A Review on the Way Forward in Construction through Industrial Revolution 5.0

Abstract

1. Introduction

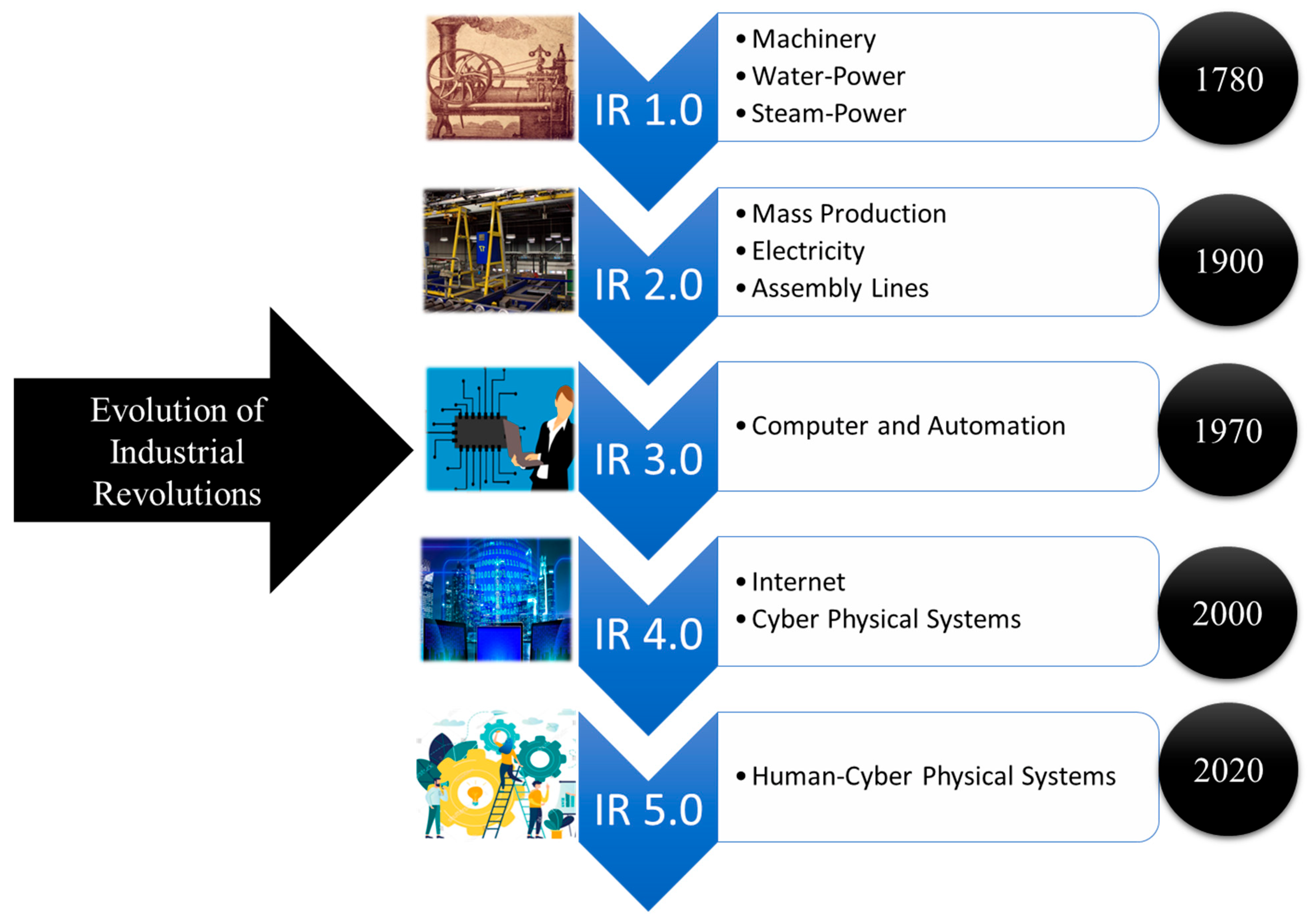

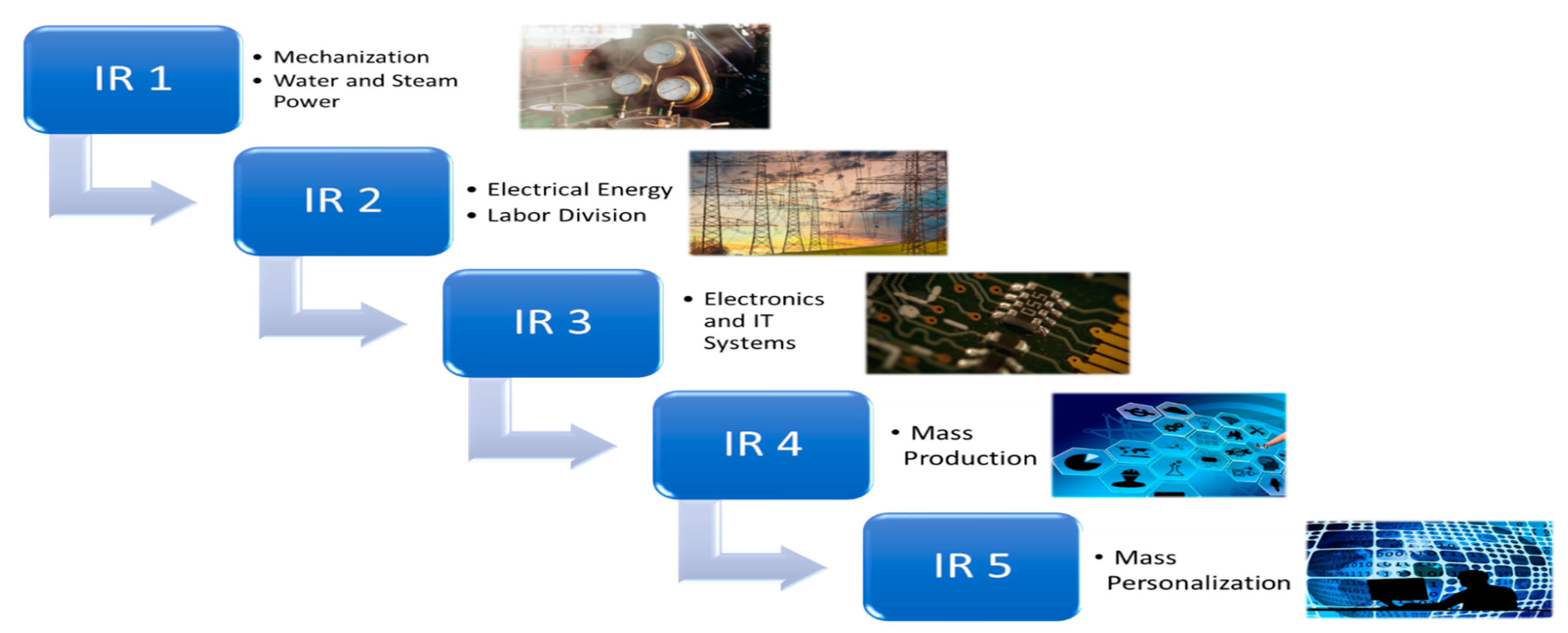

2. History of Industrial Revolutions

2.1. Industrial Revolution 1.0

2.2. Industrial Revolution 2.0

2.3. Industrial Revolution 3.0

2.4. Transformation of IR 3.0 to 4.0

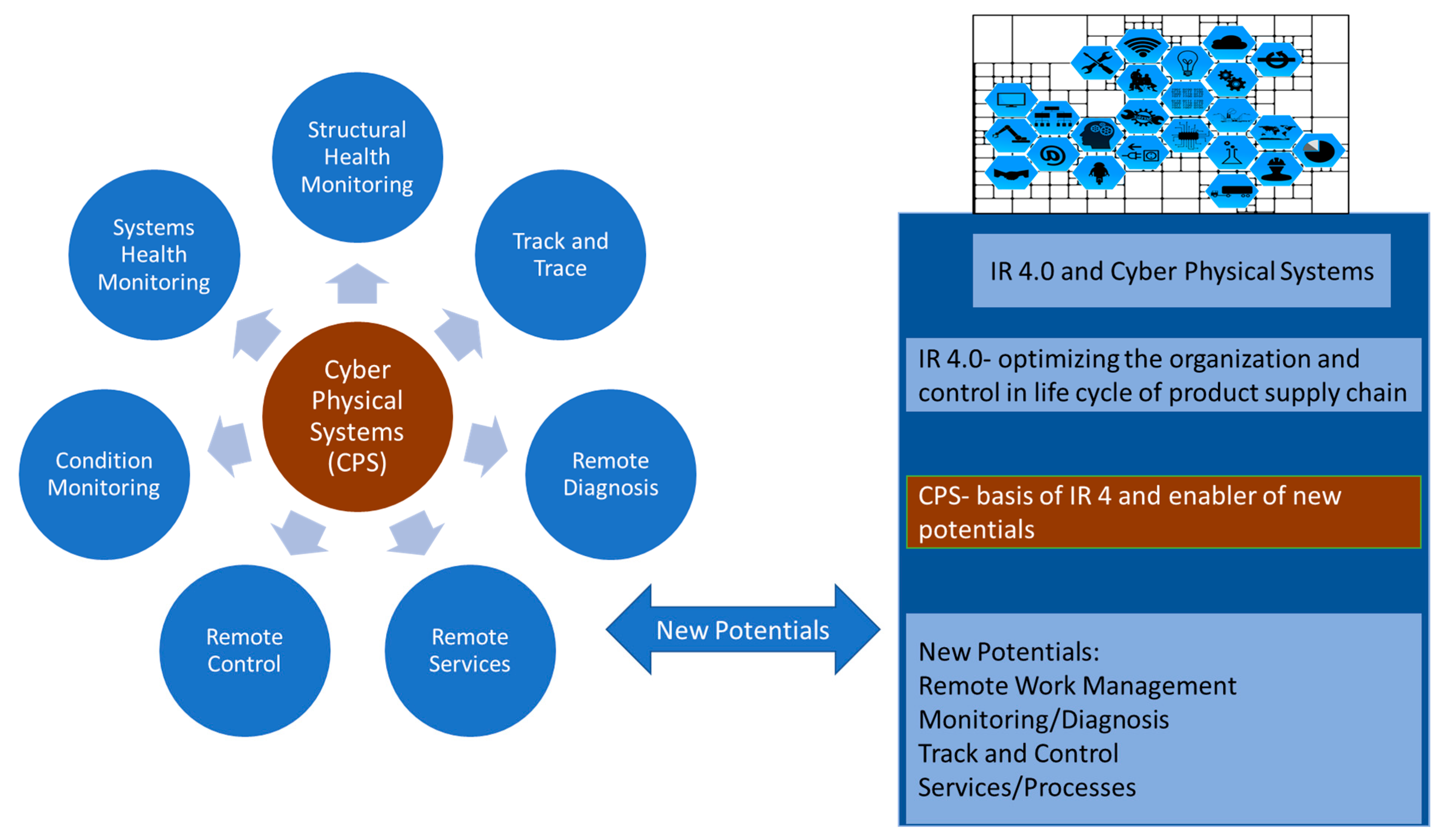

2.5. Industrial Revolution 4.0

2.6. Transformation of IR 4.0 to 5.0

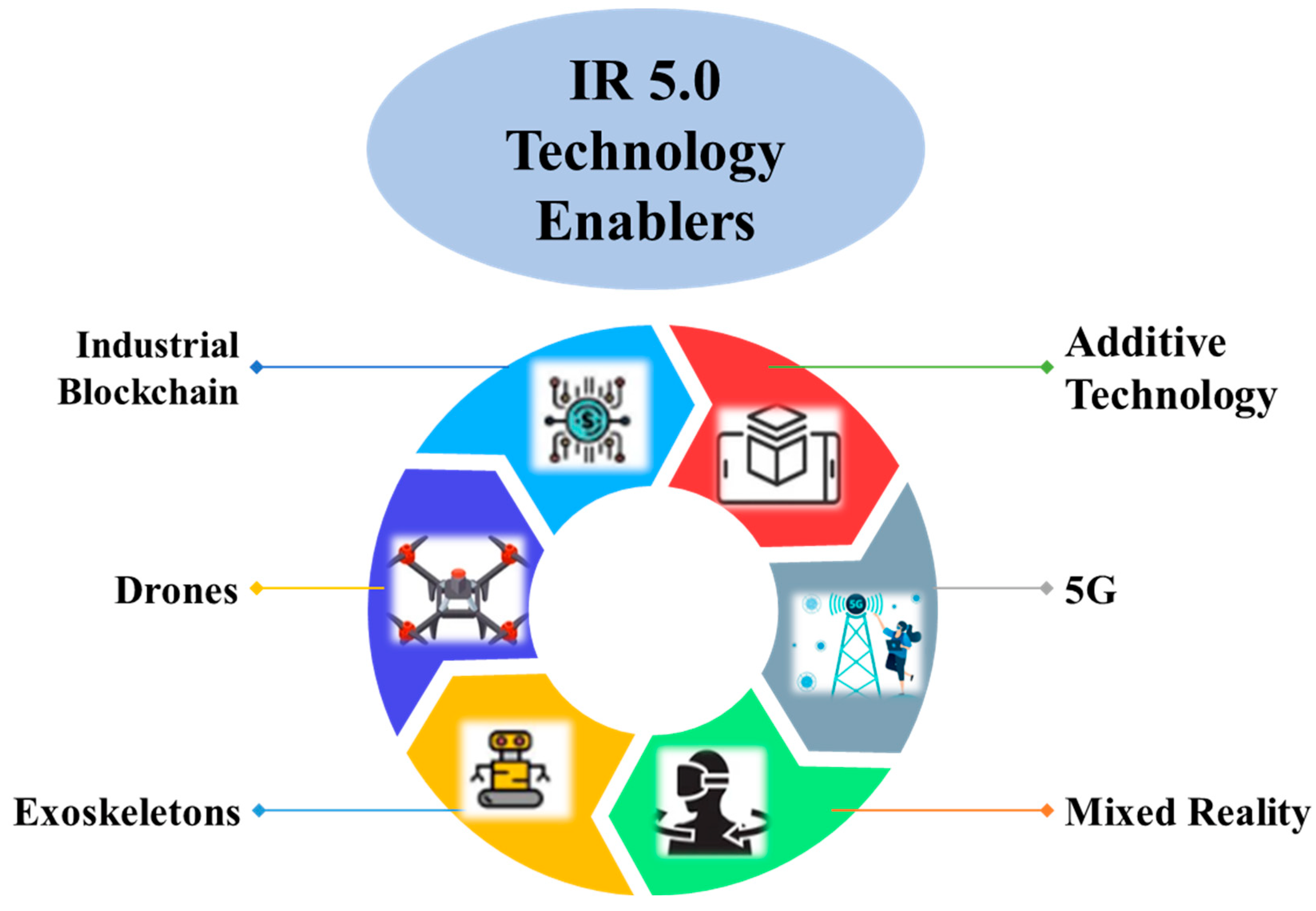

3. Industrial Revolution 5.0

3.1. Sustainability and Resiliency

3.2. Collaboration between Machines and People

3.3. Enhancing Client Experience and Going All out on Personalization

3.4. Reasons to Adopt IR 5.0 Enabling Technologies

- The use of augmented reality (AR) and virtual reality (VR) for inclusivity, training, and industrial testing;

- Sophisticated safety gear and working tools that improve human skills through robotic tools and data communication;

- Automatic speech and gesture detection:

- 4.

- Digital twins and simulations;

- 5.

- Robots that work together:

- 6.

- Human–machine integration:

- 7.

- High adaptability:

- 8.

- Reduced prices and smaller sizes:

- 9.

- Easy to use and intuitive:

- 10.

- Application to carry out a wider range of duties:

- 11.

- Increased safety:

