Shaping the Conscious Behaviors of Product Designers in the Early Stages of Projects: Promoting Correct Material Selection and Green Self-Identity through a New Conceptual Model

Abstract

:1. Introduction

- RQ1 As a product designer or an engineer, do you need to use material selection tools as well as methodologies in your daily work?

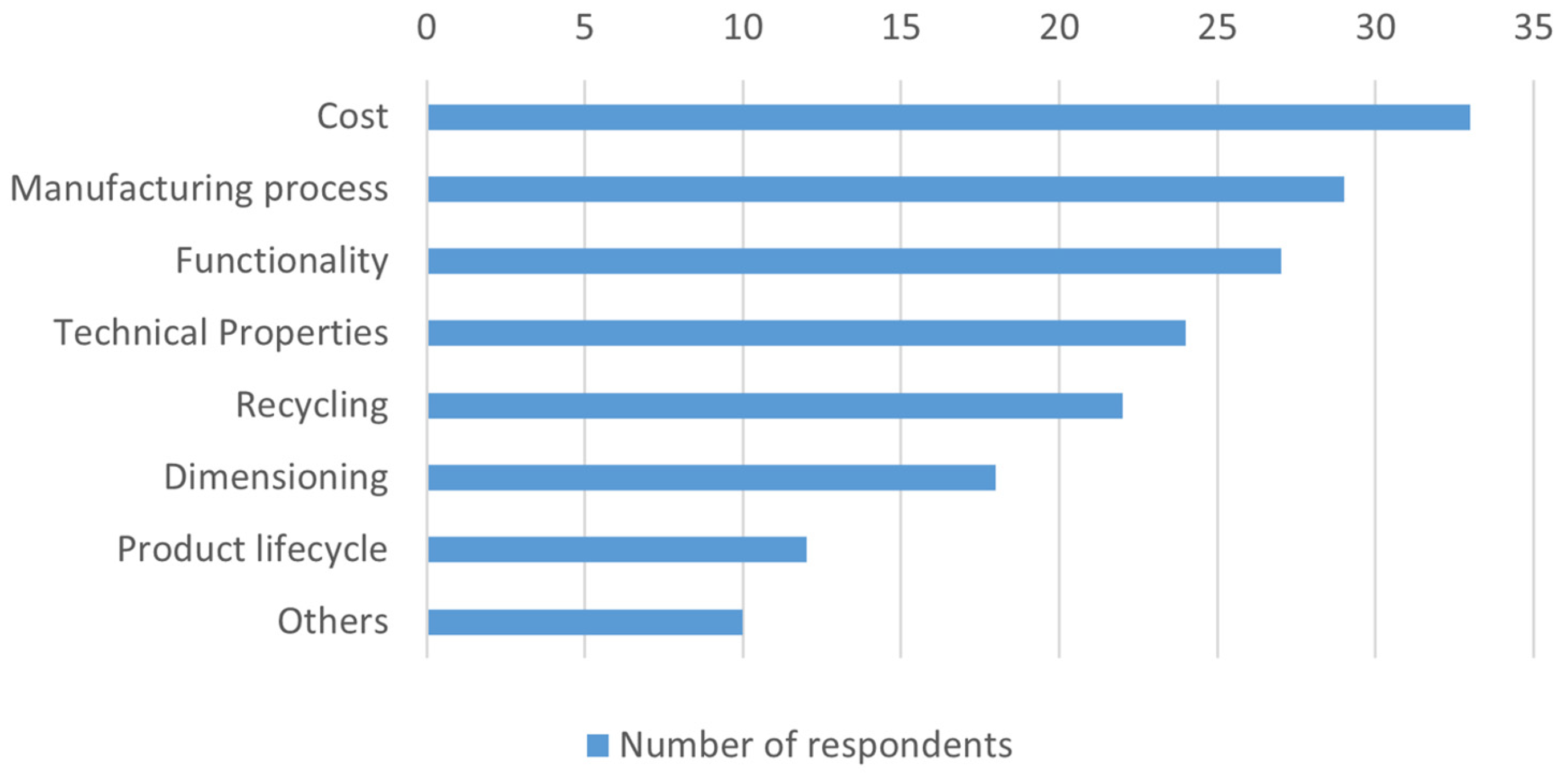

