Abstract

Biomaterials, used here to signify 100% biobased and biodegradable materials, can offer a promising solution for transitioning away from fossil-based resources, addressing the climate crisis, and combating plastic pollution. To ensure their environmental benefits, biomaterials must derive from regenerative, non-polluting feedstocks that do not compete with food or feed production. From this perspective, agricultural residues and by-products present a favorable feedstock option for biomaterials production. Although this is an improvement over sourcing them from primary crops, the sustainability of underlying agricultural systems must be considered. Furthermore, the nutrient value of biomaterials for specific soil ecosystems is often overlooked despite their compostability. In this research, we investigate the linkages between biomaterials development and regenerative agriculture, a set of farming practices that can effectively sustain the growing human population while enhancing, rather than degrading, ecosystem health. We explore interdependencies between biomaterials’ production and regenerative agriculture for biomass sourcing and nutrient return and suggest a methodological framework to identify mutual benefits. The extent to which regenerative farms can provide biomaterial feedstocks without compromising crop cultivation and ecosystem health is analyzed together with the potential of biomaterials to deliver beneficial nutrients and services to regenerative systems. Applying this framework to the Great Lakes Region, Michigan, USA, an agricultural hub facing environmental degradation and plastic pollution, reveals synergistic linkages that unlock novel circular economy opportunities, including local production of renewable biomaterials for various applications, enhancing food security and bolstering socio-ecological systems.

1. Introduction

Petrochemical feedstocks for materials manufacturing account for 14% of oil use, and are expected to drive half of oil demand growth between now and 2050, as plastic production is expected to double in the next 20 years [1,2]. Alternatives to petroleum-derived materials are crucial for mitigating the underlying causes of plastic contamination and the climate crisis. The unsustainable expansion of fossil-derived resins, fibers, and polymers has resulted in a yearly production of more than 400 million tons, which is predicted to more than double by 2050 [3,4,5]. The majority of this production ends up in landfills, with high rates of leakage into the natural environment, jeopardizing human health and ecosystems [6]. Annual greenhouse gas (GHG) emissions associated with petroleum-based materials’ production, including extraction, transportation, processing, and manufacturing, have reached nearly 1 billion tons of CO2-eq, and are anticipated to triple by 2050 [7]. Transitioning away from petroleum-based materials is a critical leverage point for decarbonizing our economy in the decades ahead.

Towards this direction, 100% biobased and compostable materials, i.e., biomaterials (herein, both conditions must hold true for materials to fall under this definition), can offer a promising alternative to petroleum-based materials, particularly in single-use and packaging applications, which represent the most prevalent uses of virgin plastics [5,8]. Although interest in biomaterials is increasing rapidly, their environmental impact depends on several factors, including feedstock sources, production methods, and end-of-life disposal options.

The use of renewable feedstocks can result in a significant reduction in GHG emissions in many instances; however, there may be other side effects of feedstock farming (e.g., corn, oil, and sugar crops), such as increased use of fertilizers and pesticides, leading to acidification and eutrophication of water bodies located downstream [3,9]. Additionally, when food crops are used for biomaterials production—which currently accounts for 0.02% of global agricultural land use—ethical concerns arise about potential competition with food production and security, especially at the local level [3]. It has been estimated that replacing all of the 170 million tons of global packaging plastics with bioplastics sourced from primary corn biomass sources would require 54% of current corn production and 60% more than Europe’s annual freshwater withdrawal [3].

Another important aspect to assess biomaterials’ sustainability is their end of life. Biodegradability refers to their capacity to decompose by natural biological processes and be broken down into simpler compounds, such as carbon dioxide, water, non-organic particles, and biomass. While all materials are theoretically biodegradable given sufficient time and suitable conditions, it is important to note that not all biodegradable materials break down into environmentally beneficial components like nutrients, as some may leave harmful residues and trace contaminants behind, such as heavy metals and microplastics. On the contrary, compostable materials, a subset of biodegradable materials, break down into organic materials that nourish soil and plants when properly composted. These materials have undergone strict testing to ensure that they can decompose within specific time frames without releasing harmful substances [3,10]. Therefore, to ensure biomaterials’ sustainability, recent attention has been placed on compostable materials derived from regenerative sources, such as agricultural residue and by-products, among other types of organic waste [3,4,8,11,12], that are able to cycle back beneficial nutrients to support soil health at their end of life (Figure 1B).

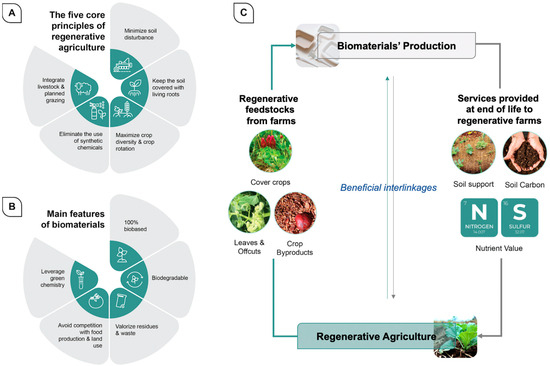

Figure 1.

Overview of the concepts considered and the interlinkages among them explored in the present study: (A) core principles of regenerative agriculture; (B) main biomaterials’ features; (C) diagram presenting the potential beneficial relationships between regenerative farms and biomaterials production considered in this study.

A promising source of sustainable feedstock for biomaterials production is agricultural residues and by-products. While this is an improvement over sourcing biomass from primary crops, it leaves the sustainability of the underlying agricultural system unquestioned. Conventional agriculture has been argued to be in need of a systemic transition towards more sustainable and regenerative models [13]. Industrial farming methods lead to deforestation, soil and water contamination, and nutrient depletion, while emitting high levels of GHGs, exacerbating global warming and climate change [13,14,15,16]. Farming systems that could feed the growing human population, while benefiting rather than degrading local ecosystems, are considered under the umbrella term of regenerative agriculture [13,15]. Regenerative agriculture is an alternative means of food production that could result in various environmental and social benefits. Despite the rapidly growing interest in this approach, there is no commonly accepted legal, scientific, or regulatory definition of it [15,16]. Many definitions and descriptions of regenerative agriculture exist, some focusing on specific farming processes (e.g., use of cover crops, integration of livestock, and reduced tillage), some on desired outcomes (e.g., improve soil health, sequester carbon, and enhance biodiversity), and some on combinations of the two [15,16]. Regenerative farming practices and their effects can vary with different geographical and social contexts [13,15,17,18]; hence, a more outcome-oriented approach could be more appropriate for the better understanding and adoption of the term, instead of a clear set of practices [19]. Regardless of the particular definition used, regenerative farming has two clear and complementary outcomes: the production of high-quality food and the improvement of the surrounding natural ecosystem [13]. A broad set of methods and practices can be applied to achieve these goals (examples of the most commonly adopted practices are presented in Table S1), tailored to the particular land and community needs of each setting. Shifting from extractive, linear thinking that prioritizes high yields above all else, and establishing cycles of regeneration by enriching soil quality, improving its carbon capture and storage capacity, and enhancing biodiversity are within the main aims of regenerative agriculture [13,15] (Figure 1A). Such an approach can fundamentally change the nature of inputs and outputs of farming systems, including the quantity and type of agricultural residues and by-products.

At the intersection of these two emerging fields, i.e., biomaterials production and regenerative farming, we identified a research gap in the understanding of potential interlinkages that could support both systems and enable sustainable materials and agricultural transitions. Understanding the type and quantity of biomass that could be sourced from regenerative agricultural systems for sustainably producing biomaterials while simultaneously identifying beneficial nutrients and services that biomaterials could provide at their end of life to support regenerative farming are critical aspects to ensuring that the sustainability goals of plastics are not pursued in isolation [19]. Interdependencies between bioplastics production and agricultural systems can reinforce sustainable practices rather than undermine or promote maladapted lock-in effects [20,21].

This study aims to provide a methodological framework to explore, identify, and assess potential beneficial links between these two fields in local contexts (Figure 1C). Stepwise approaches are suggested to examine whether regenerative farms can provide feedstocks for biomaterials production, as well as whether biomaterials can be cycled back to benefit regenerative farms. The proposed framework can guide relevant decision making and research and can be further adapted to better reflect local conditions and desired outcomes. To demonstrate the use of the suggested framework, we conducted an illustrative study in the Great Lakes Region in Michigan, USA. This region not only has considerable farming activity but is also an ecosystem of global significance facing serious pollution issues [22].

2. Materials and Methods

To design the suggested framework for identifying and assessing potential beneficial connections between regenerative agriculture and biomaterials production, the following research questions were examined.

2.1. Could Regenerative Agriculture Serve as a Resource for Biomaterials Production?

The potential of regenerative farms to provide feedstocks for making biomaterials was explored first. Lignocellulosic biomass, such as agricultural residues and forestry by-products, is a renewable, abundant feedstock, which could be ideal for the sustainable production of biomaterials. It is mostly composed of cellulose, together with smaller amounts of hemicellulose, and lignin. Cellulose is a natural polysaccharide with a wide range of applications including packaging, drug delivery, automotive and aerospace parts, and textiles [3,23,24]. Cover crop residues are an essential lignocellulosic biomass resource for regenerative farms, playing a key role in enriching soils and supporting crops, which could also serve as a promising biomaterial feedstock [23]. Therefore, cover crop residues are the main potential feedstock examined, followed by additional prospective regenerative feedstock sources.

