1. Introduction

Laser powder bed fusion (LPBF), electron beam melting (EBM), and directed energy deposition (DED) are powder-based additive manufacturing (AM) techniques revolutionising the production of metallic components. LPBF employs a high-energy laser to selectively melt layers of metal powder, enabling intricate and precise part fabrication with minimal waste. EBM utilises an electron beam to melt metal powder in a vacuum, offering excellent material properties and a reduced risk of contamination [

1]. DED, on the other hand, involves a focused laser beam to create molten metal, which is then deposited layer by layer onto a substrate, facilitating repairs, coatings, and the production of large-scale components [

2]. These techniques collectively empower industries to create intricate and customised metal parts with enhanced design flexibility and potential for sustainable manufacturing practices [

3].

Powder-based AM techniques display environmental benefits compared to traditional manufacturing methods such as casting and forging. This is especially because, since its inception, AM has significantly reduced the use of waste material [

4]. Traditional manufacturing methods often generate waste such as scrap metal during production, whereas 3D AM produces less waste since it only uses the material needed to produce the part, reducing environmental impact. One of the key benefits of AM over conventional manufacturing techniques is its ability to apply freedom of design, which is crucial for part optimisation, compared to the traditional manufacturing methods, where the geometries that can be produced are limited by the design constraints of the tooling used [

5]. AM also permits on-demand production. This reduces CO

emissions related to long transit routes and storage facilities in addition to saving production time [

6,

7].

With growing concerns about environmental impact and resource utilisation, the adoption of AM technology has gained prominence as a means to align production methods with sustainability objectives. The concept of sustainable manufacturing underscores the idea of carrying out industrial activities with minimal harm to the environment and ensuring the continuity of these practices without jeopardising the future. AM is identified as a technology that aligns with the sustainability goals by not only optimising resource consumption but also presenting opportunities for enhanced product design, reduced waste generation, and improved overall efficiency [

8]. Companies are under increasing pressure to provide transparency in their product sourcing and manufacturing processes. This requirement for transparency aligns with the growing emphasis on sustainability and the need to assess a product’s total energy usage and overall environmental impact [

9].

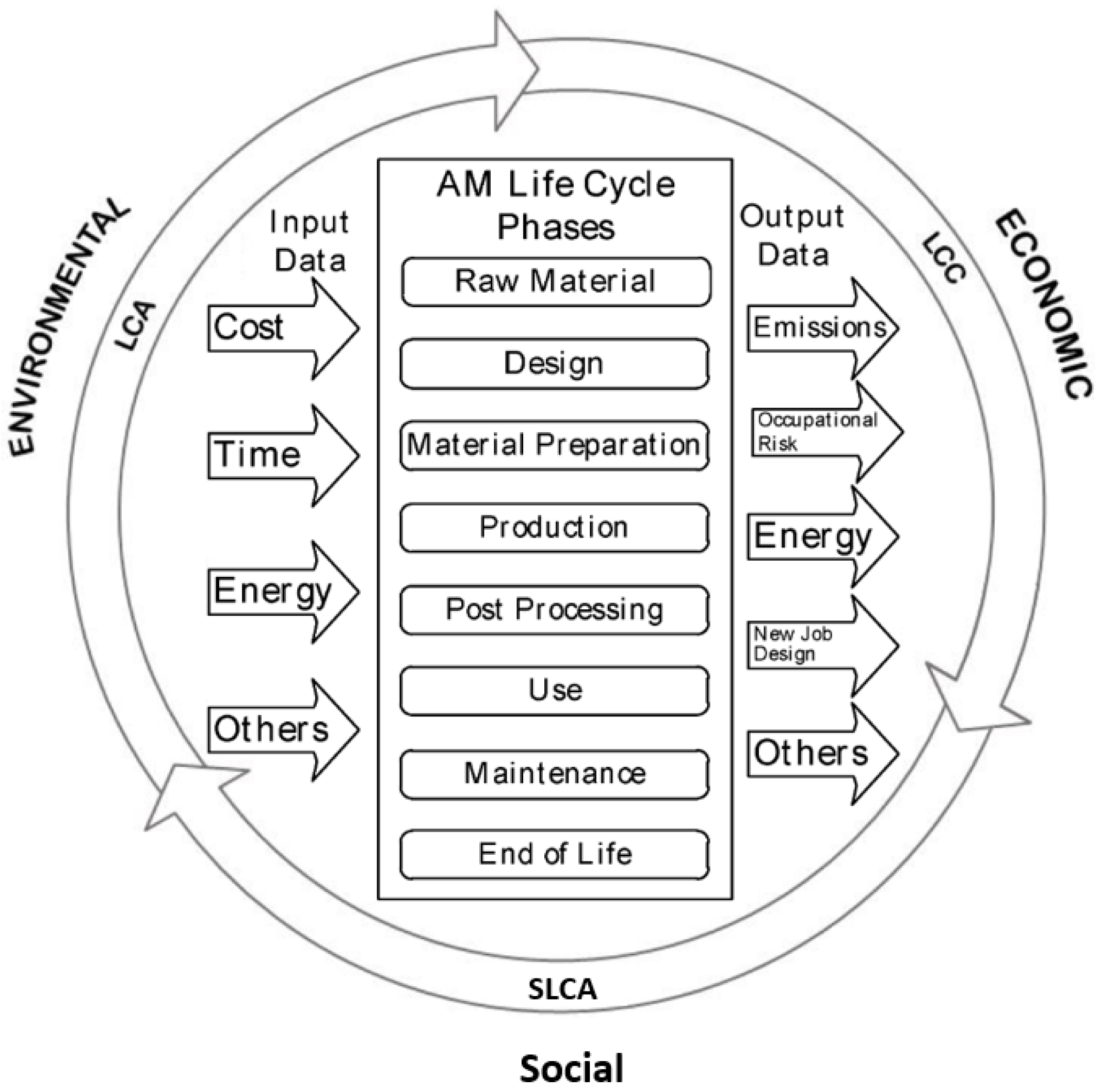

The environmental, economic, and social impact of new products should always be taken into account. These three main sustainability aspects are illustrated in

Figure 1. The life cycle assessment (LCA) method is essential for evaluating environmental effects. LCA examines a product’s impact throughout its whole life cycle, “from cradle to grave”, starting with the processing of its raw materials and ending with the waste in products [

10]. The economic and social impacts of AM can be investigated via life cycle costing (LCC) and social life cycle assessment (SLCA) concepts [

11].

