Abstract

This study presented experimental research on the alternating current (AC) impedance spectrum of graphene-enhanced cement matrix composites with dosage amounts of 0.1%, 0.2%, 0.4%, 0.8%, 1.6%, and 3.2%, respectively. The electrical properties were compared and analyzed with the Nyquist diagram, Bode diagram, and phase angle diagram. The microscopic pore structure was studied using mercury intrusion porosimetry (MIP) to establish the relationship between the pore structure parameters, the equivalent circuit fitting parameters of the AC impedance spectrum, and the mechanical properties. This study found that the incorporated graphene decreases the arc diameter of the impedance spectrum and causes the slope of the straight lines of the low-frequency region to drop. For the Bode curves, within low frequencies (1 Hz and 10 Hz), the impedance gradually increases as the graphene dosage increases. However, when the frequency is between 100 KHz and 1000 KHz, the impedance drops with an increase in the amount of graphene. According to the MIP test results, the proper incorporations of graphene increase the proportion of pores below 0.1 μm, which leads to a denser micro-structure and higher strength.

1. Introduction

Concrete is widely used in infrastructure with the advantages of convenient construction, locally available raw materials, and good compressive strength. It is currently the largest artificial construction material available [1]. However, cement-based materials have shortcomings such as high carbon footprints, high self-weight, low tensile strength, and large brittleness that limit their applications. The cement industry is often accompanied by high energy consumption and CO2 emissions [2]. In recent years, new engineering requirements for infrastructure have promoted the development of new concrete technologies. The development of nanomaterials and related technologies provides new ways to modify traditional cement-based materials [3]. The particle size of C-S-H and the primary bonding phase of cementitious materials is at the nanoscale [4]. So, nanomaterials can effectively improve the macroscopic properties of cementitious materials due to their physicochemical properties [5]. From the microstructural point of view, nanomaterials promote cement hydration by providing more microscopic nucleation points.

Graphene is currently one of the most promising two-dimensional nanomaterials, with the highest strength and hardness of the known crystal structure [6]. The tensile strength and elastic modulus of graphene are 125 GPa and 1.1 TPa, respectively. The strength is about 100 times that of ordinary steel [7]. However, graphene is a hydrophobic material, and it is easy to form a clump when making a solution, which greatly hinders the application of graphene in cement-based materials. It has been found that the oxygen-containing functional groups in graphene can react with hydration products to form chemical bonds [8,9], which can provide more reaction sites for mortar, make the growth of hydration products C-S-H and Ca(OH)2 more uniform and accelerate the hydration process and the volcanic ash effect of SiO2. In the later hydration stage, the hydration product Ca(OH)2 will continue to generate C-S-H [6], enhancing cement-based materials’ strength. In the process of studying the influence of the amount of incorporation on the microstructure of cementitious materials, when 0.05% graphene oxide is incorporated, the hydration crystal increases and becomes dense. However, when the amount of incorporation is too high, the microstructure compactness decreases, which is not conducive to the crystallization of the hydrated crystal [10,11,12].

The electrical detection methods in cementitious materials have attracted more attention due to their non-destructive nature and technical simplicity [13,14]. The AC impedance spectrum, a non-destructive testing technique, is a powerful method to study the microstructure and mechanical properties of cementitious materials [15,16]. At this stage, graphene-modified concrete’s alternating current (AC) impedance research is still relatively rare, and the microstructure and interface information of graphene-modified concrete can be extracted via impedance spectroscopy. Then, the macroscopic mechanical properties can be established [17].

This study proposes collecting the AC impedance spectroscopy of cement matrix composites with different graphene dosages and comparing the Nyquist plots, Bode plots, and phase angle diagrams. Then, the influence of different graphene dosages on the impedance spectrum of cementitious matrix composites is summarized and analyzed. Based on an appropriate equivalent circuit, parameters can be obtained by fitting the Nyquist diagram. Combined with the pore structure distribution obtained with mercury intrusion porosimetry (MIP) experiments, the relationships between the content of the pores of specific sizes and the parameters of the fitted electrical parameters are established. Furthermore, the effects of different dosages of graphene on the pore structure and electrical properties of cement matrix composites are analyzed, laying a foundation for predicting the properties of graphene-enhanced cementitious composites.

