Design and Experiment of Header Height Adaptive Adjustment System for Maize (Zea mays L.) Harvester

Abstract

:1. Introduction

2. Materials and Methods

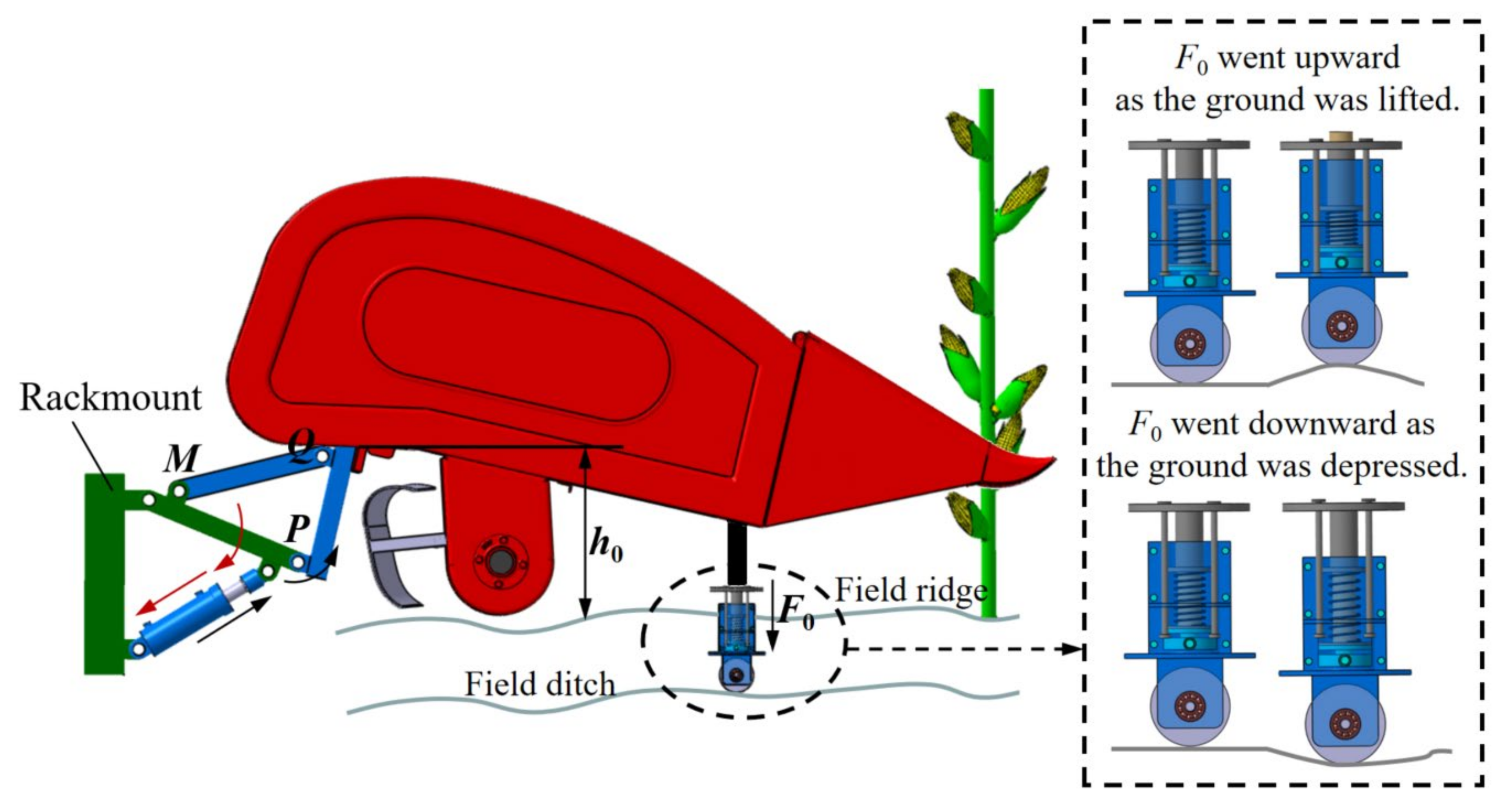

2.1. Overall Program Design of the Adaptive Adjustment System of Header Height

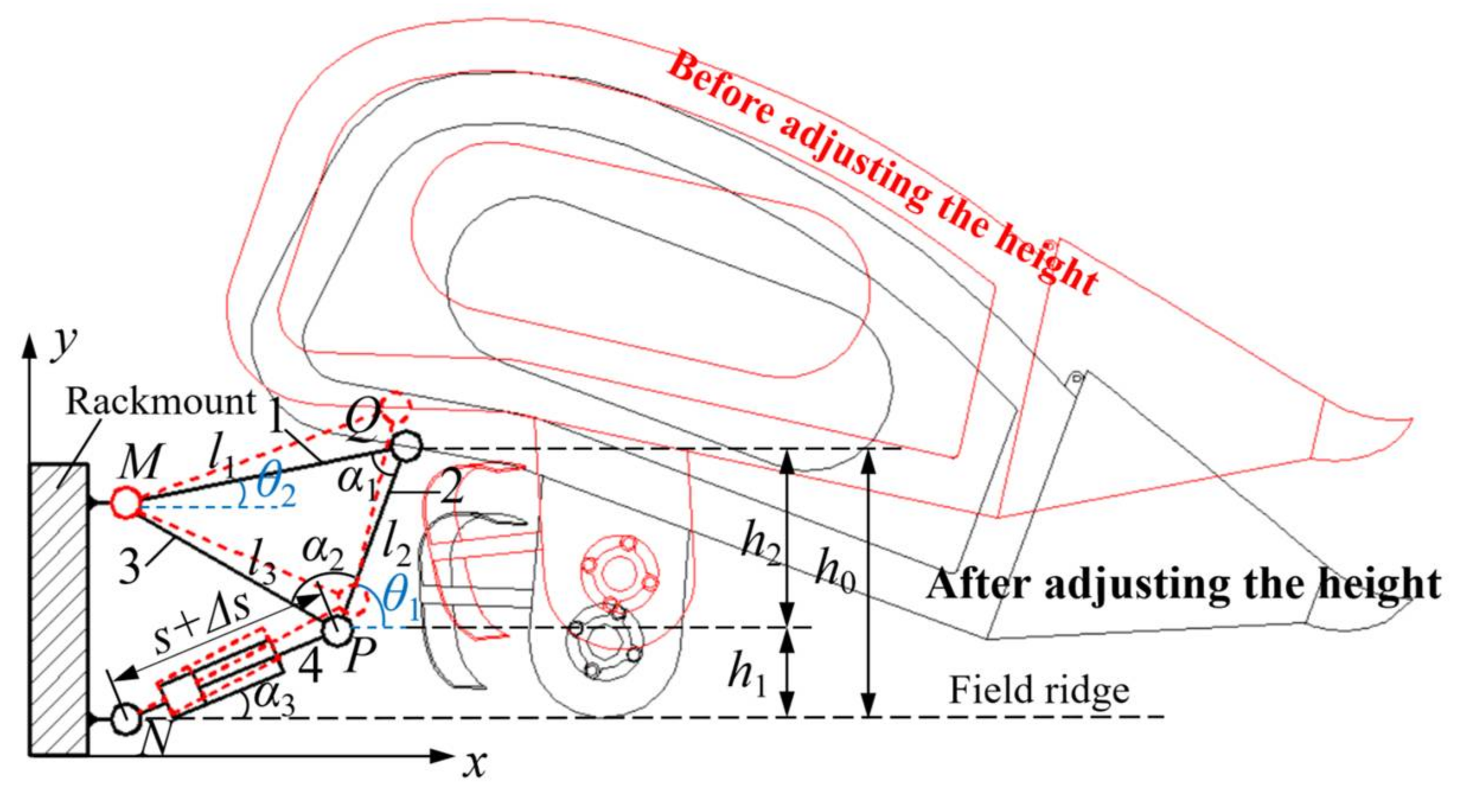