Cover crops are typically sown in rotation with, or alongside, the main/cash crops to address specific issues or deliver beneficial services, such as maintaining soil coverage, managing nutrient cycles, controlling pests, and reducing soil erosion (common services provided and problems addressed by different types of cover crops are presented in Table S2). Most cover crops are fast-growing annuals (e.g., berseem clover, Austrian winter pea, and rye), while there are a few perennials (e.g., red clover, crown vetch, and alfalfa). After providing the desired services, they either perish due to winter conditions (winter-killed cover crops), such as rye, oats, and wheat, or are mowed, trimmed, cut, or pruned, yielding sufficient quantities of biomass which can be used as compost or serve as protective layers of mulch [25,26].

Determining the appropriate amount of excess cover crop residues that could be removed from lands without damaging soil health or compromising nutrient levels is a critical factor in identifying suitable biomaterial sources from regenerative farms. Complete removal of cover crop residues should be avoided since it can harm soils. Conversely, no removal could adversely affect soil productivity and water quality, as thicker mulch mats can hinder early plant growth and reduce yields. Moreover, in some cases, excess biomass on the land can result in nitrogen robbing from the main crops, as high carbon-to-nitrogen ratios can increase biological activity and nitrogen demand. Therefore, removing a certain amount of biomass can benefit both soil and crop health [27,28,29,30,31,32,33,34,35].

Optimal removal rates of cover crop residues for use in biomaterial production should be decided based on soil type, slope, and prevailing weather conditions. Most studies suggest that less than 20–30% of the total residue amount should be removed in order to maintain soil health and productivity [27,28,29,30,31,32,33,34,35], while a study on the amount of corn stover biomass needed to maintain soil carbon and sustain soil productivity indicated that a minimum of 0.525 kg/m2 of biomass residues was needed in no-till systems [33]. However, removal rates should be adjusted in response to local settings, soil needs, and climatic conditions, while it can also happen every other year to allow soils to rest.

In a recent study [23], the composition of commonly used cover crops, i.e., rye, oat, clover, vetch, and barley, grown under regenerative practices was analyzed, with cellulose being the most dominant component (Table 1). Cellulose isolated from cover crops was characterized and compared with commercially available cellulose using spectroscopic and thermogravimetric analyses. The performed analyses indicated that the cover-crop-derived cellulose had similar peaks and patterns to commercial cellulose, showcasing the suitability of cover crop residues as feedstocks for the biopolymers industry. In addition, the maximum degradation temperature from cellulose isolated from black oat (370 °C) was higher than in commercial cellulose (350 °C), suggesting that this particular feedstock could be a good candidate for biopolymers in applications requiring relatively high temperature uses, such as for microwavable containers.

Cover crop residues can provide various cellulose-derived monomers (e.g., glucose) for the synthesis of biopolymers (Table S3), as well as cellulose fibers, cellulose derivatives (e.g., cellulose acetate, cellulose esters), and nanocellulose (e.g., cellulose nanocrystals/CNCs and cellulose nanofibers/CNFs) [23,36]. These can be used as matrices and fillers for the production of both single-use packaging materials [37], as well as materials for high-performance applications, such as biocomposites, biopolymeric films, and functional bio-nanomaterials for energy storage and biomedical devices [36]. A non-exhaustive list of examples of biomaterials that could be sourced from residual cover crops is presented in Table 1.

Regenerative farms can provide additional sources of lignocellulosic biomass besides cover crop residues. For instance, forestry residues or crop leftovers and by-products can be obtained through selective and non-destructive harvesting or pruning of the main crops (especially in case of perennial crops and trees), buffer zones, or other crops grown alongside the main crops to offer specialized services, as in the case of polycultures (examples of the services provided by polycultures in regenerative farms are presented in Table S4). Biomaterial feedstocks, including wool, cotton, nettle yarns, sisal fibers, hemp, natural latex, and cork dust can be sourced from polycultural or livestock-integrating regenerative agroecosystems [38]. Examples of biomaterials that can be produced from such lignocellulosic biomass sources are presented in Table 1.

Table 1.

Examples of biomaterials that could be produced from residues or by-products of regenerative farming.

Table 1.

Examples of biomaterials that could be produced from residues or by-products of regenerative farming.

| Lignocellulosic Biomass Source | Typical Composition [% wt.] | Examples of Derived Biomaterials | Reference | |||

|---|---|---|---|---|---|---|

| Cellulose | Hemicellulose | Lignin | Other * | |||

| Cover crop residues | ||||||

| Abruzzi rye | 25% | 25% | 3% | 46% | Biobased and compostable biopolymers, such as bio-polyethylene (bio-PE), bio-polypropylene (bio-PP), and poly(lactic) acid (PLA) | [23,36] |

| Black oat | 25% | 21% | 2% | 52% | ||

| Crimson clover | 25% | 10% | 3% | 62% | ||

| Hairy vetch | 27% | 14% | 5% | 54% | ||

| Winter barley | 20% | 21% | 1% | 53% | ||

| Main crop residues | ||||||

| Corn stover | 29–61% | 10–32% | 3–35% | 5–17% | PLA, cellulose films (e.g., cellophane), thermoplastic starch, lignocellulosic fibers, starch-based bioplastics | [39,40,41,42,43,44,45] |

| Rice straw | 28–43% | 19–27% | 5–36% | 8–48% | PLA, rice straw bioplastics and biofilms for packaging, straws, plates, and coffee cups | [43,44,46,47,48,49] |

| Wheat straw | 29–51% | 10–39% | 5–30% | 1–7% | PLA, wheat straw bioplastics for packaging, straws, plates, and coffee cups | [46,48,50] |

| Sugarcane bagasse | 40–60% | 18–57% | 18–32% | 3–15% | Bio-PE from sugarcane ethanol; bio-polyethylene terephthalate (bio-PET); biocomposites of sugarcane fibers with PLA or bio-PE for textiles and building materials; CNCs for biocomposites; foam trays and films for packaging | [44,48,49,51,52,53,54,55,56] |

| Main crop by-products and processing waste | ||||||

| Apple pomace | 39% | 29% | 20% | 12% | Apple-pectin leather, biopolymer films, fiberboards and biocomposites after mixing w/pectin, citric acid, glycerol, or biopolymers | [56,57,58,59] |

| Grape pomace | 18% | 7% | 52% | 23% | Biocomposites and biopolymer films, e.g., by mixing w/PLA, low-methoxyl pectin (LMP), and glycerol | [56] |

| Olive pomace | 25% | 34% | 34% | 7% | Biocomposites of dried and ground olive pomace w/biopolymers, e.g., PLA | [56] |

| Coconut husk | 34% | 21% | 27% | 18% | Biocomposites of untreated/silane–/sodium hydroxide-treated biomass fibers w/biopolymers, e.g., PLA, gluten polymers, and tapioca biopolymer | [56] |

| Banana peels and fibers | 63% | 19% | 5% | 13% | ||

| Pineapple leaf fibers | 66% | 20% | 4% | 10% | ||

| Mango peel | 9% | 14% | 4% | 63% | ||

| Orange waste | 19–22% | 11–21% | <1% | 55–70% | Orange waste powder biofilms after blending with maleic anhydride; fiberboards after mixing w/pectin and/or glycerol | [58,60] |

| Forestry residues and woody biomass | ||||||

| Hardwood | 38–55% | 17–40% | 18–31% | 3% | Biodegradable packaging films; cellulosic fibers, such as viscose, lyocell, modal, cellulose acetate, and cellulose triacetate; cellulose-based biocomposites, e.g., when blended w/PLA | [44,61,62,63] |

| Softwood | 33–50% | 22–40% | 25–35% | 2–3.5% | ||

| Leaves and residues from herbaceous plants | 15–95% | 20–85% | 0–40% | 4–9% | Natural dyes and pigments; blended w/biopolymers, e.g., PLA and polyethylene glycol (PEG), to form biocomposites for pharmaceutical, cosmetic, and biomedical use | [44,64,65,66] |

* Other components, e.g., starch, pectin, proteins, lipids, acids.

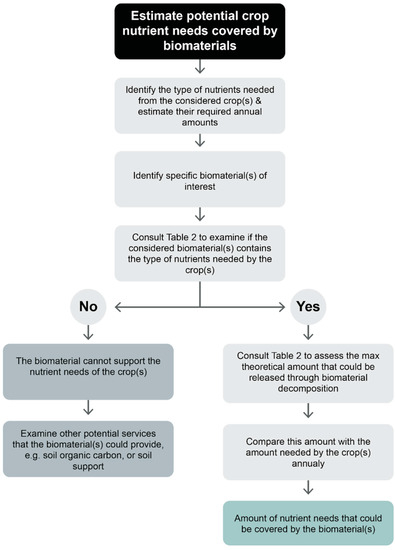

A decision tree was developed to assess the potential of a regenerative farm to provide suitable biomaterial feedstocks and evaluate their quantity and quality (Figure 2). The amount of available biomass (if any) is first quantified, considering cover crop residues or any other type of discarded biomass that could be generated and removed from the field as potential sources, e.g., discarded parts of the main crops or buffer zone pruning. This amount represents the maximum theoretically available biomaterial feedstock quantity, as processing yields have not been considered. Then, the quality of this feedstock is assessed considering its composition by consulting Table 1, and based on this, the upper bounds of the potential biomaterial amount that could be produced from this biomass are identified. Lastly, the amount of biomass needed to produce these biomaterials is estimated and translated into required amounts of arable land, harvested crops, and residues.

