Improvement of Factory Transport Efficiency with Use of WiFi-Based Technique for Monitoring Industrial Vehicles

Abstract

1. Introduction

2. Literature Review—Methods of Traffic Analysis

3. Materials and Methods

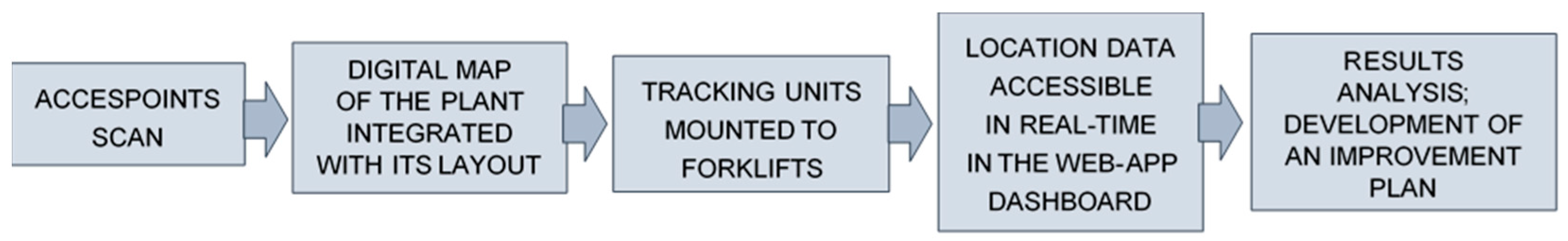

3.1. In-Building Location System

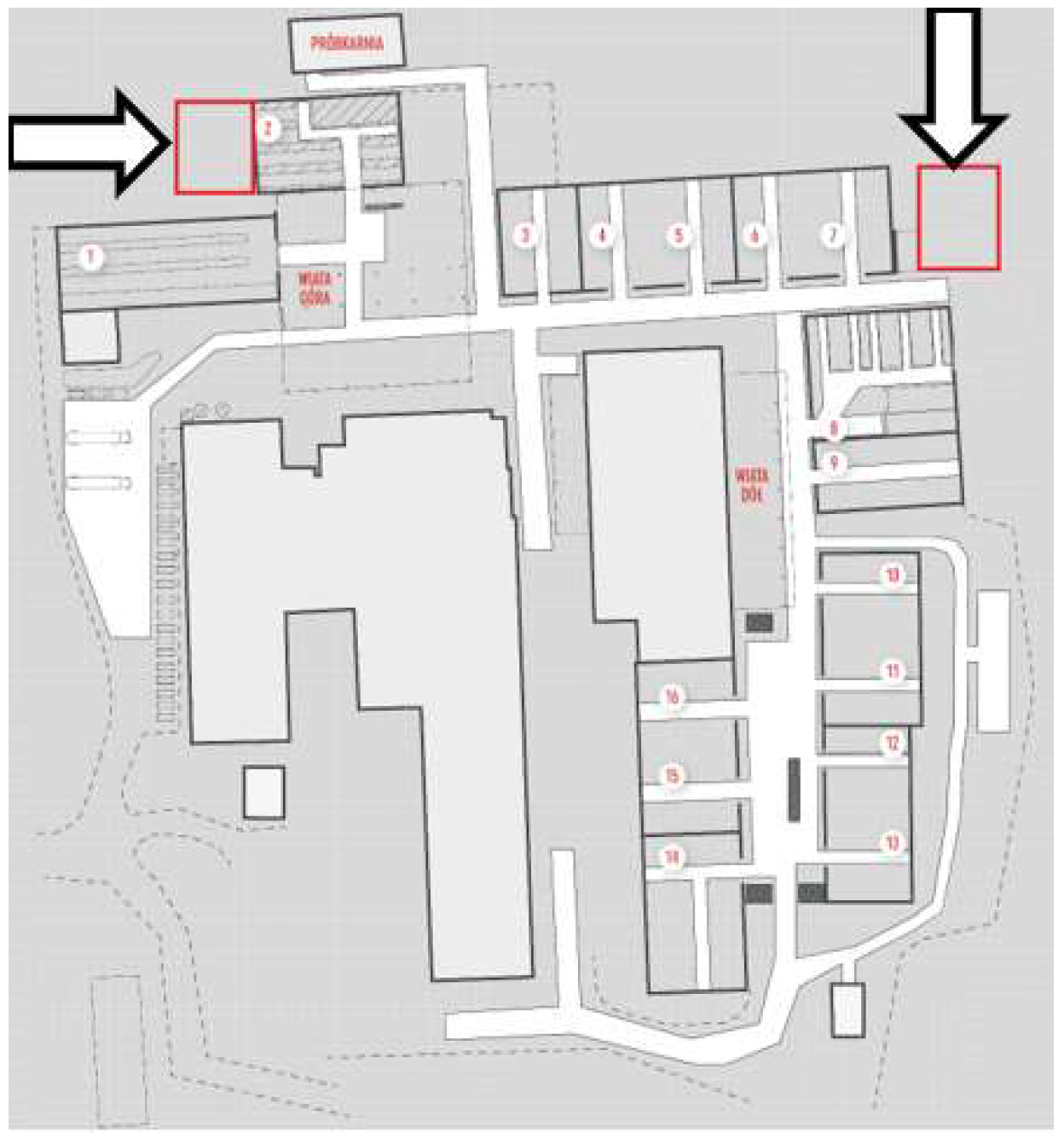

3.2. Case Study

- (1)

- Production-to-warehouse transport (Figure 2a)—receipt of finished products from the intermediate storage area, moving them to a proper warehouse and placing them on storage shelves in the way suitable for their convenient future reception.

- (2)

- Warehouse-to-packing transport (Figure 2b)—picking an order, moving it to the packing zone and preparation for loading by properly securing the goods.

- (3)

- Packing-to-loading transport (Figure 2c)—moving the load from the packing zone to the loading area and its placing on a truck.