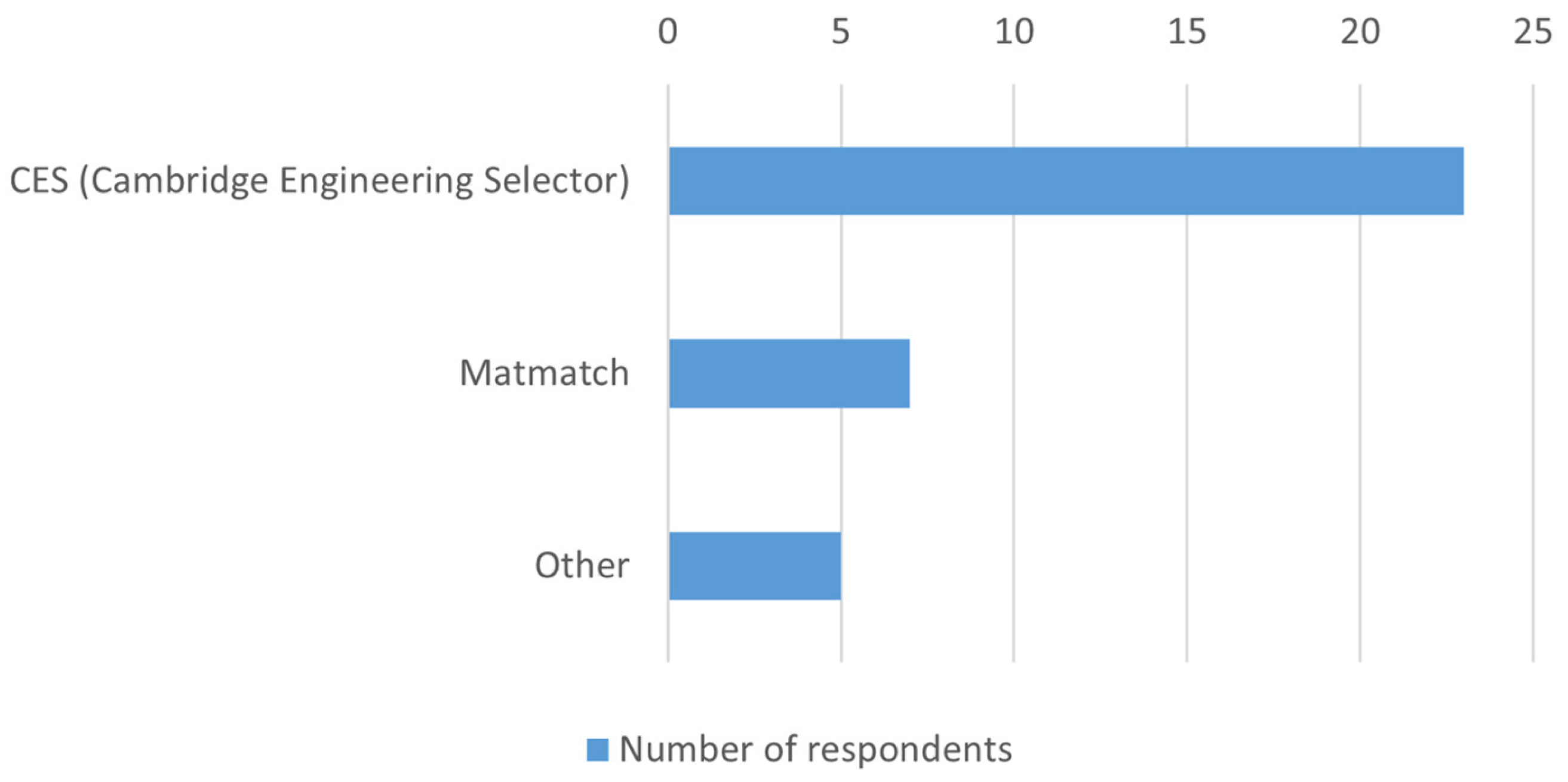

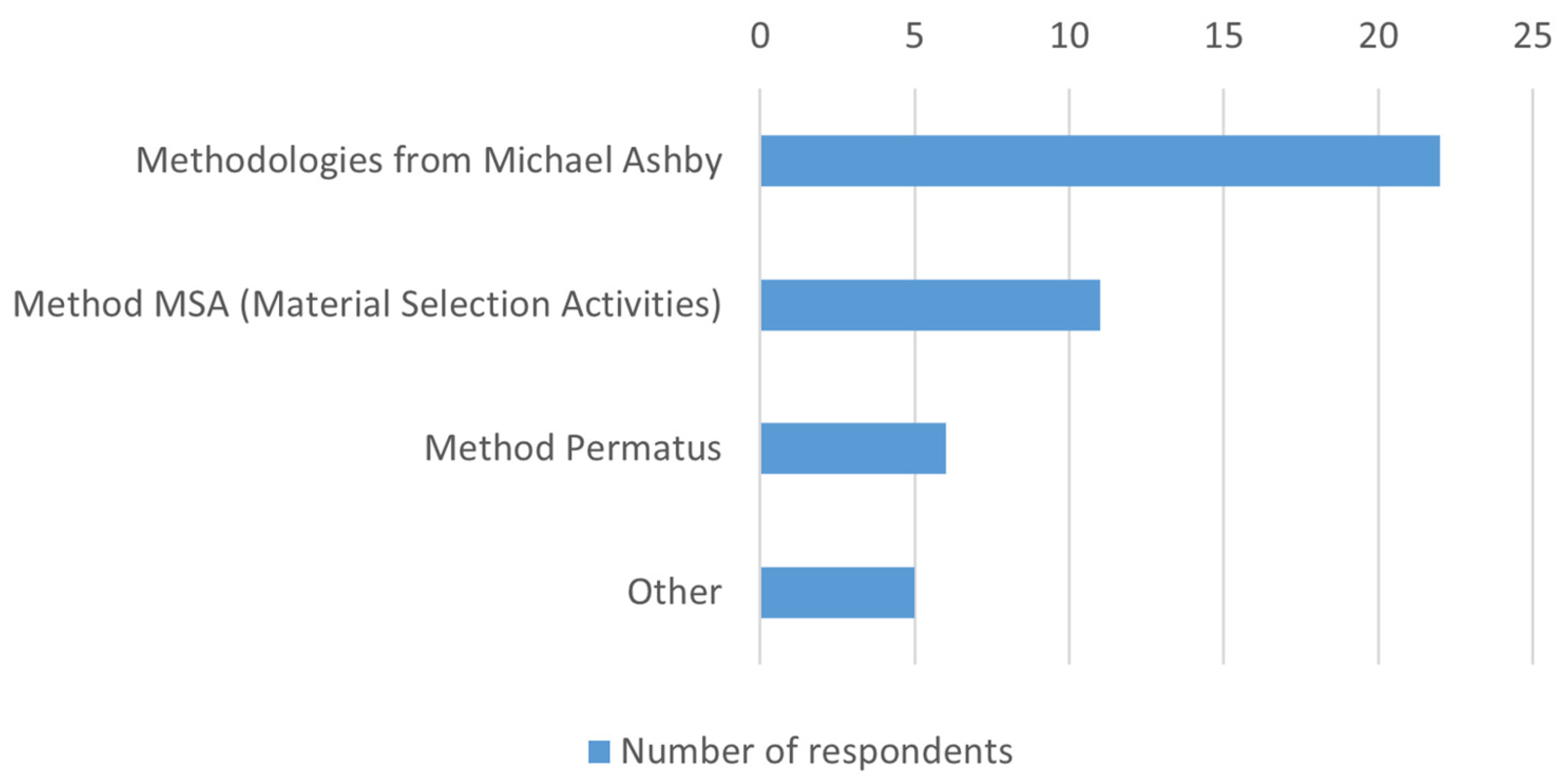

- RQ2 What are the main criteria for selecting materials that you use in your daily life? What tools and methodologies do you use?

- RQ3 What are the main difficulties you experience in the creative process phase? Do you have any suggestions for improvement?

