System-Based Integrated Nutrient Management Improves Productivity, Profitability, Energy Use Efficiency and Soil Quality in Peanut-Wheat Cropping Sequence in Light Black Soils

Abstract

1. Introduction

2. Materials and Methods

2.1. Site Description

2.2. Experimental Design and Crop Management

2.3. Measurements of Yield and Growth and Yield Parameters

2.4. Economic Analysis

2.5. Net Energy and Energy Use Efficiency

2.6. Plant Nutrient Uptake

2.7. Soil Available N, P2O5 and K2O and Soil Organic Carbon (SOC)

2.8. Soil Enzymatic Activities

2.9. Statistical Analysis

3. Results

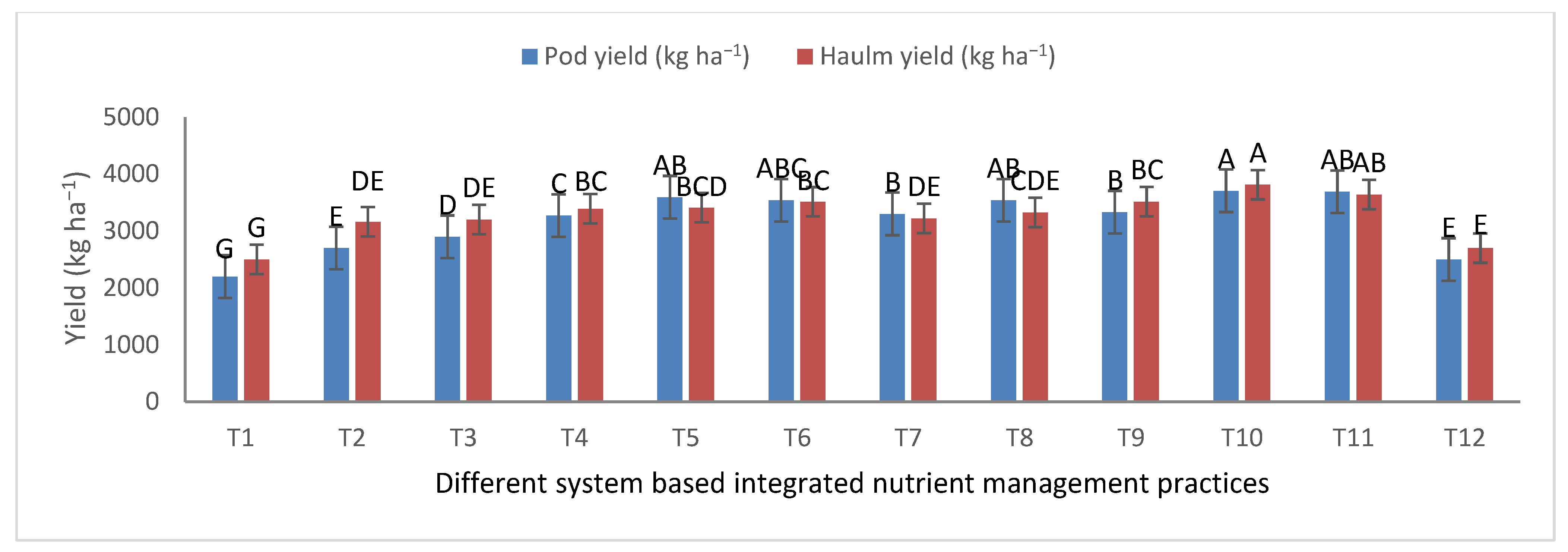

3.1. Peanut

3.2. Wheat

3.3. System Productivity, Economics and Energy Use Efficiency

3.4. Nutrient Uptake, Enzymatic Activities and Residual Soil Fertility

4. Discussion

4.1. Performance of Peanut

4.2. Performance of Wheat

4.3. System Productivity, Economics, and Energy Use Efficiency

4.4. Nutrient Uptake, Enzyme Activities and Residual Soil Fertility

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Directorate of Economics and Statistics. Agricultural Statistics at a Glance; Ministry of Agriculture and Farmer Welfare: New Delhi, India, 2021.

- FAOSTAT. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 6 October 2020).

