1. Introduction

After the advent of the internet, information, and communication technology, the Internet of Things (IoT) is considered to bring the fourth revolution of disruptive technological innovation. IoT aims to interconnect things, including sensors, actuators, embedded technologies, services, computing, communication, and other internet-connected objects. Wang et al. [

1] defined IoT as communication between passive and active networked devices. The sole purpose of the IoT is to collect data for analyzing, controlling, optimizing, and sharing information in real-time with trifling human interaction [

2]. This technology not only introduces convenience and connectivity but also reduces cost of human labor, eliminates human errors, and bringing overall efficiency to the process. IoT is expected to sense, comprehend, and quantify the surrounding environment to bring about modernization and improve quality of life [

3]. It is predicted to assist ultra-reliable and low-latency communications (URLLC) with 99.99% reliability and less than 0.5 ms of uplink latency even under a shadow-fading environment [

4].

The spectrum of IoT applications is vast, comprising wearables, traffic monitoring, e-health, agriculture, hospitality, smart grid, smart homes, energy saving, maintenance management, food production, etc. It can be safely stated that IoT is adjustable to almost any technology, bringing about mobility, efficiency, cost reduction, productivity, and agility [

5]. The data created by IoT devices form a significant part of the big data regime, adding tremendous business value and opportunities for organizations with the overall acceleration of economic growth [

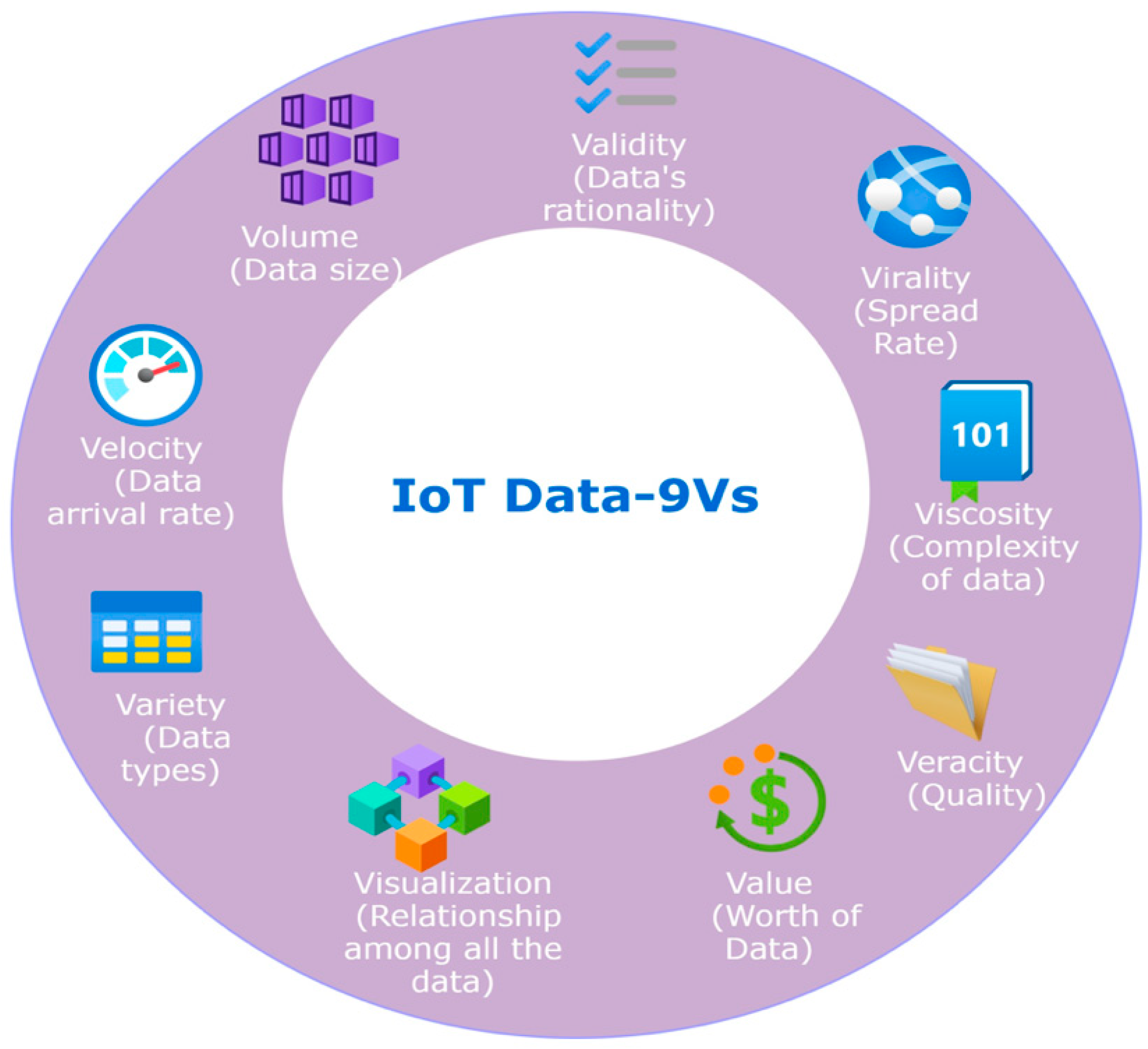

6]. The 9 V model defined for big data [

7] can be mapped directly to the multidimensional IoT dataset (see

Figure 1). The 9 Vs of IoT data lead to the direction of analytics, giving quantitative insights into each dimension.

The pros of IoT have made it important to be a part of every industry [

8]. The only industry with slow adoption of IoT technology is the construction industry. Although the construction industry is flourishing rapidly due to increased urbanization and population [

9], per a report by McKinsey, it is still the most under-digitized industry with the least involvement of IoT and artificial intelligence (AI). It is estimated that IoT will become a must-have technology for waste management, cost reduction of different construction activities, maintenance and repair, safety improvements, and requirement management for tenants.

Currently, the construction industry is facing many problems such as scarcity of material supply, environmental concerns, safety, use of different technologies among constructors, the rising cost of materials, shortage of skilled workers, inadequate design processes, transport and energy costs, delays in technology adoption, and lack of production facilities [

10]. Fakunle et al. [

11] stated that the loss of revenue and the delay in production result mainly from the insufficiency in the enforcement of building specifications and regulations. As reported by the McKinsey Global Institute, the construction industry is the most significant in the global market with 10 trillion USD in expenditures [

12]. However, its performance has been rambling compared with other sectors for decades. The overall GDP has fallen further as a result of the lockdown due to the coronavirus pandemic (COVID-19), wreaking havoc on the construction industry and having an unprecedented impact [

13]. Globally, the delays in the construction industry’s productivity are affecting not only underdeveloped but also developed countries, including Japan, the USA, the UK, etc. [

14]. Somehow, if the construction industry’s productivity matches up with the global economy in the next few years, a 1.6 trillion USD value addition can be expected [

15]. To boost productivity, investment in research and development and an infusion of the latest digital technology is required. However, the slow adoption of IoT in the construction sector may be linked to Davis’s technology acceptance model (TAM) (1989). The model states that acceptance of new technology depends on usefulness and ease of usability. These two factors, along with the location and environment of the users’ surroundings, determine users’ desire to adopt a new technology or improve the existing framework with the help of innovative technological advancements. If IoT gets completely accepted in the construction industry, it has the potential to generate new economic advantages [

15].

This study highlighted the applicability of IoT within the construction sector based on an in-depth investigation. In the literature, there is a lack of reviews on the inclusion and challenges of IoT implementation in the construction sector. This work exclusively emphasized the amalgamation of the ever-evolving IoT and the digitized, automated construction industry (Construction 4.0) drivers of developed and developing countries. By merging, relating, and contrasting widely disseminated research contributions, it draws attention to the key obstacles preventing IoT adoption in the context of Construction 4.0.

2. Scope and Outline

In this article, a systematic review is presented. As per the authors’ research, this article is the first literature review covering IoT with respect to the four major drivers of Construction 4.0, with special emphasis on developing countries. The summary of contributions offered by this study are as follows:

As the field of IoT is snowballing and the construction industry is slowly adapting to the IoT environment, a need for an up-to-date survey presenting the unification of the two areas motivated the authors to write this review. Over 200 articles from the years 2017 to 2021 were surveyed. From all these articles IoT requirements, their advantages, and effects on industrial processes were identified, along with the obstacles to IoT implementation in the construction industry.

The emerging issues linked to the core components of Construction 4.0 were identified. To overcome the gap in the literature, the status of IoT deployment in the context of Construction 4.0 was explored not only for developed but also for developing countries.

This study also focused on the challenges faced by developing countries in IoT adoption such that if approaches are devised to overcome the open issues, global successful sustainable construction is obtainable. To the best of the authors’ knowledge, no such conclusions are drawn by observing the state of IoT adoption in developing countries.

The study is beneficial for both researchers and industry professionals, as it reveals areas of high priority for future research. This article is divided into six main sections.

Section 3 outlines the concept of IoT and the trends and objectives of IoT.

Section 4 entails the methodology used for carrying out this research work and the formulation of research questions.

Section 5 surveys the state of the art of Construction 4.0, investigated literature on the role of IoT in Construction 4.0, and the hurdles in integrating IoT in the construction sector.

Section 6 presents the areas of Construction 4.0 and the status of IoT adoption by developed and developing countries in each area.

Section 7 discusses the prospects, and

Section 8 concludes the paper.

3. Concept, Objectives, and Trends in IoT

The technological development path of IoT is as follows:

The term “IoT” first appeared in Kevin Ashton’s presentation to Procter & Gamble (P&G) in 1999, where he emphasized radio frequency ID (RFID) supply chains and named his presentation “Internet of Things” [

16].

The same year, Neil Gershenfeld, a professor at MIT, in his book, “When Things Start to Think”, provided the concept of IoT without mentioning its exact name [

17].

Although the term appeared in 1999, the idea already existed when, in the early 1980s, a Coca Cola machine was connected to the web at Carnegie Mellon University. Using the web, users were able to check the machine’s status, i.e., the availability of Coca Cola in the machine [

18].

In the early days of the advent of IoT, the technology was not widely recognized because of the lack of proper sensors, hardware equipment, and the availability of the internet. The development of Bluetooth, WiFi, sensors, and big data-related technologies has made the future of IoT very promising. According to the 2015 forecast analysis by McKinsey Global Institute, IoT usage and its output value are estimated to surge from 3.9 trillion to 11 trillion USD by 2025 [

19].