4. Results and Discussion

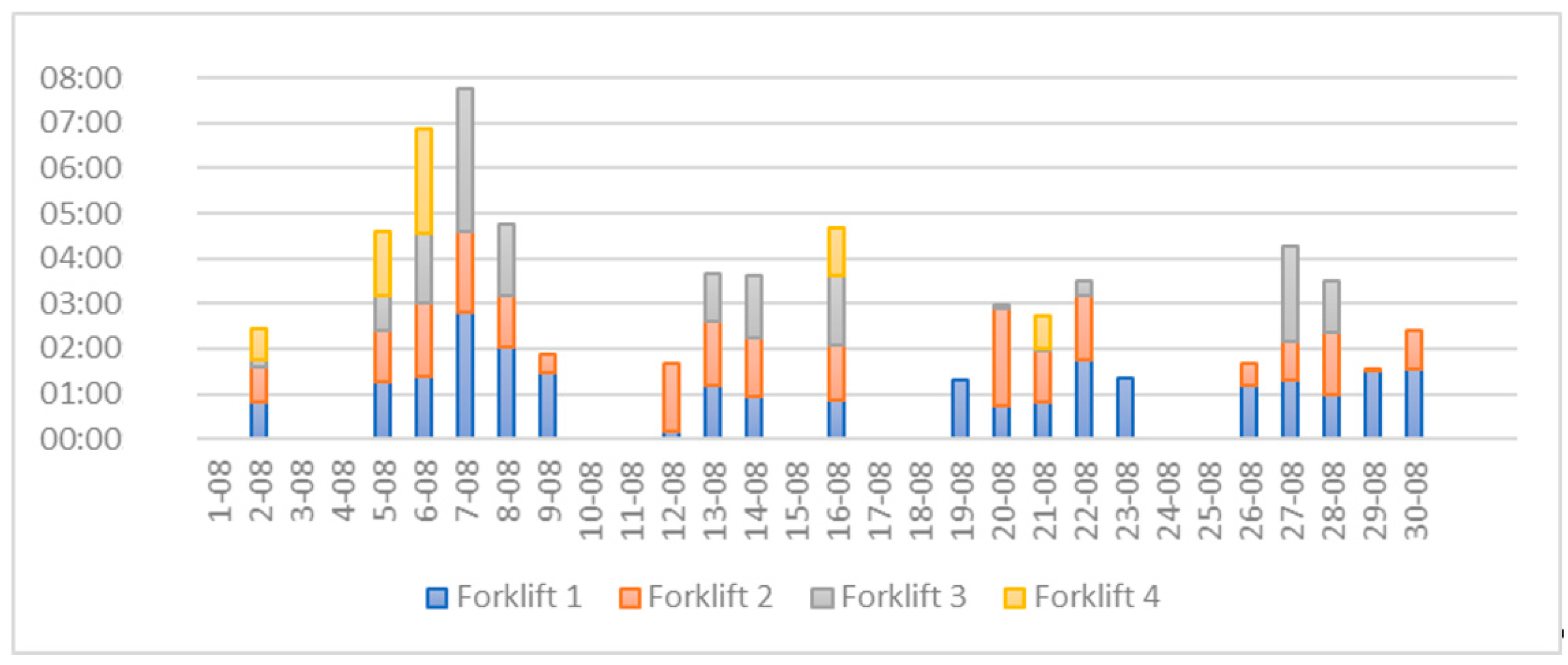

4.1. Production-To-Warehouse Transport

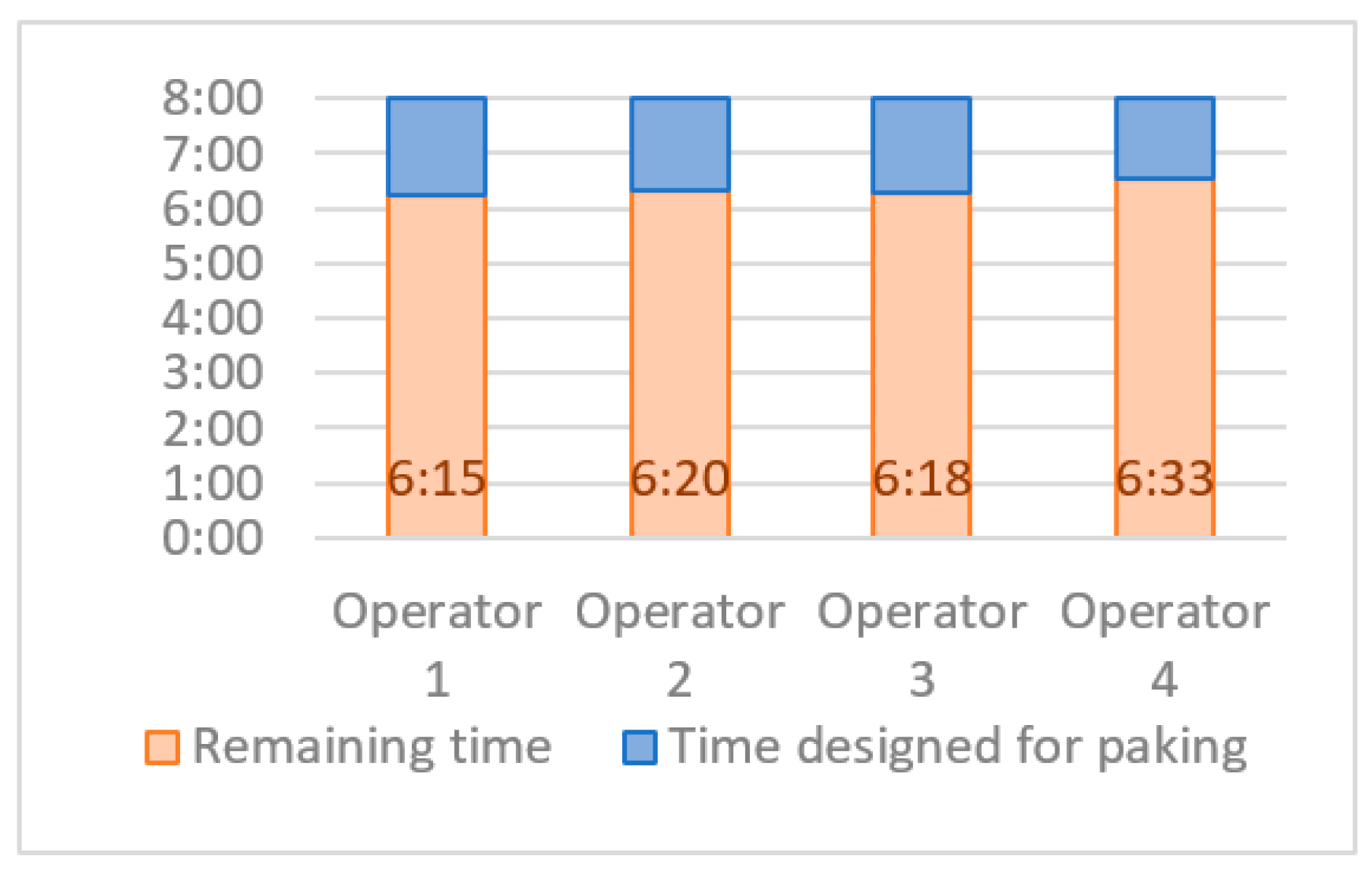

4.2. Warehouse-To-Packing Transport

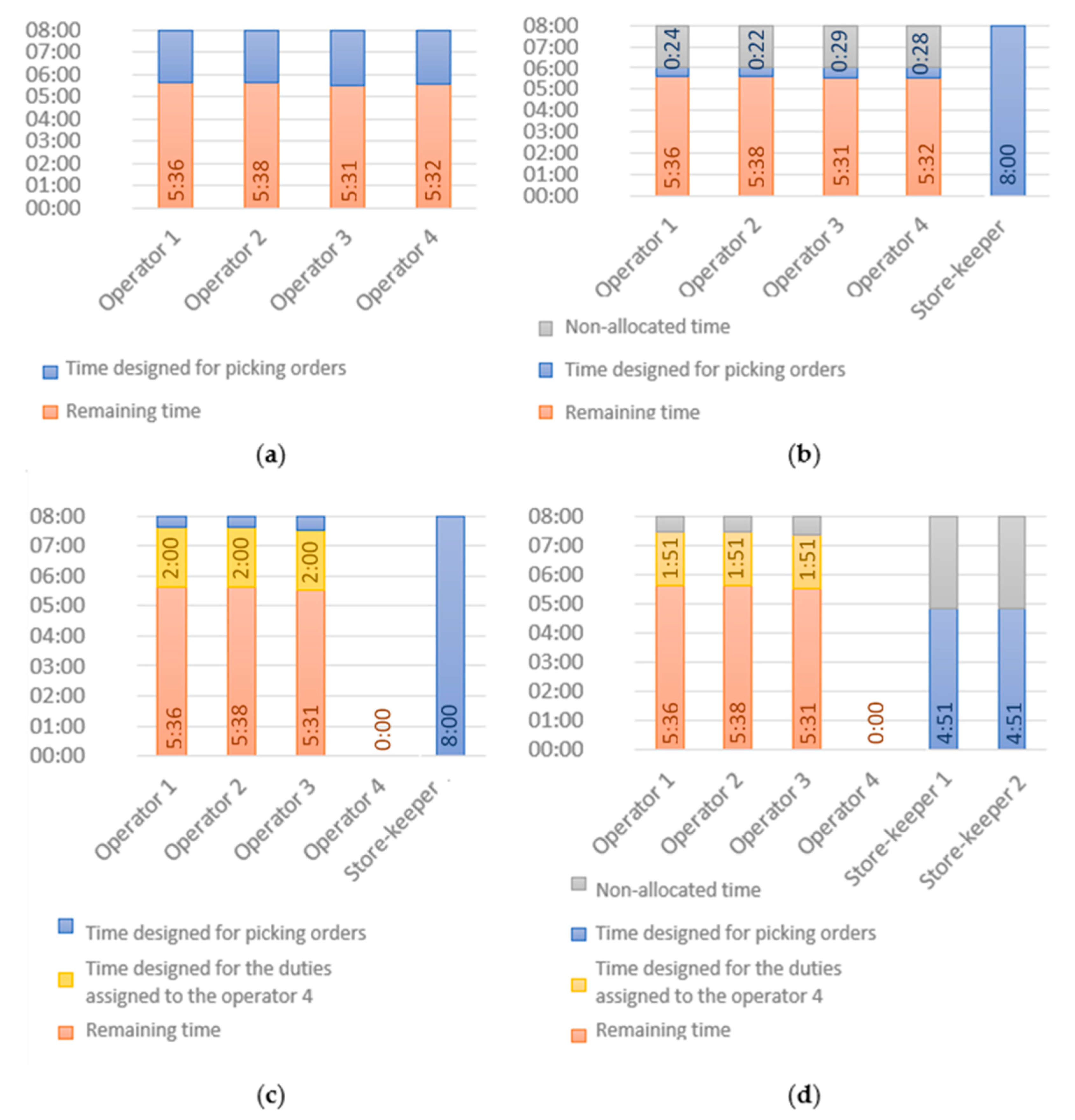

4.2.1. Mathematical Model

4.2.2. Solutions

4.3. Packing-To-Loading Transport

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Burduk, A.; Musia, ł.K. Optimization of Chosen Transport Task by Using Generic Algorithms. In Lecture Notes in Computer Science; Saeed, K., Homenda, W., Eds.; Springer: Cham, Switzerland, 2016; Volume 9842, pp. 197–205. [Google Scholar] [CrossRef]

- Gola, A.; Kłosowski, G. Application of Fuzzy Logic and Genetic Algorithms in Automated Works Transport Organization. In Advances in Intelligent Systems and Computing; Omatu, S., Rodríguez, S., Villarrubia, G., Faria, P., Sitek, P., Prieto, J., Eds.; Springer: Cham, Switzerland, 2018; Volume 620, pp. 29–36. [Google Scholar] [CrossRef]