- Veeramani, P.; Subrahmaniyan, K. Nutrient management for sustainable groundnut productivity in India—A review. Int. J. Eng. Sci. Technol. 2011, 3, 8138–8153. [Google Scholar]

- Mahrous, N.M.; Safina, S.A. Integrated use of organic, inorganic and bio fertilizers on yield and quality of two peanut cultivars grown in a sandy saline soil. Am.-Eurasian J. Agric. Environ. Sci. 2015, 15, 1067–1074. [Google Scholar]

- Mukhtar, A.A.; Odion, E.C.; Ahmed, A.; Babaji, B.A.; Aminu-Mukhtar, M.; Arunah, U.L. Comparative effects of organic manure sources and rates on performance of peanut varieties. In Proceedings of the 4th ISOFAR Scientific Conference on ‘Building Organic Bridges’ during Organic World Congress, Istanbul, Turkey, 13–15 October 2014. [Google Scholar]

- Serpil, S. An Agricultural Pollutant: Chemical Fertilizer. Int. J. Environ. Sci. Technol. 2012, 3, 77–80. [Google Scholar]

- Roy, R.; Sultana, S.; Wang, J.; Mostofa, M.G.; Sarker, T.; Rahman Shah, M.M.; Hossain, M.S. Revegetation of coal mine degraded arid areas: The role of a native woody species under optimum water and nutrient resources. Environ. Res. 2022, 204, 111921. [Google Scholar] [CrossRef] [PubMed]

- Jat, R.A.; Wani, S.P.; Sahrawat, K.L.; Singh, P.; Dhaka, S.R.; Dhaka, B.L. Recent approaches in nitrogen management for sustainable agricultural production and eco-safety. Arch. Agron. Soil Sci. 2012, 58, 1033–1060. [Google Scholar] [CrossRef]

- Hepperly, P.; Lotter, D.; Ulsh, C.Z.; Seidel, R.; Reider, C. Compost, Manure and Synthetic Fertilizer Influences Crop Yields, Soil Properties, Nitrate Leaching and Crop Nutrient Content. Compos. Sci. Util. 2013, 17, 117–126. [Google Scholar] [CrossRef]

- Deshmukh, K.K.; Khatik, S.K.; Dubey, D.P. Effect of Integrated use of inorganic, organic and bio fertilizers on production, Nutrient availability of plateau and Satpura hills. J. Soils Crops 2005, 15, 21–25. [Google Scholar]

- Thorave, D.S.; Dhonde, M.B. Morphological indices and yield attributes as influenced by integrated nutrient management in summer groundnut. Ann. Plant Physiol. 2007, 21, 186–188. [Google Scholar]

- Jat, R.A.; Ahlawat, I.P.S. Effect of organic manure and sulphur fertilization on productivity, nutrient uptake, sulphur use efficiency and economics in pigeonpea (Cajanuscajan) + groundnut (Arachis hypogaea) intercropping system. Indian J. Agron. 2011, 55, 24–29. [Google Scholar]

- Selim, M.M. Introduction to the integrated nutrient management strategies and their contribution to yield and soil properties. Int. J. Agron. 2020, 2020, 2821678. [Google Scholar] [CrossRef]

- Purbajanti, E.D.; Slamet, W.; Fuskhah, E.; Rosyida, D. Effects of organic and inorganic fertilizers on growth, activity of nitrate reductase and chlorophyll contents of peanuts (Arachis hypogaea L). Earth Environ. Sci. 2019, 250, 012048. [Google Scholar] [CrossRef]

- Singh, N.J.; Athokpam, H.S.; Devi, K.N.; Chongtham, N.; Singh, N.B.; Sharma, P.T.; Dayananda, S. Effect of farm yard manure and press mud on fertility status of alkaline soil under maize-wheat cropping sequence. Afr. J. Agric. Res. 2015, 10, 2421–2431. [Google Scholar]

- Meena, B.L.; Fagodiya, R.K.; Prajapat, K.; Dotaniya, M.L.; Kaledhonkar, M.J.; Sharma, P.C.; Meena, R.S.; Mitran, T.; Kumar, S. Legume Green Manuring. Legumes for Soil Health and Sustainable Management; Springer: Singapore, 2018; pp. 387–408. [Google Scholar]

- Dey, R.; Pal, K.K. Biofertilizers for Enhancing Groundnut Productivity; ICAR-Directorate of Groundnut Research: Junagadh, Gujarat, 2014; p. 30. [Google Scholar]

- Kumar, A.; Meena, V.S. Plant Growth Promoting Rhizobacteria for Agricultural Sustainability; Springer: Berlin, Germany, 2019; pp. 978–981. [Google Scholar]

- Yadav, R.L.; Subba Rao, A.V.M. Atlas of Cropping Systems in India; Project Directorate for Cropping Systems Research, Indian Council of Agricultural Research: Uttar Pradesh, India, 2011; p. 43. [Google Scholar]