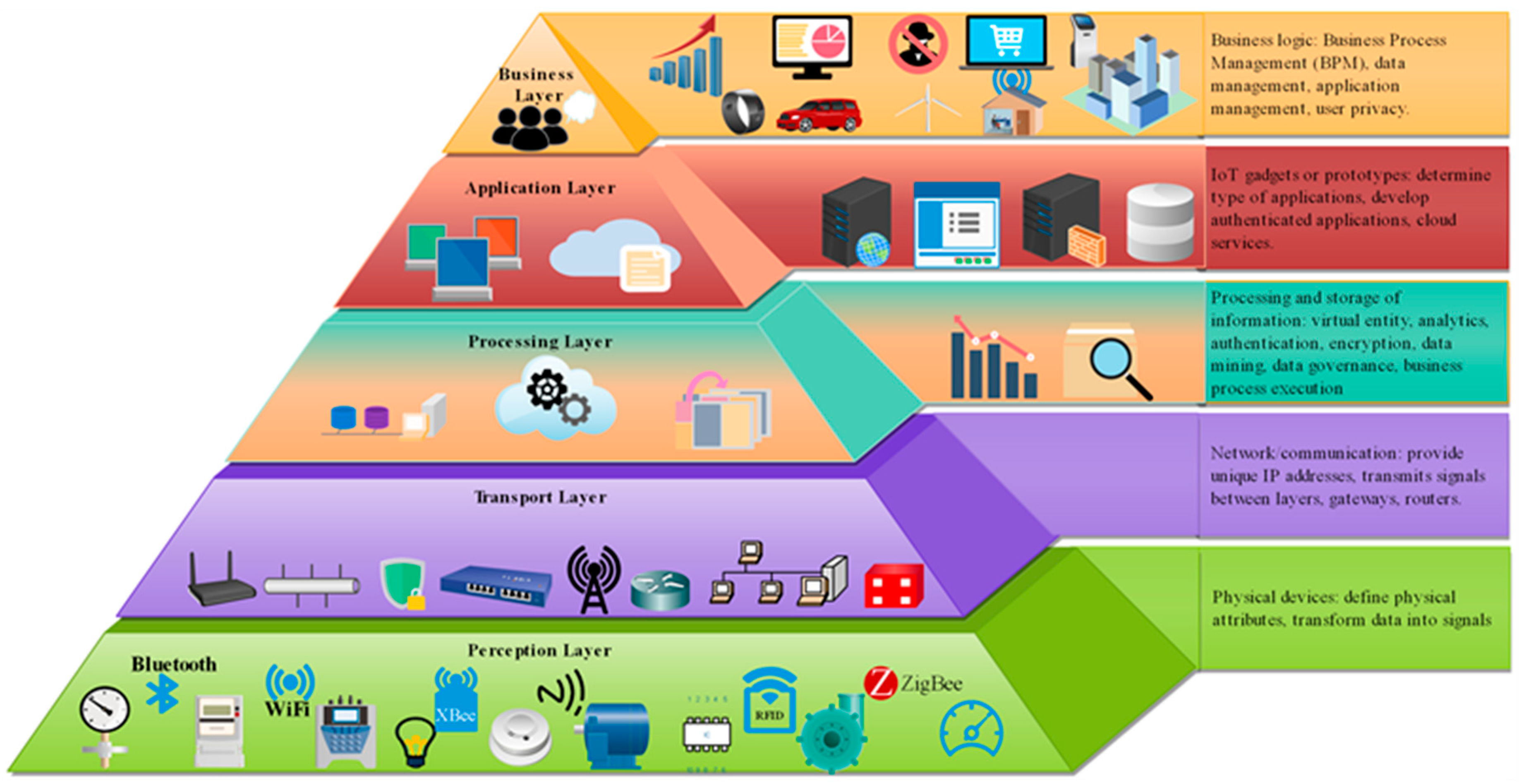

IoT in terms of its work can be defined as the sum of five layers: the perception, transmission, processing, visual, and business layers.

Perception is the sensing of data; this layer manages the smart devices and sensors across the system.

The transmission/transport layer is the network layer; it passes the data of perception layer to the processing/optimization layer. The transmission layer is also known as the communication layer as it uses communication technologies including Bluetooth, WiFi, 4G, InfraRed (IR), etc. for the transmission of data.

The processing layer is responsible for storing, processing, and performing computations on the device data; it may also take specific actions based on the available data set of the device.

The application layer is the visual layer. This layer offers interaction with the users. This layer can also activate alarms, send emails, turn a device on or off, etc.

The last layer is the business layer, which provides data analysis; it deals with delivering data to the customers in a specific required format, such as flow charts, graphs, etc. The business layer might also suggest to customers ways of improving performance. The graphical representation of the IoT layers is shown in

Figure 2.

According to the International Telecommunication Union (ITU), the basic goal of the IoT is to connect anything from anywhere at any time. Current research on the IoT focuses on devising a network that supports scalability so that anything can be connected to the network without disrupting its functionality. Other areas of IoT research emphasize providing security to the data obtained from IoT devices such that no intruder can eavesdrop, interfere, hack, or manipulate the information. Most vendors hesitate to adopt IoT because of their security, privacy, and weak policy concerns as they demand authentication and data integrity [

21]. Efficient energy utilization is another objective of IoT. Research is carried out to deploy energy harvesting techniques and efficient protocols. Many authors have suggested the integration of low-power wireless personal area networks (6LoWPAN) and internet protocol (IPv6) to prepare low-power sensor nodes [

22].

Successful implementation of IoT on any platform requires selecting proper energy-efficient sensors along with transmission technologies suitable for handling elastic and non-elastic traffic [

23]. A scalable data infrastructure is also required for handling and processing the acquired data. This compromises on-premises data centers or scalable cloud-based services. Lastly, intelligent software suites are required for extracting, analyzing, and optimizing the sensors’ data. These software suites are in charge of presenting useful information to stakeholders in the correct format. Based on investment in IoT, some stakeholders ask for advanced systems incorporating feedback actions, for example, shutting down equipment on reaching a certain temperature level.

IoT is successfully implemented in metering and grid systems, providing smart metering and smart grid systems, hence, offering improved public utility infrastructure [

24]. IoT is also transforming the medical sector by providing remote patient monitoring facilities, smart ambulances, smart biosensors, wearable devices, and telemedicine. The concept of smart homes based on Wireless Local Area Network (WLAN) standard 802.11 has also been implemented, benefitting the end users by providing comfort and improved quality of life. It is expected that the global smart home market will financially expand from 76.6 billion to 151.4 billion USD between 2018 and 2024, respectively [

25].

The application of IoT for all industries (industrial IoT-IIoT) is important to enhance the quality of industrial processes. Inefficiencies, breakdowns, and squandering of resources, along with COVID-19, are the reasons for the delay in the delivery processes, services, and the production of quality products within the allocated budget. Most of these challenges can be addressed by deploying IoT to secure the quality of the production process and reduce production costs.

The most recent work linking IoT and the construction industry is covered in [

26,

27]. The former emphasizes how IoT and digitization can be adopted in the construction industry, while the latter discusses applications of IoT in the construction industry. Another study [

28] covered the models and approaches that show stakeholders’ acceptance of IoT in Taiwan’s construction industry. The mentioned articles lack explicit discussion on how IoT is transforming the construction industry, its sub-sectors, the link of each sector with IoT, and in-depth discussion about developing countries and their struggles with IoT. Yet another study [

26] discussed IoT in the construction industry without providing an implementation perspective or focusing on specific applications, e.g., site monitoring, etc. IoT is one of seven key concepts covered in Forcael et al. [

29]’s review of Construction 4.0, along with big data, 3D printing, virtual reality, new industrial materials, artificial intelligence, and BIM. The authors hypothesized that these seven keywords are descriptive of the term “Construction 4.0”. To establish a stronger connection between the terms, the authors also advocated reformulating them. In addition, the authors mentioned two challenges of IoT implementation with respect to smart homes. An in-depth analysis of IoT implementation with respect to Construction 4.0 drives was not covered in the mentioned review. Gamil et al. [

30] reported 26 common issues with IoT implementation in their work. The authors also conducted a survey of Malaysian construction industry practitioners via questionnaire. The authors listed the top five challenges with IoT implementation in the construction sector. The study is relevant only to the context of the Malaysian construction industry, and the cited article did not specifically address the areas of Construction 4.0. Another review article on IoT, BIM, and digital twin in the construction industry [

31] discussed significant publications, funding agencies, conferences, influential authors, countries, and organizations producing research specifically on BIM. In addition, prospective areas for future study were identified. However, the role of IoT or the practical applications of IoT in different countries with regard to Construction 4.0 was not covered in the cited article. Begić and Galic [

32] also presented a review of Construction 4.0; however, the article focused primarily on BIM and provides a few examples of IoT integration with BIM. The preceding reviews lack a comprehensive discussion of the importance, implementation status, and challenges of IoT in relation to Construction 4.0 drivers. So far, no work has been found in the literature that covers the areas of Construction 4.0 and the status of IoT applications in each area with regard to the developed and emerging economies, as well as challenges unique to each area. Consequently, it is necessary to write an up-to-date survey covering systematically the role of IoT in the construction industry from an applications and implementation point of view.

4. Research Methodology

This section discusses the methodology and research questions that led to this systematic survey article. The authors followed the approach by Kim et al. [

33] and did not let the work suffer from Mathew’s principle, where the most cited papers are considered a priority for review. The authors performed four steps in designing this research.

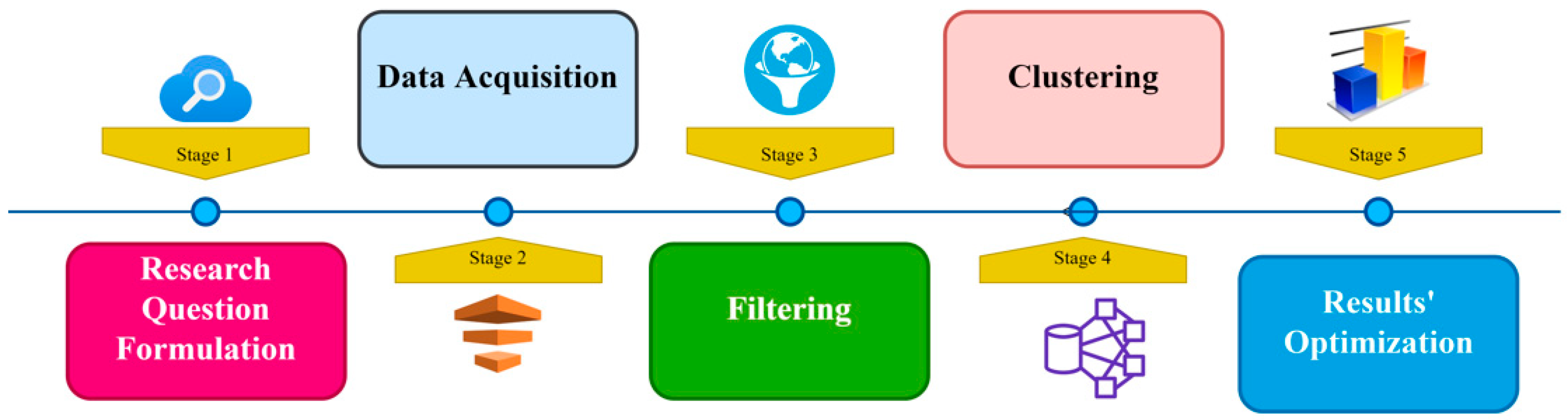

The first step was data acquisition according to the research queries. The second step was to filter the research contributions of developed and developing countries linked to IoT in the construction sector. The third step was clustering. Clustering was needed to group the research work associated with developed and developing countries. The last step was the optimization of results and qualitative analysis to extract quality work relevant to the study.

Figure 3 depicts the entire study process. The following are the research questions formulated for this work:

RQ1: What is the role of IoT in the construction industry?

RQ2: Which developed and developing countries are producing research related to the IoT and their construction industries?

RQ3: How is IoT revolutionizing the construction industry and what are the obstacles in its implementation, specifically in developing countries?

To answer the above-mentioned queries, two keywords were devised “IoT” and “Construction Industry”. However, both of these terms yielded a huge number of results. A few more keywords were then devised, compromising IoT, Industry 4.0, and Construction 4.0.

Table 1 shows the queries generated according to the Google key-terms search criterion for the proposed research work and the databases searched for the particular questions.

The research queries were generated in August 2021. IEEE Xplore, Scopus, and Google Scholar were used to obtain the required data. Conference articles were excluded from the search and only journal, magazines, and early access journal articles were considered as they represent the most significant research studies. However, conference articles/reports, which were found in the references of the selected journals, magazines, and early access articles were considered for a detailed understanding of the particular work. The results obtained are summarized in

Table 2.

After the data acquisition, the search was filtered by looking at the titles and abstracts and the number of articles was reduced to 300. Following the clustering of research related to developed and developing countries, the results were filtered again by looking for similar research, and thus 50 more articles were excluded by mutual decision. The final optimized data comprised 257 papers, which were thoroughly read and analyzed for the proposed work.