The purpose of this study is to provide an overview of the key and impending research challenges of designing sustainable alloys for powder-based AM. To this end, sustainability concepts of powder-based AM techniques for the fabrication of metallic alloy parts are investigated and reported. In addition, a method to incorporate sustainability in the AM alloy design scheme is presented, as well as a new materials science paradigm to relate processing, microstructure, properties, sustainability, and performance.

2. Life Cycle Assessment

Similar to any other manufacturing process, AM involves considerations that, in contrast to conventional technologies, may result in some environmental advantages and cost savings but may also put strain on the environment. Simple comparisons show that AM technologies require fewer feedstock raw materials (metallic powder) than traditional production methods [

13]. Unique aspects of AM, such as topological optimisation, can provide the opportunity for a reduction in materials use by 35–65% compared to traditional manufacturing technologies [

14]. They also generate less scrap, which can be as high as a 70–90% reduction compared to traditional manufacturing [

15]. However, they might be more energy-intensive. For example, an aeronautical turbine only requires 5.9 h to be manufactured by milling, whereas electron beam melting (EBM) of the same component requires 15.6 h. Therefore, EBM consumes 25% more energy than milling [

16]. The evaluation of the potential environmental effects of AM begins with the extraction of raw materials and continues through the printing process, the service life of the final products, and the environmental impacts of the produced waste [

17].

LCA is a standardised approach that enables the evaluation of the inputs, outputs, and the potential environmental impacts of a product throughout its life cycle stages. LCA is appropriate for (1) finding opportunities to improve the environmental impact of products, processes, and services; (2) providing industry, policymakers, and other stakeholders with information gathering and decision support; and (3) comparing different processes, such as manufacturing techniques or recycling routes, to see how different product systems with the same function affect the environment [

18].

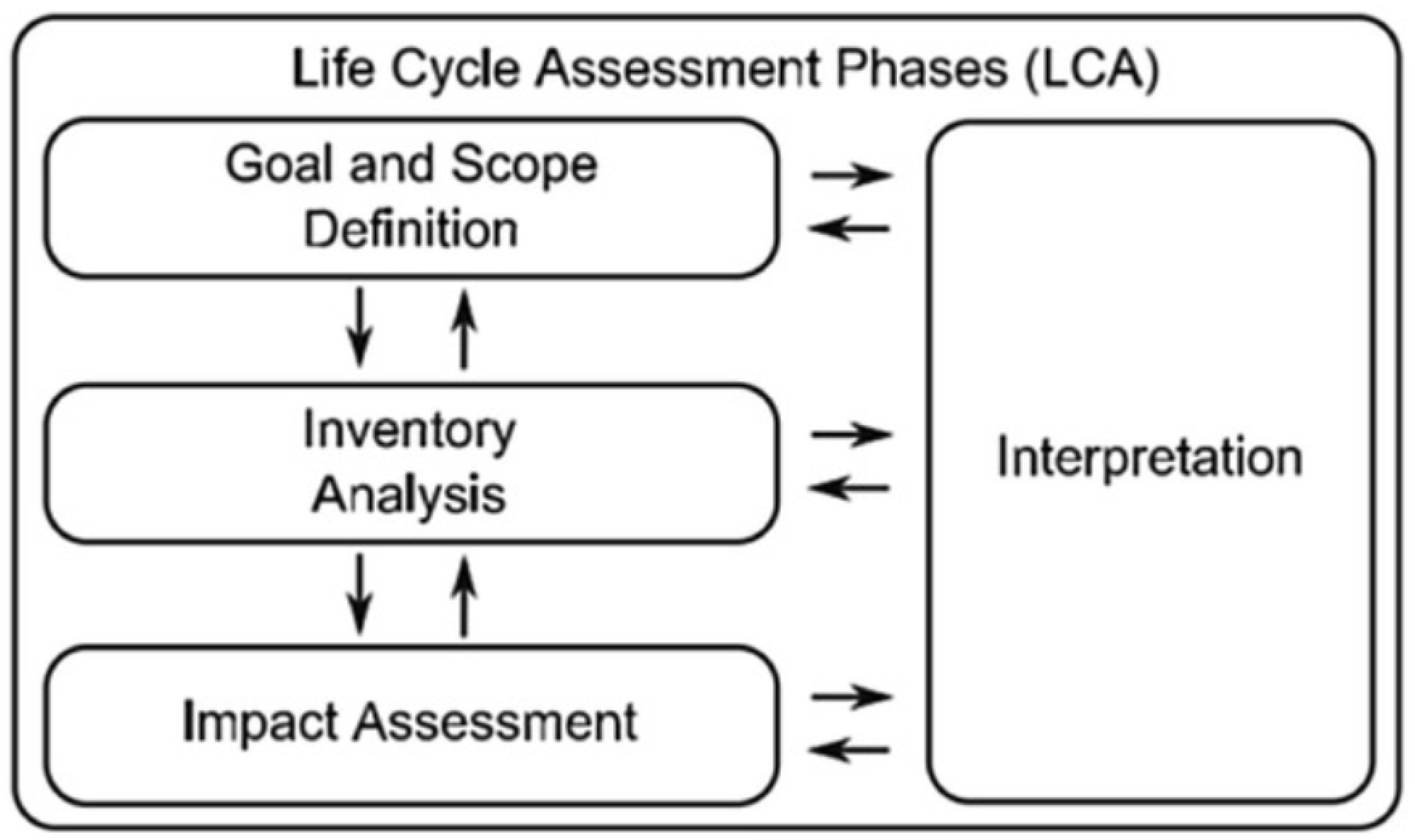

The four fundamental phases of an LCA are as follows (

Figure 2): (1) goal and scope definition, (2) life cycle inventory analysis, (3) life cycle impact assessment, and (4) interpretation of the results [

19]. The goal and scope definition aims at outlining the basic structure of the study and selecting the method for environmental impact assessment. It should also determine which unit processes must be included in the LCA, as outlined by the system boundary. A process flow diagram displaying the individual processes and how they interact is useful in describing the system.