2. Materials and Testing Methods

2.1. Materials

This study used P.O. 42.5 cement confirming Chinese specifications (GB 175-2020) [18] to prepare the mortar samples. Dry river sand was sieved to remove the particles larger than 0.3 mm for mixing the mortar. The nano-filler graphene procured from Nanjing Jicang Inc. was used to modify the cementitious composite as a nano-additive. The main properties of graphene are listed in Table 1. The SEM image of the graphene illustrates a wrinkled surface, as shown in Figure 1. The thickness of the graphene is about 2–3 nm provided by the merchant, and other properties were also provided by the merchant in the product certification. To facilitate the dispersion of graphene into the aqueous suspension, a polycarboxylate superplasticizer (Jiangsu Subote) and ultrasonic equipment were used.

Table 1.

Physical properties of graphene used in this study.

Figure 1.

SEM image of graphene.

2.2. Mix Proportion and Sample Preparation

Seven mix ratios designed in this study are shown in Table 2. The control (N) group was ordinary mortar, with a water/cement ratio of 0.6 and sand/cement ratio of 3:1. Graphene was incorporated into the mortar in 6 different dosage groups: 0.1%, 0.2%, 0.4%, 0.8%, 1.6%, and 3.2% masses of cement. The amount of superplasticizer is the same as the graphene.

Table 2.

Mix proportions.

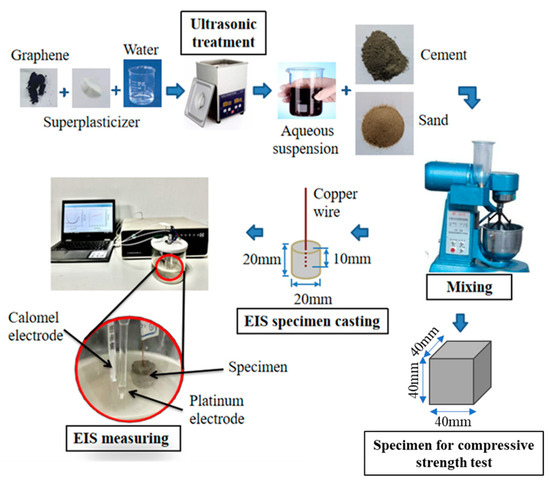

To use graphene in the modified mortar, the graphene first needs to be dispersed in water. The graphene was added to the water after the superplasticizer powder was dissolved in the water. The beaker was placed in the ultrasonic dispersing equipment, and the powdered superplasticizer was added to water, followed by the graphene. To obtain the mortar, in the mortar mixer, the sand and cement were mixed for 30 s. Then, the graphene aqueous suspension was added and then mixed for another 30 s. Cylindrical specimens for AC IMPEDANCE SPECTRUM tests were cast with a diameter of 20 mm and a height of 20 mm, and a copper wire electrode was inserted in the center, and the insertion depth was 10 mm [19,20]. Beam specimens (40 mm × 40 mm × 40 mm) were also cast for compressive strength test.

2.3. AC Impedance Spectrum Test

The AC impedance spectrum test adopted the CHI604E electrochemical workstation produced by Shanghai Chenhua Instrument Co., Ltd. (Shanghai, China), and the test solution is a saturated Ca(OH)2 solution. The test frequency was set to 1 Hz~1 MHz. To minimize errors due to resistance exposure and humidity [21], 500 mL three-electrode electrolytic cells with 20 mm spacing were used. The impedance test schematic is shown in Figure 2. The AC impedance spectroscopy was performed in an environment with a relative humidity of 70 ± 5% and a temperature of 20 ± 3 °C. The test was carried out at a temperature of 20 ± 3 °C and a relative humidity of 70 ± 5%. In order to obtain stable data, each specimen was tested three times to eliminate other errors, such as vibration [22].

Figure 2.

Experimental procedure.

2.4. MIP (Mercury Intrusion Porosimetry)

In order to further analyze the mechanism of the effect of the incorporation of graphene on the permeability of cement matrix composites, the pore structure of the specimens is analyzed with MIP. A small piece of 3–5 mm was taken from the broken specimens, weighing about 1 g. Then, an MIP test was carried out to record the amount of mercury intruded into the sample at different pressure levels. The MIP method relies on applied pressure to allow mercury to overcome the surface tension and seep into the stomata of samples to determine the porosity of different pore sizes and obtain parameters such as volume density and apparent density. In this study, four specimens, N, G1, G2, and G4, were subjected to the MIP test.