- Sharma, B.M.; Singh, R.V. Soil test and crop need based fertilizer recommendations for field crops. In Proceedings of the Training Workshop on Soil Testing for Balanced and Integrated Use of Fertilizers and Manures; Punjab Agricultural University: Ludhiana, Punjab, 2003; pp. 106–121. [Google Scholar]

- Firouzi, S.; Aminpanah, H. Energy Use Efficiency for Groundnut (Arachis hypogaea L.) Production in a Semi-mechanized Cultivation System. Ann. Biol. Res. 2012, 3, 3994–3997. [Google Scholar]

- Koocheki, A.; Ghorbani, R.; Mondani, F.; Alizade, Y.; Moradi, R. Pulses production systems in term of energy use efficiency and economic analysis in Iran. Int. J. Energy Econ. Policy 2011, 1, 95–106. [Google Scholar]

- Firouzi, S.; Nikkhah, A.; Rosentrater, K.A. An integrated analysis of non-renewable energy use, GHG emissions, carbon efficiency of groundnut sole cropping and groundnut-bean intercropping agro-ecosystems. Environ. Prog. Sustain. Energy 2017, 36, 1832–1839. [Google Scholar] [CrossRef]

- Mohanty, P.; Pany, B.K.; Sahu, G.; Mohapatra, S.; Nayak, B.K. Effect of Integrated Nutrient Management on Growth, Yield Attributes, Yield and Quality Parameters of Groundnut (Arachis hypogaea) in an Acidic Upland of Odisha. Indian J. Ecol. 2022, 49, 119–123. [Google Scholar] [CrossRef]

- Osman, A.K. Groundnut Production in Traditional Rain Fed Sector; ARC Publication: Wadmadni, Sudan, 2003. [Google Scholar]

- Mulvaney, M.J.; Devkota, P. Adjusting Crop Yield to a Standard Moisture Content. Document SS-AGR-443 in a Series of the Agronomy Department, UF/IFAS Extension. 2020. Available online: https://edis.ifas.ufl.edu/publication/AG442#:~:text=It%20would%20make%20sense%20to,1%2C240%20lb%20water%2Fac (accessed on 1 February 2022).

- Shelke, D.K. Research Techniques in Agronomy; Kalyani Publishers: New Delhi, India, 2007; pp. 1–89. [Google Scholar]

- Devasenapathy, P.; Senthilkumar, G.; Shanmugam, P.M. Energy management in crop production. Indian J Agron. 2009, 54, 80–90. [Google Scholar]

- Mittal, J.P.; Dhawan, K.C. Research Manual on Energy Requirements in Agricultural Sector; Indian Council of Agricultural Research: New Delhi, India, 1988; p. 150. [Google Scholar]

- Subbiah, B.V.; Asija, G.L. A rapid method for estimation of available N in soil. Curr. Sci. 1956, 25, 259–260. [Google Scholar]

- Koening, H.A.; Johnson, C.R. Method for estimating phosphorus. Ind. Eng. Chem. Anal. Ed. 1942, 14, 155–156. [Google Scholar]

- Kalra, Y. Handbook of Reference Methods for Plant Analysis; CRC Press Taylor & Francis Group: New York, NY, USA, 1997; pp. 115–118. [Google Scholar]

- Olsen, S.R.; Cole, C.V.; Watanabe, F.S.; Dean, L. Estimation of Available Phosphorus in Soil by Extraction with Sodium Carbonate; US Department of Agriculture: Washington, DC, USA, 1954; p. 933. [Google Scholar]

- Hanway, J.; Heidal, H.S. Soil analysis methods as used in Iowa State College Soil Testing Laboratory. Iowa State Coll. Agric. Bull. 1952, 57, 1–13. [Google Scholar]

- Walkley, A.; Black, I.A. An examination of Degtjareff method for determining soil organic matter and a proposed modification of the chromic acid titration method. Soil Sci. 1934, 37, 29–37. [Google Scholar] [CrossRef]

- Tabatabai, M.A. Soil enzymes. In Methods of Soil Analysis: Microbiological and Biochemical Properties; Bottomley, P.J., Angle, J.S., Weaver, R.W., Eds.; Soil Science Society of America: Madison, WI, USA, 1994; pp. 775–833. [Google Scholar]

- Schinner, F.; Ohlinger, R.; Kandeler, E.; Margensin, R. Methods in Soil Biology; Springer Lab Manual; Springer: Berlin, Germany, 1996; p. 426. [Google Scholar]

- Gomez, K.A.; Gomez, A.A. Statistical Procedures for Agricultural Research, 2nd ed.; John Wiley and Sons: New York, NY, USA, 1984; p. 680. [Google Scholar]

