Abstract

The two-stroke engine has many advantages, including low maintenance costs, a high specific power, and a simple structure, compared to four-stroke engines. Since two-stroke engines use a fuel–oil mixture instead of fuel alone, two-stroke engines do not need an oil pan. Unlike the lubrication system in four-stroke engines, the moving parts are lubricated with a fuel–lubricant mixture. As long as the engine is running, the fuel and lubricant burn together. The combustion of this fuel–lubricant mixture can adversely affect exhaust emissions and cause excessive carbon deposits on the spark plug. In this paper, experiments were carried out using different amounts of oil (100:3, 100:3.5, and 100:4 vol.) in a two-stroke gasoline-powered generator. In addition, we attempted to improve the lubricant’s properties by adding hBN (0.5% vol. or 1.3% wt.) to the lubricant. It was observed that the flash point and pour point did not change as a result of the addition of hBN to the lubricant, and the density and viscosity index increased linearly depending on the amount of hBN. In a series of experiments, the generator was examined for performance and emissions. With the addition of hBN, there was a significant decrease in the specific fuel consumption and exhaust gas temperature, the CO2 increased, and the CO and HC decreased. These results show that hBN improves combustion. As a result, it was reported that reducing the amount of lubricant leads to increased emissions and decreased performance. It was found that when 0.5% hBN by volume is added to the lubricant, the lubricating property improves, and thus, the amount of oil added to the fuel can be reduced to an acceptable level (from 100:4 to 100:3.5) without causing mechanical failure in the engine.

1. Introduction

Although the popularity of internal combustion engines has decreased due to the tendency toward electrification in vehicles, internal combustion engines are predicted to be used for many more years due to their widespread use. In addition to vehicles, internal combustion engines are used extensively in agricultural systems, industrial systems, and electricity generation systems. Although the share of two-stroke engines in all internal combustion engines is not exactly known, their value to the world economy is estimated to be tens of billions of US dollars.

Two-stroke engines, which have been used since the 1880s, have many advantages, such as low maintenance costs, a high specific power (power-to-weight ratio), and the ability to operate in different positions (vertical or horizontal) [1,2]. Two-stroke engines are frequently preferred for simple agricultural machines that are used in processes such as lawn mowing, sawing, spraying, and trimming; electric generators (especially with a low power capacity); and transportation vehicles such as mopeds. These types of two-stroke engines are generally crank-compressed, gasoline-powered, carbureted, air-cooled, and naturally aspirated [3,4]. Since the moving parts of two-stroke engines are lubricated with lubricant that is added to the fuel, they do not need an oil pan (sump) like four-stroke engines [5]. As long as the engine is running, the fuel and lubricant burn together. The combustion of this fuel–lubricant mixture can cause excessive carbon deposits on the spark plug and adversely affect exhaust emissions [6,7].

Two-stroke engine lubricant directly affects exhaust emissions and engine performance since it is mixed into the fuel and burned together with the fuel. For this reason, two-stroke engine lubricants must have different characteristics than four-stroke engine oils. When four-stroke engine lubricant is mixed with gasoline, gumming occurs within a few days [8,9]. However, the stickiness requirement is different in two-stroke engine lubricant than in four-stroke engine lubricant. The recommended fuel/lubricant ratio for a two-stroke engine varies based on the engine manufacturer and the type of lubricant and is usually between 16:1 and 100:1. When a fuel/lubricant ratio that is different than the recommended one is used, it has negative effects on the engine life, engine performance, and exhaust emissions [1,8]. Compared to four-stroke engines, two-stroke engines have a higher lubricant consumption. Lubricant consumption in four-stroke engines increases or decreases depending on the usage characteristics of the engine. However, in two-stroke engines, the oil added to the fuel is ejected from the exhaust whether it burns or not. Therefore, lubricant consumption in two-stroke engines is not related to the operating characteristics of the engine. For this reason, it is desirable to use the least possible amount of lubricant in two-stroke engines [1]. Two-stroke engine lubricant can be mineral, semi-synthetic, or fully synthetic. Although fully synthetic lubricants are recommended for high performance in two-stroke engines today, mineral or semi-synthetic lubricants are often preferred because they are cheaper than fully synthetic ones. In addition, the amount of lubricant to be mixed into the fuel varies according to the preferred lubricant type.

Although the addition of lubricant to two-stroke engines negatively affects emissions, various fuel injection strategies, air humidification, and various gas exchange strategies, as well as systems that are similar to the lubrication system in four-stroke engines, are being developed to minimize this environmental problem. Despite all these efforts, two-stroke engines operating with fuel–lubricant mixtures are still widely used [1,2]. For this reason, in addition to the development of existing engine technology, the development of lubricants that regulate emissions or have better lubricating properties in two-stroke engines should also be considered an important research topic.

As an alternative to today’s engine lubricants, rapeseed [10], jatropha [11,12], palm [13], and wild mustard [14] non-edible and/or eco-friendly plant-based bio-lubricants are being produced, and efforts are being made to improve their parameters and characteristics, such as spark plug fouling [6], emissions [6,10,13], thermal aging [11,12], friction [11,12], wear [12,13], viscosity [13], foaming characteristics [13], engine performance [10,13], and tribological behaviors [12]. However, in order to improve the properties of the existing engine lubricant, the use of nano-additives such as Al2O3 (aluminum oxide) [15,16,17], TiO2 (titanium oxide) [15,16,17], MoS2 (molybdenum disulfide) [18,19], WS2 (tungsten disulfide) [18], Cr2AlC (chromium aluminum carbide) [19], La(OH)3 (lanthanum(III) hydroxide) [20], graphene oxide [20], ZnO (zinc oxide) [21], CuO (copper oxide) [22], and hBN (hexagonal boron nitride) [23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42] is becoming widespread. Each of the additives listed here improves certain properties of the lubricant and may have advantages or disadvantages over each other. hBN is an additive with significant potential to improve the properties of lubricants. The use of nano-additives such as BN (boron nitride) [23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42] is also becoming widespread. It was reported that, thanks to these nano-additives (hBN and others), the tribological and thermo-physical properties of the oil, such as the anti-wear performance, friction coefficient, viscosity, and thermal conductivity [15,19,20,21,22,24,26,27,28,34,35,36,37,41,42], are improved. On the other hand, it was stated that nano-additive oil has effects such as a reduction in the total friction power losses, an increase in the mechanical efficiency, an improvement in fuel economy, and increased engine torque in internal combustion (gasoline or diesel) engines [13,14,16,17,18,26,43]. The sizes of these nano-additives are in the range of 10–120 nm, and 0.2–3% by volume is added to the oil [15,24,31,43].

