Abstract

The aim of this review study is to understand the current state and practice of sustainability innovation in the textile industry. The textile industry is regarded as one of the industries that faces the biggest challenges in incorporating sustainability in its business practices. In this study, we conducted a systematic review to synthesize empirical knowledge relevant to sustainable innovation in the textile industry. From the systematic search process, 41 papers that were identified met the criteria of inclusion and were then analyzed qualitatively using thematic analysis. The findings showed that the attention of researchers toward sustainability innovation has increased in the recent years. Sustainability innovation practices in the textile industry were identified. Sustainability product innovation includes ecodesign, ecolabel, life cycle assessment, materials, and packaging. Sustainability process innovation includes cleaner production, ecoefficiency, waste handling, supply chain management, and enzymatic textile processing in process innovation. Sustainability organizational innovation includes the environmental management system (EMS) and corporate policy, collaboration, business model innovation, culture and knowledge management, and enzymatic textile processing. This study found that the dominant sustainability innovation practice discussed in the textile industry is more related to the ecological innovation aspect compared to social innovation. As consumer demand for ecofriendly products is growing, as are more stringent regulations, it is important for business players and policymakers to develop sustainability innovation in the textile industry together.

1. Introduction

The textile industry employs tens of millions of people worldwide and is one of the global industries that provides basic daily human needs [1]. This is not surprising given its nature as the second most important basic need in human life after food and water [2]. The transformation process is also quite complex, beginning with fibers and yarn and ending with fabrics that involve various operations and produce various types of specific products. The textile industry produces a variety of products, including agrotextiles, automotive textiles, construction textiles, geotextiles, industrial textiles, medical textiles, protective textiles, and sport textiles [3,4]. In 2021, the global textile industry will be worth more than USD 1.04 trillion [5]. In spite of the disruption caused by the pandemic, the demand for textiles is likely to expand in the future, particularly with the rise of digitization and e-commerce as well as customer demand for a variety of items from this industry [6].

While the textile sector is well-known for its many positive contributions to the economy, it is also well-known for its considerable environmental and social issues when it comes to long-term sustainability [3]. There are a number of environmental concerns, including the fact that this industry consumes a great deal of energy and emits a great deal of pollutants. Water, fuel, and chemicals are all commonly used as essential resources in the textile business, and they are utilized in large quantities. A significant amount of water is consumed by the textile industry, which requires more than three trillion gallons of fresh water per year for fabric manufacturing around the world [1]. Chemicals emitted into the environment from textile treatment and dyeing activities account for approximately one-third of all chemicals released into the environment [7], not to mention the massive amount of toxic waste that has been dumped in the soil, the air, and the water throughout the years [3].

On a social level, the textile sector is characterized by challenges that typically occur in the supply chain, where issues such as child labor, low-wage labor, and other unethical activities are prevalent [8]. In the textile sector, finished items are transported from developing to developed countries in approximately 80% of the total flow [9]. Low labor costs, as well as labor relations and environmental legislation that is less stringent than that found in developed economies, make developing countries popular production locations for manufacturers. The use of child labor has been outlawed in a number of markets, including in North America and Europe. Poor working conditions and limited job mobility are also a source of concern because it is regarded as unethical when workers in this sector are paid poorly and have poor working conditions while large corporations make large profits and government earns large sums of money from exports, as is the case in the oil and gas industry [10]. Other unethical activities, such as the sourcing of raw materials that do not take into consideration social and environmental responsibilities, are also prevalent in the industry [8].

As a result of these numerous issues, prior academics have conducted a variety of studies in an attempt to make the textile business more environmentally friendly. Examples of these issues include product design [11], treatment of associated pollutants [12,13], barriers encountered [14], circular economy [15], production process [16,17], or corporate social responsibility [18]. There are, however, very few studies that examine the sustainability issue in industrial textiles via the lens of sustainability innovation, despite the fact that the textile sector is well-known for its constant need for innovation. Innovation has been occurring in the textile industry for a long period of time and is critical not only to the textile business, but to other industries as well [19]. Furthermore, sustainability is viewed as the primary driver of current and future innovation [20,21].

Therefore, the purpose of this study is to synthesize empirical knowledge relevant to sustainable innovation in the textile industry through the use of a systematic review approach according to the aggregation procedure of [22]. More specifically, the following are the research questions addressed in this study: “What is the current state of research on sustainability innovation in the textile industry?” and “How is sustainability innovation practiced in the textile industry?” The primary contribution of this study is to lay the groundwork for future research by launching a systematic review of the textiles industry through the lens of sustainability innovation.

The implication of this paper for other researchers is that our paper can document which innovation the textile industry has conducted and what innovation will occur in the coming years. The second implication is that the practices within the textile industry have been innovated to achieve sustainability. It is expected that the findings of this study will provide academics, practitioners, and policymakers with an overview and insight into how to continue to serve daily human needs through the development of a more innovative and sustainable textile industry.

2. Materials and Methods

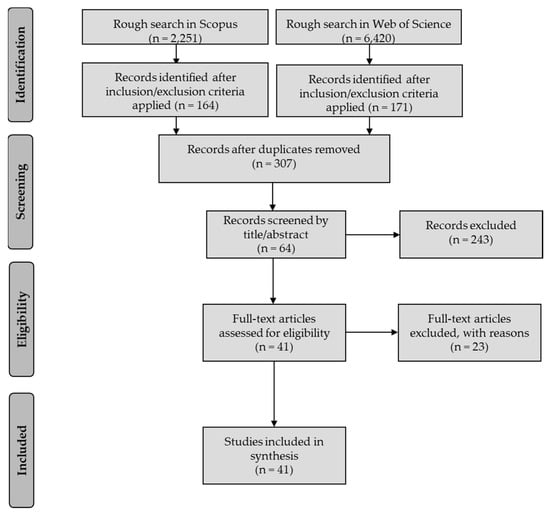

To obtain accurate results for the literature review process, we followed the PRISMA protocols, expressed in reference [21], as a method that comprises a three-stage procedure. The first stage is selecting the main semantic word search on a search engine in a specific database that generally produces chosen articles [23,24]. The second stage is selecting articles into more specific semantic words to obtain more particular articles than the previous filtering process [23]. The third stage is analyzing and synthesizing from the journals in the second stage and connecting the paper’s results by summarizing, analyzing, and synthesizing according to the available historical and retrospective papers’ period until the present. This approach can assist us in a classified category based on sustainability-oriented innovations categorized as product, process, and organizational innovations [25]. We classified each category into the first as the current state of research that indicated how sustainable innovation in the textile industry was conducted, achieved, and expected in the coming years. The second category is the practice that demonstrates the various practices applied in the first category system. These stages are described in the following paragraphs.

In the first stage, the material of our paper focuses on gray literature to obtain quality papers. We classified the search material with the peer-review process to ensure the journal meets the highest level of scientific standing. We chose search terms that were related to sustainability and innovation. The keyword sustainability innovation is more detailed considering the coverage, including eco innovation or green innovation and social innovation [23]. The search terms formed are: ((sustain* OR eco* OR green OR social*) AND innovate* AND textile). The inclusion/exclusion criteria set limited the type of document to journal articles to obtain documents that have been through a strict peer-review process compared to other document types. The language was limited to English (Table 1). The results for each combination produced about 8000 articles in total, with about 6240 from the Scopus database and about 2251 from the Web of Sciences database.

Table 1.

Inclusion and exclusion criteria.

In the second stage, a systematic review was carried out on the Scopus and Web of Science databases, which are known for their comprehensive coverage and the quality of the selected journals. Then, the process continued with the search and filtering process. A rough search in the Scopus and Web of Science databases yielded more than 8000 articles. After applying inclusion/exclusion criteria, 164 and 171 papers were obtained in both databases. So, in total, 335 journals were included. After the metadata search results from the two databases were merged and duplication was removed, a total of 307 articles were obtained. Subsequently, the records were filtered based on title/abstract, resulting in 64 pieces. Finally, full-text articles were assessed to ensure eligibility, and 41 publications were obtained that were very relevant to the investigated topic.