- Gregor, T.; Krajčovič, M.; Więcek, D. Smart Connected Logistics. Procedia Eng. 2017, 192, 265–270. [Google Scholar] [CrossRef]

- Dohn, K. Selected problems of logistics in production—Internal transportation processes organization. WUT J. Transp. Eng. 2009, 70, 47–58. [Google Scholar]

- Antosz, K.; Stadnicka, D. Lean Philosophy Implementation in SMEs—Study Results. Procedia Eng. 2017, 182, 25–32. [Google Scholar] [CrossRef]

- Senderska, K.; Mares, A.; Vaclav, S. Spaghetti Diagram Application For Workers’ Movement Analysis. UPB Sci. Bull. Ser. D 2017, 79, 1. [Google Scholar]

- Kanaganayagam, K.; Muthuswamy, S.; Damoran, P. Lean methodologies to improve assembly line efficiency: An industrial application. Int. J. Ind. Syst. Eng. 2015, 20, 104–116. [Google Scholar] [CrossRef]

- Mangiola, S.; Papenfuss, A.T. tidyHeatmap: An R package for modular heatmap production based on tidy principles. J. Open Source Softw. 2020, 2472, 5. [Google Scholar] [CrossRef]

- Pryke, A.; Mostaghim, S.; Nazemi, A. Heatmap Visualization of Population Based Multi Objective Algorithms. In Lecture Notes in Computer Science; Obayashi, S., Deb, K., Poloni, C., Hiroyasu, T., Murata, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; Volume 4403, pp. 361–375. [Google Scholar] [CrossRef]

- Yeong, D.J.; Velasco-Hernandez, G.; Barry, J.; Walsh, J. Sensor and Sensor Fusion Technology in Autonomous Vehicles: A Review. Sensors 2021, 2140, 2140. [Google Scholar] [CrossRef] [PubMed]

- Suganuma, N.; Uozumi, T. Development of an autonomous vehicle-System overview of test ride vehicle in the Tokyo Motor Show 2011. In Proceedings of the SICE Annual Conference, Akita, Japan, 18–19 August 2012; pp. 215–218. [Google Scholar]

- Rahiman, W.; Zainal, Z. An Overview of Development GPS Navigation for Autonomous Car. In Proceedings of the 8th IEEE Conference on Industrial Electronics and Applications (ICIEA), Melbourne, Australia, 19–21 June 2013. [Google Scholar] [CrossRef]

- Campbell, S.; O’Mahony, N.; Krpalcova, L.; Riordan, D.; Walsh, J.; Murphy, A.; Ryan, C. Sensor Technology in Autonomous Vehicles: A review. In Proceedings of the 29th Irish Signals and Systems Conference (ISSC), Belfast, UK, 21–22 June 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Terán, M.; Aranda, J.; Carrillo, H.; Mendez, D.; Parra, C. IoT-based system for indoor location using bluetooth low energy. In Proceedings of the IEEE Colombian Conference on Communications and Computing (COLCOM), Cartagena, Colombia, 16–18 August 2017; pp. 1–6. [Google Scholar]

