Dynamic Modulus Prediction Validation for the AASHTOWare Pavement ME Design Implementation in Egypt

Abstract

:1. Introduction

2. Literature Review

- E*: The hot mix asphalt dynamic modulus, in 105 psi;

- η: The asphalt binder viscosity, in 106 poise;

- f: The loading frequency, in Hz;

- Va: The air voids, %;

- Va: The air voids, %;

- Va: The air voids, %;

- ρ38: The cumulative retained on the 3/8” sieve, %;

- ρ4: The cumulative retained on sieve number 4, %;

- ρ200: The percentage passing Sieve No. 200.

| Temperature | Ranges from 0 to 130 °F |

| Frequency | Ranges from 0.1 Hz to 25 Hz |

| Binder | 9 unmodified asphalt binders 14 modified asphalt binders |

| Aggregate | 39 different types of aggregates |

| Asphalt Mix | unmodified asphalt binders are used with 171 mixes modified asphalt binders are used with 34 mixes |

| Compaction | Samples are compacted using Gyratory and Kneading |

| Specimen Size | Cylindrical specimen of four times eight inches for kneading compaction And Cylindrical specimens with 2.75 × 5.5 for Gyratory compaction |

| Aging | No aging |

| Data Points | 2750 |

- |Gb*|: The binder complex shear modulus, psi;

- δ: The phase angle of the binder, degrees;

- All other variables are as previously defined.

3. Research Objectives

- Establishing an HMA E* database by laboratory measuring the E* of locally produced HMA mixes frequently used in Egypt;

- Evaluating the performance of the E* prediction models integrated in the AASHTOWare Pavement ME for the locally produced hot asphalt mixtures;

- Studying the effect of the predicted E* values, from the investigated AASHTOWare prediction models, on the AASHTOWare six performance indicators; FC, LC, TC, RAC, RT, and IRI.

4. Materials and Methods

4.1. Plant-Produced Local HMA Mixes

4.2. Experimental Program

4.2.1. Asphalt Binder Characterization

- fc: The frequency, in Hertz;

- fs: The frequency (fc/2ᴨ), in Hertz;

- ηfs,T: The viscosity of the asphalt binder as a function of fs and TR, in cP;

- δ: The asphalt binder phase angle, in degree;

- |Gb*|: the asphalt binder shear modulus, in Pa.