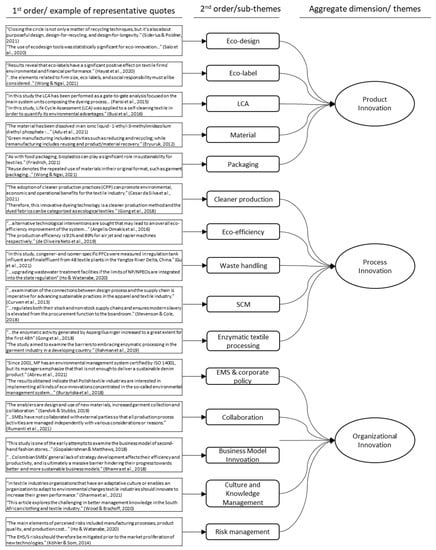

In the last stage, we aggregated analysis and synthesis by extracting information from the entire literature reviewed into certain specific components and describing their relationship according to product, process, and organizational innovations. At the same time, the synthesis was carried out by organizing various analysis results to develop knowledge that cannot be obtained by reviewing the works of the literature individually [26]. The emphasis on analysis and synthesis refers to two research questions addressed in this study: the current state of research and the sustainability of innovation practices in the textile industry. The current state of research includes the year it was published, the journal in which it was published, the context, and the methodology. To provide a transparent picture of the coding process, visualization is given in the form of a data structure [27] (Figure 1).

Figure 1.

PRISMA flow diagram for sustainability innovation in the textile industry.

3. Results

In this section, the results are presented to address the research questions. The first question is about the current state of sustainability innovation in the textile industry. The second question is about the practices of sustainability innovation in the textile industry.

3.1. Current State of Research

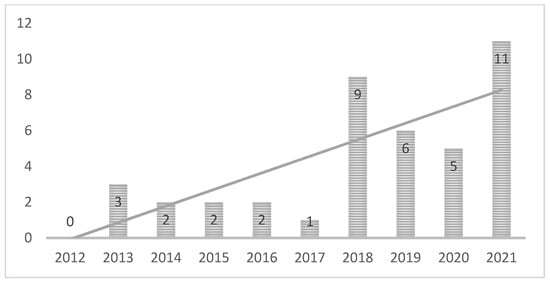

The trend line of publications in the last ten years is increasing, as shown in Figure 2. The most publications occurred in the last four years, especially in 2021, with 11 publications. Concern for sustainability in the textile industry has indeed been around for a long time, but it appears that concern for sustainability innovation has become more visible in this decade, with the trend of increasing attention.

Figure 2.

Trend line publication year.

Journals that serve as outlets for publications in this area vary, with the journal containing the most articles being the Journal of Cleaner Production (17 articles). This international and multidisciplinary journal covers a wide range of research topics related to sustainability and cleaner production. Following that, there were three journals with multiple articles, all of which specialized in textile and fashion, namely, the Journal of Fashion Marketing and Management (3), Clothing and Textiles Research Journal (2), and Fibers and Textiles in Eastern Europe (1). Following that were 17 journals with one article each, which were primarily a mix of business and management-based journals and journals specializing in textile and fashion (Table 2).

Table 2.

Publication Outlets.

The research context spans several continents (Table 3), with Europe being the most prevalent with 36 publications focusing on it. Italy had the most contexts studied in Europe (nine), followed by Finland and Germany (four each), Denmark and the United Kingdom (three each), then other European countries. Italy, unsurprisingly, is the most researched context, as it is known as the world’s fashion center, with cities such as Turin, Florence, Rome, and Milan representing as fashion industry centers [28]. This result is consistent with previous findings regarding ecoinnovation, where both researchers and the research context are dominated in Europe [29]. Other continents are studied in a limited number of publications. The Americas, both North and South, are represented in seven publications, with Brazil being the most studied context (4), followed by the United States (2), then Colombia, and then Peru (1 each). Botswana and South Africa are the only two studies set in Africa (1 each).

Table 3.

Research context.

The surprising result is that Asia, which is currently the center of global textile production and faces numerous severe sustainability challenges, is actually a region that is still understudied. China, India, and Bangladesh, the world’s largest garment and textile producers, are only represented by a few publications, with one each. This is in stark contrast to Europe, which has over 35 publications. Indeed, it is common knowledge that serious environmental and social concerns exist in the garment and textile industry, such as water and chemical consumption, wastewater discharge, and employment issues [30]. There are also a number of studies that are not context-specific (nine) because they are usually a chemical composition test, particularly for the development of raw materials. As for the rest, one study is global, while no study has an Australian context.

Table 4 summarizes the research method most employed in those studies. Our review discovered that the majority of the methods used were interviews (12 studies, or around 30%), chemical examination (12 studies, or approximately 30%), case studies (8 studies, or about 20%), and surveys (7 studies, or around 17%). The rest comprises a focus group, with one study. If we categorized interviews, case studies, and focus group discussions into one category, it would be the dominant method used (in total, in 21 out of 41 studies) in the articles. These methods are qualitative approaches usually used to explore a newly developed field that necessitates an in-depth understanding of sustainability in the textile market. There is a growing concern for academicians and practitioners through various innovations toward the ideal stage of a sustainable process.

Table 4.

Research method.

Experimentation and the qualitative approach play a significant role in the studies included in this review. Experiments take the most common form of chemical examinations, which are likely to be widely used in conjunction with material testing as part of product and/or process innovation in the coming years. The chemical examination can also be described as an exploratory endeavor. These efforts include, for example, investigations into new approaches to producing sustainable and regenerative cellulose fibers [31], or the use of magnets to improve the manufacturing process [32]. Another type of experimentation is the creation of machines capable of producing 3D stitch-bonded fabrics [33].

In particular, methods such as case studies and surveys across the different countries were used. The case studies indicated intensive research on assessing how sustainable innovation affects business and environmental performance—followed by the survey that collects information on sustainable innovation technologies or perspective choice based on respondent expertise in particular countries with similar purposes. The results indicate that the case studies that develop intensive efforts in a specific country have been improved [33] but need more improvement [34] to enhance organizational [35] and environmental performance [36]. Otherwise, the survey results imply two segments; the first is evaluating existing efforts of sustainable innovation that require more customer [37], social, and ecological value [38]. The second is promoting initiatives for the next sustainability stage that more collaboration between multistakeholders [39] toward a fully sustainable innovation transition agenda [38].

3.1.1. Themes and Subthemes

The identification of sustainability innovation themes in the textile industry is based on the type of innovation (Table 5). Product innovation, process innovation, and organizational innovation are the three types of innovation under consideration [34,35]. The following is a discussion of each of the sustainability innovation practices in the textile industry as identified in the reviewed studies.

Table 5.

Themes and subthemes (n = 41 articles) [36].

3.1.2. Product Innovation

There are several practices related to product innovation that are discussed in the literature including ecodesign, life-cycle analysis, ecolabel, material, organic, ethics, and packaging.

- Ecodesign

Ecodesign is a systematic effort to integrate environmental considerations and product and process development [11]. In contrast to traditional product design, ecodesign is a more comprehensive approach because it looks at the entire supply chain by considering not only the recycle aspect, but also how the design has a purpose, both for recycling and for longevity [39]. By using three large fashion and apparel cases that operate globally, it was found that design in the industry is one of the environmental competences that includes the Five Rs, namely, reimagining, redesigning, reusing, reducing, and recycling [35]. This competency is an effective way to reach internal efficiency because it can significantly reduce energy use as well as wastage. The tools used in ecodesign that are popular in the textile industry include ecolabel, carbon footprint, life cycle analysis, design for sustainability, and water footprint [11]. Some of these tools are discussed specifically in the next subthemes.

- 2.

