Abstract

In the strive for an environmentally conscious energy sector, a sustainable supply of natural gas necessitates comprehensive strategies that prioritise the prevention of gas leakages, ensuring minimal ecological harm while harnessing the benefits of this valuable resource. Though all sectors are putting their efforts into coping with the problems associated with the energy crisis, one of the many ways is to reduce distribution losses, particularly in the gas sector. The loss impacts include methane escaping to the environment to affect ozone, direct financial loss, non-availability of gas to the domestic, commercial, and industrial sectors, public safety hazards and indirect environmental impacts. There is a dire need to improve the natural gas distribution system, which has its own insight problems to be addressed. This work aims to investigate leakages in domestic, commercial and industrial gas distribution lines with different times, volumes and pressures using a pressure profiling technique. As a result of this investigation, around 293 million cubic feet (MMCF) of natural gas is saved, which is enough volume to feed approximately 16,000 domestic consumers for 365 days. The same energy content is equivalent to 21 million pounds of coal, which emits 64 million pounds of carbon dioxide, whereas natural gas would have 50% less CO2 emissions, and that is apart from the tangible pollution and waste associated with the use of coal.

1. Introduction

Growth in the population has led many minds to think about ways to use energy in the most expedient approach possible. Whether it was a century ago or now, humans have always needed some semblance of energy to cater for their needs in a variety of means. Among these exigencies, wood and coal have been employed as modes of power and energy from the very beginning [1]. Since there will always be a stipulation for energy, finding a power source large enough to meet those requirements is a difficulty. This energy source needs to be reliable, renewable, recurrent, and not a factor in climate change [2]. Furthermore, it holds greater value to responsibly manage existing natural resources such as natural gas while also enhancing these resources through additional pathways, like the biogas–biomethane cycle [3]. This approach strengthens the foundational resource base and propels the bioeconomy toward a more sustainable future [4].

More sources of energy were found by humans when development became institutionalised by modernism, and this led to major discoveries, which include oil, natural gas, nuclear energy, hydel power, wind, etc. The single largest human influence on climate is the use of fossil fuels. The world community has acknowledged the urgent need to address and reduce CO2 emissions from fuel combustion that enter the atmosphere over the last 20 years [5,6]. Amidst these fossil fuels, natural gas is the most immaculate. Since it is a hydrocarbon-rich gas, the high energy released from its combustion makes it very useful. Moreover, because it emits fewer gases that could harm the environment than other fossil fuels, it has become a major source of energy in this era [7]. In the near future, the global energy system is sought to shift from high- to low-carbon and then no-carbon future in the next two decades. In this regard, a four-country study demonstrates the necessity of including low-carbon fossil fuels in the discourse of energy transition to meet the sociological, political, and economic needs of the respective nations [8]. Therefore, natural gas plays a very strategic role in the energy system. Previously, its storage and transport were arduous in comparison to oil, and hence it lagged the ability to surpass. However, over the past few years, this has changed, and all market consumers have started using it as a major source of energy [9]. Today, a significant portion of the world’s energy mix comes from natural gas. In Pakistan, natural gas has an industrial role as a raw resource for the manufacturing of fertiliser, CO2 for drinks, and hydrogen from methane [10].

Studies report that natural gas has many benefits in the form of slowing down environmental concerns, protecting public health, saving the local environment, and improving quality of life when it is used for household, commercial and industrial purposes [11]. However, with every positive aspect of a certain phenomenon, there always remains a drawback. Where natural gas is the cleanest and safest fuel to use, it also has dangers associated in the form of cost effectiveness, transport safety, environmental hazards, gas loss, etc. Over the course of years, one of the most significant issues discovered in the management and control of natural gas is unaccounted gas loss, which has led to many innovative techniques to counter the damage and vulnerabilities of this problem [12]. Therefore, the use of natural gas in an efficient manner holds as much importance as ultimately using it in comparison to other fuels.

Like many other dangerous gasses, natural gas, which has the highest percentage in Pakistan’s energy mix, is also transported through pipelines, and Pakistan also follows the same trend [13]. Following the COVID-19 pandemic, the price of natural gas skyrocketed as the world hurriedly switched to using it in place of diesel for transportation and coal for energy generation. The procedure became more active as natural gas consumption rose [14]. Additionally, since there is a global attempt to terminate the use of coal, redirecting to alternative fuels and power sources has driven up the cost of energy. This increasingly important aspect emphasises the proportion of financial loss caused by gas volume losses in Pakistan’s distribution and transmission systems.

It is evident that Pakistan’s current economic condition, the loss of gas due to theft, leaks, or inefficient burning, will eventually result in lost income, health costs, and a deteriorating environment. Consequently, gas will become more exorbitant, and, as a result, more people will switch to cheaper fuels like coal and furnace oil. The usage of less expensive gasoline will result in an unpleasant work environment for millions of people [15]. In addition, environmental restraints like polluting ponds, rivers, etc., with solid liquid and dust waste from coal, oil, rubber, plastic, etc., have a negative impact on the ecosystem we live in. The effect of this on the air quality, cultivation, and crops has become more noticeable over the last decade [16]. Hence, leakage of natural gas should be reduced as much as possible to prevent any such damages caused by this process.

With global importunity for energy poised to increase by more than half in the next three decades, the supply of safe, definitive, and budgeted gas and oil continues to be of foundational importance to contemporary economies. Central to this dispensation are the pipelines that transport this energy. Pipeline transport is not only safe but also found to be the cheapest means of transport for fuels. However, pipeline damage that results in unintentional gas release has the potential to produce fire, explosion, and the spread of hazardous gas, all of which might have serious negative effects on society, the economy, and the environment.

