Evaluating the Technical, Economic, and Environmental Performance of Solar Water Heating System for Residential Applications–Comparison of Two Different Working Fluids (Water and Glycol)

Abstract

:1. Introduction

2. Materials and Methods

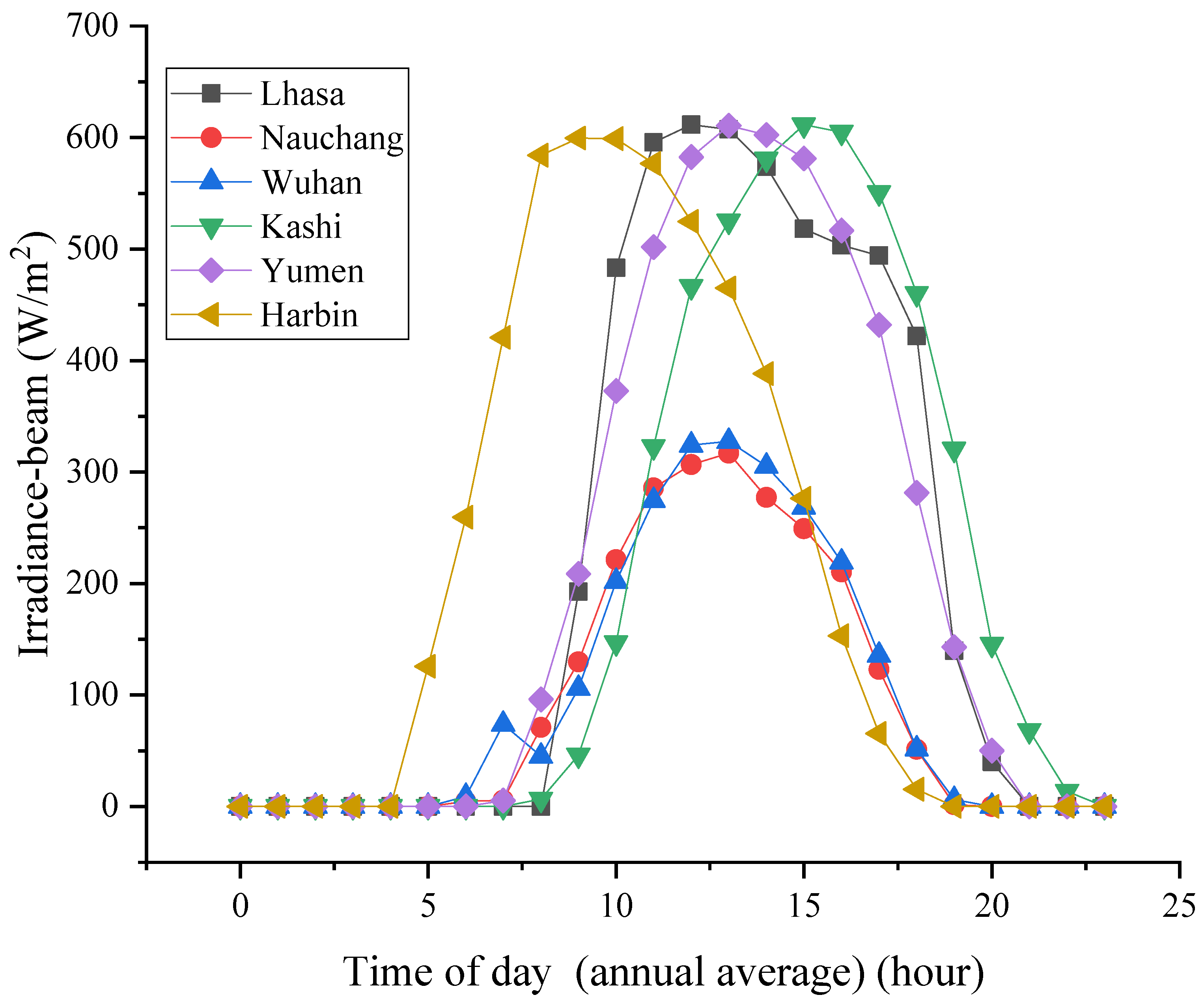

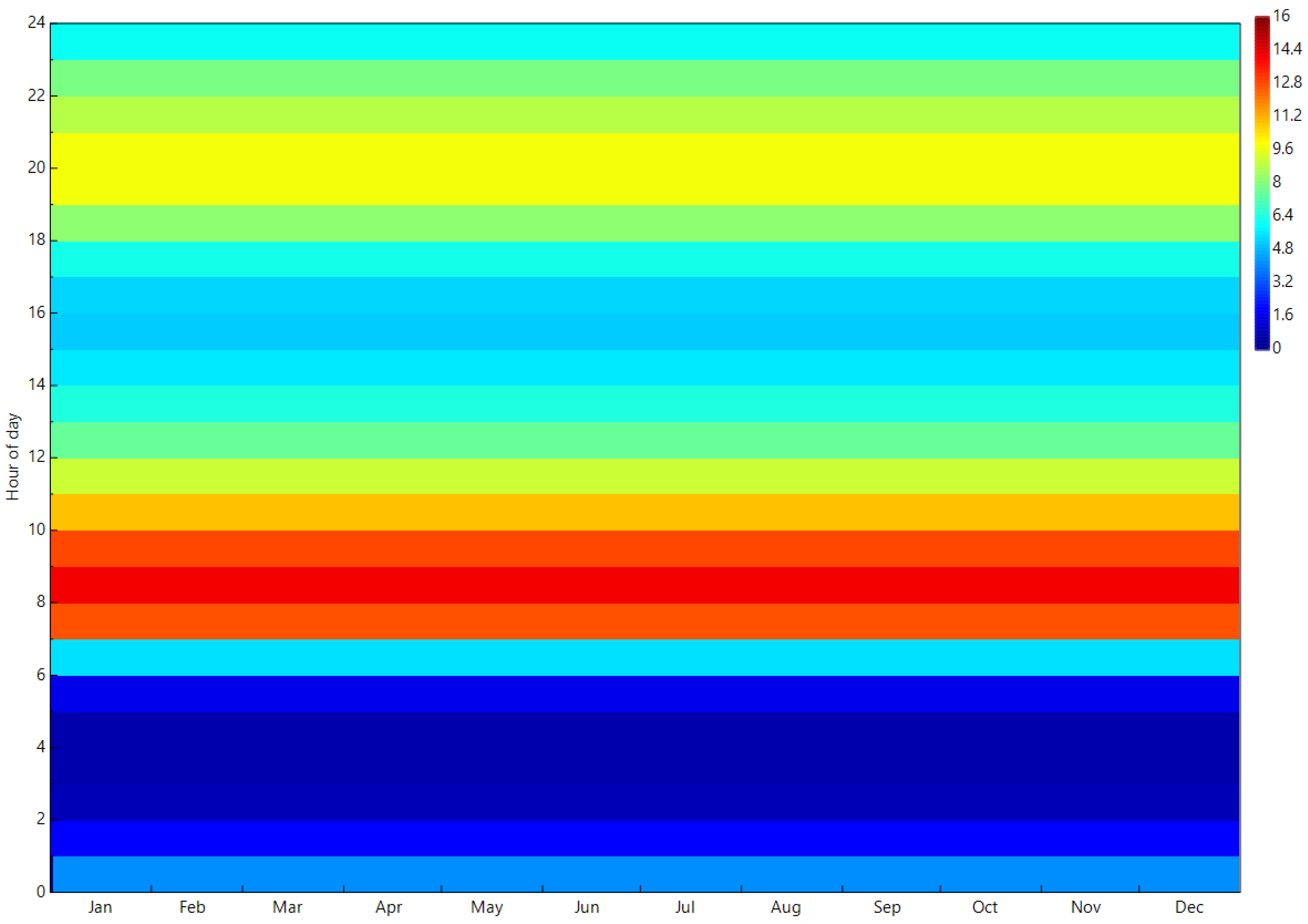

2.1. The Weather Characteristics of the Study Area

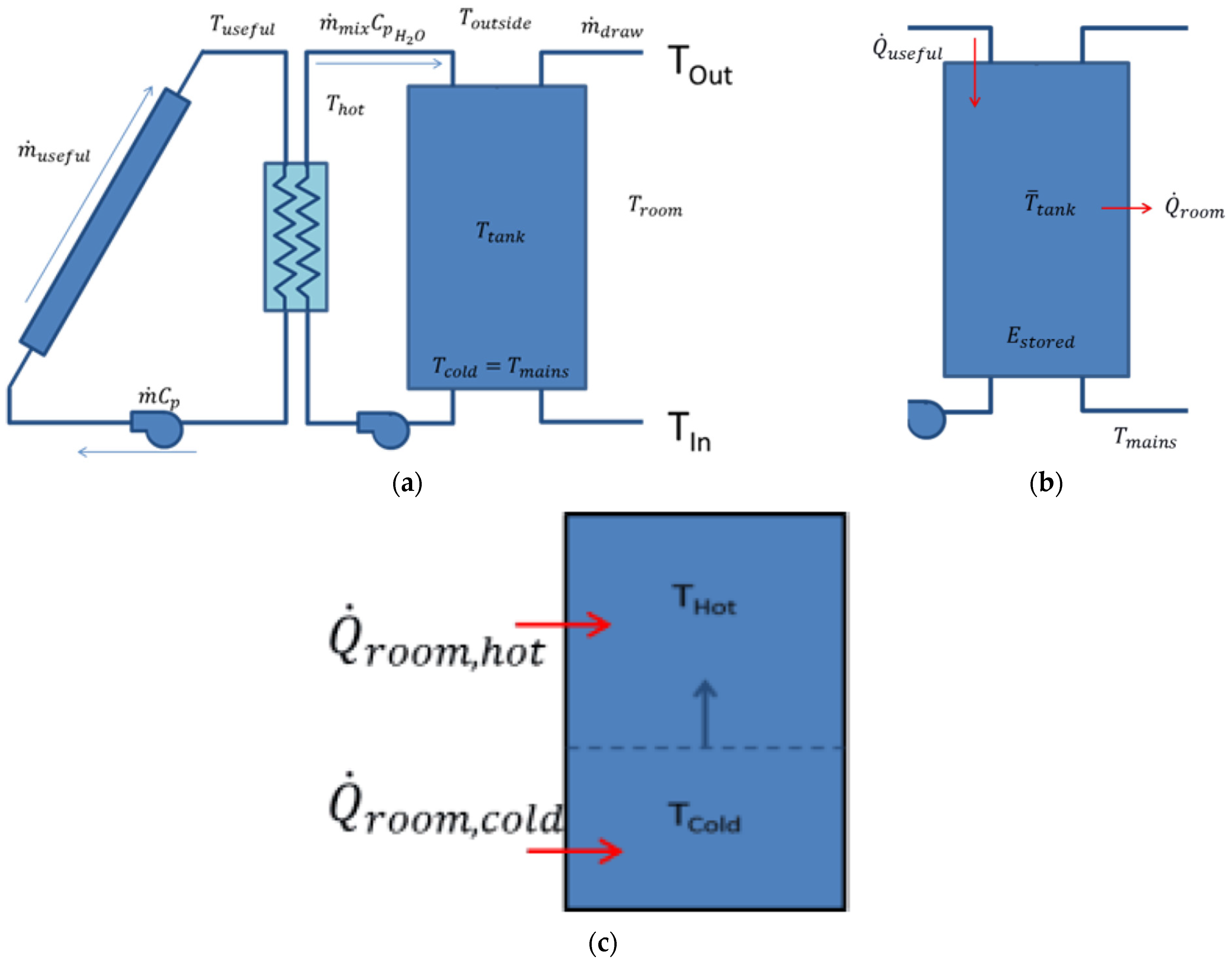

2.2. Modeling of SWHS in the SAM Model

2.3. System Used for the Assessment of the Glazed Flat-Plate SWH

2.4. Financial Parameters for the Modeling

3. Results and Discussion

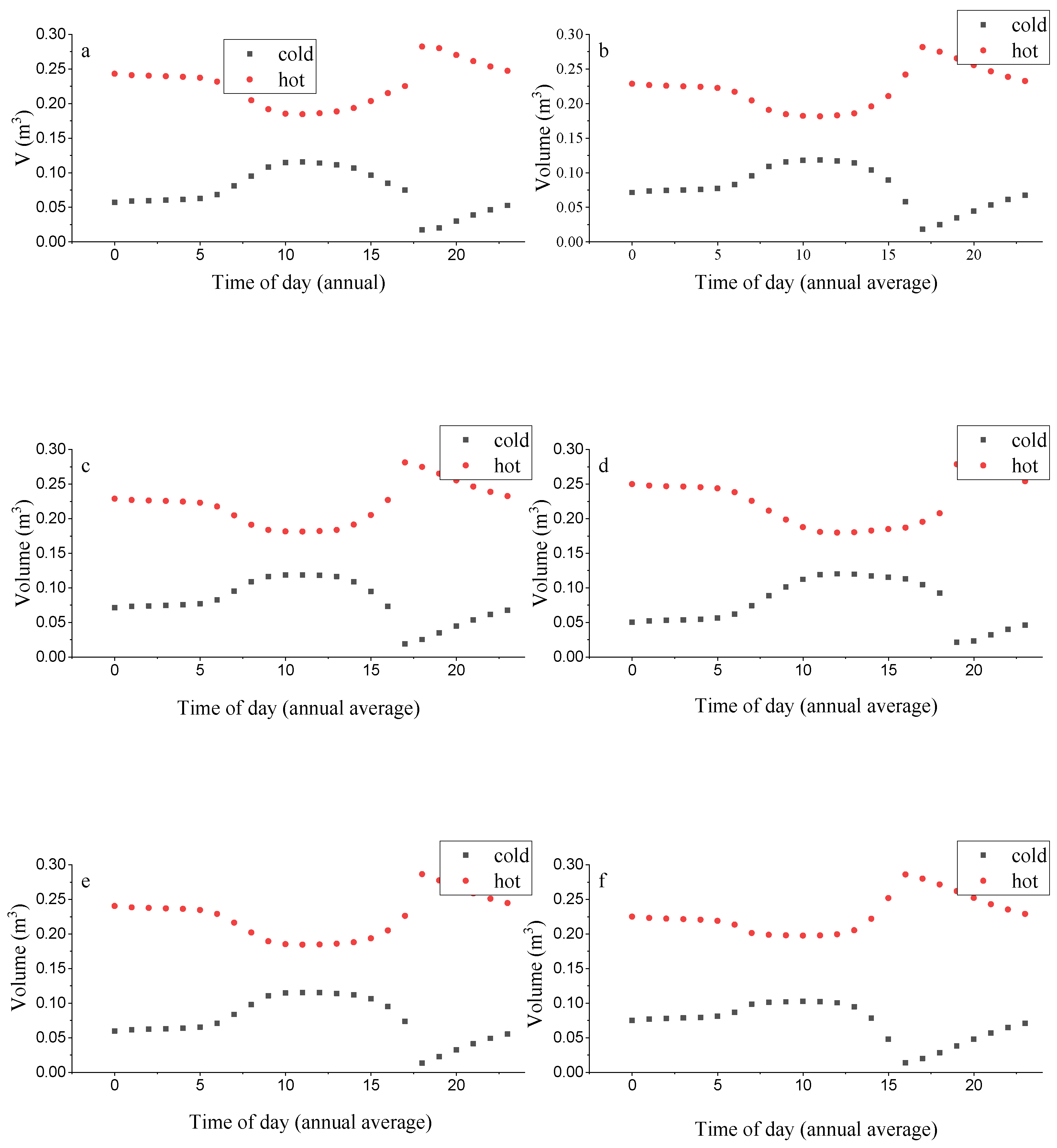

3.1. Technical Performance of the SWHS

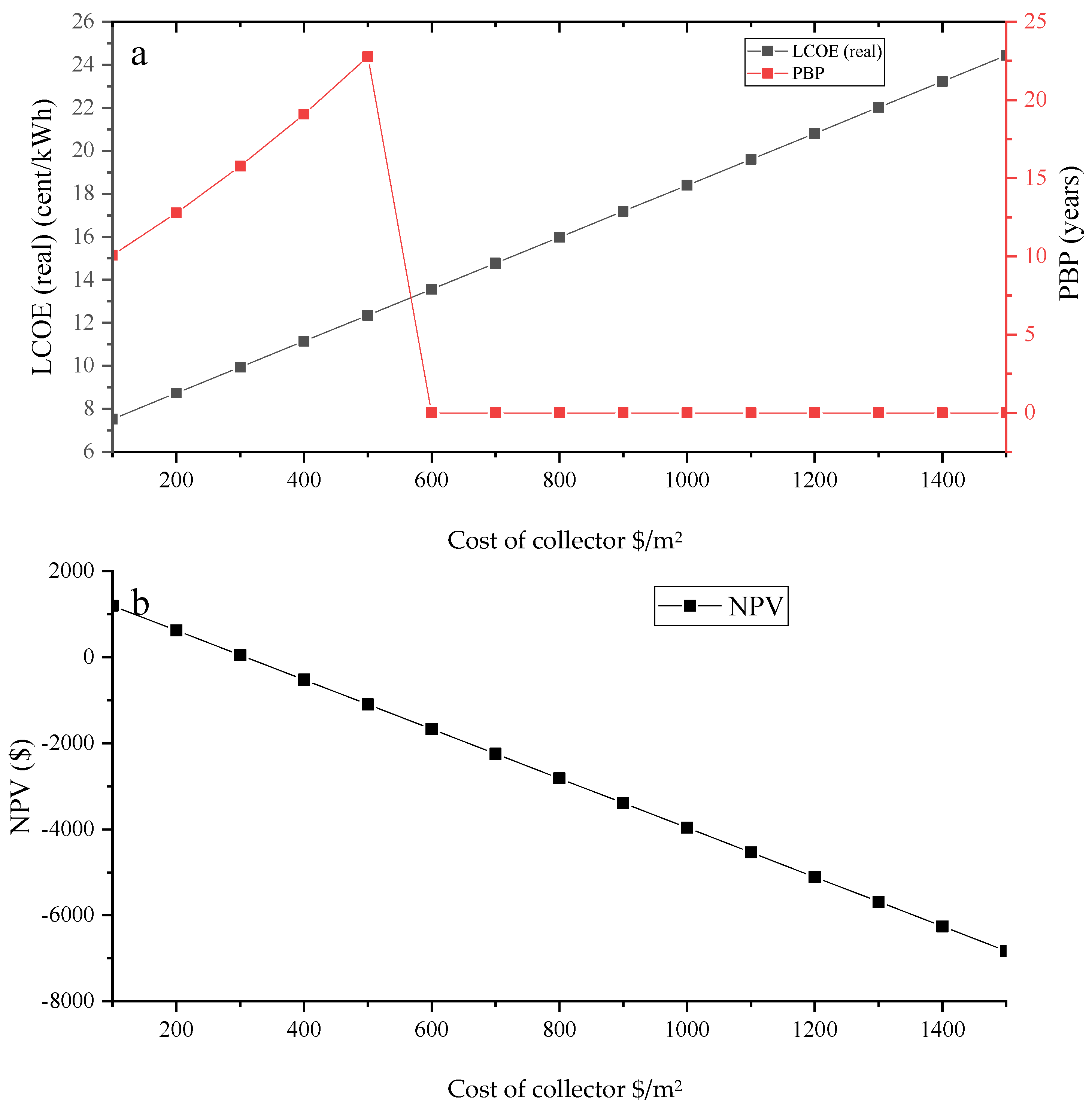

3.2. Economic Performance of the SWHS

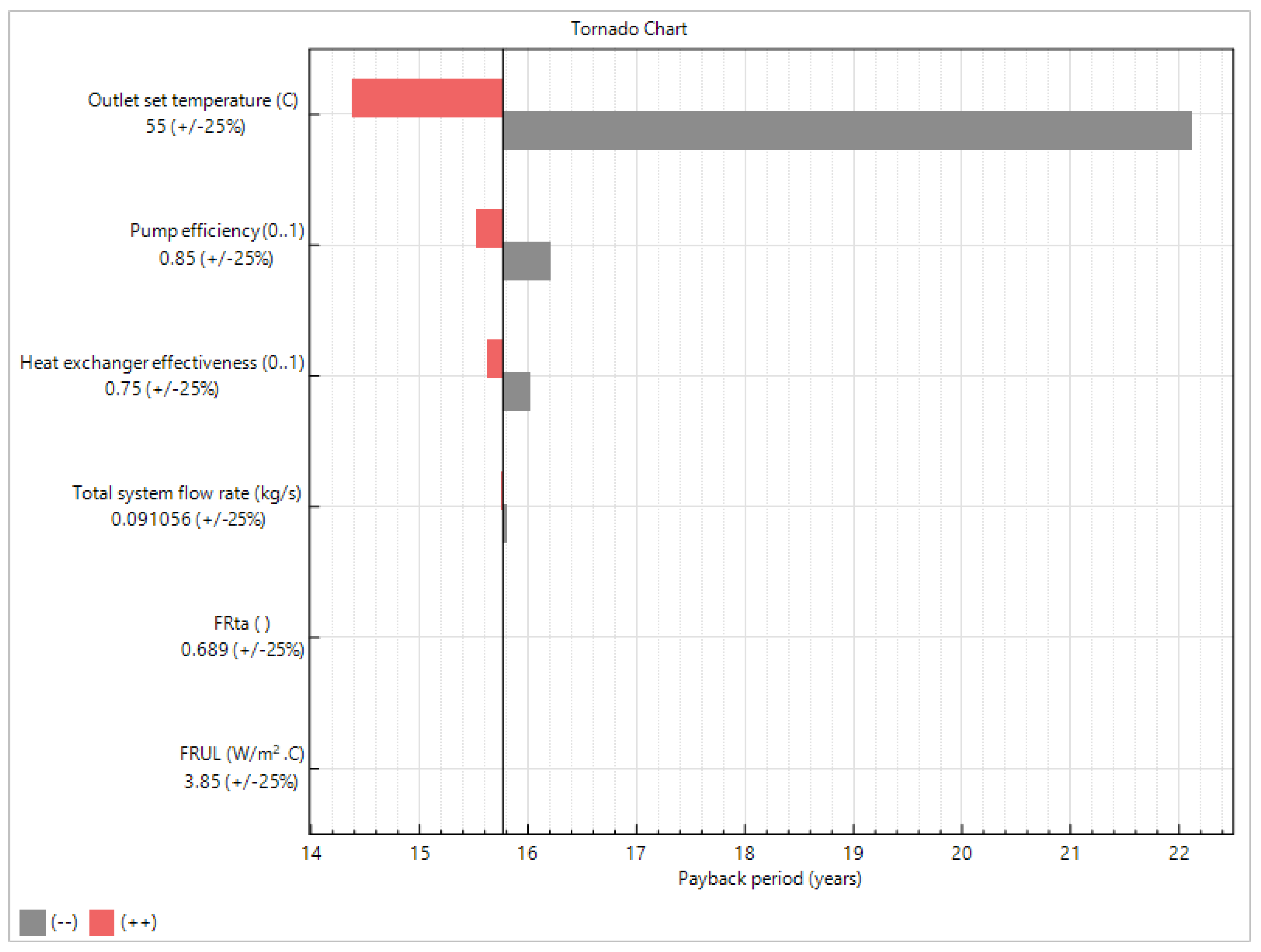

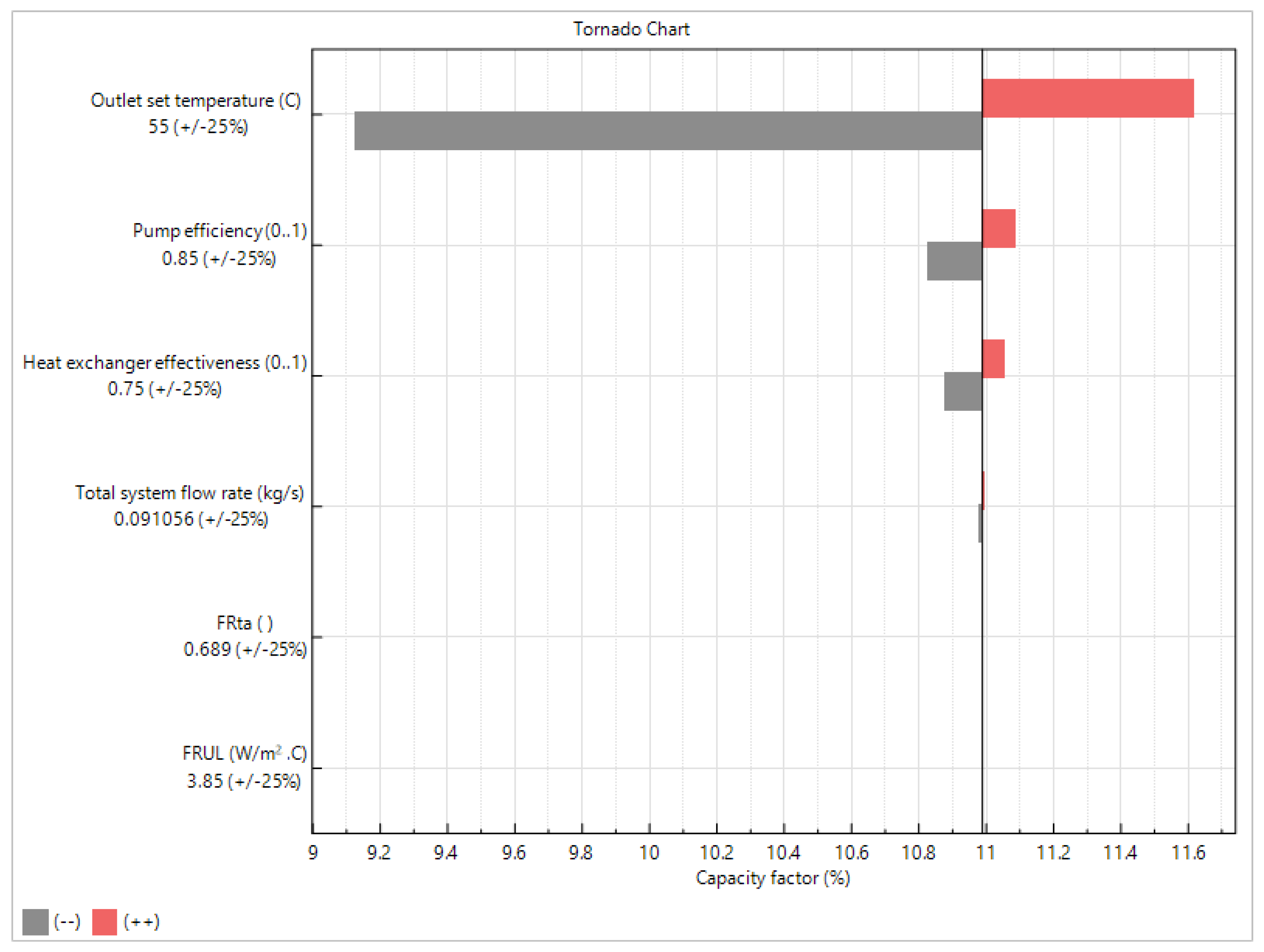

3.3. Sensitivity Analysis of Key Performance Indicators

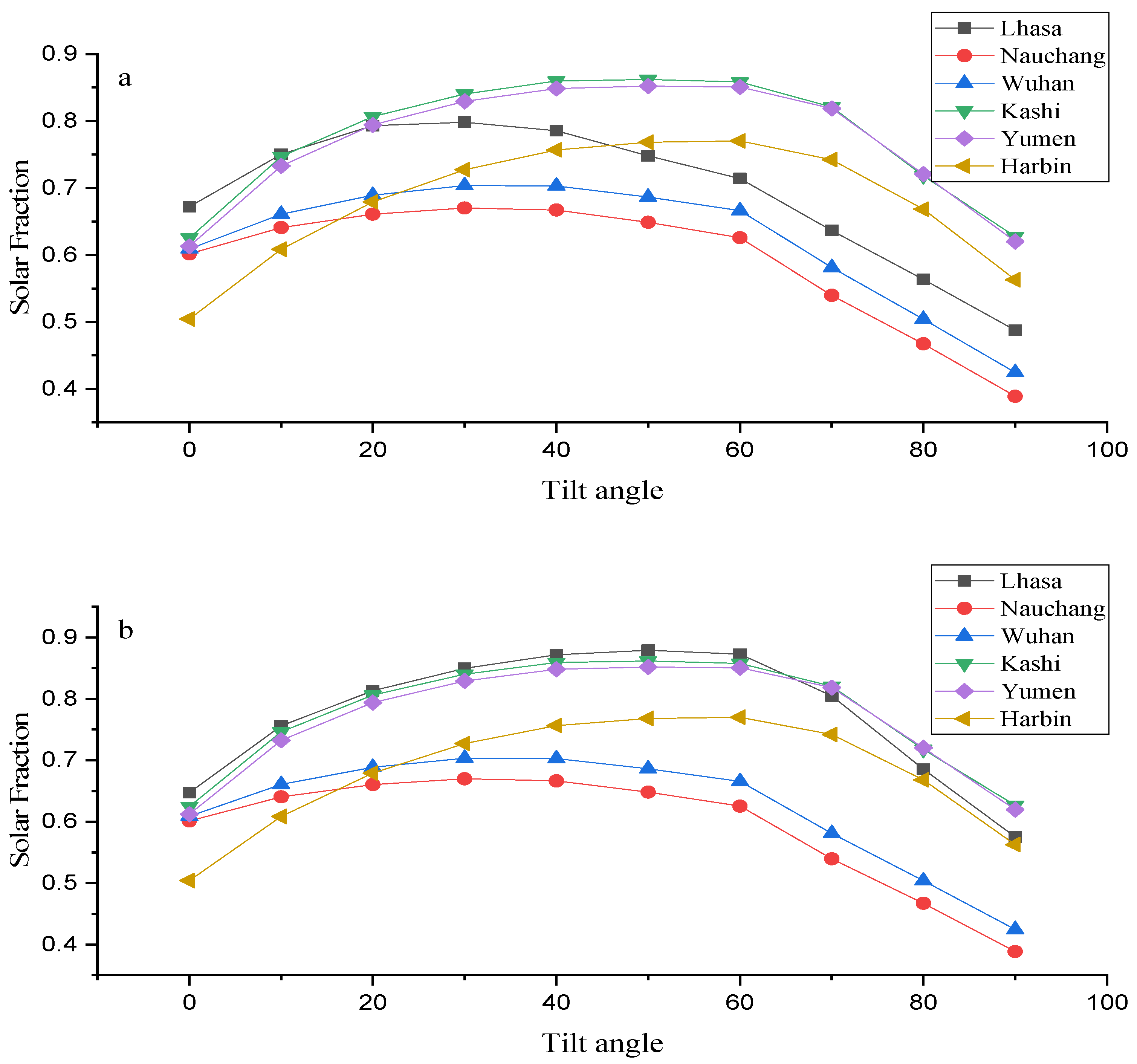

3.3.1. Sensitivity Analysis of the Tilt Angle and the Effect of the Cost of the Collector on the Economics of the SWHS