- Ecolabel

An ecolabel is a certification seal given to an environmentally friendly product that meets the criteria established by the ecolabel awarding authority [73]. Ecolabels in the textile industry promote ecofriendly practices such as sustainable production and reduction of harmful chemicals in textiles. The standard requirements of ecolabels used in the textile industry usually required certified firms to use environmentally friendly raw materials and technologies, use less water, and discharge less effluent into water [74]. Currently, there are more than 450 ecolabels used in different industries [75]. For the textile industry, among the popular ecolabels are bluesign standards, which are concerned with all inputs used in the production process so as to reduce the ecological footprint; BMP certified cotton originating from Australia, which is concerned with growing cotton that is environmentally friendly; and Ecoproof, which is managed by TUV Rheinland, which focuses on environmental and social aspects throughout the life cycle of the textile industry [74,75]. There are several types of ecolabels, namely, Type I ecolabel, which is certified by an independent body and becomes the gold standard for consumers; Type II ecolabel, which is self-declared by the manufacturer; and Type III ecolabel, which is voluntarily declared related to product life cycle and often for B2B [11].

- 3.

- Life Cycle Assessment (LCA)

Life cycle analysis (LCA) is a methodology for identifying critical points in industrial processes as well as opportunities for improving various technological solutions in order to achieve and promote environmental innovation and efficiency [68]. LCA is important in the textile industry because each stage of the industrial process has the potential to have a significant environmental and social impact from the manufacturing stage, which may involve the use of toxic chemicals or a large amount of energy, to the end-of-life stage, where some products emit hazardous chemicals after being disposed of in a landfill [22,76]. The LCA is a widely used method in the textile industry, in which internal stimuli are more frequently used [11]. Prior authors used LCA for self-cleaning textiles with the findings that the new machine-washable fabric is very cost-effective and would meet market demand [64].

The dyeing process is an important stage in the textile industry because it adds a lot of value and has a lot of technical complexity, a lot of energy consumption, and a lot of pollution [63]. The proposed innovative dying is a combination of low-impact bio-dyes and a new tinctorial dry pretreatment using plasma technology. As a result, direct energy consumption is reduced by 55 percent, indirect energy consumption is reduced by 70 percent, raw material consumption is reduced by 60 percent, and emissions are reduced by about 55 percent [67]. When compared to conventional fabrics, spun-dyed fabrics have a half to one-third of the environmental impact [77]. The relative benefits in Austria are higher than in China or the United States, where coal-based electricity grids are the norm.

- 4.

- Material

The material theme refers to efforts to reduce, replace, or use more sustainable materials as part of sustainability innovation [78]. This form of sustainability innovation is critical because the majority of materials used in the textile industry are unsustainable, such as fibers derived from fossil fuel sources [31]. To provide more sustainable fibers, for example, an innovative effort is being made to develop regenerative cellulose filaments from a paper mill sludge-based material dissolved in an ionic liquid. When compared to less sustainable materials, the result is fibers that are both regenerative and competitive [31]. Material modification can also be aimed at the end-of-life phase, as was demonstrated by previous authors by targeting the recovery of end-of-life textiles with multistage cascading and advancement of textile fiber-reinforced composite (TFRC) materials for building applications [49]. There are innovations in outdoor and medical protective clothing that evaluate liquid repellency and end-user requirements to replace fluorochemicals with more sustainable materials [52].

Using environmentally friendly substances during the washing and finishing process on special purpose products and home textiles, researchers discovered that capillarity increased from 131 to 152 mm, and the skin’s microflora was restored, making it safer to use [55]. This also helps for the continuity of the water ecosystem [79]. Other researchers made similar advances in developing antimicrobial textile materials using nanoemulsion of medical textiles for wound care applications [56]. Researchers are also interested in recycled materials in addition to material replacement and substitution. Textile-to-textile recycle systems, in the context of Scandinavia, are an important component of a circular fashion supply chain that faces major challenges in terms of technology, R&D costs, and supply chain complexity [53]. Price is both a determinant and a barrier in forming more sustainable consumer behavior, according to the findings. Consumers who are more concerned about the environment are more willing to pay for this type of product [43].

- 5.

- Packaging

The form of sustainability innovation in addition to dealing with the main textile material can also be related to packaging. Although not too many are found from the articles reviewed, packaging, for example, one study discusses the importance of minimizing the use of packaging or, more specifically, minimizing the use of harmful packaging and reusing garment packaging during end-of-life and other equipment such as sewing needles [35]. A more specific study on packaging demonstrated that like food packaging, apparel packaging also plays a significant role for a more sustainable textile industry [40]. The research conducted through the development of ideas about bioplastics for fashion retailers was obtained from in-depth interviews with 64 experts from the industry. Packaging in the textile industry is strategic for several reasons, namely, it can be the first impulse for buyers to buy, and it also shows a significant portion that is disposed of in third countries [42].

3.1.3. Process Innovation

There are several practices related to process innovation, including cleaner production, ecoefficiency, waste handling, supply chain management, technology, and enzyme-based textile processing. Indeed, all forms of these sustainability innovation practices are related to each other; however, the discussion is given to the tendency of each study to discuss the particular concept in more depth.

- Cleaner Production

Cleaner production reflects an integrative preventive environmental business strategy aimed at increasing overall efficiency and lowering risks to people and the environment while producing quality products [80]. Based on evidence from more than 100 large textile companies, it is evidenced that cleaner production practices improve operational, economic, and environmental performance, as well as are useful for communicating with stakeholders and gaining a long-term competitive advantage [38]. Cleaner production can be achieved through various innovative processes such as alternative dyeing technology using biomass pigment based on bioconversion or finishing process using nanotechnology [57,66,69]. When linked to the SDGs, cleaner production particularly contributes to the SDGs 9 (industry, innovation, and infrastructure), 12 (sustainable production and consumption), and 15 (protect the terrestrial life) [50]. In the context of SMEs, open innovation as well as economic incentives and government support encourage SMEs to progress toward cleaner production [44,54]. By researching 182 Indonesian batik SMEs, it was found a statistically significant relationship between open innovation and cleaner production, which implies that cleaner production can be achieved through open innovation [42].

- 2.

- Ecoefficiency

Ecoefficiency is an organization’s ability to provide competitively priced goods and services while minimizing environmental impact and resource use throughout their lifecycles, or, in simple terms, the idea of “creating more value with less environmental impact” [81]. Ecoefficiency is critical for the textile industry because it consumes a lot of resources such as water, electricity, and various types of chemicals over the course of a long process [68]. An investigation into the environmental impact of the textile industry water use systems based in Biella, Italy, found that resource efficiency can be supported by smart pumping systems, automatic dye and chemical dispensing, low liquor ratio jet dyeing machines, as well as pollution prevention and control through the use of natural dyes, advanced oxidation processes using Fenton’s reagent, and membrane bioreactors [65]. By developing an innovative dyeing protocol, it reported that they reduced production costs by about 50% and reduced CO2 emissions by around 55% compared to conventional protocols [66].

Ecoefficiency is mostly generated by technology. Technology reflects the replacement of machines or equipment with the latest technology that allows reduction of environmental impact [50]. This can be accomplished by increasing resource efficiency or reducing pollution from the process [65,66]. Smart pumping systems, jet dyeing, and jet waving looms are examples of resource-efficient technologies. Savings on jet weaving looms, for example, include the fact that with nearly the same resource consumption, it can provide nearly twice the performance of the old technology (880 RPM compared to 490 RPM) [50]. Examples of pollution-prevention technology include the advanced oxidation process and membrane bioreactors [65]. The total value added through replacement technology compared to the total investment made gave positive returns, providing about 1.5 times the baseline of the old technology [63].

- 3.