Pipelines are frequently vulnerable to various problems, including those caused by the actions of third parties, corrosion, mechanical or material failure, and natural events. Leakage can result from a variety of factors, including internal friction, corrosion, and external mishaps (such as dealing with bulldozers, excavators, underground work, etc.). According to the report, failures brought on by corrosion and external interference are the main reasons for pipeline damage incidents. Events brought on by outside meddling are distinguished by potentially dire outcomes. The frequency of corrosion is almost identical to that of external interference, although the effects are significantly less severe [17]. An expansion wave enters the pipe when a hole is made on the surface, which causes the gas to flow toward the damaged area. Therefore, natural gas is squandered in significant amounts into the earth and the environment because of accidents, pipeline ruptures, and corrosion leaks in the pipeline [18].

Furthermore, timely and accurate gas pipeline leak detection is crucial to the entire management of the pipeline system’s integrity. The two primary concerns in this research are the location of the leakage detection and the estimation of the leakage amount. Natural gas pipeline leak detection and analysis have been studied to various degrees [19]. Various methods like acoustic leak detection have always been used in this regard [20]. Pipelines must be constantly monitored for leaks to reduce environmental, human health, safety, and societal hazards. The development of any leak detection system comes with many challenges, which hinder the process. These challenges encompass the need for real-time leak alerts, the attainment of necessary sensitivity to detect minor leaks, the precision in pinpointing leak locations, the prevention of false alarms, and the development of a cost-effective approach [21].

On the other hand, pipeline fluids are frequently hazardous, corrosive, and flammable media [22]. Therefore, pipeline leaking gravely contaminates the environment, causing economic loss of resources and products. As a result, managing pipeline safety and preventing accidents is necessary in all nations. When it comes to calculating leakage, numerous published books and manuscripts delve into the topic of viscous compressible flow within pipes, particularly focusing on scenarios involving two adiabatic and isothermal flow states [23]. The soundness of infrastructure systems providing power, natural gas, and potable water is an intrinsic part of societal readiness to unanticipated hazards [24]. Correcting pipeline leaks and damages also improves consumer protection and saves lives [25]. Significant strategies for recognizing gas spillage are uncovered in the open literature to prevent said circumstances [26].

Some studies [27] have suggested that the use of gas would be preferable over the use of oil from a climatic viewpoint. Burning natural gas produces less CO2 per unit, but its transport through pipelines renders more chances of methane emission, which is a much more potent greenhouse gas than carbon dioxide. In the short term, the impact of methane emissions on the environment is 25 times greater than that of CO2, as per US Environmental Protection Agency [28], whereas as per a report from the UN environment program, it is 80 times more potent to the global warming compared to CO2 for a period of 20 years [29]. However, a recent study suggests that switching from coal to gas would lessen climate change if the global average fractional leakage linked to natural gas production and distribution is below 4.3–5.7%. If the fractional gas loss is less than 2.4–2.9%, using gas would be better for the environment than oil [30].

Based on operational activities and inevitable gas escape during various necessary procedures, the permitted maximum of gas loss in the gas distribution system is 2% according to international regulations. The loss of a substantial amount of gas is a key aspect that can help in this situation because of the high rate of energy demand and rising clean fuel prices. Aside from economics, the system’s leaks endanger the environment by leaking into the soil and jeopardising fertility. Using the pressure profiling technique, this research made it possible to comprehend a nexus strategy for determining the elements causing gas loss in distribution systems. The study helped to identify the sources causing measurement errors which result in unexpected gas loss and locate system leaks by a pressure profiling technique.

2. Methodological Procedure

In this work, MiniElcor Elgas EVC (Electronic Volume Corrector) made by Elgas (model FTZU 08 ATEX 0324X) was used to store all the data relating to the gas pressure, corrected and uncorrected volume, temperature values, magnetic sensor alarm to detect any attempt to the theft of gas, fault volume in case of faulty pressure transducer or faulty temperature measurement. TELVES (version 4.2) software was used to secure the retrieval of data stored in the EVC. Different capacity gas meters ranging from 200 cft/hr to 7000 cft/hr were used to measure the gas flow volume. Geographical information system ‘QGIS’ (version 3.10) was used to analyse geospatial information of gas consumers, which is used to correct the area codes that result in accurate reconciliation of gas volume supplied to different areas. An underground gas detection device INSPECTRA (made by GAZOMAT) was used for the detection of underground gas leakage.

The first step in the research was the collection of relevant data that includes the information of all consumers, metering installations, and data stored in the available EVCs installed in the field. In the second stage, the analysis of data was carried out, which resulted in the identification of under-measurements regarding wrong/less pressure factor application to a large number of domestic consumers. The application of the pressure factor was started by inspecting the pressures of domestic consumers at peak times. Peak time was selected since higher pressure is supplied during peak consumption times to facilitate consumers. Since planning based on inaccurate data cannot produce target results, various anomalies regarding the wrong punching of gas volume of a large number of consumers were corrected, and it resulted in an accurate reconciliation of gas volume. Figure S1 in Supplementary Information can be consulted for the details of these methodological steps.

