Dual Effects of N-Butanol and Magnetite Nanoparticle to Biodiesel-Diesel Fuel Blends as Additives on Emission Pattern and Performance of a Diesel Engine with ANN Validation

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Materials Sources

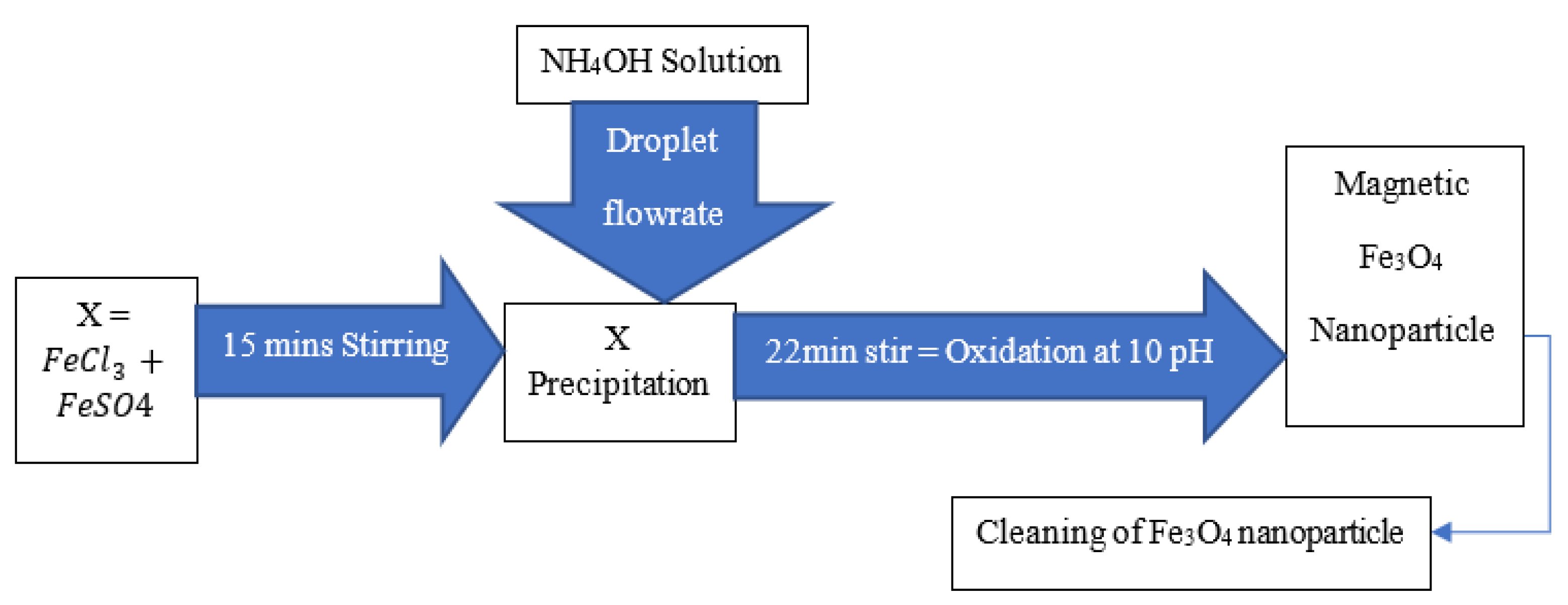

2.2. Methods for Processing Blends and Experimentation

2.3. Fuel Blending

2.4. Engine Set-Up and Specification

2.5. Engine Operating Conditions for Experiment

3. Artificial Neural Network Modelling (ANN Model)

4. Results of Experiments and Discussions

4.1. Particle Size Impact

4.2. Characterisation of Fuel Samples

4.3. Performance Parameters

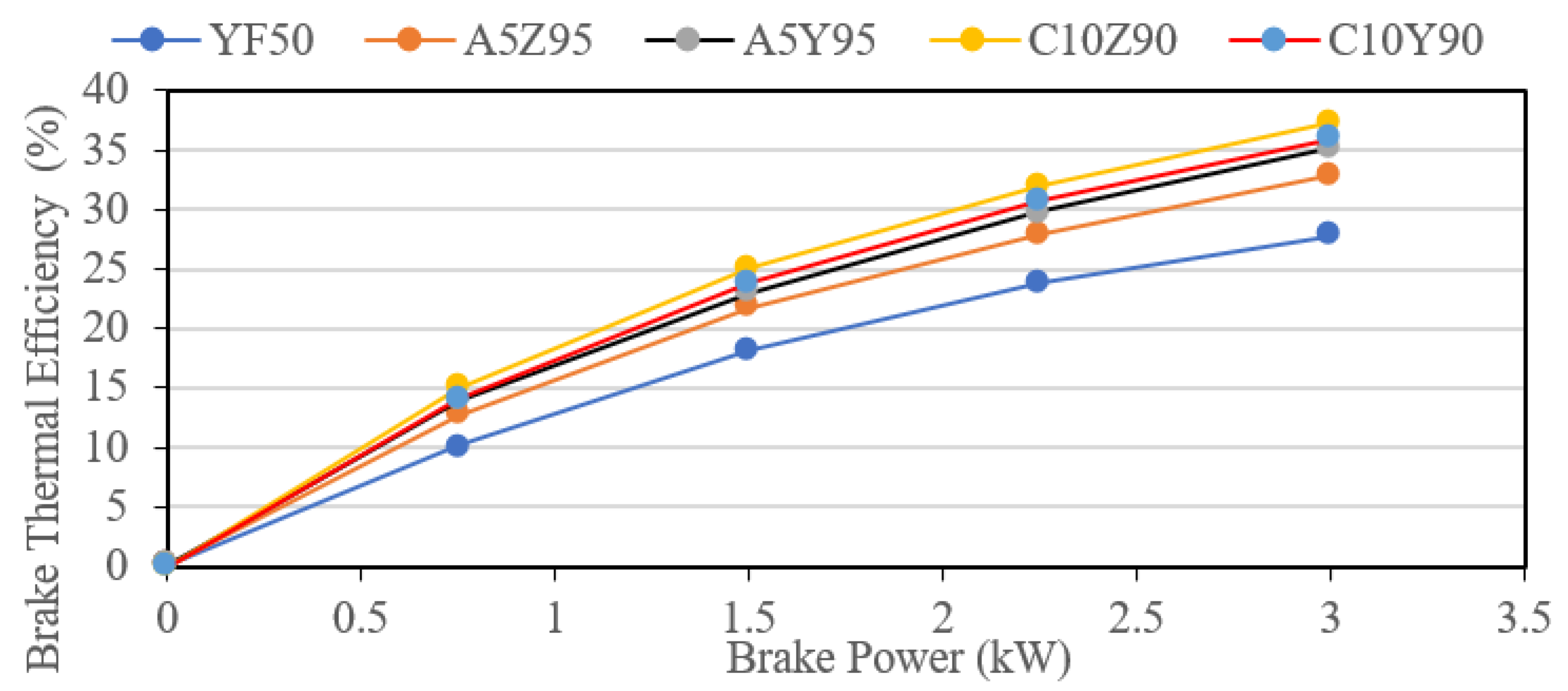

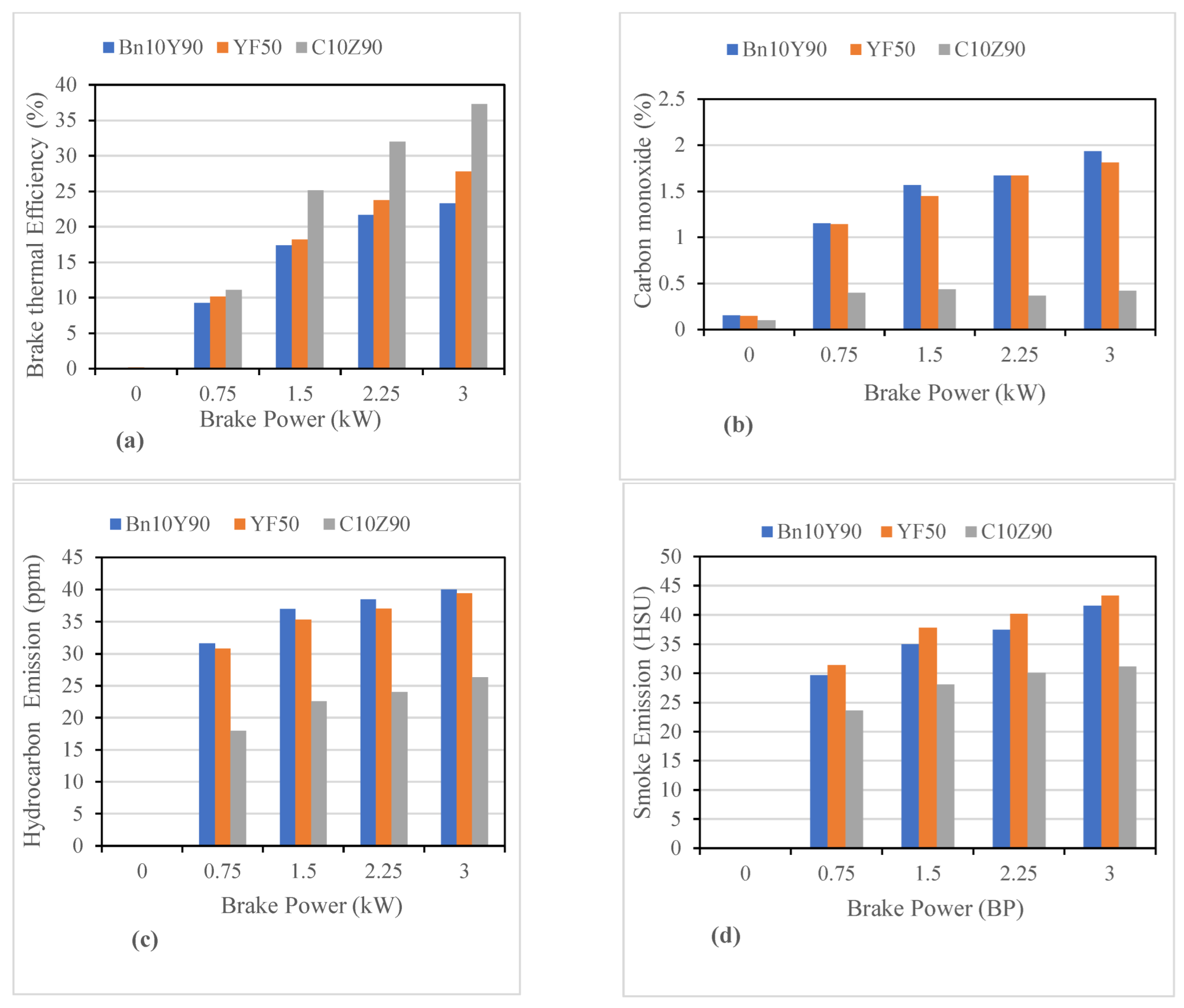

4.3.1. Brake Thermal Efficiency (BTE)

4.3.2. Brake Specific Fuel Consumption (BSFC)

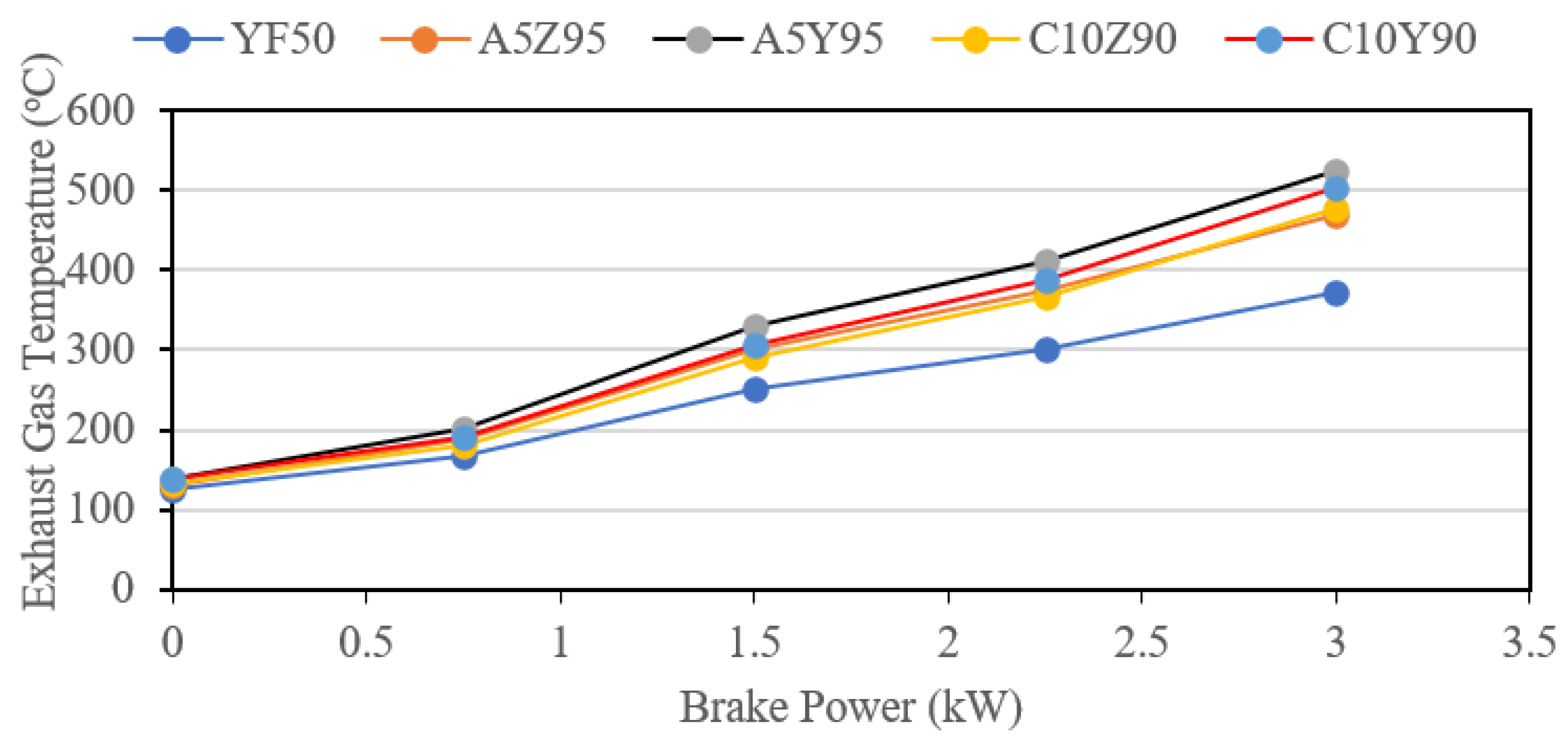

4.3.3. Exhaust Gas Temperature (EGT)

4.4. Emission Parameters

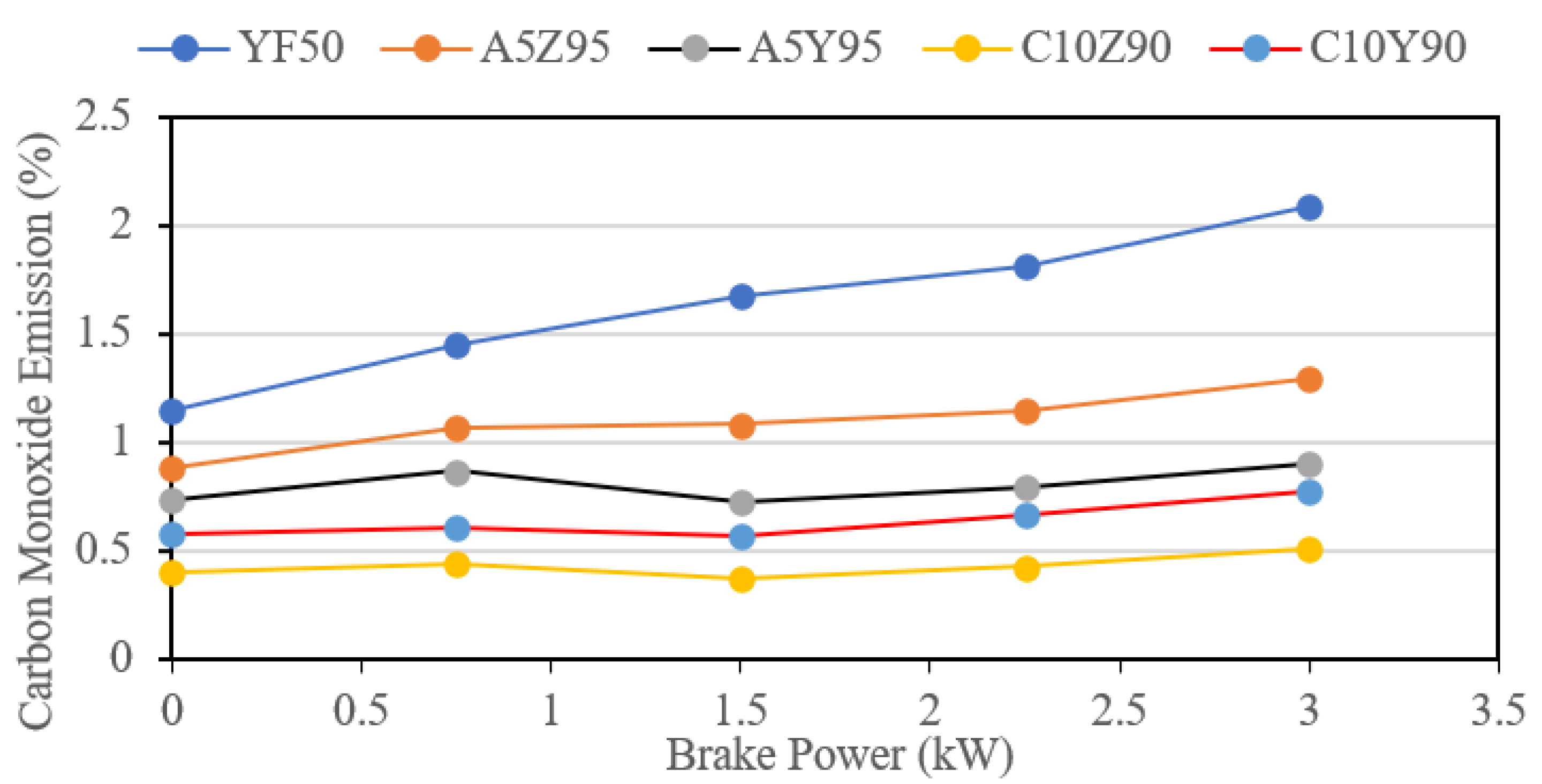

4.4.1. Carbon Monoxide Emission (CO)

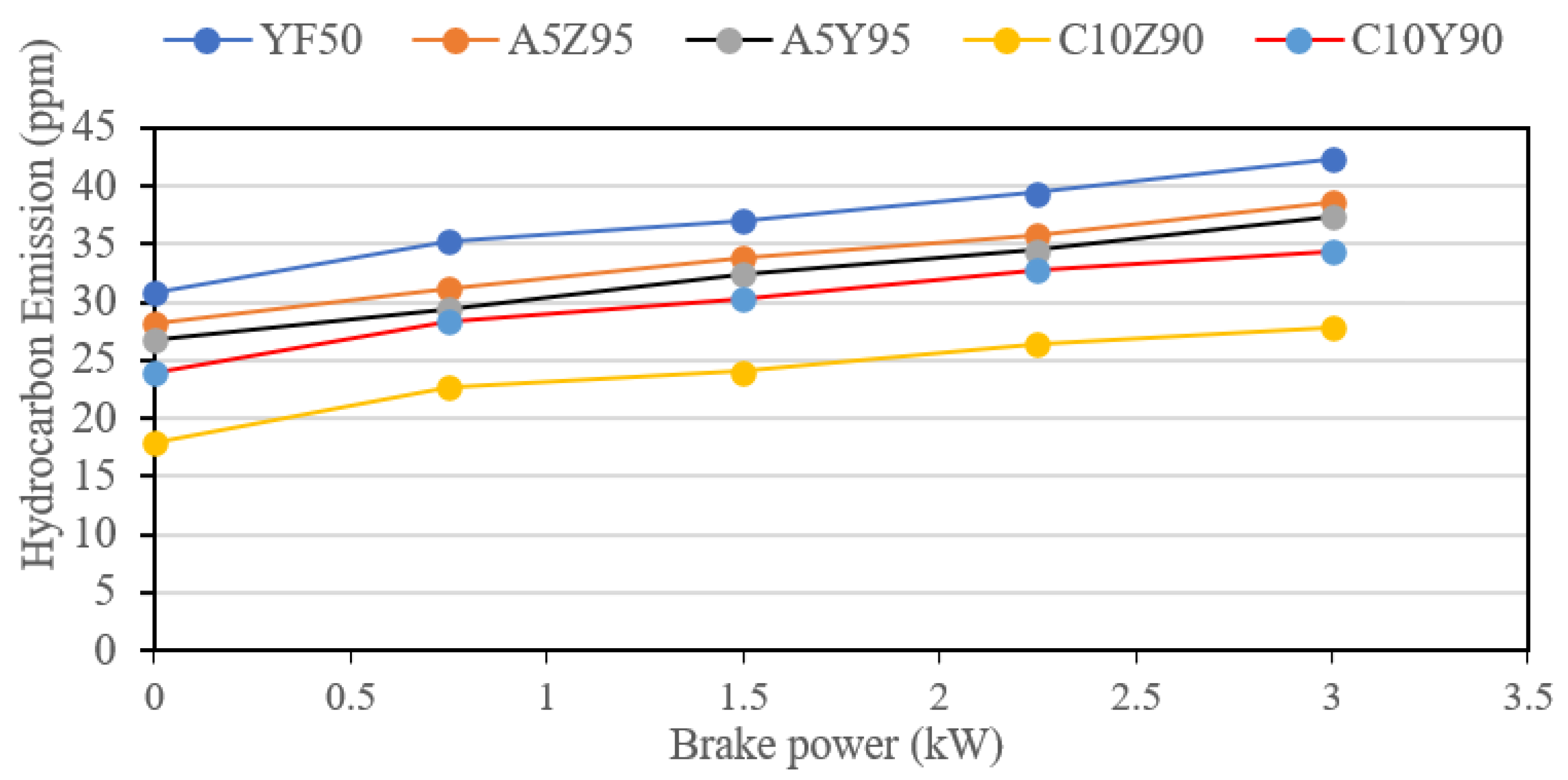

4.4.2. Hydrocarbon Emission (HC)