- Waste Handling

Waste handling is a form of sustainability innovation that focuses on activities to reduce, reuse, or recycle waste [78]. In the textile industry, waste is one of the big issues that is a global concern. To effectively deal with waste, strategic steps suggested by the reviewed works of the literature include paying attention to raw materials, waste management, and understanding and shaping consumer behavior. Based on study to 48 textile companies in the area of Yangtze River Delta in China and found that the highest levels of pollution were found in chemical fiber manufacturing’s raw material, especially PFCs, or perfluorinated compounds, which are commonly used in finishing [39]. Pollution reduction can also be conducted with raw material providers by asking suppliers with certain agreement schemes to regenerate waste generated from the company’s production process [37]. In addition, efforts to reduce waste are also carried out by innovating raw materials so that the waste produced can later be reduced so that it can comply with existing regulations while providing added value for the company [47,51]. The current regulations in Vietnam, for example, restrict the use of endocrine-disrupting surfactants, which makes it necessary for textile companies to comply with these provisions [47]. In terms of waste management, examples of innovations include the use of magnetic titania nanophotocatalists for photocatalytic creation of fuel gases, which in principle converts waste into energy [32]. Additionally, another example is the development of an integrated system of plasma pretreatment and biosynthesis [68]. Understanding and shaping consumer behavior through various communication channels, including digital channels, is equally important because currently, consumer interest is increasing, and activities such as garment recycling as an effort to build circular products are starting to become the “new normal” [58].

- 4.

- Supply Chain Management

Supply chain management refers to a company’s relationship toward upstream (raw material) and downstream (distribution) processes, which in the textile industry are highly complex and involve complex local and international networks [72]. Several innovative points that arise regarding supply chain management are supply chain traceability, modern slavery, and upstream and downstream connectivity. Supply chain traceability, especially for luxury brands, has become the norm, which is expected to also apply to nonluxury brands. Supply chain traceability can be carried out at various stages of the supply chain, starting from pre-procurement and procurement to sales and post-sales. Specific factors that can be investigated in these various stages, for example, are the carbon footprint, bribery, child labor [43], disposal mechanism, or export control. In terms of modern slavery, it is known that identifying hidden modern slavery, which usually involves labor agencies, is currently a difficult challenge, as revealed by a study of more than 100 firms in the clothing and textile industry in the United Kingdom [61]. Finally, strengthening the relationship with upstream and downstream is also a challenge because all phases in the supply chain are inter-related with each other so that it is necessary to strengthen long-term relationships, among others, through flexibility as well as the development of creative thinking so that from design to commercialization, the sustainability of innovation can be maintained [72].

- 5.

- Enzymatic textile process

The enzymatic textile process occurs at various stages of multifaceted textile production, from raw fabric production to finishing, in both textile mill and laundry operations [54]. Fiber modification in the raw fabric production stage, desizing and scouring in the preparation stage, bleach cleaning and dyeing in the dyeing stage, and softening in the finishing stage are some of the examples [54]. Another example is the use of crude enzymes from Aspergillus niger to convert tea polyphenols as a precursor into pigments via bioconversion or enzymatic synthesis of biodyes at a semi-industrial scale using a bioreactor and reverse osmosis apparatus [57]. The use of enzymes in evidence has been shown to reduce energy consumption while also reducing waste [57,68]. However, there are various challenges in implementing the enzymatic-based textile process originating from socioeconomic and regulatory factors [54].

- 6.

- Organizational innovation

There are several practices related to organizational innovation, including environmental management systems (EMS) and corporate policy, collaboration, business models, culture and knowledge management, and risk management.

- 7.

- Environmental management system (EMS) and corporate environmental policy

EMS and corporate environmental policy are a systematic approach to integrating environmental aspects in company management, with prominent programs commonly used being ISO 14001 and the Ecomanagement and Audit Scheme (EMAS) [82]. EMS can be formal, standardized, and widely accepted, or it can be an internal corporate environmental policy that is not as advanced as international certifications such as ISO 14001. This is especially true for SMEs with limited resources [78]. EMS and corporate environmental policy could facilitate companies in articulating their environmental and social responsibilities in a way that all company stakeholders can understand [36]. Based on an analysis of 56 Polish textile companies, it was concluded that the external barrier to EMS implementation is primarily the lack of government incentives and macroeconomic conditions [61].

- 8.

- Collaboration

Collaboration refers to the mutually beneficial cooperation of several parties in order to achieve a common goal. Collaboration is critical because the textile industry’s major challenges necessitate collaboration among various social actors in order to develop more sustainable textile industry solutions. When collaborating, trust needs to be established, as do collaborator capabilities, learning perspectives, and cultural compatibility [36,72]. Three parties that collaborate in common are known as the triple helix, covering industry, government, and knowledge institutions such as universities and research centers [39,53]. By using a case in luxury fashion, it was found that collaboration to find innovative solutions can be conducted from the upstream of the supply chain, considering that 70% of emissions can be traced from the upstream [43]. Collaboration provides tangible benefits in the form of optimization of resource usage, sharing of facilities or logistics capabilities, and enabling more systemic changes in the industry [39]. SMEs rarely collaborate with outside parties and collaboration needs to be conducted not only at the operational level, but also at the strategic level [34,42].

- 9.

- Business Model

The business model discussed in sustainability innovation is specifically related to circular business models (CBMs), which is a way for companies to create value to increase resource efficiency through longer product life and closing material loops [83]. CBMs are closely related to supply chain structure and change the rebound effect [37,39]. The rebound effect reflects changes in consumption patterns through the mechanism of re-spending and substituting consumption [39,84]. The rebound effect reflects increased efficiency, which often results in cost savings, allowing individuals to buy more [85]. Some examples of studies on business models at the second-hand fashion stores in the USA, where it was found that customers are the main partners as well as suppliers for stores, and the profit is minimal considering it should also be shared with the customers; and a study in the context of Colombia which found that barriers in developing a more sustainable business model can come from the lack of awareness on social impact, legislation, and relevant knowledge [57,60]. It was argued that formulating an innovative business model, rather than just product or process innovation, was required for a circular economy because it was a viable way to reuse products and materials [61]. Young entrepreneurs and consumers were identified as key actors in the development of innovative business models in the textile industry as having greater potential [60,67].

- 10.

- Culture and knowledge management

Culture reflects the collection of assumptions and behavior within the organization, while knowledge management is more about how companies manage their knowledge that determines how companies can innovate [86,87]. Green culture as an adaptive attitude that is a cultural attribute that allows organizations to be adaptive to environmental changes [38]. This is necessary considering the increasing social and political pressure to contribute to green products. The formation of this culture affects the innovation capacity of employees and organizations, ultimately determining a company’s performance [40]. Strengthening knowledge capabilities and sharing are two cultural traits that are critical for organizational survival and success. Successful firms were evidenced to have better systems and practices for capturing and managing knowledge both internally and externally [44]. In the context of South Africa, the biggest challenge in knowledge management is the loss of valuable knowledge about suppliers and their practices [44].

- 11.

- Risk Management

Risk management is an inseparable part of innovation because product and process development are inextricably linked to the potential side effects and risks. Prior researchers examined environmental risk management practices, which include ecological risk, health risk management, technical risk, and financial risk, in the context of Vietnam, which is moving toward chemical elimination [45]. It was found that the perception of financial risk and benefits moderated by market strategy determines attitude and tentative behavior [47]. Risk assessment related to EHS/S environmental, human health and safety, and sustainability is difficult to assess by conventional risk analysis such as failure mode effect analysis (FMEA) or SWOT, and what is recommended is a life-cycle perspective to mitigate risk in various stages of the product, including the time of commercialization [70].

The data structure that illustrates the coding process of the first-order concept in the form of an example of direct quotes from the literature reviewed and the second-order concept of the subthemes and aggregated dimensions as central themes can be seen in Figure 3.

Figure 3.

Coding of themes and subthemes [11,31,34,35,36,37,38,40,42,44,45,48,51,52,55,57,58,59,61,63,64,66,68,70,72,75].

The product innovation practiced in the textile industry is innovating to produce products that are safer, more efficient, healthier, and environmentally friendly and use less material, less waste, and less energy. These activities include ecodesign, ecolabel, life-cycle analysis, material, and packaging. The dominant innovation that commonly appears in textile products appear in the disclosure statement through labeling that the product has passed sustainable production measures. This labeling product will be the following requirement that every stakeholder in the textile industry should adopt to ensure that this label is genuine, accurate, and credible.