QGIS application was used for this activity to correctly geocode all consumers based on physical locations. It was also used for the identification of low-pressure pockets of domestic consumers. The Pareto principle (80-20 rule) was implemented, which identified a 20% area that had a loss of 80% even after pressure factor application. It resulted in identifying 8 areas where the loss ranged from 20% to 35%. In addition, the anomalies identified during the research regarding low pressure at the tail ends of the network and that regarding high loss lead to a high percentage of leakage in the underground network. At this stage, the analysis of the previously performed survey was carried out to identify any anomaly. This discovered the wrong practice of ignoring leakages by not tracing down the source of leakage. Since the UGLD equipment identifies the presence of methane percentage, only exposing the pointed areas does not always serve the purpose. This practice of pressure profiling, as a whole, identified a high rate of leakages in the pipeline network of different sizes ranging from 1-inch to 6-inch diameter pipelines.

Pakistan’s economy is still in development; hence, it cannot afford any form of monetary loss. Gas acquired from sources is delivered to cities via high-pressure transmission pipelines, where its pressure is controlled, and measurements are made prior to its provision to distribution systems. In Pakistan, burning or processing natural gas provides more than 50% (including domestic and imported gas) of the country’s energy needs. In the distribution system, gas is transported to domestic, commercial and industrial consumers through various regulating and measuring stations called town border stations (TBS) and district regulatory stations (DRS). Purchased gas is not always equivalent to sold gas; some of the volume stays in the system as pack volume, and the remainder is available for sale. A portion of the gas volume is used by the transportation system for operational purposes.

Unaccounted-for gas is the discrepancy between the volume of gas billed to each downstream consumer’s individual meter and the volume of gas that flows through the custody point measurement station [31]. The operating activities include the compression process, pigging, purging, and valve assembly operations. Nearly 4.5% of the gas volume purchased may be used as unaccounted-for gas (UFG) compensation. The volume lost in the system above 4.5% is not acknowledged for compensation, and its financial equivalence is taken as a direct loss. The main causes of UFG include gas theft, pipeline ruptures, and measurement errors in the equipment that is already in place [32].

The gap between the amount of gas that is now available for purchase and the amount of gas that is sold can reach 8 to 10%, which is close to five times the 2% international standard. Stakeholders have argued for raising the cap considering the local conditions, which are exceptional in Pakistan’s instance. The new baseline is set at 5%, with an additional 2.6% contingent on KMI (key monitoring indicators) [33]. The system’s political influence, consumer gas theft, unauthorised load enhancement, unauthorised increase in delivery pressure for fixed factor billing customers, under-sizing of meters due to excessive overloading, the vulnerability of transmission system/infrastructure to terrorism, etc., are some of the bases for various ground realities. Above all these variables, the system’s leaks are significant enough, which can be deduced from the fact that gas loss from a hole in a natural gas pipeline measuring 0.8 mm in diameter is about tripled with rising pressure from 1 psig to 30 psig [34].

There are leakages in gas distribution infrastructure mainly due to the ageing factor of the network—the presence of old iron pipes with outdated coating materials resulting in leakages round the clock. These pipeline networks are typically exposed to electromagnetic fields of electric poles, damaged coatings, and materials with incredibly low coefficients of resistance. Three main types of damage are caused by the leaks. Leakages result in a significant loss to the national exchequer in direct economic terms. Leakages are growing in underground sewerage lines, etc., and they are exceedingly dangerous as the cause of fire accidents that result in fatalities [35]. About 80% of pipeline accidents occur because of several types of corrosion, including general corrosion, corrosion cracking under discarded coating, point corrosion, and corrosion cracking under stress [36]. Underground leaks destroy the soil in which they are present, directly harming the trees and plants.

As of now, control activities are carried out to cater to increased trends in gas loss, such as vigilance/inspections of all consumers in regular intervals, inspection of underground network for identification of leakages, above-ground leakage identification and rectification from consumer installation and operational installations, theft control by inspections of disconnected consumers from time to time. It also includes the removal of the abundant service lines of old disconnected consumers. Low pressure generally accumulates in lowering the billed volume of all categories of consumers. Low pressure, however, contributes to existing leakages in the system in proportion to the volume consumed by consumers during peak times.

Following the suggested activities for the past few years, the gas loss still needs to be up to the new flexible limits allowed by the concerned regulator. Despite all remedies, there is still a loss in gas volume. This means there is a need to apply a new strategy after investigation and analysis of the existing system. Taking the subject area of study as Nowshera Virkan, the loss is up to 11% of the total volumetric loss. This research primarily focuses on the work path to improve the efficiency of the distribution network of distribution systems in the SNGPL area (Nowshera Virkan, Gujranwala), with 24,000 domestic consumers fed through 40 regulating stations. The pattern of gas consumption in the summer season is mainly in the industrial sector, whereas domestic consumption increases as the winter season approaches due to space heating and water heating. The area selected for the research activity is the part of Region Gujranwala, which has an isolated distribution and transmission system. The Nowshera Virkan area accumulates 99% as domestic consumers, a few commercial and special domestic consumers and only three industrial consumers.

