Design for Optimally Routing and Scheduling a Tow Train for Just-in-Time Material Supply of Mixed-Model Assembly Lines

Abstract

1. Introduction

- (1)

- Determine the amount of tours.

- (2)

- Decide the scheduling route for each tour.

- (3)

- Decide on the delivery schedule of the tow train.

- (4)

- Determine the wagons to be loaded each tour of the tow train.

2. Literature Review

3. Mathematical Model

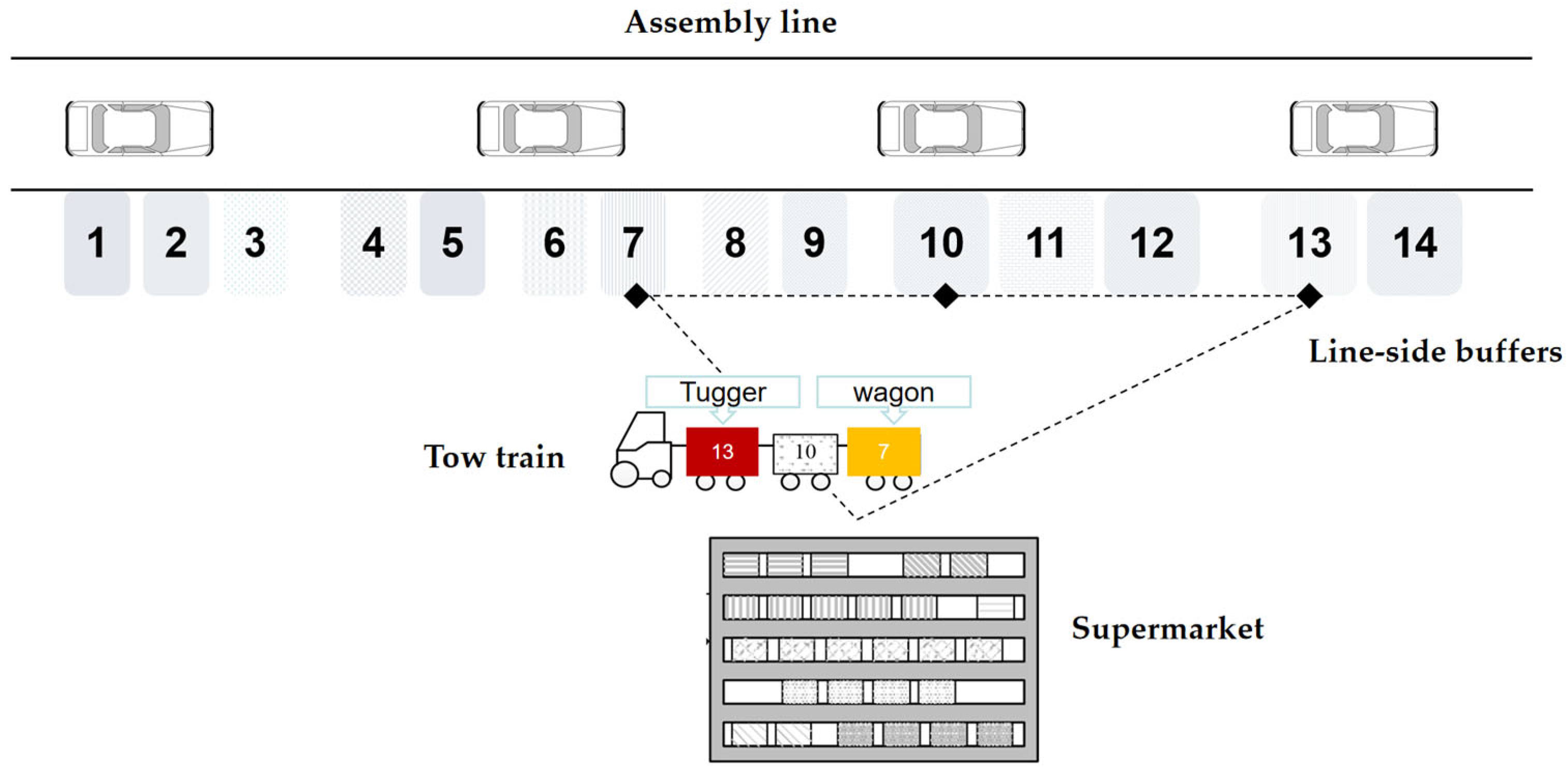

3.1. Details of an Assembly Line

- (1)

- The traveling distance between the supermarket and a part buffer; the distance between one part’s buffer to another are presupposed.

- (2)

- No part is allowed to arrive after its due time, i.e., part shortage is not allowed.

- (3)

- The velocity of a tow train is constant; acceleration and deceleration are not considered.

- (4)

- The loading time and the unloading time are constant.

- (5)

- The road cannot be jammed with traffic of trains.

- (6)

- For each part, a train can load one wagon of each delivery and the capacity of wagons is limited.

- (7)

- For each delivery, a tow train is allowed to have a limited number of wagons; part of the wagon is loaded last but unloaded first.

- (8)

- On the mixed-model assembly line, a product will stay at the workstation for a cycle time and can be assembled with one or more kinds of parts that can be consumed once.

- (9)

- A tugger can tow up to three wagons at a time, i.e., one trip delivered no more than three kinds of parts.