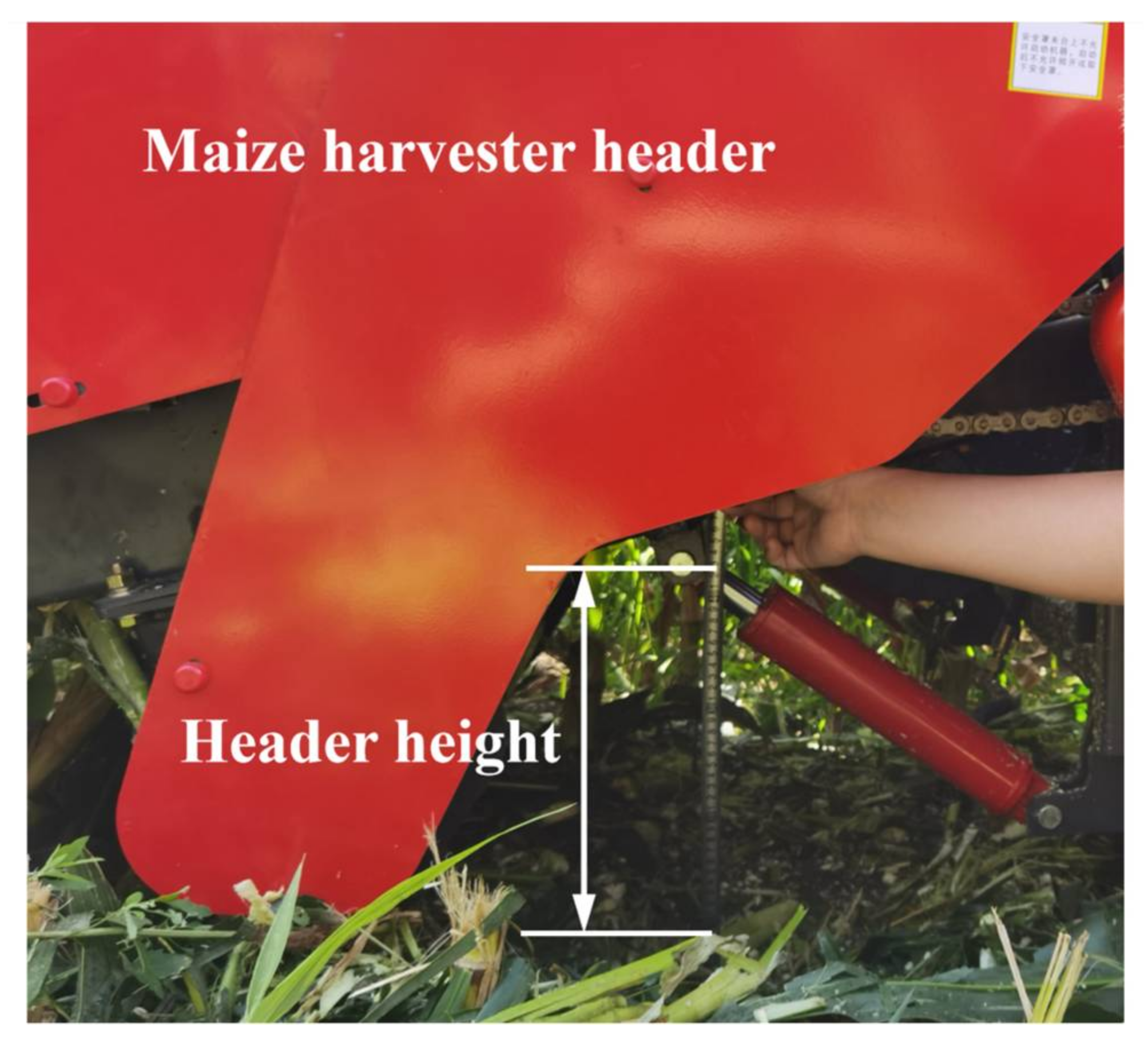

2.1.1. Structure and Composition

2.1.2. Working Principle

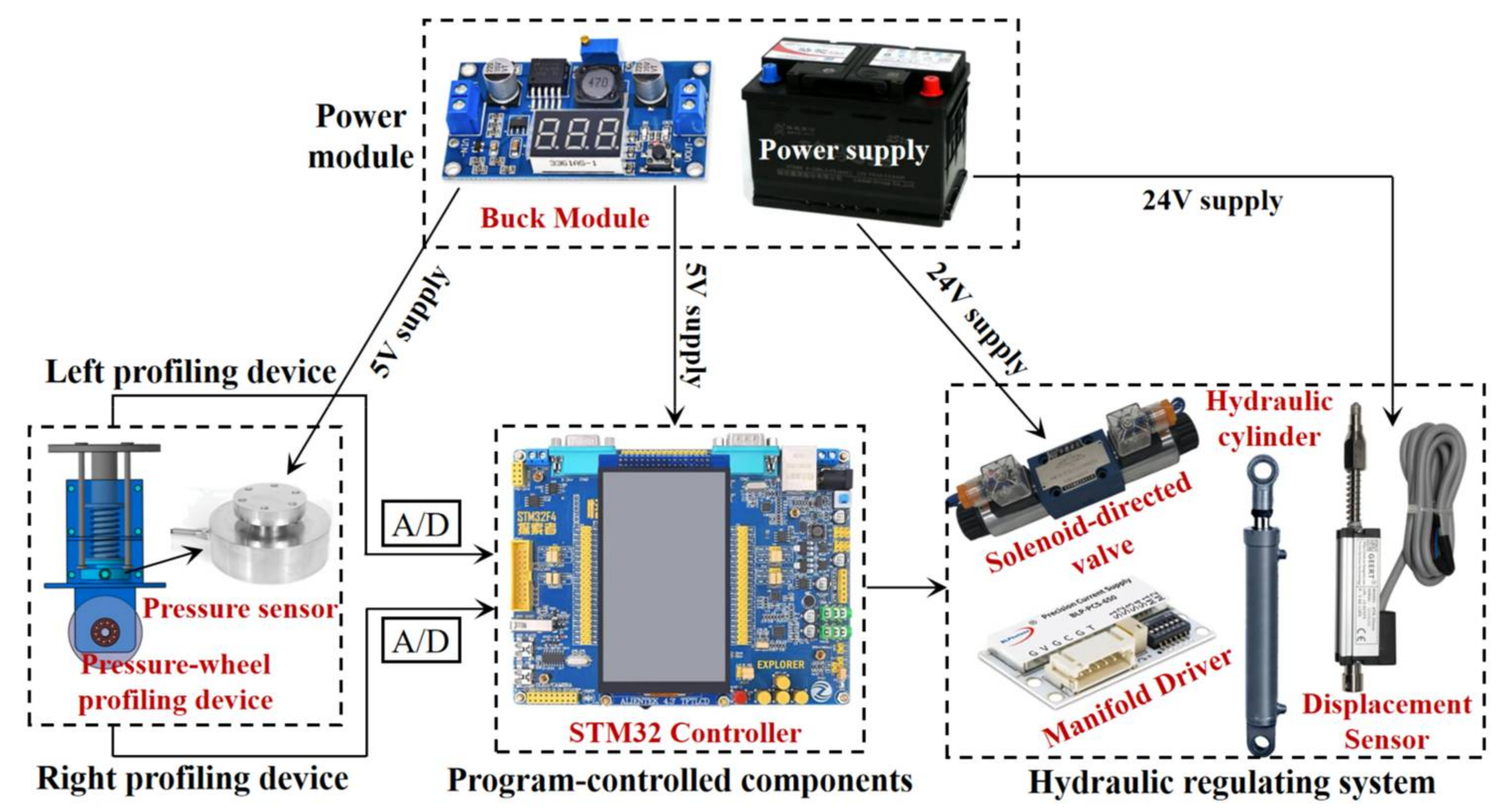

2.2. Hardware Design of the Adaptive Adjustment System of Header Height

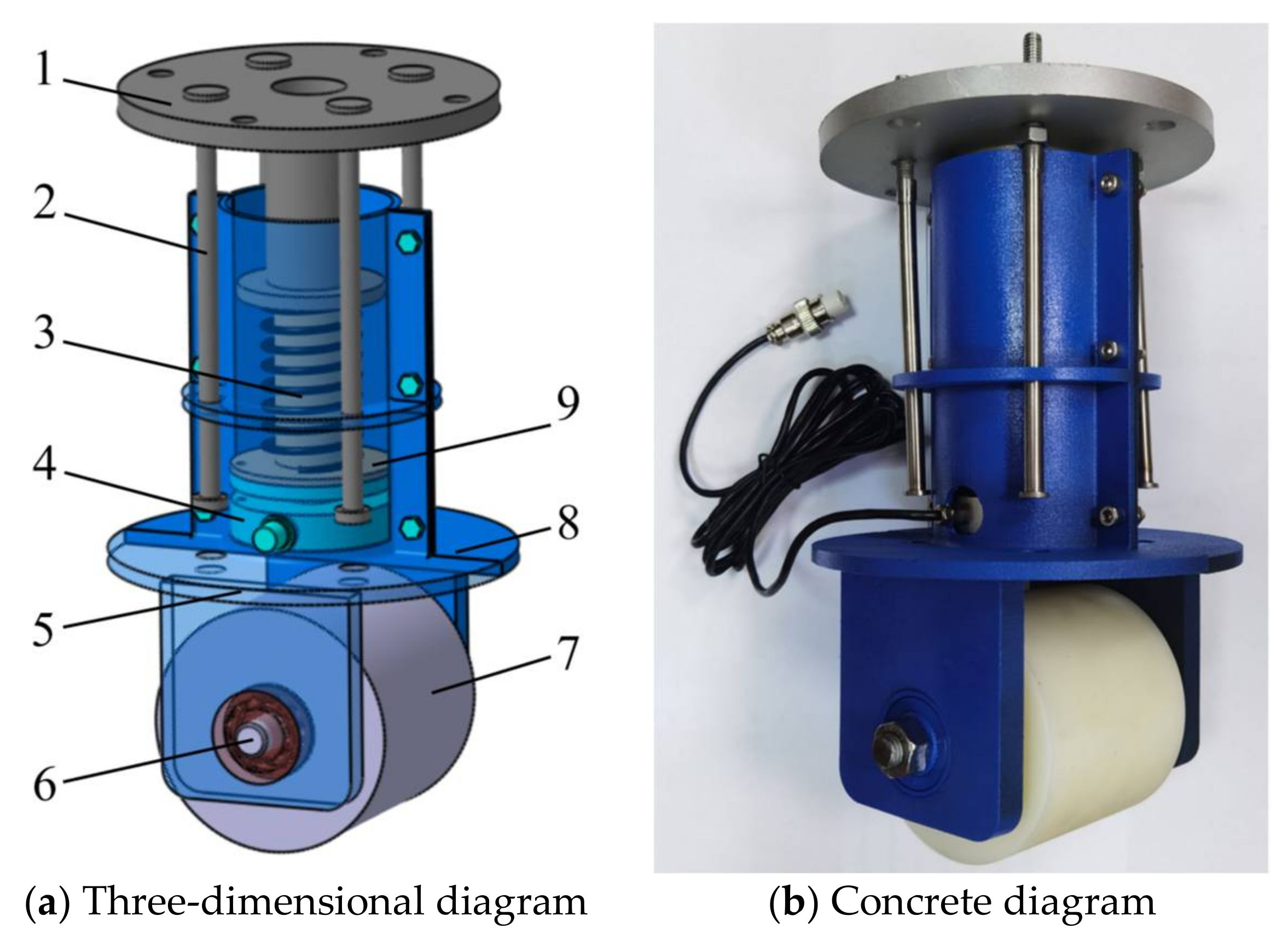

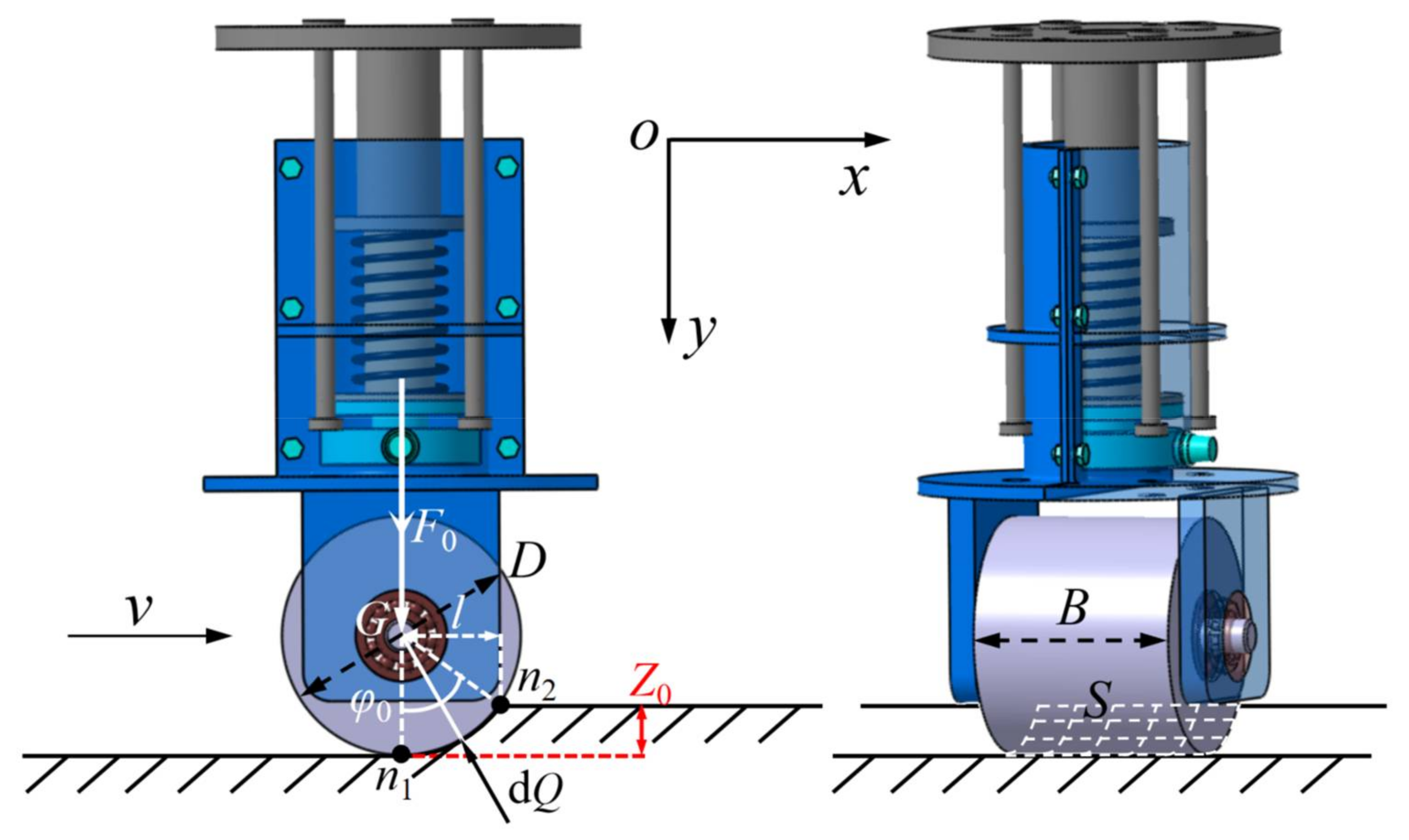

