3 | 15.3 ± 0.3 | 54 ± 1 | |||

| 8 | (0.125) | 958 ± 7 | 1043 ± 2 | 15.3 ± 0.3 | 51 ± 1 | |||

| [25] | LPBF and heat treated in vacuum | Sieving only | 1 | 0.090 | 839 | 1012 | 7 | 14 |

| 12 | 0.103 | 934 | 1052 | 12 | 30 | |||

| 18 | 0.119 | 921 | 1056 | 17 | 42 | |||

| 24 | 0.122 | 918 | 1051 | 7 | 12 | |||

| 31 | 0.119 | 897 | 1041 | 10 | 18 | |||

| 38 | 0.121 | 989 | 1095 | 17 | 47 | |||

| [4] | LPBF and HIP at 920 °C 102 MPa 2 h | Sieving only | 1 | 0.11 | 879 ± 7.6 | 984 ± 0.6 | 14 ± 0.6 | 44 ± 0.6 |

| 4 | 0.13 | 871 ± 6.0 | 988 ± 1.0 | 15 ± 0.6 | 45 ± 1.2 | |||

| 17 | 0.12 | 893 ± 3.1 | 1001 ± 0.6 | 15 ± 0.0 | 47 ± 0.0 | |||

| 31 | 0.11 | 881 ± 3.6 | 1003 ± 1.2 | 15 ± 0.6 | 44 ± 0.6 | |||

| [49] | LPBF and heat treated at 704 °C 1 h | Sieving only | 0 | 0.10 | 992 | 1090 | 14.0 | - |

| 15 | 0.12 | 978 | 1073 | 14.5 | - | |||

| [14] | EBM, preheat to 730 °C | Sieving only | 0 | 0.08 | 834 ± 10.0 | 920 ± 10.0 | 16 ± 0.3 | 54 ± 3.0 |

| 2 | 0.097 | 870 ± 8.0 | 970 ± 10.0 | 15 ± 0.3 | 46 ± 3.0 | |||

| 6 | 0.14 | 822 ± 25.0 | 910 ± 20.0 | 14 ± 1.0 | 53 ± 4.0 | |||

| 11 | 0.17 | 892 ± 4.5 | 987 ± 3.5 | 18 ± 0.8 | 50 ± 1.0 | |||

| 16 | 0.18 | 940 ± 3.6 | 1028 ± 4.1 | 15 ± 1.8 | 42 ± 4.1 | |||

| 21 | 0.19 | 960 ± 30.0 | 1039 ± 2.7 | 16 ± 0.9 | - | |||

3.3. Assessment of Powder Processing Methodology

4. Conclusions

- Powder particle size showed negligible variation through the 10 recycles. The D50 size only changed from 33 µm to 31 µm.

- Powder compaction and flowability also showed negligible variation through the powder cycles. The Hausner ratio showed a slight stronger correlation with R index, indicating a better compaction in the powder. In general, the changes of Hausner ratio and Hall flow rate are still marginal and have no effect on powder packing and spreading.

- Oxygen pickup increases with more powder recycles. The powder oxygen content showed stronger linear correlation to the R index (which considers the whole powder usage history) than recycle number and BV ratio. With the fixed processing conditions (chamber oxygen level and laser process parameters), the powder degraded close to the Grade 23 limit after about 40% powder consumption or 10 builds in this work with 0.107% in the virgin powder to 0.129% in the 10th recycled powder.

- The tensile properties showed slight change in yield strength while ultimate strength and ductility (elongation and reduction of area) only fluctuated slightly. The yield strength had the best linear correlation to the BV ratio, then R index and least to recycle number. This implies that the in situ powder degradation (due to thermal exposure and spatters) probably had a more detrimental effect on the yield strength. A possible reason is the potential defects from more spatters generated in a larger printing volume.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015. [Google Scholar]

- Oros Daraban, A.E.; Negrea, C.S.; Artimon, F.G.P.; Angelescu, D.; Popan, G.; Gheorghe, S.I.; Gheorghe, M. A Deep Look at Metal Additive Manufacturing Recycling and Use Tools for Sustainability Performance. Sustainability 2019, 11, 5494. [Google Scholar] [CrossRef]

- Strondl, A.; Lyckfeldt, O.; Brodin, H.; Ackelid, U. Characterization and Control of Powder Properties for Additive Manufacturing. TMS 2015, 67, 549–554. [Google Scholar] [CrossRef]