Figure 2.

Decision tree for estimating upper bounds of potential biomaterial production from regenerative farms.

2.2. Could Biomaterials Serve as a Resource for Regenerative Agriculture?

The potential role of compostable biomaterials in promoting regenerative agriculture at their end of life was analyzed. Emphasis was placed on exploring whether biomaterial composting could support the nutrient needs of crops, while additional advantageous services, including suppression of weeds and soil support, were also considered.

Maintaining a consistently high level of soil fertility is essential for the growth and productivity of crops, requiring the supply of both macronutrients, such as nitrogen (N), phosphorus (P), and potassium (K), and micronutrients, i.e., mineral elements needed for plant growth in trace quantities, such as boron (B) and iron (Fe). The most essential nutrients that should be supplied to crops are presented in Table S5. Although macronutrients are required in large amounts, with N being the most crucial, micronutrient deficiencies can also harm yields and profitability [67,68].

Cover cropping, livestock integration, and use of composted biological materials like crop residues or food and animal waste are the most common regenerative agricultural practices for providing nutrients to crops and soil. Compost and manure, especially from feedlots, enrich the soil with essential nutrients which are released gradually over a longer period than traditional fertilizers [69,70]. Nutrient concentration in crop residues depends on several factors such as season, adopted management practices, crop harvest time, and location, and varies in different residues, e.g., leaves and husks contain more nutrients than stalks [70]. Cover crops also affect the nutrient cycling in soils; for example, legume cover crops fix atmospheric N through N-fixing bacteria, which convert atmospheric N into plant-available forms, while cereal cover crops effectively scavenge and absorb the remaining N left over from previous crops, reducing N leaching potential [71].

Based on their composition, different biomaterials could potentially provide primary and secondary nutrients back to regenerative agricultural fields. The potential of biomaterials to provide nutrient return flows at their end of life and support the nutrient needs of crops as compost in regenerative farms was assessed based on their nutrient content (Table 2).

Table 2.

Nutrient content of commonly used biopolymers and biomaterial ingredients *.

Table 2.

Nutrient content of commonly used biopolymers and biomaterial ingredients *.

| Biopolymer/Biomaterial Ingredient | Nutrient Content (%) | Reference |

|---|---|---|

| Chitin | N: 6% | [72,73] |

| Chitosan | N: 6–7% | [74] |

| Sodium alginate | Na: 4% | [75] |

| iota-Carrageenan | S/SO42−: 28–30% | [76,77] |

| kappa-Carrageenan | S/SO42−: 25–30% | [77] |

| Gelatin | N: 17–18% | [78,79] |

| Keratin | N: 15–18%; S/SO42−: 2–5% | [80] |

| Casein | N: 13%; P: 1% | [81,82] |

| Collagen | N: 18% | [83] |

| Whey protein | N: 13% | [84] |

| Calcium carbonate | Ca: 40% | [85] |

| Egg shells | Ca: 38% | [86] |

| Mussel shells | Ca: 38% | [87] |

| Oyster shells | Ca: 38% | [87] |

| Silk fibroin | N: 18% | [88,89] |

* N: Nitrogen; Na: Sodium; S: Sulfur; SO42−: Sulphate ion; Ca: Calcium.

In addition to meeting nutrient requirements, when biomaterials reach the end of their life, they can be an excellent source of carbon (C), a critical element for soil health and function. Soil organic C plays a vital role in soil structure, promoting physical stability, improving soil aeration and water retention, and reducing erosion and nutrient leaching risks. Agricultural fields’ chemical composition and biological productivity depend on soil organic C, which affects their fertility and nutrient-holding capacity. Carbohydrate polymers from microbial and plant sources, such as bacterial cellulose and polyhydroxyalkanoates (PHAs), as well as polymers from starch and lignin, contain high levels of C. Lignin, for example, has a C content of approximately 65 wt.%, while cellulose has a C content of approximately 44 wt.%. Thus, incorporating lignocellulosic biopolymer sheets, films, and other objects into the soil can reintroduce C and organic matter, which is beneficial for plants and soil microbes [62].

A decision tree was developed to assess the potential contributions of specific biomaterials to support the nutrient needs of crops grown in regenerative farms (Figure 3). The nutrient requirements of the crops under consideration are first identified and quantified. Then, the nutrient content of specific biomaterials is estimated using Table 2. If the required nutrients are present in biomaterials’ composition, the maximum theoretical amount of these nutrients that could be released during biomaterials’ decomposition are calculated. This amount is then compared with crops’ needs to assess the potential biomaterials contribution.

Figure 3.

Decision tree for assessing the potential nutrient needs of crops grown in regenerative farms that could be met by biomaterials.

In addition to biodegradation benefits, biopolymer sheets can be used for covering roots and soil to reduce light penetration or retaining moisture and suppressing weeds, serving as an alternative to synthetic landscape fabrics. They can also offer soil support and stabilization, reducing the risk of soil erosion and agricultural run-off.

3. Results

To demonstrate the use of the developed framework, we implemented it in the Great Lakes Region in Michigan, USA, given the global significance of its ecosystem, its important agricultural value, and the pollution challenges that it faces.

3.1. The Case of Great Lakes Region, Michigan, USA

The Great Lakes is a binational region between the United States (US) and Canada including portions of eight US states, Illinois, Indiana, Michigan, Minnesota, New York, Ohio, Pennsylvania, and Wisconsin, along with the Canadian province of Ontario (Figure 4). The Great Lakes, comprising Lakes Superior, Michigan, Huron, Erie, and Ontario, are among the most important global natural resources, supplying 21% of the world’s and 84% of North America’s surface freshwater. The Great Lakes basin is home to 200 rare species, serves as a drinking water source to more than 40 million people, and offers essential ecosystem services including water filtration, nutrient cycling, and carbon storage. The area provides ideal conditions for agriculture, by way of its climate and soil fertility, contributing 7% of US farm production. The agricultural areas of the Great Lakes region mostly produce corn, soybeans, and hay crops, as well as 15% of US dairy products, while generating USD 14.5 billion in annual agricultural sales [22,90,91,92].

The whole state of Michigan falls under the Great Lakes watershed (Figure 4). The area grows a wide variety of crops, rendering Michigan the second most diverse US state, after California, both in terms of agricultural production volumes and per area of cultivated land. The state leads the nation’s production of several crops, including asparagus, black beans and cranberries, cucumbers, tart cherries, Niagara grapes, and squash [92,93].

However, due to the growing development and intensification of the region’s farmland, many places struggle with water quality issues, loss of essential fish and wildlife habitats, and an increase in toxic cyanobacterial blooms [90,94]. Pollution, caused by urban runoff and sprawl, sewage disposal, agricultural intensification, and other sources, damages aquatic ecosystems and poses risks to human health [91].

Figure 4.

Map and land uses of the Great Lakes watershed [22,95].

By adopting regenerative agriculture practices, soil stability in the area could be significantly increased, avoiding sediment and nutrient release into water bodies while improving water quality and local ecosystems. The adoption of such practices has been accelerated during the last decade and several projects and strategies have been initiated (Table S6), yet less than 10% of the total cultivated area in Michigan today can be considered regenerative. The main crops cultivated in Michigan under regenerative agricultural practices, both in acres of land and in kilograms of production, are row crops, e.g., corn and soybeans, juice and wine grapes, apples, blueberries, and to a smaller extent cannabis.

In the case of row crops, the main regenerative practices applied concern reduced or no tillage, use of locally sourced compost and manure for improving soil fertility and plant health, as well as application of carbon sources, such as fish, molasses, and organic acids to enhance soil organic carbon levels. Cover crops are also very common, primarily cereal rye. As it can coexist with almost any crop, cereal rye is easy to cultivate, is cold-hardy, and has high nitrogen content. Diverse species of cover crops including 5–10 species at the same time, such as radishes, clovers, legumes, and vetch are used in the area. Polycultures and crop rotation are important for soil health when row crops are cultivated. Crop rotation of corn, cover crops, and soybeans, is applied to increase biomass and biodiversity while replacing essential nutrients.

For perennial crops, such as blueberries and apples, more compost and less manure are applied, while fish, sugar, and organic acids are commonly used as carbon sources. In addition, soil microbes are applied in various forms, e.g., compost tea, to increase biological activity and enhance soil health. Roots and planting rows are often covered with mulch, wood chips, or synthetic landscape fabrics to suppress weeds and retain soil moisture. While cover crops are not as important for growing perennials, farmers do use them to reduce the need for herbicides. The most common cover crop blends for this purpose include clovers, radishes, sun hemp, and sunflowers. Polycultures and crop rotation are not common in perennial crop systems.