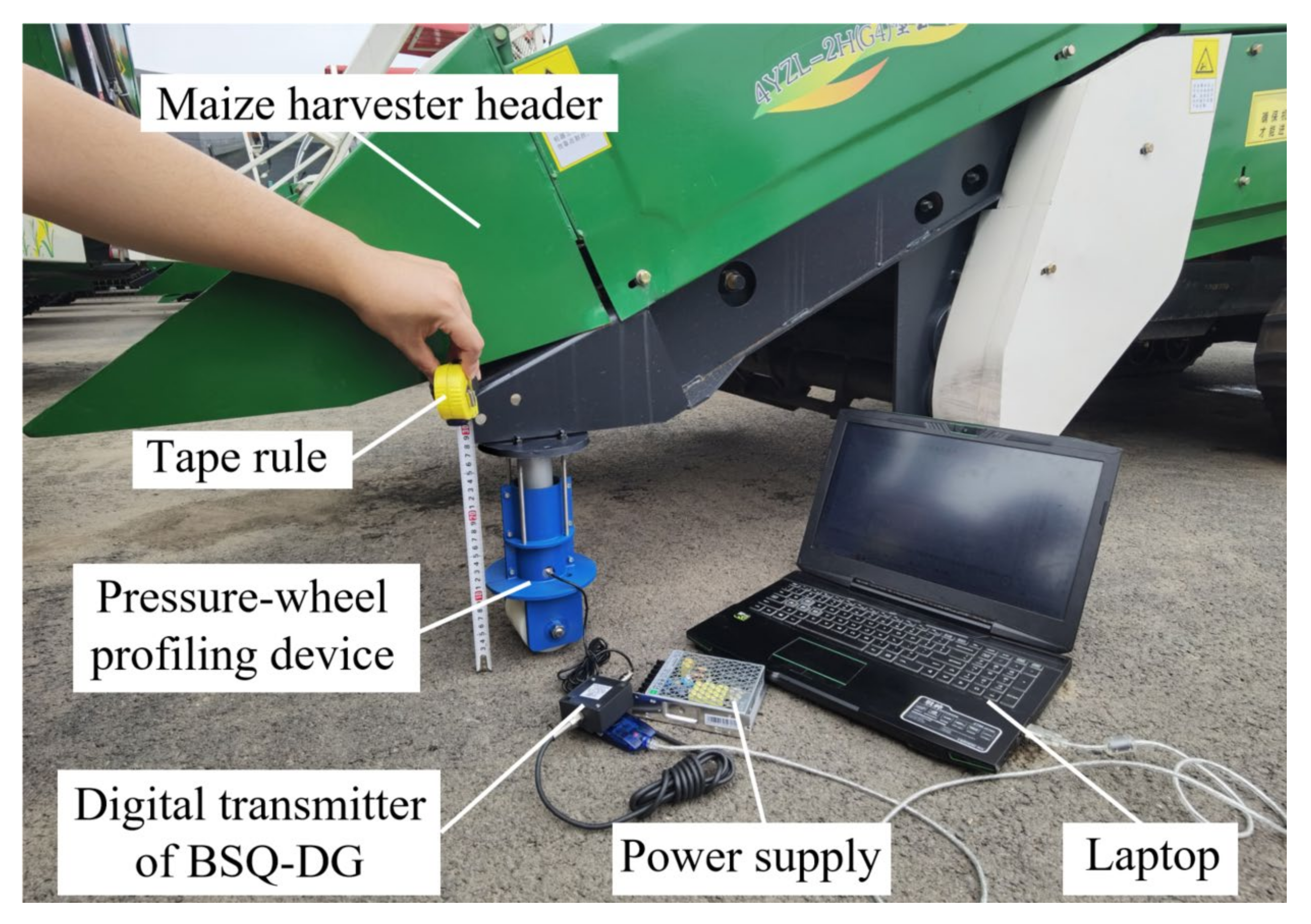

2.2.1. Design of Pressure-Wheel Profiling Device

2.2.2. Design of Hydraulic Regulating Mechanism

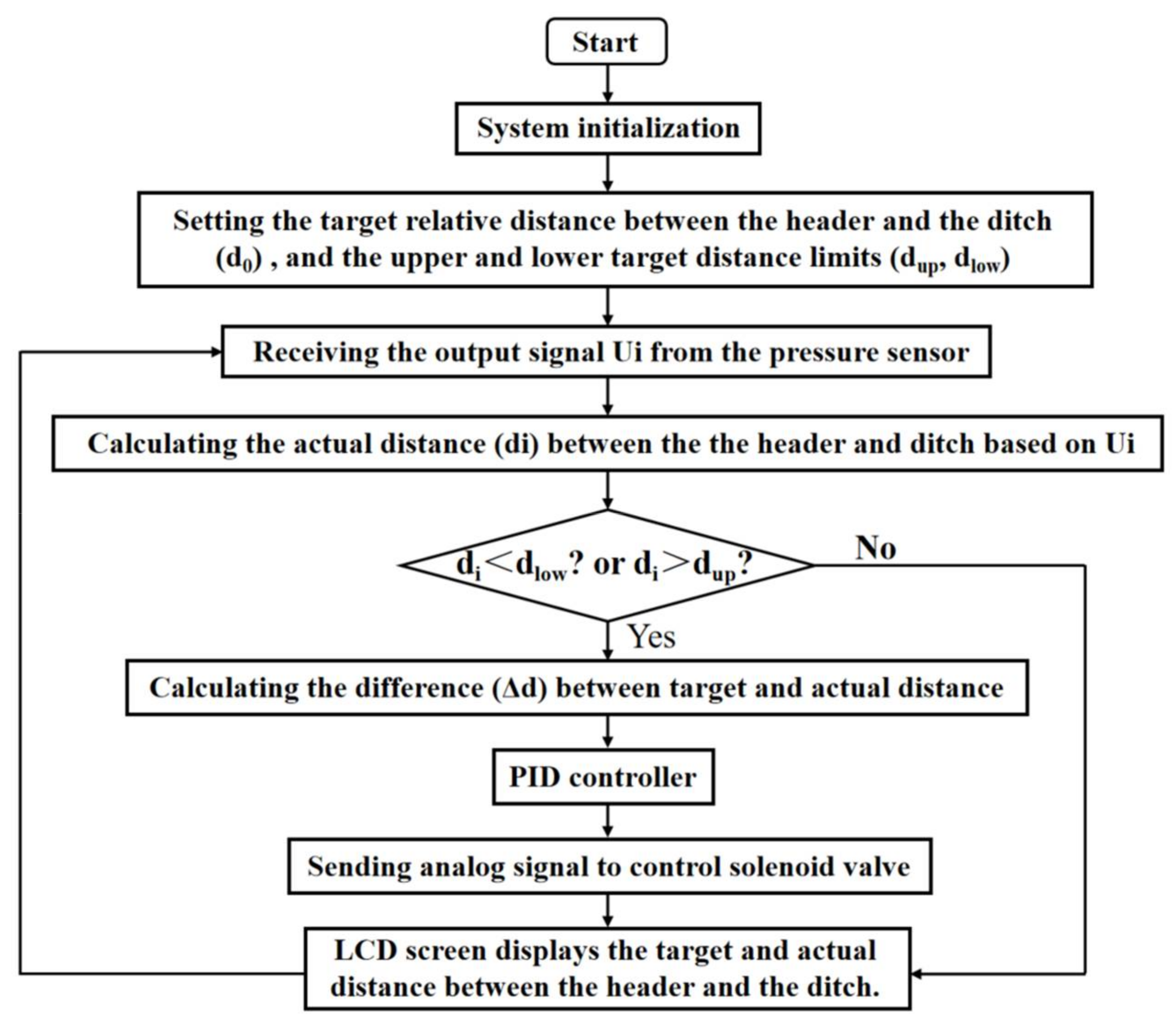

2.3. Software Design of the Adaptive Adjustment System of Header Height

2.3.1. Calibration of Pressure-Wheel Profiling Device