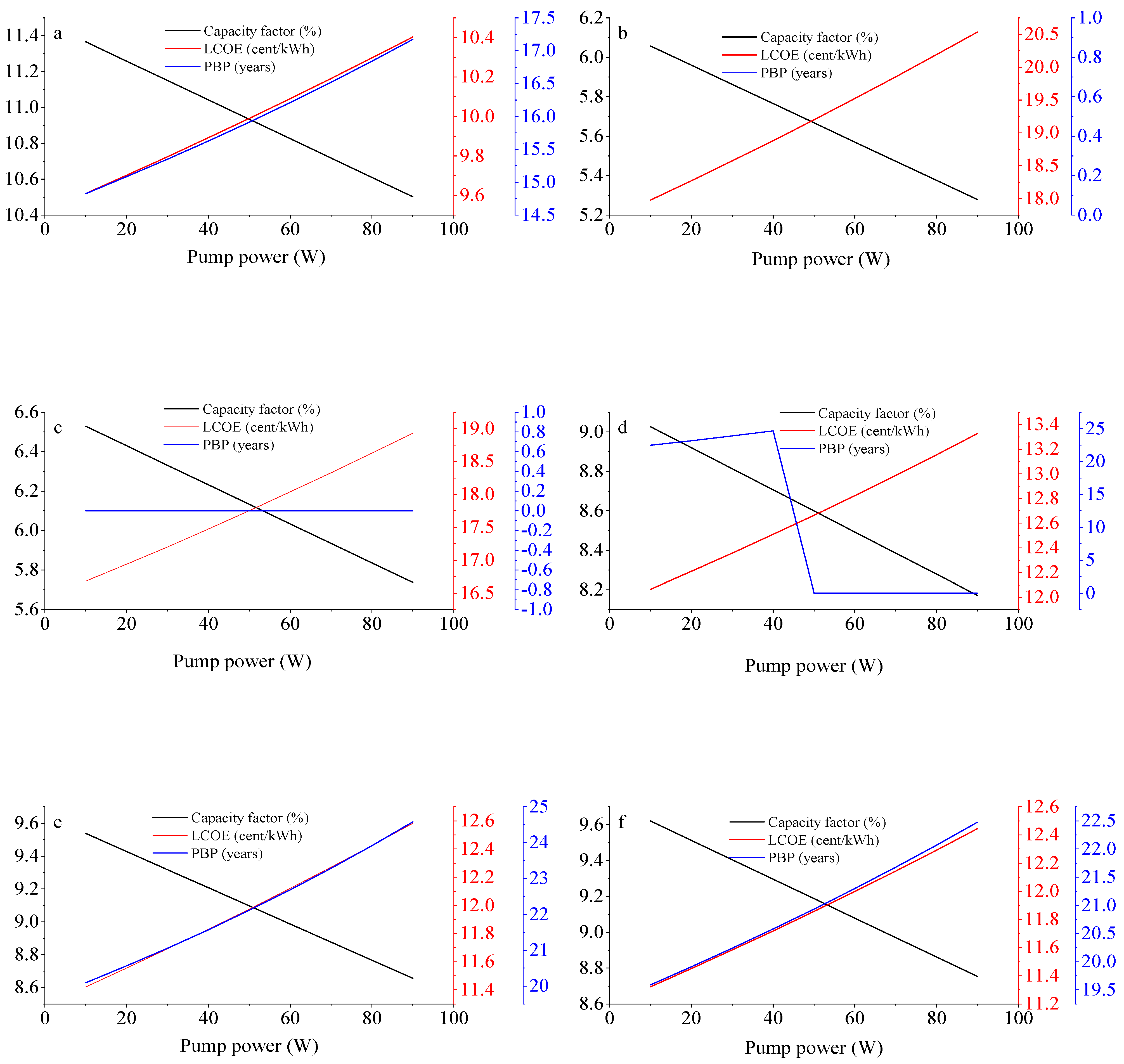

3.3.2. Effect of Pump Power on the Capacity Factor, LCOE and PBP

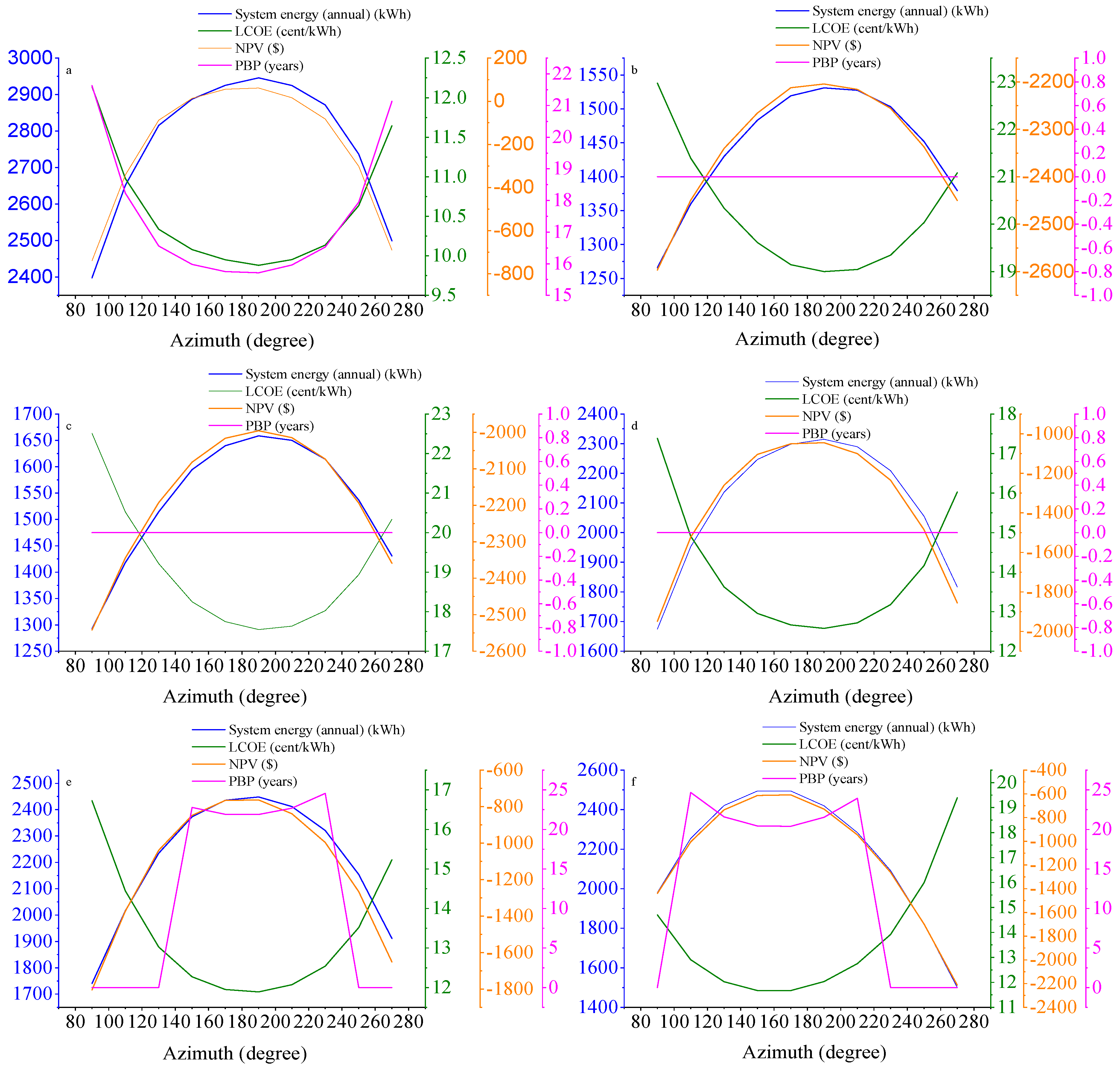

3.3.3. Parametric Study on the SWHS

3.4. Environmental Impact Assessment

4. Conclusions and Policy Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations and Nomenclature

| CF | Capacity Factor (%) |

| G | Global incident solar radiation in W/m2 |

| GHG | Greenhouse Gases |

| IPCC | Intergovernmental Panel on Climate Change |

| LCOE | Levelized cost of energy (USD/kWh) |

| PVGIS | Photovoltaic Geographical Information System |

| NPV | Net Present Value (USD) |

| NREL | National Renewable Energy Laboratory |

| RE | Renewable Energy |

| SAM | System Advisor Model |

| SWHS | Solar Water Heating System |

| WST | Water Storage Tank |

| Cash inflow (USD) | |

| Surface area of WST, (m2) | |

| Collector area (m2) | |

| Ambient temperature (°C) | |

| Inlet temperature (°C) | |

| Incidence angle modifier | |