The most commonly applied compost is sourced from dairy manure and other locally collected organic residues and is commercially supplied. Its typical composition (% wt.) is 1 N, 1 K, 1 or 0.5 P and it is usually applied once per year, either in spring or in fall. It can also be mixed with chicken manure compost to increase N content from 1 to 4. Municipal compost is used by some farmers in the area as well.

Representative examples of biomaterials that could be sourced from regenerative farms as well as potential benefits from biomaterials biodegradation in regenerative fields in the Great Lakes–Michigan region have been identified following the assessment methodology presented in previous sections and the decision trees of Figure 2 and Figure 3, considering relevant literature and feedback from local stakeholders.

3.2. Biomaterials That Could Be Sourced from Regenerative Fields in Great Lakes Region, Michigan, USA

Michigan ranks as the third-largest state in terms of apple production in the US, following Washington and New York [96]. Therefore, apples were selected as the representative crop for the purposes of our analysis. The proposed methodology was applied at Earth First Farms [97], one of the largest regenerative apple producers in the Great Lakes region, owning 85 acres (~344,000 m2) of certified organic apple orchards. The farm, which has been certified organic since 2007, is located in Southwest Michigan and operates multiple properties of apples, fruits, and vegetables spanning over 100 acres of rolling land. The steps outlined in Figure 2 were followed to assess the quantity and quality of potential biomass sources for use as biomaterials feedstock.

Since apples are perennial crops, cover crops are not used. Locally sourced, commercial composting manure from turkey or cow is added to the soil as a primary macronutrient source, with cow manure being the most preferable option. Typically, the composting manure contains ~5% of N and 1–2 tons of it are added once per year, always in the fall; it has been shown that a constant amount of 45 kg of N/acre needs to be present in the soil. It takes three years for the composting manure to fully release its nutrients into the soil (1/3 of nutrient content is released each year). Foliar application of macro- and micronutrients, such as Boron (B), Potassium (K), and Magnesium (Mg), is implemented via liquified sprays, as the farm’s soil type is B-deprived. Molasses, fish hydrolysate, and compost tea are also applied for extra nutrients and biological activation to enable nutrient cycling and enhance disease and pest control. Foliar applications take place continuously throughout the growing season.

Earth First Farms cultivates 100–120 apple trees per acre, producing about 3500 kg of apples per acre and yielding 270–320 tons of apples yearly. Cider is also produced. Although cover crops are not used, other organic residue streams are generated, including imperfect or irregular-looking apples and pulp residue from cider making, which are discarded from production. It is estimated that 14–23 tons of the total production are discarded annually either as imperfect apples or as cider pulp residue. Additional organic residues are generated from trimming, pruning, and mowing the apple trees once a year in the winter. The total annually trimmed biomass is estimated to be 230–270 kg/acre. Larger trimmings such as branches, which represent less than 5% of the total trimmed biomass, i.e., around 11–14 kg/acre, are collected and burnt, while the remaining are applied on the aisles between the trees to enhance biological activity and maintain biodiversity. The amount of annually generated biomass sources that could be used as biomaterials feedstock is presented in Table 3.

Table 3.

Biomass residues generated annually from Earth First Farms.

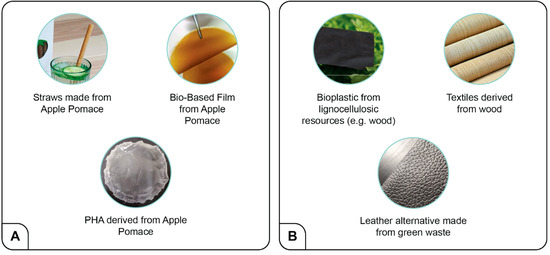

Apple residues can be collected and pressed to make apple pomace. The acidic nature of apple pomace, with its high sugar and low protein content, makes it unsuitable for landfilling and animal feedstock [59,98,99,100,101]. It has a high moisture and biodegradable organic content which can be used for bioplastic production. As shown in Table 1, apple pomace consists mainly of cellulose (~40% wt.). Following the methods described in Gustafsson et al., 2019 [59], biobased films and 3D fiberboards can be made by blending the apple pomace with glycerol, a colorless, odorless, viscous biobased liquid, widely used as a sweetener in the food industry, and citric acid monohydrate, a tricarboxylic acid found in citrus fruits (Figure 5A). These biomaterials may be suitable for various applications of high market demand, such as edible/disposable tableware or food packaging. Considering an average of 18.5 tons of apple pomace generated annually, about 925 tons of biobased polymer films (tensile strength: ~16.5 MPa; elongation ~11%) [59] and 25 tons of fiberboards (tensile strength: ~5.8 MPa; elongation ~1.5%) [59] could be produced per year from Earth First Farms alone. These biomaterials could potentially displace substantial quantities of petroleum-based plastics, addressing the pressing issue of plastic pollution in the area; it is estimated that nearly 10,000 tons of plastic debris enter the Great Lakes every year [102]. Additionally, they can help tackle concerns associated with the disposal of apple pomace waste.

Figure 5.

Examples of biomaterials that could be derived from biomass sourced from the analyzed regenerative apple orchards: (A) Examples of biomaterials that could be made from apple pomace [59,103,104]; (B) examples of biomaterials that could be made from hardwood residues [62,105,106].

The trimmed biomass could be also used to produce biopolymers, as according to Table 1, hardwood residues contain significant amounts of cellulose (38–55%), followed by hemicellulose (17–40%) and lignin (18–31%) [44,61,62,63]. The collected trimmed biomass could produce biodegradable, lignocellulosic bioplastic films if blended with chlorine chloride, oxalic acid, and water, following the approach described in Xia et al., 2021 [62] (Figure 5B). Considering an average of 1 ton of trimmed biomass generated annually, about 35 kg of strong, lignocellulosic bioplastic of very high tensile strength (~128 MPa) could be produced from Earth First Farms. The resulting lignocellulosic bioplastic exhibits excellent water stability, resistance to ultraviolet light, and improved thermal stability. It is both compostable by natural microorganisms and recyclable through mechanical disintegration, while it demonstrates significantly lower environmental impacts compared to petrochemical-based plastics like polyvinyl fluoride (PVF) and acrylonitrile butadiene styrene (ABS). Such biopolymers hold strong potential to replace widely used petrochemical plastics in various applications from packaging and agricultural mulching films to construction and automotive parts [62].

3.3. Potential Beneficial Biomaterials Services for Regenerative Farms in Great Lakes Region, Michigan, USA

To estimate potential crop nutrient needs that could be covered by biomaterials in the region of interest, the steps presented in Figure 3 were followed. Better Way Farms [107], a family-owned and operated farm in South Haven, Michigan, producing transitional blueberries certified organic by the US Department of Agriculture (USDA), was selected as a case study, as blueberries are among the most common regenerative crops cultivated in the area.

Better Way Farms are practicing cover cropping (clover, buckwheat, legumes, radishes) and composting, while they avoid any use of toxic chemicals. They grow seven different varieties of highbush blueberries on a total of 104 acres of land (the variety ‘Elliott’ covers ~20 acres; ‘Aurora’: ~20 acres; all other five varieties are ~15 acres each). Their yields vary, with an average typical yield of 2000 kg/acre, which is slightly lower than the state’s average yield for conventional berries (~2300 kg/acre). However, conventional farms in Michigan can achieve yields greater than 3600 kg/acre.

Cover crop blends are applied to all 104 acres and are mainly composed of three different types of clovers, some legumes, buckwheat, and oats. Cover crops are reseeded every three years. They are mowed—not terminated—to allow easy access to the main crops, and all the generated plant biomass stays on the field. No residues or any other potential waste biomass sources are generated.

Nitrogen (N) is the most significant nutrient needed by blueberries. About 546 kg/acre of locally sourced, commercial compost is applied as fertilizer twice per year (once at the beginning of April and once after six weeks) containing ~0.02 kg N/kg, as the crops need ~20 kg N/acre/yr. These N amounts could be potentially sourced from natural biopolymers, such as chitin or gelatin.

Chitin is the second most abundant polysaccharide biopolymer occurring in nature after cellulose [108] and can be readily sourced from the shells of crustaceans that are by-products of the seafood industry, or from mixed food waste by harvesting black soldier flies [109]. Chitin degrades in soil producing carbon dioxide and ammonium-N. A relevant soil incubation study demonstrated that chitin contains ~6 wt.% N [73], which is released as ammonium-N in the soil after biodegradation (Table 2). Hence, ~330 kg of chitin biopolymer would be needed yearly per acre (or 80 g chitin/m2) to cover the N needs of blueberries at Better Way Farms (Figure 6).

Figure 6.

Nutrients that could be potentially sourced from natural biopolymers at their end of life to cover the needs of blueberries at regenerative farms.

Gelatin, a protein derived from collagen sourced from animal waste, is commonly used to make biomaterials, and could also be used to cover the N needs of blueberries. Gelatin contains 17 wt.% N [78,79] (Table 2); hence, ~120 kg of gelatin per acre (or 30 g gelatin/m2) would be needed annually to provide 20 kg N per acre (Figure 6).