- Kuxdorf-Alkirata, N.; Brückmann, D. Reliable and low-cost indoor localization based on bluetooth low energy. In Proceedings of the 3rd International Symposium on Wireless Systems within the Conferences on Intelligent Data Acquisition and Advanced Computing Systems (IDAACS-SWS), Offenburg, Germany, 26–27 September 2016; pp. 92–96. [Google Scholar]

- Stavrou, V.; Bardaki, C.; Papakyriakopoulos, D.; Pramatari, K. An Ensemble Filter for Indoor Positioning in a Retail Store Using Bluetooth Low Energy Beacons. Sensors 2019, 4550, 19. [Google Scholar] [CrossRef] [PubMed]

- Ding, K.; Jiang, P.; Su, S. RFID-enabled social manufacturing system for inter-enterprise monitoring and dispatching of integrated production and transportation tasks. Robot. Comput. Integr. Manuf. 2018, 49, 120–133. [Google Scholar] [CrossRef]

- Röhrig, C.; Heß, D.; Künemund, F. Constrained Kalman filtering for indoor localization of transport vehicles using floor-installed HF RFID transponders. In Proceedings of the 2015 IEEE International Conference on RFID (RFID), Tokyo, Japan, 16–18 September 2015; pp. 113–120. [Google Scholar]

- Xiong, Z.; Song, Z.; Scalera, A.; Ferrere, E.; Sottile, F.; Brizzi, P.; Tomasi, R.; Spirito, M.A. Hybrid WSN and RFID indoor positioning and tracking system. J. Embedded Systems 2013, 6, 1–15. [Google Scholar] [CrossRef]

- Xu, B.; Gang, W. Random sampling algorithm in RFID indoor location system. In Proceedings of the Third IEEE International Workshop on Electronic Design, Test and Applications (DELTA’06), Kuala Lumpur, Malaysia, 17–19 January 2006; p. 6. [Google Scholar] [CrossRef]

- Gladysz, B.; Santarek, K.; Lysiak, C. Dynamic Spaghetti Diagrams. A Case Study of Pilot RTLS Implementation. In Advances in Intelligent Systems and Computing; Burduk, A.D., Mazurkiewicz, D., Eds.; Springer: Cham, Switzerland, 2018; Volume 637, pp. 238–248. [Google Scholar]

- Gutewort, D.; Semm, A.; Erfurth, C. Raising Awareness of SMEs for Real-Time Locating Systems (RTLS) in Intralogistics. In Communications in Computer and Information Science; Krieger, U.R., Eichler, G., Erfurth, C., Fahrnberger, G., Eds.; Springer: Cham, Switzerland, 2021; Volume 1404, pp. 223–236. [Google Scholar]

- Zhang, Y.; Wu, L. Application of RFID and RTLS Technology in Supply Chain Enterprise. In Proceedings of the 6th International Conference on Wireless Communications Networking and Mobile Computing (WiCOM), Chengdu, China, 23–25 September 2010; pp. 1–4. [Google Scholar]

- Curran, K.; Furey, E.; Lunney, T.; Santos, J.; Woods, D.A.; McCaughey, A. An evaluation of indoor location determination technologies. J. Locat. Based Serv. 2011, 5, 61–78. [Google Scholar] [CrossRef]

- Lashkari, A.H.; Parhizkar, B.; Ngan, M.N.A. WIFI-Based Indoor Positioning System. In Proceedings of the Second International Conference on Computer and Network Technology, Washington, DC, USA, 23–25 August 2010; pp. 76–78. [Google Scholar] [CrossRef]

- Sabanci, K.; Yigit, E.; Ustun, D.; Toktas, A.; Aslan, M.F. WiFi Based Indoor Localization: Application and Comparison of Machine Learning Algorithms. In Proceedings of the XXIIIrd International Seminar/Workshop on Direct and Inverse Problems of Electromagnetic and Acoustic Wave Theory (DIPED), Tbilisi, Georgia, 24–27 September 2018; pp. 246–251. [Google Scholar] [CrossRef]

