Intensification of Rice-Fallow Agroecosystem of South Asia with Oilseeds and Pulses: Impacts on System Productivity, Soil Carbon Dynamics and Energetics

Abstract

1. Introduction

2. Materials and Methods

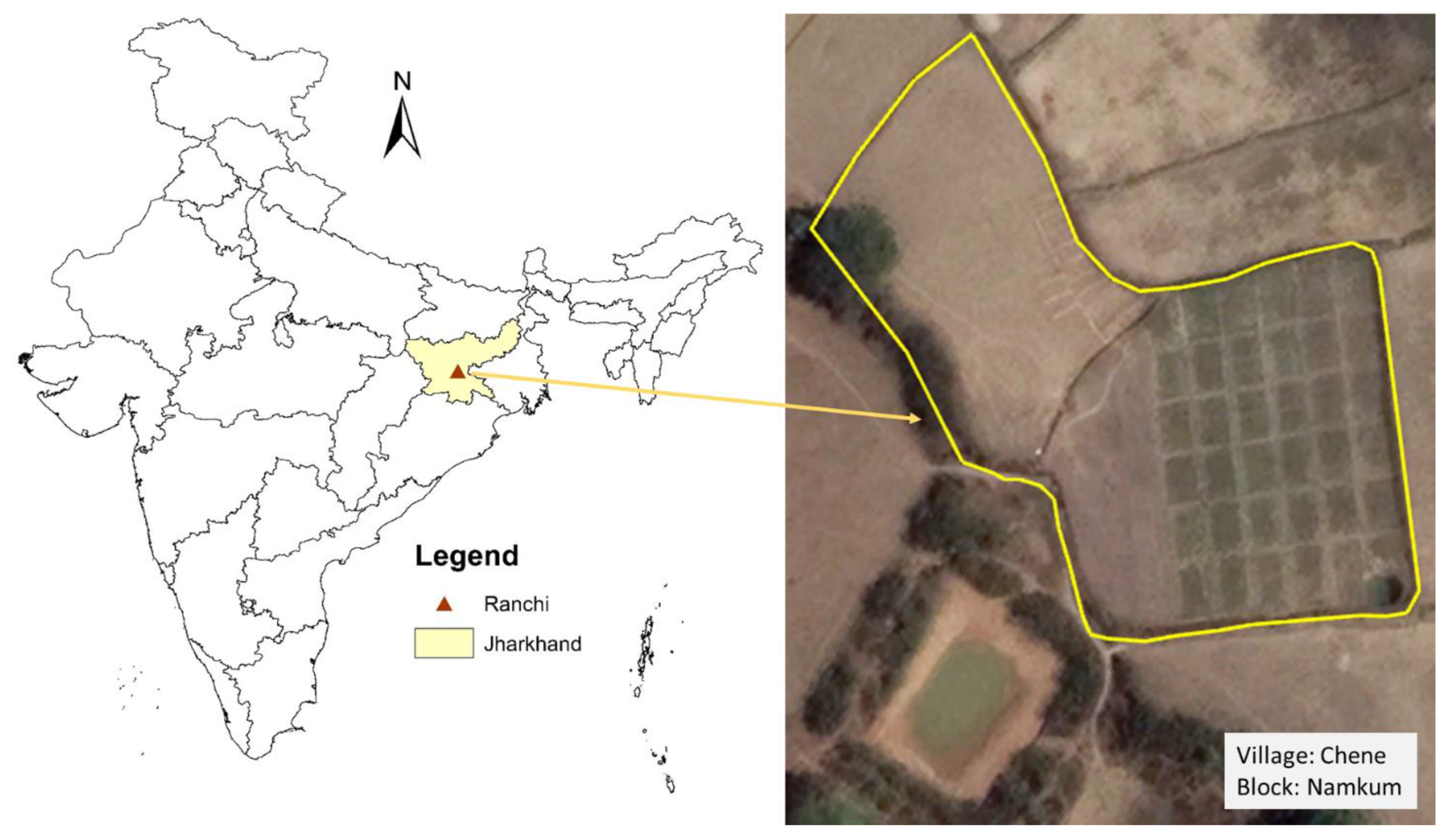

2.1. Experimental Sites

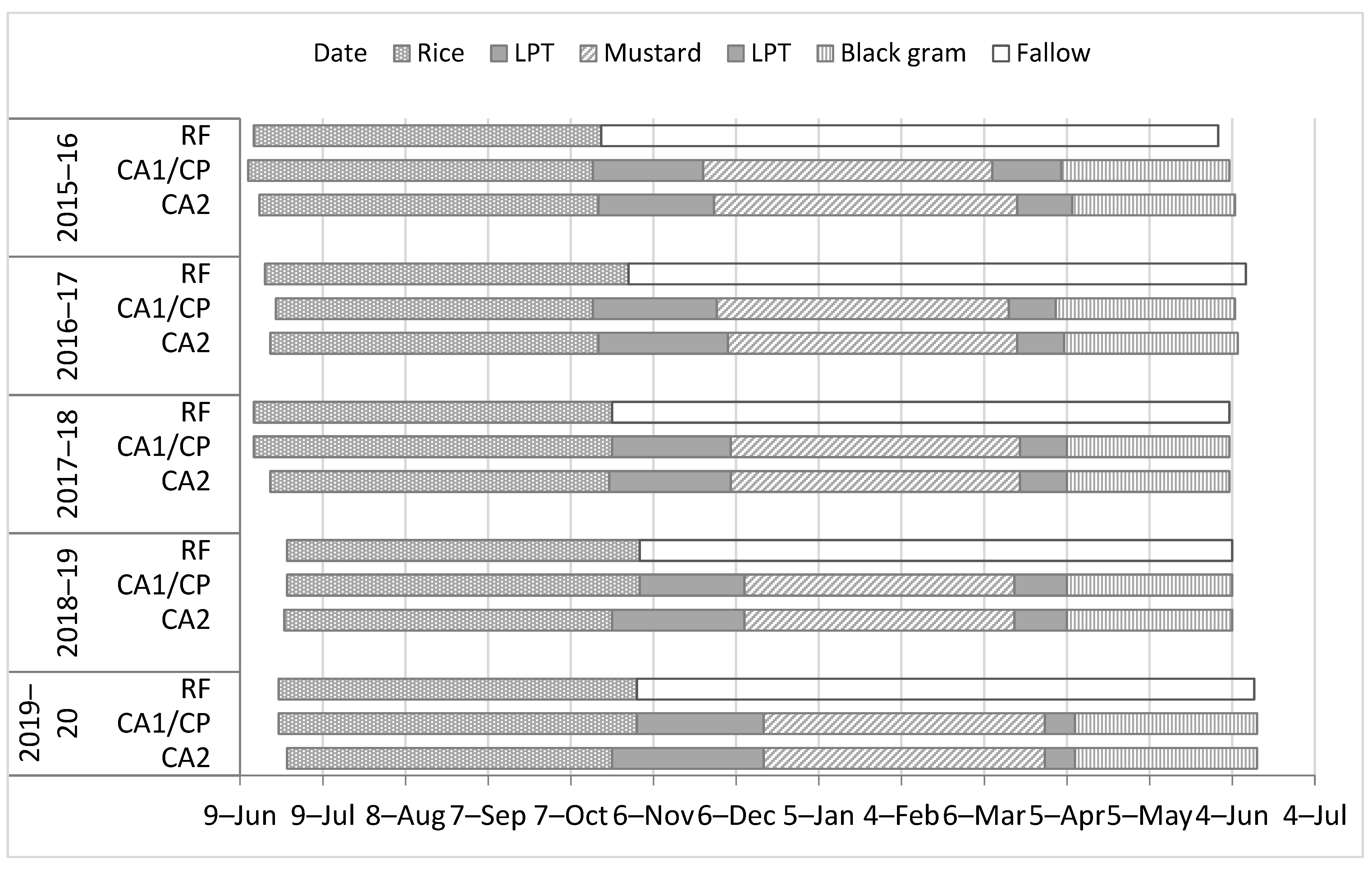

2.2. Experiment Details

2.3. Soil Sampling and Analysis

2.4. Total Soil Organic Carbon

2.5. Oxidizable Organic Carbon Fractions

2.6. Active and Passive Pools

2.7. Biological Properties of the Soil

2.8. Crop Yield and System Rice Equivalent Yield (SREY)

2.9. Energy Budgeting

2.10. Carbon Budgeting

2.11. Irrigation Management

2.12. Crop Water Use and Water Productivity

2.13. Statistical Analysis

3. Results

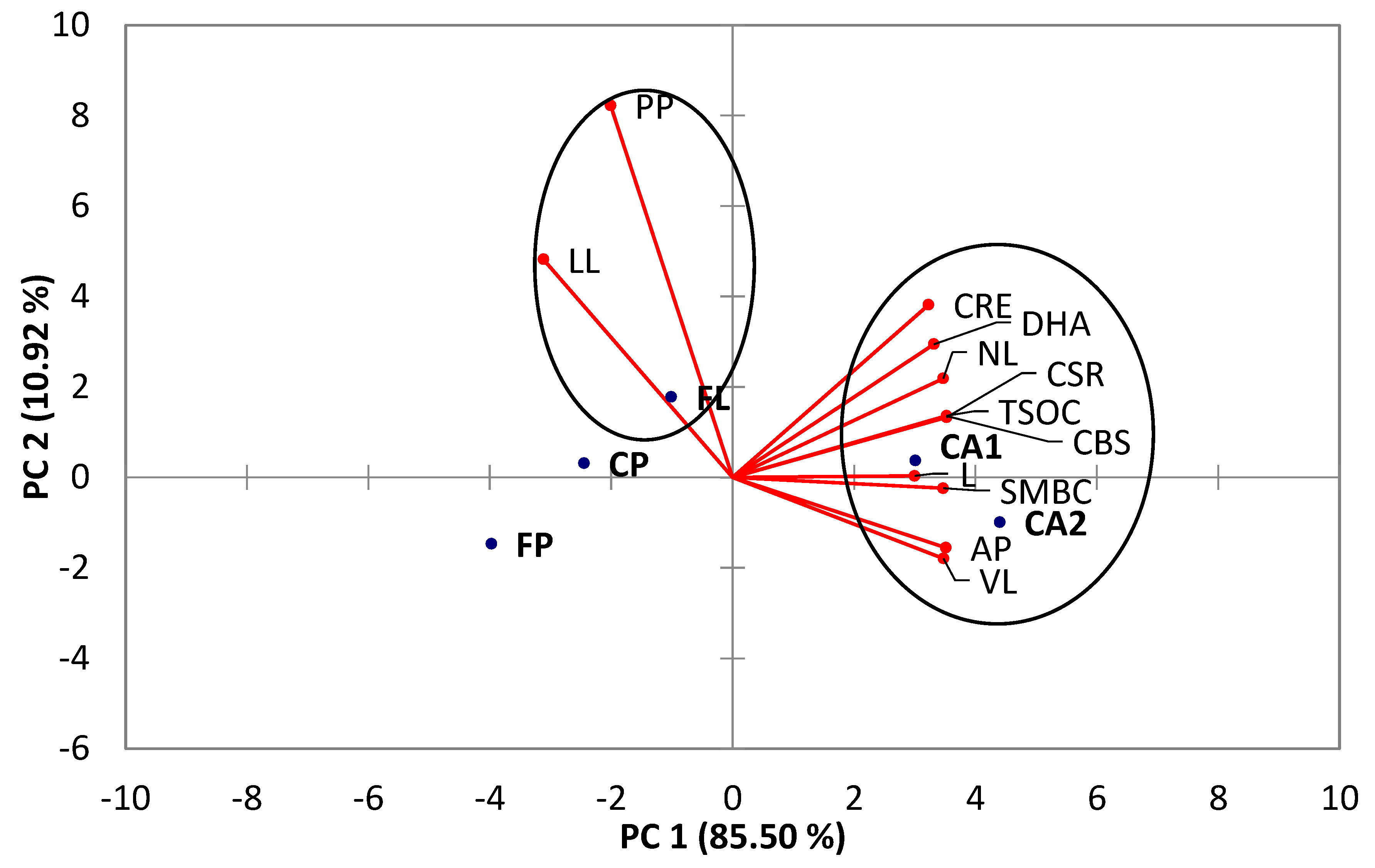

3.1. Total Soil Organic Carbon

3.2. Soil organic Carbon Fraction

3.3. Active and Passive Pool of Carbon

3.4. Carbon Build-Up and Retention

3.5. Soil Microbial Biomass Carbon and Dehydrogenase Activities

3.6. Crop and System Yield

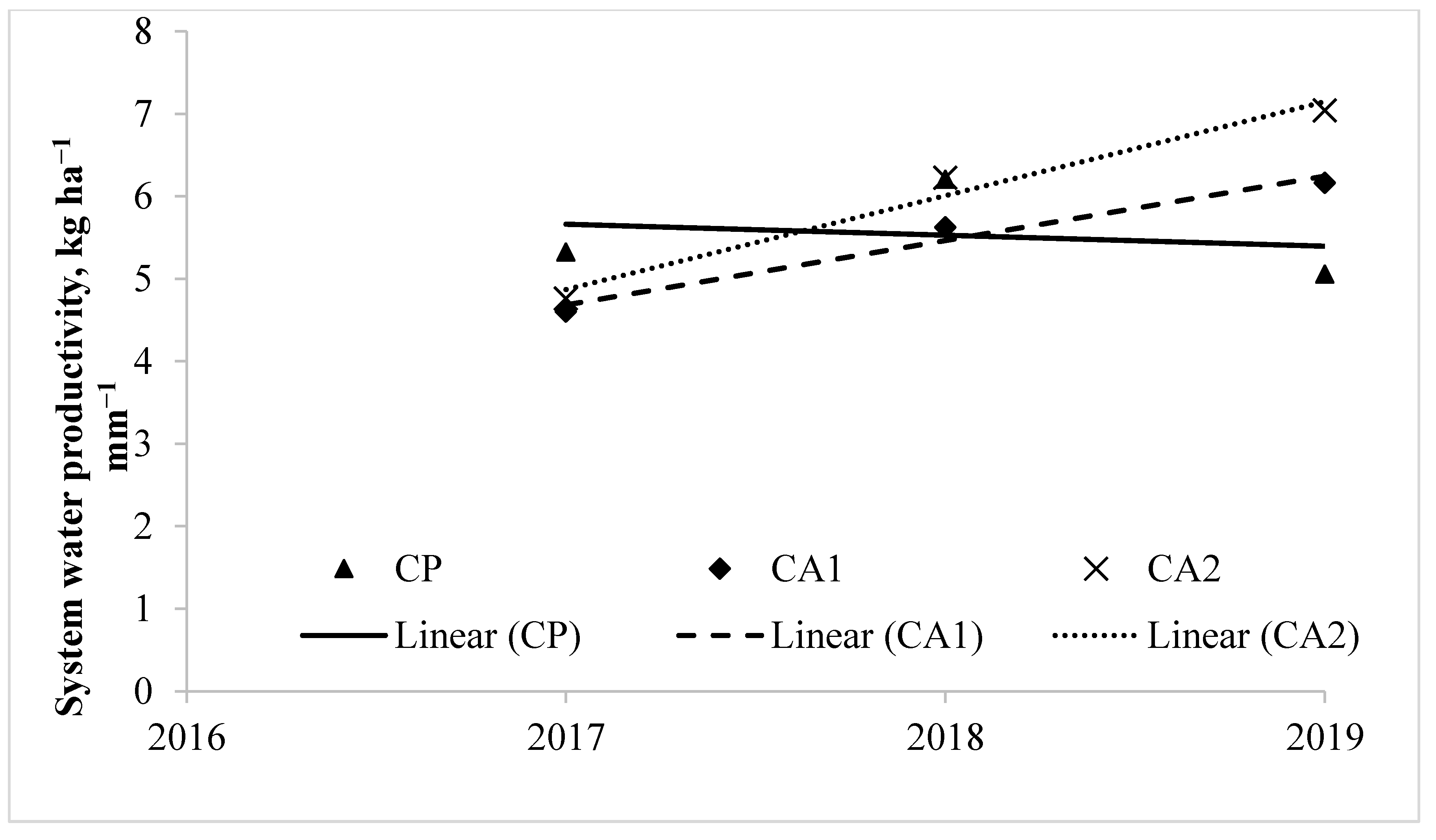

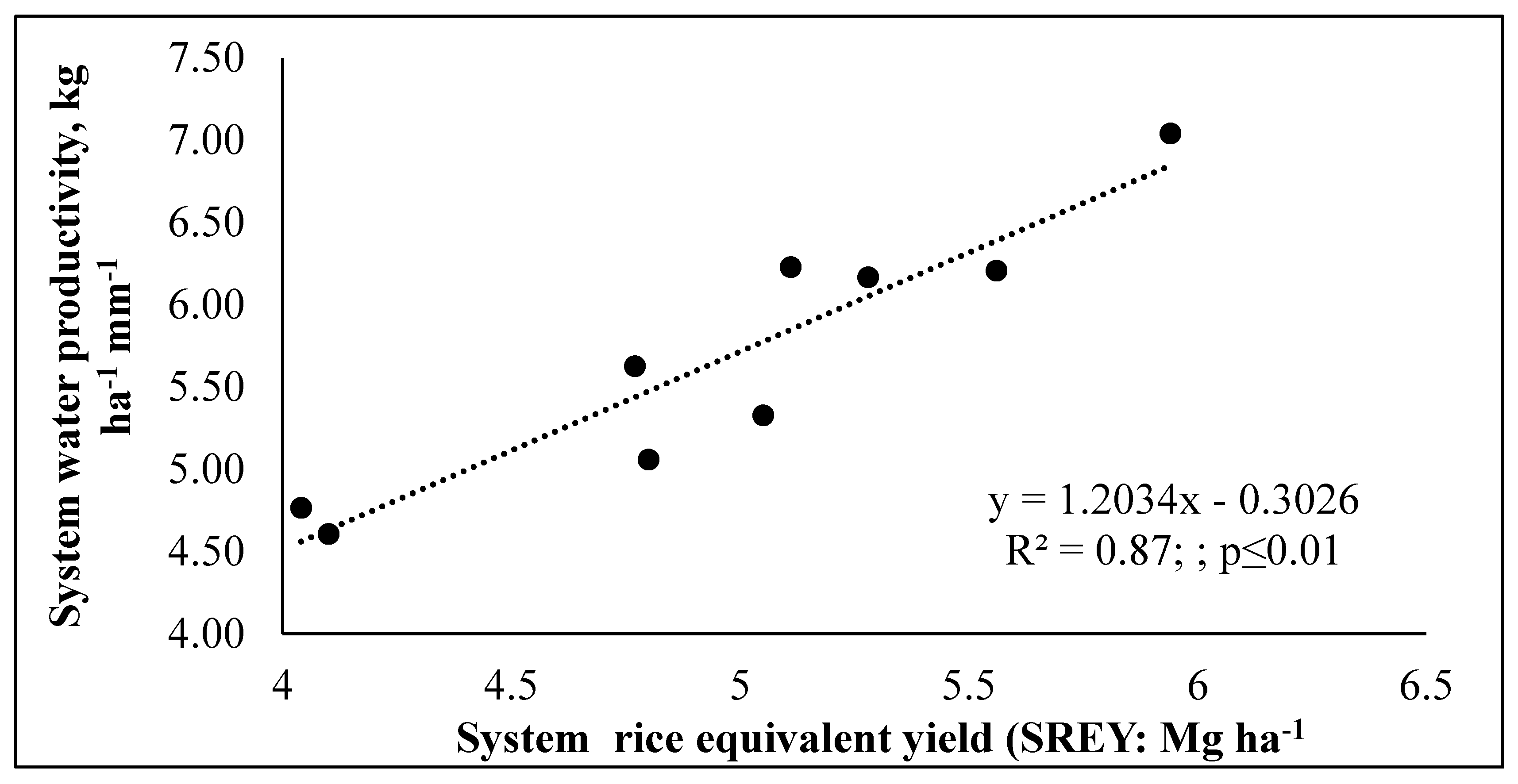

3.7. Crop Water Use and Water Productivity

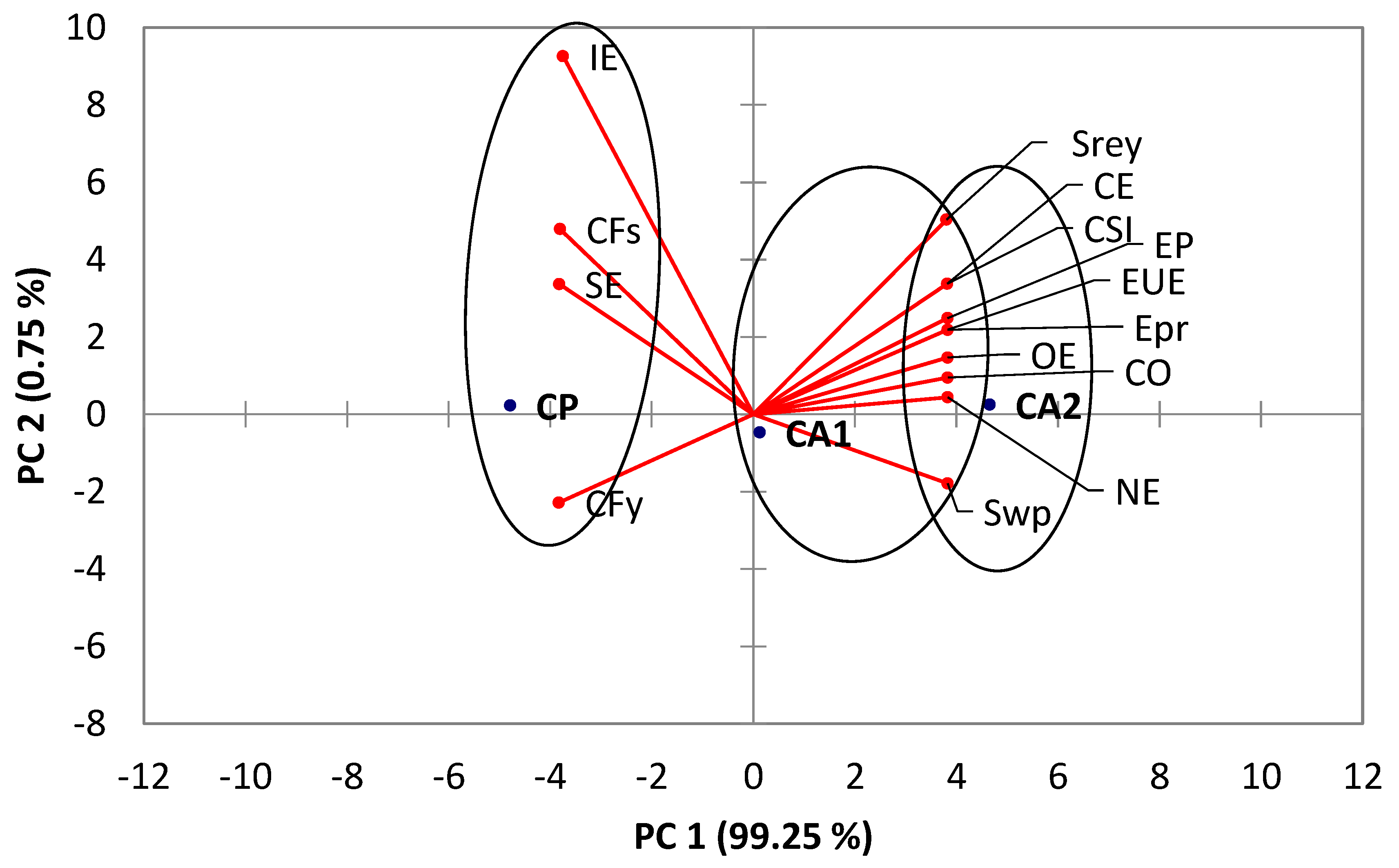

3.8. Energy Budgeting

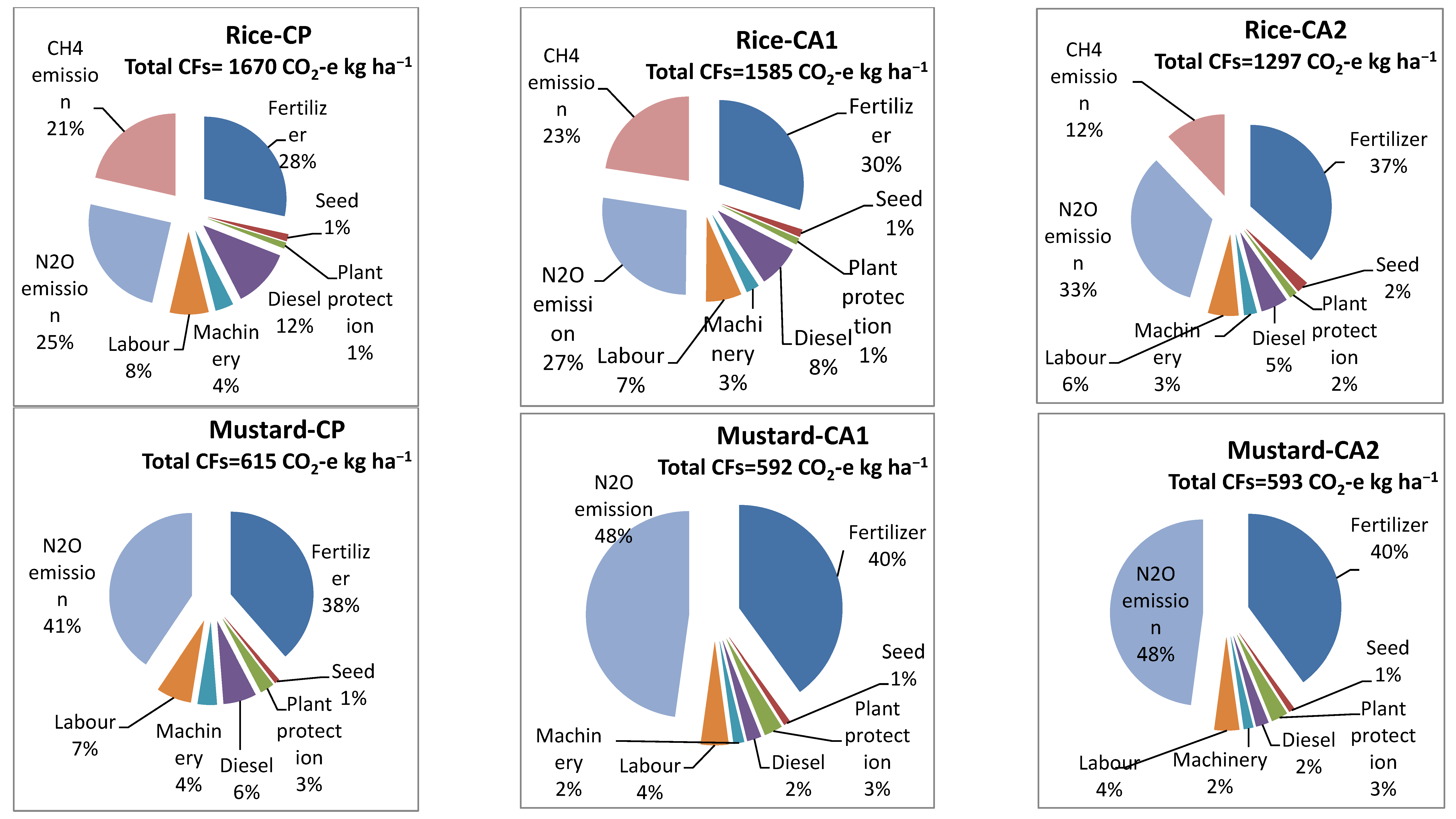

3.9. Carbon Budgeting