2. Literature Review

3. Materials and Methods

4. Results

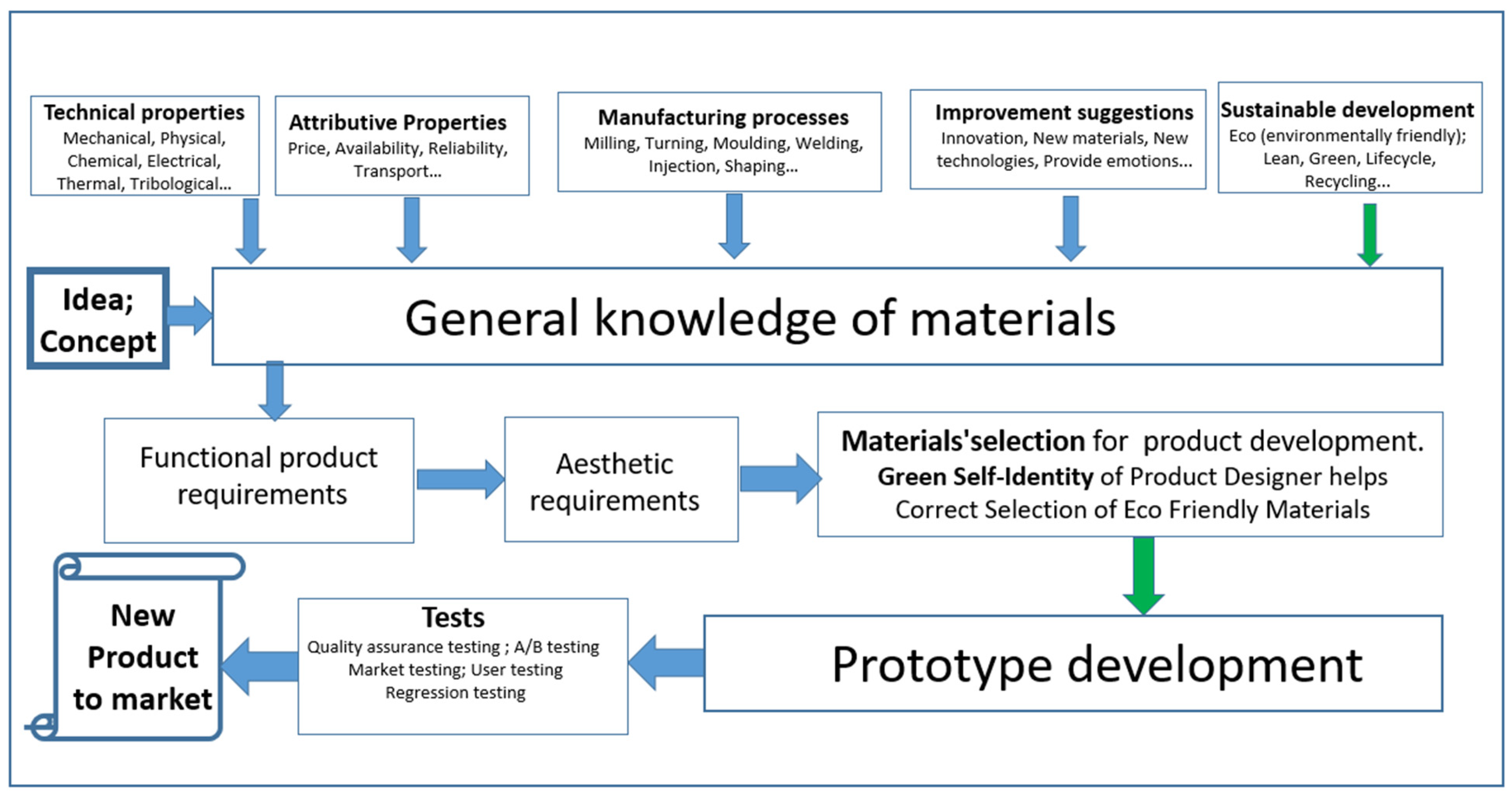

4.1. The New Model Based on the Basic Modular Methodology for a New Product Project

4.2. The Contribution of Green Materials to Designers’ Green Self-Identity towards Sustainability

5. Discussion

5.1. Mechanical and Physical Properties

5.2. Attributive Properties

5.3. Aesthetic and Emotional Aspects of Product Design

5.4. Manufacturing Processes for the Materialization of a New Product

5.5. The Importance of Quality Management in Material Selection for a New Product

5.6. Green Self-Identity in the Early Stage of Design towards Sustainability

6. Conclusions

- RQ1 As a product designer or an engineer, do you need to use materials selection tools as well as methodologies in your daily work?

- RQ2: What are the main criteria for selecting materials that you use in your daily life? What tools and methodologies do you use?

- RQ3: What are the main difficulties you experience in the creative process phase? Do you have any suggestions for improvement?

7. Limitations of This Work and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Ethical Statement

References

- Ranga, M.; Etzkowitz, H. Triple Helix systems: An analytical framework for innovation policy and practice in the Knowledge Society. Ind. High. Educ. 2013, 27, 237–262. [Google Scholar] [CrossRef]

- Ljungberg, L.Y. Materials selection and design for development of sustainable products. Mater. Des. 2007, 28, 466–479. [Google Scholar] [CrossRef]