5. Construction 4.0

This section discusses the role of IoT in Construction 4.0. It covers the problems solved by IoT in the construction sector, how IoT helps in improving the state of existing industries, and how it benefits customers, manufacturers, and engineering firms. Moreover, the challenges that the construction industry may face while adapting to the IoT environment are discussed in detail.

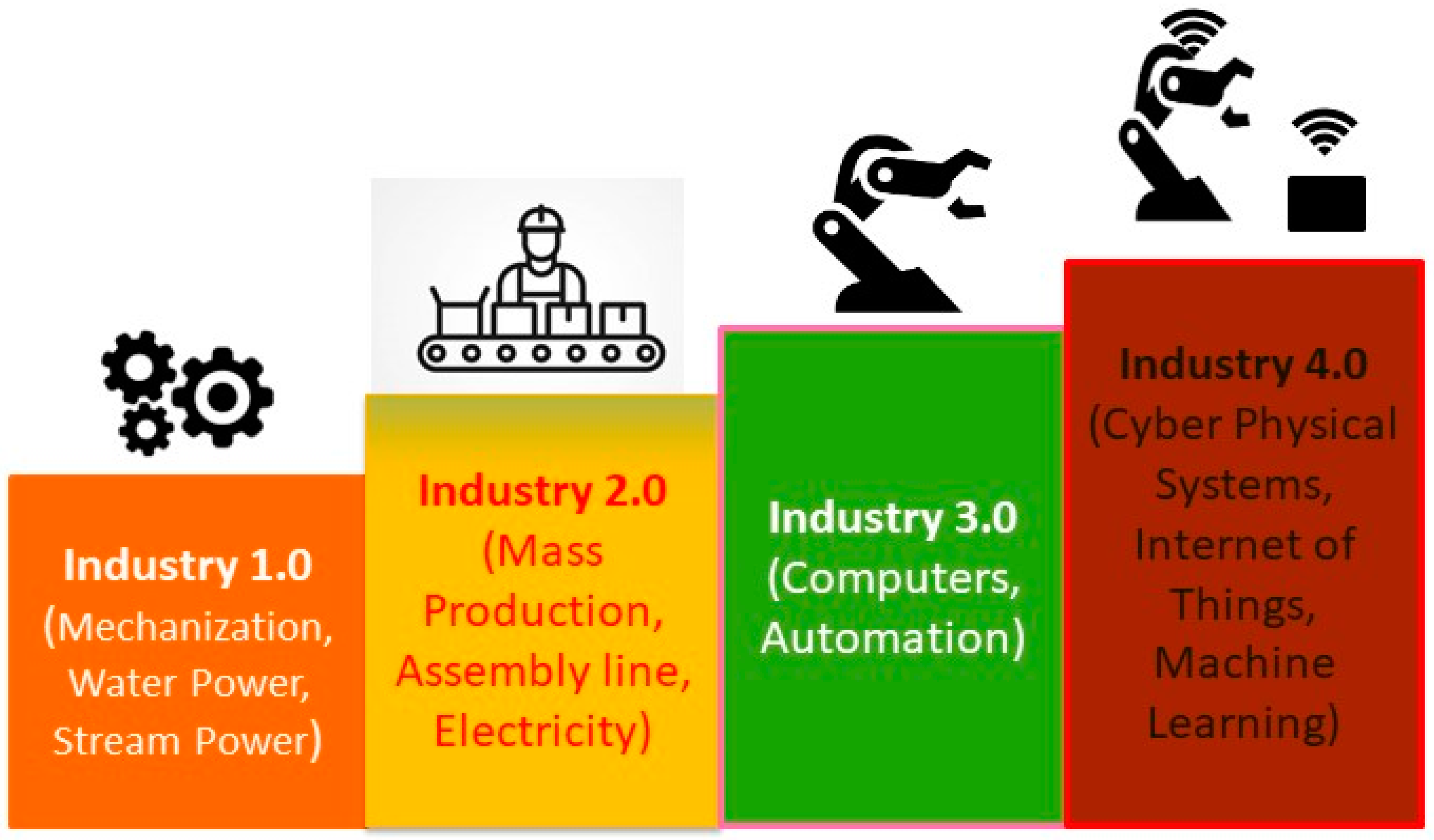

With the advent of water and steam-powered engines and machine tools in the late 17th and early 18th centuries, the performance of manual labor shifted to more optimal labor performance. This was the start of the first industrial revolution, now known as “Industry 1.0”. The introduction of electricity and steel during the 18th and 19th centuries led to the second industrial revolution or “Industry 2.0”, which transformed the manufacturing environment. Henry Ford also pioneered the mass production assembly line, making Industry 2.0 the greatest revolution of the time. With the transformation of analog machinery to digital ones and the involvement of automation software in industries, the world witnessed the third industrial revolution, Industry 3.0. The Industry 3.0 revolution began in the 1950s and continues to this day. In 2011, Kagermann published the concept of Industry 4.0, and in 2013, the German National Academy of Science and Engineering (ACATECH) published the Industry 4.0 platform. It was a concept developed by the German nation from 2013 to 2020 to strengthen its leadership in manufacturing industries.

The most important aspects of Industry 4.0 are interconnectivity, real-time data, machine learning, and automation [

34]. Industry 4.0 mentions IoT as creating an environment where anything and anyone can communicate and collaborate. Industry 4.0 is about modern techniques supporting every element of the industry and sustainability. According to Schwab [

35], three major driving factors of Industry 4.0 are physical, digital, and biological technology domains. It affects human life in terms of how they live, work, and have relationships. Industrialized nations have already formulated detailed plans to adopt Industry 4.0, including Made in China 2025, Society 5.0 in Japan, and Manufacturing USA. However, developing or underdeveloped nations are still lagging in terms of technology, industrialization, and well-established communication structure to successfully adopt this idea.

Figure 4 depicts the industrial revolution process.

Construction 4.0 is the instantiation of the concept derived from Industry 4.0, allowing ubiquitous connectivity technologies to make real-time decisions. The idea of Construction 4.0 is to fully automate every aspect of the project for its complete life cycle. Automation involves all the stages of the construction process, including planning, design, operation, and construction. Even in the world of digitization, the construction industry still depends on manual labor, heavy machinery, and a business model that has not been updated much over the past fifty or more years. Despite IoT technologies’ potential to enable continuous real-time interaction and automation in industries, their application in construction is relatively unexplored.

5.1. Role of IoT in Construction 4.0

According to a report by McKinsey, global investment in the construction industry in 2017 was approximately 11 trillion USD and is predicted to surge to 14 trillion USD in 2025. Still, the industry is criticized due to its low productivity, which can be credited to slow technological advancements and digitization. To introduce optimization to the construction industry, one major step is the inculcation of IoT. Like Industry 4.0, the critical concept of Construction 4.0 is ubiquitous automation with seamless connectivity, which is possible with the help of IoT. The four primary areas of industrial automation include project visioning and engineering; assembly and manufacturing; sales and operations planning; and service management. The IoT facilitates the automation of all these four areas. It makes automation with machines relatively easy, processes real-time data within split seconds, and manages the optimal usage of the resources with minimal cost involvement and risks [

36]. Although the concept of embracing IoT is relatively slow in the construction industry because of the complexity and the high risks of failure of construction projects, IoT is still used in the construction sector. An example of IoT usage is by a construction company in New York for the safety of workers. Workers are provided with a clip-on IoT device that can send an alert signal to the site safety manager if the gadget drops by three feet. The idea is to immediately notify the safety site manager of any falls. One more example is the monitoring of trucks, their location, and the activity of different vehicles and other assets by an IoT firm Trimble. Another example of IoT in Construction 4.0 is concrete curing. Concrete with embedded sensors follows the curing of cementitious composites in real-time [

37]. This enables contractors to monitor and schedule their activities to avoid any uncertainty or delay. Although IoT is used in some areas of the construction industry, many areas are yet to be explored.

Different scientific groups and research institutes are doing their best to integrate IoT applications into all areas of the construction industry to create awareness of the advantages that this technology can bring to the world. In the last few years, researchers have presented the concepts of smart infrastructure, buildings, communities, and cities. Additionally, several researchers have explored the idea of IoT for better construction, safety, health, and project management over the past few years. Glaeser et al. [

38] stated that if companies record their data from planning to their final output, the quality and content of operational data can be utilized to optimize and establish intelligent systems. These intelligent systems can be used for the optimization of urban construction, improvement of urban life, monitoring and assessment of underground pipelines, creation of precast components, etc. It is anticipated that if the construction industry can implement IoT, it will lead to a 22–29% savings of the total costs, equivalent to a profit of 75–96 billion USD per year [

39].

5.2. Obstacles to the Adoption of IoT in Construction 4.0

Despite the countless advantages of IoT implementation in several industries, the construction industry is still hesitant to adapt to the concept. The challenges faced and the complex construction environment poses many problems. However, disinclination to fully automate the construction processes is present among construction firms. According to Oesterreich and Teuteberg [

40], the reasons for hesitancy towards IoT include the complexity of IoT infrastructure, the uncertainty of results, the fragmented supply chain, the short-term thinking of the managers, and the environment. From the extracted literature, the major issues hindering the effective implementation of IoT in Construction 4.0 are highlighted. The top seven issues are represented in

Figure 5.

5.2.1. Lack of Knowledge

Debasish Mridha, an American philosopher said that “Fear comes from a lack of knowledge and a state of ignorance. The best remedy for fear is to gain knowledge,” which is the same as the case with construction managers. Fear of the adoption of IoT and failure to produce quality output is the consequence of a lack of knowledge about the advantages of IoT. According to Li et al. [

41], lack of understanding of IoT technology, its identification, performance evaluation, and selection are the main reason for the slow acceptance of IoT in the construction sector. The inclination of stakeholders of the construction industry to incorporate IoT applications is usually not very high [

28]. Compared with large-sized companies, small-sized companies are more reluctant to adopt advanced technologies because of a negligible awareness of the potential merits and challenges associated with advanced technologies [

42].

Overall, there is a lack of educational resources to embark on IoT knowledge. The client, contractor, and consultant all show poor confidence in implementing IoT due to their minimal exposure to the technology. Additionally, because most of the construction projects are large-scale, introducing or doing trials of new technology becomes an obstacle due to the fear of failure. To get the most out of technology, both the short- and long-term benefits, as well as the challenges, must be discussed at the executive level with practitioners.

5.2.2. Lack of Trained Labor

A critical challenge for the construction industry is to adopt IoT without sufficient training. The construction field is already short of workers due to the COVID-19 pandemic. As the JOLTS survey states, the field is short of 350,000 workers [

43], and adopting IoT means a further reduction in labor because workers are not aware of and trained to handle IoT. According to the Signals report from Microsoft, 29% of companies facing difficulties in adopting IoT are blaming a lack of knowledge and training, and nearly half of the companies with active IoT initiatives are trying to cope with a shortage of skilled laborers. Because the construction sector lacks competent IoT supporters, investment in training personnel is required to fill the skills gap.

5.2.3. Security Risks

The increasing complexity of IoT networks also magnifies the security challenges. The complexity of IoT systems is attributed to several connected devices, generating a tremendous amount of data. Attacking an IoT network is possible as the devices are an easy target for intrusion. Even though various security improvement strategies are developed to protect IoT devices from cyber-attacks, security protocols are not well-maintained [

44]. The major security risks related to IoT can be classified under three categories: (1) data confidentiality and integrity; (2) network security; and (3) inadequate physical hardening.