3. Results and Analysis

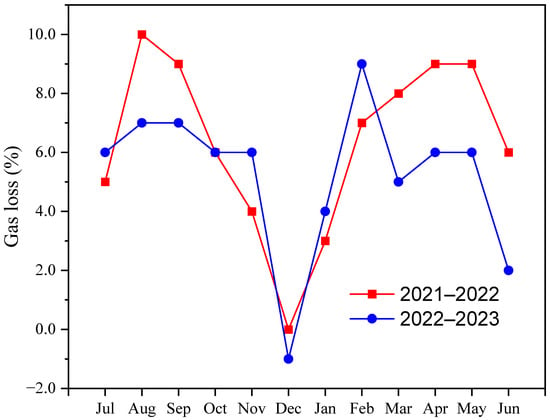

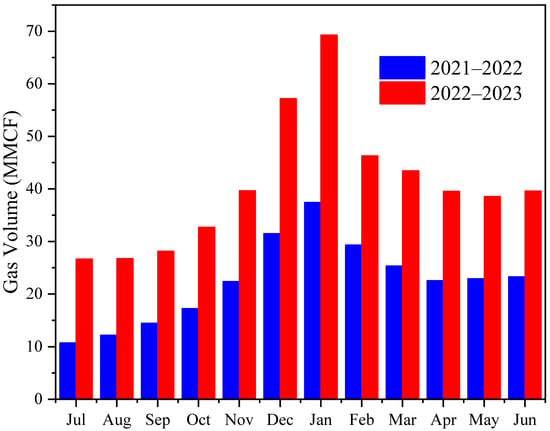

Figure 1 shows the percentage loss of natural gas in the Gujranwala region for the fiscal years 2022 and 2023. However, the volumetric loss of Nowshera Virkan was 17%, which is higher than the overall loss of the region. Table S1 in the Supplementary Information file shows the unaccounted-for gas (UFG) of the Gujranwala region with respect to gas loss. The Gujranwala region is performing better in comparison to other regions in terms of gas volumetric loss control. Still, the annual volumetric loss of the region is 1.4 BCF. The findings of the research work conducted in Nowshera Virkan (a sub-urban part of Gujranwala) were implemented in other parts of the region to the extent of convenient applicability to minimise the loss.

Figure 1.

Gas volume loss for Gujranwala region for fiscal years 2021–2022 and 2022–2023.

Figure 1 shows the percentage loss is high in the summer seasons as the overall gas volume consumed and billed dropped down to 1481 MMCF in the month of June 2022 from high consumption in winter with a maximum of 2523 MMCF in January 2022 (Table S1 in Supplementary Information). Billed volume in the winter season increases in the domestic sector due to freezing weather. The consumption drop in the summer months is more likely to influence the leakage factor to contribute to the volumetric loss. It is clear that the trend of loss in the summer months is as high as 9.7% in the month of 2020 and least in the winter month of December 2021 at 0.2%.

One more factor of weekly pricing of RLNG in the industrial sector influences the volume billed. Higher price negatively affects the sale volume, reducing the billed volume. The available pack volume becomes more vulnerable to leakage in the system.

Furthermore, the clarity that the above data illustrates is that loss in the volume of gas is decreasing in the winter season and increases in the summer. This fact demonstrates that the gas network system has serious leakages that need to be identified and rectified. Had there been no leakages in the system? Ideally, the above trend would not have reflected the increasing trend of UFG in summer months and the decreasing trend of UFG in winter months when the demand for gas remains high compared to the supply; therefore, the gas leakage is overcome by consumption by domestic consumers. Also, the gas consumption in the winter season is primarily by domestic consumers, as the priority set by GOP is for the domestic sector, before the industrial sector.

Therefore, there is a high chance that due to high domestic demand with low-volume supply, the industrial sector is deprived of gas supply in the winter months. The CNG sector remains closed during winter months, with only supply to special export-oriented businesses.

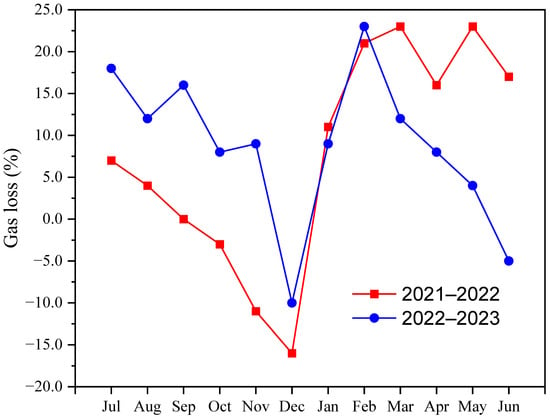

Figure 2 shows the percentage gas loss in the sub-urban area of Nowshera Virkan, with 24,000 domestic consumers, 20 commercial and special domestic and three industrial consumers. The research activities were thoroughly implemented in this area. Additionally, the outcome of activities could be implemented in other parts of the Gujranwala Region to enhance the measurement accuracy. The comparison of volumetric loss in Nowshera Virkan in 2021–2022 and 2022–2023 is given in Table S2 in the Supplementary Information file for more details.

Figure 2.

Percentage gas loss of SMS Nowshera Virkan for fiscal years 2021–2022 and 2022–2023.

A significant reduction in the gas loss in Nowshera Virkan can be observed as presented in Figure 2. As a result of pressure profiling activity in Nowshera Virkan, out of 24,000 domestic consumers, 1400 m were identified, which were causing problematic measurements. These meters were identified by analysing the billing pattern and on-site flow, proven by calculating the running load by the movement of the meter index in unit time. A domestic single stove consumes 10 CFH at 8 inches of W.C. pressure. An accurate meter takes 129 s to pass a 10 dm3 volume at a 0.29 psig pressure. If a meter takes more time than 129 s, it means the meter is slow, causing under-measurement. It is generally only possible to inspect some 24,000 domestic meters, for instance. Therefore, a data analysis technique is applied to identify potential meters which can be physically inspected on site. An average household should consume a 0.42 HM3 volume, which is equivalent to having a single stove run for 5 h at different times in 24 h. Different areas can have different rates of consumption depending upon the economic condition of the households. Therefore, consumers were identified where the monthly gas consumption of individual consumers was less than 0.42 HM3 in summer or the consumption of any consumer was less than the average monthly consumption of other consumers in the same neighbourhood. The number of different measurement-related anomalies is shown in Table 1.

Table 1.

