Comprehensive Analysis of Compression Ratio, Exhaust Gas Recirculation, and Pilot Fuel Injection in a Diesel Engine Fuelled with Tamarind Biodiesel

Abstract

:1. Introduction

2. Material and Methods

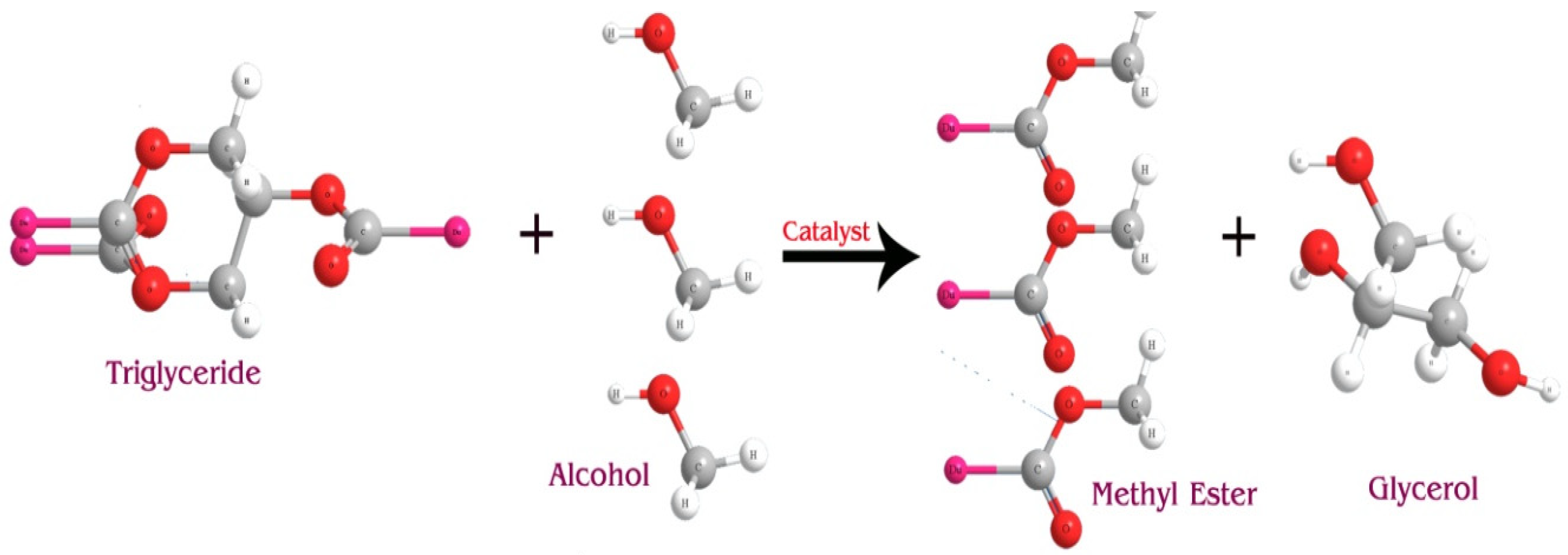

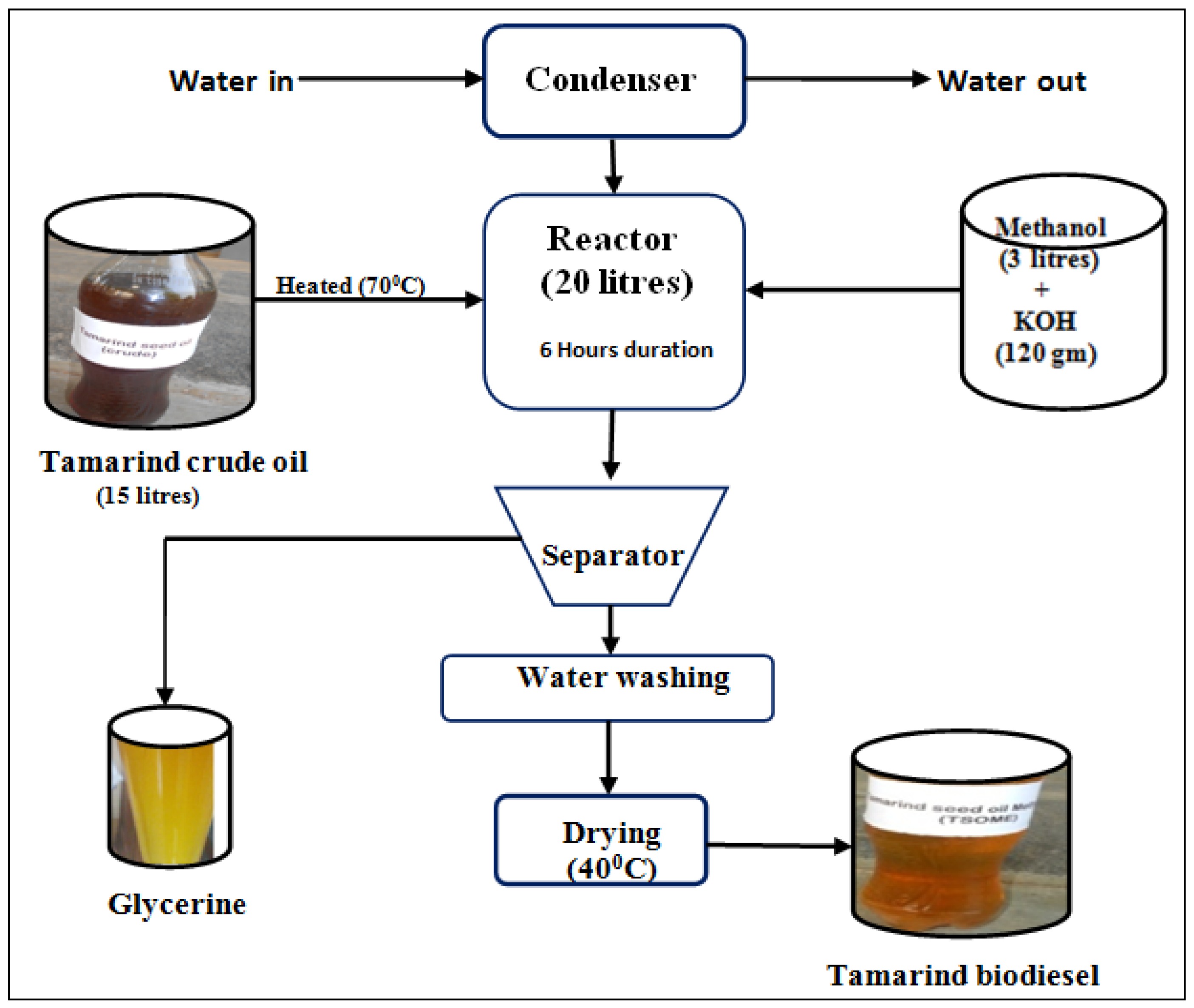

Transesterification Process

3. Experimental Setup

Error Analysis

4. Results and Discussion

4.1. Brake Specific Fuel Consumption (BSFC)

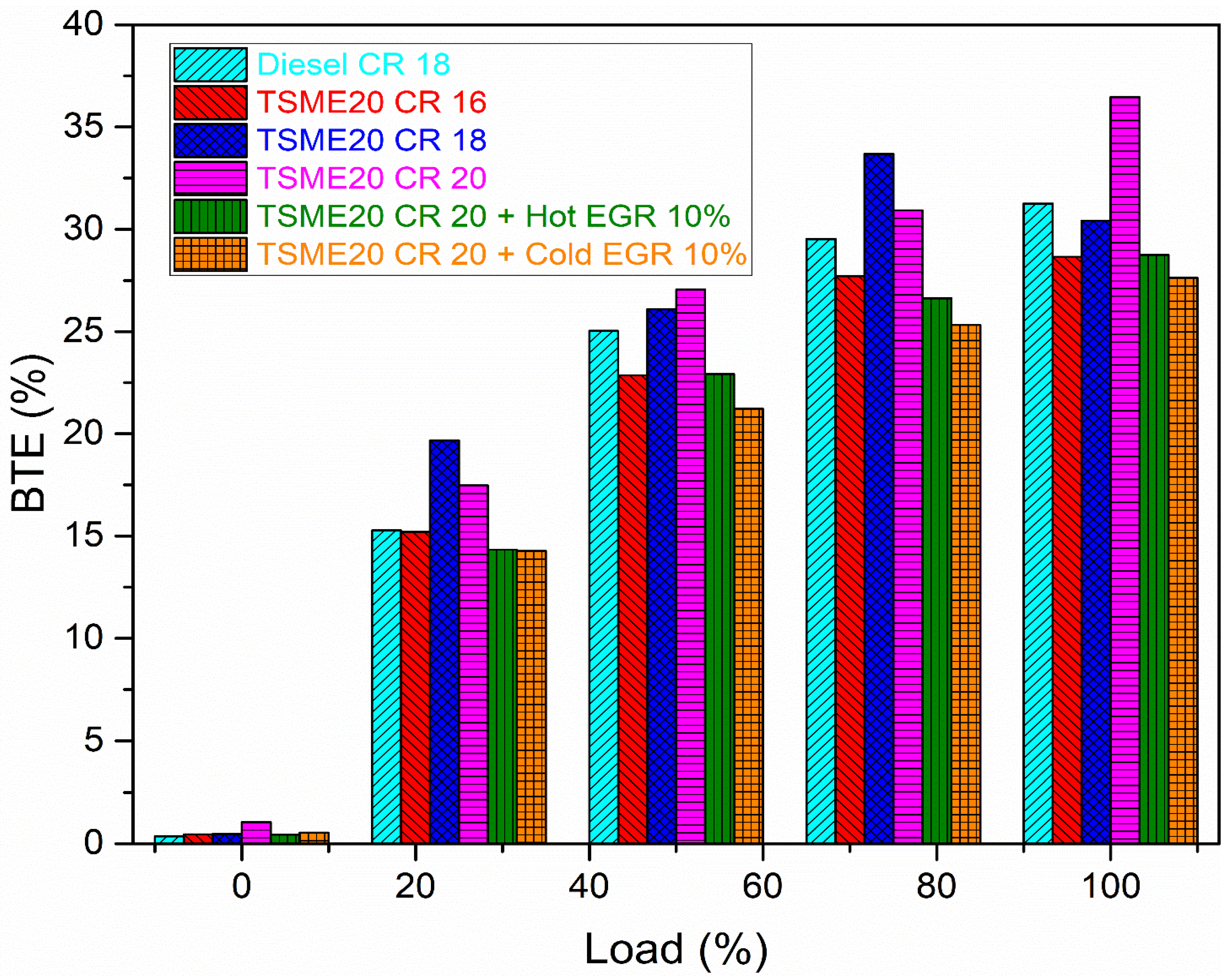

4.2. Brake Thermal Efficiency (BTE)

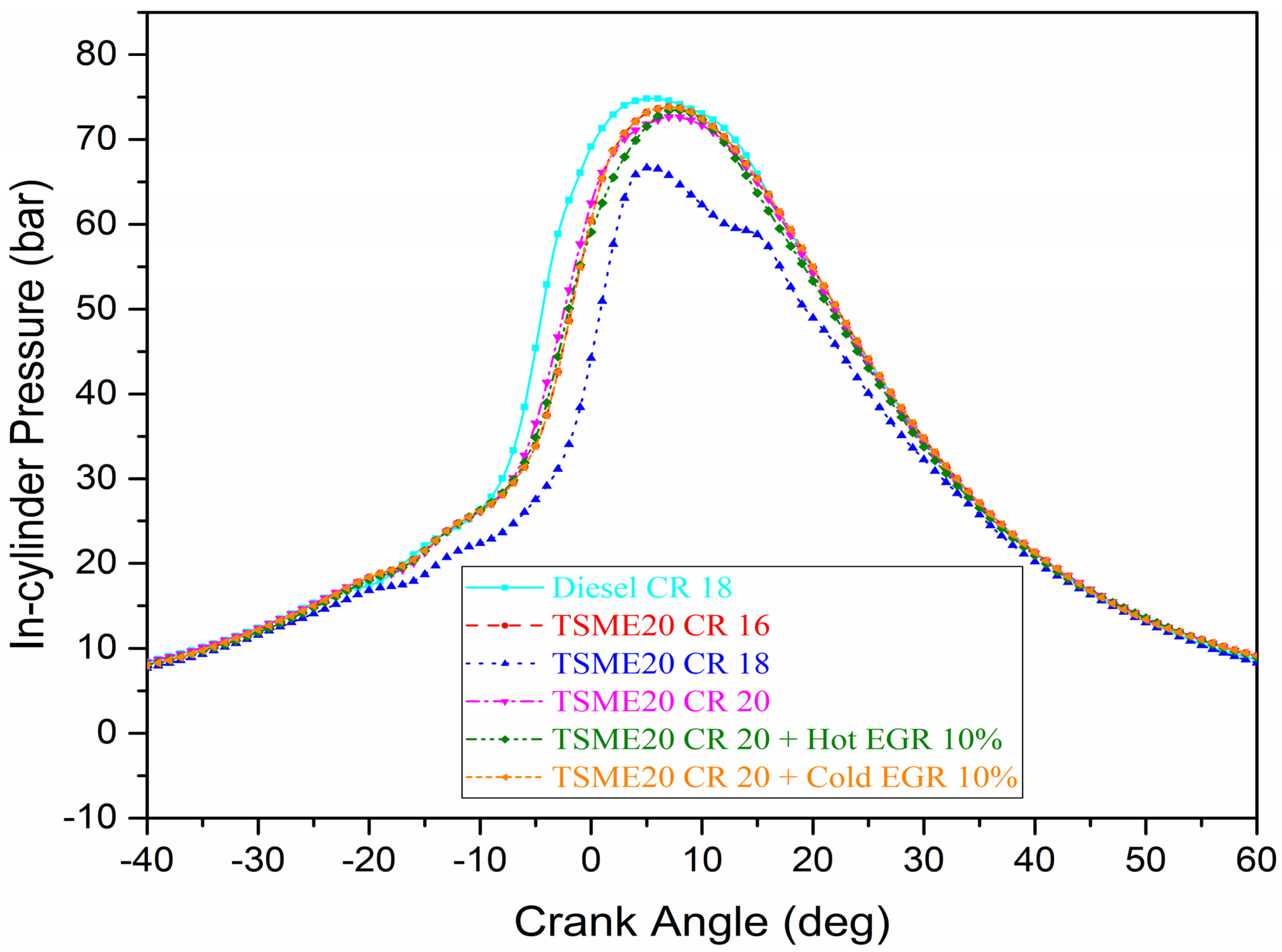

4.3. In-Cylinder Pressure

4.4. Heat Release Rate (HRR)

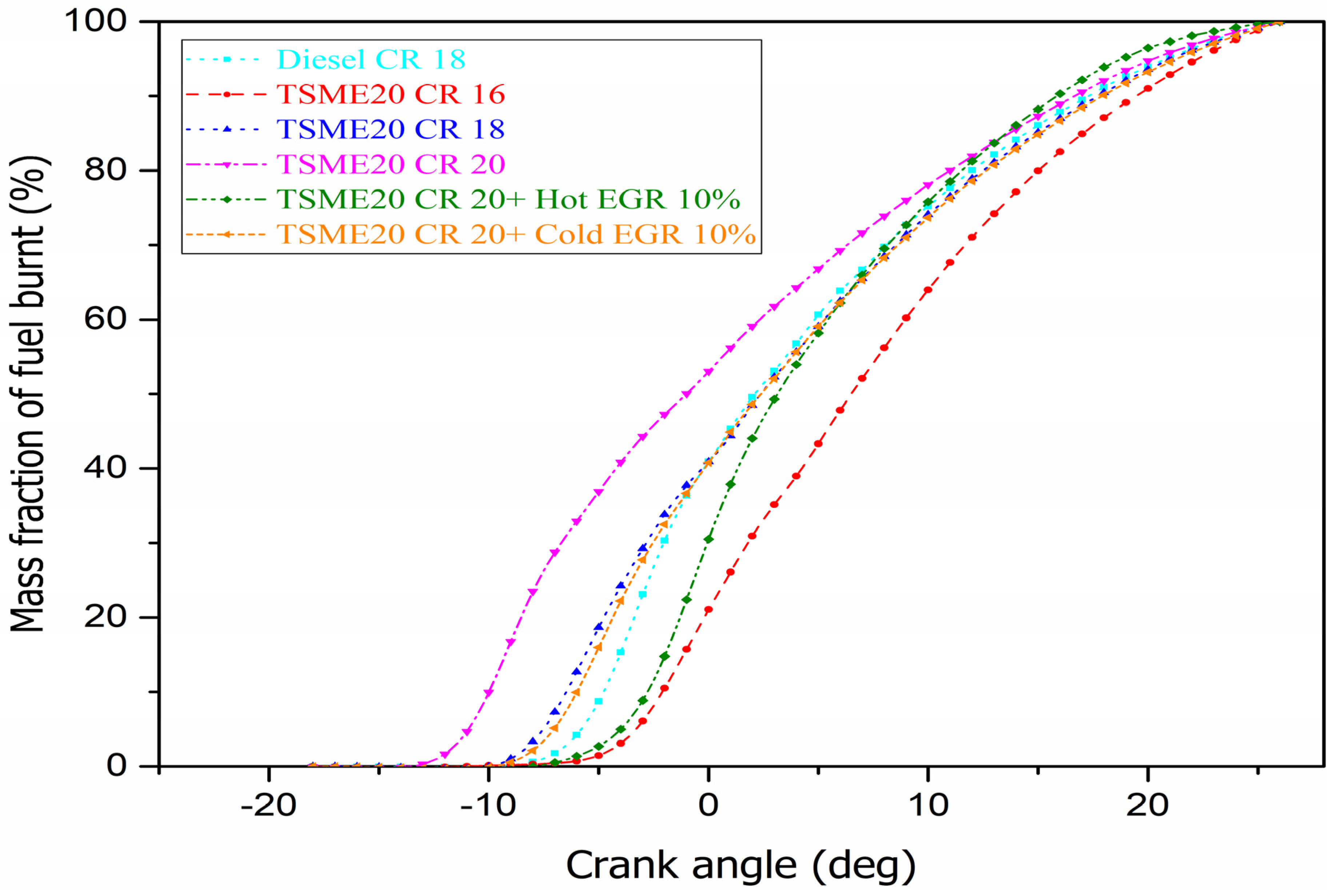

4.5. Mass Fraction of Fuel Burnt (MFB)

4.6. CO Emission

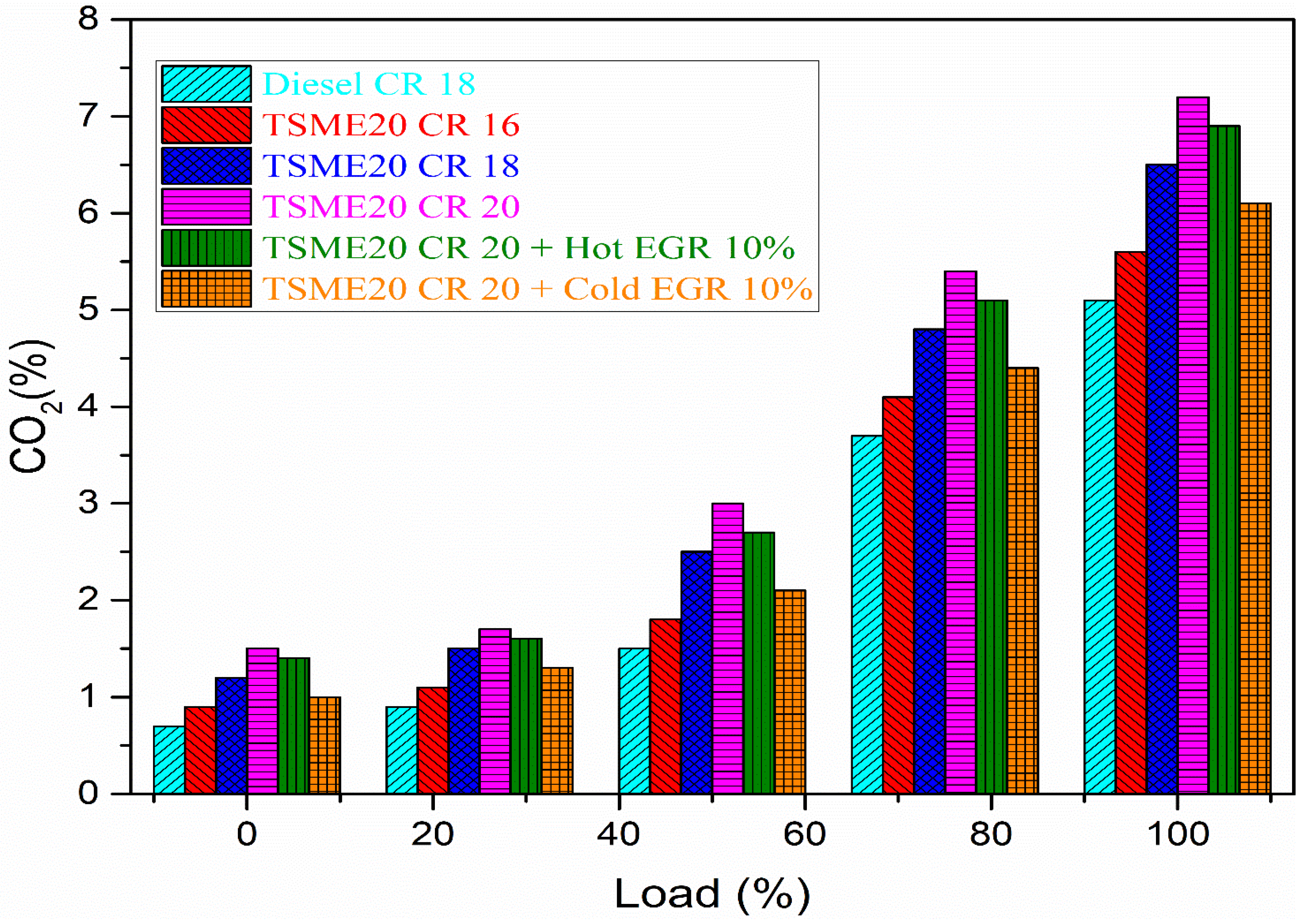

4.7. CO2 Emission

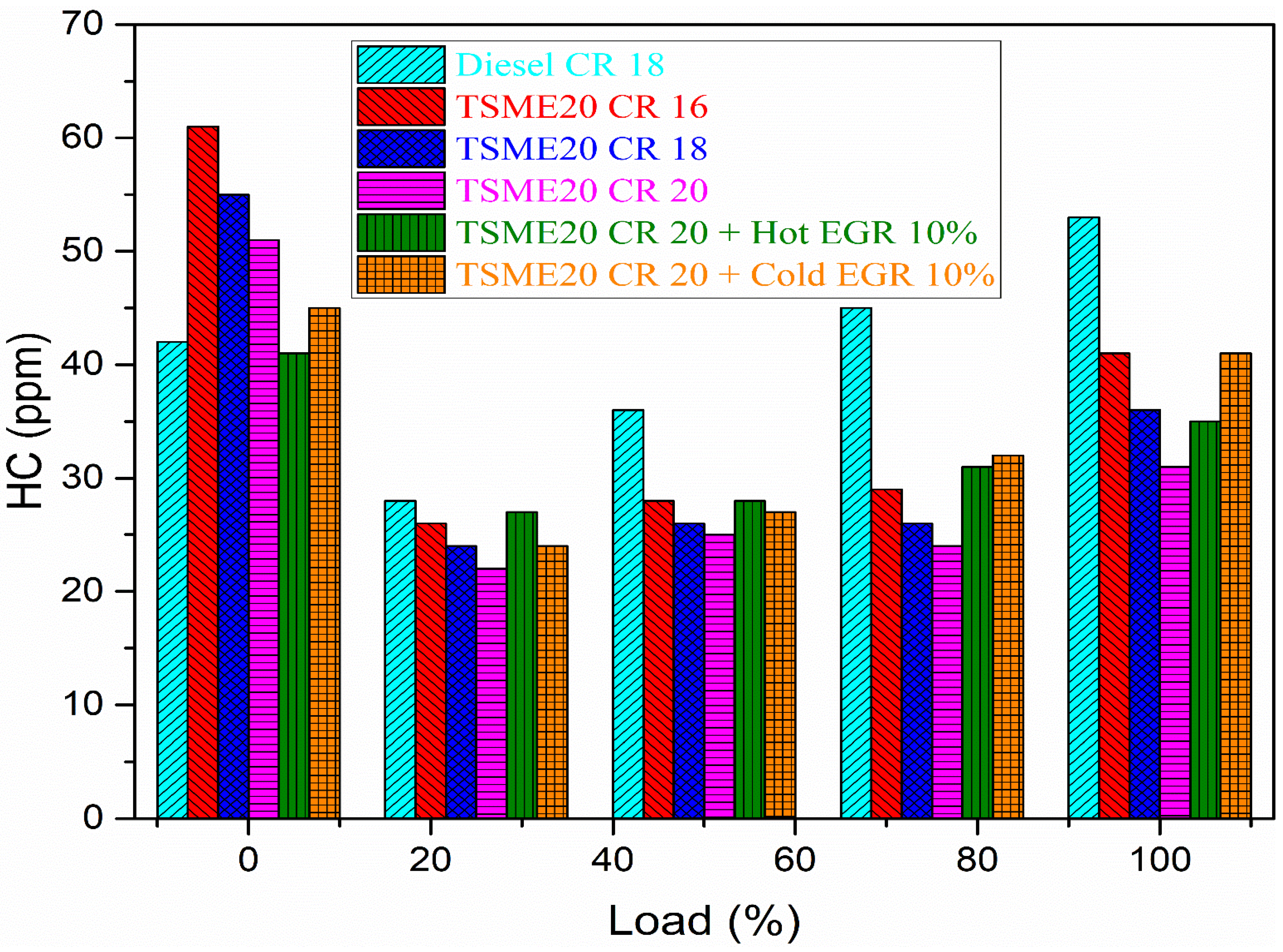

4.8. HC Emission

4.9. NOx Emission

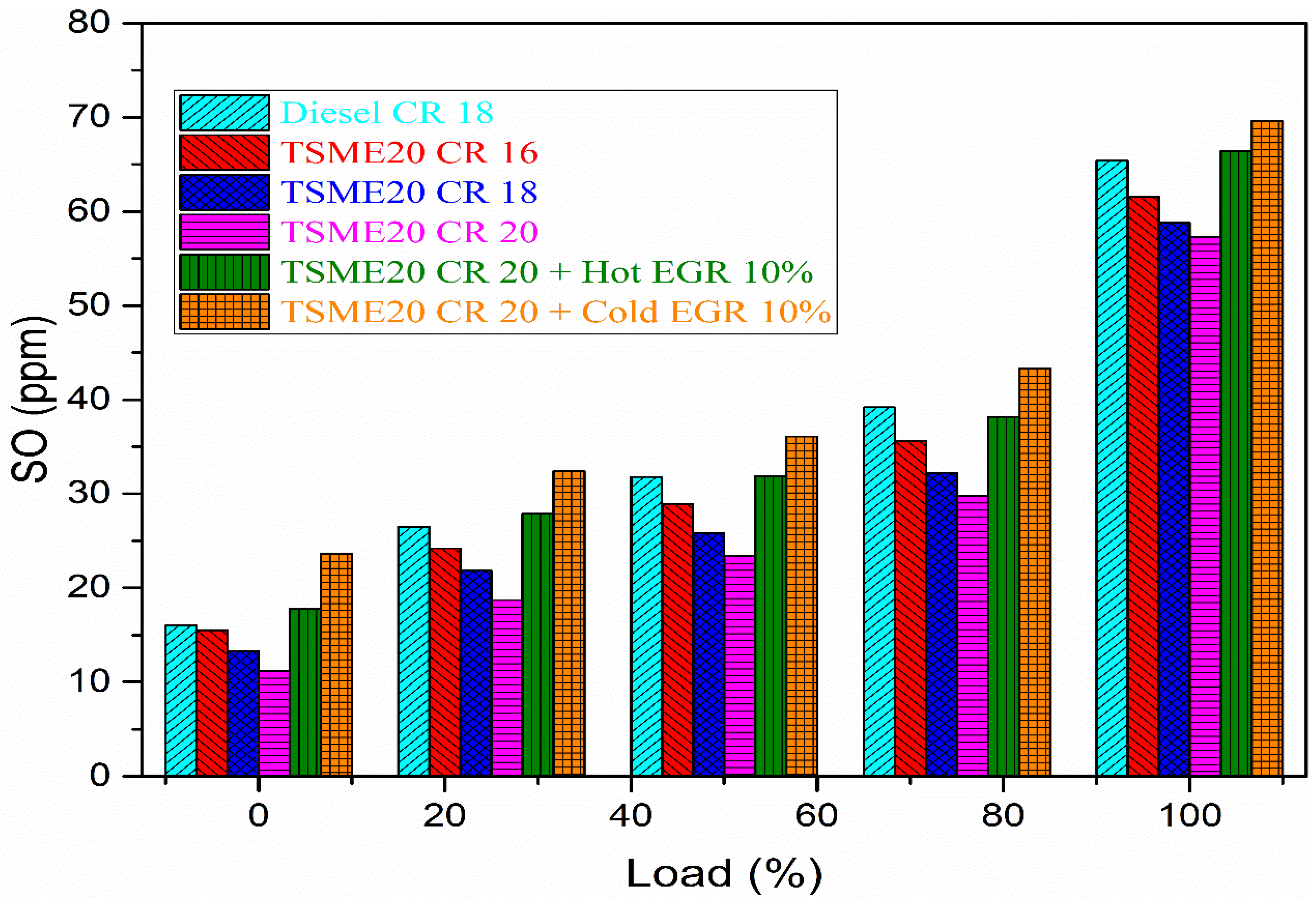

4.10. SO Emission

5. Conclusions

- ➢

- Tamarind biodiesel exhibits great potential as a viable source of biodiesel. Abundantly available at minimal cost, it holds the promise of being readily scalable for large-scale production.