The second innovations practice is a process innovation that requires cleaner production, ecoefficiency, waste handling, sustainable supply chain management, and enzymatic textile processes. We assessed the various innovations that had been practiced in the textile industry. In contrast, other innovations such as enzymatic textile processing, supply chain management, and cleaner production will be the next challenge in processing innovation in the textile industry.

The last innovation is organizational innovation practices, which discusses how the organization dimension is a critical driver to innovate for sustainability. In the current state of research, the fundamental aspect of essential drivers is to support innovation in sustainability. The literature review results suggest that more collaboration and business model innovation is crucial to strengthening. In contrast, EMS and corporate policy, risk, and culture knowledge management will be more challenging in the coming decades.

4. Discussion

This study sets out with the purpose to evaluate the current state of research on sustainability innovation in the textile industry, as well as to identify themes and subthemes related to sustainability innovation practices in the industry. The attention of researchers has increased in the last decade. This is not surprising, as reflected in almost all the papers reviewed, which highlight in their background the tough challenge faced by textile industry from the sustainability perspective and emphasize the need for new innovative approaches for this industry. These challenges exist in every life cycle starting from the premanufacturing to the end-of-life [45]. That is why LCA is one of the most researched sustainability innovation practices along with materials, ecolabel, ecodesign, cleaner production, collaboration, and business model [64,66,67]. In premanufacturing, for example, fiber and fabric production, issues such as child labor or the use of hazardous chemicals or those from protected species are often involved [54]. It is known that most of the pollution at disposal can be traced to raw materials. In the manufacturing phase, the use of toxic chemicals and the extensive consumption of resources are highlighted [3]. In the use and end-of-life phases, the focus is mainly on the disposal problem [22].

The urge to innovate more sustainably is driven by various factors, both internally and externally. Internally, there is an awareness that cleaner and more efficient production, as seen in sustainability innovation practices such as ecoefficiency, cleaner production, or technology replacement, has a positive impact on company performance. For example, the energy savings used have almost doubled, reducing production costs and emission levels compared to traditional methods [50,65,68]. The external pressure seems to be stronger, especially that from increasing demand for innovative and sustainable products from customers as well as from regulations. Sustainability will be a significant factor in consumer purchasing mass market apparels in 2025, according to a McKinsey study released in 2020 [6]. The increasing demand from consumers for sustainable and innovative products makes companies, whether they like it or not, able to adapt to this trend [68]. This changing trend is in line with the increasing role of digitization and e-commerce in business [6]. Regulation is also a strong driver and tool for coercion to encourage companies in the textile industry to innovate more sustainably [47,51].

This study found that the dominant sustainability innovation practice discussed in the textile industry is more related to the ecological innovation aspect compared to social innovation. All sustainability innovation practices discussed are mostly about ecoinnovation, whether it be in product innovation such as ecodesign, LCA, material, or packaging; on process innovation such as cleaner production, ecoefficiency, or waste handling; or on organizational innovation such as EMS implementation or business model innovation. One of the social issues discussed is modern slavery, which is included in the subtheme of supply chain management, which is discussed specifically by Stevenson and Cole (2018). Another study that discusses social issues, such as child labor or bribery in the procurement of raw materials or distribution of finished goods, is that in reference [45]. Sustainability innovation, especially in the form of cleaner production, contributes to SDGs 9 (industry, innovation, and infrastructure), 12 (sustainable production and consumption), and 15 (climate action) when linked to the SDGs (protect the terrestrial life) [48].

It is interesting no note that there are several sustainability innovation practices that are unique to the textile industry, such as ecolabeling on product innovation or enzymatic textile processing on process innovation. To name a few, popular ecolabels in the textile industry include the bluesign standard, which is concerned with all inputs used in the manufacturing process in order to reduce the ecological footprint; BMP certified cotton, which comes from Australia and is concerned with growing cotton in an environmentally friendly manner; and Ecoproof, which considers environmental and social aspects throughout the textile industry’s life cycle [74,75]. Some examples of enzymatic textile processing include fiber modification in the raw fabric production stage, desizing and scouring in the preparation stage, bleach cleaning and dyeing in the dyeing stage, and softening in the finishing stage [54]. Another example is the semi-industrial scale use of crude enzymes from Aspergillus niger to convert tea polyphenols as a precursor into pigments via bioconversion or enzymatic synthesis of biodyes using a bioreactor and reverse osmosis apparatus [57].

Common themes that are also discussed in almost all the articles reviewed are the barriers to practicing sustainability innovation in the textile industry. An example of internal barrier is a lack of awareness of the need to innovate sustainably, which can be due to a lack of knowledge regarding recent innovation impact toward environmental and social aspects, as well as a lack of information regarding market needs for innovative and sustainable products [46,59]. Barriers that are also frequently mentioned are related to investment and production costs, including technology replacement, R&D costs, or material replacement, which in turn makes the selling price to consumers high and reduces the attractiveness of the product [43,53]. The external barrier in developing sustainability innovation practices in the textile industry, for example, is the lack of government support in the form of financial incentives and nonfinancial support. Lack of government support is considered to hinder sustainability innovation’s growth and development to a more advanced stage [54,63]. Another barrier is the challenges faced when seeking potential collaboration partners, namely, in the form of culture and capability compatibility [36,72]. Unstable macroeconomic conditions are also considered to be a barrier in the development of sustainability innovation [63]. Meanwhile, there are also more implicit barriers, namely, hidden unethical practices in the textile supply chain, such as modern slavery practices that involve labor agencies [61].

Asia is an understudied region despite being the center of global textile production and faces numerous severe sustainability challenges. For example, only a handful of publications represent China, India, and Bangladesh, the world’s most significant garment and textile producers. This situation contrasts that of Europe, where there is dominant research in those areas. Indeed, the sustainability challenges of a particular industry in a specific region may not be directly proportional to the number of studies in that region. Similar to sustainability innovation studies primarily conducted in advanced economies, especially Europe, most researchers are from Europe [27,81]. However, this is a reminder of the importance of conducting more in-depth research on the textile industry in Asia, which is the current center of garment and textile production.

After we analyzed and synthesized the sustainable innovation, we mapped the current state of research into two shortcomings and future research innovation in the industry according to the innovation objectives. We defined the objective for each innovation according to the aggregation characteristic that we conducted in the Section 3. We separated the path of innovation research according to current states as the research was conducted. The future direction that innovation will be in the shortly coming period, and future research innovation is the expected research that will be prominent in the following decades.

We separated the future into two categories. The shortly coming innovations are the innovations that will be already available and will be urgently required to be expanded in the shortly coming period. This innovation has been identified as mature and is receiving attention from policymakers and market practitioners that achieved the objective of sustainability. Future research should be conducted on the innovation that has been investigated but has not entirely been implemented by the industry and has already drawn the attention of market practitioners, policymakers, and academia as a significant prospect of innovation for sustainability in the textile market. For a complete definition about our mapping, please see Table 6.

Table 6.

The research path of sustainable innovation in the textile industry.

5. Conclusions

The aim of this study is to use a systematic review approach to synthesize empirical knowledge relevant to sustainable innovation in the textile industry. Sustainability innovation practices in terms of product innovation types include ecodesign, ecolabel, life cycle assessment, materials, and packaging; process innovation includes cleaner production, ecoefficiency, waste handling, supply chain management, and enzymatic textile processing; and organizational innovation includes EMS and corporate policy, collaboration, business model innovation, culture and knowledge management, and enzymatic textile processing. Various factors, both internal and external, drive the desire to innovate more sustainably. It is worth noting that the textile industry has its own set of sustainability innovation practices, such as ecolabeling on product innovation and enzymatic textile processing on process innovation. The barriers to practicing sustainability innovation in the textile industry such as cost, lack of knowledge, lack of government support, or macroeconomic concerns are common themes that are discussed in the articles reviewed.