The purpose of the life cycle inventory is to compile data on the processes that make up the product; this is then followed by an inventory of the inputs and outputs of the entire system. In this stage, the “cradle-to-grave” is modelled [

21] by incorporating the following steps: plotting a flowchart of the product system, gathering data, and computing an ecovector for the product as a result of an inventory analysis. The ecovector is a collection of information that shows the intensity of the product system’s use of the raw material resources as well as the amount of various substance emissions into the environment [

22]. An environmental profile is a set of data that is used to compute the environmental impacts that are represented as numerical values, or the outcomes of impact category indicators.

The application of the product’s ecovector to the derived values of impact category indicators is known as life cycle impact assessment. The classification and assignment of inventory data to the various impact categories constitute the initial stage of impact assessment. The outcome is a collection of impact category indicator results that are given in a range of precise values and units. The analysis of the results, the identification of important concerns, explaining the limitations, and providing recommendations constitute the last stage of LCA research (interpretation,

Figure 2) [

23].

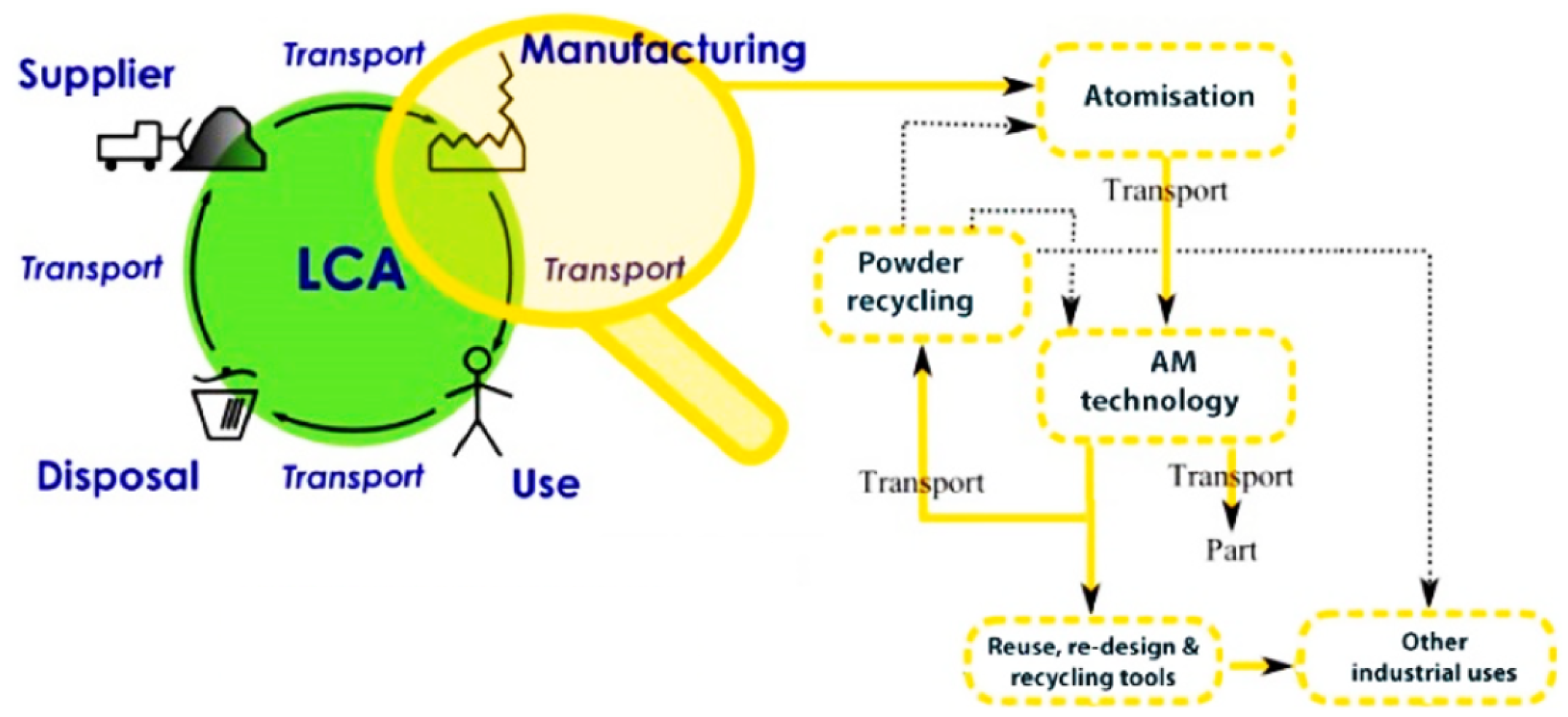

The LCA includes the processing of raw material, i.e., powder atomisation, printing processing, product distribution, usage and service, end of life treatments, recycling, and disposal from the “cradle-to-grave” perspective; all of these evaluation stages are indispensable to establishing sustainability performance.

Figure 3 provides an overview with an LCA methodology that includes tools for reuse, re-design, or recycling that may reduce the environmental effect of powder-based AM technologies.