| Delivered temperature (°C) | |

| Heat-loss coefficient of WST (W/m2·°C) | |

| Mean tank temperature, (°C) | |

| Nominal discount (%) | |

| Initial investment (USD) | |

| Cash outflow (USD) | |

| Annual costs (USD) | |

| Control volume (m3) | |

| Specific heat capacity of the working fluid (J/kg.°C) | |

| Produced energy | |

| Volume of WST | |

| Real discount | |

| Flow Rate (kg/s) | |

| Period of analysis (years) | |

| h | Enthalpy (J) |

| FRUL | Thermal losses of solar collector in ((W/m2)/°C) |

| FR (τα) | Conversion factor |

| Auxiliary electrical power, W | |

| Useful heat gain delivered, W | |

| Heat loss from the WST, W | |

| Subscripts | |

| cold | Cold node |

| draw | User draw |

| useful | Adjusted for loss |

| hot | Hot node |

| mains | From supply water |

| Density | |

| Project year | |

| α | Short-wave absorptivity of the collector |

| τ | Transmittance of cover |

References

- Kolsi, L.; Al-Dahidi, S.; Kamel, S.; Aich, W.; Boubaker, S.; Ben Khedher, N. Prediction of Solar Energy Yield Based on Artificial Intelligence Techniques for the Ha’il Region, Saudi Arabia. Sustainability 2022, 15, 774. [Google Scholar] [CrossRef]

- Hasan, H.A.; Sherza, J.S.; Abed, A.M.; Togun, H.; Ben Khedher, N.; Sopian, K.; Mahdi, J.M.; Talebizadehsardari, P. Thermal and Flow Performance Analysis of a Concentrated Linear Fresnel Solar Collector with Transverse Ribs. Front. Chem. 2023, 10, 1074581. [Google Scholar] [CrossRef] [PubMed]

- Moritz, M.; Schönfisch, M.; Schulte, S. Estimating Global Production and Supply Costs for Green Hydrogen and Hydrogen-Based Green Energy Commodities. Int. J. Hydrog. Energy 2023, 48, 9139–9154. [Google Scholar] [CrossRef]

- Bedair, A.O.M.; Shehata, A.S.; Hamad, M.S.; Tawfik, A. Energy Performance Enhancement of PV System through Proposed Back Cooling Techniques and Natural Air Draft: An Experimental Study. Int. J. Green Energy 2023, in press. [Google Scholar] [CrossRef]