- Patil, S.R.; Kadam, S.R.; Kalegore, N.K.; Dadgale, P.R. Effect of inorganic and bio-fertilizers on growth and yield of summer peanut. Adv. Res. J. Crop Improv. 2014, 5, 23–25. [Google Scholar]

- Rahevar, H.D.; Patel, P.P.; Patel, B.T.; Joshi, S.K.; Vaghela, S.J. Effect of FYM, iron and zinc on growth and yield of summer peanut (Arachis hypogaea L.) under North Gujarat Agro-climatic conditions. Indian J. Agric. Res. 2015, 49, 294–296. [Google Scholar] [CrossRef]

- Hati, K.M.; Mandal, A.K.; Misra, A.K.; Ghosh, P.K.; Bandyopadhyay, K.K. Effect of inorganic fertilizer and farmyard manure on soil physical properties, root distribution, and water-use efficiency of soybean in Vertisols of central India. Bioresour. Technol. 2006, 97, 2182–2188. [Google Scholar] [CrossRef]

- Zhang, J.B.; Yang, J.S.; Yao, R.J.; Yu, S.P.; Li, F.R.; Hou, X.J. The effects of Farmyard Manure and Mulch on soil physical properties in a reclaimed coastal tidal flat salt-affected soil. J. Integr. Agric. 2014, 13, 1782–1790. [Google Scholar] [CrossRef]

- Borrás, L.; Slafer, G.A.; Otegui, M.E. Seed dry weight response to source–sink manipulations in wheat, maize and soybean: A quantitative reappraisal. Field Crops Res. 2004, 86, 131–146. [Google Scholar] [CrossRef]

- Sanepara, D.P.; Vekariya, P.D.; Vora, V.D.; Gajera, M.S.; Akbari, K.N. Effect of Tillage and Organic Manures on Soil Moisture and Performance of Rainfed Groundnut (Arachis hypogea L.). Int. J. Bio-Resour. Stress Manag. 2015, 6, 452–456. [Google Scholar] [CrossRef]

- Gupta, G.; Parihar, S.S.; Ahirwar, N.K.; Snehi, S.K.; Singh, V. Plant growth promoting rhizobacteria (PGPR): Current and future prospects for development of sustainable agriculture. J. Microb. Biochem. Technol. 2015, 7, 96–102. [Google Scholar]

- Yasodha, M.; Chinnusamy, C. Direct and residual effect of organic manures and inorganic fertilizer application in brinjal + onion-cowpea-sunnhemp cropping system. J. Pharmacogn. Phytochem. 2019, 8, 2335–2339. [Google Scholar]

- Sharma, K.L.; Neelaveni, K.; Katyal, J.C.; Srinivasa Raju, A.; Srinivas, K.; Kusuma Grace, J.; Madhavi, M. Effect of combined use of organic and inorganic sources of nutrients on sunflower yield, soil fertility and overall soil quality in rainfed Alfisol. Commun. Soil Sci. Plant Anal. 2008, 39, 1791–1831. [Google Scholar] [CrossRef]

- Kumar, M.; Jatav, M.K.; Trehan, S.P.; Lal, S.S. Integrated nutrient management in potato-based cropping systems for eastern Indo-Gangatic plains of India. Potato J. 2009, 6, 136–142. [Google Scholar]

- Singh, G.; Virk, H.; Khanna, V. Integrated nutrient management for high productivity and net returns in lentil (Lens culinaris). J. Appl. Nat. Sci. 2017, 9, 1566–1572. [Google Scholar] [CrossRef]

- Rafiee, S.; Avval, S.H.M.; Mohammadi, A. Modeling and sensitivity analysis of energy inputs for apple production in Iran. Energy 2010, 35, 3301–3306. [Google Scholar] [CrossRef]

- Burns, R.G.; DeForest, J.L.; Marxsen, J.; Sinsabaugh, R.L.; Stromberger, M.E.; Wallenstein, M.D.; Zoppini, A. Soil enzymes in a changing environment: Current knowledge and future directions. Soil Biol. Biochem. 2013, 58, 216–234. [Google Scholar] [CrossRef]

- Tiemann, L.K.; Billings, S.A. Indirect effects of nitrogen amendments on organic substrate quality increase enzymatic activity driving decomposition in a mesic grassland. Ecosystems 2011, 14, 234–247. [Google Scholar] [CrossRef]

- Selvi, D.; Santhy, P.; Dhakshinamoorthy, M.; Maheshwari, M. Microbial population and biomass in Rhizoshpere influenced by continuous intensive cultivation and fertilization in an Inceptisol. J. Indian Soc. Soil Sci. 2004, 52, 254–257. [Google Scholar]