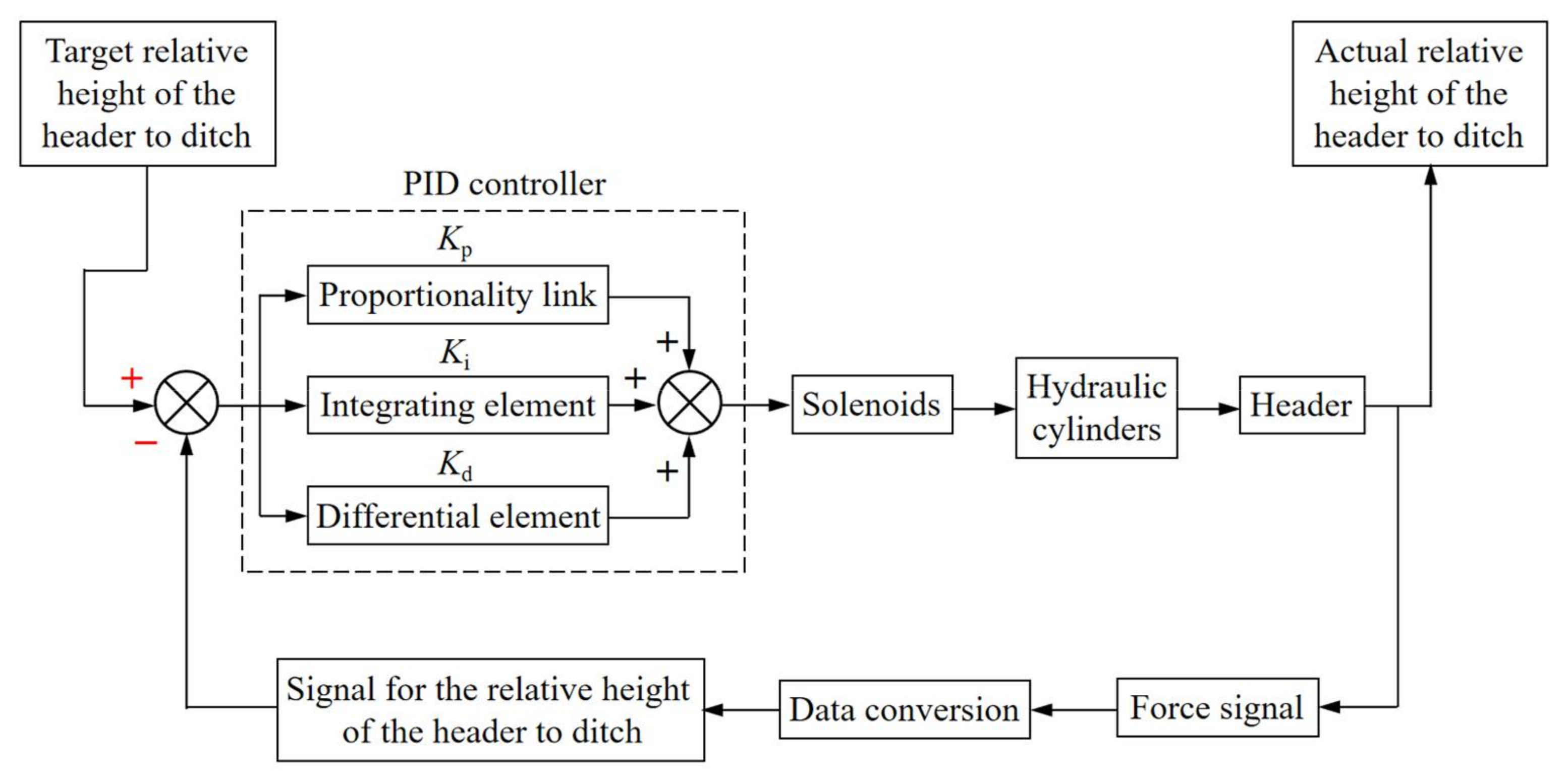

2.3.2. Control Methods for Adaptive Regulation Systems

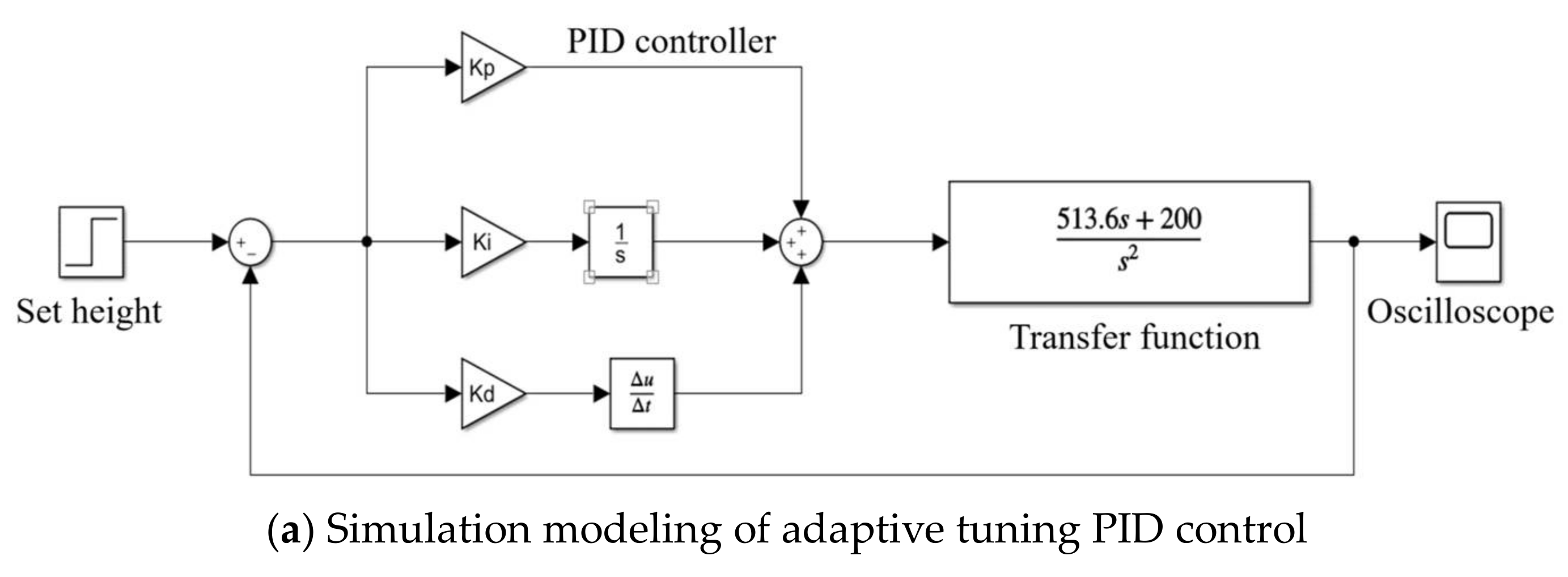

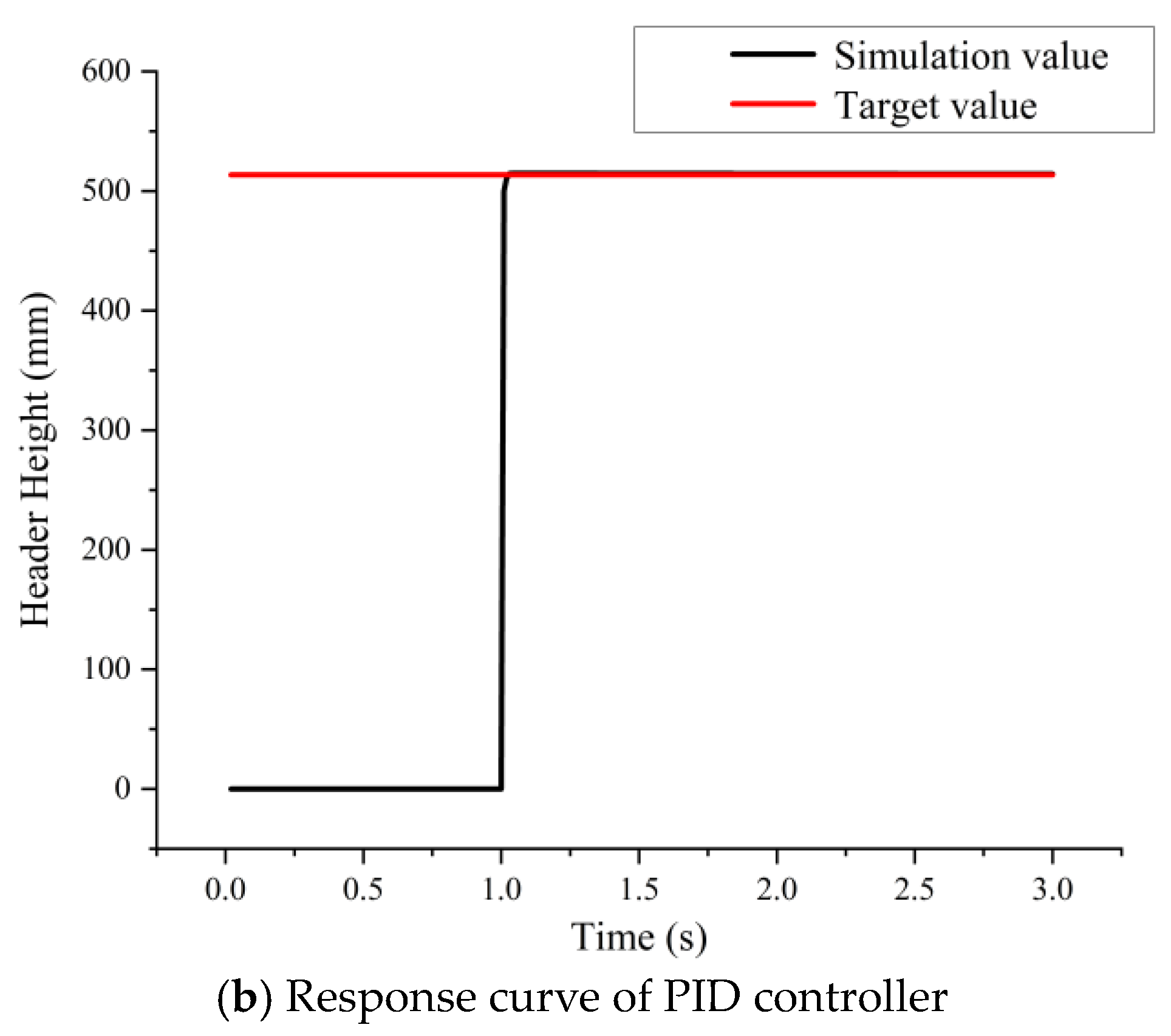

2.3.3. Simulation of Adaptive Regulation System

2.3.4. Programming of Adaptive Regulation Systems

2.4. Field Test

2.4.1. Test Site