- ➢

- Among the different compression ratios tested for the TSME20 blend, the CR20 configuration demonstrates the highest brake thermal efficiency (BTE) at 36.46%. Comparative analysis reveals a marginal decrease in BTE due to the implementation of EGR.

- ➢

- At higher compression ratios, the CRDI engine operating with TSME20 shows a significant decrease in fuel consumption, HC, and CO emissions. However, CO2 and NOx emissions were found to increase due to higher in-cylinder temperature at a higher compression ratio.

- ➢

- The introduction of cold EGR at a 10% rate proves effective in mitigating in-cylinder combustion temperatures to a sufficient degree. In comparison to the utilization of hot EGR, employing cold EGR at 10% in conjunction with the TSME20 blend demonstrates the capacity to significantly lower emissions of CO, CO2, and NOx. However, these approaches have to compromise on elevated emissions of HC and SO.

- ➢

- At the peak load condition, the combustion traits exhibited by the TSME20 blend, specifically, the heat release rate (HRR) and combustion pressure (CP), closely resemble the conventional diesel fuel when the engine is operated at a compression ratio of 18.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| BTE | Brake Thermal Efficiency |

| BSFC | Brake Specific Fuel Consumption |

| BP | Brake Power |

| IT | Injection Timing |

| EGR | Exhaust Gas Recirculation |

| CR | Compression Ratio |

| CP | Cylinder Pressure |

| HRR | Heat Release Rate |

| CO | Carbon monoxide |

| HC | Hydrocarbon |

| SO | Smoke Opacity |

| NOx | Nitrogen Oxides |

| bTDC | Before Top Dead Centre |

| TSME 20 | 20% Tamarind Seed Methyl Ester + 80% diesel |

| TSME 20 CR 16 | TSME 20 with compression ratio 16 |

| TSME 20 CR 18 | TSME 20 with compression ratio 18 |

| TSME 20 CR 20 | TSME 20 with compression ratio 20 |

| TSME 20 CR 20 + Hot EGR 10% | TSME 20 with compression ratio 20 with 10% Hot exhaust gas recirculation |