- Quintana, O.; Alvarez, J.; McMillan, R.; Tong, W.; Tomonto, C. Effects of Reusing Ti-6Al-4V Powder in a Selective Laser Melting Additive System Operated in an Industrial Setting. TMS 2018, 70, 1863–1869. [Google Scholar] [CrossRef]

- Mohd Yusuf, S.; Cutler, S.; Gao, N. Review: The Impact of Metal Additive Manufacturing on the Aerospace Industry. Metals 2019, 9, 1286. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Quinn, P.; O’Halloran, S.; Lawlor, J.; Raghavendra, R. The effect of metal EOS 316L stainless steel additive manufacturing powder recycling on part characteristics and powder reusability. Adv. Mater. Process. Technol. 2019, 5, 348–359. [Google Scholar] [CrossRef]

- Fedina, T.; Sundqvist, J.; Kaplan, A.F.H. Spattering and oxidation phenomena during recycling of low alloy steel powder in Laser Powder Bed Fusion. Mater. Today Commun. 2021, 27, 102241. [Google Scholar] [CrossRef]

- Chu, F.; Zhang, K.; Shen, H.; Liu, M.; Huang, W.; Zhang, X.; Liang, E.; Zhou, Z.; Lei, L.; Hou, J.; et al. Influence of satellite and agglomeration of powder on the processability of AlSi10Mg powder in Laser Powder Bed Fusion. J. Mater. Res. 2021, 11, 2059–2073. [Google Scholar] [CrossRef]

- Bonatti, R.S.; Meyer, Y.A.; Bortolozo, A.D.; Costa, D.; Osório, W.R. Morphology and size effects on densification and mechanical behavior of sintered powders from Al-Si and Al-Cu casting alloys. J. Alloys Compd. 2019, 786, 717–732. [Google Scholar] [CrossRef]

- Satizabal, L.M.; Caurin, H.F.N.; Meyer, Y.A.; Padilha, G.S.; Bortolozo, A.D.; Osório, W.R. Distinct heat treatments and powder size ratios affecting mechanical responses of Al/Si/Cu composites. J. Compos. Mater. 2021, 55, 3589–3605. [Google Scholar] [CrossRef]

- Bonatti, R.S.; Meyer, Y.A.; Padilha, G.S.; Bortolozo, A.D.; Osório, W.R. Silicon Content Affecting Corrosion Behavior of Alp/Sip Composites in a Biodiesel Blend. Corrosion 2020, 76, 1109–1121. [Google Scholar] [CrossRef] [PubMed]

- Nandwana, P.; Peter, W.; Dehoff, R.; Lowe, L.; Kirka, M.; Medina, F.; Babu, S. Recyclability Study on Inconel 718 and Ti-6Al-4V Powders for Use in Electron Beam Melting. Metall. Mater. Trans. B 2016, 47, 754–762. [Google Scholar] [CrossRef]

- Tang, H.; Qian, M.; Liu, N.; Zhang, X.; Yang, G.; Wang, J. Effect of Powder Reuse Times on Additive Manufacturing of Ti-6Al-4V by Selective Electron Beam Melting. TMS 2015, 67, 555–563. [Google Scholar] [CrossRef]

- Popov, V.V.; Katz-Demyanetz, A.; Garkun, A.; Bamberger, M. The effect of powder recycling on the mechanical properties and microstructure of electron beam melted Ti-6Al-4 V specimens. Addit. Manuf. 2018, 22, 834–843. [Google Scholar] [CrossRef]

- Liu, Z.; He, B.; Lyu, T.; Zou, Y. A Review on Additive Manufacturing of Titanium Alloys for Aerospace Applications: Directed Energy Deposition and Beyond Ti-6Al-4V. JOM 2021, 73, 1804–1818. [Google Scholar] [CrossRef]

- Jang, T.-S.; Kim, D.; Han, G.; Yoon, C.-B.; Jung, H.-D. Powder based additive manufacturing for biomedical application of titanium and its alloys: A review. Biomed. Eng. Lett. 2020, 10, 505–516. [Google Scholar] [CrossRef]

- Lütjering, G. Titanium, 2nd ed.; Springer: Berlin, UK; New York, NY, USA, 2007. [Google Scholar]

- Leicht, A. Aspects of Building Geometry and Powder Characteristics in Powder Bed Fusion; Chalmers Tekniska Hogskola: Göteborg, Sweden, 2018. [Google Scholar]