Reuse, re-design, and recycling tools include the methods used to recycle and reuse powder in AM production or other industrial processes, additive repairs, the design/re-design of complex parts, part consolidation, and the remanufacturing of existing parts utilising various AM technologies [

24,

25]. A special vacuum cleaner is utilised in the AM process to remove all excess metallic powder from the printing chamber after printing. Recycled powder is frequently utilised in the AM process or returned for reconditioning, but it can also be used in another industries.

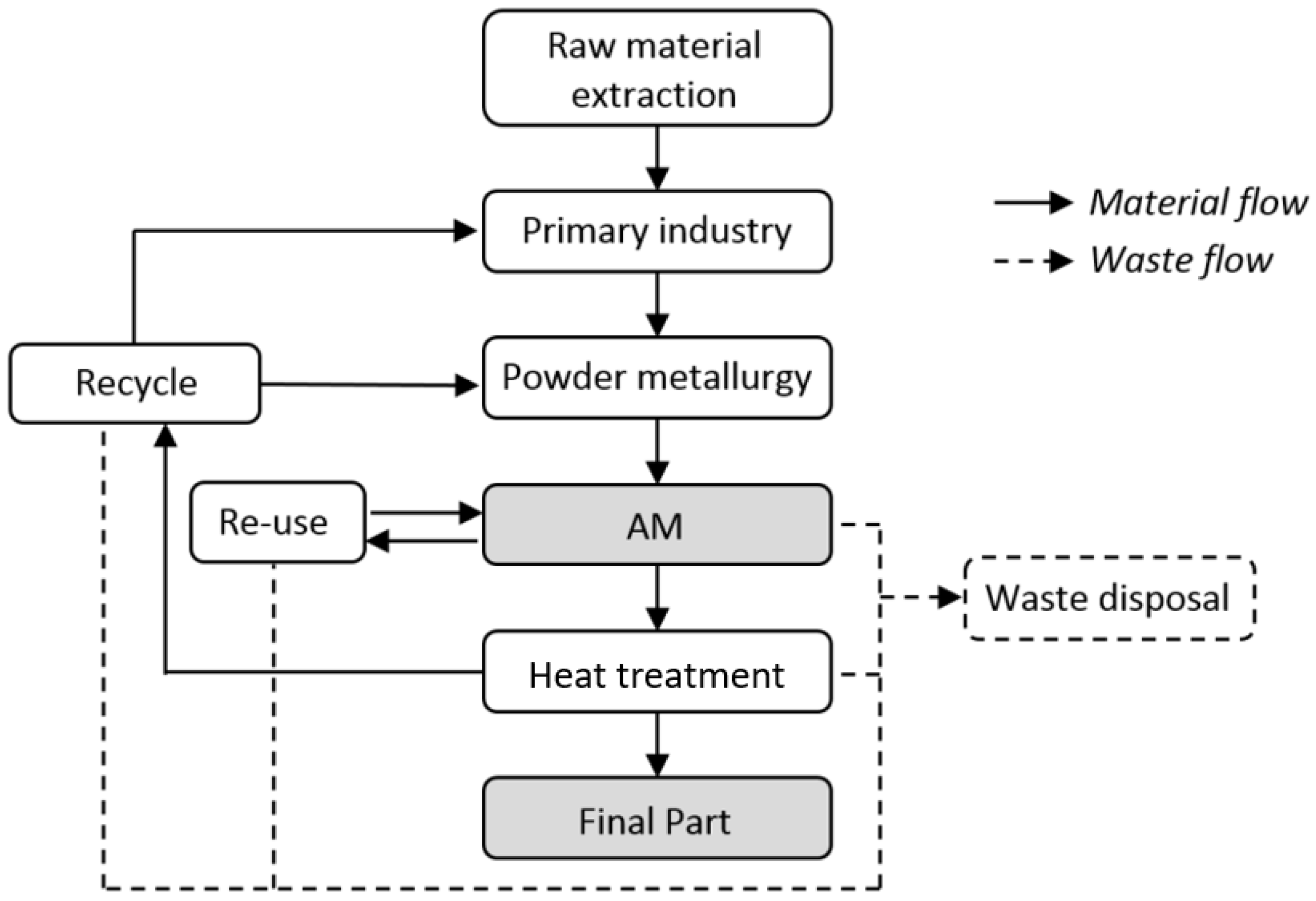

The effects of AM processes on the environment depend on numerous AM processing parameters such as the layer thickness and scan speed, as well as the chemical composition of the alloy. According to

Figure 4, the main environmental effects of AM are categorised into (i) energy consumption, (ii) waste management, and (iii) air pollution.

2.1. Energy Consumption

Energy and time are crucial aspects to take into account in production systems since they determine efficiency, productivity, and cost in AM. The energy consumption during AM is mainly divided into two categories: primary and secondary. Primary energy is defined as the energy needed to change the metallic powder’s characteristics and shape [

27]. It is also known as direct printing energy. Primary energy includes supplying powder, obtaining and maintaining the right thermal and atmospheric conditions in the build chamber, powering motors to position beam delivery systems, melting the metallic powder with a high power beam, and monitoring and controlling the build process with integrated sensors and controllers. The energy used by the supporting parts or accessories of AM systems is referred to as secondary energy [

28].

It is frequently believed that the high-power beams (laser or electron beams) used to melt the powder are the metal AM equipment with the highest power utilisation. The productive operating state is defined as the amount of energy used during deposition by the high-energy beam subsystems. The energy consumption of the various AM subsystems has been measured by numerous research efforts, with wildly disparate outcomes. In addition to the heat sources, the atmospheric controls used in various AM techniques, such as vacuum pumps to remove air from the system in EBM consumes high energy. In some systems, heaters are also used to maintain stable temperatures, control thermal residual stresses caused by strong temperature gradients, or to pre-heat the substrate for better deposition of the layer on top of it [

29]. Finer deposition geometries are leading to finer diameter powders and thinner layers, at the cost of additional time and energy expended for dramatically increasing the number of layers needed to build a part. Material delivery subsystems in powder beds include a powder hopper and a spreader or recoater bar to spread layers of powder. Significant amounts of time and energy are spent on these auxiliary subsystems, which could be seen as unproductive [

30].