| TSME 20 CR 20 + Cold EGR 10% | TSME 20 with compression ratio 20 with 10% Cold exhaust gas recirculation |

References

- Khounani, Z.; Abdul Razak, N.N.; Hosseinzadeh-Bandbafha, H.; Madadi, M.; Sun, F.; Fattah, I.M.R.; Karimi, K.; Gupta, V.K.; Aghbashlo, M.; Tabatabaei, M. Assessing the environmental impacts of furfural production in a poplar wood biorefinery: A study on the role of mannitol concentration and catalyst type. Ind. Crops Prod. 2023, 203, 117230. [Google Scholar] [CrossRef]

- Ejaz, A.; Babar, H.; Ali, H.M.; Jamil, F.; Janjua, M.M.; Fattah, I.M.R.; Said, Z.; Li, C. Concentrated photovoltaics as light harvesters: Outlook, recent progress, and challenges. Sustain. Energy Technol. Assess. 2021, 46, 101199. [Google Scholar] [CrossRef]

- Santhosh, N.; Afzal, A.; Ağbulut, Ü.; Alahmadi, A.A.; Gowda, A.C.; Alwetaishi, M.; Shaik, S.; Hoang, A.T. Poultry fat biodiesel as a fuel substitute in diesel-ethanol blends for DI-CI engine: Experimental, modeling and optimization. Energy 2023, 270, 126826. [Google Scholar]