Sulfur (S) is another essential nutrient needed by blueberries. S deficiency of crops, reported with increasing frequency over the past two decades on a worldwide scale, reduces yield and affects the quality of harvested products [110]. The compost used by Better Way Farms contains 0.04 kg S/kg. Considering that ~1000 kg of compost is applied annually per acre in Better Way Farms, it can be concluded that blueberries need ~40 kg S/acre/yr. Iota-type carrageenan is a natural polysaccharide biopolymer obtained from red seaweeds which has an ester sulfate content of about 28–30% per weight [76,77] (Table 2). Therefore, ~145 kg iota-type carrageenan would be needed per acre (or 35 g of iota-type carrageenan per m2) to cover the annual S needs of blueberries s at Better Way Farms (Figure 6).

Moreover, given the fact that biopolymers and biomaterials are mostly made from carbon (C), e.g., chitin contains around 40–50 wt.% C [111,112], by cycling back these materials to agricultural fields at their end of life, significant amounts of C could be locked in the soil, instead of being released in the atmosphere as in the case of incineration of petroleum-based plastics.

4. Discussion

This study is the first of its kind to explore how biomaterials—materials that are 100% biobased and compostable—could be sourced from, and cycled back to support, regenerative agricultural systems, informing a key principle of the circular economy: the regeneration of natural systems. It lays the foundation for creating circular economy practices through local, synergistic schemes of biomaterials production and regenerative farming. A methodological framework is suggested to explore, identify, and assess potential beneficial links between these two fields. By applying this framework to local contexts and translating the generated insights into practice, biomaterials production could be incentivized, avoiding plastic pollution while simultaneously helping to draw down carbon through the promotion of healthy soils.

By applying the developed framework to the Michigan part of the Great Lakes region, it was shown that regenerative agricultural systems can provide a significant feedstock source for biomaterials production in cases where cover crop residues or other sources of waste biomass, such as discarded crop parts, are allowed to be removed from the field (as in the case of Earth First Farms). By quantifying the availability of potential biomass sources and analyzing their quality, these can be matched with different types of relevant biopolymers or biomaterials. In addition, the biomaterials market can be an essential resource for regenerative agriculture systems, enabling a potential paradigm shift from conventional to regenerative farming if biomaterials are applied to such systems after their end of life. Various beneficial contributions of biomaterials to regenerative farms have been identified, including acting as fertilizer and supporting the nutrient needs of crops (as in the case of Better Way Farms), or as a means of pest and weed control or as soil support.

These interesting and mutually beneficial linkages between regenerative farming and biomaterials production industries could enable the production of locally sourced, sustainable materials for packaging, clothing, or structural applications, substituting their petroleum-based counterparts, while enhancing food security and resilience of socio-ecological systems. Such beneficial impacts become even more timely and relevant in the Great Lakes Region, given the vulnerability of its ecosystem and the existing pollution issues.

The proposed framework could be adapted and applied to different regions and socio-economic settings. By accounting for local issues, needs, and practices, it could be used to inform and guide decisions on potential interventions or incentives aimed at enhancing soil conditions and benefiting local industries, or be incorporated into sustainable farming schemes and policies, e.g., [113]. It could also be expanded considering a larger database of information on potential biomaterial applications. For example, data mining and data curation tools could make this approach amenable to other areas of the world. They would also facilitate application of machine learning approaches, which require large data sources that can be readily accessed.

Although lignocellulosic biomass sourced from regenerative farms holds great potential as a feedstock for biomaterials, its conversion into fermentable cellulose and hemicellulose sugars is complex and needs further research and development. This complexity arises from the presence of protective, phenolic, cross-linked lignin polymer networks, requiring additional pretreatment steps. Research towards future biorefineries aiming to facilitate the purification, liberation, and separation of monomers from lignocellulosic biomass is underway [3,114,115,116]. To reduce environmental impact, these biorefinery processes must enhance efficiency and align with green chemistry principles, including the use of non-toxic chemicals and reduced energy demands. This will enable the production of polymer building blocks in a cost-competitive and sustainable manner.

Further research is needed to estimate actual biomaterial production from various regenerative feedstocks, considering processing yields, biorefining challenges, and potential feedstock supply or availability constraints. Additionally, it is essential to monitor and comprehend the precise amount of nutrients released from biomaterials to soils over time. Moreover, the feasible carbon content that can be added to soil ecosystems from carbon-rich biomaterials after their end of life requires clarification. Exploring the potential economic impacts of regenerative agricultural practices and coupled biomaterials production on local farmers, communities, and industries would also be worthwhile.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su151914306/s1. References [117,118,119,120,121,122,123,124,125,126,127,128] are cited in Supplementary Materials.

Author Contributions

Conceptualization and methodology development: A.G. and P.M.S.; Investigation, data collection, and analysis: P.M.S.; Data curation and interpretation: P.M.S. and A.G.; Technical input: J.C.M.; Writing—original draft preparation, P.M.S.; Writing—review and editing A.G., P.M.S., L.C. and J.C.M.; Visualization: L.C. and P.M.S.; Funding acquisition: A.G. and L.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by The Wege Foundation, based in Grand Rapids, MI, USA (Grant No. 4356).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available from the authors upon request.

Acknowledgments

We thank Tom Rosenfeld from Earth First Farms and Joseph Jessup from Better Way Farms for their valuable insights and useful information about the operation of their farms and the implementation of regenerative agricultural practices. We acknowledge Dane Terrill from Crop Services International, supporting regenerative farms in Michigan, for providing us with an overview of the regenerative agricultural practices applied in the Great Lakes area, and for his beneficial suggestions and local contacts. We also thank Tanner Starbard from Mad Agriculture for the valuable information regarding regenerative agricultural practices and his recommendations. Last but not least, the support of the Materiom team members, Pilar Bolumburu, Zoe Kremer, and Svetlana Lezina, in gathering useful information and helping with the graphics design is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- International Energy Agency: The Future of Petrochemicals. Available online: https://www.iea.org/reports/the-future-of-petrochemicals (accessed on 5 August 2023).

- Yale Environment 360: The Plastics Pipeline: A Surge of New Production Is on the Way. Available online: https://e360.yale.edu/features/the-plastics-pipeline-a-surge-of-new-production-is-on-the-way (accessed on 5 August 2023).

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Fernandez, J.G.; Dritsas, S. The biomaterial age: The transition toward a more sustainable society will be determined by advances in controlling biological processes. Matter 2020, 2, 1352–1355. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M. Plastic Pollution. 2018. Available online: https://ourworldindata.org/plastic-pollution (accessed on 14 July 2023).

- UN Environment Programme: Our Planet Is Chocking on Plastic. Available online: https://www.unep.org/interactives/beat-plastic-pollution/?gclid=CjwKCAjw5MOlBhBTEi-wAAJ8e1ssCIc8iH3pn72w_yrdo9f9AOO0kSrTvFRZl0tJ7yqbe2a6F0wIv0hoCN8YQAvD_BwE (accessed on 14 July 2023).

- Hamilton, L.A.; Feit, S. Plastic & Climate: The Hidden Costs of a Plastic Planet. 2019. Available online: https://www.ciel.org/wp-content/uploads/2019/05/Plastic-and-Climate-FINAL-2019.pdf (accessed on 14 July 2023).

- Hernández, V.; Ibarra, D.; Triana, J.F.; Martínez-Soto, B.; Faúndez, M.; Vasco, D.A.; Gordillo, L.; Herrera, F.; García-Herrera, C.; Garmulewicz, A. Agar Biopolymer Films for Biodegradable Packaging: A Reference Dataset for Exploring the Limits of Mechanical Performance. Materials 2022, 15, 3954. [Google Scholar] [CrossRef] [PubMed]

- Nanda, S.; Azargohar, R.; Dalai, A.K.; Kozinski, J.A. An assessment on the sustainability of lignocellulosic biomass for biorefining. Renew. Sustain. Energy Rev. 2015, 50, 925–941. [Google Scholar] [CrossRef]

- European Commission—Energy, Climate Change, Environment: Biobased, Biodegradable and Compostable Plastics. Available online: https://environment.ec.europa.eu/topics/plastics/biobased-biodegradable-and-compostable-plastics_en (accessed on 14 July 2023).

- Yaradoddi, J.S.; Banapurmath, N.R.; Ganachari, S.V.; Soudagar, M.E.M.; Mubarak, N.M.; Hallad, S.; Hugar, S.; Fayaz, H. Biodegradable carboxymethyl cellulose based material for sustainable packaging application. Sci. Rep. 2020, 10, 21960. [Google Scholar] [CrossRef]

- Azmin, S.N.H.M.; Nor, M.S.M. Development and characterization of food packaging bioplastic film from cocoa pod husk cellulose incorporated with sugarcane bagasse fibre. J. Bioresour. Bioprod. 2020, 5, 248–255. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation—Regenerative Agriculture. Available online: https://ellenmacarthurfoundation.org/articles/regenerative-agriculture (accessed on 14 July 2023).

- US EPA—Global Greenhouse Gas Emissions Data. Available online: https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data (accessed on 14 July 2023).