In general, nano-additives added to lubricants can be successfully separated for reuse via various mechanical and chemical methods after the life of the lubricant is completed. However, some of the internal combustion engine oils are discharged to the environment from the exhaust line during use in the engine. Since the fuel–lubricant mixture is used in two-stroke engines, almost all of the lubricant is discharged to the environment from the exhaust line. In particular, the need to separate nano dimensional metal and its derivative materials, whose environmental effects are unknown, may occur before they are discharged from the exhaust line to the environment. In this case, it may be possible to physically or chemically collect/dispose of these nano-sized materials by developing systems such as various filters and catalytic methods [44,45].

Today, there are many studies on the use of hexagonal-shaped BN (hBN) nano-powders as additives in lubricants [19,23,24,25,26,27,28,29,30,31,33,38,39,40,41,42,43,46,47,48,49]. hBN is commonly produced as 30–100 nm particles. The hexagonal nature of BN particles gives this material an excellent lubricating property. hBN is also called “white graphite” due to its similar and superior properties when compared to graphite. Some of the superior features of hBN are a low friction coefficient, thermal expansion, and a high thermal conductivity, temperature stability, and load capacity [23,24,25,26,28,31,46,49]. When the tribological properties of the lubricant are examined by blending the 70 nm hBN with the engine lubricant at a certain rate (usually 0.5 vol.% or 1 wt. %), it is known that the friction coefficient decreases by approximately 50%, and the viscosity index increases by approximately 3% [40,41]. In order to prevent sedimentation, a certain amount of oleic acid (usually 0.3% vol.) is used together with hBN as a surfactant. However, a visible sedimentation was observed when hBN added to engine oil was kept at room temperature for approximately 720 h [23,24,34]. When the effect of adding hBN to lubricant on the performance of internal combustion engines was examined, it was determined that 0.5 vol. % of hBN achieved the best results [43]. It is extremely important to consider the nanoparticle additive in the lubricant and to examine its effect on the tribological and performance properties of mechanical systems. This was characterized via UV spectroscopy and differential scanning calorimetry by adding 0.5–1% (wt.) hBN for a diesel engine lubricant. As a result of the characterization, it was reported that 1% wt. hBN was stable. However, it is an important result that there is a significant improvement in the performance and emission characteristics of the engine with the addition of 1% wt. hBN to the lubricant [26,27]. In an experimental study on the addition of hbN to lubricant for steel/steel friction, it was observed that the addition of 0.7% wt. hBN significantly reduced the friction coefficient and the wear scar diameter [37,40]. The amount of hBN added to the lubricant is also an important parameter. In this study, in four different dimensions, the proposed parameter to define the particle cluster is not only the average particle size, but also the exact particle size distribution [29]. Among the studies on hBN, the effects of adding 3% wt. 60 nm hBN and 1% wt. 500 nm hBN into the grease lubricant were compared. In experimental studies, it was observed that there is a decrease of approximately 20% in the diameter of the wear scar and the friction coefficient decreases somewhat [30]. There are not only studies on conventional lubricants. The issue of the usability of vegetable oils as base oils is still current due to the ecological damage caused by mineral oils. In a study on the effect of hBN on the tribological properties of palm oil, 70 nm hBN nanoparticles were blended at various concentrations ranging from 0% to 0.5% (vol.), the obtained lubricants were evaluated tribologically, and a characteristic improvement was reported [31]. Especially in machine manufacturing, various sustainable production techniques are applied to make processes more environmentally friendly. For example, cutting fluid is used to facilitate the cutting process during the processing of difficult-to-cut materials such as titanium alloys. The authors investigated the effects on cutting quality by adding different concentrations of hBN to conventional cutting fluid, and the minimum amount of cutting fluid was determined. As a result, it was proven that using the minimum amount of lubrication with hBN nanoparticles can reduce both the shear force and the surface roughness [32]. Instead of only adding hBN to the lubricant, materials such as graphene, graphene oxide, molybdenum disulfide, copper, and carbon fiber can also be used with hBN. Such applications are applied to improve the tribological behavior of both petroleum-based and bio-based lubricants [33,34,35,36,37,38,39].

Researchers’ consideration for the effects of hBN on lubricants can be reviewed. Before starting this study, the effect of hBN on lubrication rates was investigated. Internal combustion engines also work with metal–metal contact. In addition to this metal–metal contact, the thermal effect can play an undeniably active role. For metal–metal contact, synergistic analysis (worn surface observation, surface wettability test, and Stribeck stress) is generally preferred. The viscosity of the mixture is determined with a viscometer. A ball tribometer is used to determine the tribological properties. The point to be considered here is to prevent agglomeration [40].

Although hBN structurally resembles graphite and alumina in appearance, it has some superior properties. Compared to ceramic materials, it has a very low density. In addition, since it is an inert material, it does not enter into chemical reaction, it is resistant to high temperatures, it has good lubricating properties, and it is not toxic, which is an important reason for this study. However, many researchers have examined the lubricating properties of hBN so far [23,24,41,42,43].

Previous studies have shown that hBN as a nano-additive improves the tribological properties of lubricants, and when these lubricants are used in internal combustion engines, it provides improved engine performance and reduced emissions. However, although two-stroke engines are widely used around the world, the effect of using hBN as a nano-additive on engine performance has not been sufficiently mentioned in the literature until now, because the lubricant is also a part of the combustion process in two-stroke engines.

The fuel and lubricant used in internal combustion engines are generally petroleum based. The main environmental threat in internal combustion engines is the pollutant gases that form as a result of combustion. Various technologies are being developed for the disposal of these polluting gases. In addition, sustainable biofuels using plant or animal sources are also produced, and there are many studies on this topic in the literature [50,51,52,53]. Similarly, studies on bio-lubricants use plant or animal sources [54,55,56]. However, this paper is focused on investigating the ability to reduce the amount of lubricant that should be used without sacrificing engine performance with the nano-additive used in the lubricant, and thus, the ability to reduce the environmental impact caused by two-stroke engines.