3. Results

3.1. AC Impedance Spectrum

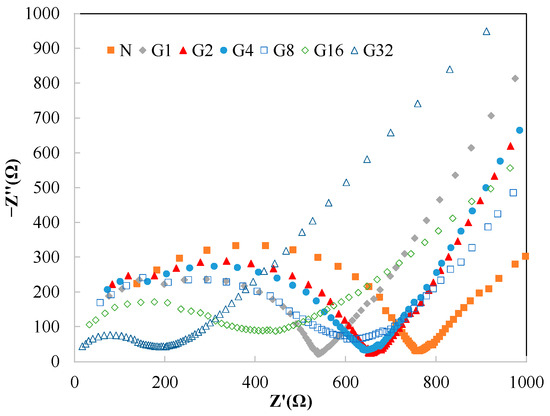

Figure 3 shows the Nyquist curves of the specimens, which are the relationship between the real Z′ and the imaginary Z″ that vary with the AC frequency, and each figure illustrates the Nyquist curves of three specimens in one group. As seen in Figure 3, the Nyquist curve is composed of a semicircular arc and a straight line, of which the high-frequency region is the circular arc and the low-frequency region is the straight line. This coincides with the impedance spectrum curve characteristics of cement matrix composites. Comparing the Nyquist curves of mortar specimens of different graphene dosages, the arc diameter of the impedance spectrum decreases with higher graphene incorporation. While increasing the dosage of nano conductive fillers, the connected conductive pathways increase. As a result, the specimen’s resistivity gradually decreases, indicating a smaller arc diameter [23]. From Figure 3, it can be found that the slope of the straight lines of the low-frequency region drops. However, when the amount of graphene reaches 3.2%, the straight line of the low-frequency region becomes an arc, which is consistent with Dhouibi’s study [24].

Figure 3.

Nyquist curves of all the samples.

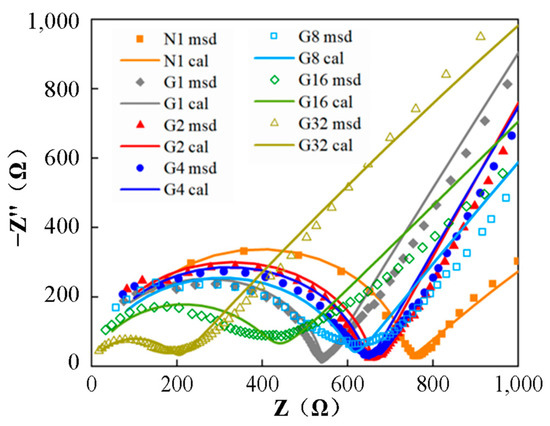

In order to more accurately grasp the difference of the Nyquist curves among varied graphene incorporations, Figure 4 was drawn by plotting the curves from each group in one coordinate. In this study, specimen 2 was taken as an example because the curve of specimen 2 is approximately between specimen 1 and specimen 3.

Figure 4.

Nyquist curves of all the groups.

As shown in Figure 4, the control group has the biggest high-frequency arc. With the increase of graphene dosages, the high-frequency arc gradually becomes smaller. However, when the incorporation dosage is 0.1%, the high-frequency arc is smaller than 0.2% and 0.4%. This may result from the particularly dense structure, which leads to a lower resistivity [25]. Moreover, when the amount of graphene is less than 0.8%, there is an obvious turn from the high-frequency arc to the low-frequency straight line.

When graphene is added to cement slurry, it causes a significant change in the electrical response of the system. In the Nyquist diagram, there is a platform region between the high-frequency and low-frequency regions, as shown in Figure 4. The range of the platform area increases with the increase of graphene doping. This is similar to the findings [8,26]. They attributed this to the enhanced double-layer polarization effect on the surface of the specimen.

The Bode curves between the frequency and the impedance of |Z| for the above specimens were plotted in Figure 5. As the AC frequency increases from 1 Hz to 1,000,000 Hz, the impedance of each group gradually decreases. Additionally, the decline rate is fast in the low-frequency zone and slow in the high-frequency zone. In order to compare the Bode curves of each group in the low-frequency region and high-frequency region, the curves of 1–10 Hz and 100,000–1,000,000 Hz are also displayed in Figure 5. It can be found that the impedance of cementitious composites gradually increases as increasing the graphene dosage when the frequency is between 1 Hz and 10 Hz. However, for the high frequency (100,000–1,000,000 Hz), the higher the amount of graphene, the lower the impedance.

Figure 5.

Bode curves of all the groups.

The phase angle curves of the specimens are shown in Figure 6. As seen from the curves, the control group has a “U” shape of the phase angle curve. With the increase in the AC frequency from 1 Hz to 1,000,000 Hz, the phase angle has a trend of first decreasing and then increasing, and the lowest value is around 10,000 Hz. When the additive amount of graphene is increased to 0.8%, 1.6%, and 3.2% in the low-frequency region (about 1–10 Hz), the phase angle has a trend of increasing instead of decreasing. After that, the trend is similar to other specimens. In addition, with the increase in the amount of graphene, this phenomenon becomes more and more obvious.