- Santos, G.; Rebelo, M.; Ramos, S.; Silva, R.; Pereira, M.; Ramos, G.N.L. Developments regarding the integration of the occupational safety and health with quality and environment management systems. In Developments Regarding the Integration of the Occupational Safety and Health with Quality and Environment Management Systems; Kavouras, I.G., Chalbot, M.-C.G., Eds.; Nova Publishers New York: New York, NY, USA, 2014; pp. 113–146. [Google Scholar]

- Díaz-Ruiz, G.; Trujillo-Gallego, M. A Six Sigma and System Dynamic Integration for Process Variability Reduction in Industrial Processes. Int. J. Qual. Res. 2021, 16, 1149–1178. [Google Scholar] [CrossRef]

- Carvalho, A.V.; Lima, T.M. Quality 4.0 and Cognitive Engineering Applied to Quality Management Systems: A Framework. Appl. Syst. Innov. 2022, 5, 115. [Google Scholar] [CrossRef]

- Zgodavova, K.; Bober, P.; Majstorovic, V.; Monkova, K.; Santos, G.; Juhaszova, D. Innovative methods for small mixed batches production system improvement: The case of a bakery machine manufacturer. Sustainability 2020, 12, 6266. [Google Scholar] [CrossRef]

- Barbarossa, C.; De Pelsmacker, P.; Moons, I. Personal values, green self-identity and electric car adoption. Ecol. Econ. 2017, 140, 190–200. [Google Scholar] [CrossRef]

- Prasad, K.; Chakraborty, S. A quality function deployment-based model for materials selection. Mater. Des. 2013, 49, 525–535. [Google Scholar] [CrossRef]

- Dutta, G.; Kumar, R.; Sindhwani, R.; Singh, R. Digitalization priorities of quality control processes for SMEs: A conceptual study in perspective of Industry 4.0 adoption. J. Intell. Manuf. 2021, 32, 1679–1698. [Google Scholar] [CrossRef]

- Patton, W.J. Materials in Industry; Prentice-Hall: Upper Saddle River, NJ, USA, 1968. [Google Scholar]

- Jain, N.; Ovhal, S.N.; Patil, V.; Kartik, K.N. Smart materials—A state-of-the-art-review. Materials Today: Proceedings. Mater. Today Proc. 2023, 82, 381–389. [Google Scholar] [CrossRef]