This study has several limitations. Since the literature search was limited to two mainstream databases, namely, Scopus and Web of Science, which are widely regarded as the largest and most comprehensive databases available today, it is possible that other relevant empirical articles were missed. Therefore, other databases can be also involved in future studies. One of the inclusion criteria in the search is a research area that is limited to business, management, and accounting or business economics, given the focus of this study, which is on aspects of innovation and sustainability, particularly from the perspective of business economics. Outside of this research area, the inclusion criteria may exclude innovative and sustainable empirical studies. Further research can broaden the scope of the study to include other research areas. A systematic review is also used in this study to obtain in-depth qualitative insight into the current state and practice of sustainability innovation from the published literature. Future research can take a more quantitative approach, such as bibliometrics or meta-analysis, to gain insight with a different approach.

Author Contributions

Conceptualization, B.H. and I.P.; methodology, B.H.; software, B.H.; validation, B.H., I.P., V.S. and Y.S.; formal analysis, B.H., I.P., V.S. and Y.S.; writing—original draft preparation, B.H., I.P., V.S. and Y.S.; funding acquisition, I.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Universitas Padjadjaran Academic Leadership Grant Scheme, grant number 1959/UN6.3.1/PT.00/2021 and The APC was funded by Universitas Padjadjaran.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Desore, A.; Narula, S.A. An Overview on Corporate Response towards Sustainability Issues in Textile Industry. Environ. Dev. Sustain. 2018, 20, 1439–1459. [Google Scholar] [CrossRef]

- Madhav, S.; Ahamad, A.; Singh, P.; Mishra, P.K. A Review of Textile Industry: Wet Processing, Environmental Impacts, and Effluent Treatment Methods. Environ. Qual. Manag. 2018, 27, 31–41. [Google Scholar] [CrossRef]

- Roy, M.; Sen, P.; Pal, P. An Integrated Green Management Model to Improve Environmental Performance of Textile Industry towards Sustainability. J. Clean. Prod. 2020, 271, 122656. [Google Scholar] [CrossRef]

- Sun, Z.; Sun, L.; Strang, K. Big Data Analytics Services for Enhancing Business Intelligence. J. Comput. Inf. Syst. 2018, 58, 162–169. [Google Scholar] [CrossRef]

- Grand View Research. Textile Market Size|Industry Analysis Report, 2021–2028; Grand View Research: San Francisco, CA, USA, 2021. [Google Scholar]

- Balchandani, A.; Beltrami, M.; Berg, A.; Hedrich, S.; Rölkens, F.; Amed, I. The State of Fashion 2021: In Search of Promise in Perilous Times; McKinsey: Atlanta, GA, USA, 2020; pp. 8–118. [Google Scholar]

- Thiry, M.C. Staying Alive: Making Textiles Sustainable. AATCC Rev. 2011, 11, 26–32. [Google Scholar]

- Guarnieri, P.; Trojan, F. Decision Making on Supplier Selection Based on Social, Ethical, and Environmental Criteria: A Study in the Textile Industry. Resour. Conserv. Recycl. 2019, 141, 347–361. [Google Scholar] [CrossRef]

- Niinimäki, K. Ethical Foundations in Sustainable Fashion. Text. Cloth. Sustain. 2015, 1, 3. [Google Scholar] [CrossRef]

- Loo, B.P.Y. The Textile and Clothing Industries under the Fifth Kondratieff Wave: Some Insights from the Case of Hong Kong. World Dev. 2002, 30, 847–872. [Google Scholar] [CrossRef]

- Salo, H.H.; Suikkanen, J.; Nissinen, A. Eco-Innovation Motivations and Ecodesign Tool Implementation in Companies in the Nordic Textile and Information Technology Sectors. Bus Strategy Environ. 2020, 29, 2654–2667. [Google Scholar] [CrossRef]

- Pattnaik, P.; Dangayach, G.S.; Bhardwaj, A.K. A Review on the Sustainability of Textile Industries Wastewater with and without Treatment Methodologies. Rev. Environ. Health 2018, 33, 163–203. [Google Scholar] [CrossRef]

- Patti, A.; Cicala, G.; Acierno, D. Eco-Sustainability of the Textile Production: Waste Recovery and Current Recycling in the Composites World. Polymers 2021, 13, 134. [Google Scholar] [CrossRef] [PubMed]

- Kazancoglu, I.; Kazancoglu, Y.; Yarimoglu, E.; Kahraman, A. A Conceptual Framework for Barriers of Circular Supply Chains for Sustainability in the Textile Industry. Sustain. Dev. 2020, 28, 1477–1492. [Google Scholar] [CrossRef]

- Jia, F.; Yin, S.; Chen, L.; Chen, X. The Circular Economy in the Textile and Apparel Industry: A Systematic Literature Review. J. Clean. Prod. 2020, 259, 120728. [Google Scholar] [CrossRef]

- Maia, L.C.; Alves, A.C.; Leão, C.P. Implementing Lean Production to Promote Textile and Clothing Industry Sustainability. In Lean Engineering for Global Development; Springer: Berlin/Heidelberg, Germany, 2019; pp. 319–343. [Google Scholar]

- Rahman, M.; Billah, M.M.; Hack-Polay, D.; Alam, A. The Use of Biotechnologies in Textile Processing and Environmental Sustainability: An Emerging Market Context. Technol. Forecast. Soc. Chang. 2020, 159, 120204. [Google Scholar] [CrossRef]

- Luque, A.; Herrero-García, N. How Corporate Social (Ir) Responsibility in the Textile Sector Is Defined, and Its Impact on Ethical Sustainability: An Analysis of 133 Concepts. Corp. Soc Responsib. Environ. Manag. 2019, 26, 1285–1306. [Google Scholar] [CrossRef]

- Hodges, N.J.; Link, A.N. Innovation by Design. Small Bus. Econ. 2019, 52, 395–403. [Google Scholar] [CrossRef]

- Nidumolu, R.; Prahalad, C.K.; Rangaswami, M.R. Why Sustainability Is Now the Key Driver of Innovation. Harv. Bus. Rev. 2009, 57–64. [Google Scholar]

- Harsanto, B.; Michaelides, R.; Drummond, H. Sustainability-Oriented Innovation (SOI) in Emerging Economies: A Preliminary Investigation from Indonesia. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1553–1557. [Google Scholar]

- Klewitz, J.; Hansen, E.G. Sustainability-Oriented Innovation of SMEs: A Systematic Review. J Clean Prod. 2014, 65, 57–75. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a Systematic Review. In The SAGE Handbook of Organizational Research Methods; Sage Publishing: Thousand Oaks, CA, USA, 2009; pp. 671–689. [Google Scholar]

- Harsanto, B. The First-Three-Month Review of Research on COVID-19: A Scientometrics Analysis. In Proceedings of the IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Cardiff, UK, 15–17 June 2020. [Google Scholar]

- Hansen, E.G.; Große-Dunker, F. Sustainability-Oriented Innovation. In Encyclopedia of Corporate Social Responsibility; Springer: Berlin/Heidelberg, Germany, 2013; pp. 2407–2417. [Google Scholar]

- Harsanto, B.; Mulyana, A.; Faisal, Y.A.; Shandy, V.M.; Alam, M. A Systematic Review on Sustainability-Oriented Innovation in the Social Enterprises. Sustainability 2022, 14, 14771. [Google Scholar] [CrossRef]

- Gioia, D.A.; Corley, K.G.; Hamilton, A.L. Seeking Qualitative Rigor in Inductive Research: Notes on the Gioia Methodology. Organ Res. Methods 2012, 16, 15–31. [Google Scholar] [CrossRef]

- Merlo, E.; Perugini, M. The Determinants of the Emergence of Turin as the First Capital of Italian Fashion Industry (1900–1960). Fash. Theory 2020, 24, 325–348. [Google Scholar] [CrossRef]