2. Experimental Setup and Procedures

2.1. Experimental Setup

A gasoline two-stroke power generator, the specifications of which are given in Table 1, is used for the experiments.

Table 1.

Technical specifications of the power generator [57].

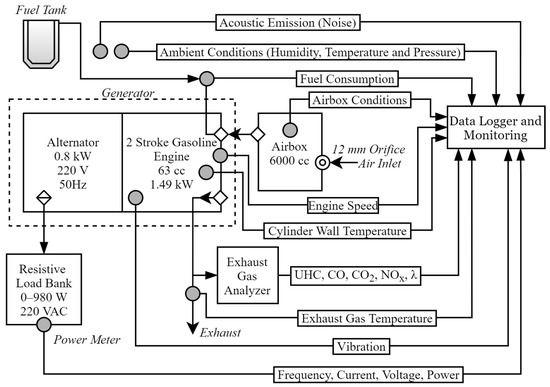

In the experimental setup, shown schematically in Figure 1, an airbox with a volume of 0.006 m3 (approximately 100 times the stroke volume) was used for the measurement of air consumption. K-type thermocouple was used for exhaust gas temperature measurement. Fuel consumption measurement was made volumetrically, and a simple setup was created using level sensors for measurement. The weather sensors were used to measure atmospheric and airbox conditions (humidity, temperature, and pressure). An exhaust gas analyzer was used for exhaust gas analysis (HC, CO, and CO2) [58]. In order to operate the generator under different load conditions, a resistive load bank and a power meter were used to keep electrical values such as frequency, current, voltage, and power under control. For the instant recording of experimental data, the LattePanda development board, which contains both a microprocessor (Intel Cherry Trail Z8350, Quad Core, 1.8 GHz, 64 bit) and a microcontroller (Atmega 32u4, 16 MHz, 8 bit, 26 GPIO), was programmed and used as a data logger [59]. The schematic of the experimental setup is given in Figure 1, the characteristics of the emission device used in the experiments are given in Table 2, and the characteristics of the instruments used in the experimental setup are given in Table 3.

Figure 1.

Schematical view of the experimental setup.

Table 2.

Technical specifications of the exhaust gas analyzer [58].

Table 3.

Some properties of the instruments used in the experimental setup [59,60,61,62,63,64].

A number of modifications were made to the power generator in order to position the measuring equipment. In order to measure the exhaust emission, the exhaust muffler was removed from the exhaust pipe, and a part was added that allows for the emission device probe and exhaust temperature thermocouple to be attached instead. Again, the filter assembly on the intake air inlet was removed, and the airbox assembly was placed in its place. A fuel consumption measuring device is located instead of the fuel tank. The power generator was run in factory settings.

2.2. Lubricant and Fuel–lubricant Mixture Preparation

In this part, first of all, the hBN was mixed with the lubricant and then the prepared lubricant was mixed with the fuel and made usable in the engine. For this study, a 70 nm hBN nano-powder (Table 4) was mixed with mineral two-stroke lubricant (Table 5). Oleic acid (Table 6) was used as a surfactant to prevent sedimentation of the hBN nano-powder in the lubricant. The sonication method was used to prepare this mixture.

Table 4.

Properties of the hexagonal boron nitride [65].

Table 5.

Properties of the mineral 2-stroke lubricant [66].

Table 6.

Properties of the oleic acid [67].

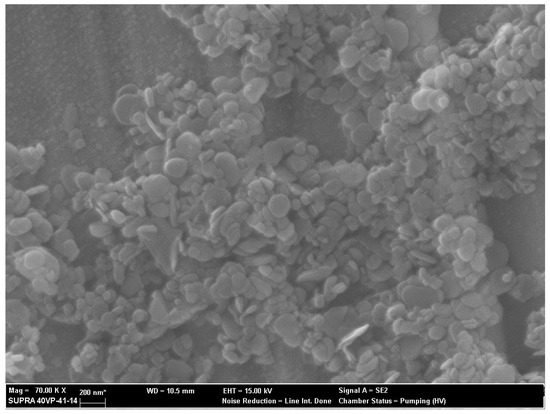

hBN nano-powder was purchased from a local supplier in Türkiye, and the nanoparticle’s morphology is hexagonal, as shown in Figure 2, with an average particle size of 70 nm. A Zeiss Supra 40VP Field Emission Scanning Electron Microscope was used to capture the image in Figure 2.

Figure 2.

The nanostructure of hexagonal boron nitride.

In this experiment, 5 mL (11.25 g) of hBN and 3 mL of oleic acid were used per liter of lubricant. The amounts of hBN and surfactant to be added to 1 L of lubricant were determined by compiling amounts from previous studies [15,16,17,18,19,20,21,22,23,24,25,26,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47]. Lubricant, hBN, and oleic acid were mixed first with a magnetic stirrer (Thermomac TM12, 650 rpm) for 12 h and then with an ultrasonic homogenizer (Bandelin RK-100, 35 kHz, 80 W) for 30 min.

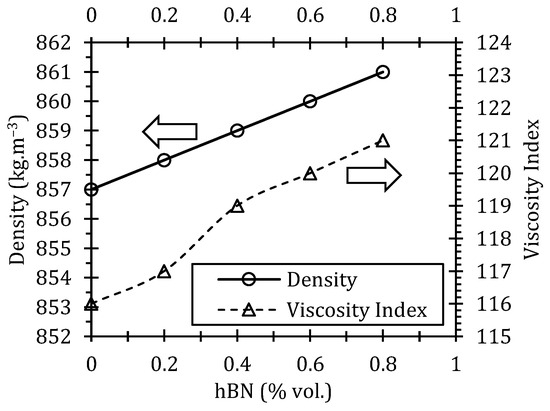

Various tests were applied to examine the effect of hBN additive on the properties of the lubricant. As a result of these tests, it was determined that the flash point and pour point did not change with the addition of hBN, and the density and viscosity index increased linearly depending on the amount of hBN (Figure 3). The sedimentation of hBN in lubricant is a known problem that was noted in previous studies [24,25,26,29]. It was observed that there was no visible sedimentation when the mixtures prepared for the experimental study were kept at room temperature for 120 h. In fact, when previous studies were examined, it was seen that the reasonable time for sedimentation observation is 720 h. In practice, it is not possible to keep the prepared mixture for such a long time. Even if precipitation occurs during this period, it is insignificant for the scope of this study. However, since the lubricant obtained in this study is used by mixing with the fuel right after it is prepared and the lubricant is not stored in any oil pan (sink) as in four-stroke engines, it was assumed that sedimentation did not occur.