The enormous environmental, economic, and societal effects of high-energy-consumption AM technologies are well known. The increased energy use has a negative impact on the environment since it increases the carbon footprint of AM. Additionally, the energy-intensive nature of AM may result in a greater depletion of resources, such as minerals and fossil fuels [

31].

Economically, the high energy consumption of AM may raise the price of the products. When compared to conventional manufacturing, high energy consumption results in higher operating costs, which has an effect on the overall economic viability of AM. Potential users may be put off by the high cost, which could also hurt the technology’s ability to compete in some sectors [

32].

The high-energy consumption of AM can also affect society through local populations and the workforce. Increased energy demand has the potential to put strain on power infrastructures in areas that rely significantly on non-renewable energy sources, leading to power shortages and disruptions. Local communities are impacted by this, which may result in social and economic instability. Additionally, if energy production techniques have a negative environmental impact, the health and well-being of local populations may be at risk, which can exacerbate socioeconomic inequality and public health issues [

33].

2.2. Waste Management

When compared to traditional manufacturing processes, AM techniques may produce 90% less waste. The waste produced by AM includes support structures created for overhanging pieces, powders that are no longer recyclable, and scrapes produced by unanticipated defects [

7,

34]. Powders may be reused in powder-based AM techniques, but only to a certain extent because of the compositional change and property degradation. Even at the forefront of promoting sustainable manufacturing, no steps have been taken to examine waste management. The type and quantity of waste produced during AM and at the end of the life of 3D-printed components are currently poorly understood.

It has been acknowledged that material recycling rates greatly contribute to environmental impact reduction; hence, practical ways to recycle material powder have been suggested. One study claimed that AM might prevent over 40% of material-related waste and allow for the reuse of 95% of material that was not used, although this conclusion has not yet been verified for all materials [

34]. As an alternative, the waste and recycled materials from AM can be managed together with other manufacturing techniques, including smelting and forming, for further processing and reuse. Most of the time, more energy and resources must be consumed. However, data on the material and energy requirements as well as the associated environmental effects of these procedures are not yet accessible [

35].

An overview of waste management throughout the AM processing stages is shown in

Figure 5. Circular economy has become the top strategy to control waste management. The circular economy is a production model that protects the value of products, materials, and resources for as long as feasible, whilst reducing waste output [

36]. Along with more conventional recycling, the circular economy model encourages the use of high-value material cycles. It is advised to use the circular economy as a strategy to deal with the rapid economic change while also protecting the environment and promoting sustainable economic growth [

36].

In general, AM enables extending the product’s lifespan through repair or reuse. Therefore, the circular economy notion can be used for this technology. However, a variety of wastes are produced during AM and subsequent heat treatment; these must also be taken into account from the perspective of the circular economy.

2.3. Air Pollution

There are two main subdomains of AM regarding air pollution: (a) air pollution that is produced by AM processes, and (b) employing AM to reduce air pollution in manufacturing. Manufacturing components from raw materials is a major source of industrial pollution. A total of 19% of global greenhouse gas emissions are specifically linked to manufacturing activities [

37]. As a result, it is necessary to use the best and most appropriate technology to reduce the air pollution caused by these operations. According to production processes, air pollution varies. The impact of AM technologies in contributing to air pollution has become a critical concern as a result of their expanding use in the academic and industrial sectors.

In conventional manufacturing, the transit of raw materials into a manufacturing plant and the transportation of finished components utilise large amounts of energy and create air pollution. A comparison between supply chain of AM and conventional manufacturing techniques is illustrated in

Figure 6. While AM has a relatively good environmental impact, it has relied significantly on fossil fuels. Even though 3D printing will not address all of the air pollution issues, it will enable the local on-demand fabrication of a variety of components, which will significantly reduce the number of links in the supply chain. Undoubtedly, 3D printing will eliminate millions of component shipping trips during the next couple of years [

38]. Additionally, post-processing produces a lot of contaminants, which can be significantly avoided for AM products, since they need minimum post-processing procedures.

For the purpose of avoiding potential harm to users’ health, precise information about emissions is necessary. The use of 3D printers has been linked to the release of potentially hazardous volatile organic compounds, as well as ultrafine particles, a type of particle matter (PM) with a nanometre-scale size of less than 100 nm [

40]. Human health is impacted by the concentrations of such pollutants in the air, especially over extended periods of time. The physical characteristics of each particle, their size, and the critical density to harm health are expected to cause severe harm through inhalation. Numerous factors, including the machine nozzle, the process temperature, the volume of the powder bed, the model of the printer, the number of printers operating simultaneously, and the temperature of the powder bed, affect the composition and concentration of their emissions.

Furthermore, the toxic gases released during the AM process, such as airborne metals, can contribute to indoor air pollution and be detrimental to workers’ health in poorly ventilated areas. There is the possibility that the disposal of waste materials and leftover powders from AM could contaminate soil and water, disrupt ecosystems, and enter the food chain [

41].

3. Life Cycle Costing

Economic viability and sustainability will play crucial roles if AM is to compete with traditional manufacturing techniques, necessitating a cost comparison of AM with other traditional manufacturing technologies. The LCC is a widely accepted strategy for economic sustainability [

42]. The term LCC refers to the assessment of all costs associated with the life cycle of a product that are directly covered by any individual or organisation influencing the product life cycle (supplier, producer, and user/consumer). Its goal is to include cost assessments at all stages of the product’s life cycle, including expenses that are typically not included in its market price, such as those incurred during use and at the end of its useful life [

43]. It starts with the initial product design and continues through manufacture and disposal.