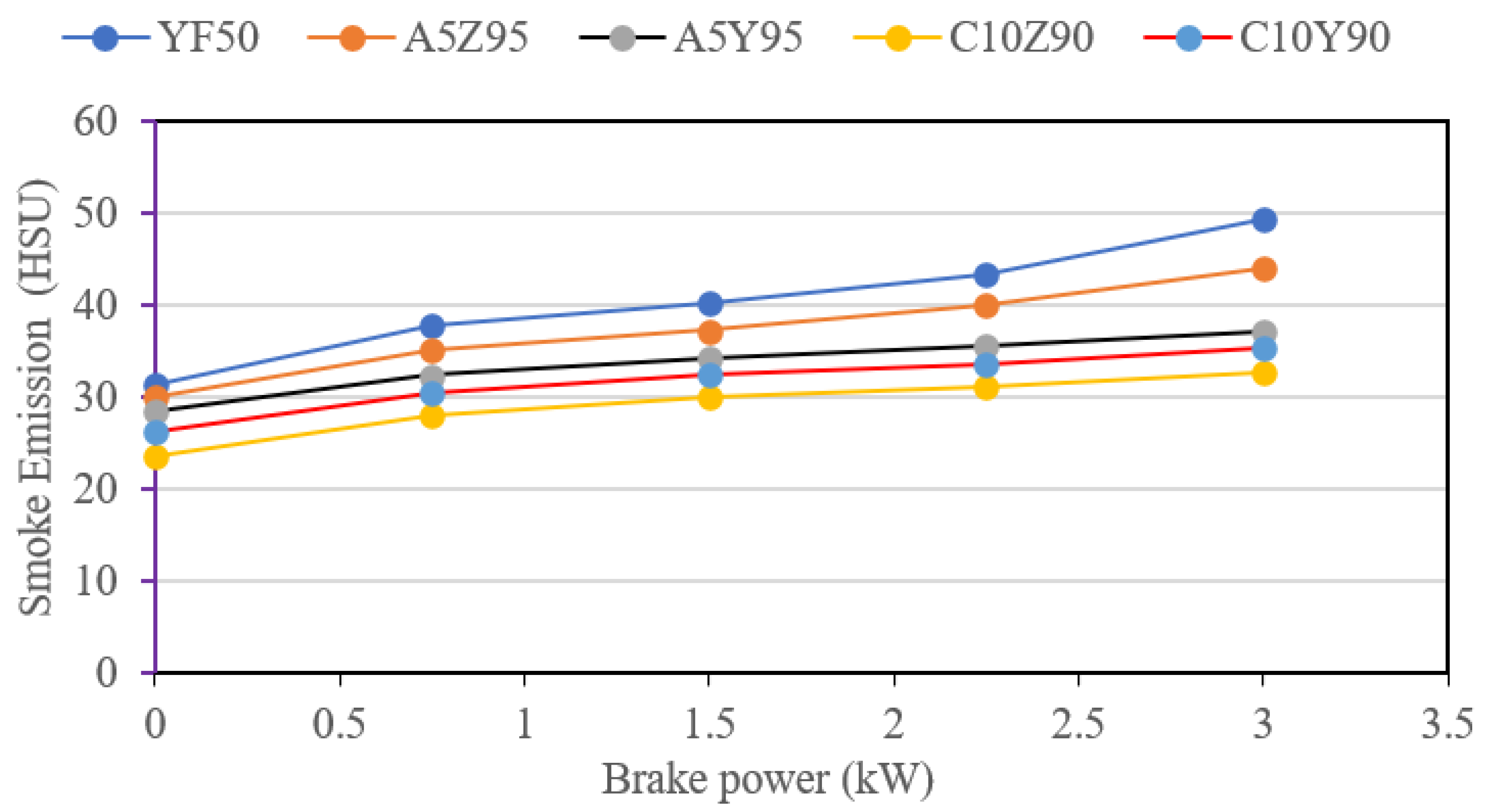

4.4.3. Smoke Emission

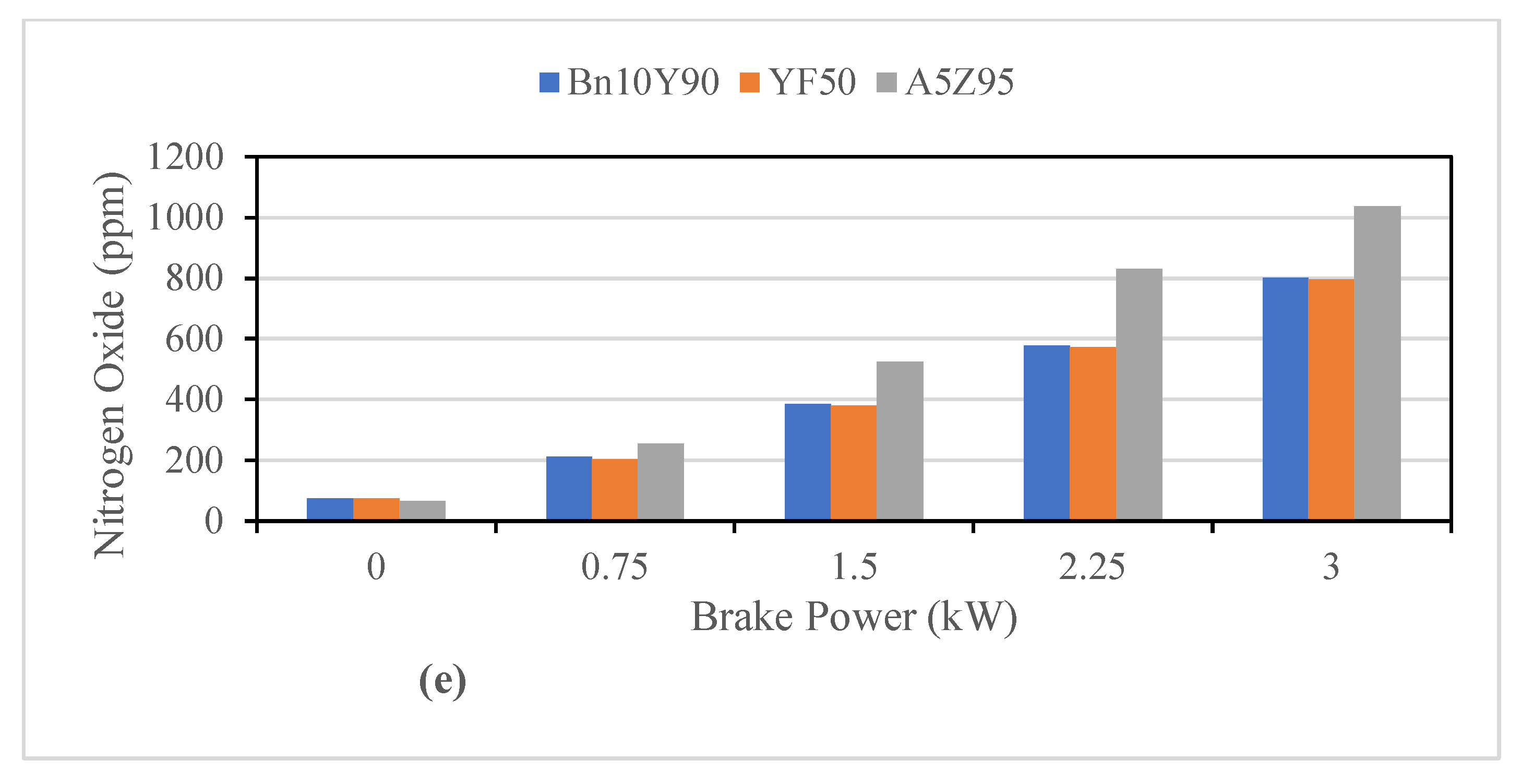

4.4.4. Nitrogen Emission (NOx)

4.4.5. Artificial Neural Network (ANN) Predictions

4.4.6. Tested Samples Comparison with Reference Fuel Sample Bn10Y90

5. Conclusions

- The application of the investigated dual additives to POME-diesel fuel yielded significant improvements with respect to performance and emission levels.

- The sample YF50 which implies application of 50 ppm nano-additive alone to POME-diesel fuel (B20) yielded lower performance in BTE than all fuel categories that contain both nano-additive and butanol.

- The addition of the dual additive significantly increased the BTE in all the samples blended with both additive and fuel sample C10Z90 showed best performance in BTE comparatively.

- The better performance of C10Z90 over other samples in BTE is based on increased dosage of nano-additive and higher biodiesel percentage composition in C10Z90 which is 30% (B30, refer Table 1), by increasing the dosage of nano-additive in the initial blend with butanol from 75 ppm to 150 ppm more catalytic inducement for combustion is thus associated with C10Z90.