3.2. Mathematical Model

3.2.1. Notations

| The set of the parts in the assembly line; | |

| The set of tours of the tow train; | |

| The set of products (cars in assembly sequence); | |

| K | The set of wagons of the tow train are loaded in one journey which are in order and meet the part need. |

| The index of the part, ; | |

| The index of the tour, ; | |

| The index of the product, | |

| k | The index of the wagon in order, . |

| The capacity of the wagon of part ; | |

| The cycle time; | |

| The time to load a container onto the multiple-load wagon; | |

| The time to unload a container from the multiple-load wagon; | |

| The demand for part in tour , the bill of material; the consumption of part p for assembly of the product m is 1 if it is used, and 0 otherwise; | |

| The max number of the multiple-load wagons in a tow train; | |

| The distance between part i buffer to part j buffer; i = 0 or j = 0 means the distance between the supermarket and the line-side buffer of part ; | |

| The initial buffer for part at the beginning of the first tour; | |

| The largest number; | |

| The smallest number; | |

| The beginning of the scheduling period considered; | |

| The end of the scheduling period considered. |

| The start time of the tour ; | |

| The arrival time of part in tour ; | |

| The arrival time of wagon k in tour ; | |

| equals 1 if tour is taken; otherwise, equals 0; | |

| equals 1 if part is transported; otherwise, equals 0; | |

| The total delivery time in tour ; | |

| equals 1 if part is delivered in tour n which is loaded at wagon k; otherwise, equals 0; | |

| equals 1 if part is lastly delivered in tour n that is taken; otherwise, equals 0; | |

| The number of parts in tour ; | |

| The inventory of the line-side buffer of part when the product m is manufactured; | |

| Intermediate variable; | |

| Intermediate variable; | |

| Intermediate variable; | |

| The intermediate variable used to calculate inventory; | |

| equals 1 if part is delivered in the line-side buffer in tour when the product is manufactured; otherwise, equals 0. |