Figure 6.

Phase angle curves of all the groups.

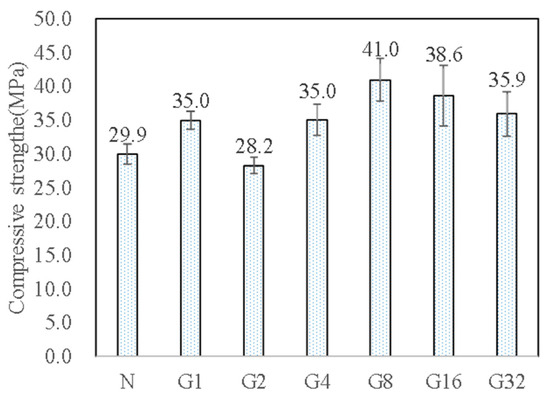

3.2. Compressive Strength

The compressive strengths of all the groups are shown in Figure 7. When the amount of graphene is 0.1%, the strength of the G1 group is 17% higher than the control group. When the graphene is increased to 0.2%, the strength of the G2 group is reduced by 6% compared with the control group. When the dosage of graphene is further increased, an increase in the strength has been observed in all the groups, with G8 having the highest strength, about 37% higher than the control group. Incorporating graphene as a nano-filler acts as a nucleation site for additional CSH growth [27]. Therefore, the incorporation of graphene is conducive to improving the cementitious material’s microstructure, thereby improving its strength. However, when the amount of graphene is as high as 0.2%, there may be nanoparticle agglomeration, resulting in an increase in the microporous size of cementitious materials, which leads to a deterioration of its mechanical properties [4]. According to the experimental phenomenon, we found that when the amount of graphene is higher than 0.4%, the working performance of the mixed mortar is poor because the graphene particles have a particularly high specific surface area. With the performance of the superplasticizer, a large amount of water is adsorbed on the surface of the graphene, resulting in a decrease in the amount of water attached to the surface of the cement particles for cement hydration. This probably explains why G8 has the highest compressive strength. However, G16 and G32 have lower strengths. It was found during the casting of the samples that G16 and G32 were hard to mix evenly.

Figure 7.

Compressive strength.

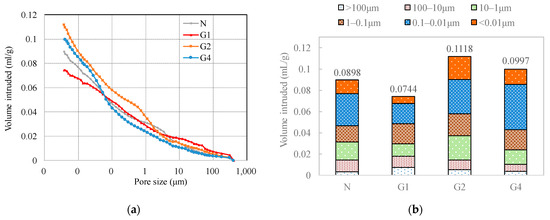

3.3. MIP

The MIP test was performed on four specimens, N, G1, G2, and G4, and the cumulative intrusion was obtained, as shown in Figure 8, where Figure 8a is the cumulative intrusion curve, and Figure 8b is the pore distribution of various sizes. According to Figure 8a, for the total amount of mercury intrusion, G1 has the lowest total intrusion, and G2 has the highest total intrusion. On comparing the four curves, it can also be found that G1 has the greatest content of pores larger than 10 μm, as can be seen, that the red line is in the highest position in the figure. On the contrary, G4 has the smallest content of pores larger than 10 μm.

Figure 8.

Cumulative intrusion of MIP. (a) Cumulative intrusion curves. (b) Pores distribution.

For a better comparison of the pore content of various sizes, the pore content of each size is extracted separately and plotted in Figure 8b, including >100 μm, 10–100 μm, 1–10 μm, 0.1–1 μm, 0.01–0.1 μm, and <0.01 μm, respectively. For the control group N, the total intrusion is 0.0898 mL/g. G1 has the lowest intrusion at 0.0744 mL/g, and G2 has the highest at 0.1118 mL/g. This is consistent with the strengths of the specimens. A greater intrusion always corresponds to a higher porosity and, as a result, a lower strength. On the contrary, a smaller intrusion coincides with a lower porosity and a higher strength. Also, from Figure 8b, although G1 has the lowest total intrusion, it has the highest intrusion for pores larger than 100 μm. The control group N has the smallest content of the pores greater than 100 μm. This may result from the fact that the water reducer has a certain air-inducing effect. G2 has a higher pore content of 1–10 μm, and many studies have shown that holes of this size do not greatly influence the strength of cement matrix composites [28]. The G2 group has the lowest strength, which can be attributed to the relatively close distance between small holes, which will cause a decrease in the strength of cement matrix composites [29].