- The doping of the nano-additive firstly in the butanol additive considerably led to higher stability profile of the nano-additive in the final blend leading to slower sedimentation rate and reduction in agglomeration formation.

- In relation to emission levels, C10Z90 further showed lower level for CO, HC and smoke but however was higher in NOx than A5Z95. This is quite expected as longer hydrocarbon chain has tendency for higher nitrogen formation at higher temperature in the combustion chamber, YF50 has lowest NOx result since the nano-additive must have acted to be secondary energy carrier and therefore stimulates the fuel particle oxidation and hence leads to lower toxic gases emission.

- Considering that the modified fuel C10Z90 has shown remarkable characteristics in improving engine performance and reducing emission level, it is thus recommended as an alternative and sustainable fuel option. Further research on nano-additive should be investigated and commercialized in automobile industries.

- The ANN model developed was able to predict the performance and emission pattern of the tested fuels and thus this model fits to be adopted to reduce cost of testing too many varieties of nanoparticles or nanofluids.

- The cost of processing nanoparticles is relatively high and may cause higher cost of the final model fuel, this can be modified through determination of alternative production techniques, hence further research is necessitated in this area.

- The notable increase in smoke level with YF50 makes it necessary for further investigation in respect to how to resolve the issue with unburnt nanoparticles which in a sense can cause other health challenges like cancer and respiratory problems.

- Nano-additive can be blended with higher viscous fluids and utilized as nano-lubricants due to improved sliding and delamination characteristics of nanoparticle which can improve the lubrication tendencies especially in hydraulic brake systems, application can be extended to nano-coolants due to their heat absorption capability making them feasible in regulating temperature in transformers, ships and nuclear reactors among others.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sener, R.; Yangaz, M.U.; Gul, M.Z. Effects of injection strategy and combustion chamber modification on a single-cylinder diesel engine. Fuel 2020, 266, 117122. [Google Scholar] [CrossRef]

- Konur, O. Biodiesel Fuels: A Scientometric Review of the Research, in Biodiesel Fuels; CRC Press: Boca Raton, FL, USA, 2021; pp. 225–248. [Google Scholar]

- Veza, I.; Said, M.F.M.; Latiff, Z.A. Progress of acetone-butanol-ethanol (ABE) as biofuel in gasoline and diesel engine: A review. Fuel Process. Technol. 2019, 196, 106179. [Google Scholar] [CrossRef]

- Sun, C.; Liu, Y.; Qiao, X.; Ju, D.; Tang, Q.; Fang, X.; Zhou, F. Experimental study of effects of exhaust gas recirculation on combustion, performance, and emissions of DME-biodiesel fueled engine. Energy 2020, 197, 117233. [Google Scholar] [CrossRef]