Data Confidentiality and Integrity

Several firms are reluctant towards IoT adoption because they are conscious of their data privacy. To introduce security to the data, the first step is strong authentication. No person without authentication credentials must be able to log in to the system. Several inappropriate security practices, such as the unconscious use of the system, not changing passwords for an extended period, and so on, increase the danger of data breaches. End-to-end strong data encryption is also essential to persuade people to use IoT in Construction 4.0.

Network Security

As already stated about the rapid growth of IoT devices, Ericson predicted the number to reach 18 billion by 2022 [

45]. Connecting this large number of low-memory and low-power devices to the networks means providing more nodes for hackers to hack/attack the network through these connected nodes (devices). As the main focus of IoT devices is to be low-powered and lightweight, these devices do not have virus protection software installed in them [

46]. Furthermore, these devices are connected to the network with wireless links for gathering, storing, and transferring data, making them more prone to security threats. A rogue device can be placed in the network to replace the original one or to integrate as a member of the system for altering or gathering sensitive information. Similarly, one strong virus can damage the whole network. The Stuxnet virus, for example, has previously proven the damage that software may bring to industrial equipment. The worm was successful in physically harming the computers that run Iran’s nuclear centrifuges. [

47].

It is quite challenging to protect the network and its layers from external threats and attacks because of the large number of connected devices, connectivity to the internet, and lack of installation and updating of strong malware protection software. All these weaknesses make IoT networks vulnerable to security threats. As a result, strong protection is required to persuade construction companies to adopt IoT technology for their organization.

Inadequate Physical Hardening

Alan Grau, president and co-founder of Icon Labs (West Des Moines, IA, USA), says “It is vital to secure the things themselves.” Apart from software security, embedded security is also very necessary as a device could be hijacked [

48]. Many IoT devices function unattended and are not kept secure. Hence, it becomes relatively easy to tamper with the devices and gain sensitive information. In Construction 4.0, devices are usually placed in the field to perform their tasks without proper surveillance. Therefore, anyone without authentication can access or take over the device. The control systems of IoT networks also pose a hardware vulnerability by providing unrestricted entry to the universal asynchronous receiver transmitter (UART). Hackers may easily modify the boot sequence and extract log-in information from the machine via UART.

To reduce the risks associated with IoT, construction organizations must thoroughly vet the IoT devices to be used on the network, install and regularly update the latest security software, implement the latest cybersecurity practices, and install the best security tools to monitor the environment.

5.2.4. Policies

The lack of policies and implementation guidelines due to the heterogeneity of connected devices is significantly impeding IoT adoption in the construction industry. No unified document mentions the suitable standards, user guidelines, and the security framework required to implement IoT in Construction 4.0. The lack of standardization of IoT architectures and slow progress in IoT research and development of Construction 4.0 makes organizations often adapt to their architectures and technologies, which impacts the market.

5.2.5. Power Management

Most IoT devices are handheld that can be placed on the construction sites in far-off areas where the only source of power is their inbuilt battery. The limited battery life of IoT devices poses a constant challenge for IoT networks [

49]. Companies must constantly keep an eye on the battery status of the battery, i.e., when it needs to be recharged or replaced. Proper power distribution is also necessary to place as many devices as necessary when required on the network.

The application of IoT in the real world is still limited by restraints, including limited battery life, network capacity, and maintenance cost [

50]. Researchers have produced several energy harvesting and edge computing methodologies for producing energy-efficient devices, protocols, routing techniques, and infrastructures for IoT applications [

51,

52,

53]. However, one of the major concerns impeding IoT adoption in the construction sector is energy and power control of intercommunicating devices.

5.2.6. Communication Infrastructure

The IoT infrastructure is an amalgamation of different devices and sensors. Every IoT system may differ due to the selection of different instruments/sensors. This leads to incompatibility between IoT devices and systems and communication and sharing service problems. Further, the integration of IoT with the conventional internet framework and network scaling is another challenge. Even if all the devices in the communication infrastructure can communicate smoothly, the next issue is available bandwidth and network latency. Real-time communication is the critical attribute of the IoT and low latency can adversely affect the IoT’s delay-sensitive and mission-critical environments. A stable, secure, and high-speed communication infrastructure is required to obtain timely and reliable data from IoT devices. For Construction 4.0, it is a very critical issue, as for any remote operation, additional equipment is needed to improve signal transmission quality across networks.

5.2.7. Expenditure

It is a common fear among industrialists that adopting IoT infrastructure means great expense because extra funds will be required to acquire technology, implement it, and then train their employees. It is assumed to be very costly for small construction companies to support heterogeneous interfaces from diverse platforms. Power bills, spectrum license charges, and daily expenditure charges of an IoT node further add to the expense of adopting IoT technology. Because of the COVID-19 pandemic, organizations are not calculating the pros and cons of the IoT technology as budgets are already tight, and adding to the IoT investment is untenable. Hence, construction companies lack the motivation to analyze the tradeoffs between potential long-term benefits, cost savings, and expenditures.

6. Areas of Construction 4.0

This section addresses the major Construction 4.0 areas that are found in the disseminated literature. It also highlights the reasons why IoT is deemed necessary in the selected areas of the construction industry with some examples from developed countries. The details of why the adoption of advanced technologies such as IoT is difficult for developing countries are also presented. The major areas which are part of Construction 4.0 are procurement, business information modeling (BIM), structural health monitoring, and construction safety. In the rest of the section, the current status of IoT implementation for each area is analyzed separately.

6.1. Procurement

As the construction industry is the backbone of the economic growth of a country, procurement is the critical success factor of a construction project. About 87% of stakeholders in the construction industry believe that purchasing raw materials is synonymous with successful project completion [

54]. Whether purchasing raw materials is a joint venture or the contractor is solely responsible, or all the parties, including contractor, consultant, and client, are involved, the project’s profitability depends on several factors, including labor, finance, weather conditions, services, logistics, and most importantly, technology.

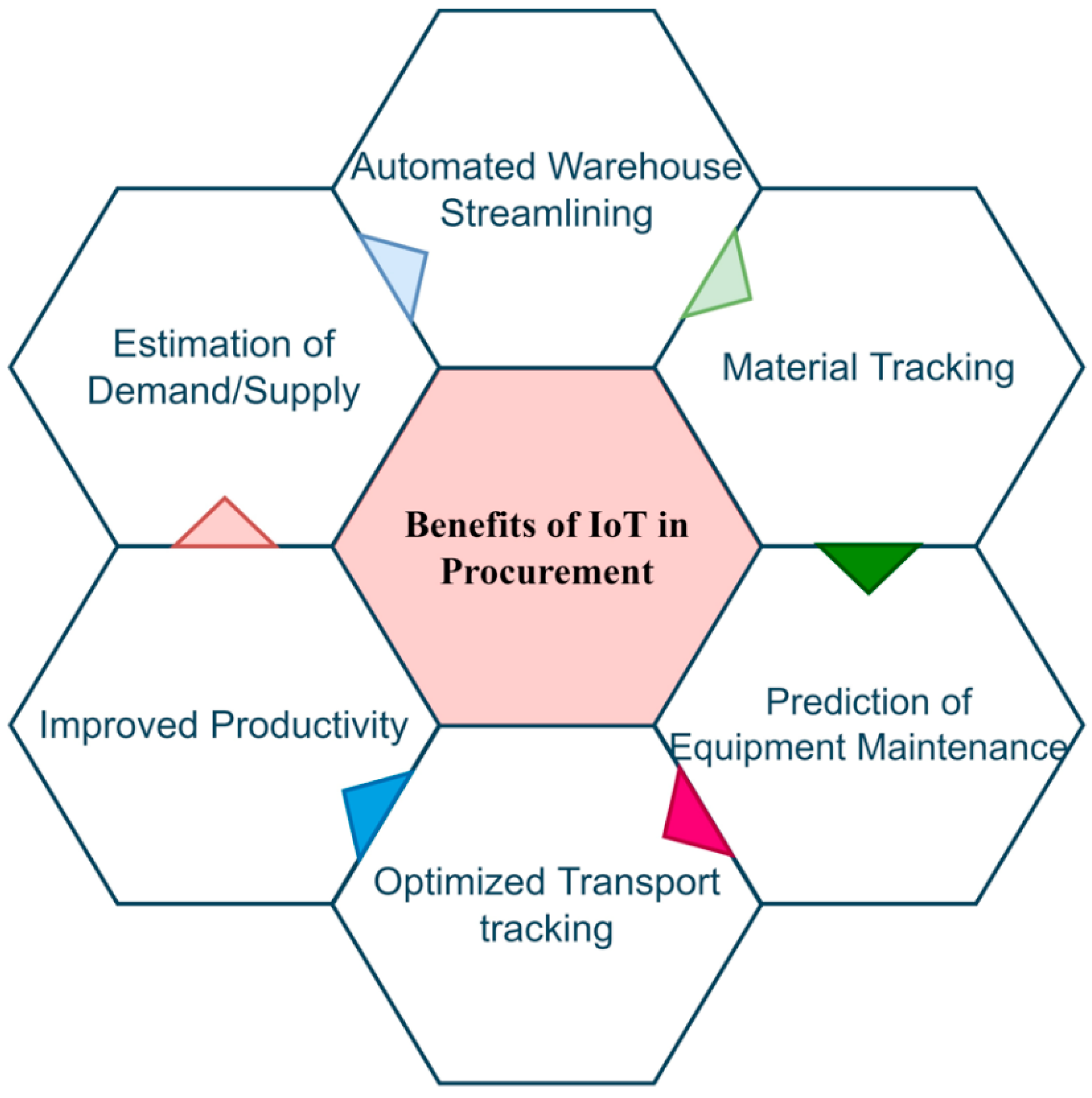

IoT can help in reducing procurement lead time and project costs. It can also help in making rapid and optimum decisions based on real-time data, current stock levels of the project, and environmental conditions. The benefits of IoT in the procurement process are shown in

Figure 6.

Just like lean construction, where reducing waste, time, effort, and pursuing perfection are the goal, the concept of lean procurement is also building up. The idea of lean methodology, which originated from the Toyota Production System (TPS), ensures that a project is completed well in time and lower costs are incurred. The IoT can ease the process of lean procurement [

55]. An example is that sensors can calculate the time a product has/hasn’t moved and generate alerts. Similarly, for the purchase and quality check of materials, sensors can achieve better management. Jinying et al. [

56] suggested that an IoT-based system, including computer-aided software, can predict the required material to be procured. 2D tagged barcode material can be sent to the construction site, and some components, including windows, doors, steel, and prefabricated beams, columns, and plates, can be equipped with sensors to know about their strength, flexural and shear behavior, stiffness, etc. [

56]. RFID at the construction site can be used to track the details of materials. All this gathered data can help companies reduce overall costs and forecast demand more precisely. Skilled data scientists can carry out market surveys using information gathered through IoT systems, i.e., they can account for weather, fuel prices, market status, etc. Overall, procurement through IoT systems can provide around 70% cost savings compared with traditional systems [

57].

According to a report from Statista [

58], the developed countries’ IoT spending in 2019 includes the United States as the leader with

$194 billion spent, followed by China and Japan with

$182 billion and

$65.4 billion expenditure, respectively. Ali et al. [

59] reported that Germany leads the Construction 4.0 field, followed by China, the United States, etc. In the developed countries of the world, most companies are using IoT for the procurement process. Skanska, a Swedish multinational construction and development company, has developed a Tag & Tack system. It uses RFIDs and barcodes on components and products in construction projects to facilitate real-time tracking of delivery, storage, and installation of products and components. Their system is achieving a cost reduction of up to 10%. The procurement software application market is expected to bring in an estimated

$5.94 billion in revenue in 2021 [

58]. By decreasing the amount of time needed to complete the ordering, invoicing, paying, and purchasing approval processes, procurement software helps to boost production and efficiency.