4. Discussion

4.1. Total SOC Stock (TSOC)

4.2. Soil Organic Carbon Pools, Carbon Stabilization and Microbial Parameters

4.3. System Productivity

4.4. Crop Water Productivity

4.5. Energy and Carbon Budgeting

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations. World Population Prospects: The 2019 Revision (Medium Variant); United Nations: New York, NY, USA, 2019. [Google Scholar]

- Van Dijk, M.; Morley, T.; Rau, M.L.; Saghai, Y. A meta-analysis of projected global food demand and population at risk of hunger for the period 2010–2050. Nat. Food 2021, 2, 494–501. [Google Scholar] [CrossRef]

- Gumma, M.K.; Thenkabail, P.S.; Teluguntla, P.; Rao, M.N.; Mohammed, I.A.; Whitbread, A.M. Mapping rice-fallow cropland areas for short-season grain legumes intensification in South Asia using MODIS 250 m time-series data. Int. J. Digit. Earth 2016, 9, 981–1003. [Google Scholar] [CrossRef]

- Kumar, R.; Sarkar, B.; Bhatt, B.P.; Mali, S.S.; Mondal, S.; Mishra, J.S.; Jat, R.K.; Meena, R.S.; Anurag, A.P.; Raman, R.K. Compara-tive assessment of energy flow, carbon auditing and eco-efficiency of diverse tillage systems for cleaner and sustainable crop pro-duction in eastern India. J. Clean. Prod. 2021, 293, 126162. [Google Scholar] [CrossRef]