3.2.2. Model

Mathematical Model Linearization Treatment

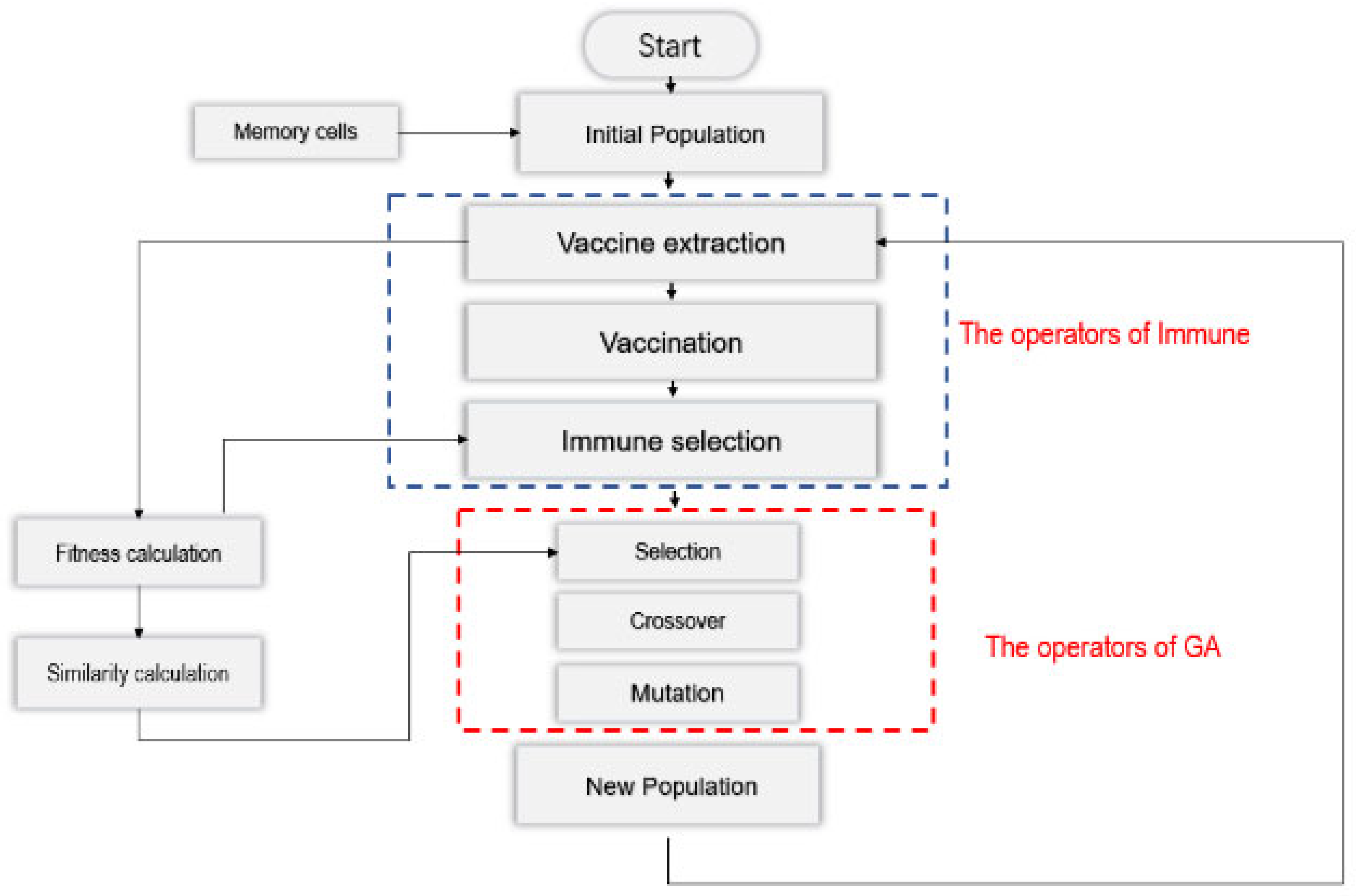

4. Artificial Immune Genetic Algorithm

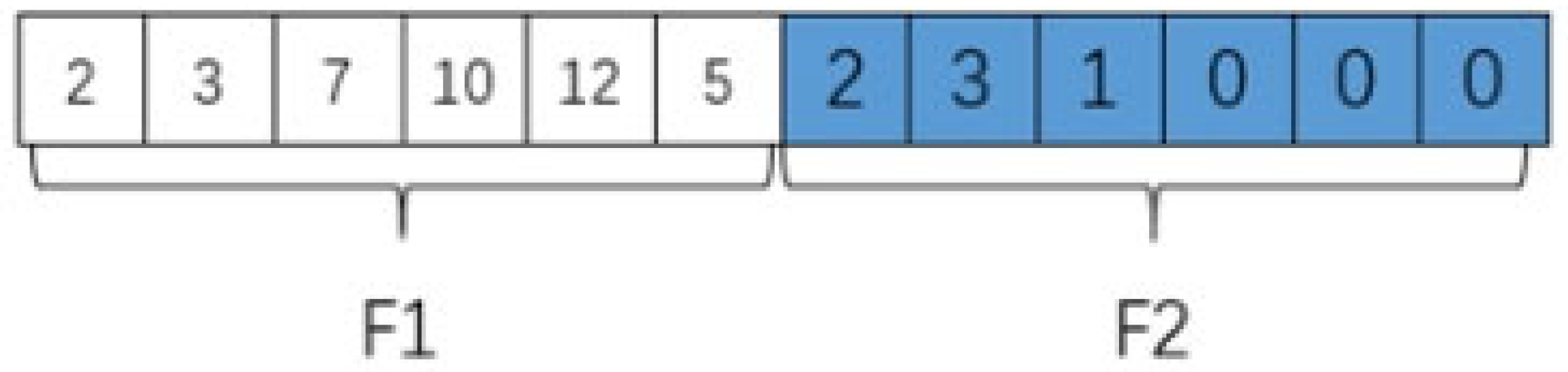

4.1. Encoding and Decoding

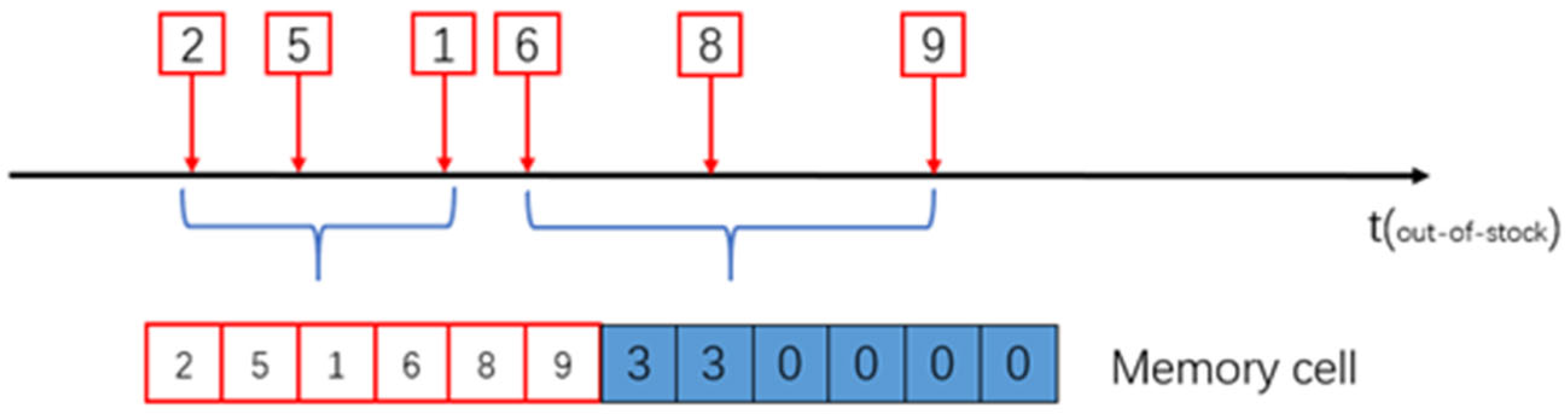

4.2. Memory Cells

- 1.

- The F2 segment of this gene is expressed with fewer transport times.

- 2.

- The order of moving parts shall be sorted according to the time of shortage as far as possible.