- Liu, H.H.; Yang, Y.N. WiFi-based indoor positioning for multi-floor Environment. In Proceedings of the TENCON 2011—2011 IEEE Region 10 Conference, Bali, Indonesia, 21–24 November 2011; pp. 597–601. [Google Scholar] [CrossRef]

- Ryu, S.; Park, B.B.; El-Tawab, S. WiFi Sensing System for Monitoring Public Transportation Ridership: A Case Study. KSCE J. Civ. Eng. 2020, 24, 3092–3104. [Google Scholar] [CrossRef]

- Uras, M.; Cossu, R.; Atzori, L. PmA: A solution for people mobility monitoring and analysis based on WiFi probes. In Proceedings of the 4th International Conference on Smart and Sustainable Technologies (SpliTech), Bol/Split, Croatia, 18–21 June 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Lesani, A.; Miranda-Moreno, L. Development and Testing of a Real-Time WiFi-Bluetooth System for Pedestrian Network Monitoring, Classification, and Data Extrapolation. IEEE Trans. Intell. Transp. Syst. 2019, 20, 1484–1496. [Google Scholar] [CrossRef]

- Rosienkiewicz, M. Artificial intelligence-based hybrid forecasting models for manufacturing systems. Maint. Reliab. 2021, 23, 263–277. [Google Scholar] [CrossRef]

- Tubis, A.A.; Poturaj, H. Challenges in the implementation of autonomous robots in the process of feeding materials on the production line as part of Logistics 4.0. LogForum 2021, 17, 411–423. [Google Scholar] [CrossRef]

| Variant I | Variant II | |

|---|---|---|

| Introduction | 1 manual worker 1 hand-operated pallet truck | 1 manual worker 1 hand-operated pallet truck |

| Resignation | - | 1 forklift operator 1 forklift truck |

| Description | Introducing to the packing station an employee with no forklift operator license. Purchasing a hand-operated pallet truck to the packing zone. | Replacing one forklift operator with one employee in the packing station. Resigning one forklift truck (sale). Purchasing a hand-operated pallet truck to the packing zone. |

| Variant I | Variant II | Variant III | |

|---|---|---|---|

| Introduction | 1 storekeeper 1 hand-operated pallet truck | 1 storekeeper 1 hand-operated pallet truck | 2 storekeepers 2 hand-operated pallet trucks |

| Resignation | - | 1 forklift operator 1 forklift truck | 1 forklift operator 1 forklift truck |

| Description | Employing a storekeeper responsible for picking a fragmented order. Purchasing a hand-operated pallet truck to be at the storekeeper’s disposal. | Replacing a forklift operator with a manual worker. Resigning one forklift truck (sale). Purchasing a hand-operated pallet truck to be at the storekeeper disposal. | Replacing a forklift operator with two storekeepers. Resigning one forklift truck (sale). Purchasing two hand-operated pallet trucks to be at the storekeepers disposal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kochańska, J.; Burduk, A.; Markowski, M.; Kłusek, A.; Wojciechowska, M. Improvement of Factory Transport Efficiency with Use of WiFi-Based Technique for Monitoring Industrial Vehicles. Sustainability 2023, 15, 1113. https://doi.org/10.3390/su15021113

Kochańska J, Burduk A, Markowski M, Kłusek A, Wojciechowska M. Improvement of Factory Transport Efficiency with Use of WiFi-Based Technique for Monitoring Industrial Vehicles. Sustainability. 2023; 15(2):1113. https://doi.org/10.3390/su15021113

Chicago/Turabian StyleKochańska, Joanna, Anna Burduk, Marcin Markowski, Alicja Kłusek, and Monika Wojciechowska. 2023. "Improvement of Factory Transport Efficiency with Use of WiFi-Based Technique for Monitoring Industrial Vehicles" Sustainability 15, no. 2: 1113. https://doi.org/10.3390/su15021113

APA StyleKochańska, J., Burduk, A., Markowski, M., Kłusek, A., & Wojciechowska, M. (2023). Improvement of Factory Transport Efficiency with Use of WiFi-Based Technique for Monitoring Industrial Vehicles. Sustainability, 15(2), 1113. https://doi.org/10.3390/su15021113