3.5. Transforming Construction Process with Construction 5.0 through IR 5.0

- (a)

- Using Advanced Automation and Robotics in Construction

- (b)

- 3D-Printed Building Modules and Additive Manufacturing

- (c)

- Digital Twin and Building Information Modelling (BIM)

- (d)

- Smart Materials and Sustainable Construction

- (e)

- Renewable Energy Integration

- (f)

- IoT and Connectivity

- (g)

- AI and Predictive Analytics

- (h)

- Modular Off-Site Construction

3.6. Role of IR 5.0 in the Manufacturing Industry

3.7. Role of IR 5.0 in the Construction Industry

3.7.1. Executing a Project with a Human Focus

3.7.2. Adaptive to Collaboration

3.7.3. The Tech That Gives Power

3.7.4. Focus on Sustainability

3.8. Barriers and Challenges in the Adoption of IR 5.0

- Using state-of-the-art technology requires more time and effort from human workers. In addition to specialized software-connected factories, Industry 5.0 demands the utilization of collaborative robotics, artificial intelligence, real-time data, and the Internet of Things [58].

- Investments in cutting-edge technologies are necessary. Adopting Industry 5.0 is expensive since smart machines and highly skilled personnel are required to increase production and efficiency [59].

- To communicate with a variety of devices and defend against potential quantum computing applications when deploying IoT nodes, authentication has been utilized in the industry. Since ICT systems lie at the heart of Industry 5.0 applications, strict security standards are required to prevent security risks [50].

- Currently, the economic impacts of Industry 5.0 in the construction industry have not been researched comprehensively and coverage of the literature on this aspect is missing. The main reason lies in the fact that it is a novel concept and has not been accepted widely by major stakeholders. The economic impacts will be studied once it is implemented globally, which is currently a piece missing from this puzzle.

3.9. Reforms with IR 5.0 in the Construction Industry

- Teams that are empowered by Industry 5.0 leverage human knowledge and innovation more frequently;

- Using technology more selectively, teams switch from mass automation to flexible solutions that can automate, or mass customize, enabling performance at scale under a variety of scenarios;

- Improved cooperation—teams use virtual co-location technology and seamless communication channels to work more effectively together;

- More environmentally friendly construction techniques—project teams place a greater emphasis on sustainability, incorporating environmental and social effects into planning and decision-making.