In the case of developing countries, not many studies or statistics are available to evaluate the current status of procurement using IoT. However, research work to accept IoT for the procurement process is still in progress. According to Yousaf et al. [

60], IoT can be used as an accelerator in inventory replenishment throughout the procurement process of the China-Pakistan Economic Corridor (CPEC), an energy and infrastructural project established under China’s Belt and Road Initiative (BRI). It can reduce inventory costs by transporting raw materials to the right location at the right time. This can be carried out with the help of RFID tags, which collect inventory data and compare it to the existing records to guarantee optimal use of inventory. Ayodeji Emmanuel Oke et al. [

61] stated that cost and power supply are the prominent issues faced by the Nigerian construction industry in adopting IoT. According to the authors, if the Nigerian government can provide a stable power supply and help in subsidizing the equipment, the construction industry in Nigeria can get benefit from IoT.

It is very clear from the literature that the application of IoT in the procurement process for developing countries is still at an early stage. Most developing countries lack the courage to adopt radical transformations. If developing countries adopt the IoT-based procurement process, the next step would be to educate procurement teams to analyze the data and gather meaningful actionable insights for better decision-making, ultimately leading to overall project profitability.

6.2. Business Information Modelling (BIM)

Recent research revealed that most businesses that adopted IoT had a positive influence on their ability to function during the pandemic [

62]. However, to date, the complete life cycle of construction projects is not entirely IoT based. Rather, IoT in the construction market is fragmented into different segments, including site monitoring, machine control, wearables, fleet management, etc. BIM is one of the most essential fragments of Construction 4.0.

BIM software enables construction professionals to plan, design, and create a digital model of a project based on real-time construction data [

63]. Data gathered from IoT infrastructure, which consists of engineering, electrical, and mechanical information combined with BIM, facilitate the coordination between contractors, sub-contractors, and all the stakeholders, helping to reduce errors and revisions. BIM can help the users as well. For example, the owner of a house may find the location, size, and number of a leaking pipe’s valve through IoT rather than doing a physical examination. According to a research case study, BIM can manage time 50% faster and save expenditure by 52.36% [

64].

Developed countries, including the US and UK, have radically adopted BIM for construction projects. According to the NBS’ 10th National BIM Report [

65], 73% of companies were well acquainted with BIM technology in 2020 for their projects. The report states that only 1% of UK companies were not aware of BIM in 2020. Furthermore, 80% of large businesses and 62% of small businesses in the UK implement BIM. As per a report from PlanRadar, a SaaS (Software as a Service) solution, approximately 70% of German and 50–60% of French construction companies use BIM at different levels [

66]. Countries such as Singapore, China, South Korea, and Japan are also implementing BIM in their projects [

66]. However, their implementation level is slower as compared with European countries. Zhou et al. [

67] described several barriers to BIM implementation in China, including limited specifications and regulations; legal issues; government directions; resistance to change of thinking mode; high cost; etc. The challenges faced by developed countries due to contractual issues and the existing legal paradigm can now be sorted out with the help of the ISO 19650 standard [

68]. The standard comprises six parts: Concepts and Principles; Assets Delivery Phase; Operational Phase of the Assets; Information Exchange; Security-Minded Approach to Information Management; and Health and Safety. All these parts assist in the deployment of BIM in the construction sector.

Despite several advantages, BIM is sluggishly adopted in the construction industry of many developing countries [

69]. While BIM is arguably highly applied in the design phase of a construction project, it lacks integration with on-site implementation. Many recent articles also confirm the slow adoption of BIM [

70,

71]. BIM research is also being conducted for developing countries to determine the time, investment, and cost tradeoffs [

72]. For example, a study was conducted in Malaysia to assess the impact of BIM on the time and cost of construction projects [

73]. The authors suggested a few strategies to use while adopting BIM. The strategies include but are not limited to enhancing public awareness using conferences, seminars, and workshops; providing clear information on the cost and benefits of sustainable materials; etc. Another developing country, Indonesia, also faces the same situation in managing the time and cost of any respective construction project [

74]. Hence, managing and or reduction in time and cost with BIM needs to be analyzed. In Pakistan, BIM implementation is as low as 11%, with the top barrier being the lack of government regulation about BIM [

75].

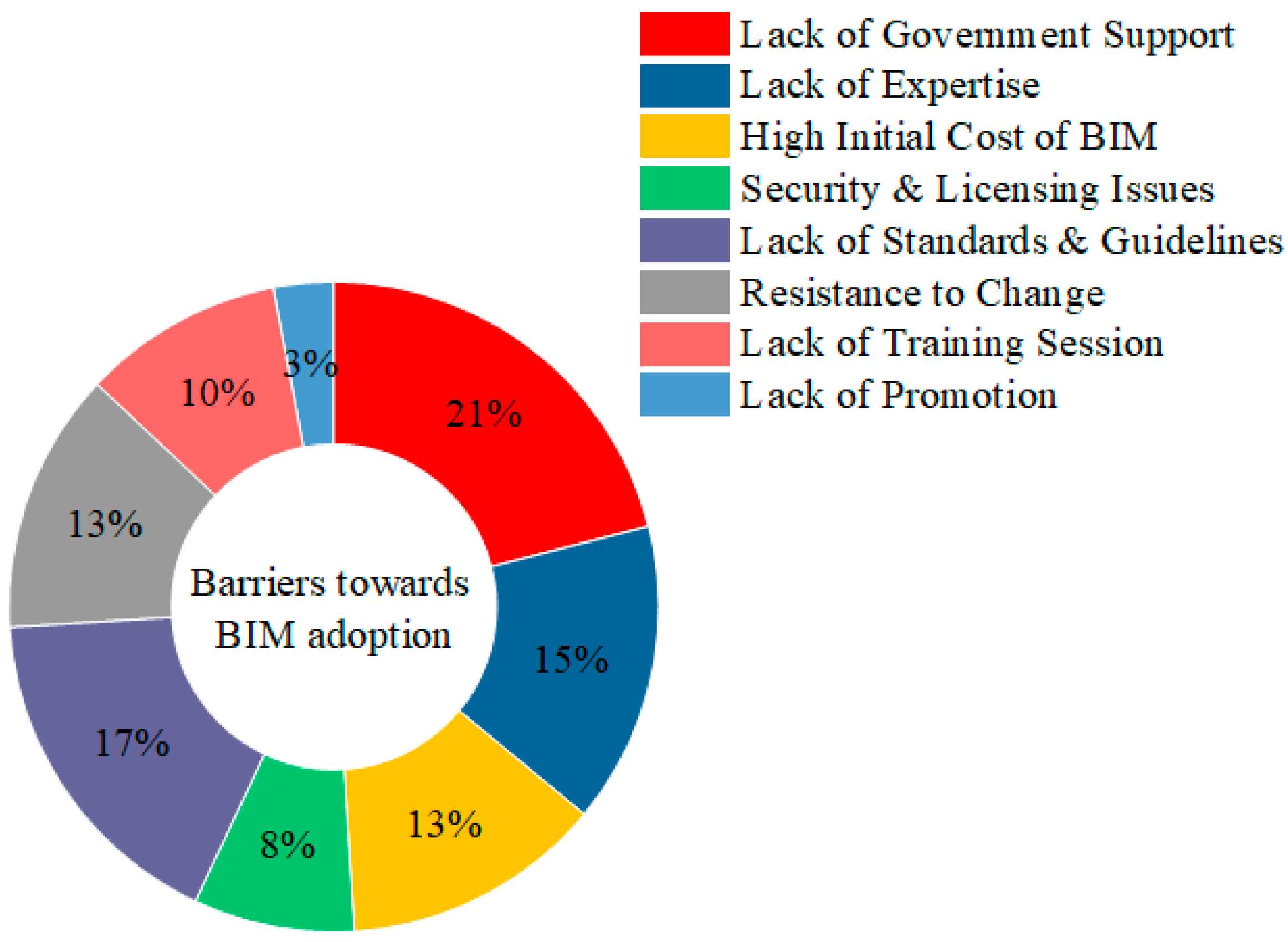

Figure 7 depicts the topmost impediments to BIM adoption identified from the disseminated literature review. A combination of IoT and BIM can unlock several potentials. However, more research work and experimentation are needed to make users and professionals well aware of the potential benefits of BIM-centered IoT deployments.

6.3. Structural Health Monitoring (SHM)

SHM using IoT involves monitoring or assessing the condition of a structure using sensors over the internet [

76]. To gather information on the current state of infrastructure assets, sensors track different variables, e.g., stress, vibration, strain, and other physical conditions. This helps monitor changes to the geometrical and material properties of the structure. SHM also screens the unavoidable aging and degradation of a structure resulting from harsh operational environments to estimate the useful life span of the infrastructure [

77]. Construction companies not using IoT applications for SHM collect data in a manual exercise where engineers visit the field to take critical measurements. The process of labor-intensive data collection is unreliable, time-consuming, and inefficient. With the aging of a structure, safety concerns also escalate. IoT sensors assess and detect deterioration inside structures, thus ensuring greater safety. SHM combined with IoT offers a cost-effective alternative for implementing a mandated 24/7 monitoring system for safety and security.

Although different innovative techniques and mathematical models have been proposed in the literature for strengthening the structures, specifically masonry walls and using laminated glass, etc. [

78,

79], the structures will inevitably deteriorate. The most prominent damages that can occur in structures are mechanical and chemical damages. Mechanical damage is caused by earthquakes, unpredictable and unfortunate events, or everyday use of structure. Chemical damage is due to oxidation, corrosion, efflorescence, and damage caused by living organisms, e.g., plants, insect pests, fungi, etc. [

80]. Both mechanical and physicochemical damage can be located anytime and anywhere using SHM integrated with IoT. The most common sensors/devices used for SHM are ultrasonic sensors, accelerometers, amplifiers, actuators, vibration sensors, lasers, cameras, piezoelectric sensors, etc. For communication between devices, many authors suggest using 6LoWPAN based on IPv6 [

81,

82].

Most developed countries have already adopted SHM systems. According to a report on ResearchAndMarkets [

83], the SHM market is expected to grow from

$1.748 million in 2019 to

$2.878 million by 2025 at a compound annual growth rate (CAGR) of 14.1% from 2020 to 2025. The report states that North America is the leading region in SHM market share worldwide. This growth rate can be attributed to the low cost of sensors, rising government regularizations, and rapid worldwide infrastructural development. A Federal Highway Administration (FHWA) report reported that more than 30% of the bridges in the US are over 50 years old and need proper SHM to ensure public safety and improve the structural life span [

84]. As far as China is concerned, it started applying SHM in the early 2000s. It has also produced several standards for SHM since then; for example, the China Project Construction Association produced CECS 333:2012 [

85]. The standard deals with five aspects of SHM: sensor selection and placement; data acquisition, filtering, and preprocessing; data transmission; damage detection and safety evaluation; and database management. Professor Zhu Mao of the University of Massachusetts Lowell mentioned that 31 bridges in China are equipped with an average of approximately 250 sensors per bridge [

86]. The sensors include temperature sensors, accelerometers, strain and corrosion sensors, etc. In previous decade, Chinese researchers have produced outstanding research covering several aspects of SHM, including advanced smart sensors, advanced data communication infrastructures, methods of damage detection and safety evaluation, etc. [

87,

88,

89]. Dubai is considered one of the most well-developed cities in the world and a very sophisticated city in the United Arab Emirates [

90]. It has introduced the concept of SHM in the construction industry for a long time [

91]. In Dubai, Burj Khalifa is the tallest free-standing structure in the world, with a height of 828 m and more than 160 stories [

92]. A temporary SHM system was first applied to Burj Khalifa in 2009, and later on, a permanent SHM system was installed [

93]. The permanent SHM system includes accelerometers, global positioning systems, seismometers, weather stations, etc. Countries such as Australia, Canada, and Denmark are also applying SHM to monitor their structures. COWI, Pure Technologies, and Structural Monitoring Systems, companies from Denmark, Canada, and Australia, respectively, are major players in the SHM market.