2.4.2. Verification Test of Automatic Adjustment of Header Height

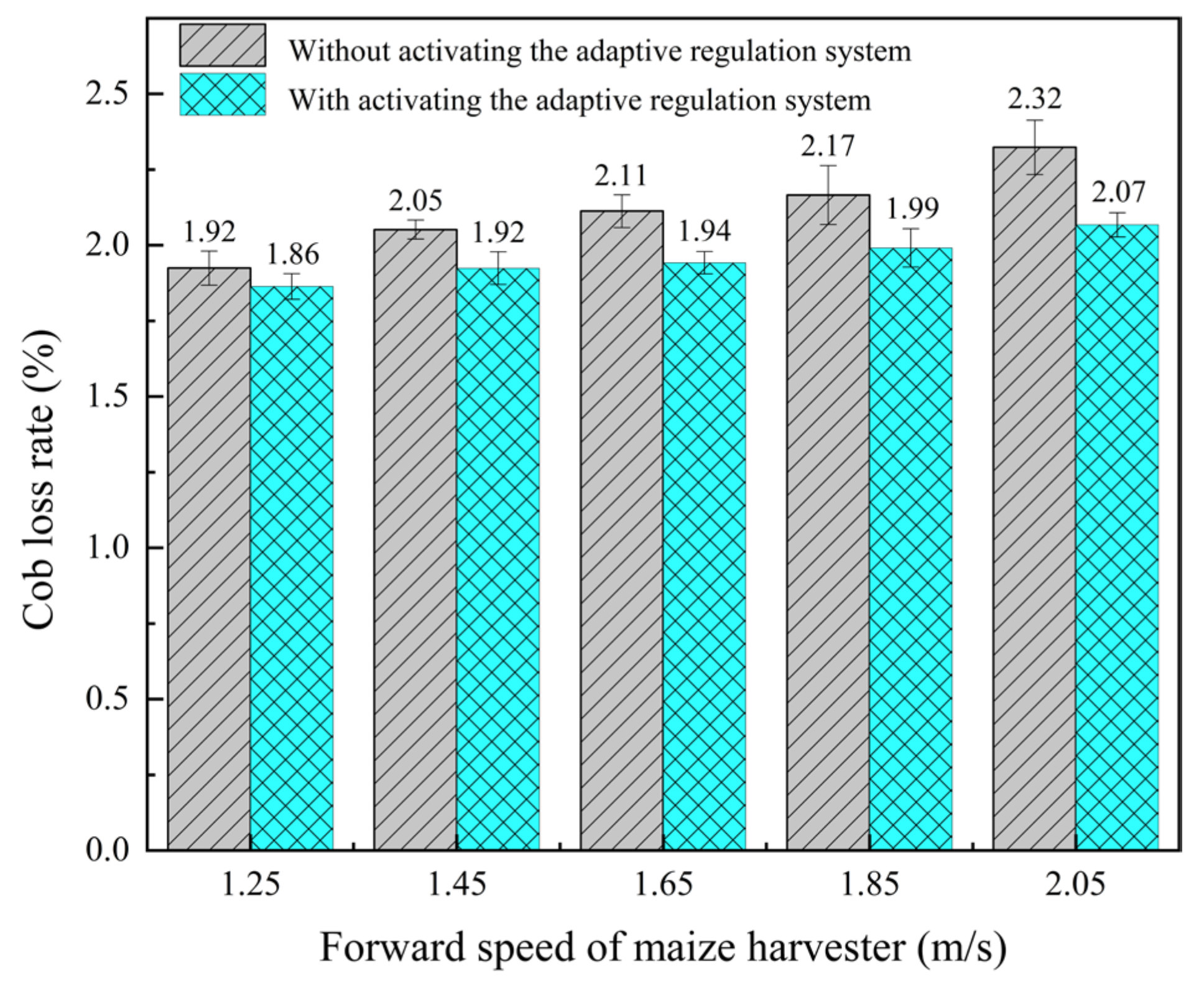

2.4.3. Comparative Tests of Cob Loss Rate

2.4.4. Comparative Tests of Coefficient of Variation for Stubble Height

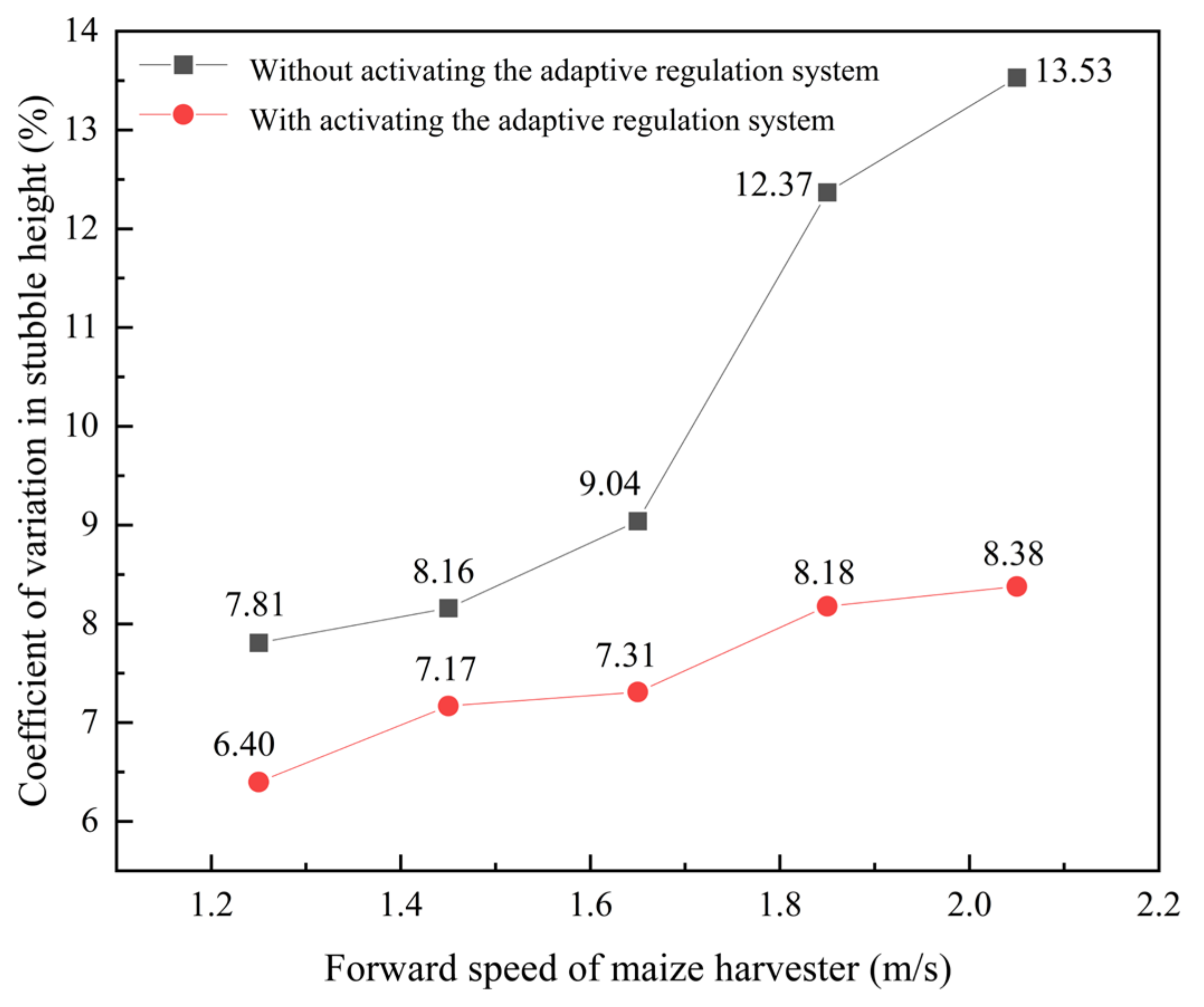

3. Results and Discussion

3.1. Errors in the Automatic Adjustment of Header Height

3.2. Cob Loss Rate

3.3. Coefficient of Variation in Stubble Height

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, J.; Yang, M.; Zhang, X.; Liu, P.; Li, S.; Peng, J. Evaluation of Wheat and Corn Harvester Selection in Hilly and Mountainous Area. Trans. CSAM 2022, 53, 150–157. [Google Scholar]