- Guoyu, J. The Effect of Oxygen Content on the Tensile Properties of SLMed Ti6Al4V Alloy. Ph.D. Thesis, Monash University, Clayton, VIC, Australia, 2017. [Google Scholar]

- Sun, Y.; Aindow, M.; Hebert, R.J. The effect of recycling on the oxygen distribution in Ti-6Al-4V powder for additive manufacturing. Mater. High Temp Microsc. Oxid. 2018, 35, 217–224. [Google Scholar] [CrossRef]

- Silverstein, R.; Eliezer, D. Hydrogen trapping in 3D-printed (additive manufactured) Ti-6Al-4V. Mater. Charact. 2018, 144, 297–304. [Google Scholar] [CrossRef]

- Peterson, J.; Issariyapat, A.; Umeda, J.; Kondoh, K. The effects of heat treatment and carbon content on the microstructure and mechanical properties of laser powder bed fusion Ti-6Al-4V with dissolved TiC particles. J. Alloys Compd. 2022, 920, 165930. [Google Scholar] [CrossRef]

- Liu, L.; Chen, C.; Zhao, R.; Wang, X.; Tao, H.; Shuai, S.; Wang, J.; Liao, H.; Ren, Z. In-situ nitrogen strengthening of selective laser melted Ti6Al4V with superior mechanical performance. Addit. Manuf. 2021, 46, 102142. [Google Scholar] [CrossRef]

- Park, S.B.; Road, B.; Kingdom, U. Investigating the Effects of Multiple Re-Use of Ti6Al4V Powder in Additive Manufacturing; Renishaw: Staffordshire, UK, 2016; pp. 1–10. [Google Scholar]

- Shalnova, S.A.; Kuzminova, Y.O.; Evlashin, S.A.; Klimova-Korsmik, O.G.; Vildanov, A.M.; Shibalova, A.A.; Turichin, G.A. Effect of recycled powder content on the structure and mechanical properties of Ti-6Al-4V alloy produced by direct energy deposition. J. Alloys Compd. 2022, 893, 162264. [Google Scholar] [CrossRef]

- Yang, K.V.; Looze, G.R.d.; Nguyen, V.; Wilson, R.S. Directed-energy deposition of Ti-6Al-4V alloy using fresh and recycled feedstock powders under reactive atmosphere. Addit. Manuf. 2022, 58, 103043. [Google Scholar] [CrossRef]

- Derimow, N.; Hrabe, N. Oxidation in Reused Powder Bed Fusion Additive Manufacturing Ti-6Al-4V Feedstock: A Brief Review. JOM 2021, 73, 3618–3638. [Google Scholar] [CrossRef]

- Guleryuz, H.; Cimenoglu, H. Oxidation of Ti–6Al–4V alloy. J. Alloys Compd. 2009, 472, 241–246. [Google Scholar] [CrossRef]

- ASTM E1409-13; Standard Test Method for Determination of Oxygen and Nitrogen in Titanium and Titanium Alloys by Inert Gas Fusion. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM E1941-10; Standard Test Method for Determination of Carbon in Refractory and Reactive Metals and Their Alloys by Combustion Analysis. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM E1447-10; Standard Test Method for Determination of Hydrogen in Titanium and Titanium Alloys by Inert Gas Fusion Thermal Conductivity/Infrared Detection Method. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM E2371-13; Standard Test Method for Analysis of Titanium and Titanium Alloys by Direct Current Plasma and Inductively Coupled Plasma Atomic Emission Spectrometry (Performance-Based Test Methodology). ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM E2651-19; Standard Guide for Powder Particle Size Analysis. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM B855-17; Standard Test Method for Volumetric Flow Rate of Metal Powders Using the Arnold Meter and Hall Flowmeter Funnel. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM B964-16; Standard Test Methods for Flow Rate of Metal Powders Using the Carney Funnel. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM B417-18; Standard Test Method for Apparent Density of Non-Free-Flowing Metal Powders Using the Carney Funnel. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM B212-21; Standard Test Method for Apparent Density of Free-Flowing Metal Powders Using the Hall Flowmeter Funnel. ASTM International: West Conshohocken, PA, USA, 2021.