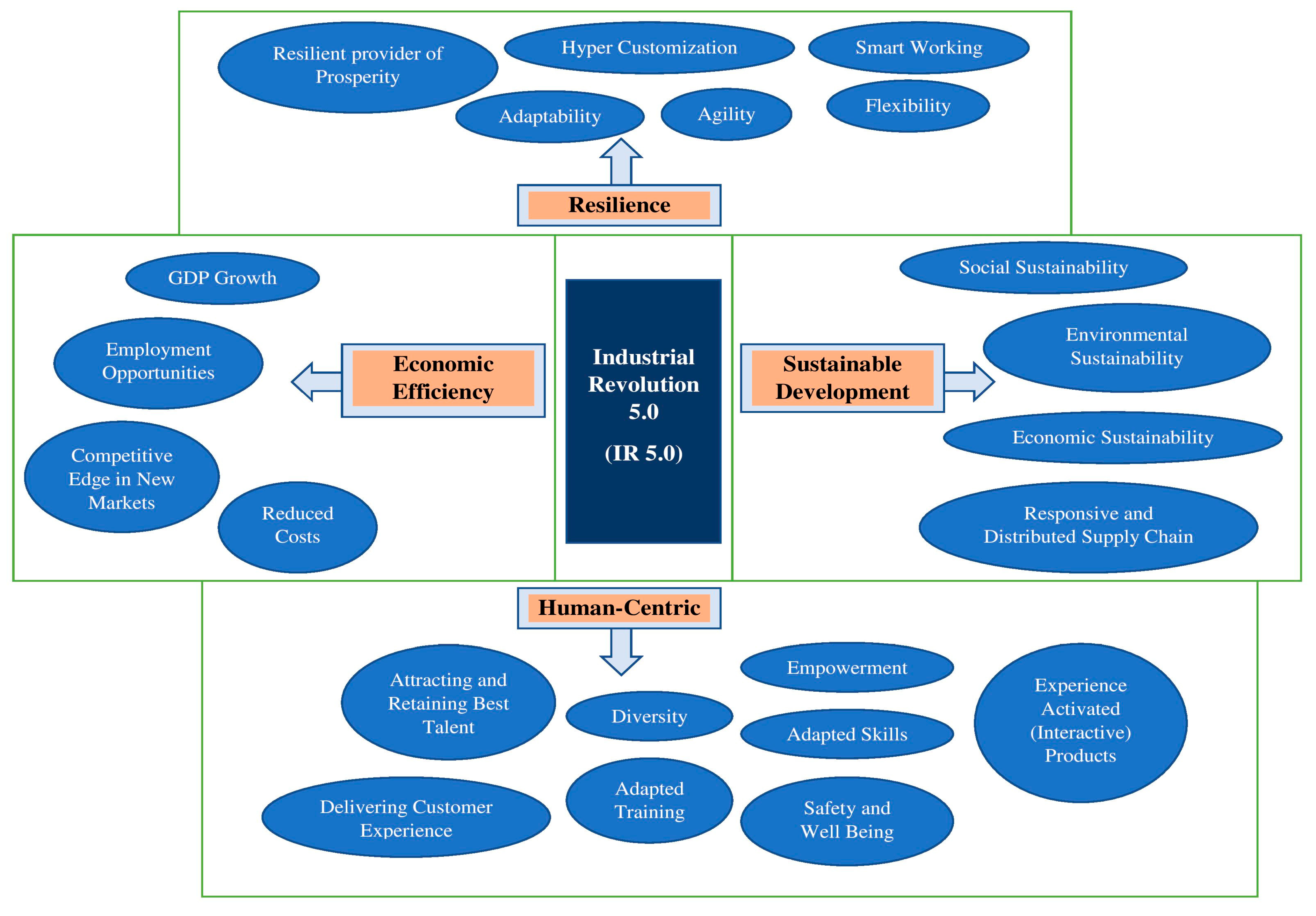

4. Conceptual Framework

4.1. IR 5.0 and Sustainability in Construction

4.1.1. Sustainable Development

4.1.2. Human-Centric

4.1.3. Economic Efficiency

4.1.4. Resilience

4.2. IR 5.0 and Managerial Insights

5. Conclusions

5.1. Practical Implications

5.2. Managerial Implications

5.3. Recommendations and Limitations for Future Research

- It is recommended to explore the education and training workshop requirements for preparing the workforce of the future to be equipped with the relevant skills and knowledge in the era of IR 5.0;

- The adoption of IR 5.0 in the context of the construction industry should be explored with a greater focus on the economy, society, and the environment;

- Government agencies, policymakers, decision-makers, stakeholders, and investors should collaborate to increase investments and minimize the regulatory hurdles in the adoption or implementation of IR 5.0-enabling technologies;

- The concept of IR 5.0 should be explored with the inclusion of real-world case studies. Although, at this moment, due to the unavailability of resources and skills, it would be a difficult job, but still, making some progress is better than no progress at all;

- The concept of IR 5.0 has not been assessed adequately in the context of sustainability. The challenges and limitations are abundant, but they can be removed through the engagement of major industry stakeholders from public and private organizations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Zamani, S.H.; Rahman, R.; Fauzi, M.; Yusof, L. Effect of COVID-19 on building construction projects: Impact and response mechanisms. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 682, p. 012049. [Google Scholar]

- Craveiroa, F.; Duartec, J.P.; Bartoloa, H.; Bartolod, P.J.J.S.D. Additive manufacturing as an enabling technology for digital construction: A perspective on Construction 4.0. Sustain. Dev. 2019, 4, 251–267. [Google Scholar] [CrossRef]

- Ilic, D.; Markovic, B.; Milosevic, D. Strategic business transformation: An industry 4.0 perspective. Econ. Law 2017, 7, 49. [Google Scholar]

- Musarat, M.A.; Alaloul, W.S.; Liew, M. Impact of inflation rate on construction projects budget: A review. Ain Shams Eng. J. 2021, 12, 407–414. [Google Scholar] [CrossRef]

- Musarat, M.A.; Alaloul, W.S.; Liew, M.; Maqsoom, A.; Qureshi, A.H. Investigating the impact of inflation on building materials prices in construction industry. J. Build. Eng. 2020, 32, 101485. [Google Scholar] [CrossRef]

- Alawag, A.M.; Alaloul, W.S.; Liew, M.; Musarat, M.A.; Baarimah, A.O.; Saad, S.; Ammad, S. Critical success factors influencing total quality management in industrialised building system: A case of malaysian construction industry. Ain Shams Eng. J. 2023, 14, 101877. [Google Scholar] [CrossRef]

- Musarat, M.A.; Alaloul, W.S.; Cher, L.S.; Qureshi, A.H.; Alawag, A.M.; Baarimah, A.O. Applications of Building Information Modelling in the Operation and Maintenance Phase of Construction Projects: A Framework for the Malaysian Construction Industry. Sustainability 2023, 15, 5044. [Google Scholar] [CrossRef]

- Locatelli, G.; Mancini, M.; Romano, E. Systems engineering to improve the governance in complex project environments. Int. J. Proj. Manag. 2014, 32, 1395–1410. [Google Scholar] [CrossRef]

- Musarat, M.A.; Alaloul, W.S.; Irfan, M.; Sreenivasan, P.; Rabbani, M.B. Health and safety improvement through Industrial Revolution 4.0: Malaysian construction industry case. Sustainability 2022, 15, 201. [Google Scholar] [CrossRef]

- Tavares, M.C.; Azevedo, G.; Marques, R.P. The Challenges and Opportunities of Era 5.0 for a More Humanistic and Sustainable Society—A Literature Review. Societies 2022, 12, 149. [Google Scholar] [CrossRef]