- Balali, A.; Valipour, A. Identification and selection of building façade’s smart materials according to sustainable development goals. Sustain. Mater. Technol. 2020, 26, e00213. [Google Scholar] [CrossRef]

- Ashby, M.F.; Cebon, D. Teaching Engineering Materials: The CES EduPack; Cambridge University: Cambridge, UK, 2007. [Google Scholar]

- Ashby, M.F. Materials Selection in Mechanical Design, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2011. [Google Scholar]

- Ruiz-Pastor, L.; Chulvi, V.; Mulet, E.; Royo, M. A metric for evaluating novelty and circularity as a whole in conceptual design proposals. J. Clean. Prod. 2022, 337, 130495. [Google Scholar] [CrossRef]

- Mesa, J.; Gonzalez-Quiroga, A.; Heriberto Maury, H. Developing an indicator for material selection based on durability and environmental footprint: A Circular Economy perspective. Resour. Conserv. Recycl. 2020, 160, 104887. [Google Scholar] [CrossRef]

- Borgianni, Y.; Fiorineschi, L.; Frillici, F.S.; Rotini, F. The process for individuating TRIZ Inventive Principles: Deterministic, stochastic or domain-oriented? Des. Sci. 2021, 7, 1–21. [Google Scholar] [CrossRef]

- Lopez-Fornies, I.; Sierra-Perez, J.; Boschmonart-Rives, J.; Gabarrell, X. Metric for measuring the effectiveness of an eco-ideation process. J. Clean. Prod. 2017, 162, 865–874. [Google Scholar] [CrossRef]

- Sá, C.; Amaral, A.; Barreto, L.; Carvalho, F.; Santos, G. Perception of the importance to implement ISO 9001 in organizations related to people linked to quality—An empirical study. Int. J. Qual. Res. 2019, 13, 1055–1070. [Google Scholar] [CrossRef]

- Noamnaa, S.; Thongphuna, T.; Kongjit, C. Transformer Production Improvement by Lean and MTM-2 Technique. ASEAN Eng. J. 2022, 12, 29–35. [Google Scholar] [CrossRef]

- Mousavi-Nasab, S.H.; Sotoudeh-Anvari, A. A new multi-criteria decision making approach for sustainable material selection problem: A critical study on rank reversal problem. J. Clean. Prod. 2018, 182, 466–484. [Google Scholar] [CrossRef]

- Dasanayaka, C.H.; Murphy, D.F.; Nagirikandalage, P.; Abeykoon, C. The application of management accounting practices towards the sustainable development of family businesses: A critical review. Clean. Environ. Syst. 2021, 3, 100064. [Google Scholar] [CrossRef]

- Prendeville, S.; O’Connor, F.; Palmer, L. Material selection for eco-innovation: SPICE model. J. Clean. Prod. 2014, 85, 31–40. [Google Scholar] [CrossRef]

- Ispas, L.; Mironeasa, C. The Identification of Common Models Applied for the Integration of Management Systems: A Review. Sustainability 2022, 14, 3559. [Google Scholar] [CrossRef]

- Doiro, M.; Fernández, J.F.; Félix, M.J.; Santos, G. ERP-machining centre integration: A modular kitchen production case study. Procédia Manuf. 2017, 13, 1159–1166. [Google Scholar] [CrossRef]

- Van Kesteren, I.E.H. Product designers’information needs in materials selection. Mater. Des. 2008, 29, 133–145. [Google Scholar] [CrossRef]

- Patel, J.D.; Trivedi, R.H.; Yagnik, A. Self-identity and internal environmental locus of control: Comparing their influences on green purchase intentions in high-context versus low-context cultures. J. Retail. Consum. Serv. 2020, 53, 102003. [Google Scholar] [CrossRef]

- Ferrante, M. Seleção de Materiais, 2nd ed.; EdUFSCar: São Carlos, SP, Brazil, 2002. [Google Scholar]

- Edwards, K.L. Selecting materials for optimum use in engineering components. Mater. Des. 2005, 26, 469–472. [Google Scholar] [CrossRef]

- Budinski, K.G. Engineering Materials: Properties and Selection; Prentice-Hall: Upper Saddle River, NJ, USA, 1996. [Google Scholar]

- Lindbeck, J.R. Product Design and Manufacture; Simon & Schuster Company: Delran, NJ, USA, 1995. [Google Scholar]

- Ashby, M.F. Material’s Selection in Mechanical Design, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 1992. [Google Scholar]

- Ashby, M.F.; Johnson, K.W. Materials and Design: The Art and Science of Material Selection in Product Design; Butterworth-Heinemann: Oxford, UK, 2002. [Google Scholar]

- Jahan, A.; Mustapha, F.; Ismail, M.Y.; Sapuan, S.M.; Bahraminasab, M.A. comprehensive VIKOR method for material selection. Mater. Des. 2011, 32, 1215–1221. [Google Scholar] [CrossRef]