- Sarıdemir, S.; Ağbulut, Ü. Combustion, performance, vibration and noise characteristics of cottonseed methyl ester–diesel blends fuelled engine. Biofuels 2019, 13, 201–210. [Google Scholar] [CrossRef]

- Ong, H.C.; Tiong, Y.W.; Goh, B.H.H.; Gan, Y.Y.; Mofijur, M.; Fattah, I.M.R.; Chong, C.T.; Alam, M.A.; Lee, H.V.; Silitonga, A.S.; et al. Recent advances in biodiesel production from agricultural products and microalgae using ionic liquids: Opportunities and challenges. Energy Convers. Manag. 2021, 228, 113647. [Google Scholar] [CrossRef]

- Hoang, A.T.; Ong, H.C.; Fattah, I.M.R.; Chong, C.T.; Cheng, C.K.; Sakthivel, R.; Ok, Y.S. Progress on the lignocellulosic biomass pyrolysis for biofuel production toward environmental sustainability. Fuel Process. Technol. 2021, 223, 106997. [Google Scholar] [CrossRef]

- Fattah, I.M.R.; Ong, H.C.; Mahlia, T.M.I.; Mofijur, M.; Silitonga, A.S.; Rahman, S.M.A.; Ahmad, A. State of the Art of Catalysts for Biodiesel Production. Front. Energy Res. 2020, 8, 101. [Google Scholar] [CrossRef]