Figure 3.

Variation of density and viscosity index depending on amount of hBN in lubricant.

A UV spectrometer (Optizen, 190–1100 nm) was used for the dispersion stability analysis of the reference lubricant (lubricant) and prepared lubricant (lubricant + hBN). The result of the UV spectroscopy analysis is shown in Figure 4. It was noticed that the lubricant and the lubricant with hBN showed a higher absorbance value of 4 (a.u). However, the absorbance trend of the reference lubricant started decreasing from the wavelength of 550 nm and reached up to 0.2 (a.u). In addition, it was observed that the absorbance values for the prepared lubricant were stable for up to 580 nm in wavelength and started to decrease up to 1.8 (a.u). The researchers of [26] said that the absorbance value of any fluid is directly associated with the dispersion stability of nanoparticles in the particular fluid; hence, the prepared lubricant showed a stronger dispersion stability and was observed to be well dispersed.

Figure 4.

UV spectroscopy analysis of lubricants (reference and prepared).

Lubricants were mixed with 95 RON regular gasoline at ratios of 100:4, 100:3.5, and 100:3 (vol). Accordingly, six experimental fuel–lubricant mixtures were obtained, three of which added hBN. The fuel–lubricant mixture was prepared via mixing with a mechanical stirrer (Isolab, 800 rpm) for 10 min.

2.3. Experimental Procedure

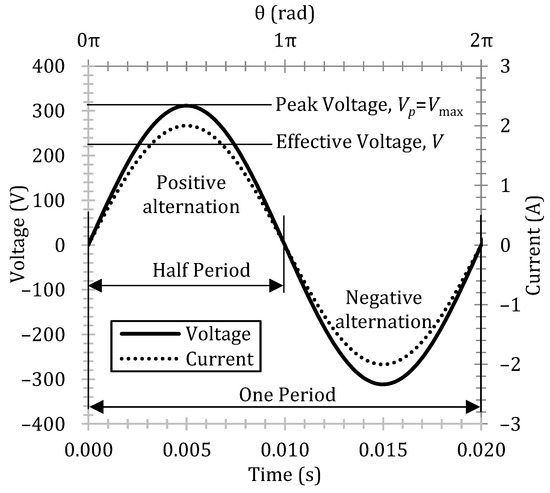

A constant speed generator (50 Hz, 3000 rpm) was used in the experiments for this study. The voltage and current curves of the alternator of a power generator for the resistive load are shown in Figure 5.

Figure 5.

Voltage and current waveforms of power generator alternator for resistive load.

Here, the peak voltage is the voltage value displayed with the oscilloscope. Electrical devices are generally labeled with effective voltage, and there is a relationship between the peak voltage and effective voltage. The effective voltage of the power generator used is 220 VAC. Accordingly, the power expression for the resistive load can be calculated as follows:

Here, can be accepted, and is the electrical power. In the generator, there is a mechanical connection between the alternator and the internal combustion engine. It is known that the mechanical efficiency here is . Accordingly, the engine power can be calculated as follows:

For example, when , , and . According to the standard document [68], the environmental correction factor () should be calculated depending on external factors (humidity, pressure, and temperature) in internal combustion engine tests.

Here, , , and are the dry pressure, temperature, and relative humidity of the air in the experimental environment, respectively. It is desirable that the value calculated here is in the range of 0.93–1.07. Accordingly, the corrected power for the internal combustion engine is expressed as follows:

The specific fuel consumption () is expressed as the ratio of fuel consumption () to .

In this study, three different fuel–lubricant values were experienced for five different electrical power values, and the effects of hBN on emission and performance were investigated. The engine speed was adjusted by controlling the alternator frequency for each power value. In addition, the stable load conditions are provided by the external and continuous cooling of the resistive load bank.

3. Results and Discussion

The oleic acid used here is actually a boundary lubricant and is frequently encountered in the literature [23,24,26]. In order to determine whether it has an effect on the performance change in engine tests, only oleic acid was added to the lubricant and compared with the reference lubricant. In the experimental study, it was reported that the addition of oleic acid did not have a significant effect on the engine performance. Therefore, the effects of hBN on engine performance could be tested in this study.

The fuel consumption change depending on the load Is shown in Figure 6. Fuel consumption increases with the load. However, although hBN is used as a lubricant additive, the lubricant is also burned with the fuel in two-stroke engines. Therefore, it is seen that hBN has a reducing effect on fuel consumption. In addition, as the lubricant ratio in the fuel is reduced, the fuel consumption increases. However, it seems possible to use a lower ratio of lubricant with the addition of hBN to the lubricant. In other words, it is possible to use the ratio of 100:3.5 by adding hBN to the lubricant instead of the reference ratio of 100:4.0. This means that oil consumption can be reduced by 12.5% thanks to hBN, provided that it provides the same performance under the same conditions. For low engine loads, the effect of hBN on fuel consumption appears more clearly.

Figure 6.

Fuel consumption change depending on load.

The specific fuel consumption is a fundamental expression of efficiency for internal combustion engines, and it is desired to be as low as possible. The specific fuel consumption tends to increase as the maximum torque and maximum power conditions are approached. The specific fuel consumption change depending on the load is shown in Figure 7. As the load increases, the specific fuel consumption decreases. However, as the amount of lubricant in the fuel decreases, the specific fuel consumption increases. When hBN is added to the lubricant, the specific fuel consumption is reduced. The probable reason for this is that the hBN additive improves the lubrication, thus increasing the engine performance. In addition, it seems possible to use a lower ratio of lubricant with the addition of hBN to the lubricant.