3.4. SEM

The G32 group specimens were cut and polished to prepare SEM specimens and observe the images, as shown in Figure 9. Figure 9a shows several graphene nanosheets embedded in flocculent CSH and in contact with each other, forming conductive pathways, which contribute to reducing the resistivity of graphene-reinforced mortar. The graphene nanosheets are intertwined with CSH, and due to the ultra-high strength of the graphene nanosheet, it will inevitably have a positive contribution to the mechanical properties of the cement matrix composite. In addition, a large number of graphene nano-sheets roughly parallel to each other can also be found in the mortar, as shown in Figure 9b. The graphene sheet in a parallel state will exhibit capacitance characteristics when applying a voltage to the graphene-reinforced cement matrix composite. In addition, large amounts of needle-like calciferite and flake calcium hydroxide are also found in Figure 9b. In general, graphene nanosheets in cement matrix composites help improve their mechanical properties, and the changes in their electrical properties are also obvious, including reducing resistivity and increasing capacitance characteristics.

Figure 9.

SEM images. (a) Contact mode of graphene nano-platelets. (b) Parallel mode of graphene nano-platelets.

4. Discussion

4.1. Fitting Method and Fitting Parameters

A complex electrochemical system is formed when a cementitious specimen is connected to this small voltage [17]. In general, the microstructure of cementitious materials is greatly complex, and difficult to characterize comprehensive electrochemical characteristics [30,31]. The impedance characteristics of the solid-phase, liquid–liquid, and solid–liquid interfaces of the specimen can be explained by selecting existing equivalent circuits.

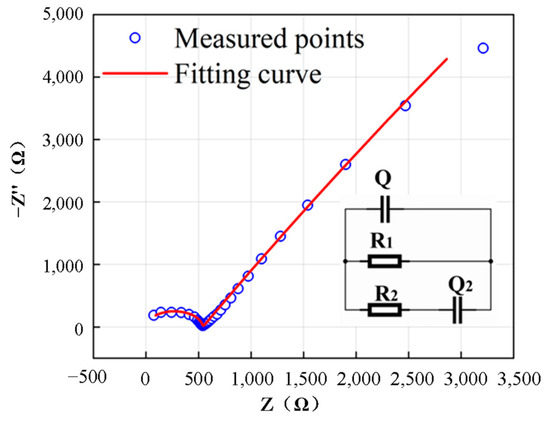

Figure 10 is an example of a fitted circuit model and fitting results. The equivalent circuit model is a circuit model proposed based on simplifying the microstructure model of cementitious materials [22], where Q is the dielectric capacitance associated with the continuous concrete matrix, R1 is the charge transfer resistance of the cementitious material in the cementitious material, R2 is the resistance in the discontinuous conductive path in the pore solution, and Q2 is related to the discontinuous cement slurry layer in the concrete. The impedance spectrum data is fitted with a fitted circuit, and all the data have reasonable fitting results. The error is less than 6%. The fitting results of each set of specimens are shown in Figure 11, and the parameters are shown in Table 3.

Figure 10.

Fitting circuit model.

Figure 11.

Fitting curves.

Table 3.

Fitting results for AC impedance spectrum.

According to Table 3, 1/Q gradually decreases with the increase in the graphene dosage; this is because Q expresses the dielectric capacitance associated with the continuous concrete matrix. The more graphene is incorporated, the more continuous conductive phases; the larger Q, the smaller 1/Q. R1 represents the arc diameter of the high-frequency region, so it also shows a law of decrease as the amount of graphene increases. Although R2 is given in Table 3, it is not difficult to find that the regularity of R2 is not very obvious. Q2 regularities are also not obvious, so they are no longer listed.