- Musarat, M.A.; Alaloul, W.S.; Hameed, N.; Qureshi, A.H.; Wahab, M.M.A. Efficient Construction Waste Management: A Solution through Industrial Revolution (IR) 4.0 Evaluated by AHP. Sustainability 2022, 15, 274. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.W.A.; Mohammed, B.S. Industry revolution IR 4.0: Future opportunities and challenges in construction industry. In MATEC Web of Conferences; EDP Sciences: Castanet-Tolosan, France, 2018; Volume 203, p. 02010. [Google Scholar]

- Harley, C.K. Reassessing the industrial revolution: A macro view. In The British Industrial Revolution; Routledge: Abingdon, UK, 2018; pp. 160–205. [Google Scholar]

- Chen, Q.; de Soto, B.G.; Adey, B.T. Construction automation: Research areas, industry concerns and suggestions for advancement. Autom. Constr. 2018, 94, 22–38. [Google Scholar] [CrossRef]

- Hossain, M.A.; Nadeem, A. Towards digitizing the construction industry: State of the art of construction 4.0. In Proceedings of the ISEC, Riverside, CA, USA, 8 September 2019; Volume 10. [Google Scholar]

- Sherwani, F.; Asad, M.M.; Ibrahim, B.S.K.K. Collaborative robots and industrial revolution 4.0 (ir 4.0). In Proceedings of the 2020 International Conference on Emerging Trends in Smart Technologies (ICETST), Karachi, Pakistan, 26–27 March 2020; IEEE: New York, NY, USA, 2020; pp. 1–5. [Google Scholar]

- More, C. Understanding the Industrial Revolution; Routledge: Abingdon, UK, 2002. [Google Scholar]

- Sawhney, A.; Riley, M.; Irizarry, J. (Eds.) Construction 4.0: An Innovation Platform for the Built Environment; Routledge: Abingdon, UK, 2020; ISBN 9780429398100. [Google Scholar]

- Kamaruzaman, M.; Hamid, R.; Mutalib, A.; Rasul, M. Comparison of engineering skills with IR 4.0 skills. Int. J. Online Biomed. Eng. Ijoe 2019, 15, 15–28. [Google Scholar] [CrossRef]

- Yavari, F.; Pilevari, N. Industry revolutions development from Industry 1.0 to Industry 5.0 in manufacturing. J. Ind. Strateg. Manag. 2020, 5, 44–63. [Google Scholar]

- Atkeson, A.; Kehoe, P.J. The Transition to a New Economy after the Second Industrial Revolution; National Bureau of Economic Research Cambridge: Cambridge, MA, USA, 2001. [Google Scholar]

- Salah, B. Real-Time Implementation of a Fully Automated Industrial System Based on IR 4.0 Concept. Actuators 2021, 10, 318. [Google Scholar]

- Taalbi, J. Origins and pathways of innovation in the third industrial revolution. Ind. Corp. Change 2019, 28, 1125–1148. [Google Scholar]

- Qureshi, A.H.; Alaloul, W.S.; Manzoor, B.; Musarat, M.A.; Saad, S.; Ammad, S. Implications of machine learning integrated technologies for construction progress detection under industry 4.0 (IR 4.0). In Proceedings of the 2020 Second International Sustainability and Resilience Conference: Technology and Innovation in Building Designs (51154), Sakheer, Bahrain, 11–12 November 2020; IEEE: New York, NY, USA, 2020; pp. 1–6. [Google Scholar]

- Seltsikas, P.; Currie, W.L. Evaluating the application service provider (ASP) business model: The challenge of integration. In Proceedings of the 35th Annual Hawaii International Conference on System Sciences, Big Island, Hawaii, 10 January 2002; IEEE: New York, NY, USA, 2002; pp. 2801–2809. [Google Scholar]

- Marques, I.A. Shaping the Future of Industry: How Can Vanguard Technology Improve Our Lives? 2021. Available online: https://run.unl.pt/handle/10362/138158 (accessed on 20 March 2023).

- Alaloul, W.S.; Liew, M.; Zawawi, N.A.W.A.; Kennedy, I.B. Industrial Revolution 4.0 in the construction industry: Challenges and opportunities for stakeholders. Ain Shams Eng. J. 2020, 11, 225–230. [Google Scholar] [CrossRef]

- Aghimien, D.; Aigbavboa, C.; Matabane, K. Impediments of the fourth industrial revolution in the South African construction industry. In Collaboration and Integration in Construction, Engineering, Management and Technology; Springer: Berlin/Heidelberg, Germany, 2021; pp. 223–227. [Google Scholar]

- Carvalho, N.; Chaim, O.; Cazarini, E.; Gerolamo, M. Manufacturing in the fourth industrial revolution: A positive prospect in sustainable manufacturing. Procedia Manuf. 2018, 21, 671–678. [Google Scholar] [CrossRef]

- Shahroom, A.A.; Hussin, N. Industrial revolution 4.0 and education. Int. J. Acad. Res. Bus. Soc. Sci. 2018, 8, 314–319. [Google Scholar] [CrossRef]

- Erol, S.; Jäger, A.; Hold, P.; Ott, K.; Sihn, W. Tangible Industry 4.0: A scenario-based approach to learning for the future of production. Procedia CiRp 2016, 54, 13–18. [Google Scholar] [CrossRef]

- De Lange, M.; De Waal, M. Owning the city: New media and citizen engagement in urban design. In Urban Land Use; Apple Academic Press: Cambridge, MA, USA, 2017; pp. 109–130. [Google Scholar]

- Maresova, P.; Soukal, I.; Svobodova, L.; Hedvicakova, M.; Javanmardi, E.; Selamat, A.; Krejcar, O. Consequences of industry 4.0 in business and economics. Economies 2018, 6, 46. [Google Scholar] [CrossRef]

- Bloem, J.; Van Doorn, M.; Duivestein, S.; Excoffier, D.; Maas, R.; Van Ommeren, E. The fourth industrial revolution. Things Tighten 2014, 8, 11–15. [Google Scholar]

- Popkova, E.G.; Ragulina, Y.V.; Bogoviz, A.V. Fundamental differences of transition to industry 4.0 from previous industrial revolutions. In Industry 4.0: Industrial Revolution of the 21st Century; Springer: Berlin/Heidelberg, Germany, 2019; pp. 21–29. [Google Scholar]