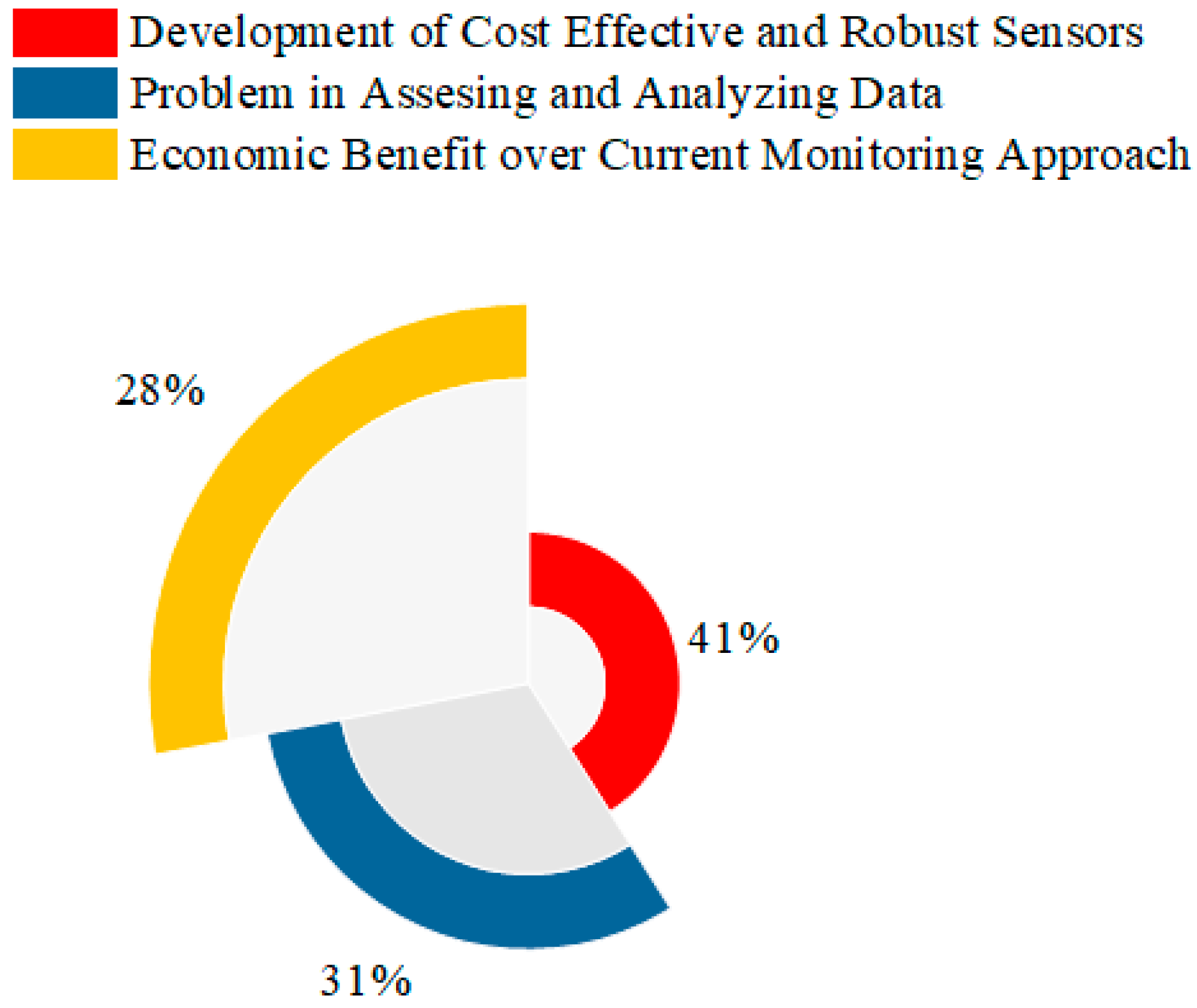

In developing countries such as India, Nepal, and Pakistan, SHM is a requirement of time. These countries experience causalities every year because of the earthquakes originating from the Himalayan region. Nepal was affected by a catastrophic earthquake in 2015, which killed nearly 9000 people and injured about 22,000 [

94]. If the infrastructure in Nepal had been evaluated structurally as per the SHM standards, the earthquake would not have been so devastating. The main reasons for the limited implementation of SHM in developing countries are complications associated with the installation of SHM; high installation costs; continuous monitoring costs; fear of inaccurate results due to errors in readings; challenges in data analysis; lack of technical proficiency; and slow growth in terms of infrastructure and smart homes. Adapted from different research [

95,

96], the three main barriers to SHM adoption are shown in

Figure 8. SHM technology plays a pivotal role in life safety benefits. However, a fast transition from research to practical work is needed to grow the embryonic stages of SHM.

6.4. Construction Safety

The construction sites are the riskiest environments [

97], with dynamic activities happening around the clock. Workers who engage in construction activities get exposed to several safety hazards such as falls, trench collapse, scaffold collapse, use of electrical devices and heavy machines in damp locations, etc. According to the International Labor Organization, approximately six thousand fatalities are reported in the construction industry worldwide every year, with about 30% of deaths due to falls from heights [

98]. In 2018, the US faced 28% of work fatalities in the construction sector, the highest fraction among other industries [

99]. Similarly, in 2019, the rate of deaths in the construction industry in the UK was 1.31 per 100,000 workers, three-fold higher than the industry average [

100]. From 1997 to 2014, China faced a death toll that averaged above 2500 annually because of construction accidents [

101].

The Oregon Occupational Safety and Health Division has used the term “safety and health program” to describe workplace practices to analyze and mitigate illnesses and injuries [

102]. Traditional methods for identifying safety issues and accidents at construction sites are manual, relying on manual data collection and reporting [

103]. As the issues are recognized and reported late, follow-up measures are also taken late, endangering the lives of construction workers.

The use of IoT in the construction industry allows for real-time safety and physical condition monitoring of laborers, thus providing real-time solutions to hazards [

104]. Devices such as smart glasses, protective vests, wearable cameras, smart helmets, etc. are already available in the market for robust safety monitoring [

105]. Work related to monitoring workers’ ergonomics and postures, heart rate, temperature, and other hazards using accelerometers, gyroscopes, ECG/EKG, infrared, and RFID sensors has already been carried out [

106,

107,

108]. Several research studies have also proposed or developed cutting-edge approaches and technologies for construction worker safety surveillance. However, complex construction with vulnerable environments has restricted construction safety applications [

109].

Chung et al. [

57] reported that IoT systems for construction site safety can provide 78% cost-savings compared with manual systems and 65% cost-savings compared with sensor systems. According to a report, Global Construction 2030, published by Oxford Economics and Global Construction Perspectives, the global construction output is expected to reach 15.5 trillion USD worldwide by 2030, with the US, China, and India contributing to 57% of the growth [

110]. However, construction safety is still of the highest concern, despite the growth rate. Developed countries have already adopted IoT-based construction safety practices. SolePower is a US-based IoT company that manufactures work boots with IoT sensors embedded in the boots to monitor workers’ fatigue. Another US-based company, StrongArm Technologies, produces a device called the “Fuse Platform,” which uses IoT sensors to monitor the musculoskeletal injuries of employees [

111]. Hong Kong has also improved construction safety practices [

112]. The Hong Kong government is focusing its efforts on legislative amendments, including site safety-related legal actions that can be applied to construction safety management [

113]. Plinx, a UK-based business, also develops a construction safety system that monitors workers’ proximity to dangers. The system raises worker awareness of hazards by equipping construction sites with sensor-based tags that reliably detect workers’ location and deliver audiovisual feedback in the hazard proximity. The business has developed three tags: team tag, hazard tag, and machine tag for determining distances between workers; reducing the risk of the machine to pedestrian collision; generating alerts when an operative enters a forbidden zone. According to GlobalData, the wearable technology sector is predicted to increase from

$23 billion in 2018 to

$54 billion by 2023.

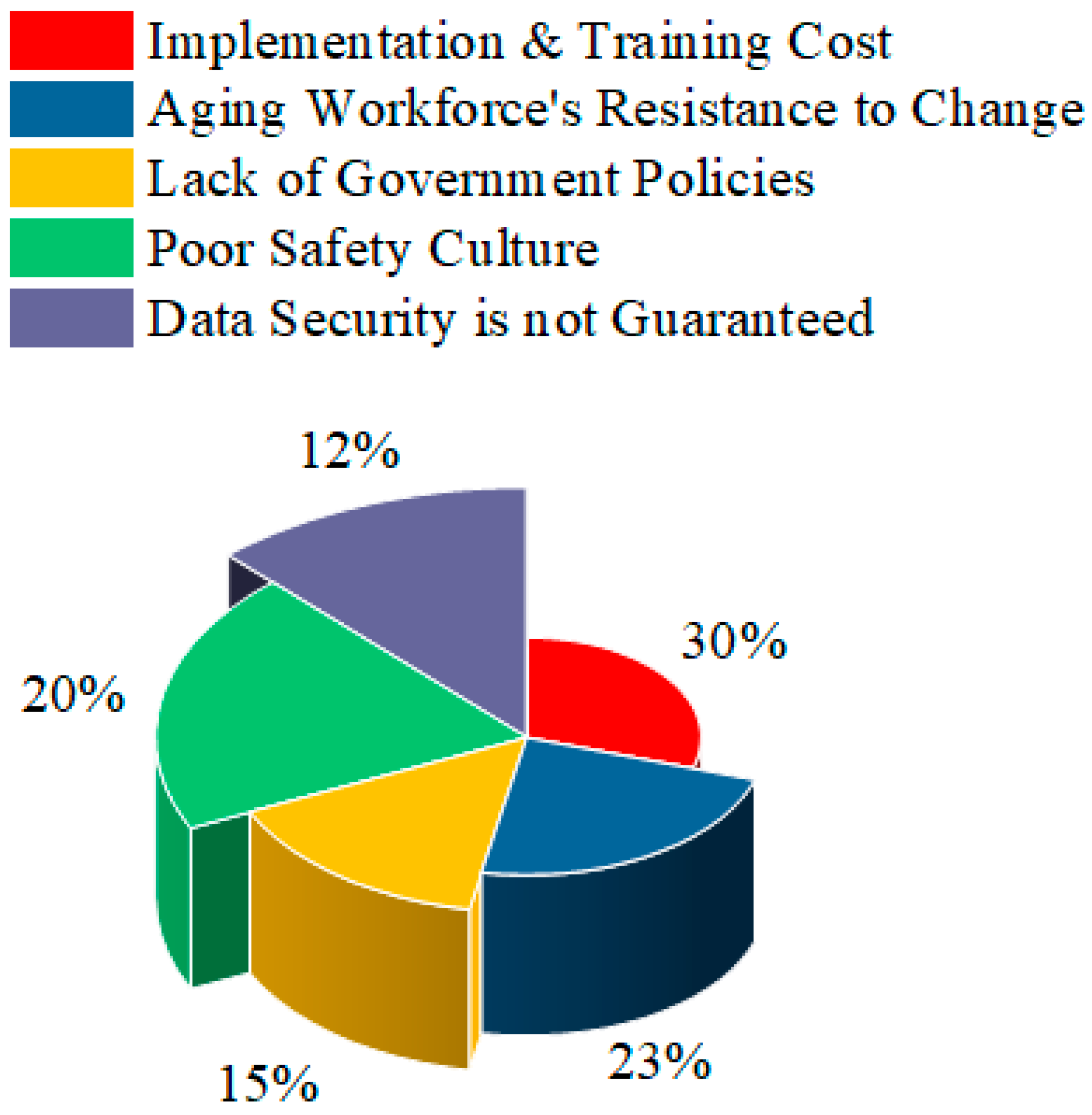

In developing countries, the implementation of IoT for construction safety is still in its early stages. Iraq is one of the developing countries where safety assurances in the construction industry are not followed [

114]. Although the construction industry of Iraq is rapidly growing with government support, the rate of accidents in the construction industry of Iraq is still high. In 2018, there were 38% more industrial accidents in Iraq [

115]. Apart from the significance of safety in the construction industry, there has been no or negligible focus on safety in the Iraqi construction industry for a long time. Recent studies related to the Malaysian construction industry also reveal that occupational health and safety practices are not properly implemented and appropriate actions are required to prevent the situation from worsening [

116]. The Malaysian construction industry is the third most dangerous industry, resulting in the highest number of fatalities. [

117]. In other developing countries such as Cambodia and Vietnam, common safety and health management practices are either missing or not implemented properly in the construction industry [

118]. To prevent poor Cambodian workers from risking their lives for less than 10 USD a day, government authorities and construction professionals must develop robust safety programs to facilitate safety performance improvements [

119]. According to the studied literature [

118,

119,

120], the main hindrances to implementing construction safety are shown in

Figure 9.