- Ramalhete, P.S.; Senos, A.M.R.; Aguiar, C. Digital tools for material selection in product design. Mater. Des. 2010, 31, 2275–2287. [Google Scholar] [CrossRef]

- Vitorino, N.; Abrantes, J.C.C.; Frade, J.R. Quality criteria for phase change materials selection. Energy Convers. Manag. 2016, 124, 598–606. [Google Scholar] [CrossRef]

- Bendig, D.; Kleine-Stegemann, L.; Gisa, K. The green manufacturing framework—A systematic literature review. Clean. Eng. Technol. 2023, 13, 100613. [Google Scholar] [CrossRef]

- Thoits, P.A.; Virshup, L.K. Me’s and we’s: Forms and functions of social identities. In Self and Identity: Fundamental Issuses; Oxford University Press: Oxford, UK, 1997; pp. 106–133. [Google Scholar]

- Farag, M.M. Quantitative methods of materials substitution: Application to automotive components. Mater. Des. 2008, 29, 374–380. [Google Scholar] [CrossRef]

- Karana, E.; Hekkert, P.; Kandachar, P. Material Considerations in Product Design: A survey on crucial material aspects used by product designers. Mater. Des. 2008, 29, 1081–1089. [Google Scholar] [CrossRef]

- Kothari, C.R. Research Methodology Methods and Techniques; New Age International (P) Ltd.: New Delhi, India, 2004. [Google Scholar]

- Attenborough, D. A Life on Our Planet—My Witness Statement and a Vision for the Future; Grand Central Publishing: New York, NY, USA, 2020. [Google Scholar]

- Santos, G.; Barbosa, J. QUALIFOUND—A modular tool developed for Quality Improvement in Foundries. J. Manuf. Technol. Manag. 2006, 17, 351–362. [Google Scholar] [CrossRef]

- Khan, N.; Ali1, A.; Syed, T.H.; Mirza, M.B. Identification and Synthesis of Business Performance Improvement Factors Framework of ISO Management System Standards Certified Companies. J. Posit. Sch. Psychol. 2022, 6, 6583–6601. Available online: http://journalppw.com (accessed on 15 January 2023).

- Chen, H.-M.; Kuo, T.-C.; ChenImpacts, J.-L. Impacts on the ESG and financial performances of companies in the manufacturing industry based on the climate change related risks. J. Clean. Prod. 2022, 380, 134951. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Y.; Li, H.; Wen, D. Identification and analysis of barriers to the effectiveness of ISO 45001 certification in Chinese certified organisations: A DEMATEL-ISM approach. J. Clean. Prod. 2023, 383, 135447. [Google Scholar] [CrossRef]

- Huzaim, N.H.M.; Rahim, S.Z.A.; Musa, L.; Abdellah, A.E.-H.; Abdullah, M.M.A.B.; Rennie, A.; Rahman, R.; Garus, S.; Błoch, K.; Sandu, A.V.; et al. Potential of Rapid Tooling in Rapid Heat Cycle Molding: A Review. Materials 2022, 15, 3725. [Google Scholar] [CrossRef] [PubMed]

- Francisco, M.G.; Junior, O.C.; Sant’Anna, A.M.O. Design for six sigma integrated product development reference model through systematic review. Int. J. Lean Six Sigma 2020. ahead-of-print. [Google Scholar] [CrossRef]

- Ipek, M.; Selvi, I.H.; Findik, F.; Torkul, O.; Cedimoĝlu, I.H. An expert system based material selection approach to manufacturing. Mater. Des. 2013, 7, 331–340. [Google Scholar] [CrossRef]

- Sánchez, J.M.; Priest, J.W. Product Development and Design for Manufacturing, 2nd ed.; Marcel Dekker: New York, NY, USA, 2001. [Google Scholar]

- Norman, D.A. Emotional Design—Why We Love (or Hate) Everyday Things; Basic Books Publisher: New York, NY, USA, 2004. [Google Scholar]

- Lefteri, C. Making It: Manufacturing Techniques for Product Design; Continuum International Publishing Group: London, UK, 2007. [Google Scholar]

- Damic, M. Exploring the Moderating of National Culture on the Relations between ISO 9001 and Organizational Innovativeness. Int. J. Qual. Res. 2021, 16, 429–448. [Google Scholar] [CrossRef]

- Cardoso, R.P.; Reis, J.S.M.; Silva, D.E.W.; Barros, J.G.M.; Sampaio, N.A.S. How to perform a simultaneous optimization with several response variables. Rev. Gestão Secr. 2023, 14, 564–578. [Google Scholar] [CrossRef]

- Barbosa, A.S.; Silva, L.B.; Naomi, S. Item response theory-based validation of an integrated management system measurement instrument. J. Clean. Prod. 2021, 328, 129546. [Google Scholar] [CrossRef]

- Črv, S.; Markič, M. Contribution of the QMS principles to company performance. Int. J. Qual. Res. 2022, 17, 227–242. [Google Scholar] [CrossRef]