- Schreefel, L.; Schulte, R.P.O.; De Boer, I.J.M.; Schrijver, A.P.; Van Zanten, H.H.E. Regenerative agriculture—The soil is the base. Glob. Food Secur. 2020, 26, 100404. [Google Scholar] [CrossRef]

- Newton, P.; Civita, N.; Frankel-Goldwater, L.; Bartel, K.; Johns, C. What Is Regenerative Agriculture? A Review of Scholar and Practitioner Definitions Based on Processes and Outcomes. Front. Sustain. Food Syst. 2020, 4, 194. [Google Scholar] [CrossRef]

- Tan, S.S.; Kuebbing, S.E. A synthesis of the effect of regenerative agriculture on soil carbon sequestration in Southeast Asian croplands. Agric. Ecosyst. Environ. 2023, 349, 108450. [Google Scholar] [CrossRef]

- Schreefel, L.; Van Zanten, H.H.E.; Groot, J.C.J.; Timler, C.J.; Zwetsloot, M.J.; Schrijver, A.P.; Creamer, R.E.; Schulte, R.P.O.; de Boer, I.J.M. Tailor-made solutions for regenerative agriculture in the Netherlands. Agric. Syst. 2022, 203, 103518. [Google Scholar] [CrossRef]

- Breuer, A.; Janetschek, H.; Malerba, D. Translating sustainable development goal (SDG) interdependencies into policy advice. Sustainability 2019, 11, 2092. [Google Scholar] [CrossRef]

- Conti, C.; Zanello, G.; Hall, A. Why are agri-food systems resistant to new directions of change? A systematic review. Glob. Food Secur. 2021, 31, 100576. [Google Scholar] [CrossRef]

- Spangler, K.; Schumacher, B.L.; Bean, B.; Burchfield, E.K. Path dependencies in US agriculture: Regional factors of diversification. Agric. Ecosyst. Environ. 2022, 333, 107957. [Google Scholar] [CrossRef]

- The Nature Conservancy—Agriculture in the Great Lakes. Available online: https://www.nature.org/en-us/about-us/where-we-work/priority-landscapes/great-lakes/great-lakes-agriculture-/ (accessed on 14 July 2023).

- Shahi, N.; Joshi, G.; Min, B. Potential sustainable biomaterials derived from cover crops. Bioresources 2020, 15, 5641–5652. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef]

- Maryland Department of Agriculture. Available online: https://mda.maryland.gov/resource_conservation/counties/Tip6.pdf (accessed on 15 July 2023).

- Carlson, S.; Stockwell, R. Research priorities for advancing adoption of cover crops in agriculture-intensive regions. J. Agric. Food Syst. Community Dev. 2013, 3, 125–129. [Google Scholar] [CrossRef]

- Andrews, S.S. Crop Residue Removal for Biomass Energy Production: Effects on Soils and Recommendations. USDA White Paper. 2006. Available online: https://www.nrcs.usda.gov/sites/default/files/2022-10/Crop_Residue_Removal_for_Biomass_Energy_Production.pdf (accessed on 15 July 2023).

- Nelson, R.G. Resource assessment and removal analysis for corn stover and wheat straw in the Eastern and Midwestern United States—Rainfall and wind-induced soil erosion methodology. Biomass Bioenergy 2002, 22, 349–363. [Google Scholar] [CrossRef]

- Perlack, R.D.; Wright, L.L.; Turhollow, A.F.; Graham, R.L.; Stokes, B.J.; Erbach, D.C. Biomass as Feedstock for a Bioenergy and Bioproducts Industry: The Technical Feasibility of a Billion-Ton Annual Supply. Oak Ridge National Laboratory Technical Report. 2005. Available online: https://info.ornl.gov/sites/publications/Files/Pub57812.pdf (accessed on 15 July 2023).

- Shinners, K.J.; Binversie, B.N.; Savoie, P. Harvest and storage of wet and dry corn stover as a biomass feedstock. In Proceedings of the 2003 American Society of Agricultural and Biological Engineers ASABE Annual Meeting, Las Vegas, NV, USA, 27–30 July 2003. [Google Scholar]

- Karlen, D.L.; Andrews, S.S.; Wienhold, B.J.; Zobeck, T.M. Soil quality assessment: Past, present and future. J. Integr. Biosci. 2008, 6, 3–14. [Google Scholar]

- Sokhansanj, S.; Kumar, A.; Turhollow, A.F. Development and implementation of integrated biomass supply analysis and logistics model (IBSAL). Biomass Bioenergy 2006, 30, 838–847. [Google Scholar] [CrossRef]

- Wilhelm, W.W.; Johnson, J.M.; Hatfield, J.L.; Voorhees, W.B.; Linden, D.R. Crop and soil productivity response to corn residue removal: A literature review. Agron. J. 2004, 96, 1–17. [Google Scholar] [CrossRef]

- Al-Kaisi, M. How Much Crop Residue to Remove. Iowa State University Extension and Outreach. 2012. Available online: https://crops.extension.iastate.edu/cropnews/2012/04/how-much-crop-residue-remove (accessed on 15 July 2023).

- Wilhelm, W.W.; Johnson, J.M.; Karlen, D.L.; Lightle, D.T. Corn stover to sustain soil organic carbon further constrains biomass supply. Agron. J. 2007, 99, 1665–1667. [Google Scholar] [CrossRef]

- Shaghaleh, H.; Xu, X.; Wang, S. Current progress in production of biopolymeric materials based on cellulose, cellulose nanofibers, and cellulose derivatives. RSC Adv. 2018, 8, 825–842. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Ji, Y.; Bourg, V.; Bilgen, M.; Meredith, J.C. Chitin-and cellulose-based sustainable barrier materials: A review. Emergent Mater. 2020, 3, 919–936. [Google Scholar] [CrossRef]

- Re-FREAM Website. Available online: https://re-fream.eu/syntropia/ (accessed on 15 July 2023).

- Woźniak, M.; Ratajczak, I.; Wojcieszak, D.; Waśkiewicz, A.; Szentner, K.; Przybył, J.; Borysiak, S.; Goliński, P. Chemical and structural characterization of maize stover fractions in aspect of its possible applications. Materials 2021, 14, 1527. [Google Scholar] [CrossRef] [PubMed]

- Mensah, M.B.; Jumpah, H.; Boadi, N.O.; Awudza, J.A. Assessment of quantities and composition of corn stover in Ghana and their conversion into bioethanol. Sci. Afr. 2021, 12, e00731. [Google Scholar] [CrossRef]

- Rentoy, F.A.M.; Angot, D.R.; Mabaquiao, J.R.; Larroder, A. Development of Cellulose-Based Bioplastic from Corn Stalks. Publiscience 2020, 1–6. Available online: http://www.publiscience.org/development-of-cellulose-based-bioplastic-from-corn-stalks/ (accessed on 15 July 2023).

- Chong, T.Y.; Law, M.C.; Chan, Y.S. The potentials of corn waste lignocellulosic fibre as an improved reinforced bioplastic composites. J. Polym. Environ. 2021, 29, 363–381. [Google Scholar] [CrossRef]

- Marichelvam, M.K.; Jawaid, M.; Asim, M. Corn and rice starch-based bio-plastics as alternative packaging materials. Fibers 2019, 7, 32. [Google Scholar] [CrossRef]

- Machado, G.; Santos, F.; Lourega, R.; Mattia, J.; Faria, D.; Eichler, P.; Auler, A. Biopolymers from lignocellulosic biomass: Feedstocks, production processes, and applications. In Lignocellulosic Biorefining Technologies, 1st ed.; Ingle, A.P., Chandel, A.K., da Silva, S.S., Eds.; Wiley: Hoboken, NJ, USA, 2020; pp. 125–158. [Google Scholar]

- Stoyanova, N.; Spasova, M.; Manolova, N.; Rashkov, I.; Kamenova-Nacheva, M.; Staleva, P.; Tavlinova-Kirilova, M. Electrospun PLA-Based Biomaterials Loaded with Melissa officinalis Extract with Strong Antioxidant Activity. Polymers 2023, 15, 1070. [Google Scholar] [CrossRef]

- Bakker, R.R.C.; Elbersen, H.W.; Poppens, R.P.; Lesschen, J.P. Rice Straw and Wheat Straw-Potential Feedstocks for the Biobased Economy. NL Agency Ministry of Economic Affairs. 2013. Available online: https://edepot.wur.nl/288866 (accessed on 15 July 2023).

- Bilo, F.; Pandini, S.; Sartore, L.; Depero, L.E.; Gargiulo, G.; Bonassi, A.; Federici, S.; Bontempi, E. A sustainable bioplastic obtained from rice straw. J. Clean. Prod. 2018, 200, 357–368. [Google Scholar] [CrossRef]

- Maraveas, C. Production of sustainable and biodegradable polymers from agricultural waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef]

- Varghese, S.A.; Pulikkalparambil, H.; Promhuad, K.; Srisa, A.; Laorenza, Y.; Jarupan, L.; Nampitch, T.; Chonhenchob, V.; Harnkarnsujarit, N. Renovation of Agro-Waste for sustainable food packaging: A Review. Polymers 2023, 15, 648. [Google Scholar] [CrossRef] [PubMed]

- Eco World Website. What Is Wheat Straw Plastic? Available online: https://ecoworldonline.com/what-is-wheat-straw-plastic/ (accessed on 15 July 2023).