4.2.2. Preparation of E* Samples

4.2.3. Measuring the Dynamic Modulus

5. Results and Discussion

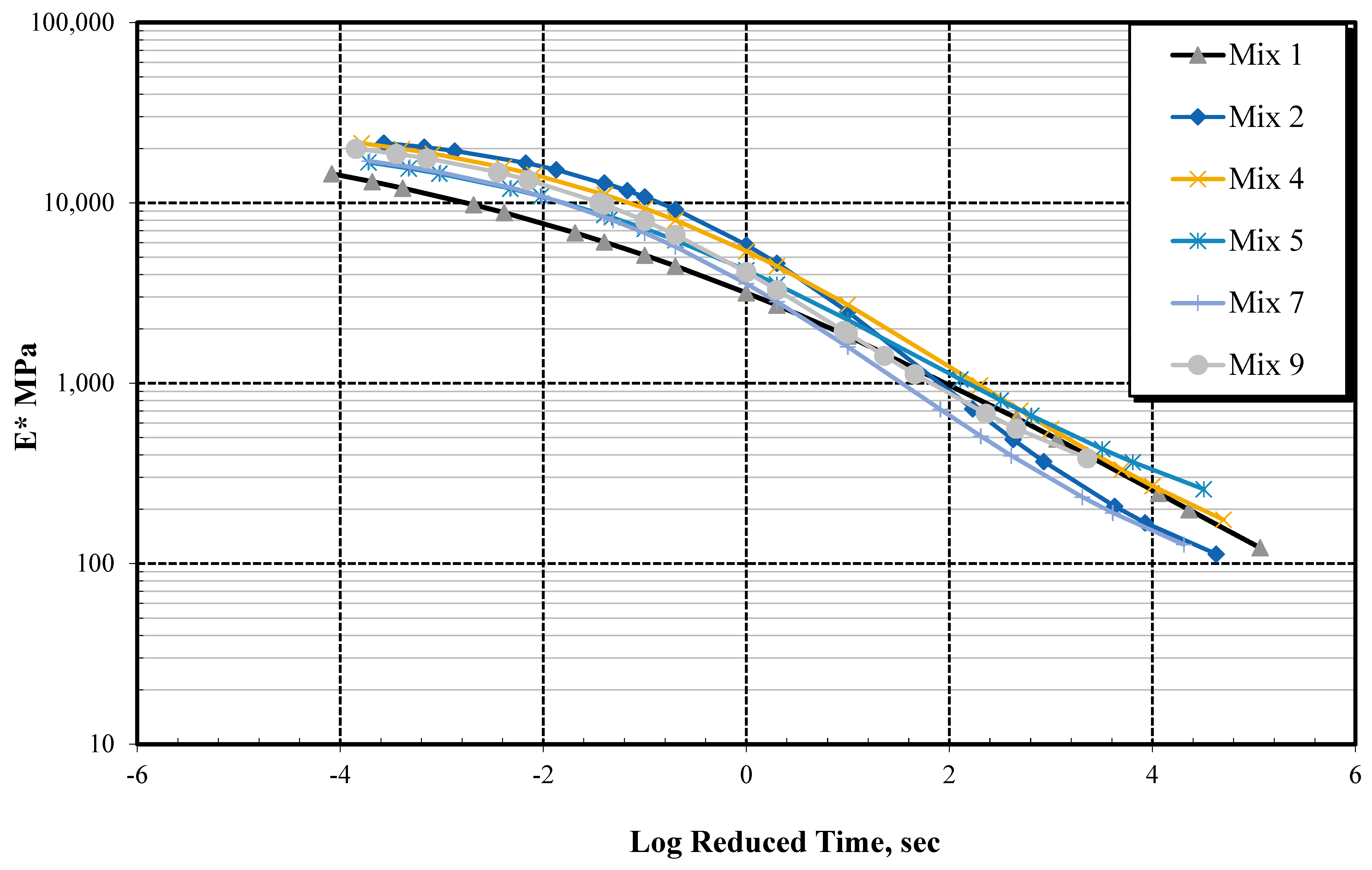

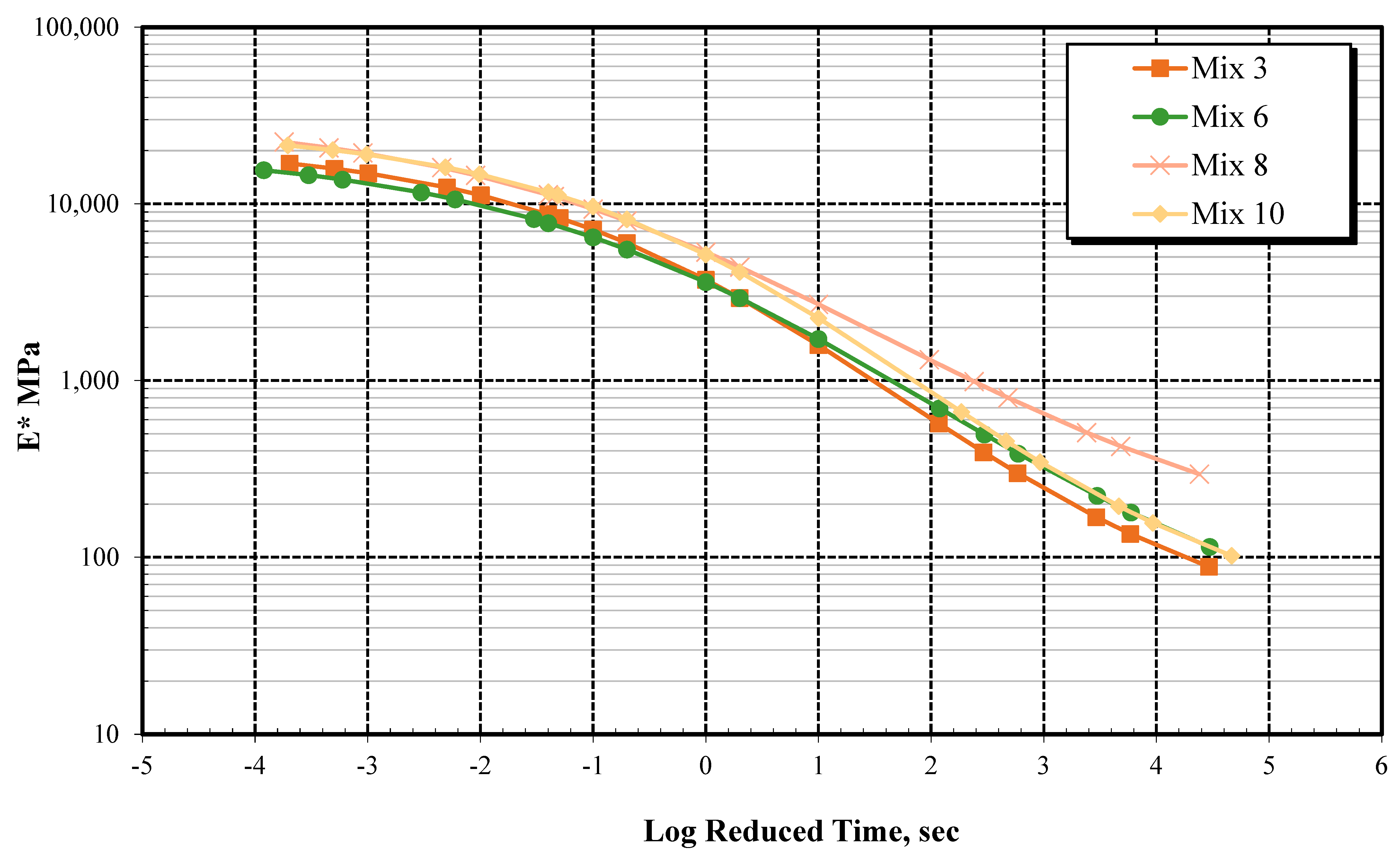

5.1. Dynamic Modulus Prediction

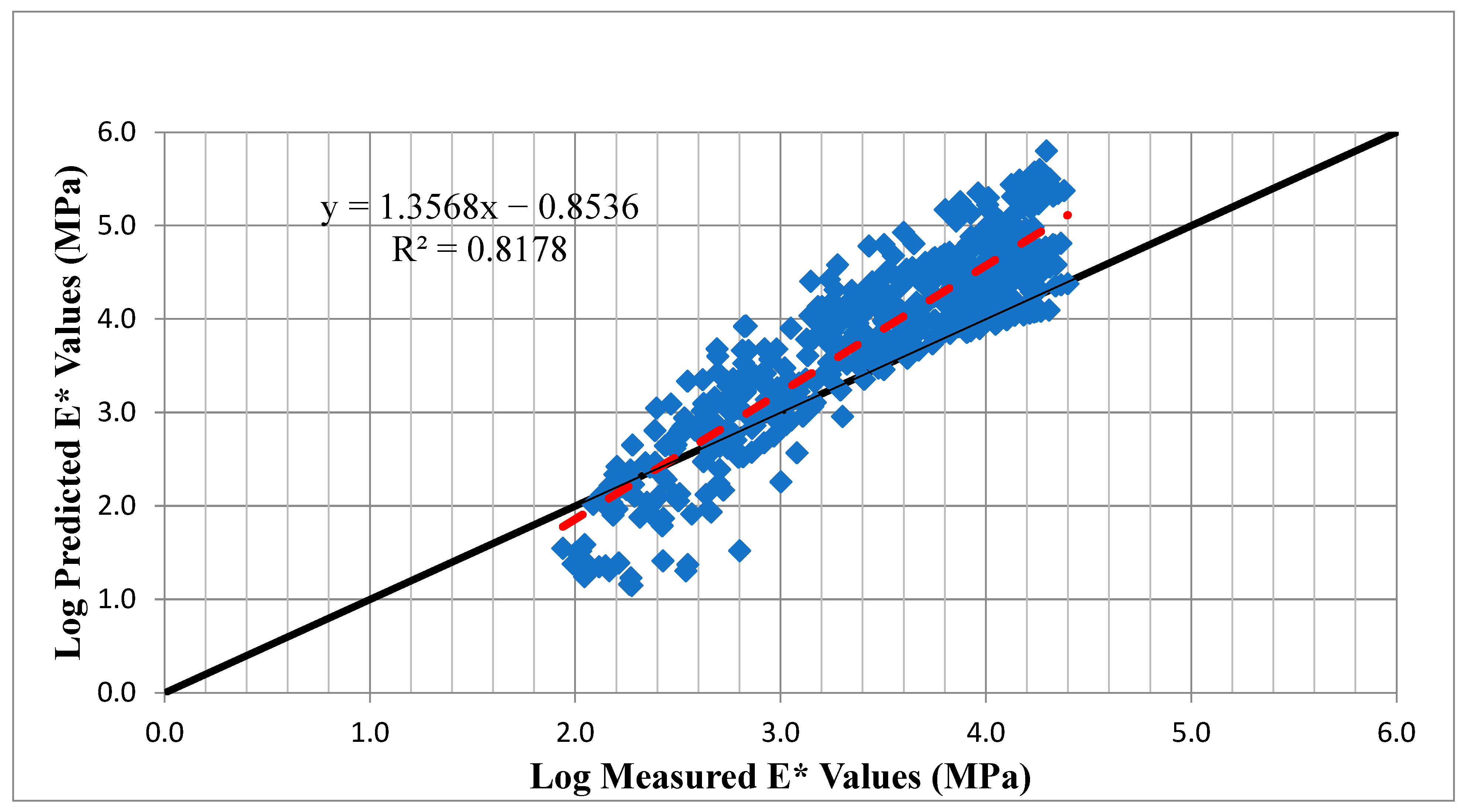

5.2. Assessment of the Performance of E* Prediction Models

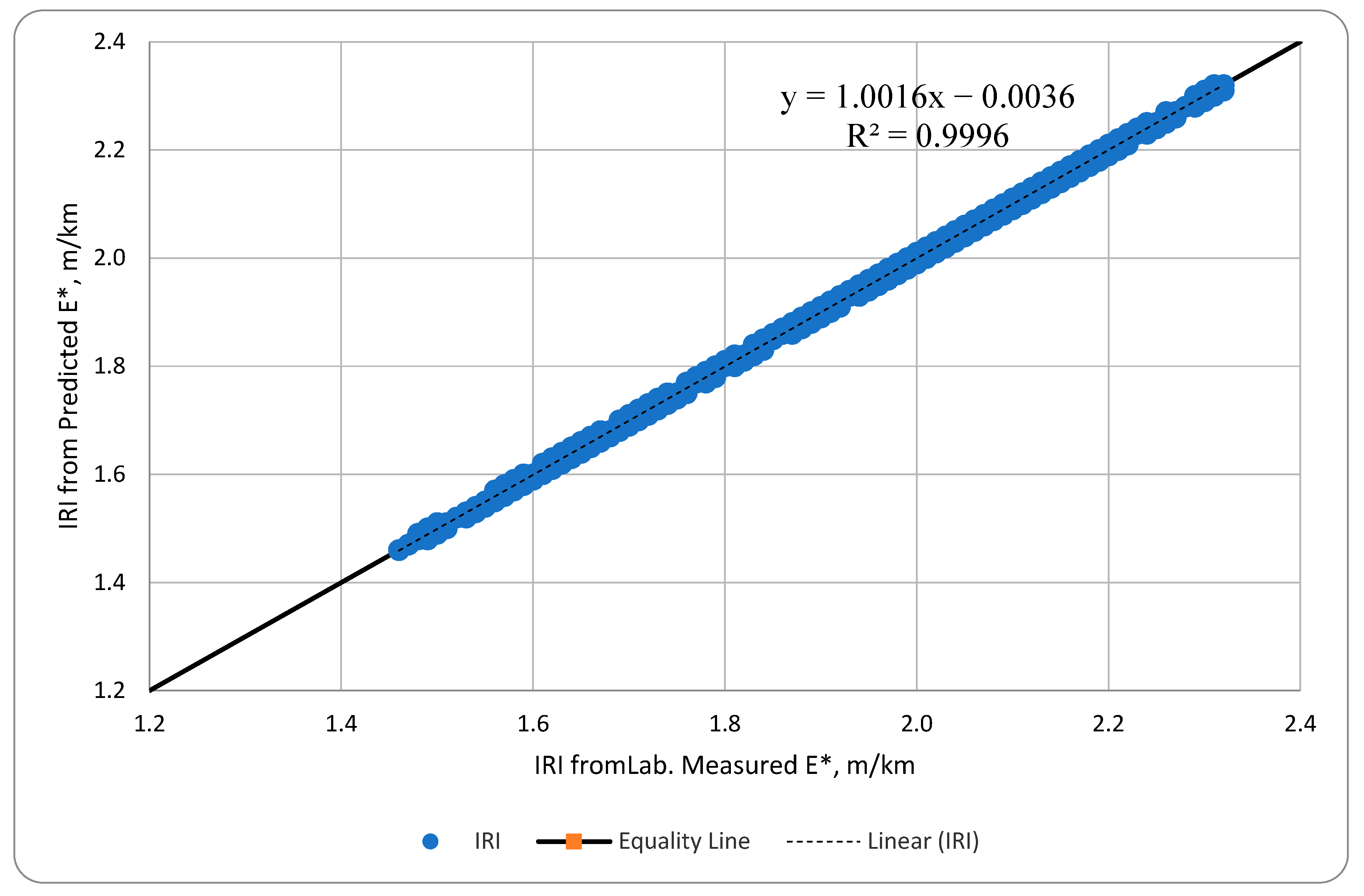

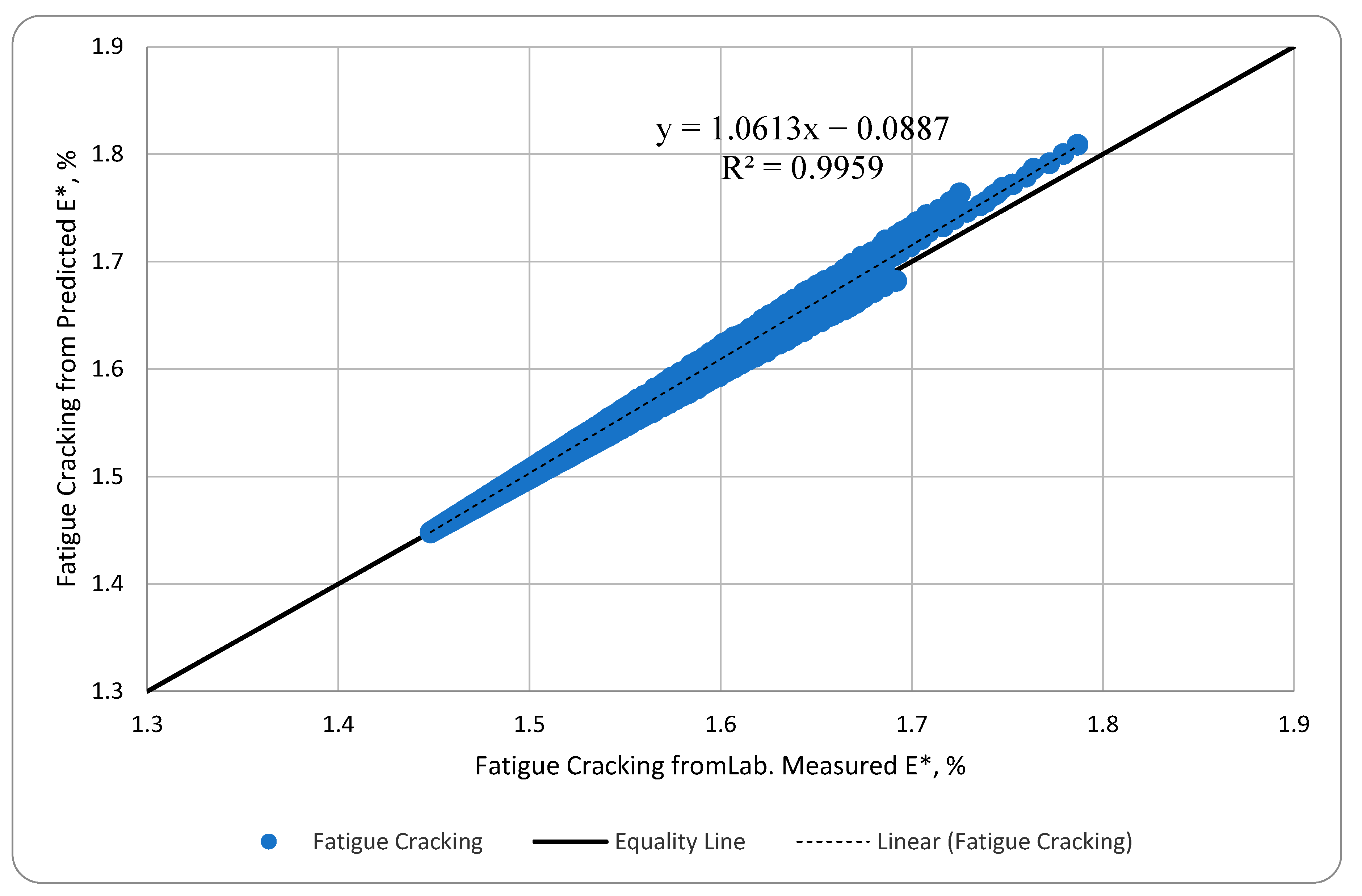

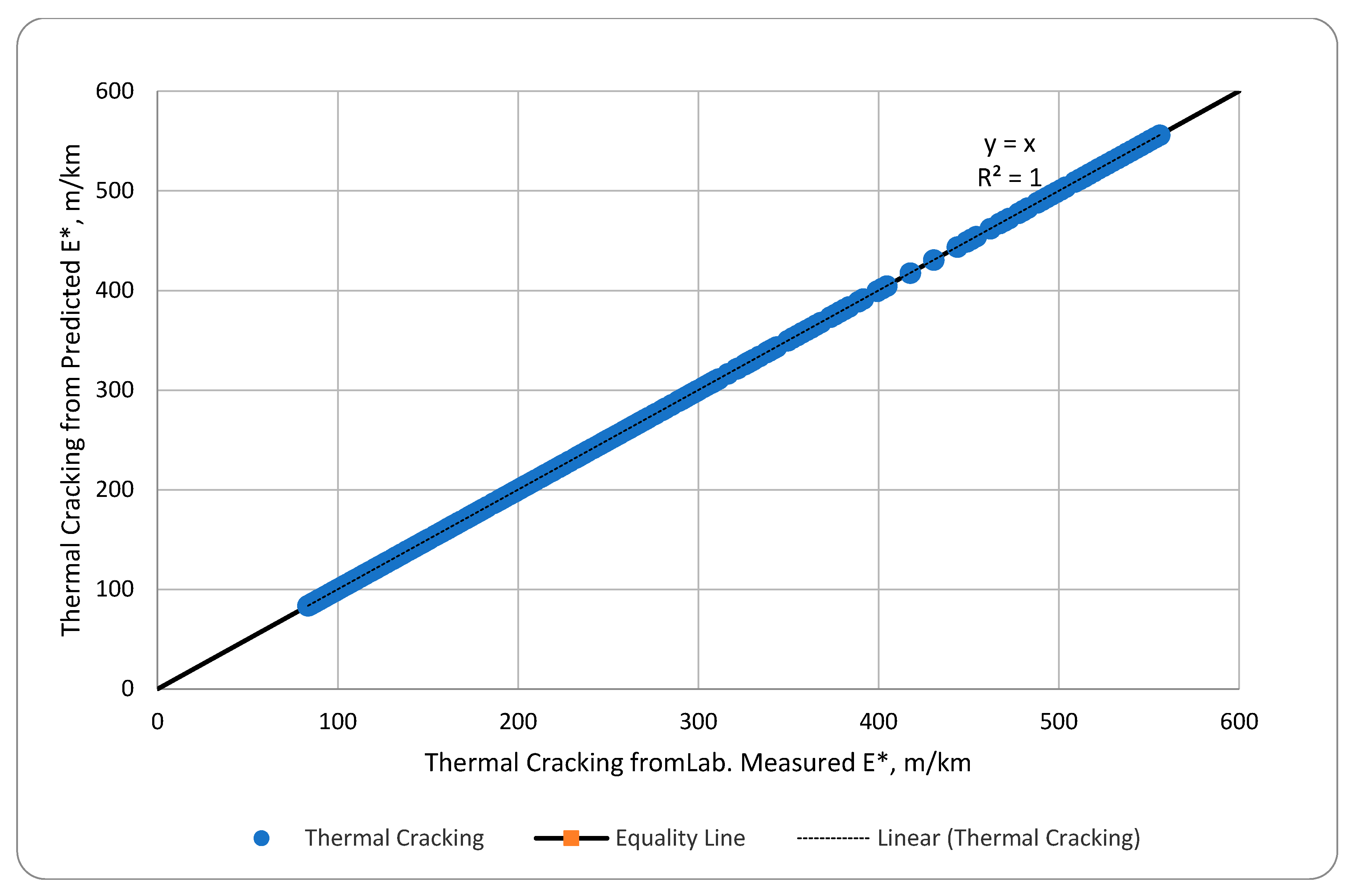

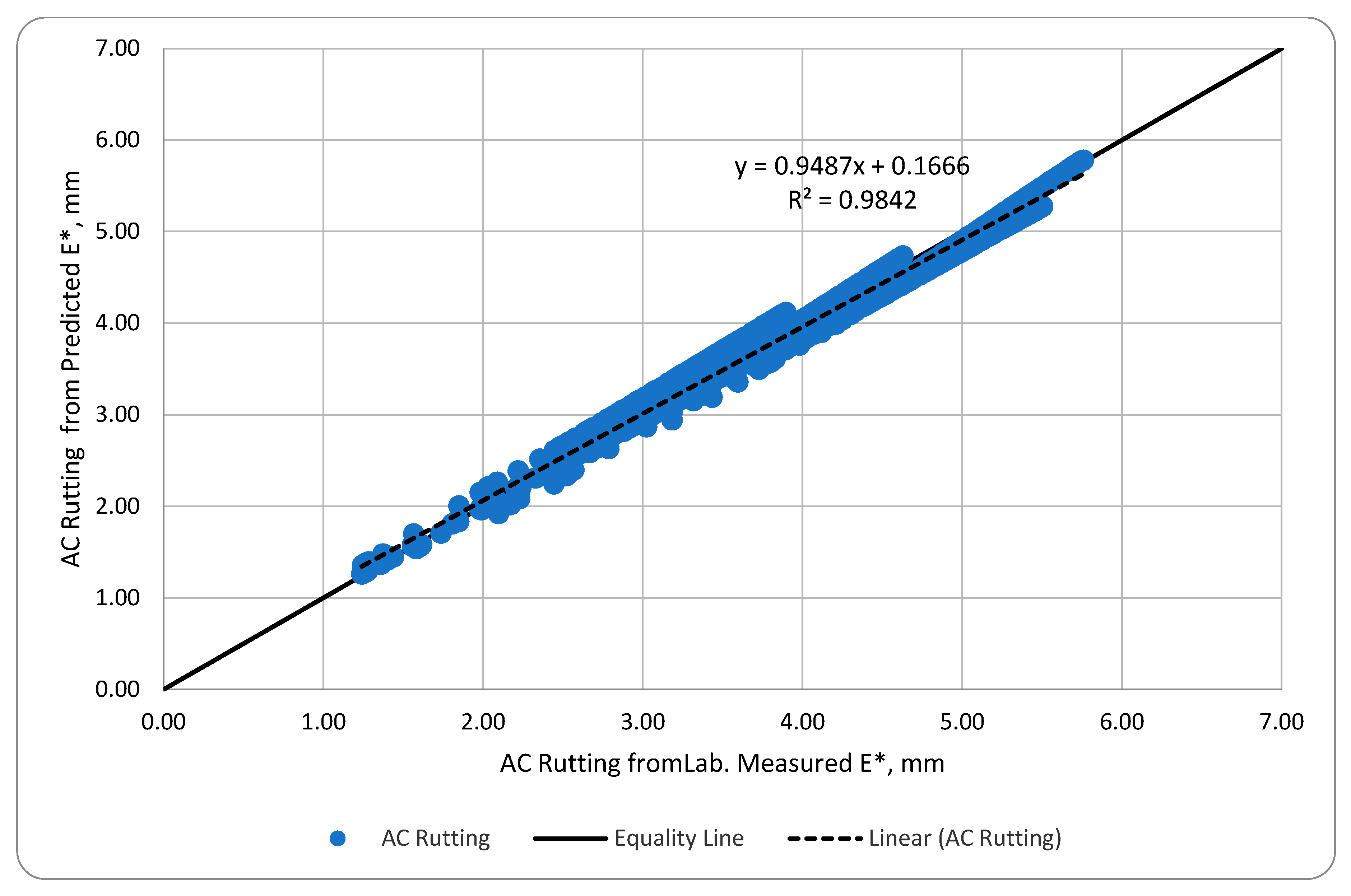