Figure 7.

Specific fuel consumption change depending on load.

An increase in the excess air ratio means that the in-cylinder mixture becomes poorer, that is, the amount of fuel (hence the amount of lubricant) in the air decreases. This value changes depending on the power demand of the user. Since the lubricant in two-stroke engines is also a component of the combustion process, the variation in the excess air coefficient can also be used to comment on the combustion process. The change in the excess air ratio depending on the load is shown in Figure 8. According to Table 1, the maximum power of the internal combustion engine is 1490 W. However, this power value can be reached at operating conditions higher than 3000 rpm. Therefore, the engine is operating under partial load conditions. As the engine load increases, the excess air ratio increases. However, as the amount of lubricant in the fuel decreases, the excess air ratio increases. It is observed that the excess air ratio increases significantly when hBN is added to the lubricant. With the addition of hBN, the engine operating conditions become closer to full combustion conditions. With the addition of hBN to the lubricant, the engine also operates with a high excess air ratio. At the same load conditions, it is seen that hBN has a positive effect on combustion and, therefore, on engine performance.

Figure 8.

Excess air ratio change depending on load.

The variation of the exhaust gas temperature depending on the load is shown in Figure 9. As the load increases, the exhaust gas temperature rises. It can be stated that the addition of hBN has a lowering effect on the exhaust gas temperature, especially in high load conditions. Reducing the amount of lubricant in the fuel increases the exhaust gas temperature. Based on the graphs above, it can be said that the addition of hBN not only improves the properties of the lubricant, but also improves combustion.

Figure 9.

Exhaust gas temperature change depending on load.

The engine performance results here show that the addition of hBN to the lubricant not only improves the tribological properties of the lubricant, but also partially improves the engine performance. This situation is compatible with the results in the literature, e.g., [23,24,26,28,43].

In this paper, the CO2, CO, and HC values were measured as exhaust emissions. In Figure 10, the change in CO2 depending on the load is examined. As it is known, the high CO2 level in a combustion event is an indication that complete combustion is approaching. In general, it is seen that the CO2 value tends to increase as the load increases. However, as the ratio of lubricant in the fuel decreases, the CO2 value increases. This shows that the lubricant has a negative effect on the combustion characteristics. However, the addition of hBN to the lubricant causes an increase in CO2. In addition, it seems possible to use a lower ratio of lubricant with the addition of hBN to the lubricant.

Figure 10.

CO2 emission change depending on load.

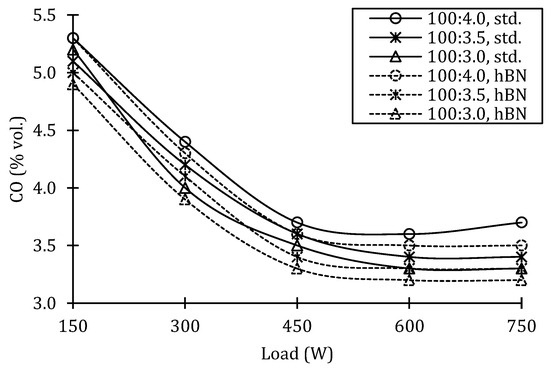

In Figure 11, the change in CO depending on the load is examined. As it is known, CO is a product of incomplete combustion. As the load increases, the CO value tends to decrease. As the ratio of lubricant in the fuel decreases, the CO value decreases. In addition, the addition of hBN to the lubricant causes a decrease in CO emissions. In addition, it seems possible to use a lower ratio of lubricant with the addition of hBN to the lubricant.

Figure 11.

CO emission change depending on load.

In Figure 12, the change in the unburned HC depending on the load is examined. As the load increases, the HC tends to decrease. As the lubricant ratio in the fuel decreases, the HC decreases. In addition, the addition of hBN to the lubricant causes a decrease in HC emissions. In addition, it seems possible to use a lower ratio of lubricant with the addition of hBN to the lubricant.

Figure 12.

HC emission change depending on load.

In general, the addition of hBN to the lubricant improves both the characteristics of the lubricant and the combustion. Thus, it was observed that both the performance and emissions were reduced. In general, it is desirable to increase CO2 emissions and decrease HC and CO emissions in an internal combustion engine. Here, the parameter that affects the emission values is definitely the amount of lubricant in the fuel. It is clearly seen that with the reduction in the amount of lubricant, there is an improvement in the emissions. When talking about emissions here, it should be taken into account that hBN is also exhausted into the environment. However, considering that the amount of lubricant in the fuel is 4% and the amount of hBN in the oil is 0.5%, there is 0.45 g of hBN in each liter of fuel. It is currently unpredictable whether this amount will cause environmental and health problems if it is released into the environment. However, since it is known that hBN is not toxic and does not react chemically, this value was ignored for this study, and a study was not conducted on it. Today, mechanical or chemical systems in which these nanoparticles can be selected/collected from the exhaust gases are developed, e.g., [44,45], and thus, recovery can be applied. However, such a system was not used in this study.

4. Conclusions

In this study, the effect of adding hBN (70 nm) to the lubricant substance (mineral oil) of two-stroke engines in terms of emissions was experimentally investigated. For this, the experiments were carried out using different amounts of lubricant (100:3, 100:3.5, and 100:4 vol.) in a two-stroke power generator. In addition, we tried to improve the lubricating properties by adding hBN (0.5% vol. or 1.3% wt.) to the lubricant. In a series of experiments, a power generator was examined for its performance and emissions. The experiments were carried out under constant velocity–variable load conditions. A fuel–oil mixture is used in two-stroke engines, and the amount of oil that is used directly affects the emission values. Using less lubricant than necessary causes mechanical problems, and using too much lubricant causes environmental problems. For this, it is necessary to use the least possible amount of lubricant in order to reduce the environmental problems caused by two-stroke engines without sacrificing performance. In this study, it was experimentally proven that by adding 0.5% hBN, the lubricating properties of the lubricant can be improved, and less lubricant can be added to the fuel. When adding hBN to the lubricant, precipitation was prevented for up to 120 h by using oleic acid as the surfactant. As a result of the addition of hBN to the lubricant, it was observed that the flash point and pour point did not change, and the density and viscosity index increased linearly depending on the amount of hBN. The engine performance improves slightly when the amount of lubricant used is reduced. Thus, adding hBN to the lubricant indirectly contributes to fuel economy. As a general evaluation, by adding hBN to the lubricants of two-stroke engines, the engine needs less lubricant without sacrificing performance, and thus, the emission from the lubricant can be reduced. In addition to the results in this paper, topics such as the long-running performance of the engine, the in-cylinder pressure, the cylinder surface wear, spark plug fouling, and the performance at variable engine speeds can be studied. In addition, in this study, the experiments were carried out for the most preferred hBN ratio according to the information in the literature. The amount of hBN can be optimized by repeating the experiments for different hBN ratios.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All the data related to this study will be shared without hesitation when requested from cagriorman@gazi.edu.tr.