4.3. Fitness

4.3.1. The Time of Shortage

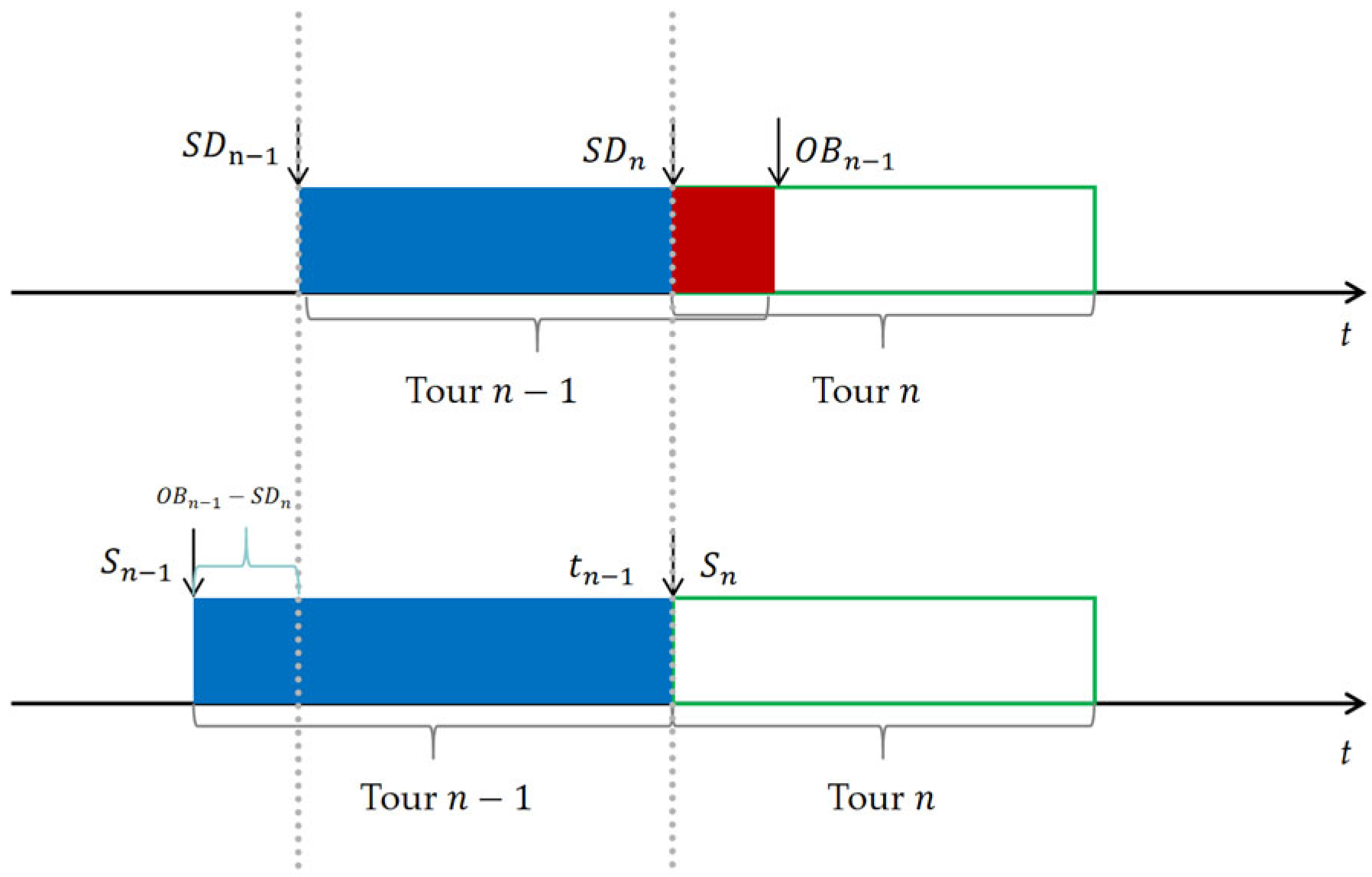

4.3.2. The Departure Time of the Train

4.3.3. Adjust Schedule of the Departure Time

4.3.4. The Value of Fitness Function

4.4. The Calculation of Similarity

4.5. Selection

4.6. Crossover

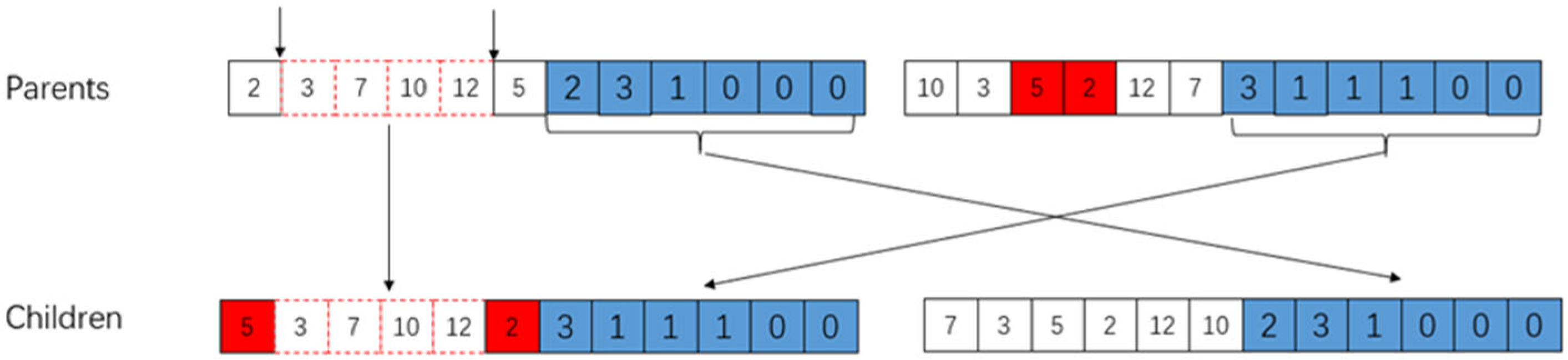

4.7. Mutation