- Saurabh, K.; Kumar, R.; Mishra, J.S.; Singh, A.K.; Mondal, S.; Meena, R.S.; Choudhary, J.S.; Biswas, A.K.; Kumar, M.; Roy, H.S.; et al. Sustainable intensification of rice fallows with oilseeds and pulses: Effects on soil aggregation, organic carbon dynamics, and crop productivity in eastern Indo-Gangetic Plains. Sustainability 2022, 14, 11056. [Google Scholar] [CrossRef]

- Singh, A.K.; Das, B.; Mali, S.S.; Bhavana, P.; Shinde, R.; Bhatt, B.P. Intensification of rice-fallow cropping systems in the Eastern Plateau region of India: Diversifying cropping systems and climate risk mitigation. Clim. Dev. 2020, 12, 791–800. [Google Scholar] [CrossRef]

- Sharma, P.K.; De-Datta, S.K. Effect of puddling on soil physical properties and processes. In Soil Physics and Rice; International Rice Research Institute: Los Banos, CA, USA, 1985; pp. 217–234. [Google Scholar]

- Bonin, C.L.; Lal, R. Aboveground productivity and soil carbon storage of biofuel crops in Ohio. GCB Bioenerg. 2014, 6, 67–75. [Google Scholar] [CrossRef]

- Adhya, T.K.; Singh, O.N.; Swain, P.; Ghosh, A. Rice in Eastern India: Causes for low productivity and available options. J. Rice Res. 2008, 2, 1–5. [Google Scholar]

- NAAS. Improving Productivity of Rice Fallows; Policy Paper No. 64; National Academy of Agricultural Sciences: New Delhi, India, 2013; p. 16. [Google Scholar]