Acknowledgments

We thank Metin Gürü (Gazi University, Türkiye) for her support in the procurement of hBN nano-powder and SEM imaging, and Emre Arabacı (Pamukkale University, Türkiye) for her support in the preparation of the testbench.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Heywood, J.B. Two-Stroke Cycle Engine: It’s Development, Operation and Design, 1st ed.; Taylor & Francis: New York, NY, USA, 1999; pp. 1–9. [Google Scholar]

- Krishna, A.S.; Mallikarjuna, J.M.; Kumar, D. Effect of engine parameters on in-cylinder flows in a two-stroke gasoline direct injection engine. Appl. Energy 2016, 176, 282–294. [Google Scholar] [CrossRef]

- Savioli, T.; Zardin, B.; Borghi, M. Development of a 2-Stroke GDI Engine. Energy Procedia 2017, 126, 1091–1098. [Google Scholar] [CrossRef]

- Mattarelli, E.; Cantore, G.; Rinaldini, C.A. Advances in the design of two-stroke, high speed, compression ignition engines. In Advances in Internal Combustion Engines and Fuel Technologies, 1st ed.; Intech Open: Rijeka, Croatia, 2013; pp. 149–182. [Google Scholar]

- Singh, A.K. Castor oil-based lubricant reduces smoke emission in two-stroke engines. Ind. Crops Prod. 2011, 33, 287–295. [Google Scholar] [CrossRef]

- Zulfattah, Z.M.; Zulkifli, N.W.M.; Masjuki, H.H.; Harith, M.H.; Syahir, A.Z.; Norain, I.; Arslan, A. Effect of bio-based lubricant towards emissions and engine breakdown due to spark plug fouling in a two-stroke engine. J. Clean. Prod. 2019, 221, 215–223. [Google Scholar] [CrossRef]

- Broatch, A.; Margot, X.; Novella, R.; Gómez-Soriano, J. Combustion noise analysis of partially premixed combustion concept using gasoline fuel in a 2-stroke engine. J. Energy 2016, 107, 612–624. [Google Scholar] [CrossRef]

- Blair, G.P. Design and Simulation of Two-Stroke Engines; Society of Automotive Engineers: Warrendale, PA, 1996; pp. 8–73. [Google Scholar]

- Caines, A.J.; Haycock, R.F.; Hillier, J.E. Automotive Lubricants Reference Book; John Wiley & Sons: Warrendale, PA, USA, 2004; pp. 89–216. [Google Scholar]

- Arumugam, S.; Sriram, G.; Ellappan, R. Bio-lubricant-biodiesel combination of rapeseed oil: An experimental investigation on engine oil tribology, performance, and emissions of variable compression engine. J. Energy 2014, 72, 618–627. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I.; Gallardo-Hernández, E.A.; Gómez-Guarneros, M.; Pérez-González, J.; Godínez-Salcedo, J.G. Alteration of lubricity of Jatropha oil used as bio-lubricant for engines due to thermal ageing. Renew. Energy 2020, 149, 1197–1204. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I.; Gallardo-Hernández, E.A.; Pérez-González, J.; Marín-Santibáñez, B.M.; Lewis, R. Effects of Jatropha lubricant thermo-oxidation on the tribological behaviour of engine cylinder liners as measured by a reciprocating friction test. Wear 2019, 426, 910–918. [Google Scholar] [CrossRef]

- Cheenkachorn, K.; Fungtammasan, B. Development of engine oil using palm oil as a base stock for four-stroke engines. J. Energy 2010, 35, 2552–2556. [Google Scholar] [CrossRef]

- Öğüt, H.; Oğuz, H.; Aydın, F.; Ciniviz, M.; Deveci, H. The investigation of the use of plant-based wild mustard and boron doped oil as engine lubrication oil in diesel engines. Renew. Energy 2019, 136, 79–83. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H.; Mai, L.; Qingping, C.; Turkson, R.F.; Bicheng, C. Improving the tribological characteristics of piston ring assembly in automotive engines using Al2O3 and TiO2 nanomaterials as nano-lubricant additives. Tribol. Int. 2016, 103, 540–554. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H.; Mai, L.; Bicheng, C.; Turkson, R.F.; Qingping, C. Reducing frictional power losses and improving the scuffing resistance in automotive engines using hybrid nanomaterials as nano-lubricant additives. Wear 2016, 364, 270–281. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Fuming, P.; Younus, H.A.; Abdelkareem, M.A.; Essa, F.A.; Elagouz, A.; Xianjun, H. Fuel economy in gasoline engines using Al2O3/TiO2 nanomaterials as nanolubricant additives. Appl. Energy 2018, 211, 461–478. [Google Scholar] [CrossRef]

- Sgroi, M.F.; Asti, M.; Gili, F.; Deorsola, F.A.; Bensaid, S.; Fino, D.; Dassenoy, F. Engine bench and road testing of an engine oil containing MoS2 particles as nano-additive for friction reduction. Tribol. Int. 2017, 105, 317–325. [Google Scholar] [CrossRef]

- Davis, D.; Shah, A.F.; Panigrahi, B.B.; Singh, S. Effect of Cr2AlC nanolamella addition on tribological properties of 5W-30 engine oil. Appl. Surf. Sci. 2019, 493, 1098–1105. [Google Scholar] [CrossRef]