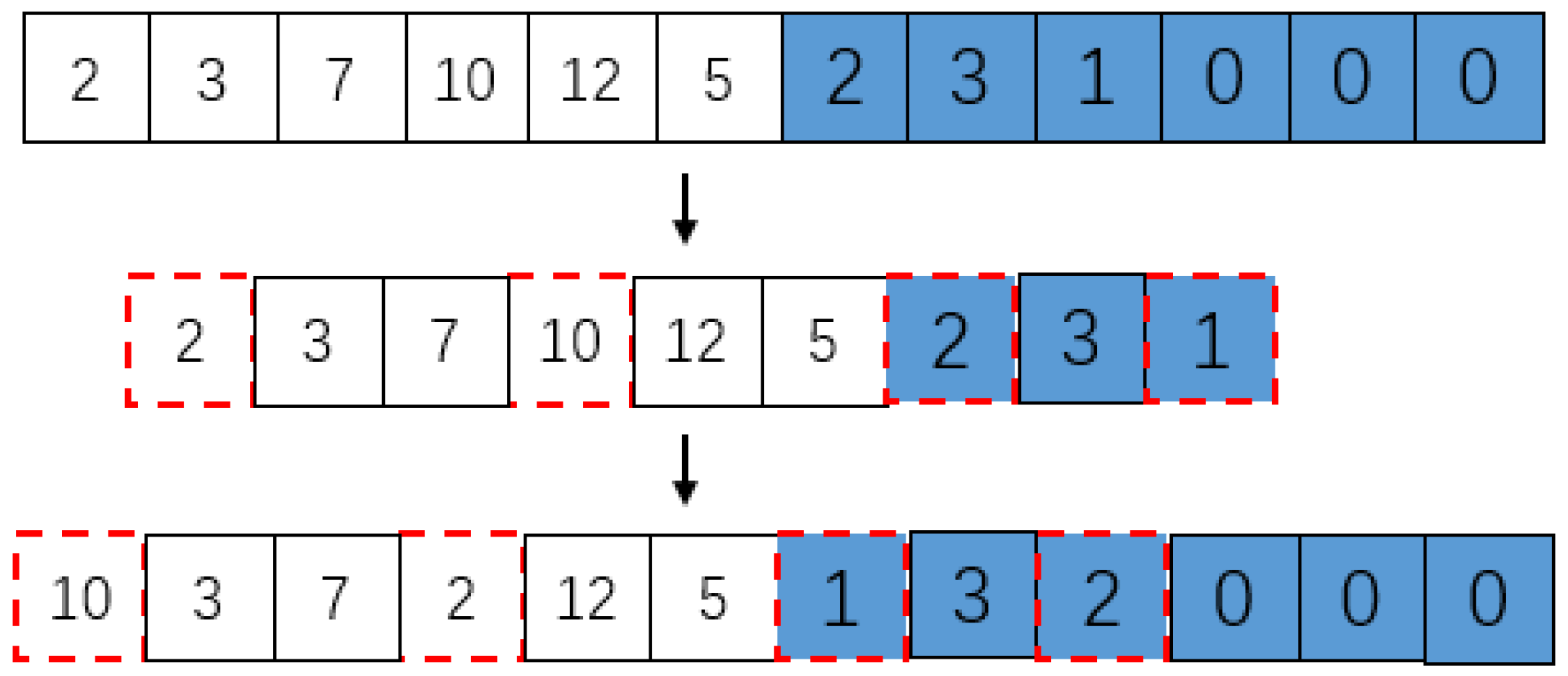

4.8. The Operations of Immunity

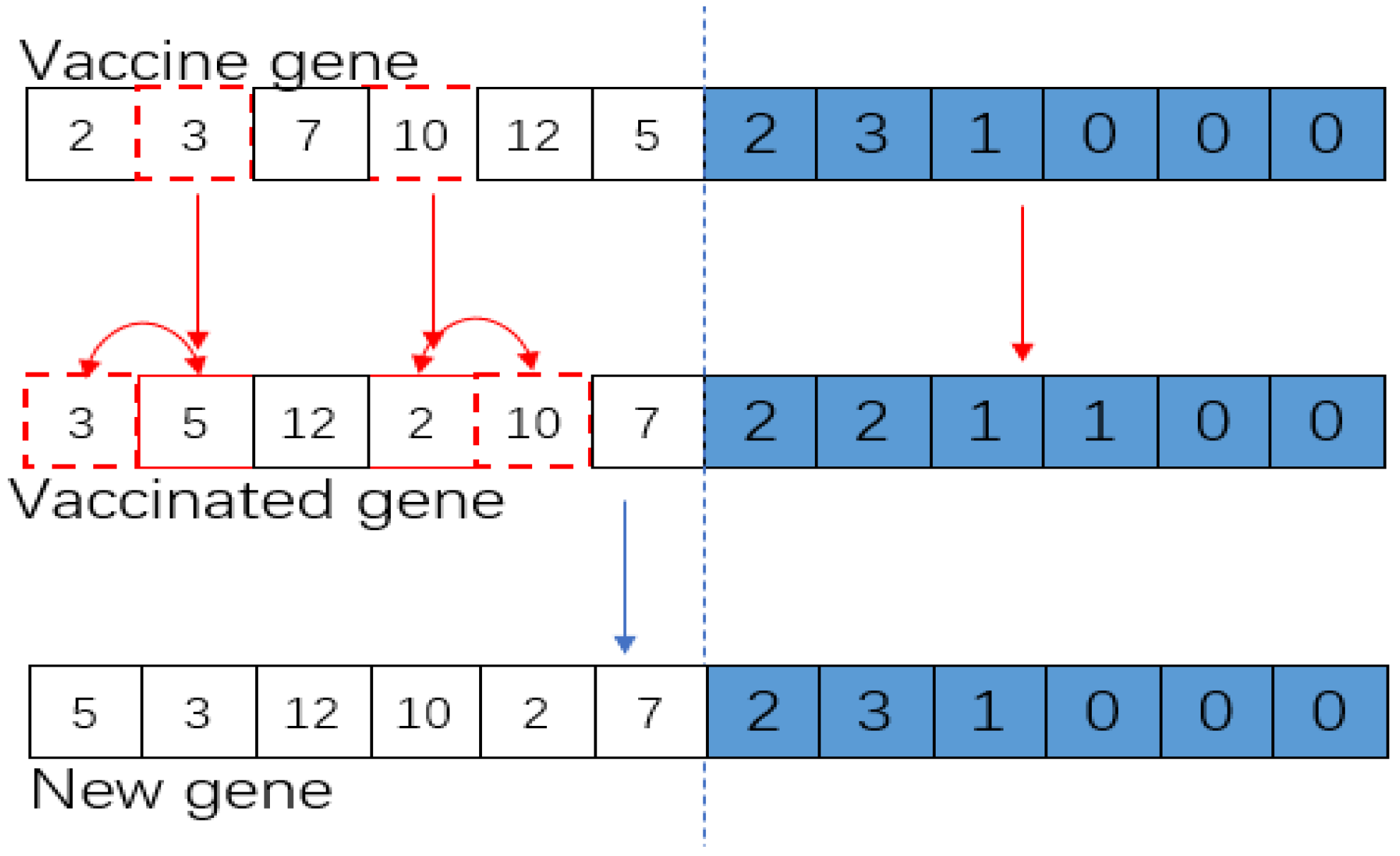

4.8.1. Vaccine Extraction and Vaccination

4.8.2. Immunity selection

5. Computational Results

5.1. The Assumptions of an Assembly Line

5.2. Results and Discussion

6. Concluding Remarkets and Future Direction

- (1)