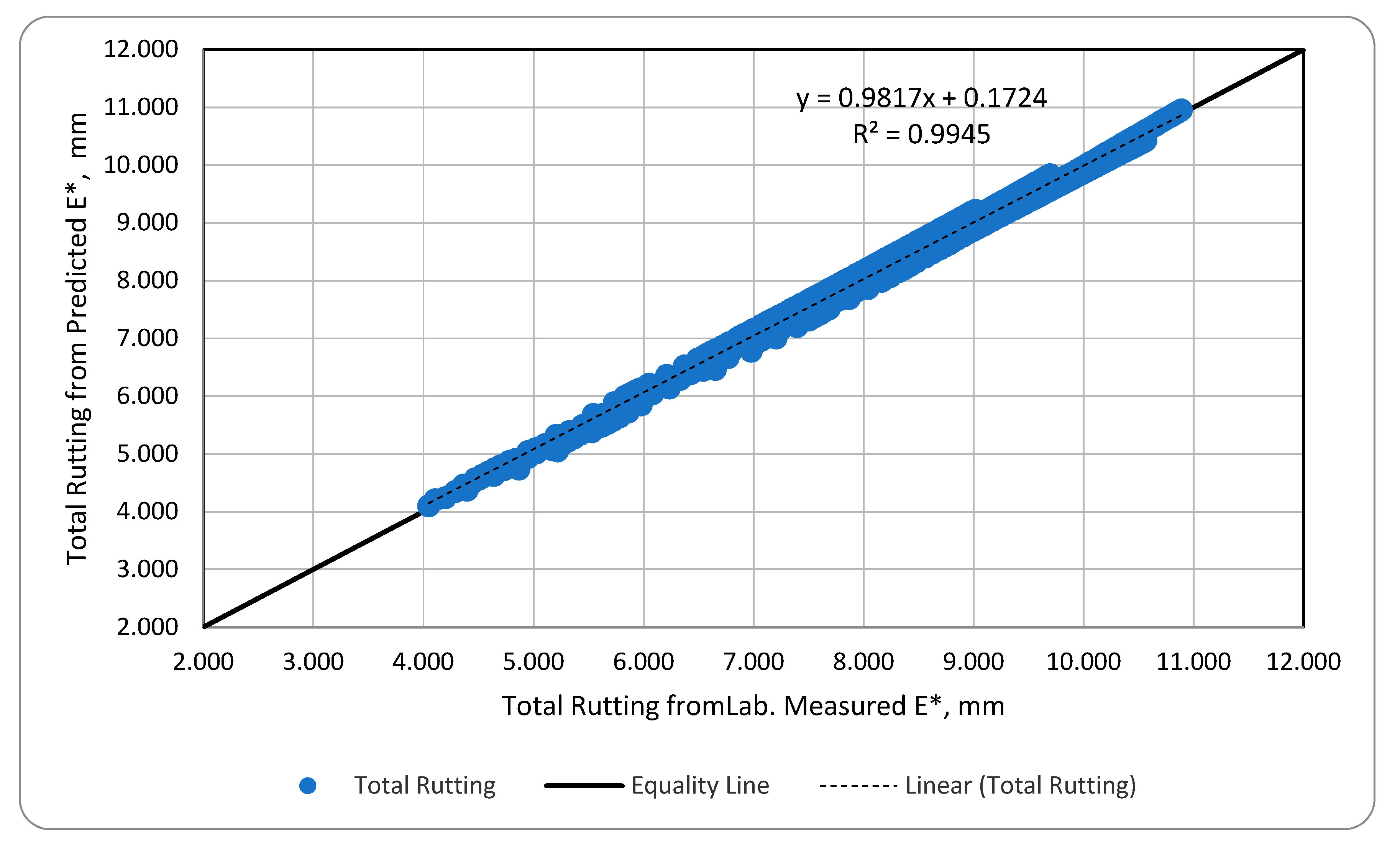

5.3. E*Prediction Effect on the AASHTOWare Pavement Performance Prediction

| Setup No | Climate Zone | AC1 (Surface Layer) and AC2 (Binder Course) Combinations |

|---|---|---|

| 1 | Cairo | Mix 3 and Mix 2 |

| 2 | Cairo | Mix 6 and Mix 5 |

| 3 | Cairo | Mix 8 and Mix 7 |

| 4 | Cairo | Mix 10 and Mix 9 |

| 5 | Alexandria | Mix 3 and Mix 2 |

| 6 | Alexandria | Mix 6 and Mix 5 |

| 7 | Alexandria | Mix 8 and Mix 7 |

| 8 | Alexandria | Mix 10 and Mix 9 |

| 9 | Aswan | Mix 3 and Mix 2 |

| 10 | Aswan | Mix 6 and Mix 5 |

| 11 | Aswan | Mix 8 and Mix 7 |

| 12 | Aswan | Mix 10 and Mix 9 |

6. Summary, Conclusions, and Recommendations

- The NCHRP 1-37A prediction model yielded poor E* predictions with high bias and high scatter for the Egyptian HMA mixes with a coefficient of determination (Adjusted R2) of 0.18 and Se/Sy of 0.92 in the logarithmic scale. Thus, this model is not recommended to predict the E* for the Egyptian asphalt mixtures unless it is re-calibrated.

- The NCHRP 1-40D model yielded very good E* predictions with low bias and scatter for the Egyptian HMA mixes with an adjusted R2 of 0.86 and Se/Sy of 0.38 and, hence, it can be used satisfactorily to predict E* of the Egyptian asphalt mixtures.

- NCHRP 1-40D prediction model is recommended to regionally predict the Egyptian HMA mixes’ dynamic modulus, while the NCHRP 1-37A prediction model is not recommended for predicting the Egyptian HMA mixes’ dynamic modulus without further recalibration.