- Marcu, T.; Todea, M.; Gligor, I.; Berce, P.; Popa, C. Effect of surface conditioning on the flowability of Ti6Al7Nb powder for selective laser melting applications. Appl. Surf. Sci. 2012, 258, 3276–3282. [Google Scholar] [CrossRef]

- Artamonov, V.V.; Bykov, A.O.; Bykov, P.O.; Artamonov, V.P. Measurement of the tap density of metal powders. Powder Metall. Met. Ceram. 2013, 52, 237–239. [Google Scholar] [CrossRef]

- Cao, S.; Chen, Z.; Lim, C.; Yang, K.; Jia, Q.; Jarvis, T.; Tomus, D.; Wu, X. Defect, Microstructure, and Mechanical Property of Ti-6Al-4V Alloy Fabricated by High-Power Selective Laser Melting. TMS 2017, 69, 2684–2692. [Google Scholar] [CrossRef]

- ASTM E8/E8M; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- Alamos, F.J.; Schiltz, J.; Kozlovsky, K.; Attardo, R.; Tomonto, C.; Pelletiers, T.; Schmid, S.R. Effect of powder reuse on mechanical properties of Ti-6Al-4V produced through selective laser melting. Int. J. Refract. Met. Hard Mater. 2020, 91, 105273. [Google Scholar] [CrossRef]

- Suzuki, M.; Sato, H.; Hasegawa, M.; Hirota, M. Effect of size distribution on tapping properties of fine powder. Powder Technol. 2001, 118, 53–57. [Google Scholar] [CrossRef]

- Kaleem, M.A.; Alam, M.Z.; Khan, M.; Jaffery, S.H.I.; Rashid, B. An experimental investigation on accuracy of Hausner Ratio and Carr Index of powders in additive manufacturing processes. Met. Powder Rep. 2020, 76 (Suppl. S1), S50–S54. [Google Scholar] [CrossRef]

- Shen, H.; Rometsch, P.; Wu, X.; Huang, A. Influence of Gas Flow Speed on Laser Plume Attenuation and Powder Bed Particle Pickup in Laser Powder Bed Fusion. JOM 2020, 72, 1039–1051. [Google Scholar] [CrossRef]

- Harkin, R.; Wu, H.; Nikam, S.; Quinn, J.; McFadden, S. Reuse of Grade 23 Ti6Al4V Powder during the Laser-Based Powder Bed Fusion Process. Metals 2020, 10, 1700. [Google Scholar] [CrossRef]

- Denti, L.; Sola, A.; Defanti, S.; Sciancalepore, C.; Bondioli, F. Effect of Powder Recycling in Laser-based Powder Bed Fusion of Ti-6Al-4V. Manuf. Technol. 2019, 19, 190–196. [Google Scholar] [CrossRef]

- Carrion, P.; Soltani-Tehrani, A.; Phan, N.; Shamsaei, N. Powder Recycling Effects on the Tensile and Fatigue Behavior of Additively Manufactured Ti-6Al-4V Parts. JOM 2019, 71, 963–973. [Google Scholar] [CrossRef]

| Ti | Al | V | Fe | O | C | N | H | |

|---|---|---|---|---|---|---|---|---|

| wt.% | Balance | 6.27 | 3.94 | 0.20 | 0.107 | 0.019 | 0.009 | 0.002 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koushik, T.; Shen, H.; Kan, W.H.; Gao, M.; Yi, J.; Ma, C.; Lim, S.C.V.; Chiu, L.N.S.; Huang, A. Effective Ti-6Al-4V Powder Recycling in LPBF Additive Manufacturing Considering Powder History. Sustainability 2023, 15, 15582. https://doi.org/10.3390/su152115582

Koushik T, Shen H, Kan WH, Gao M, Yi J, Ma C, Lim SCV, Chiu LNS, Huang A. Effective Ti-6Al-4V Powder Recycling in LPBF Additive Manufacturing Considering Powder History. Sustainability. 2023; 15(21):15582. https://doi.org/10.3390/su152115582

Chicago/Turabian StyleKoushik, Tejas, Haopeng Shen, Wen Hao Kan, Mu Gao, Junlan Yi, Chao Ma, Samuel Chao Voon Lim, Louis Ngai Sum Chiu, and Aijun Huang. 2023. "Effective Ti-6Al-4V Powder Recycling in LPBF Additive Manufacturing Considering Powder History" Sustainability 15, no. 21: 15582. https://doi.org/10.3390/su152115582

APA StyleKoushik, T., Shen, H., Kan, W. H., Gao, M., Yi, J., Ma, C., Lim, S. C. V., Chiu, L. N. S., & Huang, A. (2023). Effective Ti-6Al-4V Powder Recycling in LPBF Additive Manufacturing Considering Powder History. Sustainability, 15(21), 15582. https://doi.org/10.3390/su152115582