The anomalies found during the inspection of domestic gas meters installed under SMS Nowshera Virkan.

There were 105 m found in DR (does not register gas). During the inspection, these meters do not register gas when a load of up to 20% of meter capacity is run through the meter. Beyond this load, the meter was working, yet registering gas on the minus side. These flows are usually not sizable enough to be accurately assessed visually. These meters were sent to DMIS (domestic meter inspection shop) to quantify the under-measurement.

Table 1 shows that there were 4510 leakages during the activity performed, and pressure enhancements of 15,070 were found during peak hours of consumption of domestic consumers. The ADP was updated in the database, enabling to generate next bills as per the corrected volume by applying the correct pressure factor thereof. During the activity, 142 m were found, which were tested on various flow rates. The results came out to be negative at low flow rates of up to 20 CFH. Since the maximum consumption pattern by consumers is between 5 CFH and 30 CFH, which is up to 20% of meter rated capacity of domestic meters (mostly 6 m3 per hour), the minus-recorded meters were not registering gas at actual flow rates by consumers which were resulting in under-measurement and under-billing. A case-wise inspection will be conducted to further establish the volume consumed by the consumer, and it will be recovered accordingly.

There are two categories of consumer billing processes. One is fixed factor billing, and the other is real-time correction factor billing. Other than domestic consumers, they are provided with an EVC (electronic volume corrector). In fixed factor billing, the gas connection is provided with a gas regulator with fixed downstream pressure. In case the gas pressure is increased from the regulator at the site, it causes under-measurement unless it is not corrected in the billing system. Generally, consumers attempt to alter the pressure setting of regulators to secure an unregistered volume of gas to reduce gas bills.

Here is the sample-based analysis of the difference in delivery pressure downstream of domestic consumers. The peak time for domestic consumers is from 07:00 to 10:00 hours for urban areas and from 05:00 to 08:00 hours for rural areas. Therefore, analysis for a sample-based study was performed to establish the volumetric difference that is involved in the application of pressure based on peak and off-peak time.

In light of the above demonstration in Table 2, it can be seen that it holds significance to measure the ADP of domestic consumers to achieve accurate billing. The work was carried out for 15,000 consumers in a similar pattern to secure unregistered volumes of gas. The activity of application of actual delivery pressure as per actual site conditions is measured over a continuous activity in the region, and the impact and comparison with the preceding year are presented in Figure 3.

Table 2.

Gas pressure measured in peak and off-peak hours in the Gujranwala region out of 8 million consumers for the period of 30 days.

Figure 3.

Volumetric gain by measuring ADP during peak hours.

Figure 3 shows a comparison of the impact of actual delivery pressure before and after analytical outcomes for prioritising the inspections of domestic consumers based on high-percentage loss areas with a low percentage of underground leakages, healthy pressure availability in peak hours, and high per-consumer average of consumers. The graph shows a phenomenal increase in the impact of the application of pressure factors on consumers while applying an analytical approach.

3.1. Idle Night Flows

Ideally, if the closed system of the pipeline is leak-free, it should pack at the set pressure from the supply point, particularly at a time when any consumer is not consuming gas. At the point when the network is packed at a set pressure, the flows from the supply station become zero. EVC data analysis of consumption patterns of different localities revealed that there are idle flows up to 1500 CFH that extend during night hours from 22:00 to 06:00 hours on a daily basis. Theoretically evaluating the schematic gas pressure and volume supply of a housing society with 1000 consumers, it can be concluded that a 1500 CFH flow is abnormally high. This indicates that there is a leakage in the system that is continued round the clock, which is not permitting the system be packed at a set pressure. For a healthy network with no leakages, the system would pack at the set pressure, and flows would become zero after meeting the requirement. These sample data are taken for summer months to eliminate the use of water heaters and space heating, which are normally required in winter months only.

3.2. Inadequate Set Pressure

Pressure available at different service points, including the tail ends across the network of a closed locality, was measured at different times of the day for analysis. The pressure trend indicated the inadequacy of set pressure in comparison to the demand at peak hours. Pressure at the tail ends was close to zero in peak time. During peak time, when most of the consumers are using gas, the flow rises to 8000 CFH. This is the time when inadequate pressure faced by consumers at the tail ends results in non-consumption by those consumers. This factor reduces the consumed volume of gas at a particular time when it is needed. This case was resolved by applying the pressure profiling technique as an example. Before identification and rectification of leakages in the underground network and above-ground installations, peak pressure was set at 5 psig on a daily basis twice a day In morning and evening peak times. For the rest of the time, a 1 psig pressure was set to reduce the number of leakages in the system, as leakages are directly proportional to increase in pressure. Consequent to the leakage identification and rectification, the profiling activity was stopped after confirmation of the system packs at a set pressure with no volume loss in the network.

3.3. Different Peak/Off-Peak Times

It is important to identify the peak time of a particular area before setting downstream pressure for any locality. This can be achieved by analysing the pattern of gas consumption. The urbanised area has different times of gas requirements than rural and sub-urban areas. It was established from the data of consumption that gas consumed in 12 h of the day from 10:00 through 21:00 hours at night is 70% of the total gas passing through the Town border station. The remaining 30% of gas passing through the TBS designate these hours as off-peak hours.

The idle flows from 21:00 to 09:00 hours are uniform and consistent on an everyday basis. The consumption of peak hours is almost 70% of total consumption, while 30% of the flow passes through TBS from 21:00 to 09:00 hours. Also, the consumption trend reveals the proportional increase in the flow resulting in flows of peak as well as off-peak hours, and the increasing trend is also similar. This shows that there is an additional load added on the network, which is the use of gas around the clock. As per historic observations, leakages in the system exhibit such trends. Therefore, a thorough survey resulted in the identification of two main issues, including a bogus line which was found connected to the live network where the end cap was not installed from where the gas leakage started, and the gas pipeline which was found damaged during construction work, not reported by the third party involved. Consequent to the analysis of data on gas consumption, the following observations were drawn.