- Giri, N.C.; Mohanty, R.C. Agrivoltaic System: Experimental Analysis for Enhancing Land Productivity and Revenue of Farmers. Energy Sustain. Dev. 2022, 70, 54–61. [Google Scholar] [CrossRef]

- Huang, P. The Verticality of Policy Mixes for Sustainability Transitions: A Case Study of Solar Water Heating in China. Res. Policy 2019, 48, 103758. [Google Scholar] [CrossRef]

- Masson-Delmotte, V.; Zhai, P.; Pirani, A.; Connors, S.L.; Péan, C.; Berger, S.; Caud, N.; Chen, Y.; Goldfarb, L.; Gomis, M.I.; et al. (Eds.) Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2021. [Google Scholar]

- Endale, A. Analysis of Status, Potential and Economic Significance of Solar Water Heating System in Ethiopia. Renew. Energy 2019, 132, 1167–1176. [Google Scholar] [CrossRef]

- Koçak, B.; Fernandez, A.I.; Paksoy, H. Review on Sensible Thermal Energy Storage for Industrial Solar Applications and Sustainability Aspects. Sol. Energy 2020, 209, 135–169. [Google Scholar] [CrossRef]

- Jahangiri Mamouri, S.; Bénard, A. New Design Approach and Implementation of Solar Water Heaters: A Case Study in Michigan. Sol. Energy 2018, 162, 165–177. [Google Scholar] [CrossRef]

- Jahangiri, M.; Akinlabi, E.T.; Sichilalu, S.M. Assessment and Modeling of Household-Scale Solar Water Heater Application in Zambia: Technical, Environmental, and Energy Analysis. Int. J. Photoenergy 2021, 2021, 663033. [Google Scholar] [CrossRef]

- Jahangiri Mamouri, S.; Gholami Derami, H.; Ghiasi, M.; Shafii, M.B.; Shiee, Z. Experimental Investigation of the Effect of Using Thermosyphon Heat Pipes and Vacuum Glass on the Performance of Solar Still. Energy 2014, 75, 501–507. [Google Scholar] [CrossRef]

- Jafari Mosleh, H.; Jahangiri Mamouri, S.; Shafii, M.B.; Hakim Sima, A. A New Desalination System Using a Combination of Heat Pipe, Evacuated Tube and Parabolic Trough Collector. Energy Convers. Manag. 2015, 99, 141–150. [Google Scholar] [CrossRef]

- Şerban, A.; Bărbuţă-Mişu, N.; Ciucescu, N.; Paraschiv, S.; Paraschiv, S. Economic and Environmental Analysis of Investing in Solar Water Heating Systems. Sustainability 2016, 8, 1286. [Google Scholar]