- Bhatt, R.; Kukal, S.S.; Busari, M.A.; Arora, S.; Yadav, M. Sustainability issues on rice–wheat cropping system. Int. Soil Water Conserv. Res. 2016, 4, 64–74. [Google Scholar] [CrossRef]

- Bandyopadhyay, P.K.; Halder, S.; Mondal, K.; Singh, K.C.; Nandi, R.; Ghosh, P.K. Response of Lentil (Lens culinaries) to Post-rice Residual Soil Moisture Under Contrasting Tillage Practices. Agric. Res. 2018, 7, 463–479. [Google Scholar] [CrossRef]

- Naik, S.K.; Das, B.; Kumar, S.; Bhatt, B.P. Evaluation of Major and Micronutrient Status of Acid Soils of Different Mango Orchards. Int. J. Fruit Sci. 2015, 15, 10–25. [Google Scholar] [CrossRef]

- Cornish, P.S.; Choudhury, A.; Kumar, A.; Das, S.; Kumbakhar, K.; Norrish, S.; Kumar, S. Improving crop production for food secu-rity and improved livelihoods on the East India Plateau II. Crop options, alternative cropping systems and capacity building. Agric Syst. 2015, 137, 180–190. [Google Scholar] [CrossRef]

- Godfray, H.C.J.; Beddington, J.R.; Crute, I.R.; Haddad, L.; Lawrence, D.; Muir, J.F.; Pretty, J.; Robinson, S.; Thomas, S.M.; Toulmin, C. Food security: The chal-lenge of feeding 9 billion people. Science 2010, 327, 812–818. [Google Scholar] [CrossRef] [PubMed]