- Pombal, T.; Ferreira, L.P.; Sá, J.C.; Pereira, M.T.; Silva, F.J.G. Implementation of Lean Methodologies in the Management of Consumable Materials in the Maintenance Workshops of an Industrial Company. Procedia Manuf. 2019, 38, 975–982. [Google Scholar] [CrossRef]

- Yülek, M.A. Industrial Policies and Outcomes: A Comparison of Pre-Liberalized Korean and Turkish Economies. J. Comp. Asian Dev. 2016, 15, 179–200. [Google Scholar] [CrossRef]

- Ibrahim, Y.M.; Hami, N.; Abdulameer, S.S. A Scale for Measuring Sustainable Manufacturing Practices and Sustainability Performance: Validity and Reliability. Qual. Innov. Prosper. 2020, 24, 59–74. [Google Scholar] [CrossRef]

- Rodrigues, J.; Sá, J.C.; Silva, F.; Ferreira, L.; Santos, G. Lean Management “Quick-Wins”: Results of Implementation. A Case Study. Qual. Innov. Prosper. J. 2019, 23, 3–21. [Google Scholar] [CrossRef]

- Akram, M.; Kumar, C.; Parkash; Chachar, F.A.; Khan, A. A Study on Waste Disposal Management in Textile Industry: A Case Study of Gul Ahmed. South Asian Manag. Rev. 2022, 1, 14–36. [Google Scholar] [CrossRef]

- Tonjang, S.; Thawesaengskulthai, N. Total Quality and Innovation Management in Healthcare (TQIM-H) for an Effective Innovation Development: A Conceptual Framework and Exploratory Study. Appl. Syst. Innov. 2022, 5, 70. [Google Scholar] [CrossRef]

- Firoiu, D.; Ionescu, G.H.; Pîrvu, R.; Bădîrcea, R.; Patrichi, I.C. Achievement of the sustainable development goals (SDG) in Portugal and forecast of key indicators until 2030. Technol. Econ. Dev. Econ. 2022, 28, 1649–1683. [Google Scholar] [CrossRef]

- Sutoová, A.; Grzincic, M. Creation of defects Catalogue for Nonconforming Product Identification in the Foundry Organization. Qual. Innov. Prosper. 2013, XVII, 52–58. [Google Scholar] [CrossRef]

- Vásquez-Millalén, C.; Gil-Marín, M.; Vera-Ruiz, S. Social Report Model framed within the framework of Sustainable Accounting. Res. Mil. Soc. Sci. J. 2023, 13, 3944–3958. [Google Scholar]

- Ortíz-Barrios, M.; Petrillo, A.; De Felice, F.; Jaramillo-Rueda, N.; Jiménez-Delgado, G.; Borrero-López, L. A Dispatching-Fuzzy AHP-TOPSIS Model for Scheduling Flexible Job-Shop Systems in Industry 4.0 Context. Appl. Sci. 2021, 11, 5107. [Google Scholar] [CrossRef]

- Barbosa, A.S.; Silva, L.B.; Morioka, S.N.; Silva, J.M.N.; Souza, V.F. Integrated management systems and organizational performance: A multidimensional perspective. Total Qual. Manag. Bus. Excell. 2023, 34, 1469–1507. [Google Scholar] [CrossRef]

- Toki, G.F.I.; Ahmed, T.; Hossain, E.; Alave, R.K.K.; Faruk, O.; Mia, R.; Islam, S.R. Single Minute Exchange Die (SMED): A sustainable and well-timed approach for Bangladeshi garments industry. Clean. Eng. Technol. 2023, 12, 100592. [Google Scholar] [CrossRef]

- Singh, P.K.; Maheswaran, R. Analysis of social barriers to sustainable innovation and digitisation in supply chain. Environ. Dev. Sustain. 2023. [Google Scholar] [CrossRef] [PubMed]

- Guillén, M.F. 2030, Major Global Trends. A Shock That Will Change the Future of Everything; St. Martin Publishing Group: New York, NY, USA, 2020. [Google Scholar]

- Pollini, B.; Rognoli, V. Early-stage material selection based on life cycle approach: Tools, obstacles and opportunities for design. Sustain. Prod. Consum. 2021, 28, 1130–1139. [Google Scholar] [CrossRef]

- Omrany, H.; Ghaffarianhoseini, A.; Chang, R.; Ghaffarianhoseini, A.; Rahimian, F.P. Applications of Building information modelling in the early design stage of high-rise buildings. Autom. Constr. 2023, 152, 104934. [Google Scholar] [CrossRef]

- Subramanian, V.; Peijnenburg, W.J.G.M.; Vijver, M.G.; Blanco, C.B.; Cucurachi, S.; Guinée, J.B. Approaches to implement safe by design in early product design through combining risk assessment and Life Cycle Assessment. Chemosphere 2023, 311, 137080. [Google Scholar] [CrossRef]