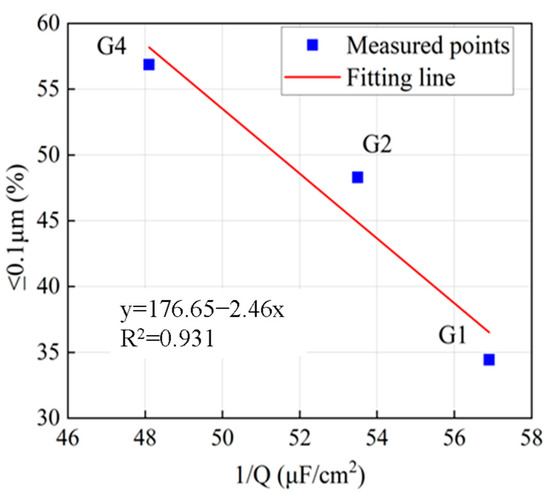

4.2. Relationship between the Fitted Parameters and Microstructure

Double-layer capacitors can often be used to describe the microstructure of mortar [30,32], and the parameters of the double-layer capacitor can reflect changes in graphene content in mortar. The common cement particle size is 50 μm, which is much larger than the equivalent size of graphene. According to the MIP test results, the incorporation of graphene increases the proportion of pores below 0.1 μm. With the increase in graphene dosage, the proportion of pore size below 0.1 μm increases, and the proportion of pore size below 0.1 μm in G4 group specimens increases by more than 65% compared with the G1 group. The relationship between the double-layer capacitor Q and the microscopic pore is established, as shown in Figure 12, which shows a positive proportional relationship between them. Moreover, the equation with a linear equation is fitted to obtain a linear equation with a higher correlation coefficient. In addition, the decrease in pore connectivity does not only mean a decrease in porosity but also greatly impacts the diffusion effect.

Figure 12.

Fitted diagram of ≤0.01 μm porosity ratio and 1/Q in G1, G2 and G4.

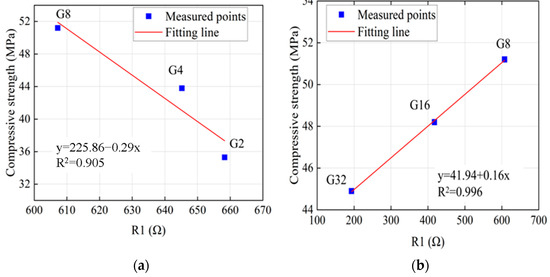

The compressive strength of G2, G4, and G8 showed an upward trend, and the compressive strength of G8 increased by 45% compared with G2. The compressive strength of G8, G16, and G32 showed a gradual downward trend, and the compressive strength of G32 was weakened by 16% compared with G8. The relationship between the impedance spectrum parameter R1 and the compressive strength is established, as shown in Figure 13. A linear equation with a primary linear equation is fitted, and a linear equation with a high correlation coefficient greater than 90% is obtained.

Figure 13.

Fitting diagram of R1 and compressive strength relationship. (a) Among G2, G4, G8. (b) Among G8, G16, G32.

It is worth noting that in the test results, the compressive strength of G1 is higher than the control, and the compressive strength of the six groups of compressive specimens increased with the amount of doping, reached the maximum value in G8, and then decreased. In the six groups of graphene-containing specimens, only G2 has a compressive strength lower than N. Previous test results show that an appropriate amount of graphene can accelerate the hydration process and improve the compactness of cementitious materials. In contrast, excessive graphene will hinder the hydration process. The incorporation of graphene in G1 is conducive to the hydration reaction, while the pore proportion below 0.1 μm is reduced compared with N. For G2, G4, and G8, although the amount of graphene hinders the hydration reaction, it continues to optimize the pore structure and improve the degree of compactness. Therefore, the compressive strength is further improved, and the charge transfer resistance R1 in C-S-H is reduced. The obstruction of graphene to hydration reaction in G8, G16, and G32 is further strengthened, the compactness of the microstructure decreases, the compressive strength is weakened, and the decline of R1 is further increased.

5. Conclusions

According to the investigation of the AC impedance spectrum and microstructure of graphene-modified concrete, the following conclusions can be drawn:

- (1)

- As the incorporated graphene content increases, the arc diameter of the impedance spectrum decreases, and the slope of the straight lines of the low-frequency region drops.

- (2)

- For the Bode curves, within low frequencies (1 Hz and 10 Hz), the impedance of the mortar gradually increases as the graphene dosage increases. However, when the frequency is between 100,000 Hz and 1,000,000 Hz), the impedance drops with a higher amount of graphene.

- (3)

- According to the MIP test results, the incorporation of graphene increases the proportion of pores below 0.1 μm. The SEM results show that the graphene nanosheets embedded in CSH can be in contact with each other to form conductive pathways, as well as parallel to each other, probably exhibiting capacitance characteristics.

- (4)

- There is a linear relationship between the double-layer capacitor Q and the microscopic pore content smaller than 0.1 μm.