- Zhang, Z.; Li, S.; Han, Z.; Bai, X.; Li, T.; Zhang, B. Design and Test of a New Type Header of Corn Harvester for Reaping Both Corn Stalk and Spike. In Proceedings of the 2017 ASABE Annual International Meeting, Spokane, WA, USA, 16–19 July 2017; p. 1701395. [Google Scholar]

- Li, Z.; Jianqun, Y.; Qiang, Z.; Chuanxin, L.; Xvwen, F. Design and Experimental Study of Bionic Reverse Picking Header for Fresh Corn. Agriculture 2022, 13, 93. [Google Scholar]

- Nigon, B.J.; Shinners, K.J.; Cook, D.E. Harvester Modifications to Alter Composition and Dry Matter of Corn-Silage. Appl. Eng. Agric. 2016, 32, 157–167. [Google Scholar]

- Tao, C.; Fan, C.; Zhang, D.; Li, Y.; LI, Y.; Zhao, H. Research Progress of Maize Mechanized Harvesting Technology. Trans. CSAM 2019, 50, 1–13. [Google Scholar]

- Xu, H. Research on Intelligent Control Design of Sugarcane Harvest; Guangxi University of Science and Technology: Liuzhou, China, 2022. [Google Scholar]

- Liu, H. Research on Structural Optimization and Control Strategies for Adaptive Wheat Cutting Tables; Shandong University of Technology: Zibo, China, 2022. [Google Scholar]

- Liu, Y. Design and Experiment of Wide Folding Rape Windrower Based on Crawler Type Power Chassis; Huazhong Agricultural University: Wuhan, China, 2022. [Google Scholar]

- Long, Z.; Xiang, Y.; Li, Y.; Hu, Z.; Liu, A.; Dai, X. Adaptive Adjustment System of Header Height Based on Inclination Sensor. J. China Agric. Univ. 2021, 26, 200–208. [Google Scholar]

- Song, Y. Design and Test of Adaptive Adjustment System for Combine Harvester Header Height; Huazhong Agricultural University: Wuhan, China, 2022. [Google Scholar]

- Liu, G.; Ni, Y.; Yang, T.; Qi, Y.; Jin, C. Design and Experiment of Header Height Automatic Control System for Soybean Harvester. J. Chin. Agric. Mech. 2023, 44, 155–160. [Google Scholar]

- Sun, Y.; Xu, L.; Jing, B.; Chai, X.; Li, Y. Development of A Four-point Adjustable Lifting Crawler Chassis and Experiments in A Combine Harvester. Comput. Electron. Agric. 2020, 173, 105416. [Google Scholar] [CrossRef]

- Zhang, Z. Design and Analysis of Hydraulic Lifting System of Combine Harvester Cutting Table; Shandong University of Science and Technology: Qingdao, China, 2019. [Google Scholar]

- Zhang, C. Research on Header Profiling and Crop Height Measurement Method; Southeast University: Nanjing, China, 2019. [Google Scholar]

- Liao, Y.; Xiang, Y.; Wu, M.; Liu, D.; Cheng, Y.; Li, Y. Design and Test of the Adaptive Height Adjustment System for Header of the Combine–Harvester. J. Hunan Agric. Univ. 2018, 44, 326–329. [Google Scholar]

- Ni, Y.; Jin, C.; Chen, M.; Yuan, W.; Qian, Z. Computational Model and Adjustment System of Header Height of Soybean Harvesters Based on Soil-machine System. Comput. Electron. Agric. 2021, 183, 105907. [Google Scholar] [CrossRef]

- Jin, C.; Liu, G.; Ni, Y.; Yang, T.; Wang, T.; Qi, Y. Design and Experiment of Header Profiling Mechanism for Combine Harvester Based on MBD-DEM Coupling. Trans. CSAE 2022, 38, 1–10. [Google Scholar]

- Geng, A.; Zhang, M.; Zhang, J.; Zhang, Z.; Gao, A.; Zheng, J. Design and Experiment of Automatic Control System for Corn Header Height. Trans. CSAM 2020, 51, 118–125. [Google Scholar]

- Gong, Y.; Jin, Z.; Bai, X.; Wang, S.; Wu, L.; Huang, W. Design and Experiment of Servo Control System for Sugarcane Header. Trans. CSAM 2023, 54, 119–128. [Google Scholar]

- Luo, N.; Meng, Q.; Feng, P.F.; Qu, Z.; Yu, Y.; Liu, D.; Müller, C.; Wang, P. China can be self-sufficient in maize production by 2030 with optimal crop management. Nat. Commun. 2023, 14, 2637. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, X.; Li, Y. Header Height Control Strategy of Harvester Based on Robust Feedback Linearization. Trans. CSAM 2020, 51, 123–130. [Google Scholar]

- Zhou, D.; Jin, C.; Ni, Y.; Zhang, G. Design and test on fuzzy control system for height of combine harvester header. Jiangsu Agric. Sci. 2019, 47, 264–267. [Google Scholar]

- Tian, W. Research and Implementation of Ultrasonic Distance Measurement System; Nanjing University of Posts and Telecommunications: Nangjing, China, 2017. [Google Scholar]

- Ji, K.; Li, Y.; Li, G.; Wang, X.; Wang, H. Design and Test of Height Auto-control Device of Combine Header. J. Agric. Mech. Res. 2023, 45, 85–89, 94. [Google Scholar]

- Li, J.; Huang, H.; Wang, Y.; Tian, L.; Ren, L. Development on Research of Soft-terrain Machine Systems. Trans. CSAM 2015, 46, 306–320. [Google Scholar]

- Zhai, G. Research on Dynamics of Combined Contact Mode of Wheel-Ground on Planetary Rovers; Beijing Jiaotong University: Beijing, Chiina, 2020. [Google Scholar]

- Zhang, J.; Yang, C.; Zhang, L.; Jiang, Y.; Wang, C. Analysis and experiment on strength and vibration characteristics of corn stubble plucking mechanism. Trans. CSAE 2018, 34, 72–78. [Google Scholar]

- Zhao, S.; Tan, H.; Wang, J.; Yang, C.; Yang, Y. Design and experiment of multifunctional integrated seeding opener. Trans. CSAE 2018, 34, 58–67. [Google Scholar]

- Tong, J.; Zhang, Z.; Chen, D.; Zhang, Q.; Ma, Y. Three-dimensional dynamic finite element analysis of interaction between toothed wheel and soil. Trans. CSAE 2014, 30, 48–58. [Google Scholar]

- Tong, J.; Zhang, Q.; Chang, Y.; Li, M.; Zhang, L.; Liu, X. Finite Element Analysis and Experimental Verification of Bionic Press Roller in Reducing Adhesion and Resistance. Trans. CSAM 2014, 45, 85–92. [Google Scholar]

- Liu, H.; Zhao, S.; Tan, H.; Yang, Y.; Zhang, X. Investigation on Press Device in Reducing Adhesion and Resistance Based on Scrape and Vibration Principle. Trans. CSAM 2018, 49, 86–92. [Google Scholar]

- Tong, J.; Zhang, Q.; Chang, Y.; Chen, D.; Dong, W.; Zhang, L. Reduction of Soil Adhesion and Traction Resistance of Ridged Bionic Press Rollers. Trans. CSAM 2014, 45, 135–140. [Google Scholar]

- Jia, H.; Tan, H.; Ma, Z.; Zhou, S.; Wang, G. Design and experiment of the straw breaking and diversion device for maize harvesters. Trans. CSAM 2022, 38, 12–23. [Google Scholar]

- Li, Y.; Guo, C.; Yao, D.; He, N.; Zhang, X.; Wu, Z.; Li, Y. Design and experiment of banana straw crushing and returning machine with anti-wrapping device supported by flailing blade. Trans. CSAE 2021, 37, 11–19. [Google Scholar]