- Badawy, M.; Alqahtani, F.; Hafez, H. Identifying the risk factors affecting the overall cost risk in residential projects at the early stage. Ain Shams Eng. J. 2022, 13, 101586. [Google Scholar] [CrossRef]

| SN. | Author (s) | Material Selection Method | Variables Used | Main Requirements for the Method |

|---|---|---|---|---|

| 1 | Patton (1968) [10] | Patton’s method | Project specifications Production specifications | Design specifications (product’s dimensions, i.e., strength, hardness, corrosion) Production specifications (shaping and molding characteristics, as well as, joining of different materials) Economic specification (minimize production cost) |

| 2 | Ashby (1992) [32] | Ashby’s method | Different classes of materials with different properties | This method is based on quantifiable properties and a correct comparison between different classes of materials and manufacturing processes This method also considers aesthetic attributes, i.e., the sensory properties of materials–to be important |

| 3 | Lindbeck (1995) [31] | Lindbeck’s method | Main characteristics of material properties | This author established that the main factors to consider in material selection must be related to material properties such as mechanical, physical, chemical, thermal, electrical, acoustic, and optical properties |

| 4 | Budinski (1996) [30] | Budinski’s method | Intrinsic properties (mechanical, physical, and chemical) Dimensional properties (size, shape, finish, and tolerances) Availability factor of materials | This author advised that the requirements for a correct material selection should be met by selecting materials in the following main categories: intrinsic properties (mechanical, physical, and chemical) and dimensional properties (size, shape, finish, and tolerances) This author was the first author to highlight the relevance of the availability factor for material selection |

| 5 | Farag (1997) [39] | Farag’s method | Reliability Product life cycle Environmental properties | This method is mainly based on the performance of the component to be idealized and comparing different alternatives He was the first author to equate reliability requirements that define the probability of the useful life (product life cycle) of a material for the determined adjacent function Service conditions related to the environmental properties of the material and product design. |

| SN. | Author (s) | Material Selection Method | Attributes | Main Requirements for the Method |

|---|---|---|---|---|

| 1 | Manzini (1986) [17] | Manzini’s method | Innovation Innovative design | This author is one of the first authors to recognize that materials are very important to promote design innovation, and consequently, product innovation In his excellent book, “The Material of Invention”, this author incorporates profound aesthetic and philosophical responses from designers in Italy, as well as the implications of designing with new materials in industrial production |

| 2 | Ashby and Johnson (2002) [33] | Ashby and Johnson’s method | Eco (environmentally friendly) | The authors reinforce the importance of the aesthetic attributes of the materials for the exhaustive material selection for the product design They create new rules, providing functionality and technique to products and idealizing them with personality Added eco (environmentally friendly) attributes |

| 3 | Karana (2008) [40] | Karana’s method | Sensorial and intangible properties Supply of emotions | This author has provided important information that can help designers to include elements such as sensorial and intangible properties in the material selection process According to this author, intangible properties are those characteristics that attribute other values, such as meanings, or provide emotions from its user, and these characteristics are difficult to identify, they cannot be identified with numbers, and it is difficult to perceive them by using the senses |

| (1) As a product designer or an engineer, do you need to use material selection tools as well as methodologies in your daily work? |

| (2) What are the main criteria for selecting materials that you use in your daily life? |

| (3) What tools and methodologies do you use? |

| (4) Do you think it will be important to conceive a new methodology or new tool or a model for selecting materials that can satisfy the needs of the design engineer or the product designer? |

| (5) What are the main difficulties you feel in the creative process phase? |

| (6) Do you have any suggestions for improvement? |

| Variables | Categories | Absolute Value | Percentage |

|---|---|---|---|

| Male | 23 | 60.52 | |

| Gender | |||

| Female | 15 | 39.47 | |

| Professional Occupation | Product design student | 8 | 21.05 |

| Engineer Product’s designer | 7 23 | 18.42 60.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Doiro, M.; Sá, J.C.; Santos, G. Shaping the Conscious Behaviors of Product Designers in the Early Stages of Projects: Promoting Correct Material Selection and Green Self-Identity through a New Conceptual Model. Sustainability 2023, 15, 14463. https://doi.org/10.3390/su151914463

Sun Z, Doiro M, Sá JC, Santos G. Shaping the Conscious Behaviors of Product Designers in the Early Stages of Projects: Promoting Correct Material Selection and Green Self-Identity through a New Conceptual Model. Sustainability. 2023; 15(19):14463. https://doi.org/10.3390/su151914463

Chicago/Turabian StyleSun, Zhonghua, Manuel Doiro, José Carlos Sá, and Gilberto Santos. 2023. "Shaping the Conscious Behaviors of Product Designers in the Early Stages of Projects: Promoting Correct Material Selection and Green Self-Identity through a New Conceptual Model" Sustainability 15, no. 19: 14463. https://doi.org/10.3390/su151914463

APA StyleSun, Z., Doiro, M., Sá, J. C., & Santos, G. (2023). Shaping the Conscious Behaviors of Product Designers in the Early Stages of Projects: Promoting Correct Material Selection and Green Self-Identity through a New Conceptual Model. Sustainability, 15(19), 14463. https://doi.org/10.3390/su151914463