- Siampour, L.; Vahdatpour, S.; Jahangiri, M.; Mostafaeipour, A.; Goli, A.; Shamsabadi, A.A.; Atabani, A. Techno-Enviro Assessment and Ranking of Turkey for Use of Home-Scale Solar Water Heaters. Sustain. Energy Technol. Assess. 2021, 43, 100948. [Google Scholar] [CrossRef]

- Benli, H. Potential Application of Solar Water Heaters for Hot Water Production in Turkey. Renew. Sustain. Energy Rev. 2016, 54, 99–109. [Google Scholar] [CrossRef]

- Fayaz, H.; Rahim, N.A.; Saidur, R.; Hasanuzzaman, M. Techno-Economıc Analysıs of Evacuated Tube Solar Water Heater Usıng F-Chart Method. IOP Conf. Ser. Mater. Sci. Eng. 2018, 358, 012016. [Google Scholar] [CrossRef]

- Raza, S.A.; Ahmad, S.S.; Ratlamwala, T.A.H.; Hussain, G.; Alkahtani, M. Techno-Economic Analysis of Glazed, Unglazed and Evacuated Tube Solar Water Heaters. Energies 2020, 13, 6261. [Google Scholar] [CrossRef]

- Muthuraman, U.; Shankar, R.; Nassa, V.K.; Karthick, A.; Malla, C.; Kumar, A.; Kumar, P.M.; Rahim, R.; Bharani, M. Energy and Economic Analysis of Curved, Straight, and Spiral Flow Flat-Plate Solar Water Collector. Int. J. Photoenergy 2021, 2021, 5547274. [Google Scholar] [CrossRef]

- García, J.L.; Porras-Prieto, C.J.; Benavente, R.M.; Gómez-Villarino, M.T.; Mazarrón, F.R. Profitability of a Solar Water Heating System with Evacuated Tube Collector in the Meat Industry. Renew. Energy 2019, 131, 966–976. [Google Scholar] [CrossRef]

- Yılmaz, İ.H. Residential Use of Solar Water Heating in Turkey: A Novel Thermo-Economic Optimization for Energy Savings, Cost Benefit and Ecology. J. Clean. Prod. 2018, 204, 511–524. [Google Scholar] [CrossRef]

- Khedher, N.B. Experimental Evaluation of a Flat Plate Solar Collector Under Hail City Climate. Eng. Technol. Appl. Sci. Res. 2018, 8, 2750–2754. [Google Scholar] [CrossRef]

- Pambudi, N.A.; Nanda, I.R.; Saputro, A.D. The Energy Efficiency of a Modified V-Corrugated Zinc Collector on the Performance of Solar Water Heater (SWH). Results Eng. 2023, 18, 101174. [Google Scholar] [CrossRef]

- Odoi-Yorke, F.; Akpahou, R.; Opoku, R.; Mensah, L.D. Technical, Financial, and Emissions Analyses of Solar Water Heating Systems for Supplying Sustainable Energy for Hotels in Ghana. Sol. Compass 2023, 7, 100051. [Google Scholar]

- Ibrahim, M.M.; El Berry, A.; Ashour, K. Experimental and theoretical study of smart energy management solar water heating system for outdoor swimming pool application in egypt. Front. Heat Mass Transf. 2022, 18, 9. [Google Scholar] [CrossRef]

- Singh, S.; Anand, A.; Shukla, A.; Sharma, A. Environmental, Technical and Financial Feasibility Study of Domestic Solar Water Heating System in India. Sustain. Energy Technol. Assess. 2021, 43, 100965. [Google Scholar] [CrossRef]

- Naveed Arif, M.; Waqas, A.; Ahmed Butt, F.; Mahmood, M.; Hussain Khoja, A.; Ali, M.; Ullah, K.; Mujtaba, M.A.; Kalam, M.A. Techno-Economic Assessment of Solar Water Heating Systems for Sustainable Tourism in Northern Pakistan. Alex. Eng. J. 2022, 61, 5485–5499. [Google Scholar] [CrossRef]

- Azad Gilani, H.; Hoseinzadeh, S. Techno-Economic Study of Compound Parabolic Collector in Solar Water Heating System in the Northern Hemisphere. Appl. Therm. Eng. 2021, 190, 116756. [Google Scholar] [CrossRef]

- Alsayed, M.F. Solar Water Heater Sizing and Economic Evaluation for Local Hospital. In Proceedings of the 2021 12th International Renewable Engineering Conference (IREC), Amman, Jordan, 14 April 2021; IEEE: New York, NY, USA, 2021; pp. 1–6. [Google Scholar]

- Urban, F.; Geall, S.; Wang, Y. Solar PV and Solar Water Heaters in China: Different Pathways to Low Carbon Energy. Renew. Sustain. Energy Rev. 2016, 64, 531–542. [Google Scholar] [CrossRef]

- World Bank Services, etc., Value Added (% of GDP). 2015. Available online: https://data.worldbank.org/indicator/NV.SRV.TOTL.ZS?locations=CN (accessed on 4 May 2023).

- IEA IEA SHC||Solar Heat Worldwide. Available online: https://www.iea-shc.org/solar-heat-worldwide (accessed on 26 April 2023).

- Huang, J.; Fan, J.; Furbo, S. Feasibility Study on Solar District Heating in China. Renew. Sustain. Energy Rev. 2019, 108, 53–64. [Google Scholar] [CrossRef]

- Aly, A.; Bernardos, A.; Fernandez-Peruchena, C.M.; Jensen, S.S.; Pedersen, A.B. Is Concentrated Solar Power (CSP) a Feasible Option for Sub-Saharan Africa?: Investigating the Techno-Economic Feasibility of CSP in Tanzania. Renew. Energy 2019, 135, 1224–1240. [Google Scholar] [CrossRef]

- Ezeanya, E.K.; Massiha, G.H.; Simon, W.E.; Raush, J.R.; Chambers, T.L. System Advisor Model (SAM) Simulation Modelling of a Concentrating Solar Thermal Power Plant with Comparison to Actual Performance Data. Cogent Eng. 2018, 5, 1524051. [Google Scholar] [CrossRef]

- Hamilton, W.T.; Neises, T.W. Dispatch Optimization of Electric Thermal Energy Storage within System Advisor Model. J. Energy Storage 2023, 61, 106786. [Google Scholar] [CrossRef]

- Hamilton, W.T.; Newman, A.M.; Wagner, M.J.; Braun, R.J. Off-Design Performance of Molten Salt-Driven Rankine Cycles and Its Impact on the Optimal Dispatch of Concentrating Solar Power Systems. Energy Convers. Manag. 2020, 220, 113025. [Google Scholar] [CrossRef]

- Gafurov, T.; Usaola, J.; Prodanovic, M. Modelling of Concentrating Solar Power Plant for Power System Reliability Studies. IET Renew. Power Gener. 2015, 9, 120–130. [Google Scholar] [CrossRef]

- Abdelhady, S.; Borello, D.; Shaban, A. Techno-Economic Assessment of Biomass Power Plant Fed with Rice Straw: Sensitivity and Parametric Analysis of the Performance and the LCOE. Renew. Energy 2018, 115, 1026–1034. [Google Scholar] [CrossRef]

- SAM Solar Water Heating—System Advisor Model—SAM. Available online: https://sam.nrel.gov/solar-water-heating.html (accessed on 24 April 2023).