- Qureshi, A.A.; Narayanasamy, G.; Chhonkar, P.K.; Balasundram, V.R. Direct and residual effect of phosphate rocks in presence of phosphate solubilizers and FYM on the available P, organic carbon and viable counts of phosphate solubilizers in soil after soybean, mustard and wheat crops. J. Indian Soc. Soil Sci. 2005, 53, 97–100. [Google Scholar]

- Liang, Q.; Chen, H.Q.; Gong, Y.S.; Yang, H.F.; Fan, M.S.; Kuzyakov, Y. Effect of 15 years of manure and mineral fertilizers on enzyme activities in particle-size fractions in a North China Plain soil. Eur. J. Soil Biol. 2014, 60, 112–119. [Google Scholar] [CrossRef]

- Myint, A.K.; Yamakawa, T.; Kajihara, Y.; Zenmyo, T. Application of different organic and mineral fertilizers on the growth, yield and nutrient accumulation of rice in a Japanese ordinary paddy field. Sci. World J. 2010, 5, 47–54. [Google Scholar] [CrossRef]

- Sharma, S.K.; Sharma, S.N. Integrated nutrient management for sustainability of rice (Oryza sativa)-wheat (Triticum aestivum L.) cropping system. Indian J. Agric. Sci. 2002, 72, 573–576. [Google Scholar]

- Karad, G.U.; Babariya, N.B.; Viradiya, M.B.; Parmar, J.K.; Deshmukh, S.D.; Polara, K.B. Effect of integrated nutrient management on yield and active pools of soil organic carbon under groundnut-wheat system of typic Haplustept in long term fertilizer experiment. J. Pure Appl. Microbiol. 2016, 10, 787–794. [Google Scholar]

| Treatment Numbers with Abbreviations | Nutrients Used in Peanut | Nutrients Used in Wheat |

|---|---|---|

| T1; Cont. | No fertilizer | No Fertilizer |

| T2; P50RDF + W100RDF | 50% RDF | 100% RDF |

| T3; P75RDF + W75RDF | 75% RDF | 75% RDF |

| T4; P100RDF + W100RDF | 100% RDF | 100% RDF |

| T5; P75RDF+5tFYM + W75RDF | 75% RDF + 5 t/ha FYM | 75% RDF |

| T6; P75RDF+2.5tFYM + W100RDF | 75% RDF + 2.5 t/ha FYM | 100% RDF |

| T7; P75RDF+2.5t ex situ GM + W75RDF | 75% RDF + 2.5 t/ha GM | 75% RDF |

| T8; P50RDF+5t ex situ GM + W100RDF | 50% RDF + 5 t/ha GM | 100% RDF |

| T9; P100RDF+PGPR + W100RDF+Azot. | 100% RDF + PGPR | 100% RDF + Azotobacter |

| T10; P100RDF+5tFYM+PGPR + W75RDF | 100% RDF + 5 t/ha FYM + PGPR | 75% RDF |

| T11; P75RDF+5tFYM+PGPR + W100RDF | 75% RDF + 5 t/ha FYM + PGPR | 100% RDF |

| T12; FF | 100 kg ha−1 DAP | 100 kg ha−1 DAP |

| S. No. | Particulars | Units | Equivalent Energy (MJ) |

|---|---|---|---|

| Inputs | |||

| 1. | Human labour | ||

| Man | Man-hour | 1.96 | |

| Woman | Woman-hour | 1.57 | |

| 2. | Electric motor | kg | 64.8 |

| 3. | Electricity | KWh | 11.93 |

| 4. | Farm machinery | kg | 62.7 |

| 4. | Diesel fuel | L | 56.30 |

| 5. | Irrigation water | m3 | 1.02 |

| 6. | Chemical fertilizers | ||

| a. | N | kg | 60.60 |

| b. | P2O5 | kg | 11.10 |

| c. | K2O | kg | 6.70 |

| 7. | Superior chemical | kg | 120 |

| 8. | FYM | kg (dry mass) | 0.3 |

| 9. | Biofertilizers | kg | 10.0 |

| 10. | Green manuring | kg (dry mass) | 18.0 |

| 11. | Seed of crops | ||

| Peanut | kg | 25 | |

| Wheat | kg | 14.7 | |

| Outputs | |||

| Grain (wheat) | kg | 14.7 | |

| Pod (peanut) | kg | 25 | |

| Straw (wheat) | kg | 12.5 | |

| Haulm (peanut) | kg | 10 | |

| Treatments | Plant Height at Harvest (cm) | LAI at 45 DAS | Mature Pods Plant−1 at Harvest | Dry Weight of Mature Pods Plant−1 (g) | 100 Kernel Weight (g) | Shelling Percentage |