- Appavu, P.; Madhavan, V.R.; Venu, H.; Mariadoss, A. Effect of fuel additives and exhaust gas recirculation in biodiesel fuelled CI engine: A review. Int. J. Ambient. Energy 2019, 42, 1803–1809. [Google Scholar] [CrossRef]

- Fayyazbakhsh, A.; Pirouzfar, V. Comprehensive overview on diesel additives to reduce emissions, enhance fuel properties and improve engine performance. Renew. Sustain. Energy Rev. 2017, 74, 891–901. [Google Scholar] [CrossRef]

- Veza, I.; Said, M.F.M.; Latiff, Z.A. Recent advances in butanol production by acetone-butanol-ethanol (ABE) fermentation. Biomass Bioenergy 2020, 144, 105919. [Google Scholar] [CrossRef]

- Lapuerta, M.; Armas, O.; Fernández, J.R. Effect of biodiesel fuels on diesel engine emissions. Prog. Energy Combust. Sci. 2008, 34, 198–223. [Google Scholar] [CrossRef]

- Knothe, G. Biodiesel and renewable diesel: A comparison. Prog. Energy Combust. Sci. 2010, 36, 364–373. [Google Scholar] [CrossRef]

- Bakthavatchalam, B.; Habib, K.; Saidur, R.; Saha, B.B.; Irshad, K. Comprehensive study on nanofluid and ionanofluid for heat transfer enhancement: A review on current and future perspective. J. Mol. Liq. 2020, 305, 112787. [Google Scholar] [CrossRef]

- Opia, A.C.; Kameil, A.H.M.; Syahrullail, S.; Johnson, C.A.; Izmi, M.I.; Hilmi, C.D.Z.; Rahim, A.B.A. Eichhornia crassipes nanoparticles as a sustainable lubricant additive: Tribological properties optimization and performance under boundary lubrication regime. Ind. Crop. Prod. 2022, 175. [Google Scholar] [CrossRef]

- Lee, C.; Xu, E.Z.; Liu, Y.; Teitelboim, A.; Yao, K.; Fernandez-Bravo, A.; Kotulska, A.M.; Nam, S.H.; Suh, Y.D.; Bednarkiewicz, A.; et al. Giant nonlinear optical responses from photon-avalanching nanoparticles. Nature 2021, 589, 230–235. [Google Scholar] [CrossRef]

- Sanches, M.; Marseglia, G.; Ribeiro, A.; Moreira, A.; Moita, A. Nanofluids Characterization for Spray Cooling Applications. Symmetry 2021, 13, 788. [Google Scholar] [CrossRef]

- Shukla, M.; Tripathi, G.; Farooqui, S.A.; Sinha, A.K.; Dhar, A. Effect of Au/CeO2 as fuel borne catalysts on performance, combustion and emissions characteristics of CI engine. Clean. Eng. Technol. 2021, 5, 100335. [Google Scholar] [CrossRef]

- Selvan, V.A.M.; Anand, R.; Udayakumar, M. Effect of Cerium Oxide Nanoparticles and Carbon Nanotubes as fuel-borne additives in Diesterol blends on the performance, combustion and emission characteristics of a variable compression ratio engine. Fuel 2014, 130, 160–167. [Google Scholar] [CrossRef]

- Vairamuthu, G.; Sundarapandian, S.; Kailasanathan, C.; Thangagiri, B. Experimental investigation on the effects of cerium oxide nanoparticle on Calophyllum inophyllum (Punnai) biodiesel blended with diesel fuel in DI diesel engine modified by nozzle geometry. J. Energy Inst. 2016, 89, 668–682. [Google Scholar] [CrossRef]

- Sivakumar, M.; Sundaram, N.S.; Kumar, R.R.; Thasthagir, M.H.S. Effect of aluminium oxide nanoparticles blended pongamia methyl ester on performance, combustion and emission characteristics of diesel engine. Renew. Energy 2018, 116, 518–526. [Google Scholar] [CrossRef]

- Venu, H.; Madhavan, V. Effect of Al2O3 nanoparticles in biodiesel-diesel-ethanol blends at various injection strategies: Performance, combustion and emission characteristics. Fuel 2016, 186, 176–189. [Google Scholar] [CrossRef]

- Ramesh, D.; Kumar, J.D.; Kumar, S.H.; Namith, V.; Jambagi, P.B.; Sharath, S. Study on effects of Alumina nanoparticles as additive with Poultry litter biodiesel on Performance, Combustion and Emission characteristic of Diesel engine. Mater. Today: Proc. 2018, 5, 1114–1120. [Google Scholar] [CrossRef]

- Wu, Q.; Xie, X.; Wang, Y.; Roskilly, T. Effect of carbon coated aluminum nanoparticles as additive to biodiesel-diesel blends on performance and emission characteristics of diesel engine. Appl. Energy 2018, 221, 597–604. [Google Scholar] [CrossRef]

- Tewari, P.; Doijode, E.; Banapurmath, N.R.; Yaliwal, V.S. Experimental investigations on a diesel engine fuelled with multiwalled carbon nanotubes blended biodiesel fuels. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 72–76. [Google Scholar]

- Basha, J.S.; Anand, R. Performance, emission and combustion characteristics of a diesel engine using Carbon Nanotubes blended Jatropha Methyl Ester Emulsions. Alex. Eng. J. 2014, 53, 259–273. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Taghizadeh-Alisaraei, A.; Ghobadian, B.; Abbaszadeh-Mayvan, A. Performance and emission characteristics of a CI engine fuelled with carbon nanotubes and diesel-biodiesel blends. Renew. Energy 2017, 111, 201–213. [Google Scholar] [CrossRef]

- Selvaganapthy, A.; Sundar, A.; Kumaragurubaran, B.; Gopal, P. An experimental investigation to study the effects of various nano particles with diesel on DI diesel engine. ARPN J. Sci. Technol. 2013, 3, 112–115. [Google Scholar]

- Javed, S.; Murthy, Y.S.; Satyanarayana, M.; Reddy, R.R.; Rajagopal, K. Effect of a zinc oxide nanoparticle fuel additive on the emission reduction of a hydrogen dual-fuelled engine with jatropha methyl ester biodiesel blends. J. Clean. Prod. 2016, 137, 490–506. [Google Scholar] [CrossRef]

- Fangsuwannarak, K.; Triratanasirichai, K. Improvements of palm biodiesel properties by using nano-TiO2 additive, exhaust emission and engine performance. Rom. Rev. Precis. Mech. Opt. Mechatron. 2013, 43, 111–118. [Google Scholar]

- Nanthagopal, K.; Ashok, B.; Tamilarasu, A.; Johny, A.; Mohan, A. Influence on the effect of zinc oxide and titanium dioxide nanoparticles as an additive with Calophyllum inophyllum methyl ester in a CI engine. Energy Convers. Manag. 2017, 146, 8–19. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, A.; Badruddin, I.; Banapurmath, N.; Akram, N. The effect of nano-additives in diesel-biodiesel fuel blends: A comprehensive review on stability, engine performance and emission characteristics. Energy Convers. Manag. 2018, 178, 146–177. [Google Scholar] [CrossRef]