At present, in circumstances where it is generally not possible to depute all resources on a single area, a thorough analysis is necessary to identify the area where further equipment should be used to save cost. Therefore, before deploying UGLD equipment for the identification of underground leakages in the area, the area-wise gas reconciliation was analysed. This activity helped identify 104 leakages which had no sign from above the ground.

Above-ground leakage activity was carried out in the time just after the peak time of morning consumption. It was observed that there was no leakage in the above-ground CMS installations. However, several gas regulators were found leaking from their safety vent valves. This matter was urgently investigated to reveal that most consumers were facing low-pressure issues during the peak time of use of gas. Therefore, they self-managed to adjust regulators to their limits. Subsequently, right after the peak time passed, the upstream high pressure started leaking the excess pressure from the regulator body when consumers stopped using gas. This phenomenon was identified due to the pressure supply to the locality. The flow of 13 MCF/h was observed passing through the check meter at the TBS. This high flow at relatively low pressure indicated that downstream consumption potential is high, and in order to counter low-pressure issues, consumers adjusted their gas regulator on their own, which caused regulators to overflow when upstream pressure started increasing right after the peak hour. To rectify this problem, all overflowing regulators were replaced with new ones, and a variable pressure setting was applied at the TBS in accordance with the requirement of gas by consumers. This type of leakage cannot be assessed routinely. A major contribution was made by increasing the billed volume of consumers, reducing the leakage content, and resolving low pressure issues.

Pressure drop with the volumetric flows at different offtakes along the supply main line was studied, and the real-time analysis helped in identifying a segment of 2 km where UGLD activity identified a corroded area of the pipe. The MS 6-inch Dia pipeline was replaced in a rehabilitation program. This helped in reducing the volumetric flow of the SMS Nowshera Virkan by keeping the optimum pressure supply.

There were a few measuring gadgets identified which were needed to register gas properly. The meter of M/S Master tiles and ceramics stopped applying correction factors against pressure and temperature and the corrected volume seized to increment accordingly. The meter was replaced, and the consumed volume was assessed based on the pressure trend uncorrected volume measured by the meter. The volume was charged to the consumer and recovered.

The cathodic protection status of the network was compared with the area that was newly commissioned with healthy protection status. It was seen that the cathodic protection of certain areas was highlighted as low despite the amount of current drawn from the TR unit being adequate till its upper safe limits. The intensity of the current was tracked down from different points of service lines in the area. A certain area was highlighted where test pits were arranged for further inspection of the coating condition, which was found damaged at intervals with pitting on the pipeline surface. The area was recommended for rehabilitation of the old network with 6-inch and 2-inch diameters.

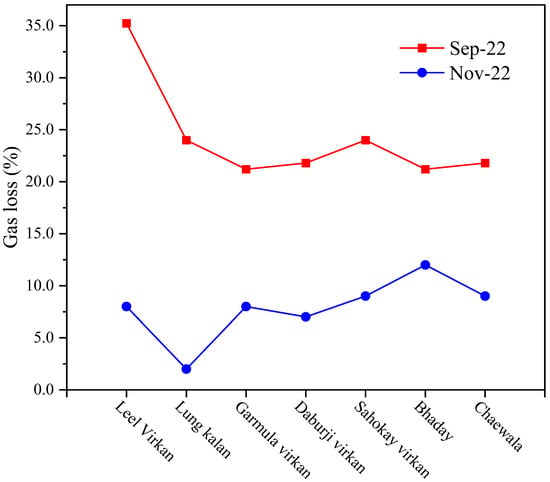

In the areas of Nowshera Virkan, which were identified with higher loss in comparison to other areas, corrective research activities were performed. The results are presented in Figure 4, and the corresponding volumetric data are presented in Table S3 in the Supplementary Information file.

Figure 4.

Comparative percentage gas loss at various town border stations (TBS) of Nowshera Virkan for September and November 2022.

Figure 4 shows the results of volumetric gas loss in segmented areas of Nowshera Virkan before and after the pressure profiling study. The theoretical outcome of above-ground leakage rectification, vigilance, measurement errors, and pressure factor application revealed the existence of high-volume leakage in the system. Therefore, scanning for leakage was performed here as a priority, and leakages were identified as shown in Figure 5.

Figure 5.

Underground gas leakage detections at (a) a 4-inch polyethylene main line with a 2-inch offtake line, (b) a 1.25-inch polyethylene feeder main line with two visible cuts, (c) a 4-inch mild steel pipeline, and (d) a 2-inch polyethylene line damaged by excavation activity.

There were 350 leakages identified around 24,000 consumers who were drawing gas from SMS Nowshera Virkan; the previous number of leakages identified was only 24. It was very important to continue to apply the analytical pressure profiling approach, which is a non-destructive technique to ascertain the existence of the leakage in the system so that timely UGLD activity could be performed to save time and gas; otherwise, in the general schedule, an area scanned today will need be rescanned after the period of 3 years, and any newly generated leakage, regardless of the volume involved, has a greater chance to continue happening for a minimum period of 3 years.