|---|---|---|---|---|---|---|

| T1 | 28.0 E | 1.6 E | 11.7 D | 10.9 E | 35.0 E | 62.3 C |

| T2 | 29.0 DE | 1.8 E | 14.2 C | 11.7 D | 37.5 ABCD | 63.1 BC |

| T3 | 29.6 DE | 2.5 D | 14.2 C | 12.4 C | 37.5 ABCD | 62.6 C |

| T4 | 30.5 CD | 2.6 CD | 15.2 C | 12.9 B | 36.1 CDE | 62.1 C |

| T5 | 31.4 ABC | 2.7 CD | 17.3 B | 14.0 A | 38.3 A | 66.1 A |

| T6 | 30.6 BCD | 2.6 CD | 17.2 B | 13.9 A | 37.7 ABC | 65.7 A |

| T7 | 30.1 CD | 2.5 D | 14.5 C | 12.8 BC | 36.9 ABCD | 64.7 AB |

| T8 | 31.7 ABC | 2.5 D | 14.5 C | 14.2 A | 38.1 AB | 64.6 AB |

| T9 | 30.6 BCD | 2.9 BC | 17.3 B | 13.1 BC | 36.5 BCDE | 63.6 B |

| T10 | 32.5 A | 3.1 AB | 18.8 A | 14.5 A | 38.4 A | 65.4 A |

| T11 | 32.2 AB | 3.4 A | 18.4 AB | 14.4 A | 38.2 A | 65.5 A |

| T12 | 29.8 D | 1.7 E | 14.0 C | 11.4 DE | 35.9 DE | 63.5 BC |

| Treatments | Plant Height at Harvest (cm) | Dry Matter Plant−1 at 60 DAS (g) | SPAD at 60 DAS | Total Tillers per Metre Row at Harvest | Effective Tillers per Metre Row at Harvest | Ear Length (cm) | Spikelet Plant−1 | 1000 Seed Weight (g) |

|---|---|---|---|---|---|---|---|---|

| T1 | 62.3 G | 2.2 G | 41.73 F | 67.4 H | 59.2 E | 6.6 D | 14.5 D | 29.7 D |

| T2 | 69.0 E | 2.5 EFG | 43.67 DE | 76.0 G | 70.1 D | 7.5 C | 18.1 C | 35.1 C |

| T3 | 70.2 DE | 2.5 DEF | 44.76 CD | 78.6 FG | 76.2 C | 7.6 BC | 18.5 C | 36.1 BC |

| T4 | 70.9 D | 2.6 CDE | 46.10 BC | 84.7 DE | 77.3 C | 7.6 BC | 18.5 C | 37.4 B |

| T5 | 72.4 BC | 2.7 CD | 46.70 AB | 86.7 CD | 78.1 C | 7.8 ABC | 19.3 ABC | 40.4 A |

| T6 | 71.4 CD | 3.1 B | 46.58 AB | 86.1 DE | 78.0 C | 7.8 ABC | 19.0 ABC | 39.6 A |

| T7 | 70.5 D | 2.5 DEF | 44.90 CD | 80.1 F | 76.9 C | 7.8 ABC | 19.4 ABC | 37.1 BC |

| T8 | 72.9 AB | 3.1 B | 46.78 AB | 83.7 E | 77.3 C | 7.7 ABC | 18.9 ABC | 40.4 A |

| T9 | 71.1 CD | 2.6 CDE | 45.68 BC | 87.0 CD | 79.1 C | 7.7 BC | 18.8 BC | 37.3 B |

| T10 | 73.5 AB | 3.3 AB | 46.97 AB | 95.6 B | 87.2 B | 8.2 AB | 20.0 AB | 41.5 A |

| T11 | 74.3 A | 3.5 A | 48.10 A | 103.7 A | 95.5 A | 8.3 A | 20.4 A | 41.5 A |

| T12 | 67.6 F | 2.3 FG | 42.98 EF | 89.5 C | 68.1 D | 7.3 C | 15.6 D | 31.3 D |

| Treatments | Peanut Equivalent Yield (kg ha−1) | Net Returns (INR ha−1) | B:C Ratio | Net Energy (MJ ha−1) | Energy Use Efficiency | ||||