- The NCHRP 1-40D-model-predicted E* values have no significant effect on the AASHTOWare Pavement ME pavement performance prediction in terms of FC, TC, LC, RAC, RT, and IRI. Thus, the E* of the Egyptian HMA mixes can be satisfactory predicted using the NCHRP 1-40D-prediction model to be used as a material input in the AASHTOWare Pavement ME for the purposes of the design and analysis of the Egyptian flexible pavement.

- AASHTOWare Pavement ME design can be implemented regionally in Egypt to design and analyze flexible pavement provided that the Superpave grading system parameters (the complex modulus and the phase angle) of the asphalt binders are measured or fundamentally predicted using the A and VTS temperature-viscosity parameters to lead the software to predict the E* using the NCHRP 1-40D prediction model.

- Enlarge the database for the Egyptian HMA dynamic modulus considering all different varieties in the Egyptian pavement materials including more aggregate gradations and volumetric properties;

- Study the performance of the NCHRP 1-40D model in predicting the Egyptian E* using different types of modified asphalt binders;

- The NCHRP 1-37A E* prediction model needs to be calibrated for the Egyptian mixes;

- The AASHTOWare Pavement ME transfer functions to predict the pavement performance need to be validated and regionally calibrated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- AASHTOWare Pavement ME Design. Available online: https://www.aashtoware.org/products/pavement/pavement-me-design/ (accessed on 1 January 2021).

- Khattab, A.M.; El-Badawy, S.M.; Elmwafi, M. Evaluation of Witczak E* predictive models for the implementation of AASHTOWare-Pavement ME Design in the Kingdom of Saudi Arabia. Constr. Build. Mater. 2014, 64, 360–369. [Google Scholar] [CrossRef]

- ARA Inc. ERES consultants’ division. In Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures; NCHRP 1-37A Final Report, Transportation Research Board; National Research Council: Washington, DC, USA, 2004. [Google Scholar]

- Birgisson, B.; Sholar, G.; Roque, R. Evaluation of a predicted DM for Florida mixtures. J. Transp. Res. Board 2005, 1929, 200–207. [Google Scholar] [CrossRef]

- Obulareddy, S. Fundamental Characterization of Louisiana HMA Mixtures for the 2002 Mechanistic-Empirical Design Guide. Master’s Thesis, Louisiana State University, Baton Rouge, LA, USA, 2006. [Google Scholar]

- Azari, H.; Al-Khateeb, G.; Shenoy, A.; Gibson, N. Comparison of simple performance Test |E*| of accelerated loading facility mixtures and prediction |E* | use of NCHRP 1-37 A and Witczak’s new equations. J. Transp. Res. Board 2007, 1998, 1–9. [Google Scholar] [CrossRef]

- Tran, N.H.; Hall, K.D. Evaluating the predictive equation in determining dynamic moduli of typical asphalt mixtures used in Arkansas. J. Assoc. Asph. Paving Technol. 2005, 74, 1–17. [Google Scholar]

- Al-Khateeb, G.; Shenoy, A.; Gibson, N.; Harman, T. A new simplistic model for DM predictions of asphalt paving mixtures. J. Assoc. Asph. Paving Technol. 2006, 75, 1254–1293. [Google Scholar]

- Christensen, D.W.; Pellinen, T.; Bonaquist, R.F. Hirsch model for estimating the modulus of asphalt concrete. J. Assoc. Asph. Paving Technol. 2003, 72, 97–121. [Google Scholar]

- Andrei, D.; Witczak, M.W.; Mirza, W. Appendix CC-4: Development of a Revised Predictive Model for the Dynamic (Complex) Modulus of Asphalt Mixtures. In Development of the 2002 Guide for the Design of New and Rehabilitated Pavement Structures; Final document, NCHRP Project1-37A; Transportation Research Board of the National Academies: Washington, DC, USA, 1999; pp. 66–204. [Google Scholar]

- Bari, J.; Witczak, M.W. Development of a new revised version of the Witczak E* predictive model for hot mix asphalt mixtures. J. Assoc. Asph. Paving Technol. 2006, 75, 381–424. [Google Scholar]

- Flintsch, G.W.; Loulizi, A.; Diefenderfer, S.D.; Diefenderfer, B.K.; Galal, K.A. Asphalt material characterization in support of mechanistic-empirical pavement design guide implementation in Virginia. J. Transp. Res. Board 2008, 2057, 114–125. [Google Scholar] [CrossRef]

- Dongre, R.; Myers, L.; D’Angelo, J.; Paugh, C.; Gudimettla, J. Field evaluation of Witczak and Hirsch models for predicting DM of Hot-Mix Asphalt. J. Assoc. Asph. Paving Technol. Proc. Tech. Sess. 2005, 74, 381–442. [Google Scholar]

- Kim, Y.R.; King, M.; Momen, M. Typical Dynamic Moduli Values of Hot Mix Asphalt in North Carolina and Their Prediction, CD-ROM. In Proceedings of the 84th Annual Meeting, Washington, DC, USA, 9–13 January 2005; TRB: Washington, DC, USA, 2005. [Google Scholar]

- Schwartz, C. Evaluation of the Witczak DM Prediction Model, CD-ROM. In Proceedings of the 84th Annual Meeting, Washington, DC, USA, 9–13 January 2005; TRB: Washington, DC, USA, 2005. [Google Scholar]

- Pellinen, T.K.; Witczak, M.W. Use of stiffness of Hot-Mix Asphalt as a simple performance test. Transp. Res. Rec. 2002, 1789, 80–90. [Google Scholar] [CrossRef]

- Singh, D.; Zaman, M.M.; Commuri, S. Evaluation of Predictive Models for Estimating DM of HMA Mixes Used in Oklahoma. In Proceedings of the TRB Annual Meeting, Washington, DC, USA, 23–27 January 2011. [Google Scholar]

- Robbins, M.M.; Timm, D.H. Evaluation of DM predictive equations for southeastern United States asphalt mixtures. J. Transp. Res. Board 2011, 2210, 122–129. [Google Scholar] [CrossRef]

- Moussa, G.S.; Owais, M. Pre-trained deep learning for hot-mix asphalt DM prediction with laboratory effort reduction. Constr. Build. Mater. 2020, 265, 120239. [Google Scholar] [CrossRef]

- Behnood, A.; Golafshani, E.M. Predicting the DM of asphalt mixture using machine learning techniques: An application of multi biogeography-based programming. Constr. Build. Mater. 2021, 266, 120983. [Google Scholar] [CrossRef]

- Xu, W.; Huang, X.; Yang, Z.; Zhou, M.; Huang, J. Developing hybrid machine learning models to determine the DM (e*) of asphalt mixtures using parameters in witczak 1-40d model: A comparative study. Materials 2022, 15, 1791. [Google Scholar] [CrossRef] [PubMed]

- Daneshvar, D.; Behnood, A. Estimation of the dynamic modulus of asphalt concretes using random forests algorithm. Int. J. Pavement Eng. 2022, 23, 250–260. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, J.; Li, X.; Qiao, Y.; Zhang, R.; Kumar, G.S. Investigating the effects of ensemble and weight optimization approaches on neural networks’ performance to estimate the dynamic modulus of asphalt concrete. Road Mater. Pavement Des. 2023, 24, 1939–1959. [Google Scholar] [CrossRef]