- Foley, J.A.; Ramankutty, N.; Brauman, K.A.; Cassidy, E.S.; Gerber, J.S.; Johnston, M.; Mueller, N.D.; O’Connell, C.; Ray, D.K.; West, P.C.; et al. Solutions for a cultivated planet. Nature 2011, 478, 337–342. [Google Scholar] [CrossRef]

- Pittelkow, C.M.; Liang, X.; Linquist, B.A.; van Groenigen, K.J.; Lee, J.; Lundy, M.E.; van Gestel, N.; Six, J.; Venterea, R.T.; van Kessel, C. Productivity Limits and Po-tentials of the Principles of Conservation Agriculture. Nature 2015, 517, 365–368. [Google Scholar] [CrossRef] [PubMed]

- Knapp, S.; van der Heijden, M.G. A global meta-analysis of yield stability in organic and conservation agriculture. Nat. Commun. 2018, 9, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Buffett, H.G. Reaping the benefits of no-tillage farming. Nature 2012, 484, 455. [Google Scholar] [CrossRef] [PubMed]

- Briones, M.J.; Schmidt, O. Conventional tillage decreases the abundance and biomass of earthworms and alters their community structure in a global meta-analysis. Glob. Chang. Biol. 2017, 23, 4396–4419. [Google Scholar] [CrossRef]

- Jat, H.S.; Datta, A.; Choudhary, M.; Sharma, P.C.; Yadav, A.K.; Choudhary, V.; Vishu, G.M.; Jat, M.L.; McDonald, A. Climate Smart Agriculture practices improve soil organic carbon pools, biological properties and crop productivity in cereal-based systems of North-West India. Catena 2019, 181, 104059. [Google Scholar] [CrossRef]

- Liu, C.; Cutforth, H.; Chai, Q.; Gan, Y. Farming tactics to reduce the carbon footprint of crop cultivation in semiarid areas. A review. Agron. Sustain. Dev. 2016, 36, 1–16. [Google Scholar] [CrossRef]

- Subbiah, B.V.; Asija, G.L. A rapid method for the estimation of nitrogen in soil. Curr. Sci. 1956, 26, 259–260. [Google Scholar]

- Bray, R.H.; Kurtz, L.T. Determination of total, organic, and available forms of phosphorus in soils. Soil Sci. 1945, 59, 39–46. [Google Scholar] [CrossRef]

- Page, A.L.; Miller, R.H.; Keeney, D.R. Chemical and Microbiological Properties. In Methods of Soil Analysis Part 2, 2nd ed.; Soil Science Society of America: Madison, WI, USA, 1982. [Google Scholar]

- BAU. Crop Production Technology. Birsa Kisan Diary; Birsa Agricultural University: Ranchi, India, 2010; p. 18. [Google Scholar]

- Piper, C.S. Soil and Plant Analysis; University of Adelaide: Adelaide, Australia, 1950. [Google Scholar]

- Nelson, D.W.; Sommers, L.E. Total carbon, organic carbon, and organic matter. In Methods of Soil Analysis, 2nd ed.; Page, A.L., Ed.; ASA Monograph 9(2): Madison, WI, USA, 1982; pp. 539–579. [Google Scholar]

- Samal, S.; Rao, K.; Poonia, S.; Kumar, R.; Mishra, J.; Prakash, V.; Mondal, S.; Dwivedi, S.; Bhatt, B.; Naik, S.K.; et al. Evaluation of long-term conservation agriculture and crop intensification in rice-wheat rotation of Indo-Gangetic Plains of South Asia: Carbon dynamics and productivity. Eur. J. Agron. 2017, 90, 198–208. [Google Scholar] [CrossRef] [PubMed]

- Das, T.; Bhattacharyya, R.; Sharma, A.; Das, S.; Saad, A.; Pathak, H. Impacts of conservation agriculture on total soil organic carbon retention potential under an irrigated agro-ecosystem of the western Indo-Gangetic Plains. Eur. J. Agron. 2013, 51, 34–42. [Google Scholar] [CrossRef]

- Ghosh, P.K.; Venkatesh, M.S.; Hazra, K.K.; Kumar, N. Long-term effect of pulses and nutrient management on soil organic carbon dynamics and sustainability on an inceptisol of indo-gangetic plains of india. Exp. Agric. 2012, 48, 473–487. [Google Scholar] [CrossRef]

- Mandal, B.; Majumder, B.; Bandyopadhyay, P.K.; Hazra, G.C.; Gangopadhyay, A.; Samantaray, R.N.; Mishra, A.K.; Chaudhury, J.; Saha, M.N.; Kundu, S. The potential of cropping systems and soil amendments for carbon sequestration in soils under long-term ex-periments in subtropical India. Glob. Chang Biol. 2007, 13, 357–369. [Google Scholar] [CrossRef]

- Chan, K.Y.; Bowman, A.; Oates, A. Oxidizible organic carbon fractions and soil quality changes in an oxic paleustalf under different pasture leys. Soil Sci. 2001, 166, 61–67. [Google Scholar] [CrossRef]

- Walkey, A.; Black, T.A. An examination of the Dugtijaraff method for determining soil organic matter and proposed modification of the chronic and titration method. Soil Sci. 1934, 37, 23–38. [Google Scholar]

- Vance, E.D.; Brookes, P.C.; Jenkinson, D.S. An extraction method for measuring soil microbial biomass C. Soil Biol. Biochem. 1987, 19, 703–707. [Google Scholar] [CrossRef]

- Casida, L.E., Jr.; Klein, D.A.; Santoro, T. Soil dehydrogenase activity. Soil Sci. 1964, 98, 371–376. [Google Scholar] [CrossRef]

- Choudhary, M.; Rana, K.S.; Bana, R.S.; Ghasal, P.C.; Choudhary, G.L.; Jakhar, P.; Verma, R.K. Energy budgeting and carbon foot-print of pearlmillet-mustard cropping system under conventional and conservation agriculture in rainfed semi-arid agro-ecosystem. Energy 2017, 141, 1052–1058. [Google Scholar] [CrossRef]

- Yadav, G.S.; Lal, R.; Meena, R.S.; Datta, M.; Babu, S.; Das, A.; Layek, J.; Saha, P. Energy budgeting for designing sustainable and environmentally clean/safer cropping systems for rainfed rice fallow lands in India. J. Clean. Prod. 2017, 158, 29–37. [Google Scholar] [CrossRef]

- Lal, B.; Gautam, P.; Panda, B.; Tripathi, R.; Shahid, M.; Bihari, P.; Guru, P.; Singh, T.; Meena, R.; Nayak, A. Identification of energy and carbon efficient cropping system for ecological sustainability of rice fallow. Ecol. Indic. 2020, 115, 106431. [Google Scholar] [CrossRef]

- Pratibha, G.; Srinivas, I.; Rao, K.; Raju, B.; Thyagaraj, C.; Korwar, G.; Venkateswarlu, B.; Shanker, A.K.; Choudhary, D.K.; Srinivasarao, C. Impact of conservation agriculture practices on energy use efficiency and global warming potential in rainfed pigeonpea–castor systems. Eur. J. Agron. 2015, 66, 30–40. [Google Scholar] [CrossRef]

- Tubiello, F.N.; Salvatore, M.; Ferrara, A.F.; House, J.; Federici, S.; Rossi, S.; Biancalani, R.; Golec, R.D.C.; Jacobs, H.; Flammini, A.; et al. The contribution of agriculture, forestry and other land use activities to global warming, 1990–2012. Glob. Change Biol. 2015, 21, 2655–2660. [Google Scholar] [CrossRef] [PubMed]

- Padre, T.A.; Rai, M.; Kumar, V.; Gathala, M.; Sharma, P.C.; Sharma, S.; Nagar, R.K.; Deshwal, S.; Singh, L.K.; Jat, H.S.; et al. Quantifying changes to the global warming potential of rice-wheat systems with the adoption of conservation agriculture in north-western India. Agric. Ecosyst. Environ. 2016, 219, 125–137. [Google Scholar] [CrossRef]