Author Contributions

Conceptualization, S.W. and Q.L.; methodology, Q.L.; software, Q.L.; validation, S.W., Z.C. and Q.L.; formal analysis, S.W.; investigation, S.W.; resources, S.W.; data curation, S.W. and Z.C.; writing—original draft preparation, S.W. and Z.C.; writing—review and editing, Q.L., Y.H., K.L. and X.W.; visualization, Z.C.; supervision, Q.L.; project administration, Q.L.; funding acquisition, S.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work is financially supported by Gansu Province Youth Science Foundation (20JR5RA079) Research Project of State Grid Gansu Electric Power Corporation (52273019000B).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Koenders, E.A.B.; Pepe, M.; Martinelli, E. Compressive strength and hydration processes of concrete with recycled aggregates. Cem. Concr. Res. 2014, 56, 203–212. [Google Scholar] [CrossRef]

- Valipour, M.; Yekkalar, M.; Shekarchi, M.; Panahi, S. Environmental assessment of green concrete containing natural zeolite on the global warming index in marine environments. J. Clean. Prod. 2014, 65, 418–423. [Google Scholar] [CrossRef]

- Nazar, S.; Yang, J.; Thomas, B.S.; Azim, I.; Ur Rehman, S.K. Rheological properties of cementitious composites with and without nano-materials: A comprehensive review. J. Clean. Prod. 2020, 272, 122701. [Google Scholar] [CrossRef]

- Chintalapudi, K.; Pannem, R.M.R. An intense review on the performance of graphene oxide and reduced graphene oxide in an admixed cement system. Constr. Build. Mater. 2020, 259, 120598. [Google Scholar] [CrossRef]

- Sharma, S.; Kothiyal, N.C. Comparative effects of pristine and ball-milled graphene oxide on physico-chemical characteristics of cement mortar nanocomposites. Constr. Build. Mater. 2016, 115, 256–268. [Google Scholar] [CrossRef]

- Pei, C.; Zhu, J.H.; Xing, F. Photocatalytic property of cement mortars coated with graphene/TiO2 nanocomposites synthesized via sol–gel assisted electrospray method. J. Clean. Prod. 2021, 279, 123590. [Google Scholar] [CrossRef]

- Sou, Y.; Guo, R.; Xia, H.; Yang, Y.; Zhou, B.; Zhao, Z. A review of graphene oxide/cement composites: Performance, functionality, mechanisms, and prospects. J. Build. Eng. 2022, 53, 104502. [Google Scholar]

- Musavi, S.M.; Barahuie, F.; Irani, M.; Safamanesh, A.; Malekpour, A. Enhanced properties of phase change material -SiO2-graphene nanocomposite for developing structural–functional integrated cement for solar energy absorption and storage. Renew. Energy 2021, 174, 918–927. [Google Scholar] [CrossRef]

- Hu, M.; Guo, J.; Li, P.; Chen, D.; Xu, Y.; Feng, Y.; Yu, Y.; Zhang, H. Effect of characteristics of chemical combined of graphene oxide-nanosilica nanocomposite fillers on properties of cement-based materials. Constr. Build. Mater. 2019, 225, 745–753. [Google Scholar] [CrossRef]

- Sharma, S.; Singh, S.; Khare, N. Enhanced photosensitization of zinc oxide nanorods using polyaniline for efficient photocatalytic and photoelectrochemical water splitting. Int. J. Hydrog. Energy 2016, 41, 21088–21098. [Google Scholar] [CrossRef]

- Yu, L.; Bai, S.; Guan, X. Graphene oxide–silica nanocomposites reinforced mortars: Mechanical properties, permeability and microstructure. Constr. Build. Mater. 2022, 344, 128290. [Google Scholar] [CrossRef]

- Liu, H.; Yu, Y.; Liu, H.; Jin, J.; Liu, S. Hybrid effects of nano-silica and graphene oxide on mechanical properties and hydration products of oil well cement. Constr. Build. Mater. 2018, 191, 311–319. [Google Scholar] [CrossRef]

- Huang, J.; Gao, Y.; Luo, J.; Wang, S.; Li, C.; Chen, S.; Zhang, J. Editors’ Choice—Review—Impedance Response of Porous Electrodes: Theoretical Framework, Physical Models and Applications. J. Electrochem. Soc. 2020, 167, 166503. [Google Scholar] [CrossRef]

- Chi, L.; Wang, Z.; Lu, S.; Zhao, D.; Yao, Y. Development of mathematical models for predicting the compressive strength and hydration process using the EIS impedance of cementitious materials. Constr. Build. Mater. 2019, 208, 659–668. [Google Scholar] [CrossRef]

- Maurya, K.K.; Rawat, A.; Jha, G. Smart materials and electro-mechanical impedance technique: A review. Mater. Today Proc. 2020, 33, 4993–5000. [Google Scholar] [CrossRef]