- Wu, B.; Song, H.; Li, C.; Song, R.; Zhang, T.; Hu, X. Enhanced tribological properties of diesel engine oil with Nano-Lanthanum hydroxide/reduced graphene oxide composites. Tribol. Int. 2020, 141, 105951. [Google Scholar] [CrossRef]

- Dinesh, R.; Prasad, M.G.; Kumar, R.R.; Santharaj, N.J.; Santhip, J.; Raaj, A.A. Investigation of tribological and thermophysical properties of engine oil containing nano-additives. Mater. Today Proc. 2016, 3, 45–53. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, Y.; Wang, J.; Gao, C.; Zhang, S.; Zhang, P.; Zhang, Z. Interactions of Cu nanoparticles with conventional lubricant additives on tribological performance and some physicochemical properties of an ester base oil. Tribol. Int. 2020, 141, 105941. [Google Scholar] [CrossRef]

- Abdullah, M.I.H.C.; Abdollah, M.F.B.; Amiruddin, H.; Tamaldin, N.; Nuri, N.R.M. Optimization of Tribological Performance of hBN/AL2O3Nanoparticles as Engine Oil Additives. Procedia Eng. 2013, 68, 313–319. [Google Scholar] [CrossRef]

- Abdullah, M.I.H.C.; Abdollah, M.F.B.; Amiruddin, H.; Tamaldin, N.; Nuri, N.R.M. The potential of hBN nanoparticles as friction modifier and antiwear additive in engine oil. Mech. Ind. 2016, 17, 104. [Google Scholar] [CrossRef]

- Ay, N.; Ay, G.M.; Göncü, Y. Environmentally friendly material: Hexagonal boron nitride. Bor. Dergisi. 2016, 1, 66–73. [Google Scholar]

- Ramteke, S.M.; Chelladurai, H. Effects of hexagonal boron nitride based nanofluid on the tribological and performance, emission characteristics of a diesel engine: An experimental study. Eng. Rep. 2020, 2, e12216. [Google Scholar] [CrossRef]

- He, J.; Sun, J.; Meng, Y.; Yan, X. Preliminary investigations on the tribological performance of hexagonal boron nitride nanofluids as lubricant for steel/steel friction pairs. Surf. Topogr. Metrol. Prop. 2019, 7, 015022. [Google Scholar] [CrossRef]

- Ramteke, S.; Chelladurai, H. Examining the role of hexagonal boron nitride nanoparticles as an additive in the lubricating oil and studying its application. Proc. Inst. Mech. Eng. Part N J. Nanomater. Nanoeng. Nanosyst. 2020, 234, 19–36. [Google Scholar] [CrossRef]

- Senyk, S.; Chodkiewicz, A.; Gocman, K.; Szczęśniak, B.; Kałdoński, T. Hexagonal nano and micro boron nitride: Properties and lubrication applications. Materials 2022, 15, 955. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Bu, Y.; Guan, P.; Yang, Y.; Qing, J. Tribological properties of hexagonal boron nitride nanoparticles as a lubricating grease additive. Lubr. Sci. 2023, in press. [Google Scholar] [CrossRef]

- Abdollah, M.F.B.; Amiruddin, H.; Jamallulil, A.D. Experimental analysis of tribological performance of palm oil blended with hexagonal boron nitride nanoparticles as an environment-friendly lubricant. Int. J. Adv. Manuf. Technol. 2020, 106, 4183–4191. [Google Scholar] [CrossRef]

- Osman, K.A.; Yılmaz, V.; Ünver, H.Ö.; Şeker, U.; Kılıç, S.E. Slot milling of titanium alloy with hexagonal boron nitride and minimum quantity lubrication and multi-objective process optimization for energy efficiency. J. Clean. Prod. 2020, 258, 120739. [Google Scholar] [CrossRef]

- Nomède-Martyr, N.; Vitulin, M.; Joseph, H.; Thomas, P. Moringa oil with graphite and hexagonal boron nitride particles as additives for lubrication. Diam. Relat. Mater. 2022, 124, 108930. [Google Scholar] [CrossRef]

- del Río, J.M.L.; López, E.R.; Fernández, J. Tribological properties of graphene nanoplatelets or boron nitride nanoparticles as additives of a polyalphaolefin base oil. J. Mol. Liq. 2021, 333, 115911. [Google Scholar] [CrossRef]

- Xia, R.; Lou, D.; Younes, H.; Haiston, J.; Chen, H.; Hong, H. Synergistic effect of hexagonal boron nitride and carbon nanofibers on tribological behavior of nanolubricant. Tribol. Int. 2023, 177, 107957. [Google Scholar] [CrossRef]

- Kumari, S.; Chouhan, A.; Konathala, L.S.K.; Sharma, O.P.; Ray, S.S.; Ray, A.; Khatri, O.P. Chemically functionalized 2D/2D hexagonal boron Nitride/Molybdenum disulfide heterostructure for enhancement of lubrication properties. Appl. Surf. Sci. 2022, 579, 152157. [Google Scholar] [CrossRef]

- Samanta, S.; Sahoo, R.R. Covalently linked hexagonal boron nitride-graphene oxide nanocomposites as high-performance oil-dispersible lubricant additives. ACS Appl. Nano Mater. 2020, 3, 10941–10953. [Google Scholar] [CrossRef]

- Zang, C.; Yang, M.; Liu, E.; Qian, Q.; Zhao, J.; Zhen, J.; Zhang, R.; Jia, Z.; Han, W. Synthesis, characterization and tribological behaviors of hexagonal boron nitride/copper nanocomposites as lubricant additives. Tribol. Int. 2022, 165, 107312. [Google Scholar] [CrossRef]

- Nasser, K.I.; del Río, J.M.L.; Marino, F.; López, E.R.; Fernández, J. Double hybrid lubricant additives consisting of a phosphonium ionic liquid and graphene nanoplatelets/hexagonal boron nitride nanoparticles. Tribol. Int. 2021, 163, 107189. [Google Scholar] [CrossRef]

- Bin Abdollah, M.F.; Amiruddin, H.; Alif Azmi, M.; Mat Tahir, N.A. Lubrication mechanisms of hexagonal boron nitride nano-additives water-based lubricant for steel–steel contact. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 1038–1046. [Google Scholar] [CrossRef]