- In this paper, based on the variable path of a mixed-integer nonlinear programming model to optimize the production line in terms of line-side buffering capacity and the number of deliveries at the same time to solve the complexity of the non-linear model, the model is converted into a linear model.

- (2)

- To make up for the drawback that the integer mathematical model can only solve small-scale problems and the solution period is too long when solving large-scale problems, this paper proposes an intelligent algorithm, the artificial immune genetic algorithm, to ensure that the assembly line does not run out of stock and can obtain a better distribution solution in a short time. Compared to the GA, experiments show that the AIGA has better performance on a large scale, proving that the proposed method can improve the local search ability and quality of the solution.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Halim, N.H.A.; Yusuf, N.; Jaafar, R.; Jaffar, A.; Kaseh, N.A.I.; Azira, N.N. Effective material handling system for JIT automotive production line. Procedia Manuf. 2015, 2, 251–257. [Google Scholar] [CrossRef][Green Version]

- Ağlan, C.; Durmusoglu, M.B. A complete design methodology for lean in-plant logistics to assembly line using ad principles. Int. J. Ind. Eng. 2019, 26, 766–796. [Google Scholar]

- Liu, X.; Yang, X.; Lei, M. Optimisation of mixed-model assembly line balancing problem under uncertain demand. J. Manuf. Syst. 2021, 59, 214–227. [Google Scholar] [CrossRef]

- Yin, Q.; Luo, X.; Hohenstein, J. Design of mixed-model assembly lines integrating new energy vehicles. Machines 2021, 9, 352. [Google Scholar] [CrossRef]

- Fathi, M.; Rodríguez, V.; Fontes, D.B.; Alvarez, M.J. A modified particle swarm optimisation algorithm to solve the part feeding problem at assembly lines. Int. J. Prod. Res. 2016, 54, 878–893. [Google Scholar] [CrossRef]

- Kilic, H.S.; Durmusoglu, M.B. Advances in assembly line parts feeding policies: A literature review. Assem. Autom. 2015, 35, 57–68. [Google Scholar] [CrossRef]

- Boysen, N.; Emde, S.; Hoeck, M.; Kauderer, M. Part logistics in the automotive industry: Decision problems, literature review and research agenda. Eur. J. Oper. Res. 2015, 242, 107–120. [Google Scholar] [CrossRef]

- Fathi, M.; Alvarez, M.J.; Hassani Mehraban, F.; Rodríguez, V. A multiobjective optimization algorithm to solve the part feeding problem in mixed-model assembly lines. Math. Probl. Eng. 2014, 2014, 654053. [Google Scholar] [CrossRef]

- Fathi, M.; Rodríguez, V.; Alvarez, M.J. A novel memetic ant colony optimization-based heuristic algorithm for solving the assembly line part feeding problem. Int. J. Adv. Manuf. Technol. 2014, 75, 629–643. [Google Scholar] [CrossRef]

- Zhou, B.H.; Shen, C.Y. Multi-objective optimization of material delivery for mixed model assembly lines with energy consideration. J. Clean. Prod. 2018, 192, 293–305. [Google Scholar] [CrossRef]

- Li, H.; Zhu, S.; Tolba, A.; Liu, Z.; Wen, W. A Reliable Delivery Logistics System Based on the Collaboration of UAVs and Vehicles. Sustainability 2023, 15, 12720. [Google Scholar] [CrossRef]

- Ci, C. A Study on Machine Learning Based Multiple-Load Carrier Real-Time Scheduling Approaches. Ph.D. Thesis, Jiao Tong University, Shanghai, China, 2014. [Google Scholar]

- Rao, Y.Q.; Wang, M.C.; Wang, K.P.; Wu, T.M. Scheduling a single vehicle in the just-in-time part supply for a mixed-model assembly line. Comput. Oper. Res. 2013, 40, 2599–2610. [Google Scholar] [CrossRef]

- Zhou, B.; Peng, T. Scheduling the in-house logistics distribution for automotive assembly lines with just-in-time principles. Assem. Autom. 2017, 37, 51–63. [Google Scholar] [CrossRef]

- Satoglu, S.I.; Sahin, I.E. Design of a just-in-time periodic material supply system for the assembly lines and an application in electronics industry. Int. J. Adv. Manuf. Technol. 2013, 65, 319–332. [Google Scholar] [CrossRef]

- Fang, W.; Guan, Z.; Su, P.; Luo, D.; Ding, L.; Yue, L. Multi-Objective Material Logistics Planning with Discrete Split Deliveries Using a Hybrid NSGA-II Algorithm. Mathematics 2022, 10, 2871. [Google Scholar] [CrossRef]

- Gödri, I. Improving Delivery Performance in High-Mix Low-Volume Manufacturing by Model-Based and Data-Driven Methods. Appl. Sci. 2022, 12, 5618. [Google Scholar] [CrossRef]

- Song, T.; Zhou, J. Research and implementation of lean production mode in shipbuilding. Processes 2021, 9, 2071. [Google Scholar] [CrossRef]