- Sánchez, M.; Gregori, J.; Alonso, C.; García-Jareño, J.J.; Takenouti, H.; Vicente, F. Electrochemical impedance spectroscopy for studying passive layers on steel rebars immersed in alkaline solutions simulating concrete pores. Electrochim. Acta 2007, 52, 7634–7641. [Google Scholar] [CrossRef]

- Pichór, W.; Frąc, M.; Radecka, M. Determination of percolation threshold in cement composites with expanded graphite by impedance spectroscopy. Cem. Concr. Compos. 2022, 125, 104328. [Google Scholar] [CrossRef]

- GB 175-2020; Common Portland Cement. Chinese National Standards: Beijing, China, 2020. (In Chinese)

- Liu, Q.; Tang, H.; Chi, L.; Chen, K.; Zhang, L.; Lu, C. Evolution of Electrochemical Impedance Spectra Characteristics of Cementitious Materials after Capturing Carbon Dioxide. Sustainability 2023, 15, 2460. [Google Scholar] [CrossRef]

- Tang, H.; Qian, J.; Qin, J.; Li, Z.; Jia, X.; Yue, Y.; Dai, F. Electrochemical behavior of steel bars in magnesium phosphate cement. Cem. Concr. Res. 2023, 169, 107167. [Google Scholar] [CrossRef]

- He, F.; Wang, R.; Shi, C.; Chen, C.; Lin, L.; An, X. Error evaluation and correction of stray impedance during measurement and interpretation of AC impedance of cement-based materials. Cem. Concr. Compos. 2016, 72, 190–200. [Google Scholar] [CrossRef]

- Hu, X.; Shi, C.; Liu, X.; Zhang, J.; de Schutter, G. A review on microstructural characterization of cement-based materials by AC impedance spectroscopy. Cem. Concr. Compos. 2019, 100, 1–14. [Google Scholar] [CrossRef]

- Shi, M.; Chen, Z.; Sun, J. Determination of chloride diffusivity in concrete by AC impedance spectroscopy. Cem. Concr. Res. 1999, 29, 1111–1115. [Google Scholar] [CrossRef]

- Dhouibi, L.; Triki, E.; Raharinaivo, A. The application of electrochemical impedance spectroscopy to determine the long-term effectiveness of corrosion inhibitors for steel in concrete. Cem. Concr. Compos. 2002, 24, 35–43. [Google Scholar] [CrossRef]

- Gu, P.; Xu, Z.; Xie, P.; Beaudoin, J.J. Application of A.C. impedance techniques in studies of porous cementitious materials. (I): Influence of solid phase and pore solution on high frequency resistance. Cem. Concr. Res. 1993, 23, 1007–1015. [Google Scholar] [CrossRef]

- McCarter, W.J.; Chrisp, T.M.; Starrs, G.; Adamson, A.; Basheer, P.A.M.; Nanukuttan, S.V.; Srinivasan, S.; Green, C. Characterization of physio-chemical processes and hydration kinetics in concretes containing supplementary cementitious materials using electrical property measurements. Cem. Concr. Res. 2013, 50, 26–33. [Google Scholar] [CrossRef]

- Dalal, S.P.; Dalal, P. Experimental investigation on strength and durability of graphene nanoengineered concrete. Constr. Build. Mater. 2021, 276, 122236. [Google Scholar] [CrossRef]

- Raj, A.; Sathyan, D.; Mini, K.M. Physical and functional characteristics of foam concrete: A review. Constr. Build. Mater. 2019, 221, 787–799. [Google Scholar] [CrossRef]

- Diamond, S. Aspects of concrete porosity revisited. Cem. Concr. Res. 1999, 29, 1181–1188. [Google Scholar] [CrossRef]

- Kong, L.; Hou, L.; Bao, X. Application of AC impedance technique in study of lightweight aggregate-paste interface. Constr. Build. Mater. 2015, 82, 332–340. [Google Scholar] [CrossRef]

- Vicente, C.; Castela, A.S.; Neves, R.; Montemor, M.F. Assessment of the influence of concrete modification in the water uptake/evaporation kinetics by electrochemical impedance spectroscopy. Electrochim. Acta 2017, 247, 50–62. [Google Scholar] [CrossRef]

- Sánchez, I.; Nóvoa, X.R.; de Vera, G.; Climent, M.A. Microstructural modifications in Portland cement concrete due to forced ionic migration tests. Study by impedance spectroscopy. Cem. Concr. Res. 2008, 38, 1015–1025. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).