- Kim, J.; Byron, T.; Sholar, G.; Kim, S. Development of DM Testing and Data Interpretation Capability; Research Report FL/DOT/SMO/08-514; State Materials Office: Alachua County, FL, USA, 2008. [Google Scholar]

- Clyne, T.R.; Li, X.; Marastenau, M.O.; Skok, E.L. Dynamic and Resilient Modulus of Mn/DOT Asphalt Mixtures; Final Report MN/RC—2003-09; University of Minnesota: Minneapolis, MN, USA, 2003. [Google Scholar]

- Cho, Y.-H.; Park, D.-W.; Hwang, S.-D. A predictive equation for DM of asphalt mixtures used in Korea. Constr. Build. Mater. 2010, 24, 513–519. [Google Scholar] [CrossRef]

- Mohammad, L.N.; Saadeh, S.; Obulareddy, S.; Cooper, S. Characterization of louisiana asphalt mixtures using simple performance tests. In Proceedings of the 86th Annual Meeting of the Transportation Research Board, Washington, DC, USA, 21–25 January 2007; TRB: Washington, DC, USA, 2007. [Google Scholar]

- Awed, A.; El-Badawy, S.; Bayomy, F.; Santi, M. Influence of MEPDG binder characterization input level on predicted DM for idaho asphalt concrete mixtures. In Proceedings of the Transportation Research Board 90th Annual Meeting, Washington, DC, USA, 23–27 January 2011. [Google Scholar]

- Georgouli, K.; Loizos, A.; Plati, C. Calibration of DM predictive model. Constr. Build. Mater. 2016, 102, 65–75. [Google Scholar] [CrossRef]

- El-Badawy, S.; Awed, A.; Bayomy, F. Evaluation of the MEPDG DM prediction models for asphalt concrete mixtures. In Proceedings of the First Congress of Transportation and Development Institute (TDI), Chicago, IL, USA, 13–16 March 2011. [Google Scholar]

- Far, M.; Underwood, B.; Ranjithan, S.; Kim, R.; Jackson, N. Application of artificial neural networks for estimating DM of asphalt concrete. In Transportation Research Record 2127; Transportation Research Board: Washington, DC, USA, 2009; pp. 173–183. [Google Scholar]

- El-Badawy, S.; Bayomy, F.; Awed, A. Performance of MEPDG DM predictive models for asphalt concrete mixtures: Local calibration for idaho. J. Mater. Civ. Eng. 2012, 24, 1412–1421. [Google Scholar] [CrossRef]

- Yousefdoost, S.; Vuong, B.; Rickards, I.; Armstrong, P.; Sullivan, B. Evaluation of DM predictive models for typical Australian asphalt mixes. In Proceedings of the 15th AAPA International Flexible Pavements Conference, Brisbane, Australia, 22–25 September 2013; pp. 22–25. [Google Scholar]

| Research Authors, Date, and Reference Number | Major Findings | Number of Mixes and E* Measurement | Goodness of Fit of Statistics | Country/State |

|---|---|---|---|---|

| Khattab et al., 2014 [2] | In order to advance the adoption of the mechanistic-empirical approach in Saudi Arabia, this research was conducted. The performance of the two E* prediction models (NCHRP 1-37A and NCHRP 1-40D) was studied. It was discovered that there is some bias and data scatter in both models. It was discovered that the NCHRP 1-37A performed better than the NCHRP 1-40D. | 25 mixes, 2592 measurement | Conventional Binder Testing 1-37A Se/Sy = 0.46, R2 = 0.79 1-40D Se/Sy = 0.55, R2 = 0.70 SuperPave Binder Testing 1-37A Se/Sy = 0.39, R2 = 0.85 1-40D Se/Sy = 0.43, R2 = 0.82 | Kingdom of Saudi Arabia |

| Obulareddy, 2006 [5] | It was discovered that the Witczak 1-37A model overpredicted the E* values for the local mixes. The Witczak 1-37A model’s prediction power was higher at higher temperatures. | 15 mixtures/1350 data points | Se/Sy = 0.34, R2 = 0.89 | Louisiana, USA |

| Birgisson et al., 2005 [4] | They discovered that the E* was typically predicted more accurately by the Witczak 1-37A model. At higher temperatures than at lower ones, it was noticed that the Witczak 1-37A model prediction power was higher. | 28 mixes/448 data points | R2 = 0.8421 | Florida, USA |

| Kim et al., 2008 [24] | It was found that the Witczak 1-37A model is over predicting the E* values with better correlations observed at low and intermediate temperatures. | 42 Mixes | NA | North Carolina, USA |

| Clyne et al., 2003 [25] | It was concluded that the Witczak 1-37A model was generally underestimating the E* values. Also, it was found that the prediction accuracy was observed to be better at the lower temperatures compared to higher temperatures. | 4 mixes/600 data points | N/A | Minnesota, USA |

| Cho et al., 2010 [26] | The performance of NCHRP and Hirsch models were studied. It was found that their performance was not consistent and vary depending of the HMA type. Finally, they recommended the need to establish the E* ranges of the regional HMA mixtures. | 4 mixes/540 data points | R2 = 0.98 | Korea |

| Dongre et al., 2005 [13] | They concluded that the NCHRP 1-37A model was overestimating the E*. | 5 mixes/1152 data points | Se/Sy = 0.311, R2 = 0.90 | USA |

| Mohammad et al., 2007 [27] | They found that the NCHRP 1- 37A model was generally underestimating the E*. | 13 mixes/1170 data points | R2 = 0.9217 to 0.9867 | Louisiana, USA |

| Azari et al., 2007 [6] | It was found that the Witczak 1- 37A model was generally overpredicting the E*. | 6 mixes/100 samples/2500 data points | R2 = 0.917 | USA |

| Flintsch et al., 2008 [12] | The NCHRP 1-37A model was generally overestimating the predicted E* values with some values reported to be nearly double the measured E* values. | 11 mixes | N/A | Virginia, USA |

| Awed et al., 2011 [28] | It was concluded that the NCHRP 1-40D model has the best E* prediction power especially with conventional mixes. | 22 mixes 888 data points | Conventional Binder Data 1-37A Se/Sy = 0.41, R2 = 0.83 1-40D Se/Sy = 0.42, R2 = 0.83 SuperPave Binder Data 1-37A Se/Sy = 0.38, R2 = 0.86 1-40D Se/Sy = 0.48, R2 = 0.78 Level 3 MEPDG Binder 1-37ASe/Sy = 0.33, R2 = 0.89 1-40D Se/Sy = 0.49, R2 = 0.77 | Idaho, USA |

| Georgouli et al., 2016 [29] | It was found that the NCHRP model was highly estimating the E* values compared with the Hirsch model which was found to under-predict the E* values. Generally, the Witczak 1-37A model had closer predicted E* values to the measured E* values. Also, the air voids effect was assessed on the prediction power of the Witczak 1-37A model. It was found that for wearing course mixtures with air void content >16%, the model was highly under-predicting the measured E* while at <16% air voids the model performed satisfactorily. | 15 mixes/45 samples/1350 data points | R2 = 0.83 | Greece |