- Sule, A.; Lattif, Z.A.; Abas, M.A. Prospects and Challenges of Nanofluids as Improved Fuel for Diesel and Gasoline Engines: A Critical Review; Taylor and Francis: London, UK, 2021. [Google Scholar]

- Veza, I.; Said, M.F.M.; Latiff, Z.A.; Abas, M.A. Application of Elman and Cascade neural network (ENN and CNN) in comparison with adaptive neuro fuzzy inference system (ANFIS) to predict key fuel properties of ABE-diesel blends. Int. J. Green Energy 2021, 18, 1510–1522. [Google Scholar] [CrossRef]

- Veza, I.; Roslan, M.F.; Said, M.F.M.; Latiff, Z.A.; Abas, M.A. Cetane index prediction of ABE-diesel blends using empirical and artificial neural network models. Energy Sources Part A: Recover. Util. Environ. Eff. 2020, 1–18. [Google Scholar] [CrossRef]

- Veza, I.; Said, M.F.M.; Latiff, Z.A.; Hasan, M.F.; Jalal, R.I.A.; Ibrahim, N.M.I.N. Simulation of predictive kinetic combustion of single cylinder HCCI engine. AIP Conf. Proc. 2019, 2059, 020017. [Google Scholar] [CrossRef]

- Jain, A.; Anthonysamy, S.; Ananthasivan, K.; Gupta, G. Studies on the ignition behaviour of boron powder. Thermochim. Acta 2010, 500, 63–68. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Subbarao, R.; Johny, A.; Mohan, A.; Tamilarasu, A. Experimental studies on the effect of metal oxide and antioxidant additives with Calophyllum Inophyllum Methyl ester in compression ignition engine. J. Clean. Prod. 2017, 166, 474–484. [Google Scholar] [CrossRef]

- Yadav, J.; Ramesh, A. Injection strategies for reducing smoke and improving the performance of a butanol-diesel common rail dual fuel engine. Appl. Energy 2018, 212, 1–12. [Google Scholar] [CrossRef]

- Barabás, I.; Todoruț, I.-A. Utilization of Biodiesel-Diesel-Ethanol Blends in CI Engine. InTech 2011. [Google Scholar] [CrossRef]

- Subbaiah, G.V.; Gopal, K.R.; Hussain, S.A.; Prasad, B.D.; Reddy, K.T.; Pradesh, A. Rice bran oil biodiesel as an additive in diesel-ethanol blends for diesel engines. Int. J. Res. Rev. Appl. Sci. 2010, 3, 334–342. [Google Scholar]

- Rahimi, H.; Ghobadian, B.; Yusaf, T.; Najafi, G.; Khatamifar, M. Diesterol: An environment-friendly IC engine fuel. Renew. Energy 2009, 34, 335–342. [Google Scholar] [CrossRef]

- Goel, V.; Kumar, N.; Singh, P. Impact of modified parameters on diesel engine characteristics using biodiesel: A review. Renew. Sustain. Energy Rev. 2018, 82, 2716–2729. [Google Scholar] [CrossRef]

- Khan, M.; Sharma, R.; Kadian, A.K.; Hasnain, S.M.M. An assessment of alcohol inclusion in various combinations of biodiesel-diesel on the performance and exhaust emission of modern-day compression ignition engines—A review. Mater. Sci. Energy Technol. 2021, 5, 81–98. [Google Scholar] [CrossRef]

- Yage, D.; Junjie, Z.; Shun, C.C.; Xuelong, M.; Jinbao, Z.; Haiyong, P.; Tao, W. Comparative study on combustion and particulate emissions for diesel-biodiesel and diesel-diglyme blends. Fuel 2021, 313, 122710. [Google Scholar] [CrossRef]

- Zuo, L.; Wang, J.; Mei, D.; Dai, S.; Adu-Mensah, D. Experimental investigation on combustion and (regulated and unregulated) emissions performance of a common-rail diesel engine using partially hydrogenated biodiesel-ethanol-diesel ternary blend. Renew. Energy 2022, 185, 1272–1283. [Google Scholar] [CrossRef]

- Bendu, H.; Deepak, B.; Murugan, S. Multi-objective optimization of ethanol fuelled HCCI engine performance using hybrid GRNN–PSO. Appl. Energy 2017, 187, 601–611. [Google Scholar] [CrossRef]

- Kalaimurugan, K.; Karthikeyan, S.; Periyasamy, M.; Mahendran, G.; Dharmaprabhakaran, T. Experimental studies on the influence of copper oxide nanoparticle on biodiesel-diesel fuel blend in CI engine. Energy Sources, Part A: Recover. Util. Environ. Eff. 2019, 1–16. [Google Scholar] [CrossRef]

- Senthil Kumar, M.S.V. Karthic, and P. Pradeep, Investigations on the influence of ethanol and water injection techniques on engine’s behavior of a hydrogen—biofuel based dual fuel engine. Int. J. Hydrog. Energy 2018, 43, 21090–21101. [Google Scholar] [CrossRef]

- Huang, Z.; Huang, J.; Luo, J.; Hu, D.; Yin, Z. Performance enhancement and emission reduction of a diesel engine fueled with different biodiesel-diesel blending fuel based on the multi-parameter optimization theory. Fuel 2021, 314, 122753. [Google Scholar] [CrossRef]

- Sivalakshmi, S.; Balusamy, T. Effect of biodiesel and its blends with diethyl ether on the combustion, performance and emissions from a diesel engine. Fuel 2013, 106, 106–110. [Google Scholar] [CrossRef]

- Najafi, G. Diesel engine combustion characteristics using nano-particles in biodiesel-diesel blends. Fuel 2018, 212, 668–678. [Google Scholar] [CrossRef]

- Rajak, U.; Ağbulut, U.; Veza, I.; Dasore, A.; Sarıdemir, S.; Verma, T.N. Numerical and experimental investigation of CI engine behaviours supported by zinc oxide nanomaterial along with diesel fuel. Energy 2021, 239, 122424. [Google Scholar] [CrossRef]

- Manigandan, S.; Ponnusamy, V.K.; Devi, P.; Oke, S.A.; Sohret, Y.; Venkatesh, S.; Vimal, M.; Gunasekar, P. Effect of nanoparticles and hydrogen on combustion performance and exhaust emission of corn blended biodiesel in compression ignition engine with advanced timing. Int. J. Hydrogen Energy 2019, 45, 3327–3339. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, M.; Badruddin, I.A.; Banapurmath, N.; Khan, T.Y.; Bashir, M.N.; Akram, N.; Farade, R.; Afzal, A. The effects of graphene oxide nanoparticle additive stably dispersed in dairy scum oil biodiesel-diesel fuel blend on CI engine: Performance, emission and combustion characteristics. Fuel 2019, 257. [Google Scholar] [CrossRef]