LCC focuses on crucial indicators for selecting the most cost-effective option among a range of possibilities. LCC frequently relies on the widely accepted investment appraisal technique known as net present value (NPV). This method allows for the comparison of several choices when determining the profitability of a project or product based on the necessary operational cash flows and investments. The profitability is determined over a specific time period. This enables taking into account various life cycle phases over a product’s predetermined lifespan [

44].

In order to quantify the expenses associated with AM, the process chain must be understood. Various AM technologies each have unique features that have an impact on the process and its total price. Despite this, the various AM methods and the required parts have a significant impact on manufacturing speed, energy use, and the necessity for post-processing.

Because of this, choosing to adopt AM frequently entails balancing manufacturing costs and added value. Thus, the lifespan costs approach provides a suitable framework. Lifecycle costs take into account more than only the purchase price (from a customer’s perspective) or production costs (from a producer’s perspective). Costs develop during the course of a product’s whole lifecycle.

AM has the capacity to reduce expenses in many different contexts. This begins with time savings in part design. Costs associated with storage and assembly can also be greatly decreased. Additionally, managing and controlling fewer subcontractors is made easier by integrating an assembly into a single item. However, the company is not the only place where cost savings and added value can be realised [

45]. There are extra benefits to the client by improving functionality and lowering product lifecycle costs. As

Figure 7 illustrates, compared to traditional production (milling), AM may have distinct cost benefits during various stages. The product conception and definition phase, when the specifications are outlined and a draft is created, serves as the foundation for both technologies. The following step, design and development, entails prototyping, manufacturing, and quality-related activities in addition to design, finite element analysis, and optimisation. The costs associated with optimisation and design for AM are higher even if prototyping is significantly cheaper with AM. Because of this, AM generally results in greater costs than milling in the design and development step [

46].

The production costs of AM, which include the use of machines, waste, and post-processing, are significantly higher than milling. The installation efforts are approximately the same for both technologies. However, the AM advantages are evidently strongest throughout the phase of usage and maintenance, where it can save up to 43% of the manufacturing costs, which is typically the longest period of each product (

Figure 7). The weight has a significant impact on the amount of fuel used in aerospace. The lever weighs 43% less in the AM version than in the conventional design. Both technologies’ disposal costs are comparable and have no impact on the outcome [

46].

4. Social Life Cycle Assessment

Even though there are a variety of tools and techniques used to evaluate the social consequences of product manufacturing, SLCA is the approach that is most frequently utilised by the international community [

47,

48]. The SLCA technique was created to assess how items and processes affect people and society throughout their entire life cycle. Its main objective is to present a thorough understanding of the effects of a specific technology or manufacturing method such as AM on individuals and communities. SLCA explores the social facets of sustainability in addition to typical economic assessments. The purpose of SLCA in the context of AM is to discover, evaluate, and reduce any potential societal hazards and advantages connected to the technology. Examining aspects such as worker well-being, working circumstances, community involvement, and general social well-being are part of this.

In order to fully evaluate products and services within the perspective of sustainable development, SLCA is regarded as an LCA methodology that complements environmental LCA and LCC. By considering a product’s whole life cycle, from extraction to disposal, the SLCA technique evaluates the societal implications of a product from a life cycle viewpoint.

A general SLCA includes a number of steps to assess a product’s social impacts. It comprises strategies and tactics for gathering and modifying the data. The social and socioeconomic factors that this general technique evaluates are connected to the manufacturing procedures and other commercial activities that occur during a product’s life cycle and are responsible for any positive or negative effects on stakeholders [

49]. Improving the social conditions of a product throughout its life cycle is the major objective of SLCA studies. In an effort to enhance organisational performance and, as a result, the well-being of its stakeholders, it also seeks to spark a discussion among decision-makers about the significance of social and economic elements of production and consumption.

As indicated in

Figure 8, the five main stakeholder categories where the social impacts of AM can be traced and quantified are (1) workers, (2) the local community, (3) society, (4) the value chain, and (5) consumers. Due to these stakeholders’ relationships to the product under assessment, it is considered that they have similar interests. Each stakeholder category has subcategories with significant themes (see arrows in

Figure 8). These subcategories are organised and assessed using inventory indicators [

7]; these may be quantitative, semi-quantitative, or qualitative.

Health and safety, equal opportunities, a fair wage, psychological working conditions, working hours, child labour, and social benefits are significant factors for workers. The most pressing issues facing the local community are local employment and access to non-material resources [

50]. Promoting social responsibility, upholding intellectual property rights, and maintaining supplier relationships are the responsibilities of value chain participants. Conflict avoidance and reduction are society’s top priorities.

A framework was created by Naghshineh et al. [

48] to evaluate the social impact of an AM product. The five phases of their proposed framework were (1) aim and scope definition, (2) stakeholder category selection, (3) data-gathering methodology, (4) aggregation method, and (5) outcome interpretation. The scope constraints must be indicated because the fundamental objective of the proposed framework is to present a method for assessing the social effects of an AM product during its full life cycle.

Depending on the stakeholder groups, several data collection techniques may be used. The most popular methods for gathering data include management interviews, stakeholder questionnaires, and reports supplied by national statistics data. The indicator scores must then be combined into a single final score that represents the product life cycle score using a mathematical model, which must then be created. To obtain a final score that corresponds to the life cycle score for AM goods, the scores from each stage of the life cycle must be combined. This final overall score demonstrates the social impact of the AM product on its stakeholders.

5. Predicting Sustainability before Printing

The capacity to reduce CO

emissions, decrease the overall environmental footprint, and promote sustainability should all be taken into account when choosing an AM technology. This should be compared to wrought manufacturing using a quantitative model. Depending on CO

reduction objectives, the price of CO

certificates, and the general political and public attitude, such model could encourage the use of AM in applications where it is now perceived to be too expensive. However, it should only be used as a guide and must be backed up by trustworthy LCAs. This is because specific procedures, components, or parts could have issues, necessitating the use of people who are sufficiently knowledgeable and skilled in AM [

12].