- Yunus Khan, T.M.; Atabani, A.E.; Badruddin, I.A.; Ankalgi, R.F.; Mainuddin Khan, T.K.; Badarudin, A. Ceiba pentandra, Nigella sativa and their blend as prospective feedstocks for biodiesel. Ind. Crops Prod. 2015, 65, 367–373. [Google Scholar] [CrossRef]

- Elkelawy, M.; Bastawissi, H.A.-E.; Esmaeil, K.K.; Radwan, A.M.; Panchal, H.; Sadasivuni, K.K.; Suresh, M.; Israr, M. Maximization of biodiesel production from sunflower and soybean oils and prediction of diesel engine performance and emission characteristics through response surface methodology. Fuel 2020, 266, 117072. [Google Scholar] [CrossRef]

- Dharma, S.; Hassan, M.H.; Ong, H.C.; Sebayang, A.H.; Silitonga, A.S.; Kusumo, F.; Milano, J. Experimental study and prediction of the performance and exhaust emissions of mixed Jatropha curcas-Ceiba pentandra biodiesel blends in diesel engine using artificial neural networks. J. Clean. Prod. 2017, 164, 618–633. [Google Scholar] [CrossRef]

- Kumar, M.S.; Prabhahar, M.; Sendilvelan, S.; Singh, S.; Venkatesh, R.; Bhaskar, K. Combustion, performance and emission analysis of a diesel engine fueled with methyl esters of Jatropha and fish oil with exhaust gas recirculation. Energy Procedia 2019, 160, 404–411. [Google Scholar] [CrossRef]

- Kader, M.; Islam, M.; Parveen, M.; Haniu, H.; Takai, K. Pyrolysis decomposition of tamarind seed for alternative fuel. Bioresour. Technol. 2013, 149, 1–7. [Google Scholar] [CrossRef] [PubMed]

- El-Adawy, M.; El-Kasaby, M.; Eldrainy, Y.A. Performance characteristics of a supercharged variable compression ratio diesel engine fueled by biodiesel blends. Alex. Eng. J. 2018, 57, 3473–3482. [Google Scholar] [CrossRef]

- Kathirvel, S.; Layek, A.; Muthuraman, S. Performance characteristics of CI engine using blends of waste cooking oil methyl ester, ethanol and diesel. Int. J. Ambient. Energy 2020, 41, 570–581. [Google Scholar] [CrossRef]

- Bala Prasad, K.; Dhana Raju, V.; Ahamad Shaik, A.; Gopidesi, R.K.; Sreekara Reddy, M.B.S.; Soudagar, M.E.M.; Mujtaba, M.A. Impact of injection timings and exhaust gas recirculation rates on the characteristics of diesel engine operated with neat tamarind biodiesel. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–19. [Google Scholar] [CrossRef]

- Rosha, P.; Mohapatra, S.K.; Mahla, S.K.; Cho, H.; Chauhan, B.S.; Dhir, A. Effect of compression ratio on combustion, performance, and emission characteristics of compression ignition engine fueled with palm (B20) biodiesel blend. Energy 2019, 178, 676–684. [Google Scholar] [CrossRef]

- Nanthagopal, K.; Ashok, B.; Raj, R.T.K. Influence of fuel injection pressures on Calophyllum inophyllum methyl ester fuelled direct injection diesel engine. Energy Convers. Manag. 2016, 116, 165–173. [Google Scholar] [CrossRef]

- Anbarasu, A.; Karthikeyan, A. Effect of injection pressure on the performance and emission characteristics of CI engine using canola emulsion fuel. Int. J. Ambient. Energy 2017, 38, 314–319. [Google Scholar] [CrossRef]

- Mohiuddin, K.; Kwon, H.; Choi, M.; Park, S. Effect of engine compression ratio, injection timing, and exhaust gas recirculation on gaseous and particle number emissions in a light-duty diesel engine. Fuel 2021, 294, 120547. [Google Scholar] [CrossRef]

- Shi, X.; Liu, B.; Zhang, C.; Hu, J.; Zeng, Q. A study on combined effect of high EGR rate and biodiesel on combustion and emission performance of a diesel engine. Appl. Therm. Eng. 2017, 125, 1272–1279. [Google Scholar] [CrossRef]

- Kumar, V.; Mahla, S.K. Influence of EGR on a CI engine running on 20% blend of jatropha biodiesel. Mater. Today Proc. 2021, 43, 273–280. [Google Scholar]

- Damodharan, D.; Sathiyagnanam, A.P.; Rajesh Kumar, B.; Ganesh, K.C. Cleaner emissions from a DI diesel engine fueled with waste plastic oil derived from municipal solid waste under the influence of n-pentanol addition, cold EGR, and injection timing. Environ. Sci. Pollut. Res. 2018, 25, 13611–13625. [Google Scholar] [CrossRef] [PubMed]

- Patil, V.; Thirumalini, S. Effect of cooled EGR on performance and emission characteristics of diesel engine with diesel and diesel-karanja blend. Mater. Today Proc. 2021, 46, 4720–4727. [Google Scholar] [CrossRef]

- Deka, M.; Mahanta, P.K.; Choudhury, N.D. Effect of EGR on Performance and Emission Characteristics of a Diesel Engine Fueled with Yellow Oleander Seed Oil Biodiesel. In Advances in Thermofluids and Renewable Energy: Select Proceedings of TFRE 2020; Springer: Singapore, 2020; pp. 351–363. [Google Scholar]

- Pan, M.; Huang, R.; Liao, J.; Ouyang, T.; Zheng, Z.; Lv, D.; Huang, H. Effect of EGR dilution on combustion, performance and emission characteristics of a diesel engine fueled with n-pentanol and 2-ethylhexyl nitrate additive. Energy Convers. Manag. 2018, 176, 246–255. [Google Scholar] [CrossRef]

- Kumar, P.V.; Ashok, B.; Vignesh, R.; Bhasker, J.P.; Kumar, A.N. Evaluation of performance, emissions and combustion attributes of CI engine using palmyra biodiesel blend with distinct compression ratios, EGR rates and nano-particles. Fuel 2022, 321, 124092. [Google Scholar] [CrossRef]

- Esakki, T.; Rangaswamy, S.M.; Jayabal, R. An experimental study on biodiesel production and impact of EGR in a CRDI diesel engine propelled with leather industry waste fat biodiesel. Fuel 2022, 321, 123995. [Google Scholar] [CrossRef]

- Kumar, B.R.; Saravanan, S.; Rana, D.; Nagendran, A. Combined effect of injection timing and exhaust gas recirculation (EGR) on performance and emissions of a DI diesel engine fuelled with next-generation advanced biofuel–diesel blends using response surface methodology. Energy Convers. Manag. 2016, 123, 470–486. [Google Scholar] [CrossRef]