- Khan, H.; Soudagar, M.E.M.; Kumar, R.H.; Safaei, M.R.; Farooq, M.; Khidmatgar, A.; Banapurmath, N.R.; Farade, R.A.; Abbas, M.M.; Afzal, A.; et al. Effect of Nano-Graphene Oxide and n-Butanol Fuel Additives Blended with Diesel—Nigella sativa Biodiesel Fuel Emulsion on Diesel Engine Characteristics. Symmetry 2020, 12, 961. [Google Scholar] [CrossRef]

- Jayakrishnan, B.; Senthilkumar, D. Experimental Study of Nano Additive-Added Biodiesel Blend to Improve the Engine Performance Characteristics. In Intelligent Manufacturing and Energy Sustainability; Springer: Berlin/Heidelberg, Germany, 2021; pp. 381–389. [Google Scholar] [CrossRef]

- Raju, P.; Masimalai, S.K.; Ganesan, N.; Karthic, S. Engine’s behavior on hydrogen addition of waste cooking oil fueled light duty diesel engine–A dual fuel approach. Energy 2020, 194. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, M.; Badruddin, I.A.; Banapurmath, N.; Bin Ali, M.A.; Kamangar, S.; Cho, H.M.; Akram, N. An investigation on the influence of aluminium oxide nano-additive and honge oil methyl ester on engine performance, combustion and emission characteristics. Renew. Energy 2019, 146, 2291–2307. [Google Scholar] [CrossRef]

- Kumar, M.H.; Raju, V.D.; Kishore, P.S.; Venu, H. Influence of injection timing on the performance, combustion and emission characteristics of diesel engine powered with tamarind seed biodiesel blend. Int. J. Ambient. Energy 2018, 41, 1007–1015. [Google Scholar] [CrossRef]

| Sample | Fuel Blend Ratios | |

|---|---|---|

| First stage blending: + Butanol | A = BnF75 | 75 ppm Fe3O4 + Butanol 150 ppm Fe3O4 + Butanol |

| C = BnF150 | ||

| Second stage blending: Diesel + Biodiesel | Y = B20 | 80% DZ + 20% POME |

| Z = B30 | 70% DZ + 30% POME | |

| Third stage blending: First stage + Second stage | A5Y95 | 5% of A + 95% of Y |

| A5Z95 | 5% of A + 95% of Z | |

| C10Y90 | 10% of C + 90% of Y | |

| C10Z90 | 10% of C + 90% of Z |

| Engine Parameter | Specification |

|---|---|

| Engine Type | Yanmar L70N |

| Engine geometry | 4 stroke/single cylinder |

| Length of connecting rod (mm) | 102 |

| Stroke/bore (mm) | 67/78 |

| Cooling | Air cooled |

| Compression ratio (CR) | 20:1 |

| Displacement (liters) | 0.320 |

| Maximum rated output (kW) | 4.9 (at 3600 rpm) |

| Fuel tank capacity (liters) | 2.7 |

| Starting system | Electric/Recoil start |

| Lubrication system | Trochoid pump forced lubrication |

| Length × width × Height | 378 × 422 × 453 |

| By-Products of Combustion | Measuring Range | Accuracy |

|---|---|---|

| Carbon dioxide (CO2) | 0–50% vol. | ±0.3% vol.+1%mv ppm |

| Carbon monoxide (CO) | 0–1000 ppm | 5 ppm (0–99 ppm) |

| Oxygen (O2) | 0–25% vol. | ±0.2 mv |

| Nitrogen oxide (NOx) | 0–3000 ppm | 5 ppm (0–99 ppm) |

| Hydrocarbon (HC) | 0.01–4% vol. | <400 ppm (100–4000 ppm) |

| Parameter | Range in Measurement | Accuracy |

|---|---|---|

| Exhaust smoke density | 0–99% | 0.01 |

| K smoke factor (1/m) | 0–10% | 0.01 |

| Engine speed | 0–9999 (1/m) | 1/m |

| Properties | Y (B20) | Z (B30) | A5Y95 | A5Z95 | C10Y90 | C10Z90 | Method |

|---|---|---|---|---|---|---|---|

| Cetane number | 49.56 | 50.65 | 52.06 | 52.20 | 53.60 | 53.08 | ASTMD613 |

| Viscosity (mm2/s) at 40 °C | 3.91 | 3.95 | 3.98 | 4.01 | 4.09 | 4.09 | ASTM 445 |

| Density (kg/m3) at 15 °C | 853.08 | 857.14 | 859.05 | 859.88 | 860.70 | 861.04 | ASTM D4052 |

| Acid value (mgKOH/g) | 0.22 | 0.26 | 0.29 | 0.30 | 0.32 | 0.31 | ASTM D941 |

| BTE | CO | HC | Smoke | NOx | |

|---|---|---|---|---|---|

| R | 0.998 | 0.997 | 0.999 | 0.997 | 0.989 |

| R2 | 0.997 | 0.994 | 0.999 | 0.993 | 0.977 |

| MAPE (%) | 0.094 | 0.024 | 0.16 | 0.010 | 0.667 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sule, A.; Latiff, Z.A.; Abas, M.A.; Veza, I.; Soudagar, M.E.M.; Harny, I.; Epin, V. Dual Effects of N-Butanol and Magnetite Nanoparticle to Biodiesel-Diesel Fuel Blends as Additives on Emission Pattern and Performance of a Diesel Engine with ANN Validation. Sustainability 2023, 15, 1404. https://doi.org/10.3390/su15021404

Sule A, Latiff ZA, Abas MA, Veza I, Soudagar MEM, Harny I, Epin V. Dual Effects of N-Butanol and Magnetite Nanoparticle to Biodiesel-Diesel Fuel Blends as Additives on Emission Pattern and Performance of a Diesel Engine with ANN Validation. Sustainability. 2023; 15(2):1404. https://doi.org/10.3390/su15021404

Chicago/Turabian StyleSule, Ahmed, Zulkarnain Abdul Latiff, Mohd Azman Abas, Ibham Veza, Manzoore Elahi M. Soudagar, Irianto Harny, and Vorathin Epin. 2023. "Dual Effects of N-Butanol and Magnetite Nanoparticle to Biodiesel-Diesel Fuel Blends as Additives on Emission Pattern and Performance of a Diesel Engine with ANN Validation" Sustainability 15, no. 2: 1404. https://doi.org/10.3390/su15021404

APA StyleSule, A., Latiff, Z. A., Abas, M. A., Veza, I., Soudagar, M. E. M., Harny, I., & Epin, V. (2023). Dual Effects of N-Butanol and Magnetite Nanoparticle to Biodiesel-Diesel Fuel Blends as Additives on Emission Pattern and Performance of a Diesel Engine with ANN Validation. Sustainability, 15(2), 1404. https://doi.org/10.3390/su15021404