- Jat, S.L.; Parihar, C.M.; Singh, A.K.; Nayak, H.S.; Meena, B.R.; Kumar, B.; Parihar, M.D.; Jat, M.L. Differential response from nitrogen sources with and without residue management under conservation agriculture on crop yields, water-use and economics in maize-based rotations. Field Crop. Res. 2019, 236, 96–110. [Google Scholar] [CrossRef]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration. In Guidelines for Computing Crop Water Requirements; FAO Irrigation and Drainage Paper 56; FAO: Rome, Italy, 1998; p. 300. [Google Scholar]

- Salter, P.J. Methods of Determining the Moisture Characteristics of Soils. Exp. Agric. 1967, 3, 163–173. [Google Scholar] [CrossRef]

- Naik, S.K.; Maurya, S.; Bhatt, B.P. Soil organic carbon stocks and fractions in different orchards of eastern plateau and hill region of India. Agrofor. Syst. 2017, 91, 541–552. [Google Scholar] [CrossRef]

- Mondal, S.; Poonia, S.P.; Mishra, J.S.; Bhatt, B.P.; Karnena, K.R.; Saurabh, K.; Kumar, R.; Chakraborty, D. Short-term (5 years) impact of conservation agriculture on soil physical properties and organic carbon in a rice–wheat rotation in the Indo-Gangetic plains of Bihar. Eur. J. Soil Sci. 2020, 71, 1076–1089. [Google Scholar] [CrossRef]

- Chivenge, P.; Murwira, H.; Giller, K.; Mapfumo, P.; Six, J. Long-term impact of reduced tillage and residue management on soil carbon stabilization: Implications for conservation agriculture on contrasting soils. Soil Tillage Res. 2007, 94, 328–337. [Google Scholar] [CrossRef]

- Campbell, C.A.; Lafond, G.P.; Biederbeck, V.O.; Wen, G.; Schoenau, J.; Hahn, D. Seasonal trends in soil biochemical attributes: Effects of crop management on a Black Chernozem. Can. J. Soil Sci. 1999, 79, 85–97. [Google Scholar] [CrossRef]

- Ghimire, B.; Ghimire, R.; VanLeeuwen, D.; Mesbah, A. Cover crop residue amount and quality effects on soil organic carbon min-eralization. Sustainability 2017, 9, 2316. [Google Scholar] [CrossRef]

- Lou, Y.; Ren, L.; Li, Z.; Zhang, T.; Inubushi, K. Effect of Rice Residues on Carbon Dioxide and Nitrous Oxide Emissions from a Paddy Soil of Subtropical China. Water Air Soil Pollut. 2007, 178, 157–168. [Google Scholar] [CrossRef]

- Mandal, B.; Majumder, B.; Adhya, T.K.; Bandyopadhyay, P.K.; Gangopadhyay, A.; Sarkar, D.; Kundu, M.C.; Choudhury, S.G.; Hazra, G.C.; Kundu, S.; et al. Potential of double-cropped rice ecology to conserve organic carbon under subtropical climate. Glob. Chang. Biol. 2008, 14, 2139–2151. [Google Scholar] [CrossRef]

- Six, J.A.Ε.Τ.; Elliott, E.T.; Paustian, K. Soil macroaggregate turnover and microaggregate formation: A mechanism for C sequestra-tion under no-tillage agriculture. Soil Biol. Biochem. 2000, 32, 2099–2103. [Google Scholar] [CrossRef]

- Olk, D.; Cassman, K.; Schmidt-Rohr, K.; Anders, M.; Mao, J.-D.; Deenik, J. Chemical stabilization of soil organic nitrogen by phenolic lignin residues in anaerobic agroecosystems. Soil Biol. Biochem. 2006, 38, 3303–3312. [Google Scholar] [CrossRef]

- Bruelle, G.; Naudin, K.; Scopel, E.; Domas, R.; Rabeharisoa, L.; Tittonell, P. Short- to mid-term impact of conservation agriculture on yield variability of upland rice: Evidence from farmer’s fields in madagascar. Exp. Agric. 2015, 51, 66–84. [Google Scholar] [CrossRef]

- Bhattacharyya, R.; Prakash, V.; Kundu, S.; Srivastva, A.K.; Gupta, H.S. Effect of long-term manuring on soil organic carbon, bulk density and water retention characteristics under soybean-wheat cropping sequence in North-Western Himalayas. J. Ind. Soc. Soil Sci. 2004, 52, 238–242. [Google Scholar]

- Munkholm, L.J.; Schjønning, P.; Rasmussen, K.J.; Tanderup, K. Spatial and temporal effects of direct drilling on soil structure in the seedling environment. Soil Tillage Res. 2003, 71, 163–173. [Google Scholar] [CrossRef]

- Singh, V.K.; Dwivedi, B.S.; Singh, S.K.; Majumdar, K.; Jat, M.L.; Mishra, R.P.; Rani, M. Soil physical properties, yield trends and economics after five years of conservation agriculture-based rice-maize system in North-Western India. Soil Till. Res. 2016, 155, 133–148. [Google Scholar] [CrossRef]

- Venkatesh, M.S.; Hazra, K.K.; Ghosh, P.K.; Khuswah, B.L.; Ganeshamurthy, A.N.; Ali, M.; Singh, J.; Mathur, R.S. Long–term ef-fect of crop rotation and nutrient management on soil–plant nutrient cycling and nutrient budgeting in Indo–Gangetic plains of India. Arch. Agron. Soil Sci. 2017, 63, 2007–2022. [Google Scholar] [CrossRef]

- Parihar, C.; Jat, S.; Singh, A.; Kumar, B.; Singh, Y.; Pradhan, S.; Pooniya, V.; Dhauja, A.; Chaudhary, V.; Jat, M.; et al. Conservation agriculture in irrigated intensive maize-based systems of north-western India: Effects on crop yields, water productivity and economic profitability. Field Crop Res. 2016, 193, 104–116. [Google Scholar] [CrossRef]

- Choudhary, R.; Singh, P.; Sidhu, H.S.; Nandal, D.P.; Jat, H.S.; Jat, M.L. Evaluation of tillage and crop establishment methods inte-grated with relay seeding of wheat and mungbean for sustainable intensification of cotton-wheat system in South Asia. Field Crops Res. 2016, 199, 31–41. [Google Scholar] [CrossRef]

- Das, T.; Saharawat, Y.; Bhattacharyya, R.; Sudhishri, S.; Bandyopadhyay, K.; Sharma, A.; Jat, M. Conservation agriculture effects on crop and water productivity, profitability and soil organic carbon accumulation under a maize-wheat cropping system in the North-western Indo-Gangetic Plains. Field Crop Res. 2018, 215, 222–231. [Google Scholar] [CrossRef]

- Chen, G.; Kong, X.; Gan, Y.; Zhang, R.; Feng, F.; Yu, A.; Zhao, C.; Wan, S.; Chai, Q. Enhancing the systems productivity and water use efficiency through coordinated soil water sharing and compensation in strip-intercropping. Sci. Rep. 2018, 8, 10494. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.R.; Singh, R.; Dhyani, S.K. Conservation tillage and mulching for optimizing productivity in maize-wheat cropping sys-tem in the outer western Himalaya region—A review. Ind. J. Soil Conserv. 2015, 33, 35–41. [Google Scholar]

- Devasenapathy, P.; Senthilkumar, G.; Shanmugam, P.M. Energy management in crop production. Indian J. Agron. 2009, 54, 80–90. [Google Scholar]