|---|---|---|---|---|---|---|---|---|---|

| Peanut | Wheat | System | Peanut | Wheat | System | ||||

| T1 | 2802 G | 118,638 C | 3639 C | 122,277 D | 5.1 C | 1.1 C | 3.2 C | 152,247 C | 8.4 A |

| T2 | 3583 EF | 133,268 B | 17,889 B | 151,157 B | 5.4 B | 1.6 B | 3.6 AB | 188,462 B | 7.6 B |

| T3 | 3825 DE | 124,541 C | 18,189 B | 142,730 C | 5.1 C | 1.6 B | 3.5 C | 181,448 B | 7.6 B |

| T4 | 4204 C | 126,480 C | 24,189 A | 150,669 B | 5.1 C | 1.9 A | 3.6 AB | 199,179 B | 7.7 B |

| T5 | 4649 AB | 140,377 A | 24,039 A | 164,416 A | 5.6 AB | 1.8 A | 3.8 A | 202,421 A | 8.1 A |

| T6 | 4575 ABC | 142,924 A | 23,124 A | 166,048 A | 5.7 A | 1.8 A | 3.8 A | 200,460 A | 7.7 B |

| T7 | 4250 C | 139,152 B | 20,214 B | 159,366 B | 5.6 AB | 1.7 AB | 3.7 A | 186,755 B | 7.6 B |

| T8 | 4557 ABC | 142,429 A | 19,329 B | 161,758 B | 5.7 A | 1.7 AB | 3.8 A | 187,568 B | 7.2 B |

| T9 | 4323 BC | 138,872 B | 22,389 A | 161,261 B | 5.3 B | 1.8 A | 3.6 AB | 202,363 A | 7.8 B |

| T10 | 4764 A | 151,623 A | 22,689 A | 174,312 A | 6.0 A | 1.8 A | 3.9 A | 213,136 A | 8.3 A |

| T11 | 4795 A | 149,972 A | 26,274 A | 176,246 A | 5.9 A | 1.9 A | 3.9 A | 219,032 A | 8.2 A |

| T12 | 3267 F | 126,176 C | 17,514 B | 143,690 C | 5.2 BC | 1.6 B | 3.5 C | 185,750 B | 8.8 A |

| Treatments | N Uptake by Peanut (kg ha−1) | N Uptake by Wheat (kg ha−1) | N Uptake of System (kg ha−1) | P Uptake by Peanut ((kg ha−1) | P Uptake by Wheat (kg ha−1) | P Uptake of System (kg ha−1) | K Uptake by Peanut (kg ha−1) | K Uptake by Wheat (kg ha−1) | K Uptake of System (kg ha−1) |

|---|---|---|---|---|---|---|---|---|---|

| T1 | 142.8 H | 65.6 F | 208.4 I | 18.1 G | 12.6 G | 30.7 H | 30.1 D | 48.9 E | 79.0 H |

| T2 | 151 FG | 74.3 E | 225.3 GH | 19.8 FG | 13.5 F | 33.3 G | 32.8.0 BCD | 53.3 D | 86.1 FG |

| T3 | 157.7 EF | 76.1 E | 233.8 FG | 20.0 EF | 13.9 EF | 33.9 FG | 33.0 BCD | 57.7 C | 90.7 EF |

| T4 | 164.6 D | 81.9 D | 246.5 DE | 21.6 CDE | 14.6 CDE | 36.2 CDE | 34.8 B | 65.9 B | 101.7 CD |

| T5 | 165.1 D | 85.1 BC | 250.2 D | 22.6 BC | 15.3 BC | 37.9 BC | 36.6 AB | 67.1 B | 103.7 BCD |

| T6 | 164.7 D | 84.5 BC | 249.2 D | 21.8 CD | 14.7 CD | 36.5 CD | 36.5 AB | 66.1 B | 102.6 CD |

| T7 | 158.5 DE | 80.9 D | 239.4 EF | 20.3 DEF | 14.0 DEF | 34.3 EFG | 33.1 BCD | 58.6 C | 92.2 E |

| T8 | 160.5 DE | 84.6 BC | 245.1 DE | 21.2 CDEF | 14.4 DE | 35.6 DEF | 34.8 ABC | 65.5 B | 100.3 D |

| T9 | 178.2 C | 85.1 BC | 263.3 C | 24.2 AB | 15.6 B | 39.8 B | 36.7 AB | 70.2 A | 106.9 ABC |

| T10 | 222.9 A | 87.5 B | 310.4 A | 24.8 A | 16.0 B | 40.8 A | 37.3 A | 70.8 A | 108.1 AB |

| T11 | 193.8 B | 94.3 A | 288.1 B | 23.2 AB | 17.7 A | 40.9 A | 36.7 AB | 72.8 A | 109.5 A |

| T12 | 145.4 GH | 74.0 E | 219.4 H | 19.6 FG | 13.3 FG | 32.9 G | 31.2 CD | 49.6 E | 80.8 G |

| Treatments | Available N (kg ha−1) | Available P (kg ha−1) | Available K (kg ha−1) | Soil Organic Carbon (g kg−1) | Dehydrogenase (µg TPF g−1 24 h−1) | Acid Phosphatase (μg pNP g−1 h−1) | Alkaline Phosphatase (μg p-NP g−1 h−1) |