- Yılmaz, İ.H. Optimization of an Integral Flat Plate Collector-Storage System for Domestic Solar Water Heating in Adana. Anadolu Univ. J. Sci. Technol. Appl. Sci. Eng. 2018, 19, 165–176. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- CEIC Water Consumption: City: Daily per Capita: Residential: Beijing|Economic Indicators|CEIC. Available online: https://www.ceicdata.com/en/china/water-consumption-daily-per-capita-residential/cn-water-consumption-city-daily-per-capita-residential-beijing (accessed on 7 May 2023).

- Agyekum, E.B. Techno-Economic Comparative Analysis of Solar Photovoltaic Power Systems with and without Storage Systems in Three Different Climatic Regions, Ghana. Sustain. Energy Technol. Assess. 2021, 43, 100906. [Google Scholar] [CrossRef]

- Agyekum, E.B.; Velkin, V.I. Optimization and Techno-Economic Assessment of Concentrated Solar Power (CSP) in South-Western Africa: A Case Study on Ghana. Sustain. Energy Technol. Assess. 2020, 40, 100763. [Google Scholar] [CrossRef]

- Trading Economics China Inflation Rate—April 2023 Data—1986–2022 Historical—May Forecast. Available online: https://tradingeconomics.com/china/inflation-cpi (accessed on 7 May 2023).

- Trading Economics China Sales Tax Rate—VAT—2022 Data—2023 Forecast—2006–2021 Historical—Chart. Available online: https://tradingeconomics.com/china/sales-tax-rate (accessed on 7 May 2023).

- Global Petrol Prices China Electricity Prices. September 2022. Available online: https://www.globalpetrolprices.com/China/electricity_prices/ (accessed on 8 May 2023).

- Zhou, W.; Goh, B. China Keeps Lending Benchmarks Unchanged in March, as Expected. Reuters. 20 March 2023. Available online: https://www.reuters.com/world/china/china-keeps-lending-benchmarks-unchanged-march-expected-2023-03-20/ (accessed on 8 May 2023).

- Statista China: Power Generation Emission Intensity 2021. Available online: https://www.statista.com/statistics/1300419/power-generation-emission-intensity-china/ (accessed on 8 May 2023).

| Location | Latitude (Degrees) | Longitude (Degrees) | Global Horizontal (kWh/m2/day) | Average Temperature (°C) | Average Wind Speed (m/s) |

|---|---|---|---|---|---|

| Lhasa | 30.15 | 91.39 | 5.01 | −1.30 | 1.10 |

| Nauchang | 28.69 | 115.85 | 3.67 | 18.70 | 2.70 |

| Wuhan | 30.59 | 114.30 | 3.70 | 17.80 | 2.70 |

| Kashi | 39.38 | 75.75 | 4.75 | 12.80 | 2.10 |

| Yumen | 40.24 | 97.43 | 4.83 | 10.00 | 3.70 |

| Harbin | 45.79 | 126.53 | 4.00 | 5.10 | 3.20 |

| Parameter | Value | Ref. |

|---|---|---|

| Solar tank and heat exchanger | ||

| Solar tank volume (m3) | 0.3 | [40] |

| Outlet set temperature (°C) | 55 | SAM |

| Mechanical room temperature (°C) | 20 | SAM |

| Solar tank maximum water temperature (°C) | 99 | [10] |

| Piping and pump | ||

| Pipe diameter (m) | 0.019 | SAM |

| Pipe insulation conductivity (W/m·°C) | 0.03 | SAM |

| Pipe insulation thickness (m) | 0.006 | SAM |

| Total piping length (m) | 10 | [10,21] |

| Pump power (W) | 45 | [10] |

| Pump efficiency (%) | 85 | [10,40] |

| Metric | Water as Working Fluid | Glycol as Working Fluid | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lhasa | Nauchang | Wuhan | Kashi | Yumen | Harbin | Lhasa | Nauchang | Wuhan | Kashi | Yumen | Harbin | |

| Annual AC energy saved (year 1), kWh | 2928 | 1528 | 1652 | 2313 | 2445 | 2469 | 2839 | 1527 | 1651 | 2311 | 2444 | 2468 |

| Solar fraction (year 1) | 0.80 | 0.67 | 0.70 | 0.86 | 0.85 | 0.77 | 0.85 | 0.67 | 0.70 | 0.86 | 0.85 | 0.77 |

| Aux with solar (year 1), kWh | 601.2 | 635.9 | 575.4 | 251.6 | 302.4 | 624.5 | 347.7 | 636.6 | 576.1 | 252.6 | 303.4 | 625.1 |

| Aux without solar (year 1), kWh | 3668.1 | 2280.9 | 2346.9 | 2692.9 | 2881.0 | 3225.1 | 3339.3 | 2280.9 | 2346.9 | 2692.9 | 2881.0 | 3225.1 |

| CF, (year 1), % | 11 | 5.70 | 6.20 | 8.70 | 9.20 | 9.20 | 10.70 | 5.70 | 6.20 | 8.60 | 9.10 | 9.20 |

| Metric | Water as Working Fluid | Glycol as Working Fluid | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lhasa | Nauchang | Wuhan | Kashi | Yumen | Harbin | Lhasa | Nauchang | Wuhan | Kashi | Yumen | Harbin | |

| LCOE nominal, cent/kWh | 10.73 | 20.56 | 19.01 | 13.59 | 12.85 | 12.73 | 11.07 | 20.57 | 19.02 | 13.60 | 12.86 | 12.73 |

| LCOE real, cent/kWh | 9.94 | 19.04 | 17.61 | 12.59 | 11.90 | 11.79 | 10.25 | 19.05 | 17.62 | 12.59 | 11.91 | 11.79 |

| Electricity bill without system (year 1), USD | 1366 | 1366 | 1366 | 1366 | 1366 | 1366 | 1366 | 1366 | 1366 | 1366 | 1366 | 1366 |

| Electricity bill with system (year 1), USD | 1069 | 1210 | 1197 | 1137 | 1120 | 1113 | 1078 | 1210 | 1197 | 1137 | 1120 | 1113 |

| Net savings with system (year 1), USD | 296 | 156 | 169 | 229 | 246 | 253 | 288 | 156 | 168 | 229 | 246 | 253 |

| NPV, USD | 52 | −2207 | −2006 | −1034 | −761 | −650 | −83 | −2210 | −2008 | −1037 | −764 | −653 |

| Simple PBP, years | 15.8 | - | - | - | 21.8 | 20.8 | 16.5 | - | - | - | 21.9 | 20.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agyekum, E.B.; Khan, T.; Giri, N.C. Evaluating the Technical, Economic, and Environmental Performance of Solar Water Heating System for Residential Applications–Comparison of Two Different Working Fluids (Water and Glycol). Sustainability 2023, 15, 14555. https://doi.org/10.3390/su151914555

Agyekum EB, Khan T, Giri NC. Evaluating the Technical, Economic, and Environmental Performance of Solar Water Heating System for Residential Applications–Comparison of Two Different Working Fluids (Water and Glycol). Sustainability. 2023; 15(19):14555. https://doi.org/10.3390/su151914555

Chicago/Turabian StyleAgyekum, Ephraim Bonah, Tahir Khan, and Nimay Chandra Giri. 2023. "Evaluating the Technical, Economic, and Environmental Performance of Solar Water Heating System for Residential Applications–Comparison of Two Different Working Fluids (Water and Glycol)" Sustainability 15, no. 19: 14555. https://doi.org/10.3390/su151914555

APA StyleAgyekum, E. B., Khan, T., & Giri, N. C. (2023). Evaluating the Technical, Economic, and Environmental Performance of Solar Water Heating System for Residential Applications–Comparison of Two Different Working Fluids (Water and Glycol). Sustainability, 15(19), 14555. https://doi.org/10.3390/su151914555