- Lal, R. Carbon emission from farm operations. Environ. Int. 2004, 30, 981–990. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Y.; Zhang, X.; Tian, G. Carbon footprint analysis for mechanization of maize production based on life cycle assessment: A case study in Jilin Province, China. Sustainability 2015, 7, 15772–15784. [Google Scholar] [CrossRef]

| Treatments | Total Soil Organic Carbon (Mg C ha−1) | Carbon Sequestration Rate (Mg C ha−1 year−1) | ||||

|---|---|---|---|---|---|---|

| 0–0.15 m | 0.15–0.30 m | 0.30–0.45 m | 0.45–0.60 m | Total (0–0.60 m) | ||

| FL | 15.43 b | 11.97 a | 10.87 a | 8.63 a | 46.90 b | - |

| RF | 14.45 b | 11.16 b | 10.27 a | 7.95 a | 43.83 c | −0.61 b |

| CP | 14.81 b | 11.57 b | 10.95 a | 8.07 a | 45.40 bc | −0.30 b |

| CA1 | 18.59 a | 14.40 a | 9.94 a | 6.71 b | 49.63 a | 0.55 a |

| CA2 | 18.42 a | 13.55 a | 10.38 a | 7.74 ab | 50.08 a | 0.64 a |

| Treatments | Soil Organic Carbon Fraction (Mg C ha−1 Soil) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Very Labile Pool (VLC) | Labile Pool (LC) | |||||||||

| 0–0.15 m | 0.15–0.30 m | 0.30–0.45 m | 0.45–0.60 m | Total 0–0.60 m | 0–0.15 m | 0.15–0.30 m | 0.30–0.45 m | 0.45–0.60 m | Total 0–0.60 m | |

| FL | 5.19 b | 3.25 b | 3.11 b | 2.06 a | 13.61 b | 3.38 bc | 2.88 abc | 2.40 a | 2.24 a | 10.89 b |

| RF | 4.97 b | 3.12 b | 2.86 c | 1.96 a | 12.91 b | 3.22 c | 2.64 c | 2.17 ab | 2.22 a | 10.25 b |

| CP | 5.01 b | 3.20 b | 2.92 c | 1.95 a | 13.08 b | 3.27 c | 2.75 bc | 2.39 a | 2.30 a | 10.70 b |

| CA1 | 7.51 a | 4.96 a | 3.56 ab | 2.00 a | 18.03 a | 3.58 ab | 3.36 a | 1.98 b | 1.91 a | 10.82 b |

| CA2 | 7.90 a | 5.00 a | 3.74 a | 2.15 a | 18.78 a | 3.70 a | 3.19 ab | 2.53 a | 2.32 a | 11.74 a |

| Less labile pool (LLC) | Non-labile pool (NLC) | |||||||||

| FL | 2.96 a | 2.88 a | 2.67 a | 2.19 a | 10.70 a | 3.90 b | 2.96 bc | 2.69 a | 2.15 a | 11.70 ab |

| RF | 2.73 a | 2.68 a | 2.64 a | 1.90 a | 9.95 a | 3.52 b | 2.73 c | 2.61 a | 1.86 a | 10.73 b |

| CP | 2.86 a | 2.75 a | 2.92 a | 1.83 a | 10.36 a | 3.66 b | 2.88 bc | 2.72 a | 1.99 a | 11.26 ab |

| CA1 | 2.88 a | 2.49 a | 1.91 b | 1.15 b | 8.43 b | 4.62 a | 3.58 a | 2.48 a | 1.67 a | 12.35 a |

| CA2 | 2.25 b | 1.99 b | 1.54 b | 1.36 b | 7.13 c | 4.57 a | 3.35 ab | 2.58 a | 1.92 a | 12.42 a |

| Treatments | Active Carbon Pool (Mg ha−1) | ||||

|---|---|---|---|---|---|

| 0–0.15 m | 0.15–0.30 m | 0.30–0.45 m | 0.45–0.60 m | Total 0–0.60 m | |

| FL | 8.57 b | 6.13 b | 5.51 b | 4.30 a | 24.50 c |

| RF | 8.19 b | 5.76 b | 5.02 b | 4.18 a | 23.16 d |

| CP | 8.28 b | 5.95 b | 5.30 b | 4.25 a | 23.78 cd |

| CA1 | 11.09 a | 8.32 a | 5.54 b | 3.91 a | 28.85 b |

| CA2 | 11.59 a | 8.19 a | 6.27 a | 4.47 a | 30.52 a |

| Passive carbon pool (Mg ha−1) | |||||

| FL | 6.85 b | 5.85 a | 5.36 a | 4.34 a | 22.39 a |

| FP | 6.26 b | 5.41 a | 5.25 a | 3.76 ab | 20.67 ab |

| CP | 6.53 b | 5.62 a | 5.64 a | 3.82 ab | 21.62 a |

| CA1 | 7.49 a | 6.07 a | 4.39 b | 2.82 c | 20.78 ab |

| CA2 | 6.82 b | 5.34 a | 4.11 b | 3.28 bc | 19.56 b |

| Treatments | Carbon Left in Soil (Mg ha−1) | Carbon Build-Up (%) | Carbon Retention Efficiency (%) | ||||

|---|---|---|---|---|---|---|---|

| Total | Active Pool | Passive Pool | Total | Active Pool | Passive Pool | ||

| RF | −3.06 b | −1.34 c | −1.72 a | −6.57 b | −5.43 c | −7.64 a | −30.80 c |

| CP | −1.50 b | −0.72 c | −0.78 a | −3.20 b | −2.82 c | −3.49 a | −7.35 b |

| CA1 | 2.74 a | 4.35 b | −1.62 a | 5.85 a | 17.84 b | −7.33 a | 10.95 a |

| CA2 | 3.18 a | 6.02 a | −2.84 a | 6.82 a | 24.66 a | −12.64 a | 12.52 a |

| Treatments | Soil Microbial Biomass Carbon (µg g−1) | |||

|---|---|---|---|---|

| 0–0.15 m | 0.15–0.30 m | 0.30–0.45 m | 0.45–0.60 m | |

| FL | 93.6 b | 86.8 b | 48.5 a | 22.2 a |

| RF | 84.0 b | 82.4 b | 50.2 a | 19.7 a |

| CP | 88.3 b | 87.7 b | 56.0 a | 18.2 a |

| CA1 | 121.5 a | 100.3 ab | 54.3 a | 20.7 a |

| CA2 | 118.6 a | 109.0 a | 52.1 a | 19.4 a |

| Dehydrogenase activity (µg TPF g−1 day−1) | ||||

| FL | 188.6 a | 150.6 bc | 99.5 a | 65.2 a |

| RF | 168.5 b | 152.7 c | 93.4 a | 54.1 a |

| CP | 172.5 b | 155.6 bc | 101.7 a | 60.8 a |

| CA1 | 197.8 a | 165.6 ab | 108.2 a | 59.6 a |

| CA2 | 196.1 a | 171.8 a | 111.5 a | 55.8 a |

| Treatments | Rice Yield (Mg ha−1) | Mean | ||

|---|---|---|---|---|

| 2017–2018 | 2018–2019 | 2019–2020 | ||

| RF | 3.33 a | 3.77 ab | 3.44 b | 3.51 a |

| CP | 3.49 a | 4.03 a | 3.27 b | 3.60 a |

| CA1 | 2.74 b | 3.24 c | 3.68 ab | 3.22 b |

| CA2 | 2.55 b | 3.40 bc | 4.11 a | 3.35 ab |

| Mustard yield (Mg ha−1) | ||||

| CP | 0.29 a | 0.27 b | 0.31 b | 0.29 b |

| CA1 | 0.25 a | 0.25 b | 0.32 b | 0.28 b |

| CA2 | 0.27 a | 0.31 a | 0.39 a | 0.33 a |

| Blackgram yield (Mg ha−1) | ||||

| CP | 0.22 a | 0.23 a | 0.20 b | 0.22 a |

| CA1 | 0.19 a | 0.24 a | 0.21 ab | 0.21 a |

| CA2 | 0.21 a | 0.25 a | 0.23 a | 0.23 a |

| System rice equivalent yield (Mg ha−1) | Mean | |||

| CP | 5.05 a | 5.56 a | 4.80 b | 5.14 a |

| CA1 | 4.10 b | 4.77 b | 5.28 b | 4.72 b |

| CA2 | 4.04 b | 5.11 ab | 5.94 a | 5.03 a |

| Treatments | Rice (kg ha−1 mm−1) | |||

|---|---|---|---|---|

| 2017–2018 | 2018–2019 | 2019–2020 | Mean | |

| RF | 8.36 a | 9.87 ab | 9.02 b | 9.08 bc |

| CP | 8.76 a | 10.55 a | 8.57 c | 9.30 b |

| CA1 | 7.01 c | 8.93 b | 10.69 b | 8.88 c |

| CA2 | 7.32 b | 10.13 a | 12.40 a | 9.95 a |

| Mustard (kg ha−1 mm−1) | ||||

| CP | 1.01 a | 1.12 a | 1.01 c | 1.05 c |

| CA1 | 0.99 b | 1.13 b | 1.17 b | 1.09 b |

| CA2 | 1.06 a | 1.41 a | 1.42 a | 1.30 a |

| Blackgram (kg ha−1 mm−1) | ||||

| CP | 0.84 b | 0.82 c | 0.77 c | 0.81 c |

| CA1 | 0.79 c | 0.90 b | 0.89 b | 0.86 b |

| CA2 | 0.87 a | 0.93 a | 0.96 a | 0.92 a |

| System (REY kg ha−1 mm−1) | ||||

| CP | 5.32 a | 6.20 a | 5.06 c | 5.53 b |

| CA1 | 4.60 c | 5.63 b | 6.16 b | 5.46 b |

| CA2 | 4.76 b | 6.23 a | 7.04 a | 6.01 a |

| Parameters | Treatments | Crops | ||||

|---|---|---|---|---|---|---|

| Rice | Mustard | Blackgram | Mean | System | ||

| Input energy (IE, MJ ha−1) | CP | 12,404 a | 6054 a | 5046 a | 7835 a | 23,504 a |