4. Conclusions

This work applied a different analytical approach to identify and rectify the hidden gas leakage problems associated with the customary practices to reduce loss. The application of the pressure profiling technique resulted in the identification of leakages in a 6-inch-diameter mild steel pipeline and the corroded section of a 6-inch-diameter pipeline that needed rehabilitation of the network. The pressure profiling activity helped manage the supply of variable pressure at different times of the day to meet the requirement in a more precise manner and to reduce the potential loss through leakages, ensuring healthy pressure supply to tail-end areas which are typically not able to have gas even in the summer season when the domestic requirement is comparatively lower. The selected location had all types of domestic commercial and industrial consumers with urban as well as rural consumers with varying demands for gas at different times, volume, and pressure. This activity helped reduce the volumetric loss of 293 MMCF, which is enough gas to feed 16,000 domestic consumers for 365 days a year. The same energy content is equivalent to 21 million pounds of coal, which emits 64 million pounds of carbon dioxide, whereas natural gas emits 32 million pounds of carbon dioxide. The difference is precisely 50%, and that is not including the tangible pollution and waste associated with coal use. The hazardous effects of these leakages and their rectification through other methods can also be researched in decades to come.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su151813604/s1, Figure S1: Methodological procedure; Table S1: Gas volume passed through sales meter station (SMS) and billed volume through consumer meter station (CMS) for 13 isolated SMS supply gas to different areas; Table S2: Nowshera Virkan SMS volume passed through SMS vs Volume passed Through CMS (2021–2022, 2022–2023); Table S3: Gas loss of the shortlisted areas of Nowshera Virkan in the months of September and November, 2022.

Author Contributions

T.J.B.: data analysis, resources, methodology, writing—original draft; M.A. (Muhammad Amjad): conceptualisation, methodology, data analysis, writing, investigation; S.F.R.: resources, review and editing, methodology; F.R.: data analysis and curation, review and editing; S.A.: resources, data curation, review and editing; and M.A. (Mali Abdollahian): methodology, data analysis, writing, and investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This research received funding from King Saud University through the Researchers Supporting Project, number RSP2023R387, King Saud University, Riyadh, Saudi Arabia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article or supplementary material.

Acknowledgments

The authors extend their appreciation to King Saud University for funding this work through the Researchers Supporting Project, number RSP2023R387, King Saud University, Riyadh, Saudi Arabia.

Conflicts of Interest

The authors have no conflict of interest.

References

- Englezos, P.; Lee, J.D. Gas hydrates: A cleaner source of energy and opportunity for innovative technologies. Korean J. Chem. Eng. 2005, 22, 671–681. [Google Scholar] [CrossRef]

- Datta, A.; Hossain, A.; Roy, S. An overview on biofuels and their advantages and disadvantages. Asian J. Chem. 2019, 31, 1851–1858. [Google Scholar] [CrossRef]

- D’Adamo, I.; Gastaldi, M.; Morone, P.; Rosa, P.; Sassanelli, C.; Settembre-Blundo, D.; Shen, Y. Bioeconomy of Sustainability: Drivers, Opportunities and Policy Implications. Sustainability 2022, 14, 200. [Google Scholar] [CrossRef]

- Gawel, E.; Pannicke, N.; Hagemann, N. A Path Transition Towards a Bioeconomy—The Crucial Role of Sustainability. Sustainability 2019, 11, 3005. [Google Scholar] [CrossRef]

- Perera, F. Pollution from fossil-fuel combustion is the leading environmental threat to global pediatric health and equity: Solutions exist. Int. J. Environ. Res. Public Health 2018, 15, 16. [Google Scholar] [CrossRef] [PubMed]

- Bashir, Z.; Amjad, M.; Raza, S.F.; Ahmad, S.; Abdollahian, M.; Farooq, M. Investigating the Impact of Shifting the Brick Kiln Industry from Conventional to Zigzag Technology for a Sustainable Environment. Sustainability 2023, 15, 8291. [Google Scholar] [CrossRef]

- Faramawy, S.; Zaki, T.; Sakr, A.A.E. Natural gas origin, composition, and processing: A review. J. Nat. Gas Sci. Eng. 2016, 34, 34–54. [Google Scholar] [CrossRef]

- Safari, A.; Das, N.; Langhelle, O.; Roy, J.; Assadi, M. Natural gas: A transition fuel for sustainable energy system transformation? Energy Sci. Eng. 2019, 7, 1075–1094. [Google Scholar] [CrossRef]

- Economides, M.J.; Wood, D.A. The state of natural gas. J. Nat. Gas Sci. Eng. 2009, 1, 1–13. [Google Scholar] [CrossRef]

- Shahbaz, M.; Lean, H.H.; Farooq, A. Natural gas consumption and economic growth in Pakistan. Renew. Sustain. Energy Rev. 2013, 18, 87–94. [Google Scholar] [CrossRef]

- Zhang, X.; Myhrvold, N.P.; Hausfather, Z.; Caldeira, K. Climate benefits of natural gas as a bridge fuel and potential delay of near-zero energy systems. Appl. Energy 2016, 167, 317–322. [Google Scholar] [CrossRef]

- Arpino, F.; Dell’Isola, M.; Ficco, G.; Vigo, P. Unaccounted for gas in natural gas transmission networks: Prediction model and analysis of the solutions. J. Nat. Gas Sci. Eng. 2014, 17, 58–70. [Google Scholar] [CrossRef]

- Parvini, M.; Gharagouzlou, E. Gas leakage consequence modeling for buried gas pipelines. J. Loss Prev. Process Ind. 2015, 37, 110–118. [Google Scholar] [CrossRef]

- Farooqui, S.Z. Prospects of renewables penetration in the energy mix of Pakistan. Renew. Sustain. Energy Rev. 2014, 29, 693–700. [Google Scholar] [CrossRef]