The literature on sustainability analysis for AM processes is extensive [

7,

12,

13,

17,

22,

25,

26,

28,

34,

35]. The following methods should be used to assess the viability of AM approaches:

Predictive models;

General methodologies;

Analytical methodologies;

Experimental methodologies;

LCA-based approaches;

Road mapping frameworks; and

Design for environment methodologies.

A product sustainability index (PSI) can be used to evaluate the sustainability of a product design. It has six requirements: (R1) environmental implications, (R2) resource consumption and economy, (R3) manufacturability, (R4) functionality, (R5) societal impact, and (R6) recyclability/remanufacturability. Environmental effects (R1) focus on waste and emissions over the entire product life cycle and include local, regional, and global environmental effects. Resource use and economics (R2) are concerned with making the most effective use of energy, materials, and other resources. Costs related to consumption and manufacturing are also included. Manufacturability (R3) is a critical element that is process- and system-oriented but has a significant impact on the sustainability of a product. It focuses on production, packaging, shipping, and assembly processes. Functionality (R4) includes a product’s core properties, including life and durability, modularity, and customisability. Societal effect (R5) includes operational safety, health, and ethical duties. Recyclability and remanufacturability (R6) handle product end of life. Although it also applies to the previous three stages of the product life cycle, this component primarily focuses on the post-use phase of the product (premanufacturing, manufacturing, and use).

In order to be able to quantify PSI, a number of factors related to the material, process, and end-use application need to be assessed. (1) Materials selection: Metal powders with low environmental impact, recyclability, and reduced carbon footprint should be considered in the alloy design procedure. Factors such as the source of raw materials, energy consumption in production, and toxicity of waste by-products are amongst the most significant factors that must be considered during alloy design. (2) LCA, to evaluate environmental impacts. (3) AM process optimisation: Process parameter optimisation and minimising support structures can lead to more sustainable outcomes. (4) Energy efficiency: Assessing the energy requirements of the AM process, and using renewable energy sources to power the manufacturing facility can significantly reduce the carbon footprint. (5) Waste management: Efficient waste management and recycling strategies for both unused metal powders and post-production waste should be controlled. Reusing and recycling materials can greatly contribute to sustainability. (6) Recyclability: Recyclability of a component should be quantified and considered prior to the production. (7) Data Analysis and Modelling: Alloy design and environmental impact of the products must be modelled for different manufacturing scenarios. This can help in the making of informed decisions about material choices, process parameters, and energy sources.

6. Sustainable Materials Science Paradigm

The classic materials science paradigm needs to be revisited in order to incorporate sustainability into alloy and process design. The link between processing, microstructure, properties, and performance (PMPP) is established as such a paradigm; this can be easily linked with sustainability. We can reduce the environmental impact of material production by using sustainable practices in the processing stage, such as energy-efficient methods and ethical waste management. This in turn affects microstructural development, since materials produced using sustainable techniques normally have lower carbon emissions and use fewer resources. These environmentally friendly materials may have characteristics that support societal as well as environmental objectives, such as lightweight construction for improved fuel economy or materials with fewer hazardous consequences. Therefore, products made with these eco-friendly materials perform better, leading to longer product lifespans, lower energy use during AM, and ultimately, a more eco-friendly product life cycle.

Figure 9 shows a flow diagram of the essential PMPP components and how they relate to sustainability. Environmental, economic, and social factors are measured in terms of a PSI, which might be viewed as a property in itself. The design of new powder alloys for improved sustainability is therefore tied to the entire life cycle. This approach, which is based on computational models connecting the many boxes in the schematic, may help turn AM sustainable. It raises new issues, including the sustainability of microstructures and the relationship between engineering attributes and PSI.

To estimate PSI, which includes the entire energy expenditure associated with the fabrication of an AMed component, the full cycle from metal extraction to the material’s end of life should be included.

Figure 9 shows the sequence of energy consumption for the AM of a metallic alloy. It is required to redefine PSI beyond R1–R6 (

Section 5) to include all sustainability factors, indicated in the red boxes in

Figure 9. The total energy (

), which accounts for the total life cycle energy associated with AM can be defined as [

14]:

where

is the energy associated to extraction of the metallic ores (

), melting and casting of the alloys (

), powder production via atomisation (

), AM processing (

), post-processing heat treatments and machining (

), and recycling (

).

–

should incorporate the transport energy to procure materials for each process.

It should be noted that a certain amount of material (

) can be used after each production stage that are shown in

Figure 7. The recycled fraction material (

) at each stage can be defined as:

For example, the amount of material that can be recycled after atomisation and prior to printing can be calculated by

. Therefore, as a first approach, PSI can be described quantitatively as:

In addition to energy consumption costs and recycling, air pollution corresponding to each production stage must be taken into account. Toxins such as lead, nitrogen, mercury, and sulphur dioxide (which causes acid rain) are the main pollutants from metal extraction. Benzene is the most hazardous pollutant released to air due to metal casting. The release of gases such as argon and nitrogen to the air is an issue during atomisation and AM processing and post-processing. The recycling process itself has also some air pollution issues that must be considered when an LCA is defined for AM.