- Abderrahim, M.; Bekrar, A.; Trentesaux, D.; Aissani, N.; Bouamrane, K. Manufacturing 4.0 Operations Scheduling with AGV Battery Management Constraints. Energies 2020, 13, 4948. [Google Scholar] [CrossRef]

- Zhou, B.; Zhao, Z. A hybrid fuzzy-neural-based dynamic scheduling method for part feeding of mixed-model assembly lines. Comput. Ind. Eng. 2022, 163, 107794. [Google Scholar] [CrossRef]

- Jin, W.; He, Z.; Peng, T. A JIT part supply scheduling strategy with electric transport device between central receiving store and supermarkets in the automobile industry considering energy. eTransportation 2021, 9, 100126. [Google Scholar] [CrossRef]

- Zhou, B.; Zhu, Z. Optimally scheduling and loading tow trains of in-plant milk-run delivery for mixed-model assembly lines. Assem. Autom. 2020, 40, 511–530. [Google Scholar] [CrossRef]

- Boysen, N.; Bock, S. Scheduling just-in-time part supply for mixed-model assembly lines. Eur. J. Oper. Res. 2011, 211, 15–25. [Google Scholar] [CrossRef]

- Niekurzak, M.; Lewicki, W.; Coban, H.H.; Bera, M. A Model to Reduce Machine Changeover Time and Improve Production Efficiency in an Automotive Manufacturing Organisation. Sustainability 2023, 15, 10558. [Google Scholar] [CrossRef]

- Guerrero, R.; Serrano-Hernandez, A.; Pascual, J.; Faulin, J. Simulation Model for Wire Harness Design in the Car Production Line Optimization Using the SimPy Library. Sustainability 2022, 14, 7212. [Google Scholar] [CrossRef]

- Xia, B.; Chen, T.; Wang, C. A method to solve the assembly line parts feeding problem based on variable route. In Proceedings of the 2019 2nd World Conference on Mechanical Engineering and Intelligent Manufacturing (WCMEIM), Shanghai, China, 22–24 November 2019; pp. 631–634. [Google Scholar]

| Symbol | Description | Value |

|---|---|---|

| Pc | Probability of crossover | 0.9 |

| Pm | Probability of mutation | 0.1 |

| MC | The number of memory cells | 30 |

| GP | The number of iterations of the algorithm | 80 |

| IN | The number of individuals in each generation | 400 |

| P | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| M1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 |