- Shafiq, M.; Nisar, W.B.; Savino, M.M.; Rashid, Z.; Ahmad, Z. Monitoring and controlling of unaccounted for gas (UFG) in distribution networks: A case study of Sui Northern Gas Pipelines Limited Pakistan. IFAC-PapersOnLine 2018, 51, 253–258. [Google Scholar] [CrossRef]

- Bach, W. Fossil fuel resources and their impacts on environment and climate. Int. J. Hydrogen Energy 1981, 6, 185–201. [Google Scholar] [CrossRef]

- Zhang, Y.; Weng, W.G. Bayesian network model for buried gas pipeline failure analysis caused by corrosion and external interference. Reliab. Eng. Syst. Saf. 2020, 203, 107089. [Google Scholar] [CrossRef]

- Buerck, J.; Roth, S.; Kraemer, K.; Mathieu, H. OTDR fiber-optical chemical sensor system for detection and location of hydrocarbon leakage. J. Hazard. Mater. 2003, 102, 13–28. [Google Scholar] [CrossRef]

- Batzias, F.A.; Siontorou, C.G.; Spanidis, P.M.P. Designing a reliable leak bio-detection system for natural gas pipelines. J. Hazard. Mater. 2011, 186, 35–58. [Google Scholar] [CrossRef]

- Meng, L.; Yuxing, L.; Wuchang, W.; Juntao, F. Experimental study on leak detection and location for gas pipeline based on acoustic method. J. Loss Prev. Process Ind. 2012, 25, 90–102. [Google Scholar] [CrossRef]

- Murvay, P.-S.; Silea, I. A survey on gas leak detection and localisation techniques. J. Loss Prev. Process Ind. 2012, 25, 966–973. [Google Scholar] [CrossRef]

- Zhou, M.; Zhang, Q.; Liu, Y.; Sun, X.; Cai, Y.; Pan, H. An integration method using Kernel Principal component analysis and cascade support vector data description for pipeline leak detection with multiple operating modes. Processes 2019, 7, 648. [Google Scholar] [CrossRef]

- Levenspeil, O. Engineering Flow and Heat Exchange; Plenum Press: New York, NY, USA, 1984. [Google Scholar]

- Cimellaro, G.P.; Villa, O.; Bruneau, M. Resilience-Based Design of Natural Gas Distribution Networks. J. Infrastruct. Syst. 2015, 21, 05014005. [Google Scholar] [CrossRef]

- Jackson, R.B.; Down, A.; Phillips, N.G.; Ackley, R.C.; Cook, C.W.; Plata, D.L.; Zhao, K. Natural gas pipeline leaks across Washington, DC. Environ. Sci. Technol. 2014, 48, 2051–2058. [Google Scholar] [CrossRef] [PubMed]

- Mandal, P.C. Gas Leak Detection in Pipelines & Repairing System of Titas Gas. J. Appl. Eng. 2014, 2, 23–34. [Google Scholar]

- Lelieveld, J.; Crutzen, P.P.J.; Bruhl, C. Climate Effects of Atmospheric Methane; Max-Planck-Institute for Chemistry, Airchemistry Division: Mainz, Germany, 1993. [Google Scholar]

- United States Environment Protection Agency. Importance of Methane, US EPA. Available online: https://www.epa.gov/gmi/importance-methane. (accessed on 26 August 2023).

- Environment, U. Global Methane Assessment: Benefits and Costs of Mitigating Methane Emissions, UNEP. Available online: https://www.unep.org/resources/report/global-methane-assessment-benefits-and-costs-mitigating-methane-emissions (accessed on 26 August 2023).

- Lelieveld, J.; Lechtenböhmer, S.; Assonov, S.S.; Brenninkmeijer, C.A.; Dienst, C.; Fischedick, M.; Hanke, T. Low methane leakage from gas pipelines. Nature 2005, 434, 841–842. [Google Scholar] [CrossRef] [PubMed]

- Masood, A. Pakistan’s gas crisis due to gas theft&unaccounted for gas (UFG). Int. J. Renew. Energy Technol. Res. 2013, 2, 53–58. [Google Scholar]

- Khan, F.; Khan, A.; Khan, A.; Khan, M.N.; Sadiq, M.; Akhtar, K.; Shah, S.A.; Shah, F. The role of Earth Cover and Compaction Level on the Natural Gas Leakage rate from micro holes in an underground pipeline. J. Pak. Inst. Chem. Eng. 2017, 45, 144–149. Available online: https://www.piche.org.pk/journal (accessed on 26 August 2023).

- Mughal, S.; Zulfikar, S.; Bhutto, A. Corporate Social Disclosure: A Case Study on Petroleum Industry of Pakistan. 2014. Available online: www.iiste.org (accessed on 26 August 2023).

- Wang, X.; Tan, Y.; Zhang, T.; Xiao, R.; Yu, K.; Zhang, J. Numerical study on the diffusion process of pinhole leakage of natural gas from underground pipelines to the soil. J. Nat. Gas Sci. Eng. 2021, 87, 103792. [Google Scholar] [CrossRef]

- Zhang, T.; Qin, Y.; Han, D.; Luo, Z.; Tan, Y. Numerical investigation on the leaked nature gas diffusion of underground gas pipeline through soil to atmosphere. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 804. [Google Scholar] [CrossRef]

- Timmer, R.P.; Lamb, P.J. Relations between temperature and residential natural gas consumption in the Central and Eastern United States. J. Appl. Meteorol. Climatol. 2007, 46, 1993–2013. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).