- De Poures, M.V.; Dillikannan, D.; Kaliyaperumal, G.; Thanikodi, S.; Ağbulut, Ü.; Hoang, A.T.; Mahmoud, Z.; Shaik, S.; Saleel, C.A.; Afzal, A. Collective influence and optimization of 1-hexanol, fuel injection timing, and EGR to control toxic emissions from a light-duty agricultural diesel engine fueled with diesel/waste cooking oil methyl ester blends. Process Saf. Environ. Prot. 2023, 172, 738–752. [Google Scholar] [CrossRef]

- Jayanth, B.V.; Depoures, M.V.; Kaliyaperumal, G.; Dillikannan, D.; Jawahar, D.; Palani, K.; Shivappa, G.P.M. A comprehensive study on the effects of multiple injection strategies and exhaust gas recirculation on diesel engine characteristics that utilize waste high density polyethylene oil. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–18. [Google Scholar] [CrossRef]

- Sajjad, M.O.A.; Sathish, T.; Saravanan, R.; Asif, M.; Linul, E.; Ağbulut, Ü. Combustion, performance and emission discussion of soapberry seed oil methyl ester blends and exhaust gas recirculation in common rail direct fuel injection system. Energy 2023, 278, 127763. [Google Scholar] [CrossRef]

- Sajjad, M.O.A.; Sathish, T.; Rajasimman, M.; Praveenkumar, T. Experimental evaluation of soapberry seed oil biodiesel performance in CRDI diesel engine. Sci. Rep. 2023, 13, 5699. [Google Scholar] [CrossRef]

- Kulandaivel, D.; Rahamathullah, I.; Sathiyagnanam, A.; Gopal, K.; Damodharan, D. Effect of retarded injection timing and EGR on performance, combustion and emission characteristics of a CRDi diesel engine fueled with WHDPE oil/diesel blends. Fuel 2020, 278, 118304. [Google Scholar] [CrossRef]

- Rao, G.P.; Prasad, L.S.V. Combined influence of compression ratio and exhaust gas recirculation on the diverse characteristics of the diesel engine fueled with novel palmyra biodiesel blend. Energy Convers. Manag. X 2022, 14, 100185. [Google Scholar]

- Kim, T.; Park, J.; Cho, H. Emission characteristics under diesel and biodiesel fueled compression ignition engine with various injector holes and EGR conditions. Energies 2020, 13, 2973. [Google Scholar] [CrossRef]

- Jaliliantabar, F.; Ghobadian, B.; Carlucci, A.P.; Najafi, G.; Mamat, R.; Ficarella, A.; Strafella, L.; Santino, A.; De Domenico, S. A comprehensive study on the effect of pilot injection, EGR rate, IMEP and biodiesel characteristics on a CRDI diesel engine. Energy 2020, 194, 116860. [Google Scholar] [CrossRef]

- Stel, H.; Ofuchi, E.M.; Chiva, S.; Morales, R.E.M. Numerical assessment of performance characteristics and two-phase flow dynamics of a centrifugal rotor operating under gas entrainment condition. Exp. Comput. Multiph. Flow 2022, 4, 221–240. [Google Scholar] [CrossRef]

- Veza, I.; Afzal, A.; Mujtaba, M.A.; Tuan Hoang, A.; Balasubramanian, D.; Sekar, M.; Fattah, I.M.R.; Soudagar, M.E.M.; El-Seesy, A.I.; Djamari, D.W.; et al. Review of artificial neural networks for gasoline, diesel and homogeneous charge compression ignition engine. Alex. Eng. J. 2022, 61, 8363–8391. [Google Scholar] [CrossRef]

- Atmanli, A.; Ileri, E.; Yilmaz, N. Optimization of diesel–butanol–vegetable oil blend ratios based on engine operating parameters. Energy 2016, 96, 569–580. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, T.; Huang, X. Predicting real-time fire heat release rate by flame images and deep learning. Proc. Combust. Inst. 2023, 39, 4115–4123. [Google Scholar] [CrossRef]

- Zhou, T.; Tang, P.; Ye, T. Machine learning based heat release rate indicator of premixed methane/air flame under wide range of equivalence ratio. Energy 2023, 263, 126103. [Google Scholar] [CrossRef]

- Singh Pali, H.; Sharma, A.; Kumar, M.; Anand Annakodi, V.; Nhanh Nguyen, V.; Kumar Singh, N.; Singh, Y.; Balasubramanian, D.; Deepanraj, B.; Hai Truong, T.; et al. Enhancement of combustion characteristics of waste cooking oil biodiesel using TiO2 nanofluid blends through RSM. Fuel 2023, 331, 125681. [Google Scholar] [CrossRef]

- Ouchikh, S.; Lounici, M.S.; Tarabet, L.; Loubar, K.; Tazerout, M. Effect of natural gas enrichment with hydrogen on combustion characteristics of a dual fuel diesel engine. Int. J. Hydrog. Energy 2019, 44, 13974–13987. [Google Scholar] [CrossRef]

- Azad, A.K.; Rasul, M.G.; Bhatt, C. Combustion and emission analysis of Jojoba biodiesel to assess its suitability as an alternative to diesel fuel. Energy Procedia 2019, 156, 159–165. [Google Scholar] [CrossRef]

- Huang, J.; Xiao, H.; Yang, X.; Guo, F.; Hu, X. Effects of methanol blending on combustion characteristics and various emissions of a diesel engine fueled with soybean biodiesel. Fuel 2020, 282, 118734. [Google Scholar] [CrossRef]

- Kaya, G. Experimental comparative study on combustion, performance and emissions characteristics of ethanol-gasoline blends in a two stroke uniflow gasoline engine. Fuel 2022, 317, 120917. [Google Scholar] [CrossRef]

- Kavitha, M.S.; Murugavelh, S. Optimization and transesterification of sterculia oil: Assessment of engine performance, emission and combustion analysis. J. Clean. Prod. 2019, 234, 1192–1209. [Google Scholar] [CrossRef]

- Hazar, H.; Telceken, T.; Sevinc, H. An experimental study on emission of a diesel engine fuelled with SME (safflower methyl ester) and diesel fuel. Energy 2022, 241, 122915. [Google Scholar] [CrossRef]

- Cengiz, C.; Unverdi, S.O. A CFD Study on the Effects of Injection Timing and Spray Inclusion Angle on Performance and Emission Characteristics of a DI Diesel Engine Operating in Diffusion-Controlled and PCCI Modes of Combustion. Energies 2023, 16, 2861. [Google Scholar] [CrossRef]

- Dhana Raju, V.; Nair, J.N.; Venu, H.; Subramani, L.M.; Soudagar, M.E.; Mujtaba, M.A.; Khan, T.M.Y.; Ismail, K.A.; Elfasakhany, A.; Yusuf, A.A.; et al. Combined assessment of injection timing and exhaust gas recirculation strategy on the performance, emission and combustion characteristics of algae biodiesel powered diesel engine. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 8554–8571. [Google Scholar] [CrossRef]

- Doppalapudi, A.T.; Azad, A.K.; Khan, M.M.K. Combustion chamber modifications to improve diesel engine performance and reduce emissions: A review. Renew. Sustain. Energy Rev. 2021, 152, 111683. [Google Scholar] [CrossRef]