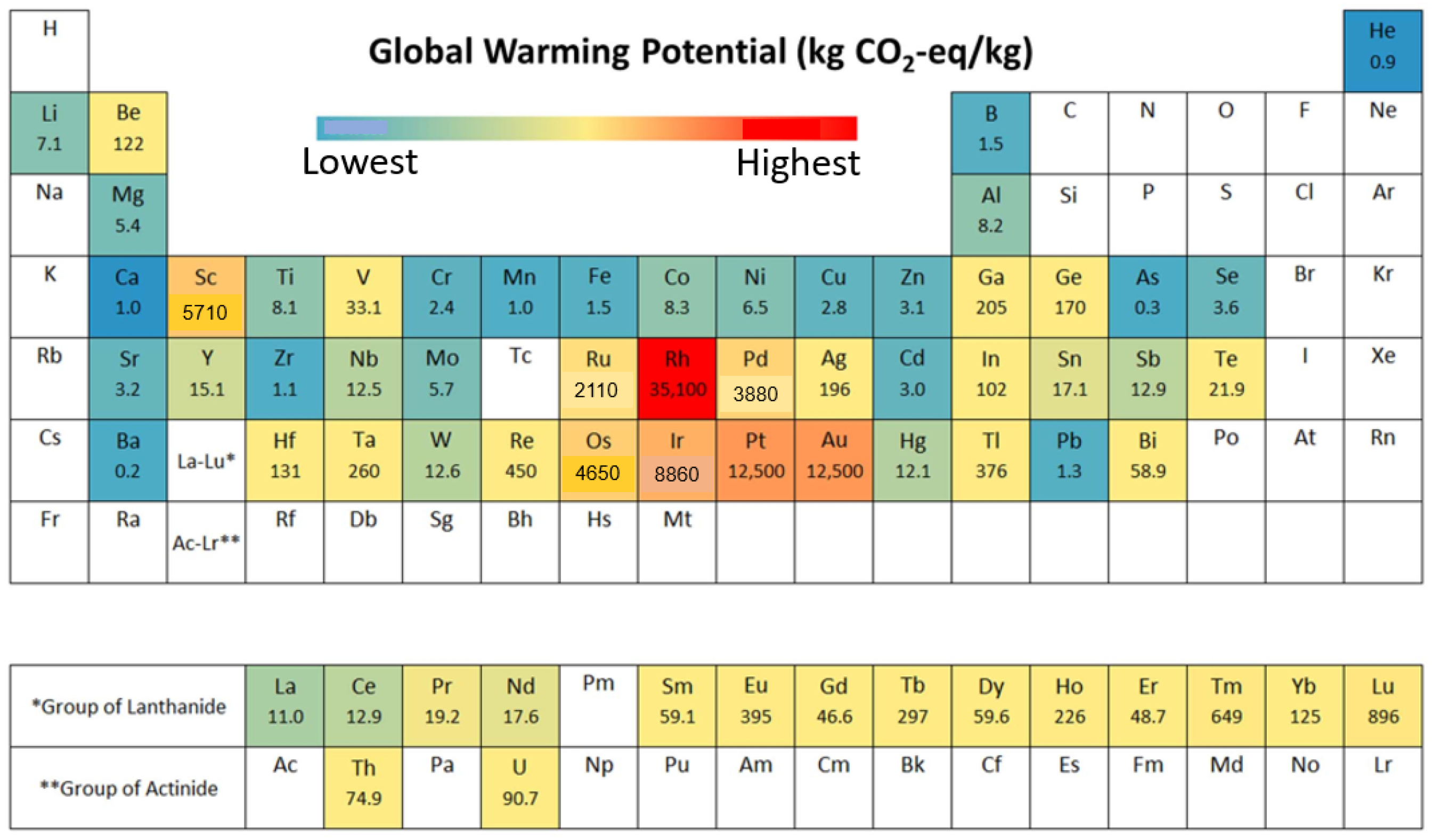

An example of how PSI can be employed in an alloy design is through the concept of global warming potential (GWP). GWP is a key indicator for assessing the environmental impact of the metal production process [

51]. This is one of the most important environmental aspects that need to be considered in developing an LCA and subsequently the PSI in the alloy design procedure. To fully evaluate the environmental impact of alloys used in AM, the PSI incorporates the idea of GWP. The GWP is an essential part of this index because it measures the greenhouse gas emissions linked to the lifecycle of a material, fully harmonising with sustainability objectives. GWP analyses can successfully identify materials that reduce carbon footprints during all stages of manufacturing, use, and disposal of alloys for AM. Manufacturers and designers can use alloys with low GWP and promote ecologically friendly material selections in the context of AM by incorporating GWP into the PSI.

Figure 10 shows the periodic table of elements with elemental GWPs; it indicates that most of the common metallic alloys, such as steels and nickel superalloys used as structural materials, in various industries contain elements with very low GWP. However, in order to computationally design novel alloys with superior properties, GWP must be taken into account, so that the best alloys with the minimum GWP are selected. Amongst common metallic elements that can be used in high-temperature refractory high-entropy alloys, V, Hf, and Ta have very high GWPs. This must be considered when one tries to evaluate the properties of such alloys to maintain the boundaries of sustainability.

The PSI expression shown in Equation (

3) needs therefore to be reviewed; it must incorporate aspects such as air pollution and global warming potential indices, which are so far not included.

7. Conclusions

This work provides a review of the principles of sustainability towards alloy design for powder-based AM. These include environmental, economic, and social impacts of AM; these are respectively appraised through life cycle assessment, life cycle costing, and social life cycle assessment. A sustainable materials science paradigm is suggested for the first time; this relates sustainability with PMPP. An example of how the product sustainability index can be estimated to link sustainability to classic PMPP is given through incorporating energy and materials consumption throughout the product life cycle. Future research is desired to integrate more sustainable data to be put into life cycle assessment procedures to make AM more sustainable.

Future research in AM sustainability should endeavour to refine existing methodologies, expand datasets, and explore novel avenues for reducing environmental impacts and promoting societal well-being. A comprehensive understanding of AM’s sustainability implications will undoubtedly shape the trajectory of manufacturing processes, fostering a more responsible and resilient industrial landscape. As technologies evolve and global awareness of environmental and social concerns intensifies, the convergence of AM and sustainability is poised to lead us towards a more promising and equitable future.