| CA1 | 10,922 b | 5325 b | 4473 b | 6907 b | 20,721 b | |

| CA2 | 9812 b | 5320 b | 4438 b | 6523 b | 19,570 b | |

| Mean | 11,046 | 5566 | 4652 | |||

| Output energy (OE, MJ ha−1) | CP | 112,023 b | 17,396 b | 9956 a | 46,459 b | 139,376 b |

| CA1 | 129,093 ab | 18,023 b | 10,957 a | 52,691 ab | 158,073 ab | |

| CA2 | 144,308 a | 21,808 a | 11,301 a | 59,139 a | 177,417 a | |

| Mean | 128,475 | 19,076 | 10,738 | |||

| Net energy (NE, MJ ha−1) | CP | 99,619 b | 11,343 b | 4910 b | 38,624 b | 115,872 b |

| CA1 | 118,170 ab | 12,698 b | 6484 a | 45,784 ab | 137,352 ab | |

| CA2 | 134,495 a | 16,488 a | 6863 a | 52,616 a | 157,847 a | |

| Mean | 117,428 | 13,510 | 6086 | |||

| Energy use efficiency (EUE) | CP | 9.42 b | 2.88 c | 1.97 b | 4.76 c | 6.00 b |

| CA1 | 12.15 b | 3.38 b | 2.45 a | 5.99 b | 7.72 ab | |

| CA2 | 15.40 a | 4.10 a | 2.54 a | 7.35 a | 9.21 a | |

| Mean | 12.32 | 3.45 | 2.32 | |||

| Energy productivity (EP, kg MJ−1) | CP | 0.276 b | 0.126 c | 0.151 c | 0.184 c | 0.207 b |

| CA1 | 0.347 b | 0.148 b | 0.181 b | 0.225 b | 0.258 ab | |

| CA2 | 0.438 a | 0.180 a | 0.196 a | 0.271 a | 0.307 a | |

| Mean | 0.354 | 0.151 | 0.176 | |||

| Specific energy (SE, MJ kg−1) | CP | 3.98 a | 7.96 a | 6.63 a | 6.19 a | 5.01 a |

| CA1 | 3.06 ab | 6.80 b | 5.53 b | 5.13 b | 3.95 b | |

| CA2 | 2.45 b | 5.57 c | 5.12 c | 4.38 c | 3.33 b | |

| Mean | 3.16 | 6.78 | 5.76 | |||

| Energy profitability (EPr) | CP | 8.42 b | 1.88 c | 0.97 b | 3.76 c | 5.00 b |

| CA1 | 11.15 b | 2.38 b | 1.45 a | 4.99 b | 6.72 ab | |

| CA2 | 14.40 a | 3.10 a | 1.54 a | 6.35 a | 8.21 a | |

| Mean | 11.32 | 2.45 | 1.32 | |||

| Parameters | Treatments | Crops | ||||

|---|---|---|---|---|---|---|

| Rice | Mustard | Blackgram | Mean | System | ||

| Carbon footprint (CFs, CO2-e kg ha−1) | CP | 1670 a | 615 a | 458 a | 914 a | 2743 a |

| CA1 | 1585 b | 592 a | 421 b | 866 b | 2598 b | |

| CA2 | 1297 c | 593 a | 421 b | 770 c | 2311 c | |

| Mean | 1517 | 600 | 433 | |||

| CFy (CO2-e kg Mg−1) | CP | 525 a | 818 a | 601 a | 648 a | 1944 a |

| CA1 | 437 b | 756 a | 521 b | 571 b | 1714 b | |

| CA2 | 320 c | 624 b | 483 b | 476 c | 1427 c | |

| Mean | 427 | 733 | 535 | |||

| Carbon input (CI, kg ha−1) | CP | 451 a | 166 a | 124 a | 247 a | 741 a |

| CA1 | 428 b | 160 a | 114 b | 234 b | 701 b | |

| CA2 | 350 c | 160 a | 114 b | 208 c | 624 c | |

| Mean | 410 | 162 | 117 | |||

| Carbon output (CO, kg ha−1) | CP | 3354 b | 432 b | 305 a | 1364 b | 4091 b |

| CA1 | 3872 ab | 447 b | 336 a | 1552 ab | 4655 ab | |

| CA2 | 4328 a | 541 a | 346 a | 1738 a | 5215 a | |

| Mean | 3852 | 473 | 329 | |||

| CSI (Carbon sustainability index) | CP | 6.43 b | 1.60 b | 1.47 b | 3.17 c | 4.52 c |

| CA1 | 8.03 b | 1.79 b | 1.97 a | 3.93 b | 5.63 b | |

| CA2 | 11.40 a | 2.39 a | 2.04 a | 5.28 a | 7.38 a | |

| Mean | 8.62 | 1.93 | 1.83 | |||

| Carbon efficiency (CE) | CP | 7.43 b | 2.60 b | 2.47 b | 4.17 c | 5.52 c |

| CA1 | 9.03 b | 2.79 b | 2.97 a | 4.93 b | 6.63 b | |

| CA2 | 12.40 a | 3.39 a | 3.04 a | 6.28 a | 8.38 a | |

| Mean | 9.62 | 2.93 | 2.83 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naik, S.K.; Mali, S.S.; Jha, B.K.; Kumar, R.; Mondal, S.; Mishra, J.S.; Singh, A.K.; Biswas, A.K.; Choudhary, A.K.; Choudhary, J.S.; et al. Intensification of Rice-Fallow Agroecosystem of South Asia with Oilseeds and Pulses: Impacts on System Productivity, Soil Carbon Dynamics and Energetics. Sustainability 2023, 15, 1054. https://doi.org/10.3390/su15021054

Naik SK, Mali SS, Jha BK, Kumar R, Mondal S, Mishra JS, Singh AK, Biswas AK, Choudhary AK, Choudhary JS, et al. Intensification of Rice-Fallow Agroecosystem of South Asia with Oilseeds and Pulses: Impacts on System Productivity, Soil Carbon Dynamics and Energetics. Sustainability. 2023; 15(2):1054. https://doi.org/10.3390/su15021054

Chicago/Turabian StyleNaik, Sushanta Kumar, Santosh Sambhaji Mali, Bal Krishna Jha, Rakesh Kumar, Surajit Mondal, Janki Sharan Mishra, Arun Kumar Singh, Ashis Kumar Biswas, Arbind Kumar Choudhary, Jaipal Singh Choudhary, and et al. 2023. "Intensification of Rice-Fallow Agroecosystem of South Asia with Oilseeds and Pulses: Impacts on System Productivity, Soil Carbon Dynamics and Energetics" Sustainability 15, no. 2: 1054. https://doi.org/10.3390/su15021054

APA StyleNaik, S. K., Mali, S. S., Jha, B. K., Kumar, R., Mondal, S., Mishra, J. S., Singh, A. K., Biswas, A. K., Choudhary, A. K., Choudhary, J. S., Hans, H., Das, A., Babu, S., Layek, J., Upadhyaya, A., Bhatt, B. P., & Chaudhari, S. K. (2023). Intensification of Rice-Fallow Agroecosystem of South Asia with Oilseeds and Pulses: Impacts on System Productivity, Soil Carbon Dynamics and Energetics. Sustainability, 15(2), 1054. https://doi.org/10.3390/su15021054