- Sabara, Z.; Mutmainnah, A.; Kalsum, U.; Afiah, I.N.; Husna, I.; Saregar, A.; Umam, R. Sugarcane bagasse as the source of nanocrystalline cellulose for gelatin-free capsule shell. Int. J. Biomater. 2022, 2022, 9889127. [Google Scholar] [CrossRef] [PubMed]

- Mokhena, T.C.; Mochane, M.J.; Motaung, T.E.; Linganiso, L.Z.; Thekisoe, O.M.; Songca, S.P. Sugarcane bagasse and cellulose polymer composites. In Sugarcane-Technology and Research, 1st ed.; Bosco de Oliveira, A., Ed.; IntechOpen: London, UK, 2018; pp. 225–240. [Google Scholar]

- Melesse, G.T.; Hone, F.G.; Mekonnen, M.A. Extraction of Cellulose from Sugarcane Bagasse Optimization and Characterization. Adv. Mater. Sci. Eng. 2022, 2022, 1712207. [Google Scholar] [CrossRef]

- Savastano Jr, H.; Santos, S.F.; Agopyan, V. Sustainability of vegetable fibres in construction. In Sustainability of Construction Materials, 1st ed.; Khatib, J.M., Ed.; Woodhead Publishing: Sawston, UK, 2009; pp. 55–81. [Google Scholar]

- Mahmud, M.A.; Anannya, F.R. Sugarcane bagasse-A source of cellulosic fiber for diverse applications. Heliyon 2021, 7, e07771. [Google Scholar] [CrossRef] [PubMed]

- Gowman, A.C.; Picard, M.C.; Lim, L.T.; Misra, M.; Mohanty, A.K. Fruit waste valorization for biodegradable biocomposite applications: A review. Bioresources 2019, 14, 10047–10092. [Google Scholar] [CrossRef]

- Materiom Website. Apple-Pectin Leather Recipe. Available online: https://materiom.org/recipe/707 (accessed on 15 July 2023).

- Bátori, V. Fruit Wastes to Biomaterials: Development of Biofilms and 3D Objects in a Circular Economy System. Doctoral Thesis, University of Borås, Borås, Sweden, 2019. [Google Scholar]

- Gustafsson, J.; Landberg, M.; Bátori, V.; Åkesson, D.; Taherzadeh, M.J.; Zamani, A. Development of bio-based films and 3D objects from apple pomace. Polymers 2019, 11, 289. [Google Scholar] [CrossRef] [PubMed]

- Ayala, J.R.; Montero, G.; Coronado, M.A.; García, C.; Curiel-Alvarez, M.A.; León, J.A.; Sagaste, C.A.; Montes, D.G. Characterization of orange peel waste and valorization to obtain reducing sugars. Molecules 2021, 26, 1348. [Google Scholar] [CrossRef]

- Tarasov, D.; Leitch, M.; Fatehi, P. Lignin–carbohydrate complexes: Properties, applications, analyses, and methods of extraction: A review. Biotechnol. Biofuels 2018, 11, 1–28. [Google Scholar] [CrossRef]

- Xia, Q.; Chen, C.; Yao, Y.; Li, J.; He, S.; Zhou, Y.; Li, T.; Pan, X.; Yao, Y.; Hu, L. A strong, biodegradable and recyclable lignocellulosic bioplastic. Nat. Sustain. 2021, 4, 627–635. [Google Scholar] [CrossRef]

- Ferrari, F.; Striani, R.; Fico, D.; Alam, M.M.; Greco, A.; Esposito Corcione, C. An Overview on Wood Waste Valorization as Biopolymers and Biocomposites: Definition, Classification, Production, Properties and Applications. Polymers 2022, 14, 5519. [Google Scholar] [CrossRef]

- Oliaei, E.; Olsén, P.; Lindström, T.; Berglund, L.A. Highly reinforced and degradable lignocellulose biocomposites by polymerization of new polyester oligomers. Nat. Commun. 2022, 13, 5666. [Google Scholar] [CrossRef] [PubMed]

- Materiom Website. Natural Dye—Sage Dye Recipe. Available online: https://materiom.org/recipe/172 (accessed on 15 July 2023).

- Materiom Website. Pigment with Burnt Japanese Knotweed (Leaves) Recipe. Available online: https://materiom.org/recipe/605 (accessed on 15 July 2023).

- University of California, Sustainable Agriculture Research and Education Program Website. Solution Center for Nutrient Management: Crop Nutrient Requirements. Available online: https://ucanr.edu/sites/Nutrient_Management_Solutions/stateofscience/Meet_Crop_Nutrient_Requirements/ (accessed on 15 July 2023).

- Pittenger, D. California Master Gardener Handbook, 2nd ed.; Division of Agriculture and Natural Resources, University of California: Oakland, CA, USA, 2014; p. 50. [Google Scholar]

- Heliae Website. 10 Regenerative Agriculture Practices Every Grower Should Follow. Available online: https://heliae.com/10-regenerative-agriculture-practices/#Composting (accessed on 15 July 2023).

- Wortmann, C.S.; Klein, R.N.; Shapiro, C.A. Harvesting Crop Residues. University of Nebraska Lincoln, Extension, Institute of Agriculture and Natural Resources. 2012. Available online: https://extensionpublications.unl.edu/assets/pdf/g1846.pdf (accessed on 15 July 2023).

- Herbert, S.J.; Liu, Y.; Liu, G. Decomposition of Cover Crop Biomass and Nitrogen Release. University of Massachusetts Amherst, Center for Agriculture, Food, and the Environment. Available online: https://ag.umass.edu/sites/ag.umass.edu/files/research-reports/1997-01-decomposition-of-cover-crops-biomass-and-nitrogen-release.pdf (accessed on 15 July 2023).

- Tshinyangu, K.K.; Hennebert, G.L. Protein and chitin nitrogen contents and protein content in Pleurotus ostreatus var. columbinus. Food Chem. 1996, 57, 223–227. [Google Scholar] [CrossRef]

- Kumeta, Y.; Inami, K.; Ishimaru, K.; Yamazaki, Y.; Sameshima-Saito, R.; Saito, A. Thermogravimetric evaluation of chitin degradation in soil: Implication for the enhancement of ammonification of native organic nitrogen by chitin addition. Soil Sci. Plant Nutr. 2018, 64, 512–519. [Google Scholar] [CrossRef]

- Ssekatawa, K.; Byarugaba, D.K.; Wampande, E.M.; Moja, T.N.; Nxumalo, E.; Maaza, M.; Sackey, J.; Ejobi, F.; Kirabira, J.B. Isolation and characterization of chitosan from Ugandan edible mushrooms, Nile perch scales and banana weevils for biomedical applications. Sci. Rep. 2021, 11, 4116. [Google Scholar] [CrossRef]

- SPICEOLOGY Website. Sodium Alginate. Available online: https://spiceology.com/products/sodium-alginate/ (accessed on 15 July 2023).

- Thermo Fisher Scientific Website. Carrageenan, Iota Type. Available online: https://www.fishersci.com/shop/products/carrageenan-iota-type-thermo-scientific/AAJ6060322 (accessed on 15 July 2023).

- Necas, J.; Bartosikova, L. Carrageenan: A review. Vet. Med. 2013, 58, 187–205. [Google Scholar] [CrossRef]

- Schrieber, R.; Gareis, H. Gelatin Handbook: Theory and Industrial Practice; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar]

- Garden Myths Website. Gelatin Powder for Plants—Is It a Good Source of Nitrogen? Available online: https://www.gardenmyths.com/gelatin-powder-plants-source-nitrogen/ (accessed on 15 July 2023).

- Sharma, S.; Gupta, A. Sustainable management of keratin waste biomass: Applications and future perspectives. Braz. Arch. Biol. Technol. 2016, 59, e16150684. [Google Scholar] [CrossRef]

- USJersey Website. Milk Marketing: True Protein vs. Total Protein. Available online: https://www.usjersey.com/Portals/0/NAJ/2_Docs/TrueProteinExplained_NAJ_1999.pdf (accessed on 15 July 2023).

- Science Direct Website. Casein. Available online: https://www.sciencedirect.com/topics/pharmacology-toxicology-and-pharmaceutical-science/casein (accessed on 15 July 2023).

- Mariotti, F.; Tomé, D.; Mirand, P.P. Converting nitrogen into protein—Beyond 6.25 and Jones’ factors. Crit. Rev. Food Sci. Nutr. 2008, 48, 177–184. [Google Scholar] [CrossRef]

- Cerbulis, J.; Farrell, H.M., Jr. Composition of milks of dairy cattle. I. Protein, lactose, and fat contents and distribution of protein fraction. J. Dairy Sci. 1975, 58, 817–827. [Google Scholar] [CrossRef]

- Nagwa Website. Question Video: Calculating the Percentage Composition of a Ternary Compound. Available online: https://www.nagwa.com/en/videos/407190505318/#:~:text=So%20the%20final%20answer%20for,%2C%20and%20oxygen%3A%2048%20percent (accessed on 15 July 2023).