- Thachnatharen, N.; Khalid, M.; Arulraj, A.; Sridewi, N. Tribological performance of hexagonal boron nitride (hBN) as nano-additives in military grade diesel engine oil. Mater. Today Proc. 2022, 50, 70–73. [Google Scholar] [CrossRef]

- Yu, Y.Y.; Abdullah, M.I.H.C.; Abdollah, M.F.B. Tribological investigation on vegetable oil enhance by hBN nanoparticles as future bio-based lubricant. Proc. Mech. Eng. Res. Day 2022, 2022, 246–247. [Google Scholar]

- Abdullah, M.I.H.C.; Fadzli, M.; Abdollah, B.; Amiruddin, H.; Tamaldin, N.; Nuri, N.R.M.; Tunggal, D. The hBN Nanoparticles as an Effective Engine Oil Additive to Enhance the Durability and Performance of a Small Diesel Engine. J. Mech. Eng. 2017, 1, 103–112. [Google Scholar]

- Li, S.; Baeyens, J.; Dewil, R.; Appels, L.; Zhang, H.; Deng, Y. Advances in rigid porous high temperature filters. Renew. Sustain. Energy Rev. 2021, 139, 110713. [Google Scholar] [CrossRef]

- Deng, Y.; Dewil, R.; Appels, L.; Van Tulden, F.; Li, S.; Yang, M.; Baeyens, J. Hydrogen-enriched natural gas in a decarbonization perspective. Fuel 2022, 318, 123680. [Google Scholar] [CrossRef]

- Talib, N.; Nasir, R.M.; Rahim, E.A. Tribological behaviour of modified jatropha oil by mixing hexagonal boron nitride nanoparticles as a bio-based lubricant for machining processes. J. Clean. Prod. 2017, 147, 360–378. [Google Scholar] [CrossRef]

- Kumari, S.; Sharma, O.P.; Gusain, R.; Mungse, H.P.; Kukrety, A.; Kumar, N.; Khatri, O.P. Alkyl-chain-grafted hexagonal boron nitride nanoplatelets as oil-dispersible additives for friction and wear reduction. ACS Appl. Mater. Interfaces 2015, 7, 3708–3716. [Google Scholar] [CrossRef] [PubMed]

- Wan, Q.; Jin, Y.; Sun, P.; Ding, Y. Tribological behaviour of a lubricant oil containing boron nitride nanoparticles. Procedia Eng. 2015, 102, 1038–1045. [Google Scholar] [CrossRef]

- Cho, D.H.; Kim, J.S.; Kwon, S.H.; Lee, C.; Lee, Y.Z. Evaluation of hexagonal boron nitride nano-sheets as a lubricant additive in water. Wear 2013, 302, 981–986. [Google Scholar] [CrossRef]

- Naik, S.N.; Goud, V.V.; Rout, P.K.; Dalai, A.K. Production of first and second generation biofuels: A comprehensive review. Renew. Sustain. Energy Rev. 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Gaurav, N.; Sivasankari, S.; Kiran, G.S.; Ninawe, A.; Selvin, J. Utilization of bioresources for sustainable biofuels: A review. Renew. Sustain. Energy Rev. 2017, 73, 205–214. [Google Scholar] [CrossRef]

- Demirbas, A. Political, economic and environmental impacts of biofuels: A review. Appl. Energy 2009, 86, S108–S117. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Chilvers, A.; Azapagic, A. Environmental sustainability of biofuels: A review. Proc. R. Soc. A 2020, 476, 20200351. [Google Scholar] [CrossRef]

- Singh, Y.; Farooq, A.; Raza, A.; Mahmood, M.A.; Jain, S. Sustainability of a non-edible vegetable oil based bio-lubricant for automotive applications: A review. Process Saf. Environ. Prot. 2017, 111, 701–713. [Google Scholar] [CrossRef]

- Cunningham, B.; Battersby, N.; Wehrmeyer, W.; Fothergill, C. A sustainability assessment of a biolubricant. J. Ind. Ecol. 2003, 7, 179–192. [Google Scholar] [CrossRef]

- Fernández-Silva, S.D.; Delgado, M.A.; Ruiz-Méndez, M.V.; Giráldez, I.; García-Morales, M. Potential valorization of waste cooking oils into sustainable bio-lubricants. Ind. Crops Prod. 2022, 185, 115109. [Google Scholar] [CrossRef]

- Specifications of the Generator. 2021. Available online: https://hyundaipower-tr.com/ (accessed on 12 January 2021).

- Sun Electric. Sun MGA1500 Modular Gas Analyser Operator’s Manual; Sun Electric Europe: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Specificatios of Main Board. 2021. Available online: https://www.lattepanda.com/products/2.html (accessed on 11 November 2021).

- Thermocouple. 2021. Available online: https://cdn-shop.adafruit.com/datasheets/MAX6675.pdf (accessed on 11 November 2021).

- Ambient Sensor. 2021. Available online: https://cdn-shop.adafruit.com/product-files/3660/BME680.pdf (accessed on 13 November 2021).

- Level Sensor. 2021. Available online: http://www.naylampmechatronics.com/img/cms/Datasheets/XKC%20Y25%20T12V.pdf (accessed on 14 November 2021).

- Energy Meter. 2021. Available online: https://haseman-electric.com/home/index.php/support/user-manuals (accessed on 13 November 2021).

- Rotary encoder. 2021. Available online: https://assets.omron.eu/downloads/datasheet/en/v2/q018_e6a2_incremental_rotary_encoder_25_mm_datasheet_en.pdf (accessed on 14 November 2021).

- Hexagonal Boron Nitride Nano Powder. 2021. Available online: https://lowerfriction.com/dry-solid-lubricant-powders/hexagonal-boron-nitride-hbn-powder/ (accessed on 14 November 2021).

- 2-Stroke Lubricant. 2021. Available online: https://oilproducts.eni.com/media/pdf/download/e-1401_ENU.pdf (accessed on 14 November 2021).

- Oleic Acid. 2021. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Oleic-acid#section=Computed-Properties (accessed on 14 November 2021).

- ISO 9249:2007; Earth-moving machinery—Engine test code—Net power. International Organization for Standardization: Geneva, Switzerland, 2007.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).