- Schiederig, T.; Tietze, F.; Herstatt, C. Green Innovation in Technology and Innovation Management—An Exploratory Literature Review. RD Manag. 2012, 42, 180–192. [Google Scholar] [CrossRef]

- Rahman, M.T.; Khandaker, N. Physical Properties of Dewatered Waste Sludge from Textile Processing Wastewater Facility for Construction Material Application. In Renewable Energy and Its Innovative Technologies; Springer: Berlin/Heidelberg, Germany, 2019; pp. 25–30. [Google Scholar]

- Adu, C.; Zhu, C.; Jolly, M.; Richardson, R.M.; Eichhorn, S.J. Continuous and Sustainable Cellulose Filaments from Ionic Liquid Dissolved Paper Sludge Nanofibres. J. Clean. Prod. 2021, 280, 124503. [Google Scholar] [CrossRef]

- Harifi, T.; Montazer, M.; Dillert, R.; Bahnemann, D.W. TiO2/Fe3O4/Ag Nanophotocatalysts in Solar Fuel Production: New Approach to Using a Flexible Lightweight Sustainable Textile Fabric. J. Clean. Prod. 2018, 196, 688–697. [Google Scholar]

- Sankaran, V.; Cherif, C. New Machine Concept for Producing 3-D Stitch-Bonded Fabrics. Fibres Text. East. Eur. 2013, 97, 92–96. [Google Scholar]

- Abreu, M.C.S.á.; Ferreira, F.N.H.; Proença, J.F.; Ceglia, D. Collaboration in Achieving Sustainable Solutions in the Textile Industry. J. Bus. Ind. Mark. 2021, 36, 1614–1626. [Google Scholar] [CrossRef]

- Wong, D.T.W.; Ngai, E.W.T. Economic, Organizational, and Environmental Capabilities for Business Sustainability Competence: Findings from Case Studies in the Fashion Business. J. Bus. Res. 2021, 126, 440–471. [Google Scholar] [CrossRef]

- Cesar da Silva, P.; Cardoso de Oliveira Neto, G.; Ferreira Correia, J.M.; Pujol Tucci, H.N. Evaluation of Economic, Environmental and Operational Performance of the Adoption of Cleaner Production: Survey in Large Textile Industries. J. Clean. Prod. 2021, 278, 123855. [Google Scholar] [CrossRef]

- Siderius, T.; Poldner, K. Reconsidering the Circular Economy Rebound Effect: Propositions from a Case Study of the Dutch Circular Textile Valley. J. Clean. Prod. 2021, 293, 125996. [Google Scholar] [CrossRef]

- Sharma, S.; Prakash, G.; Kumar, A.; Mussada, E.K.; Antony, J.; Luthra, S. Analysing the Relationship of Adaption of Green Culture, Innovation, Green Performance for Achieving Sustainability: Mediating Role of Employee Commitment. J. Clean. Prod. 2021, 303, 127039. [Google Scholar] [CrossRef]

- Gu, C.; Xu, C.; Zhou, Q.; Shen, C.; Ma, C.; Liu, S.; Yin, S.; Li, F. Congener- and Isomer-Specific Perfluorinated Compounds in Textile Wastewater from Southeast China. J. Clean. Prod. 2021, 320, 128897. [Google Scholar] [CrossRef]

- Friedrich, D. What Makes Bioplastics Innovative for Fashion Retailers? An in-Depth Analysis According to the Triple Bottom Line Principle. J. Clean. Prod. 2021, 316, 128257. [Google Scholar] [CrossRef]

- Notaro, S.; Paletto, A. Consumers’ Preferences, Attitudes and Willingness to Pay for Bio-Textile in Wood Fibers. J. Retail. Consum. Serv. 2021, 58, 102304. [Google Scholar]

- Rumanti, A.A.; Sunaryo, I.; Wiratmadja, I.I.; Irianto, D. Cleaner Production through Open Innovation in Indonesian Batik Small and Medium Enterprises (SME). TQM J. 2021, 33, 1347–1372. [Google Scholar] [CrossRef]

- Olatubosun, P.; Charles, E.; Omoyele, T. Rethinking Luxury Brands and Sustainable Fashion Business Models in a Risk Society. J. Des. Bus. Soc. 2021, 7, 49–81. [Google Scholar] [CrossRef]

- Wood, G.; Bischoff, C. Challenges and Progress in Integrating Knowledge: Cases from Clothing and Textiles in South Africa. J. Knowl. Manag. 2020, 24, 32–55. [Google Scholar] [CrossRef]

- Ho, H.T.T.; Watanabe, T. The Dynamics of Textile Firm Responses to the Restriction of Endocrine Disrupting Surfactants: A Vietnam Case Study. J. Risk Res. 2020, 23, 504–521. [Google Scholar] [CrossRef]

- Muhardi, M.; Cintyawati, C.; Adwiyah, R.; Hami, N.; Hashim, R.; Omar, S.; Shafie, S.M. The Implementation of Sustainable Manufacturing Practice in Textile Industry: An Indonesian Perspective. J. Asian Financ. Econ. Bus. 2020, 7, 1041–1047. [Google Scholar] [CrossRef]

- Achabou, M.A.; Dekhili, S.; Codini, A.P. Consumer Preferences towards Animal-Friendly Fashion Products: An Application to the Italian Market. J. Consum. Mark. 2020, 37, 661–673. [Google Scholar] [CrossRef]

- de Oliveira Neto, G.C.; Ferreira Correia, J.M.; Silva, P.C.; de Oliveira Sanches, A.G.; Lucato, W.C. Cleaner Production in the Textile Industry and Its Relationship to Sustainable Development Goals. J. Clean. Prod. 2019, 228, 1514–1525. [Google Scholar] [CrossRef]

- Echeverria, C.A.; Handoko, W.; Pahlevani, F.; Sahajwalla, V. Cascading Use of Textile Waste for the Advancement of Fibre Reinforced Composites for Building Applications. J. Clean. Prod. 2019, 208, 1524–1536. [Google Scholar] [CrossRef]

- Schellenberger, S.; Hill, P.J.; Levenstam, O.; Gillgard, P.; Cousins, I.T.; Taylor, M.; Blackburn, R.S. Highly Fluorinated Chemicals in Functional Textiles Can Be Replaced by Re-Evaluating Liquid Repellency and End-User Requirements. J. Clean. Prod. 2019, 217, 134–143. [Google Scholar] [CrossRef]

- Sandvik, I.M.; Stubbs, W. Circular Fashion Supply Chain through Textile-to-Textile Recycling. J. Fash. Mark. Manag. 2019, 23, 366–381. [Google Scholar] [CrossRef]

- Rahman, M.; Billah, M.M.; Hack-Polay, D. What Is Hindering Change? Anticipating the Barriers to the Adoption of Enzyme-Based Textile Processing in a Developing Country. Bus. Strategy Dev. 2019, 2, 137–147. [Google Scholar] [CrossRef]

- Paraska, O.; Rak, T.; Rotar, D.; Radek, N. Research on the Effect of Compositions of Ecologically Safe Substances on the Hygienic Properties of Textile Products. East.-Eur. J. Enterp. Technol. 2019, 1, 43–49. [Google Scholar] [CrossRef]

- Gotmare, V.D.; Kole, S.S.; Athawale, R.B. Sustainable Approach for Development of Antimicrobial Textile Material Using Nanoemulsion for Wound Care Applications. Fash. Text. 2018, 5, 25. [Google Scholar] [CrossRef]

- Gong, J.; Wang, F.; Ren, Y.; Li, Z.; Zhang, J.; Li, Q. Preparation of Biomass Pigments and Dyeing Based on Bioconversion. J. Clean. Prod. 2018, 182, 301–312. [Google Scholar] [CrossRef]