| M2 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 |

| M3 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 0 |

| Q | 30 | 16 | 30 | 18 | 45 | 66 | 60 | 70 | 80 | 50 | 45 | 40 | 36 | 50 |

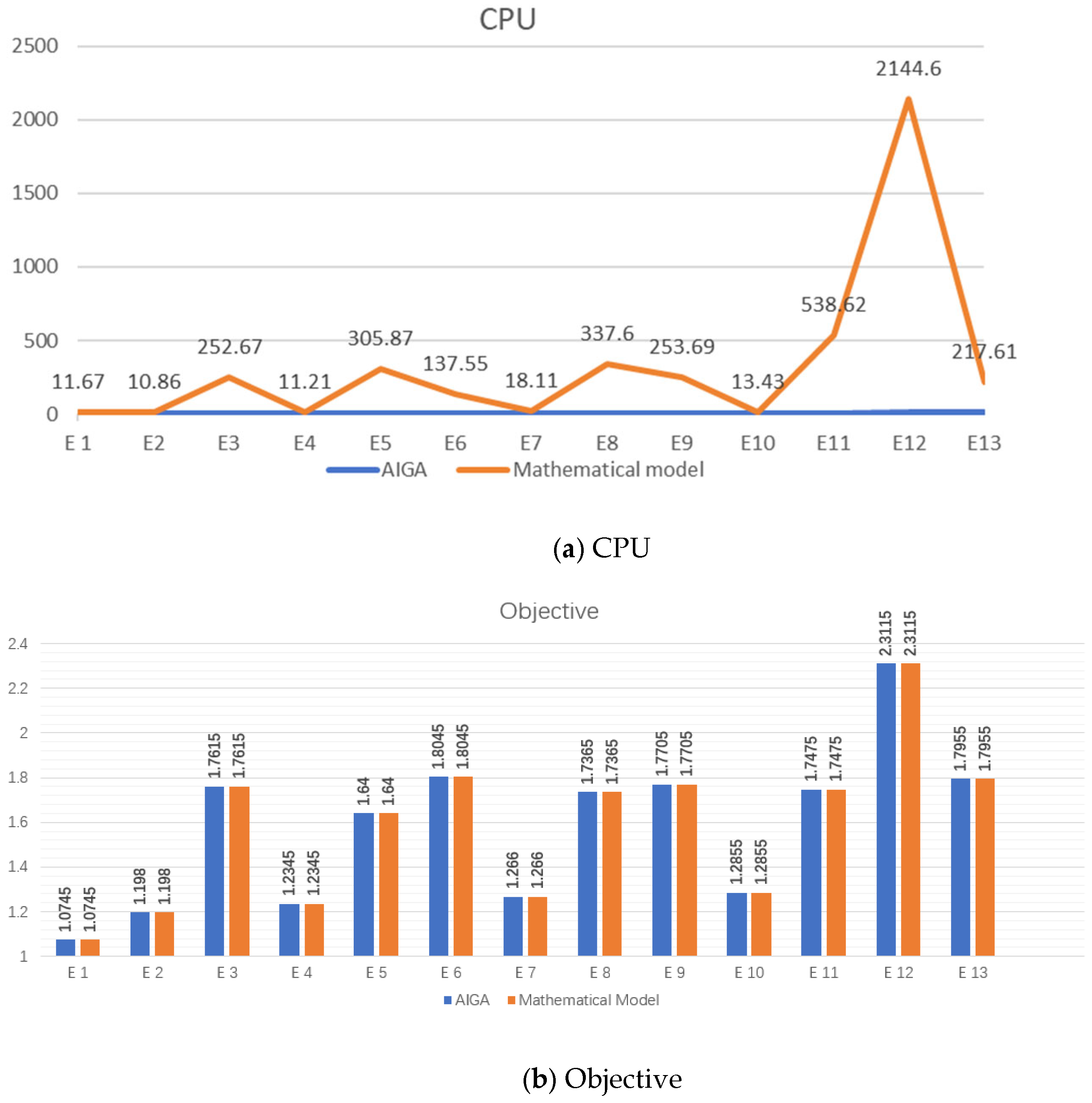

| Example | M | PN | AIGA | Mathematical Model | GA | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| N | CPU/s | Objective/108 | N | CPU/s | Objective/108 | N | CPU/s | Objective/108 | |||

| 1 | 30 | 5 | 2 | 8.45 | 1.0745 | 2 | 11.67 | 1.0745 | 2 | 4.23 | 1.0745 |

| 2 | 6 | 2 | 5.64 | 1.1980 | 2 | 10.86 | 1.1980 | 2 | 3.82 | 1.1980 | |

| 3 | 8 | 3 | 6.33 | 1.7615 | 3 | 252.67 | 1.7615 | 3 | 5.09 | 1.7615 | |

| 4 | 40 | 5 | 2 | 6.84 | 1.2345 | 2 | 11.21 | 1.2345 | 2 | 4.94 | 1.2345 |

| 5 | 7 | 3 | 7.20 | 1.6400 | 3 | 305.87 | 1.6400 | 3 | 7.20 | 1.6400 | |

| 6 | 9 | 3 | 7.13 | 1.8045 | 3 | 137.55 | 1.8045 | 3 | 4.74 | 1.8045 | |

| 7 | 50 | 5 | 2 | 7.36 | 1.2660 | 2 | 18.11 | 1.2660 | 2 | 4.85 | 1.2660 |

| 8 | 8 | 3 | 6.51 | 1.7365 | 3 | 337.60 | 1.7365 | 3 | 4.74 | 1.7365 | |

| 9 | 9 | 3 | 7.18 | 1.7705 | 3 | 253.69 | 1.7705 | 3 | 5.18 | 1.7705 | |

| 10 | 60 | 6 | 2 | 7.17 | 1.2855 | 2 | 13.43 | 1.2855 | 2 | 6.78 | 1.2855 |

| 11 | 8 | 3 | 7.32 | 1.7475 | 3 | 538.62 | 1.7475 | 3 | 5.58 | 1.7475 | |

| 12 | 12 | 4 | 10.48 | 2.3115 | 4 | 2144.60 | 2.3115 | 4 | 9.28 | 2.3250 | |

| 13 | 70 | 9 | 3 | 9.33 | 1.7955 | 3 | 217.61 | 1.7955 | 3 | 5.55 | 1.7955 |

| 14 | 10 | 4 | 8.98 | 2.1430 | - | 3600 | - | 4 | 6.66 | 2.1455 | |

| 15 | 12 | 4 | 9.23 | 2.2865 | - | 3600 | - | 4 | 5.41 | 2.3240 | |

| 16 | 80 | 10 | 4 | 10.01 | 2.1430 | - | 3600 | - | 4 | 6.71 | 2.1480 |

| 17 | 11 | 4 | 9.46 | 2.2540 | - | 3600 | - | 4 | 6.21 | 2.2695 | |

| 18 | 13 | 5 | 10.15 | 2.6710 | - | 3600 | - | 5 | 6.98 | 2.7350 | |

| 19 | 90 | 10 | 4 | 11.23 | 2.1480 | - | 3600 | - | 4 | 6.55 | 2.1480 |

| 20 | 11 | 4 | 10.68 | 2.1880 | - | 3600 | - | 4 | 6.73 | 2.1880 | |

| 21 | 13 | 5 | 11.51 | 2.6920 | - | 3600 | - | 5 | 8.01 | 2.6920 | |

| 22 | 100 | 13 | 5 | 11.68 | 2.7330 | - | 3600 | - | 5 | 7.00 | 2.7980 |

| 23 | 15 | 5 | 12.63 | 2.9205 | - | 3600 | - | 5 | 7.58 | 3.0630 | |

| 24 | 16 | 6 | 11.28 | 3.3920 | - | 3600 | - | 6 | 8.79 | 3.4670 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, B.; Zhang, M.; Gao, Y.; Yang, J.; Peng, Y. Design for Optimally Routing and Scheduling a Tow Train for Just-in-Time Material Supply of Mixed-Model Assembly Lines. Sustainability 2023, 15, 14567. https://doi.org/10.3390/su151914567

Xia B, Zhang M, Gao Y, Yang J, Peng Y. Design for Optimally Routing and Scheduling a Tow Train for Just-in-Time Material Supply of Mixed-Model Assembly Lines. Sustainability. 2023; 15(19):14567. https://doi.org/10.3390/su151914567

Chicago/Turabian StyleXia, Beixin, Mingyue Zhang, Yan Gao, Jing Yang, and Yunfang Peng. 2023. "Design for Optimally Routing and Scheduling a Tow Train for Just-in-Time Material Supply of Mixed-Model Assembly Lines" Sustainability 15, no. 19: 14567. https://doi.org/10.3390/su151914567

APA StyleXia, B., Zhang, M., Gao, Y., Yang, J., & Peng, Y. (2023). Design for Optimally Routing and Scheduling a Tow Train for Just-in-Time Material Supply of Mixed-Model Assembly Lines. Sustainability, 15(19), 14567. https://doi.org/10.3390/su151914567