7. Discussion and Prospects

The application of IoT in the context of Construction 4.0 will result in the industry’s revolution. However, research in this area, particularly for developing countries, is in its embryonic stage. Based on a mix of qualitative and quantitative analysis, this work has identified the most critical challenges being faced in the deployment of IoT products in the construction industry. Some of the highlights are as follows:

The construction industry is not the most advanced in IoT use. Investors and project managers are still hesitant to deploy the technology, as they are not well aware of its usage and are skeptical of its effectiveness [

121]. To encourage stakeholders, an independent research and development phase where a Proof-of-Concept/Prototype (offering value to the business) can be established before the actual project begins is required.

The profitability and efficiency of the construction industry directly impact global economic growth. Even though the sector is continually evolving, and new management approaches are being implemented, there are numerous issues that managers and contractor teams deal with. The complexities of IoT implementation in the construction industry analyzed in the present research will help the implementers create a more strategic view for smooth and reliable construction processes.

There is a very narrow research agenda that emphasizes the use of IoT in construction safety, structural health monitoring, business information modeling, and procurement. A substantial lack of clarity exists due to a lack of documentation, data sets, and surveys highlighting the benefits of IoT applications in the above-mentioned processes [

122]. Lack of evaluation, quantification, and analysis of available data also poses a significant problem for IoT adoption. Clear standards, guidelines, policies, and benchmarks for the use and practices of IoT devices would help to clear the haze in the construction sector.

Research conducted for IoT usage in the construction industry of developing countries is undertaken by only a few researchers [

15]. This implies that research for IoT applications in the construction industry of developing countries is even more limited. One reason might be that the introduction of new technology demands, first and foremost, a research study that evaluates, tests, validates, and improves the technology’s performance in given scenarios. Furthermore, measurements are needed to determine how this technological breakthrough may aid in the evolution of developing countries’ current construction techniques.

Despite the study’s significant contributions, the findings must be viewed considering the limitations. The study is primarily concerned with “what” questions found in the literature rather than “how.”

8. Conclusions

This work presented a comprehensive and up-to-date review of IoT adoption in the context of Construction 4.0. The review of the literature revealed that only a small number of the Construction 4.0 articles dealt with the IoT adoption challenges. Moreover, a comprehensive analysis of the implementation status and challenges with IoT adoption for Construction 4.0 drivers was not found in the literature. As a result, this study focused on the status of IoT implementation in the areas of Construction 4.0 such as procurement, business information modeling, structural health monitoring, and construction safety for developed and emerging economies, as well as the challenges unique to each area. The present study takes the first step by outlining the most significant challenges that construction managers must be aware of to avoid mistakes throughout the implementation of IoT with regard to the major drivers in the construction industry. While various issues in the construction sector related to IoT adoption have been identified in this work, future research studies are needed to determine the roots of those issues and identify potential solutions.

Author Contributions

Conceptualization, K.K., A.D., M.U.S. and M.B.; methodology, K.K., A.D., M.U.S. and M.B.; validation, K.K., A.D., M.U.S., M.B., T.O. and M.A.M.; formal analysis, K.K. and A.D.; investigation, K.K., A.D., M.U.S., M.B., T.O. and M.A.M.; data curation, K.K., A.D., M.U.S. and M.B.; writing—original draft preparation, K.K., A.D., M.U.S., M.B., T.O. and M.A.M.; writing—review and editing, K.K., A.D., M.U.S., M.B., T.O. and M.A.M.; visualization, K.K., A.D., M.U.S., M.B., T.O. and M.A.M.; supervision, T.O.; project administration, T.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, X.; Ning, Z.; Hu, X.; Wang, L.; Guo, L.; Hu, B.; Wu, X. Future communications and energy management in the Internet of vehicles: Toward intelligent energy-harvesting. IEEE Wirel. Commun. 2019, 26, 87–93. [Google Scholar] [CrossRef]

- Rafsanjani, H.N.; Ghahramani, A. Towards utilizing internet of things (IoT) devices for understanding individual occupants′ energy usage of personal and shared appliances in office buildings. J. Build. Eng. 2020, 27, 100948. [Google Scholar] [CrossRef]

- Al-Garadi, M.A.; Mohamed, A.; Al-Ali, A.K.; Du, X.; Ali, I.; Guizani, M. A survey of machine and deep learning methods for internet of things (IoT) security. IEEE Commun. Surv. Tutor. 2020, 22, 1646–1685. [Google Scholar] [CrossRef]

- Kim, K.S.; Kim, D.K.; Chae, C.-B.; Choi, S.; Ko, Y.-C.; Kim, J.; Lim, Y.-G.; Yang, M.; Kim, S.; Lim, B. Ultrareliable and low-latency communication techniques for tactile internet services. Proc. IEEE 2018, 107, 376–393. [Google Scholar] [CrossRef]

- Liang, R.; Guo, Y.; Zhao, L.; Gao, Y. Real-time monitoring implementation of PV/T façade system based on IoT. J. Build. Eng. 2021, 41, 102451. [Google Scholar] [CrossRef]

- Mohammadi, M.; Al-Fuqaha, A.; Sorour, S.; Guizani, M. Deep learning for IoT big data and streaming analytics: A survey. IEEE Commun. Surv. Tutor. 2018, 20, 2923–2960. [Google Scholar] [CrossRef]

- Khurshid, K.; Khan, A.; Siddique, H.; Rashid, I. Big data-9vs, challenges and solutions. Tech. J. 2018, 23, 28–34. [Google Scholar]

- Malik, P.K.; Sharma, R.; Singh, R.; Gehlot, A.; Satapathy, S.C.; Alnumay, W.S.; Pelusi, D.; Ghosh, U.; Nayak, J. Industrial Internet of Things and its applications in industry 4.0: State of the art. Comput. Commun. 2021, 166, 125–139. [Google Scholar] [CrossRef]

- Danish, A.; Mosaberpanah, M.A. Influence of cenospheres and fly ash on the mechanical and durability properties of high-performance cement mortar under different curing regimes. Constr. Build. Mater. 2021, 279, 122458. [Google Scholar] [CrossRef]

- Qi, B.; Razkenari, M.; Costin, A.; Kibert, C.; Fu, M. A systematic review of emerging technologies in industrialized construction. J. Build. Eng. 2021, 39, 102265. [Google Scholar] [CrossRef]

- Fakunle, F.F.; Fashina, A.A. Major delays in construction projects: A global overview. PM World J. 2020, 9, 1–15. [Google Scholar]

- Ayalew, T.; Dakhli, Z.; Lafhaj, Z. Characterization of waste in Ethiopian building construction projects. In Proceedings of the IGLC 2018-Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction towards Mature Production Management across Cultures and Frontiers, Chennai, India, 16–22 July 2018; pp. 797–806. [Google Scholar]

- Alsharef, A.; Banerjee, S.; Uddin, S.; Albert, A.; Jaselskis, E. Early impacts of the COVID-19 pandemic on the United States construction industry. Int. J. Environ. Res. Public Health 2021, 18, 1559. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.; Karimi, R.; Shirowzhan, S.; Mojtahedi, M.; Ebrahimzadeh, S.; McCarthy, D. Delay causes and emerging digital tools: A novel model of delay analysis, including integrated project delivery and PMBOK. Buildings 2019, 9, 191. [Google Scholar] [CrossRef]

- Ghosh, A.; Edwards, D.J.; Hosseini, M.R. Patterns and trends in Internet of Things (IoT) research: Future applications in the construction industry. Eng. Constr. Archit. Manag. 2021, 28, 457–481. [Google Scholar] [CrossRef]

- Irizarry, J. Construction 4.0: An Innovation Platform for the Built Environment; Routledge: London, UK, 2020. [Google Scholar]

- Gershenfeld, N. When things start to think; Macmillan: New York, NY, USA, 1999. [Google Scholar]

- Jiang, B.; Li, J.; Yue, G.; Song, H. Differential Privacy for Industrial Internet of Things: Opportunities, Applications, and Challenges. IEEE Internet Things J. 2021, 8, 10430–10451. [Google Scholar] [CrossRef]

- Manyika, J.; Chui, M. By 2025, Internet of Things Applications Could Have $11 Trillion Impact; Insight Publications: Cheltenham, Australia, 2015. [Google Scholar]

- Gwangwava, N.; Mubvirwi, T.B. Design and simulation of IoT systems using the Cisco packet tracer. Adv. Internet Things 2021, 11, 59. [Google Scholar] [CrossRef]

- Tewari, N.; Datt, G. A Systematic Review of Security Issues and challenges with Futuristic Wearable Internet of Things (IoTs). In Proceedings of the 2021 International Conference on Technological Advancements and Innovations (ICTAI), Tashkent, Uzbekistan, 10–12 November 2021; pp. 319–323. [Google Scholar]

- Shafique, K.; Khawaja, B.A.; Sabir, F.; Qazi, S.; Mustaqim, M. Internet of things (IoT) for next-generation smart systems: A review of current challenges, future trends and prospects for emerging 5G-IoT scenarios. IEEE Access 2020, 8, 23022–23040. [Google Scholar] [CrossRef]

- Ahmed, N.; De, D.; Barbhuiya, F.A.; Hussain, M.I. MAC Protocols for IEEE 802.11 ah-Based Internet of Things: A Survey. IEEE Internet Things J. 2021, 9, 916–938. [Google Scholar] [CrossRef]

- Reka, S.S.; Dragicevic, T. Future effectual role of energy delivery: A comprehensive review of Internet of Things and smart grid. Renew. Sustain. Energy Rev. 2018, 91, 90–108. [Google Scholar] [CrossRef]

- Hong, A.; Nam, C.; Kim, S. What will be the possible barriers to consumers’ adoption of smart home services? Telecommun. Policy 2020, 44, 101867. [Google Scholar] [CrossRef]

- Turner, C.J.; Oyekan, J.; Stergioulas, L.; Griffin, D. Utilizing industry 4.0 on the construction site: Challenges and opportunities. IEEE Trans. Ind. Inform. 2020, 17, 746–756. [Google Scholar] [CrossRef]

- Oke, A.E.; Arowoiya, V.A. Evaluation of internet of things (IoT) application areas for sustainable construction. Smart Sustain. Built Environ. 2021, 10, 387–402. [Google Scholar] [CrossRef]