| El-Badawy et al., 2011 [30] | They showed different performance of both NCHRP 1-37A and NCHRP 1-40D model based on the type of HMA and temperature. | 15 mixes/720 data points | Level 3 Binder Data Logarithmic scale 1-37A Se/Sy = 0.32, R2 = 0.90 1-40D Se/Sy = 0.48, R2 = 0.78 Arithmetic scale 1-37A Se/Sy = 0.26, R2 = 0.93 1-40D Se/Sy = 0.64, R2 = 0.61 Level 1 Binder Data Logarithmic scale 1-37A Se/Sy = 0.37, R2 = 0.87 1-40D Se/Sy = 0.47, R2 = 0.79 Arithmetic scale 1-37A Se/Sy = 0.57, R2 = 0.69 1-40D Se/Sy = 0.29, R2 = 0.92 | Idaho, USA |

| Singh et al., 2011 [17] | They showed different performance of both NCHRP 1-37A and NCHRP 1-40D model based on the type of HMA and temperature. | 5 mixes/1440 data points | Logarithmic scale 1-37A Se/Sy = 0.39, R2 = 0.85 1-40D Se/Sy = 0.62, R2 = 0.61 Arithmetic scale 1-37A Se/Sy = 0.53, R2 = 0.72 1-40D Se/Sy = 1.57, R2 ≤ 0.19 | Oklahoma, USA |

| Far et al., 2009 [31] | They showed different performance of both NCHRP 1-37A and NCHRP 1-40D model based on the type of HMA and temperature. | 14,309 data points | Se/Sy = 0.75, R2 = 0.85 | USA |

| El Badawy et al., 2012 [32] | They concluded that, both models, NCHRP 1-37A and NCHRP 1-40D, yielded biased E* estimates at high and/or low temperatures. Also, they found that the NCHRP 1-40 D model was less accurate and relatively higher biased in estimating the E* values compared to the NCHRP 1-37A model. | 27 mixes/1128 data points | Conventional Binder Data 1-37A Se/Sy = 0.42, R2 = 0.83 1-40D Se/Sy = 0.42, R2 = 0.83 SuperPave Binder Data 1-37A Se/Sy = 0.37, R2 = 0.86 1-40D Se/Sy = 0.46, R2 = 0.79 Level 3 MEPDG Binder 1-37A Se/Sy = 0.32, R2 = 0.90 1-40D Se/Sy = 0.48, R2 = 0.78 | Idaho, USA |

| Yousefdoost et al., 2013 [33] | A comparable Australian E* database was first established. Then, this database was used to assess the performance of different prediction models. It was found that the Witczak 137A, Hirsch and Alkhateeb models were highly biased and were under predicting the E* of the different Australian mixes while Witczak 1-40D was found to overpredict the E* values. Finally, they concluded that generally the performance, of all studied prediction models, was not satisfactory for all Australian mixes. | 15 mixes/1344 data points | 1-37A Se/Sy = 0.49 R2 = 0.82 1-40D Se/Sy = 2.29 R2 = 0.86 | Australia |

| Mix No. | Project ID/Binder Source | Asphalt Layer Type | Gradation | Pb, % | Va, % | Vbeff, % | VMA, % | VFA, % | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1″ | 3/4″ | 3/8″ | #4 | #8 | #30 | #50 | #100 | #200 | ||||||||

| Mix 1 | Nile Project/SOPC | Binder | 100 | 98.0 | 56.3 | 35.4 | 29.0 | 18.8 | 8.5 | 3.4 | 1.6 | 4.7 | 7.03 | 8.44 | 17.5 | 59.8 |

| Mix 2 | HECU/AOP | Binder | 100 | 90.2 | 44.6 | 25.2 | 21.1 | 13.7 | 4.7 | 2.5 | 1.2 | 4.4 | 7.02 | 9.25 | 18.3 | 61.6 |

| Mix 3 | HECU/AOP | Surface | 100 | 100.0 | 78.5 | 58.9 | 49.4 | 28.1 | 10.4 | 4.5 | 2.1 | 4.9 | 6.98 | 8.52 | 17.5 | 60.1 |

| Mix 4 | El Wahat/AOP | Binder | 100 | 94.0 | 57.4 | 31.1 | 20.3 | 7.9 | 4.6 | 2.6 | 1.1 | 5.2 | 7.01 | 7.08 | 16.1 | 56.4 |

| Mix 5 | M-AUC/SOPC | Binder | 100 | 93.7 | 54.4 | 34.5 | 24.7 | 12.2 | 8.0 | 4.8 | 2.2 | 4.6 | 7.01 | 7.62 | 16.6 | 57.8 |

| Mix 6 | M-AUC/SOPC | Surface | 100 | 95.6 | 67.5 | 46.3 | 35.3 | 20.0 | 14.7 | 10.0 | 2.8 | 7.2 | 7.00 | 11.70 | 20.7 | 66.0 |

| Mix 7 | M Suez/SOPC | Binder | 100 | 93.5 | 53.2 | 30.5 | 20.0 | 8.2 | 4.9 | 3.1 | 1.4 | 4.0 | 7.00 | 6.71 | 15.7 | 55.4 |

| Mix 8 | M Suez/SOPC | Surface | 100 | 96.4 | 69.2 | 50.3 | 35.4 | 17.5 | 13.0 | 9.3 | 4.3 | 6.1 | 6.99 | 13.09 | 22.1 | 68.3 |

| Mix 9 | Trial 7 (15122020)/AOP | Binder | 100 | 96.2 | 39.9 | 31.0 | 26.9 | 15.4 | 6.7 | 3.1 | 1.4 | 3.8 | 7.00 | 6.62 | 15.6 | 55.1 |

| Mix 10 | Trial 8 (15122020)/AOP | Surface | 100 | 99.4 | 55.7 | 42.4 | 36.6 | 19.7 | 7.5 | 3.6 | 1.7 | 5.3 | 6.97 | 9.68 | 18.7 | 62.6 |

| Zone | Latitude | Longitude | MAAT |

|---|---|---|---|

| Alexandria | 31.2 | 29.9 | 19 |

| Cairo | 30 | 31.88 | 25 |

| Aswan | 24 | 33.75 | 26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saudy, M.; Breakah, T.; El-Badawy, S. Dynamic Modulus Prediction Validation for the AASHTOWare Pavement ME Design Implementation in Egypt. Sustainability 2023, 15, 14030. https://doi.org/10.3390/su151814030

Saudy M, Breakah T, El-Badawy S. Dynamic Modulus Prediction Validation for the AASHTOWare Pavement ME Design Implementation in Egypt. Sustainability. 2023; 15(18):14030. https://doi.org/10.3390/su151814030

Chicago/Turabian StyleSaudy, Maram, Tamer Breakah, and Sherif El-Badawy. 2023. "Dynamic Modulus Prediction Validation for the AASHTOWare Pavement ME Design Implementation in Egypt" Sustainability 15, no. 18: 14030. https://doi.org/10.3390/su151814030

APA StyleSaudy, M., Breakah, T., & El-Badawy, S. (2023). Dynamic Modulus Prediction Validation for the AASHTOWare Pavement ME Design Implementation in Egypt. Sustainability, 15(18), 14030. https://doi.org/10.3390/su151814030