- UK Essays Website. Calcium Carbonate Composition of Brown and White Eggshells. Available online: https://www.ukessays.com/essays/chemistry/calcium-carbonate.php?vref=1 (accessed on 15 July 2023).

- Hamester, M.R.R.; Balzer, P.S.; Becker, D. Characterization of calcium carbonate obtained from oyster and mussel shells and incorporation in polypropylene. Mater. Res. 2012, 15, 204–208. [Google Scholar] [CrossRef]

- Ngo, H.T.; Bechtold, T. Analysis of the fibroin solution state in calcium chloride/water/ethanol for improved understanding of the regeneration process. Fibres Text. East. Eur. 2018, 26, 43–50. [Google Scholar] [CrossRef]

- Vickery, H.B.; Block, R.J. The Basic Amino Acids of Silk Fibroin. The Determination of the Basic Amino Acids Yielded by Proteins. J. Biol. Chem. 1931, 93, 105–112. [Google Scholar] [CrossRef]

- USDA Natural Resources Conservation Service Website. Great Lakes Restoration Initiative. Available online: https://www.nrcs.usda.gov/wps/portal/nrcs/detailfull/national/programs/initiatives/?cid=nrcsdev11_023903 (accessed on 15 July 2023).

- NFWF Website. Sustain Our Great Lakes Program. Available online: https://www.nfwf.org/programs/sustain-our-great-lakes-program (accessed on 15 July 2023).

- US EPA Website. Facts and Figures about the Great Lakes. Available online: https://www.epa.gov/greatlakes/facts-and-figures-about-great-lakes (accessed on 15 July 2023).

- Michigan Department of Agriculture & Rural Development Website. Michigan Agriculture Facts and Figures. Available online: https://www.michigan.gov/-/media/Project/Websites/mdard/documents/business-development/mi_ag_facts_figures.pdf?rev=9ca97e867d0d40b392470b02a2694e50 (accessed on 15 July 2023).

- Michigan Harmful Algal Bloom Reports Website. Available online: https://mdhhs.maps.arcgis.com/apps/webappviewer/index.html?id=b05d6b7498ca4ce29a586f1f2b9cefeb (accessed on 15 July 2023).

- Google Maps Website. North America Map. Available online: https://www.google.com/maps/@39.2152718,-99.2522544,4.37z?entry=ttu (accessed on 26 September 2023).

- USDA Website. U.S. Apple Production, by State. Available online: https://www.ers.usda.gov/data-products/chart-gallery/gallery/chart-detail/?chartId=75112 (accessed on 15 July 2023).

- Earth First Farm Website. Available online: https://www.earthfirstfarms.com/ (accessed on 15 July 2023).

- Perussello, C.A.; Zhang, Z.; Marzocchella, A.; Tiwari, B.K. Valorization of apple pomace by extraction of valuable compounds. Compr. Rev. Food Sci. Food Saf. 2017, 16, 776–796. [Google Scholar] [CrossRef] [PubMed]

- Shalini, R.; Gupta, D.K. Utilization of pomace from apple processing industries: A review. J. Food Sci. Technol. 2010, 47, 365–371. [Google Scholar] [CrossRef] [PubMed]

- Vendruscolo, F.; Albuquerque, P.M.; Streit, F.; Esposito, E.; Ninow, J.L. Apple pomace: A versatile substrate for biotechnological applications. Crit. Rev. Biotechnol. 2008, 28, 1–12. [Google Scholar] [CrossRef]

- Bhushan, S.; Kalia, K.; Sharma, M.; Singh, B.; Ahuja, P.S. Processing of apple pomace for bioactive molecules. Crit. Rev. Biotechnol. 2008, 28, 285–296. [Google Scholar] [CrossRef] [PubMed]

- Hoffman, M.J.; Hittinger, E. Inventory and transport of plastic debris in the Laurentian Great Lakes. Mar. Pollut. Bull. 2017, 115, 273–281. [Google Scholar] [CrossRef] [PubMed]

- RESET Website. Eatapple: A Fruity Alternative to the Plastic Straw. Available online: https://en.reset.org/eatapple-fruit-based-alternative-plastic-straw-06142018/ (accessed on 15 July 2023).

- Rebocho, A.T.; Pereira, J.R.; Freitas, F.; Neves, L.A.; Alves, V.D.; Sevrin, C.; Grandfils, C.; Reis, M.A. Production of medium-chain length polyhydroxyalkanoates by Pseudomonas citronellolis grown in apple pulp waste. Appl. Food Biotechnol. 2019, 6, 71–82. [Google Scholar]

- Nuo Website. Available online: https://www.nuo-design.com/ (accessed on 15 July 2023).

- BIOPHILICA Website. Available online: https://www.biophilica.co.uk/ (accessed on 15 July 2023).

- Better Way Farms Website. Available online: https://www.betterwayfarms.com/ (accessed on 15 July 2023).

- Elieh-Ali-Komi, D.; Hamblin, M.R. Chitin and chitosan: Production and application of versatile biomedical nanomaterials. Int. J. Adv. Res. 2016, 4, 411. [Google Scholar]

- Sanandiya, N.D.; Ottenheim, C.; Phua, J.W.; Caligiani, A.; Dritsas, S.; Fernandez, J.G. Circular manufacturing of chitinous bio-composites via bioconversion of urban refuse. Sci. Rep. 2020, 10, 4632. [Google Scholar] [CrossRef]

- Wilhelm Scherer, H. Sulfur in soils. J. Plant Nutr. Soil Sci. 2009, 172, 326–335. [Google Scholar] [CrossRef]

- Gao, X.; Chen, X.; Zhang, J.; Guo, W.; Jin, F.; Yan, N. Transformation of chitin and waste shrimp shells into acetic acid and pyrrole. ACS Sustain. Chem. Eng. 2016, 4, 3912–3920. [Google Scholar] [CrossRef]

- Dziedzic, I.; Kertmen, A. Methods of Chitosan Identification: History and Trends. Lett. Appl. NanoBioSci. 2023, 12, 94. [Google Scholar]

- Reddy, A.A. The soil health card Scheme in India: Lessons learned and challenges for replication in other developing countries. J. Nat. Resour. Policy Res. 2019, 9, 124–156. [Google Scholar] [CrossRef]

- Questell-Santiago, Y.M.; Galkin, M.V.; Barta, K.; Luterbacher, J.S. Stabilization strategies in biomass depolymerization using chemical functionalization. Nat. Rev. Chem. 2020, 4, 311–330. [Google Scholar] [CrossRef] [PubMed]

- Taherzadeh, M.J.; Karimi, K. Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: A review. Int. J. Mol. Sci. 2008, 9, 1621–1651. [Google Scholar] [CrossRef]

- Zhu, H.; Ma, Q.; Sheng, J.; Yang, R. Freeze–thaw repetition as an auxiliary method to promote efficient separation of hemicellulose from poplar. Green Chem. 2020, 22, 942–949. [Google Scholar] [CrossRef]

- General Mills Website. Regenerative Agriculture. Available online: https://www.generalmills.com/how-we-make-it/healthier-planet/environmental-impact/regenerative-agriculture (accessed on 15 July 2023).

- Rodale Institute Website. Regenerative Organic Agriculture and Climate Change: A Down-to-Earth Solution to Global Warming. Available online: https://rodaleinstitute.org/wp-content/uploads/rodale-white-paper.pdf (accessed on 15 July 2023).

- American Meadows Website. How to Select Cover Crops for the Home Garden. Available online: https://www.americanmeadows.com/grass-and-groundcover-seeds/how-to-select-cover-crops-for-the-home-garden#problem-solve (accessed on 15 July 2023).

- Washington State University, Center for Sustaining Agriculture and Natural Resources Website. Ecological Theories, Meta-Analysis, and the Benefits of Monocultures. Available online: https://csanr.wsu.edu/theories-meta-analysis-monocultures/ (accessed on 15 July 2023).

- Great Lakes Protection Fund Website. Available online: https://glpf.org/ (accessed on 15 July 2023).

- Grand Traverse Conservation District Website. The Great Lakes Incubator Farm. Available online: https://natureiscalling.org/glif (accessed on 15 July 2023).

- Bloomberg Website. General Mills Launches Three-Year Regenerative Dairy Pilot in Michigan in Partnership with Foremost Farms and Understanding Ag. Available online: https://www.bloomberg.com/press-releases/2020-06-16/general-mills-launches-three-year-regenerative-dairy-pilot-in-michigan-in-partnership-with-foremost-farms-and-understanding-ag (accessed on 15 July 2023).

- Sierra Club Michigan Chapter Website. Regenerative Agriculture Project. Available online: https://www.sierraclub.org/michigan/regenerative-agriculture-project (accessed on 15 July 2023).

- Michigan State University Website. Student Organic Farm. Available online: https://www.canr.msu.edu/sof/ (accessed on 15 July 2023).

- Verdant Hollow Farms Website. Available online: https://www.verdanthollowfarms.com/ (accessed on 15 July 2023).

- Beaverland Farms Website. Available online: https://www.beaverlandfarms.com/ (accessed on 15 July 2023).

- Shady Side Farm Website. Available online: https://shadysidefarm.com/ (accessed on 15 July 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).