- Dallasega, P.; Rauch, E.; Linder, C. Industry 4.0 as an enabler of proximity for construction supply chains: A systematic literature review. Comput. Ind. 2018, 99, 205–225. [Google Scholar] [CrossRef]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A literature review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- Rastogi, V.; Srivastava, S.; Mishra, M.; Thukral, R. Predictive Maintenance for SME in Industry 4.0. In Proceedings of the 2020 Global Smart Industry Conference (GloSIC), Chelyabinsk, Russia, 17–19 November 2020; IEEE: New York, NY, USA, 2020; pp. 382–390. [Google Scholar]

- Vu, T.L.A.; Le, T.Q. Development orientation for higher education training programme of mechanical engineering in industrial revolution 4.0: A perspective in vietnam. Mech. Eng. Res. Dev 2019, 42, 68–70. [Google Scholar]

- Jung, E. 4th Industrial Revolution and Boundry: Challenges and Opportunities. In Proceedings of the 2018 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 1–5 December 2018; IEEE: New York, NY, USA, 2018; pp. 1.1.1–1.1.10. [Google Scholar]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Bücker, I.; Hermann, M.; Pentek, T.; Otto, B. Towards a methodology for Industrie 4.0 transformation. In Proceedings of the International Conference on Business Information Systems, Hannover, Germany, 14–17 June 2016; Springer: Berlin/Heidelberg, Germany, 2016; pp. 209–221. [Google Scholar]

- Liu, Y.; Ma, X.; Shu, L.; Hancke, G.P.; Abu-Mahfouz, A.M. From Industry 4.0 to Agriculture 4.0: Current status, enabling technologies, and research challenges. J. Manuf. Syst. 2020, 17, 4322–4334. [Google Scholar] [CrossRef]

- Rymarczyk, J. Technologies, opportunities and challenges of the industrial revolution 4.0: Theoretical considerations. Entrep. Bus. Econ. Rev. 2020, 8, 185–198. [Google Scholar] [CrossRef]

- Insights, D.J. The Fourth Industrial Revolution: At the Intersection of Readiness and Responsibility. 2020. Available online: https://www2.deloitte.com (accessed on 20 March 2023).

- Moon, Y.; Seol, S.-S. Evaluation of the Theory of the 4 th Industrial Revolution. Asian J. Innov. Policy 2017, 6, 245–261. [Google Scholar]

- Imran, M.; Salisu, I.; Aslam, H.D.; Iqbal, J.; Hameed, I. Resource and information access for SME sustainability in the era of IR 4.0: The mediating and moderating roles of innovation capability and management commitment. Processes 2019, 7, 211. [Google Scholar] [CrossRef]

- Tien, N.H.; Nogalski, B. Developing high quality human resource to benefit from CP-TPP and IR 4.0. Int. J. Res. Manag. 2019, 1, 4–6. [Google Scholar] [CrossRef]

- Potočan, V.; Mulej, M.; Nedelko, Z. Society 5.0: Balancing of Industry 4.0, economic advancement and social problems. Kybernetes 2020, 50, 794–811. [Google Scholar] [CrossRef]

- Paschek, D.; Mocan, A.; Draghici, A. Industry 5.0—The expected impact of next industrial revolution. In Proceedings of the Thriving on Future Education, Industry, Business, and Society, Proceedings of the MakeLearn and TIIM International Conference, Piran, Slovenia, 15–17 May 2019; pp. 15–17. [Google Scholar]

- Humayun, M. Industrial Revolution 5.0 and the Role of Cutting Edge Technologies. Int. J. Adv. Comput. Sci. Appl. 2021, 12, 0121276. [Google Scholar] [CrossRef]

- Sarfraz, Z.; Sarfraz, A.; Iftikar, H.M.; Akhund, R. Is COVID-19 pushing us to the fifth industrial revolution (society 5.0)? Pak. J. Med. Sci. 2021, 37, 591. [Google Scholar] [CrossRef] [PubMed]

- Tien, N.H.; Phong, V.M.T.; Thoi, B.; Duc, L.D.M. Developing High Quality Human Resource to Take Advantages from CPTPP and IR 4.0. Int. J. Res. Financ. Manag. 2019, 2, 67–69. [Google Scholar] [CrossRef]

- Poszytek, P.J.S. The Landscape of Scientific Discussions on the Competencies 4.0 Concept in the Context of the 4th Industrial Revolution—A Bibliometric Review. Sustainability 2021, 13, 6709. [Google Scholar] [CrossRef]

- Chen, S.; Xu, H. Meta-heuristic algorithm-based human resource information management system design and development for industrial revolution 5.0. Soft Comput. 2022, 27, 4093–4105. [Google Scholar] [CrossRef]

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0: Prospect and retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

- Sindhwani, R.; Afridi, S.; Kumar, A.; Banaitis, A.; Luthra, S.; Singh, P.L. Can industry 5.0 revolutionize the wave of resilience and social value creation? A multi-criteria framework to analyze enablers. Technol. Soc. 2022, 68, 101887. [Google Scholar] [CrossRef]

- Demir, K.A.; Döven, G.; Sezen, B. Industry 5.0 and human-robot co-working. Procedia Comput. Sci. 2019, 158, 688–695. [Google Scholar] [CrossRef]

- George, A.S.; George, A.H. Industrial revolution 5.0: The transformation of the modern manufacturing process to enable man and machine to work hand in hand. J. Seybold Rep. ISSN NO 2020, 1533, 9211. [Google Scholar]

- Golić, Z. Finance and artificial intelligence: The fifth industrial revolution and its impact on the financial sector. Zb. Rad. Ekon. Fak. Istočnom Sarajev. 2019, 8, 67–81. [Google Scholar] [CrossRef]

- Lai, C.; Chundra, U.; Lee, M. Teaching and learning based on IR 4.0: Readiness of attitude among polytechnics lecturers. J. Phys. Conf. Ser. 2020, 1529, 032105. [Google Scholar]

- Maddikunta, P.K.R.; Pham, Q.-V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Marinelli, M. From Industry 4.0 to Construction 5.0: Exploring the Path towards Human–Robot Collaboration in Construction. Systems 2023, 11, 152. [Google Scholar] [CrossRef]

- Yitmen, I.; Almusaed, A.; Alizadehsalehi, S. Investigating the Causal Relationships among Enablers of the Construction 5.0 Paradigm: Integration of Operator 5.0 and Society 5.0 with Human-Centricity, Sustainability, and Resilience. Sustainability 2023, 15, 9105. [Google Scholar] [CrossRef]