- Geng, D.; Sun, Y.; Li, H.; Mou, X.; Zhang, G.; Wang, Z.; Lu, X. Design and experiment of crawler corn harvester for sloping fields. Trans. CSAE 2021, 37, 11–19. [Google Scholar]

- Tang, Z.; Liu, S.; Zhou, F.; Li, T.; Wang, J.; Li, C. Design and Experiment of Ear Harvester for Seed Corn. Trans. CSAM 2021, 52, 102–112. [Google Scholar]

- Zhang, Z.; He, J.; Li, H.; Wang, Q.; Ju, J.; Yan, X. Design and Experiment on Straw Chopper Cum Spreader with Adjustable Spreading Device. Trans. CSAM 2017, 48, 76–87. [Google Scholar]

- Pang, J.; Li, Y.M.; Ji, J.T.; Xu, L.Z. Vibration excitation identification and control of the cutter of a combine harvester using triaxial accelerometers and partial coherence sorting. Biosyst. Eng. 2019, 185, 25–34. [Google Scholar] [CrossRef]

- Yao, Y.; Song, Z.; Du, Y.; Zhao, X.; Mao, E.; Liu, F. Analysis of vibration characteristics and its major influenced factors of header for corn combine harvesting machine. Trans. CSAE 2017, 33, 40–49. [Google Scholar]

- Lai, X.; He, G.; Li, S.; Zeng, B.; Mo, H.; Teng, X.; Cao, B. Experimental research on the axial vibration of the cutting system for sugarcane harvesters. Trans. CSAE 2021, 37, 12–20. [Google Scholar]

- GB/T 34373-2017; Corn Harvest Machine—Picking Header. General Administration of Quality Supervision, Inspection and Quarantine: Beijing, China, 2017.

| Targets | Value |

|---|---|

| (Depth 0~100 mm) Average soil moisture content/% | 16.49 |

| (Depth 0~50 mm) Average soil firmness/kPa | 126.7 |

| (Depth 0~50 mm) Soil capacity/(g·cm−3) | 1.17 |

| Soil composition/% | 12.68 (Viscous particles), 64.15 (Powder particles), 23.17 (Sand particles) |

| PH-value | 7.04 |

| Organic matter content/% | 2.53 |

| Instrument | Type | Manufacturer | Range | Accuracy |

|---|---|---|---|---|

| Microcontroller | STM32F4072G | Guangzhou Starwing Electronic Technology Co., Ltd., Guangzhou City, Guangdong Province, China | / | / |

| Pressure Sensor | JHBM-H1 | Bengbu Jinnuo Sensor Co., Ltd., Bengbu, Anhui Province, China | 0~3000 N | ±10 N |

| Solenoid-directed valve | 4WE6F61B/CG24N9Z5L | Beijing Huade Hydraulic Industry Group Limited Liability Company, Beijing, China | 0~31.5 Mpa | 0.1 Mpa |

| Displacement Sensor | KTR-200 | Shenzhen Hongmai Technology Co., Ltd., Shenzhen, China | 0~200 mm | 0.01 mm |

| Hydraulic cylinder | 40-25-150 | Shandong Hengdingsheng Hydraulic Machinery Co., Ltd., Linyi City, Shandong Province, China | 0~150 mm | / |

| Test Area | Test Number | Setting Header Height/mm | Different Forward Speeds of Maize Harvester (m/s) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.25 | 1.45 | 1.65 | 1.85 | 2.05 | ||||||||

| Measured Value/mm | Deviation/mm | Measured Value/mm | Deviation/mm | Measured Value/mm | Deviation/mm | Measured Value/mm | Deviation/mm | Measured Value/mm | Deviation/mm | |||

| 1 | 1 | 516 | 520 | 4 | 507 | 9 | 522 | 6 | 522 | 6 | 495 | 21 |

| 2 | 516 | 509 | 7 | 521 | 5 | 519 | 3 | 519 | 3 | 509 | 17 | |

| 3 | 516 | 526 | 10 | 503 | 13 | 501 | 15 | 501 | 15 | 527 | 11 | |

| 4 | 516 | 510 | 6 | 507 | 9 | 529 | 13 | 529 | 13 | 508 | 8 | |

| 5 | 516 | 507 | 9 | 524 | 8 | 507 | 9 | 507 | 9 | 520 | 4 | |

| 2 | 1 | 516 | 508 | 8 | 528 | 12 | 508 | 8 | 508 | 8 | 506 | 10 |

| 2 | 516 | 510 | 6 | 522 | 6 | 525 | 9 | 525 | 9 | 525 | 9 | |

| 3 | 516 | 522 | 6 | 507 | 9 | 527 | 11 | 527 | 11 | 500 | 16 | |

| 4 | 516 | 507 | 9 | 519 | 3 | 498 | 18 | 498 | 18 | 504 | 12 | |

| 5 | 516 | 521 | 5 | 505 | 11 | 505 | 11 | 505 | 11 | 497 | 19 | |

| 3 | 1 | 516 | 504 | 12 | 503 | 13 | 524 | 8 | 524 | 8 | 521 | 5 |

| 2 | 516 | 511 | 5 | 521 | 5 | 500 | 16 | 500 | 16 | 495 | 21 | |

| 3 | 516 | 523 | 7 | 513 | 3 | 503 | 13 | 503 | 13 | 503 | 13 | |

| 4 | 516 | 510 | 6 | 499 | 17 | 521 | 5 | 521 | 5 | 524 | 8 | |

| 5 | 516 | 509 | 7 | 507 | 9 | 507 | 9 | 507 | 9 | 505 | 11 | |

| 4 | 1 | 516 | 522 | 6 | 511 | 5 | 524 | 8 | 524 | 8 | 526 | 10 |

| 2 | 516 | 505 | 11 | 528 | 12 | 510 | 6 | 510 | 6 | 506 | 10 | |

| 3 | 516 | 509 | 7 | 509 | 7 | 505 | 11 | 505 | 11 | 495 | 21 | |

| 4 | 516 | 526 | 10 | 527 | 11 | 529 | 13 | 529 | 13 | 529 | 13 | |

| 5 | 516 | 512 | 4 | 506 | 10 | 512 | 4 | 512 | 4 | 507 | 9 | |

| 5 | 1 | 516 | 523 | 7 | 525 | 9 | 525 | 9 | 525 | 9 | 494 | 22 |

| 2 | 516 | 507 | 9 | 511 | 5 | 524 | 8 | 524 | 8 | 527 | 11 | |

| 3 | 516 | 506 | 10 | 499 | 17 | 506 | 10 | 506 | 10 | 503 | 13 | |

| 4 | 516 | 513 | 3 | 508 | 8 | 513 | 3 | 513 | 3 | 524 | 8 | |

| 5 | 516 | 505 | 11 | 513 | 3 | 497 | 19 | 497 | 19 | 501 | 15 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, H.; Wang, G.; Zhou, S.; Jia, H.; Qu, M.; Xiang, M.; Gao, X.; Zhou, Z.; Li, H.; Zou, Z. Design and Experiment of Header Height Adaptive Adjustment System for Maize (Zea mays L.) Harvester. Sustainability 2023, 15, 14137. https://doi.org/10.3390/su151914137

Tan H, Wang G, Zhou S, Jia H, Qu M, Xiang M, Gao X, Zhou Z, Li H, Zou Z. Design and Experiment of Header Height Adaptive Adjustment System for Maize (Zea mays L.) Harvester. Sustainability. 2023; 15(19):14137. https://doi.org/10.3390/su151914137

Chicago/Turabian StyleTan, Hewen, Gang Wang, Shuhui Zhou, Honglei Jia, Minghao Qu, Meiqi Xiang, Xiaomei Gao, Zihao Zhou, Hailan Li, and Zhaobo Zou. 2023. "Design and Experiment of Header Height Adaptive Adjustment System for Maize (Zea mays L.) Harvester" Sustainability 15, no. 19: 14137. https://doi.org/10.3390/su151914137

APA StyleTan, H., Wang, G., Zhou, S., Jia, H., Qu, M., Xiang, M., Gao, X., Zhou, Z., Li, H., & Zou, Z. (2023). Design and Experiment of Header Height Adaptive Adjustment System for Maize (Zea mays L.) Harvester. Sustainability, 15(19), 14137. https://doi.org/10.3390/su151914137