|---|---|---|---|---|---|---|---|

| T1 | 231.6 G | 11.7 F | 337.9 H | 5.3 I | 79.2 F | 26.6 F | 127.1 F |

| T2 | 373.8 EF | 14.6 DE | 353.1 FGH | 6.0 GH | 84.7 EF | 29.3 E | 152.7 EF |

| T3 | 377.9 EF | 14.9 DE | 355.3 EFG | 6.1 G | 85.8 EF | 31.1 D | 189 DE |

| T4 | 380.4 EF | 15.3 CD | 363.8 DEF | 6.6 F | 90.2 DE | 33.4 BC | 422 C |

| T5 | 391.3 D | 17.8 AB | 379.9 D | 6.8 EF | 94.8 CD | 33.7 BC | 428.2 C |

| T6 | 412.3 CD | 17.2 BC | 379.2 D | 7.1 D | 91.5 CDE | 33.5 BC | 422.2 C |

| T7 | 377.9 EF | 15.8 CD | 358.8 EFG | 7.3 CD | 89.7 DE | 31.2 D | 212.8 D |

| T8 | 413.6 CD | 17.8 AB | 370.6 DE | 7.5 C | 99.1 BC | 33.7 BC | 465.7 B |

| T9 | 421.2 C | 16.2 BCD | 413.6 C | 7.0 DE | 90.1 DE | 32.6 C | 410.5 C |

| T10 | 454.3 B | 19.1 A | 438.5 B | 8.0 B | 105.9 AB | 35.6 A | 524.4 A |

| T11 | 485.8 A | 19.2 A | 477.4 A | 8.5 A | 108.9 A | 36.1 A | 548.8 A |

| T12 | 356.7 F | 13.3 EF | 344.8 GH | 5.8 H | 84.7 EF | 27.7 F | 133.2 F |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jat, R.A.; Jain, N.K.; Yadav, R.S.; Reddy, K.K.; Choudhary, R.R.; Zala, P.V.; Meena, H.N.; Sarkar, S.; Rathore, S.S.; Sharma, G.K.; et al. System-Based Integrated Nutrient Management Improves Productivity, Profitability, Energy Use Efficiency and Soil Quality in Peanut-Wheat Cropping Sequence in Light Black Soils. Sustainability 2023, 15, 1361. https://doi.org/10.3390/su15021361

Jat RA, Jain NK, Yadav RS, Reddy KK, Choudhary RR, Zala PV, Meena HN, Sarkar S, Rathore SS, Sharma GK, et al. System-Based Integrated Nutrient Management Improves Productivity, Profitability, Energy Use Efficiency and Soil Quality in Peanut-Wheat Cropping Sequence in Light Black Soils. Sustainability. 2023; 15(2):1361. https://doi.org/10.3390/su15021361

Chicago/Turabian StyleJat, Ram A., Navin K. Jain, Ranjit S. Yadav, Kiran K. Reddy, Raja Ram Choudhary, Pratap V. Zala, Har N. Meena, Susheel Sarkar, Sanjay S. Rathore, Gulshan K. Sharma, and et al. 2023. "System-Based Integrated Nutrient Management Improves Productivity, Profitability, Energy Use Efficiency and Soil Quality in Peanut-Wheat Cropping Sequence in Light Black Soils" Sustainability 15, no. 2: 1361. https://doi.org/10.3390/su15021361

APA StyleJat, R. A., Jain, N. K., Yadav, R. S., Reddy, K. K., Choudhary, R. R., Zala, P. V., Meena, H. N., Sarkar, S., Rathore, S. S., Sharma, G. K., Kumawat, A., Jinger, D., & Jha, P. K. (2023). System-Based Integrated Nutrient Management Improves Productivity, Profitability, Energy Use Efficiency and Soil Quality in Peanut-Wheat Cropping Sequence in Light Black Soils. Sustainability, 15(2), 1361. https://doi.org/10.3390/su15021361