- Hu, C.; Liu, P.; Yang, H.; Yin, S.; Ullah, K. A novel evolution model to investigate the collaborative innovation mechanism of green intelligent building materials enterprises for construction 5.0. AIMS Math. 2023, 8, 8117–8143. [Google Scholar] [CrossRef]

- Pan, M.; Linner, T.; Pan, W.; Cheng, H.; Bock, T. A framework of indicators for assessing construction automation and robotics in the sustainability context. J. Clean. Prod. 2018, 182, 82–95. [Google Scholar] [CrossRef]

- Ikudayisi, A.E.; Chan, A.P.; Darko, A.; Yomi, M. Integrated practices in the Architecture, Engineering, and Construction industry: Current scope and pathway towards Industry 5.0. J. Build. Eng. 2023, 73, 106788. [Google Scholar] [CrossRef]

- Roach, D.J.; Hamel, C.M.; Dunn, C.K.; Johnson, M.V.; Kuang, X.; Qi, H.J. The m4 3D printer: A multi-material multi-method additive manufacturing platform for future 3D printed structures. Addit. Manuf. 2019, 29, 100819. [Google Scholar] [CrossRef]

- Khalid, A.; Khan, Z.H.; Idrees, M.; Kirisci, P.; Ghrairi, Z.; Thoben, K.-D.; Pannek, J. Understanding vulnerabilities in cyber physical production systems. Int. J. Comput. Integr. Manuf. 2022, 35, 569–582. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, D.; Liu, Z.; Osmani, M.; Demian, P. Construction 4.0, Industry 4.0, and Building Information Modeling (BIM) for sustainable building development within the smart city. Sustainability 2022, 14, 10028. [Google Scholar] [CrossRef]

- Baghalzadeh Shishehgarkhaneh, M.; Keivani, A.; Moehler, R.C.; Jelodari, N.; Roshdi Laleh, S. Internet of Things (IoT), Building Information Modeling (BIM), and Digital Twin (DT) in construction industry: A review, bibliometric, and network analysis. Buildings 2022, 12, 1503. [Google Scholar] [CrossRef]

- Nihalani, S.; Joshi, U.; Meeruty, A. Smart materials for sustainable and smart infrastructure. Mater. Sci. Forum 2019, 969, 278–283. [Google Scholar]

- Apicella, A.; Ianniello, D.; Aversa, R. Application of nanostructured smart materials in sustainable buildings. Int. J. Sustain. Manuf. 2010, 2, 66–79. [Google Scholar] [CrossRef]

- Kaygusuz, A.; Keles, C.; Alagoz, B.B.; Karabiber, A. Renewable energy integration for smart sites. Energy Build. 2013, 64, 456–462. [Google Scholar] [CrossRef]

- Reja, V.K.; Varghese, K. Impact of 5G technology on IoT applications in construction project management. ISARC Proc. Int. Symp. Autom. Robot. Constr. 2019, 36, 209–217. [Google Scholar]

- Letourneau-Guillon, L.; Camirand, D.; Guilbert, F.; Forghani, R. Artificial intelligence applications for workflow, process optimization and predictive analytics. Neuroimaging Clin. 2020, 30, e1–e15. [Google Scholar] [CrossRef] [PubMed]

- Akter, S.; Michael, K.; Uddin, M.R.; McCarthy, G.; Rahman, M. Transforming business using digital innovations: The application of AI, blockchain, cloud and data analytics. Ann. Oper. Res. 2022, 308, 7–39. [Google Scholar] [CrossRef]

- Egege, C.O. Off-site modular construction as a method of improving construction quality and safety. Int. J. Struct. Civ. Eng. Res. 2018, 7, 259–268. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Akundi, A.; Euresti, D.; Luna, S.; Ankobiah, W.; Lopes, A.; Edinbarough, I. State of Industry 5.0—Analysis and identification of current research trends. Appl. Syst. Innov. 2022, 5, 27. [Google Scholar] [CrossRef]

- Skobelev, P.O.; Borovik, S.Y. On the way from Industry 4.0 to Industry 5.0: From digital manufacturing to digital society. Ind. 4.0 2017, 2, 307–311. [Google Scholar]

- Javaid, M.; Haleem, A.; Singh, R.P.; Haq, M.I.U.; Raina, A.; Suman, R. Industry 5.0: Potential applications in COVID-19. J. Ind. Integr. Manag. 2020, 5, 507–530. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0—A human-centric solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Gagnidze, I. Industry 4.0 and industry 5.0: Can clusters deal with the challenges?(A systemic approach). Kybernetes 2023, 52, 2270–2287. [Google Scholar] [CrossRef]

- Golovianko, M.; Terziyan, V.; Branytskyi, V.; Malyk, D. Industry 4.0 vs. Industry 5.0: Co-existence, Transition, or a Hybrid. Procedia Comput. Sci. 2023, 217, 102–113. [Google Scholar] [CrossRef]

- Aslam, F.; Aimin, W.; Li, M.; Ur Rehman, K. Innovation in the era of IoT and industry 5.0: Absolute innovation management (AIM) framework. Information 2020, 11, 124. [Google Scholar] [CrossRef]

- Lallée, S.; Pattacini, U.; Lemaignan, S.; Lenz, A.; Melhuish, C.; Natale, L.; Skachek, S.; Hamann, K.; Steinwender, J.; Sisbot, E.A. Towards a platform-independent cooperative human robot interaction system: III an architecture for learning and executing actions and shared plans. IEEE Trans. Auton. Ment. Dev. 2012, 4, 239–253. [Google Scholar] [CrossRef]

- Ugochukwu, N.A.; Goyal, S.; Arumugam, S. Blockchain-Based IoT-Enabled System for Secure and Efficient Logistics Management in the Era of IR 4.0. J. Nanomater. 2022, 2022, 7295395. [Google Scholar] [CrossRef]

- Aheleroff, S.; Huang, H.; Xu, X.; Zhong, R.Y. Toward sustainability and resilience with Industry 4.0 and Industry 5.0. Front. Manuf. Technol. 2022, 2, 951643. [Google Scholar] [CrossRef]

- Pratiwi, R.; Cakranegara, P.A.; Kamal, I.; Surahman, S. The Strategic Role of Islamic Law in Strengthening Entrepreneurial Character Education in The Era of The Industrial Revolution 5.0. J. Manaj. Bisnis 2022, 9, 234–241. [Google Scholar]

- Adel, A. Future of industry 5.0 in society: Human-centric solutions, challenges and prospective research areas. J. Cloud Comput. 2022, 11, 40. [Google Scholar] [CrossRef]