- Chen, J.-H.; Ha, N.T.T.; Tai, H.-W.; Chang, C.-A. The willingness to adopt the Internet of Things (IoT) conception in Taiwan’s construction industry. J. Civ. Eng. Manag. 2020, 26, 534–550. [Google Scholar] [CrossRef]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A literature review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- Gamil, Y.; Abdullah, M.A.; Abd Rahman, I.; Asad, M.M. Internet of things in construction industry revolution 4.0: Recent trends and challenges in the Malaysian context. J. Eng. Des. Technol. 2020, 18, 1091–1102. [Google Scholar] [CrossRef]

- Baghalzadeh Shishehgarkhaneh, M.; Keivani, A.; Moehler, R.C.; Jelodari, N.; Roshdi Laleh, S. Internet of Things (IoT), Building Information Modeling (BIM), and Digital Twin (DT) in Construction Industry: A Review, Bibliometric, and Network Analysis. Buildings 2022, 12, 1503. [Google Scholar] [CrossRef]

- Begić, H.; Galić, M. A Systematic Review of Construction 4.0 in the Context of the BIM 4.0 Premise. Buildings 2021, 11, 337. [Google Scholar] [CrossRef]

- Kim, M.C.; Zhu, Y. Scientometrics of scientometrics: Mapping historical footprint and emerging technologies in scientometrics. In Scientometrics; IntechOpen: London, UK, 2018; pp. 9–27. [Google Scholar]

- Su, T.; Li, H.; An, Y. A BIM and machine learning integration framework for automated property valuation. J. Build. Eng. 2021, 44, 102636. [Google Scholar] [CrossRef]

- Schwab, K.; Davis, N. Shaping the Future of the Fourth Industrial Revolution; Currency: Sydney, Australia, 2018. [Google Scholar]

- Anik, S.M.H.; Gao, X.; Meng, N.; Agee, P.R.; McCoy, A.P. A cost-effective, scalable, and portable IoT data infrastructure for indoor environment sensing. J. Build. Eng. 2022, 49, 104027. [Google Scholar] [CrossRef]

- Lo, K.-C.; Kwok, H.-W.T.; Siu, M.-F.F.; Shen, Q.G.; Lau, C.-K. Internet of things-based concrete curing invention for construction quality control. Adv. Civ. Eng. 2021, 2021, 9933615. [Google Scholar] [CrossRef]

- Glaeser, E.L.; Kominers, S.D.; Luca, M.; Naik, N. Big data and big cities: The promises and limitations of improved measures of urban life. Econ. Inq. 2018, 56, 114–137. [Google Scholar] [CrossRef]

- Ramasundara, Y.; Johnson, A.; Baumeister, D. Australia’s IoT Opportunity: Driving Future Growth an ACS Report, ACS. 2018. Available online: https://www.acs.org.au/insightsandpublications/reports-publications/iot-opportunity.html (accessed on 23 April 2020).

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Li, J.; Greenwood, D.; Kassem, M. Blockchain in the built environment and construction industry: A systematic review, conceptual models and practical use cases. Autom. Constr. 2019, 102, 288–307. [Google Scholar] [CrossRef]

- Qi, B.; Razkenari, M.; Li, J.; Costin, A.; Kibert, C.; Qian, S. Investigating US industry practitioners’ perspectives towards the adoption of emerging technologies in industrialized construction. Buildings 2020, 10, 85. [Google Scholar] [CrossRef]

- Akinyooye, L.; Nezamis, E. As the COVID-19 pandemic affects the nation, hires and turnover reach record highs in 2020. Mon. Lab. Rev. 2021, 144, 1. [Google Scholar]

- Conti, M.; Dehghantanha, A.; Franke, K.; Watson, S. Internet of Things security and forensics: Challenges and opportunities. Future Gener. Comput. Syst. 2018, 78, 544–546. [Google Scholar] [CrossRef]

- Kane, L.E.; Chen, J.J.; Thomas, R.; Liu, V.; McKague, M. Security and performance in IoT: A balancing act. IEEE Access 2020, 8, 121969–121986. [Google Scholar] [CrossRef]

- Hassija, V.; Chamola, V.; Saxena, V.; Jain, D.; Goyal, P.; Sikdar, B. A survey on IoT security: Application areas, security threats, and solution architectures. IEEE Access 2019, 7, 82721–82743. [Google Scholar] [CrossRef]

- Assenza, G.; Faramondi, L.; Oliva, G.; Setola, R. Cyber threats for operational technologies. Int. J. Syst. Syst. Eng. 2020, 10, 128–142. [Google Scholar] [CrossRef]

- Abomhara, M.; Køien, G.M. Cyber security and the internet of things: Vulnerabilities, threats, intruders and attacks. J. Cyber Secur. Mobil. 2015, 4, 65–88. [Google Scholar] [CrossRef]

- Dawaliby, S.; Bradai, A.; Pousset, Y. Distributed network slicing in large scale IoT based on coalitional multi-game theory. IEEE Trans. Netw. Serv. Manag. 2019, 16, 1567–1580. [Google Scholar] [CrossRef]

- Liu, X.; Ansari, N. Toward green IoT: Energy solutions and key challenges. IEEE Commun. Mag. 2019, 57, 104–110. [Google Scholar] [CrossRef]

- Min, M.; Xiao, L.; Chen, Y.; Cheng, P.; Wu, D.; Zhuang, W. Learning-based computation offloading for IoT devices with energy harvesting. IEEE Trans. Veh. Technol. 2019, 68, 1930–1941. [Google Scholar] [CrossRef]

- Faizan Ullah, M.; Imtiaz, J.; Maqbool, K.Q. Enhanced three layer hybrid clustering mechanism for energy efficient routing in IoT. Sensors 2019, 19, 829. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhang, N.; Zhang, Y.; Chen, X.; Wu, W.; Shen, X. Energy efficient dynamic offloading in mobile edge computing for internet of things. IEEE Trans. Cloud Comput. 2019, 9, 1050–1060. [Google Scholar] [CrossRef]

- Khan, M.W.A.; Ting, N.H.; Kuang, L.C.; Darun, M.R.; Mehfooz, U.; Khamidi, M.F. Green procurement in construction industry: A theoretical perspective of enablers and barriers. MATEC Web Conf. 2018, 203, 02012. [Google Scholar] [CrossRef]

- Yücenur, G.N.; Şenol, K. Sequential SWARA and fuzzy VIKOR methods in elimination of waste and creation of lean construction processes. J. Build. Eng. 2021, 44, 103196. [Google Scholar] [CrossRef]

- Xu, J.; Lu, W. Smart construction from head to toe: A closed-loop lifecycle management system based on IoT. In Proceedings of the Construction Research Congress, New Orleans, LA, USA, 2–4 April 2018; pp. 157–168. [Google Scholar]

- Chung, W.W.S.; Tariq, S.; Mohandes, S.R.; Zayed, T. IoT-based application for construction site safety monitoring. Int. J. Constr. Manag. 2020, 1–17. [Google Scholar] [CrossRef]

- Vailshery, L.S. Internet of Things (IoT)—Statistics & Facts. Available online: https://www.statista.com/topics/2637/internet-of-things/ (accessed on 2 November 2022).

- Ali, Y.; Saad, T.B.; ur Rehman, O. Integration of IoT technologies in construction supply chain networks; CPEC a case in point. Sustain. Oper. Comput. 2020, 1, 28–34. [Google Scholar] [CrossRef]

- Yousaf, Z.; Ahmad, M.; Fiaz, M. Framing of China Pak Economic Corridor (CPEC) in the Leading Press of Pakistan and China. Pak. J. Soc. Issues 2018, 3, 163–172. [Google Scholar]

- Oke, A.E.; Arowoiya, V.A.; Akomolafe, O.T. An empirical study on challenges to the adoption of the Internet of Things in the Nigerian construction industry. Afr. J. Sci. Technol. Innov. Dev. 2022, 14, 179–186. [Google Scholar] [CrossRef]

- Ashima, R.; Haleem, A.; Bahl, S.; Javaid, M.; Mahla, S.K.; Singh, S. Automation and manufacturing of smart materials in Additive Manufacturing technologies using Internet of Things towards the adoption of Industry 4.0. Mater. Today: Proc. 2021, 45, 5081–5088. [Google Scholar] [CrossRef]

- Atta, I.; Bakhoum, E.S.; Marzouk, M.M. Digitizing material passport for sustainable construction projects using BIM. J. Build. Eng. 2021, 43, 103233. [Google Scholar] [CrossRef]

- Sholeh, M.N.; Fauziyah, S.; Khasani, R.R. Effect of Building Information Modeling (BIM) on reduced construction time-costs: A case study. E3S Web Conf. 2020, 202, 02012. [Google Scholar] [CrossRef]

- National Building Specification. 10th National BIM Report. 2022. Available online: https://architecturaltechnology.com/static/3f388415-32f9-408d-85cc2c1adf13d012/TheNBSBIMReport2020.pdf (accessed on 28 October 2022).

- Al Hammoud, E. Comparing Bim Adoption Around the World, Syria’s Current Status and Furture. Int. J. BIM Eng. Sci. (IJBES) 2021, 4, 64–78. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, Y.; Yang, J.-B. Barriers to BIM implementation strategies in China. Eng. Constr. Archit. Manag. 2019, 26, 554–574. [Google Scholar] [CrossRef]

- ISO.; BSEN. Organization and Digitization of Information about Buildings and Civil Engineering Works, Including Building Information Modelling (BIM)—Information Management Using Building Information Modelling—Part 1: Concepts and Principles; BSI: London, UK, 2018. [Google Scholar]

- Vidalakis, C.; Abanda, F.H.; Oti, A.H. BIM adoption and implementation: Focusing on SMEs. Constr. Innov. 2020, 20, 128–147. [Google Scholar] [CrossRef]

- Arrotéia, A.V.; Freitas, R.C.; Melhado, S.B. Barriers to BIM adoption: A case study in Brazil. Front. Built Environ. 2021, 7, 16. [Google Scholar] [CrossRef]

- Leśniak, A.; Górka, M.; Skrzypczak, I. Barriers to BIM implementation in architecture, construction, and engineering projects—The polish study. Energies 2021, 14, 2090. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W. Development of a benchmarking model for BIM implementation in developing countries. Benchmarking Int. J. 2019, 26, 1210–1232. [Google Scholar] [CrossRef]

- Manzoor, B.; Othman, I.; Gardezi, S.S.S.; Harirchian, E. Strategies for adopting building information modeling (BIM) in sustainable building projects—A case of Malaysia. Buildings 2021, 11, 249. [Google Scholar] [CrossRef]

- Kaming, P.F.; Olomolaiye, P.O.; Holt, G.D.; Harris, F.C. Factors influencing construction time and cost overruns on high-rise projects in Indonesia. Constr. Manag. Econ. 1997, 15, 83–94. [Google Scholar] [CrossRef]

- Farooq, U.; Rehman, S.K.U.; Javed, M.F.; Jameel, M.; Aslam, F.; Alyousef, R. Investigating BIM implementation barriers and issues in Pakistan using ISM approach. Appl. Sci. 2020, 10, 7250. [Google Scholar] [CrossRef]

- Mishra, M.; Lourenço, P.B.; Ramana, G.V. Structural health monitoring of civil engineering structures by using the internet of things: A review. J. Build. Eng. 2022, 48, 103954. [Google Scholar] [CrossRef]

- Farrar, C.R.; Lieven, N.A.; Bement, M.T. An introduction to damage prognosis. In Damage Prognosis for Aerospace, Civil and Mechanical Systems; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005; pp. 1–12. [Google Scholar]

- Foraboschi, P. Buckling of a laminated glass column under test. Struct. Eng 2009, 87, 2–8. [Google Scholar]

- Foraboschi, P.; Vanin, A. New methods for bonding FRP strips onto masonry structures: Experimental results and analytical evaluations. Compos. Mech. Comput. Appl. Int. J. 2013, 4, 1–23. [Google Scholar] [CrossRef]