- Vehmas, K.; Raudaskoski, A.; Heikkilä, P.; Harlin, A.; Mensonen, A. Consumer Attitudes and Communication in Circular Fashion. J. Fash. Mark. Manag. 2018, 22, 286–300. [Google Scholar] [CrossRef]

- Gopalakrishnan, S.; Matthews, D. Collaborative Consumption: A Business Model Analysis of Second-Hand Fashion. J. Fash. Mark. Manag. 2018, 22, 354–368. [Google Scholar] [CrossRef]

- Bhamra, T.; Hernandez, R.J.; Rapitsenyane, Y.; Trimingham, R. Product Service Systems: A Sustainable Design Strategy for SMEs in the Textiles and Leather Sectors. She Ji J. Des. Econ. Innov. 2018, 4, 229–248. [Google Scholar] [CrossRef]

- Stevenson, M.; Cole, R. Modern Slavery in Supply Chains: A Secondary Data Analysis of Detection, Remediation and Disclosure. Supply Chain. Manag. 2018, 23, 81–99. [Google Scholar] [CrossRef]

- Chan, C.K.; Shin, J.; Jiang, S.X.K. Development of Tailor-Shaped Bacterial Cellulose Textile Cultivation Techniques for Zero-Waste Design. Cloth. Text. Res. J. 2018, 36, 33–44. [Google Scholar] [CrossRef]

- Burzyńska, D.; Jabłońska, M.; Dziuba, R. Opportunities and Conditions for the Development of Green Entrepreneurship in the Polish Textile Sector. Fibres Text. East. Eur. 2018, 26, 13–19. [Google Scholar] [CrossRef]

- Franco, M.A. Circular Economy at the Micro Level: A Dynamic View of Incumbents’ Struggles and Challenges in the Textile Industry. J. Clean. Prod. 2017, 168, 833–845. [Google Scholar] [CrossRef]

- Angelis-Dimakis, A.; Alexandratou, A.; Balzarini, A. Value Chain Upgrading in a Textile Dyeing Industry. J. Clean. Prod. 2016, 138, 237–247. [Google Scholar] [CrossRef]

- Busi, E.; Maranghi, S.; Corsi, L.; Basosi, R. Environmental Sustainability Evaluation of Innovative Self-Cleaning Textiles. J. Clean. Prod. 2016, 133, 439–450. [Google Scholar] [CrossRef]

- Armstrong, C.M.; Niinimäki, K.; Kujala, S.; Karell, E.; Lang, C. Sustainable Product-Service Systems for Clothing: Exploring Consumer Perceptions of Consumption Alternatives in Finland. J. Clean. Prod. 2015, 97, 30–39. [Google Scholar] [CrossRef]

- Parisi, M.L.; Fatarella, E.; Spinelli, D.; Pogni, R.; Basosi, R. Environmental Impact Assessment of an Eco-Efficient Production for Coloured Textiles. J. Clean. Prod. 2015, 108, 514–524. [Google Scholar] [CrossRef]

- Terinte, N.; Manda, B.M.K.; Taylor, J.; Schuster, K.C.; Patel, M.K. Environmental Assessment of Coloured Fabrics and Opportunities for Value Creation: Spin-Dyeing versus Conventional Dyeing of Modal Fabrics. J. Clean. Prod. 2014, 72, 127–138. [Google Scholar] [CrossRef]

- Köhler, A.R.; Som, C. Risk Preventative Innovation Strategies for Emerging Technologies the Cases of Nano-Textiles and Smart Textiles. Technovation 2014, 34, 420–430. [Google Scholar] [CrossRef]

- Hansen, E.G.; Schaltegger, S. 100 per Cent Organic? A Sustainable Entrepreneurship Perspective on the Diffusion of Organic Clothing. Corp. Gov. Int. J. Bus. Soc. 2013, 13, 583–598. [Google Scholar] [CrossRef]

- Curwen, L.G.; Park, J.; Sarkar, A.K. Challenges and Solutions of Sustainable Apparel Product Development: A Case Study of Eileen Fisher. Cloth. Text. Res. J. 2013, 31, 32–47. [Google Scholar] [CrossRef]

- UNOPS. A Guide to Environmental Labels-for Procurement Practitioners of the United Nations System; UNOPS: Copenhagen, Denmark, 2009. [Google Scholar]

- Hayat, N.; Hussain, A.; Lohano, H.D. Eco-Labeling and Sustainability: A Case of Textile Industry in Pakistan. J. Clean. Prod. 2020, 252, 119807. [Google Scholar] [CrossRef]

- Big Room Inc. Ecolabel Index | Who’s Deciding What’s Green? Available online: http://www.ecolabelindex.com/ (accessed on 20 November 2021).

- Ecosystems United. The Different Types of Ecolabels—ECOSYSTEMS UNITED. Available online: https://ecosystemsunited.com/2019/11/15/the-different-types-of-ecolabels/ (accessed on 20 November 2021).

- Eryuruk, S.H. Greening of the Textile and Clothing Industry. Fibres Text. East. Eur. 2012, 95, 22–27. [Google Scholar]

- Harsanto, B.; Permana, C.T. Sustainability-Oriented Innovation (SOI) in the Cultural Village: An Actor-Network Perspective in the Case of Laweyan Batik Village. J. Cult. Herit. Manag. Sustain. Dev. 2021, 11, 297–311. [Google Scholar] [CrossRef]

- Gumbira, G.; Harsanto, B. Decision Support System for an Eco-Friendly Integrated Coastal Zone Management (ICZM) in Indonesia. Int. J. Adv. Sci. Eng. Inf. Technol. 2019, 9, 1177–1182. [Google Scholar] [CrossRef]

- Hens, L.; Block, C.; Cabello-Eras, J.J.; Sagastume-Gutierez, A.; Garcia-Lorenzo, D.; Chamorro, C.; Herrera Mendoza, K.; Haeseldonckx, D.; Vandecasteele, C. On the Evolution of “Cleaner Production” as a Concept and a Practice. J. Clean. Prod. 2018, 172, 3323–3333. [Google Scholar] [CrossRef]

- WBCSD. Ecoefficiency: Creating More Value with Less Impact; World Business Council for Sustainable Development: Geneva, Switzerland, 2000. [Google Scholar]

- Ziegler, A.; Seijas Nogareda, J. Environmental Management Systems and Technological Environmental Innovations: Exploring the Causal Relationship. Res. Policy 2009, 38, 885–893. [Google Scholar] [CrossRef]

- Nußholz, J.L.K. Circular Business Models: Defining a Concept and Framing an Emerging Research Field. Sustainability 2017, 9, 1810. [Google Scholar] [CrossRef]

- Warmington-Lundström, J.; Laurenti, R. Reviewing Circular Economy Rebound Effects: The Case of Online Peer-to-Peer Boat Sharing. Resour. Conserv. Recycl. X 2020, 5, 100028. [Google Scholar] [CrossRef]

- Thiesen, J.; Christensen, T.S.; Kristensen, T.G.; Andersen, R.D.; Brunoe, B.; Gregersen, T.K.; Thrane, M.; Weidema, B.P. Rebound Effects of Price Differences. Int. J. Life Cycle Assess. 2008, 13, 104–114. [Google Scholar] [CrossRef]

- Schein, E.H. Organizational Culture and Leadership; John Wiley & Sons: Hoboken, NJ, USA, 2010; Volume 2. [Google Scholar]

- Plessis, M. The Role of Knowledge Management in Innovation. J. Knowl. Manag. 2007, 11, 20–29. [Google Scholar] [CrossRef]

- Adams, R.; Jeanrenaud, S.; Bessant, J.; Denyer, D.; Overy, P. Sustainability-Oriented Innovation: A Systematic Review. Int. J. Manag. Rev. 2016, 18, 180–205. [Google Scholar] [CrossRef]

- Harsanto, B.; Mulyana, A.; Faisal, Y.A.; Shandy, V.M. Open Innovation for Sustainability in the Social Enterprises: An Empirical Evidence. J. Open Innov. Technol. Mark. Complex. 2022, 8, 160. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).