- Kasinathan, P.; Pugazhendhi, R.; Elavarasan, R.M.; Ramachandaramurthy, V.K.; Ramanathan, V.; Subramanian, S.; Kumar, S.; Nandhagopal, K.; Raghavan, R.R.V.; Rangasamy, S. Realization of Sustainable Development Goals with Disruptive Technologies by Integrating Industry 5.0, Society 5.0, Smart Cities and Villages. Sustainability 2022, 14, 15258. [Google Scholar] [CrossRef]

- Müller, J.J.E.C. Enabling Technologies for Industry 5.0; European Commission: Brussels, Belgium, 2020; pp. 8–10. [Google Scholar]

- Longo, F.; Padovano, A.; Umbrello, S.J.A.S. Value-oriented and ethical technology engineering in industry 5.0: A human-centric perspective for the design of the factory of the future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Mubarak, M.F.; Mubarik, M.; Rejeb, A.; Nilashi, M. Identifying industry 5.0 contributions to sustainable development: A strategy roadmap for delivering sustainability values. Sustain. Prod. Consum. 2022, 33, 716–737. [Google Scholar] [CrossRef]

- Chen, X.; Eder, M.A.; Shihavuddin, A.; Zheng, D. A human-cyber-physical system toward intelligent wind turbine operation and maintenance. Sustainability 2021, 13, 561. [Google Scholar] [CrossRef]

- Fazal, N.; Haleem, A.; Bahl, S.; Javaid, M.; Nandan, D. Digital Management Systems in Manufacturing Using Industry 5.0 Technologies. In Advancement in Materials, Manufacturing and Energy Engineering, Vol. II; Springer: Berlin/Heidelberg, Germany, 2022; pp. 221–234. [Google Scholar]

- Hanif, M.I.; Iftikhar, L. Post COVID-19 industrial revolution 5.0. The dawn of cobot, chipbot and curbot. Pak. J. Surg. 2020, 1, 122–126. [Google Scholar] [CrossRef]

- Saniuk, S.; Grabowska, S.; Grebski, W. Knowledge and Skills Development in the Context of the Fourth Industrial Revolution Technologies: Interviews of Experts from Pennsylvania State of the USA. Energies 2022, 15, 2677. [Google Scholar] [CrossRef]

- Margherita, E.G.; Braccini, A.M. Socio-technical perspectives in the Fourth Industrial Revolution-Analysing the three main visions: Industry 4.0, the socially sustainable factory of Operator 4.0 and Industry 5.0. In Proceedings of the 7th International Workshop on Socio-Technical Perspective in IS Development (STPIS 2021), Trento, Italy, 14–15 October 2021. [Google Scholar]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- Es-sebyty, H.; Igouzal, M.; Ferretti, E. Improving stability of an ecological 3D-printed house-a case study in Italy. J. Achiev. Mater. Manuf. Eng. 2022, 111, 18–25. [Google Scholar]

- Hu, Y.; Yang, S.; Yang, J.; Vincent, G.; Chen, X. Botanical gardens support urban sustainable development: A case study from the Shanghai Chenshan Botanical Garden. Biodivers. Sci. 2017, 25, 951. [Google Scholar] [CrossRef][Green Version]

| Sr.No | Case Study | IR 4.0 Incorporation | Improvement through IR 5.0 | Reference |

|---|---|---|---|---|

| 1 | Apis or 3D-Printed House in Russia A modern method of building is the integration of the IR 4.0 construction protocol into the Russian Apis or 3D-Printed House project. This protocol uses Industry 4.0 technologies to automate and optimize the building of homes, including 3D printing, IoT sensors, advanced robotics, and data analytics. The result is a building process that is more effective and economical, wastes less labor and materials, and offers more design flexibility. This protocol offers a substantial advance in modernizing the building sector and addressing housing difficulties with creative, sustainable solutions by merging digital design, real-time monitoring, and automated construction technologies. | 3D printing, IoT sensors, Advanced Robotics, and Data Analytics | Utilization of interactive products and hyper-customization could further enhance the construction process and customer experiences. | [101] |

| 2 | TECLA house construction in Italy The implementation of cutting-edge Industry 4.0 technology in the construction industry is demonstrated by the IR 4.0 construction protocol used on the TECLA house construction project in Italy. This project embodies efficiency and sustainability because it uses a distinctive 3D printing technique and materials that are acquired locally. Real-time monitoring using IoT sensors and data analytics ensures accuracy and quality control during the construction process. The TECLA project shows how cutting-edge robotics, automation, and digital design have the potential to revolutionize the building sector and make it possible to build eco-friendly, individualized, and affordable housing solutions that meet contemporary needs. | 3D printing and IoT sensors | With the incorporation of a responsive and distributive supply chain, resource efficacy can be improved. Moreover, through human–machine interactions, the creativity of humans and the efficiency of machines can further improve construction operations. | [102] |

| 3 | Shanghai Chenshan Botanical Garden in China Technology like IoT sensors for plant monitoring, data analytics for resource optimization, and automation for maintenance and guest services might all be used in a botanical garden to implement Industry 4.0 principles. | IoT sensors, Data Analytics, and Automation | Instead of completely employing machines, humans working with intelligent devices and robots should be adopted. It is about using cutting-edge technology like the Internet of Things (IoT) and big data to enable robots to assist people in working more effectively and quickly. | [103] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Musarat, M.A.; Irfan, M.; Alaloul, W.S.; Maqsoom, A.; Ghufran, M. A Review on the Way Forward in Construction through Industrial Revolution 5.0. Sustainability 2023, 15, 13862. https://doi.org/10.3390/su151813862

Musarat MA, Irfan M, Alaloul WS, Maqsoom A, Ghufran M. A Review on the Way Forward in Construction through Industrial Revolution 5.0. Sustainability. 2023; 15(18):13862. https://doi.org/10.3390/su151813862

Chicago/Turabian StyleMusarat, Muhammad Ali, Muhammad Irfan, Wesam Salah Alaloul, Ahsen Maqsoom, and Maria Ghufran. 2023. "A Review on the Way Forward in Construction through Industrial Revolution 5.0" Sustainability 15, no. 18: 13862. https://doi.org/10.3390/su151813862

APA StyleMusarat, M. A., Irfan, M., Alaloul, W. S., Maqsoom, A., & Ghufran, M. (2023). A Review on the Way Forward in Construction through Industrial Revolution 5.0. Sustainability, 15(18), 13862. https://doi.org/10.3390/su151813862