- Mofijur, M.; Fattah, I.M.R.; Alam, M.A.; Islam, A.B.M.S.; Ong, H.C.; Rahman, S.M.A.; Najafi, G.; Ahmed, S.F.; Uddin, M.A.; Mahlia, T.M.I. Impact of COVID-19 on the social, economic, environmental and energy domains: Lessons learnt from a global pandemic. Sustain. Prod. Consum. 2021, 26, 343–359. [Google Scholar] [CrossRef] [PubMed]

- Ming, C.; Rizwanul Fattah, I.M.; Chan, Q.N.; Pham, P.X.; Medwell, P.R.; Kook, S.; Yeoh, G.H.; Hawkes, E.R.; Masri, A.R. Combustion characterization of waste cooking oil and canola oil based biodiesels under simulated engine conditions. Fuel 2018, 224, 167–177. [Google Scholar] [CrossRef]

- Frost, J.; Tall, A.; Sheriff, A.M.; Schönborn, A.; Hellier, P. An experimental and modelling study of dual fuel aqueous ammonia and diesel combustion in a single cylinder compression ignition engine. Int. J. Hydrogen Energy 2021, 46, 35495–35510. [Google Scholar] [CrossRef]

| Parameter | Fuel Blend | Operating Conditions | Inferences | References |

|---|---|---|---|---|

| Cold EGR of 10%, 20%, and 30% | 30% blend of waste plastic biodiesel | Ideal operating conditions | The application of EGR drastically reduced the NOx emissions. However, it enhances other emissions. | Damodharan et al. [22] |

| 15% cooled EGR | 20% Karanja biodiesel | CRDI diesel engine runs at normal conditions | Particulate matter reduces and slight increase in HC emissions | Patil and Thirumalini [23] |

| 15% hot EGR | Yellow Oleander biodiesel | Ideal operating conditions | NOx emissions were significantly reduced | Deka et al. [24] |

| 20% and 40% hot EGR | n-pentanol-2 ethylhexyl nitrate–diesel blends | Normal operating conditions of diesel engine | NOx and soot emissions are drastically reduced. However, a slight decrement in BTE | Pan et al. [25] |

| Type of Engine | Fuel Used | Engine Operating Parameter | Inferences | References |

|---|---|---|---|---|

| Direct Injection diesel engine | Diesel-biodiesel-1-hexanol | Fuel Injection Timing and EGR | Improved BTE with advanced fuel injection timing and significant reduction of NOx emissions with EGR | De Poures et al. [29] |

| CRDI diesel engine | Waste high-density polyethylene oil | Multiple injection timing and EGR | Improved HRR and CP NOx and smoke emissions were reduced; a slight increment in BTE | Jayanth et al. [30] |

| CRDI diesel engine | Soapberry seed oil methyl ester | EGR variation from 10% to 30% | Drastic reduction of NOx emissions | Sajjad et al. [31] |

| Single cylinder water cooled diesel engine | 20% Palmyra biodiesel | Compression ratio 20 and EGR 10% | Higher BTE, lower CO, HC smoke and NOx emissions | Rao and Prasad [34] |

| CRDI diesel engine | 20% biodiesel blend | Number of nozzles and EGR | Effectively reduced HC and NOx emissions | Kim et al. [35] |

| CRDI diesel engine | Waste cooking biodiesel | Pilot fuel injection and EGR | Higher HC and CO emissions. However, NOx emissions were reduced | Jaliliantabar et al. [36] |

| Parameter | Range of Parameters |

|---|---|

| Reaction temperature | 60–300 °C |

| Molar ratio | 5:1–40:1 |

| Pressure | 1–300 bar |

| Catalyst content | 0.5–5% |

| Reaction time | 1–360 min |

| Properties | Diesel | TSME | TSME20 | Test Method |

|---|---|---|---|---|

| Viscosity (cSt) | 3.06 | 7.26 | 3.91 | ASTMD 445 |

| Density(kg/m3) | 830 | 882 | 840 | ASTMD 1298 |

| Calorific value (MJ/kg) | 42.5 | 38.76 | 41.76 | ASTMD 4809 |

| Flash point (°C) | 53 | 156 | 71 | ASTMD 93 |

| Fire point (°C) | 58 | 161 | 75 | ASTMD 93 |

| Cetane number | 45 | 52 | 46 | ASTMD 613 |

| Engine Type | Kirloskar, CRDI Diesel Engine |

|---|---|

| Rated speed/power | 1500 rpm/4.4 kW |

| Engine bore | 87.5 mm |

| Stroke length | 110 mm |

| No. on nozzles | 03 |

| Nozzle size | 0.3 mm |

| Injection timing | 23° CA bTDC |

| Combustion geometry | Hemispherical |

| Instrument | Parameter | Uncertainty | Accuracy |

|---|---|---|---|

| AVL gas analyser | HC | ±0.2% | ±2 ppm |

| CO | ±0.2% | ±0.03% | |

| CO2 | ±0.15% | ±0.5% | |

| NOX | ±1% | ±10 ppm | |

| O2 | ±0.5% | ±0.1% | |

| AVL smoke meter | SO | ±1% | ±1% |

| Temperature indicator | T | ±0.2% | ±1 °C |

| Pressure transducer | P | ±0.15% | ±0.1 bar |

| Angle encoder | CA | ±0.2% | ±1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raju, V.D.; Veza, I.; Venu, H.; Soudagar, M.E.M.; Kalam, M.A.; Ahamad, T.; Appavu, P.; Nair, J.N.; Rahman, S.M.A. Comprehensive Analysis of Compression Ratio, Exhaust Gas Recirculation, and Pilot Fuel Injection in a Diesel Engine Fuelled with Tamarind Biodiesel. Sustainability 2023, 15, 15222. https://doi.org/10.3390/su152115222

Raju VD, Veza I, Venu H, Soudagar MEM, Kalam MA, Ahamad T, Appavu P, Nair JN, Rahman SMA. Comprehensive Analysis of Compression Ratio, Exhaust Gas Recirculation, and Pilot Fuel Injection in a Diesel Engine Fuelled with Tamarind Biodiesel. Sustainability. 2023; 15(21):15222. https://doi.org/10.3390/su152115222

Chicago/Turabian StyleRaju, Vallapudi Dhana, Ibham Veza, Harish Venu, Manzoore Elahi M. Soudagar, M. A. Kalam, Tansir Ahamad, Prabhu Appavu, Jayashri N. Nair, and S. M. Ashrafur Rahman. 2023. "Comprehensive Analysis of Compression Ratio, Exhaust Gas Recirculation, and Pilot Fuel Injection in a Diesel Engine Fuelled with Tamarind Biodiesel" Sustainability 15, no. 21: 15222. https://doi.org/10.3390/su152115222

APA StyleRaju, V. D., Veza, I., Venu, H., Soudagar, M. E. M., Kalam, M. A., Ahamad, T., Appavu, P., Nair, J. N., & Rahman, S. M. A. (2023). Comprehensive Analysis of Compression Ratio, Exhaust Gas Recirculation, and Pilot Fuel Injection in a Diesel Engine Fuelled with Tamarind Biodiesel. Sustainability, 15(21), 15222. https://doi.org/10.3390/su152115222