Physical-Mechanical Properties of Light Bark Boards Bound with Casein Adhesives

Abstract

:1. Introduction

2. Materials and Methods

3. Results

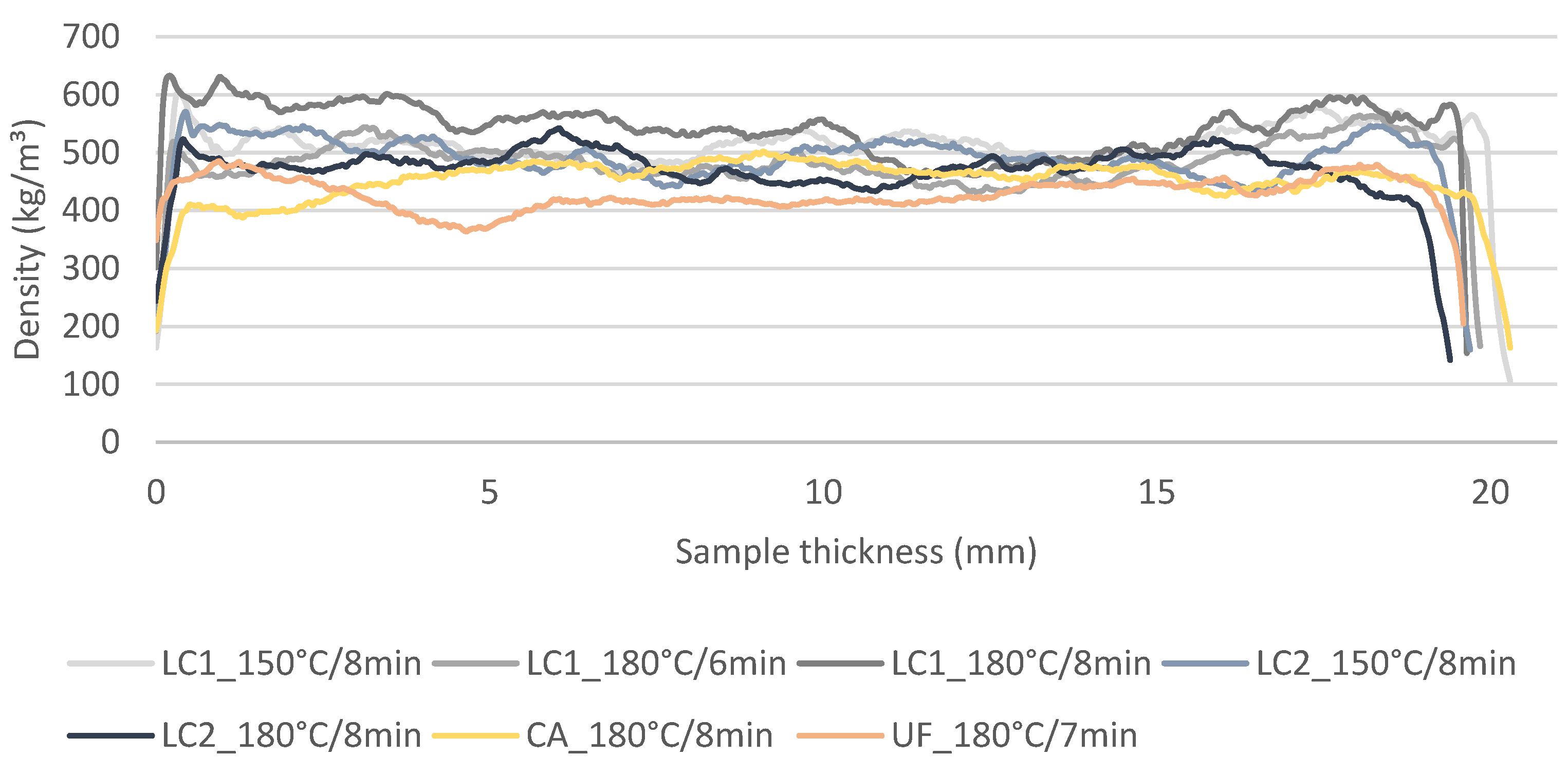

3.1. Panel Density

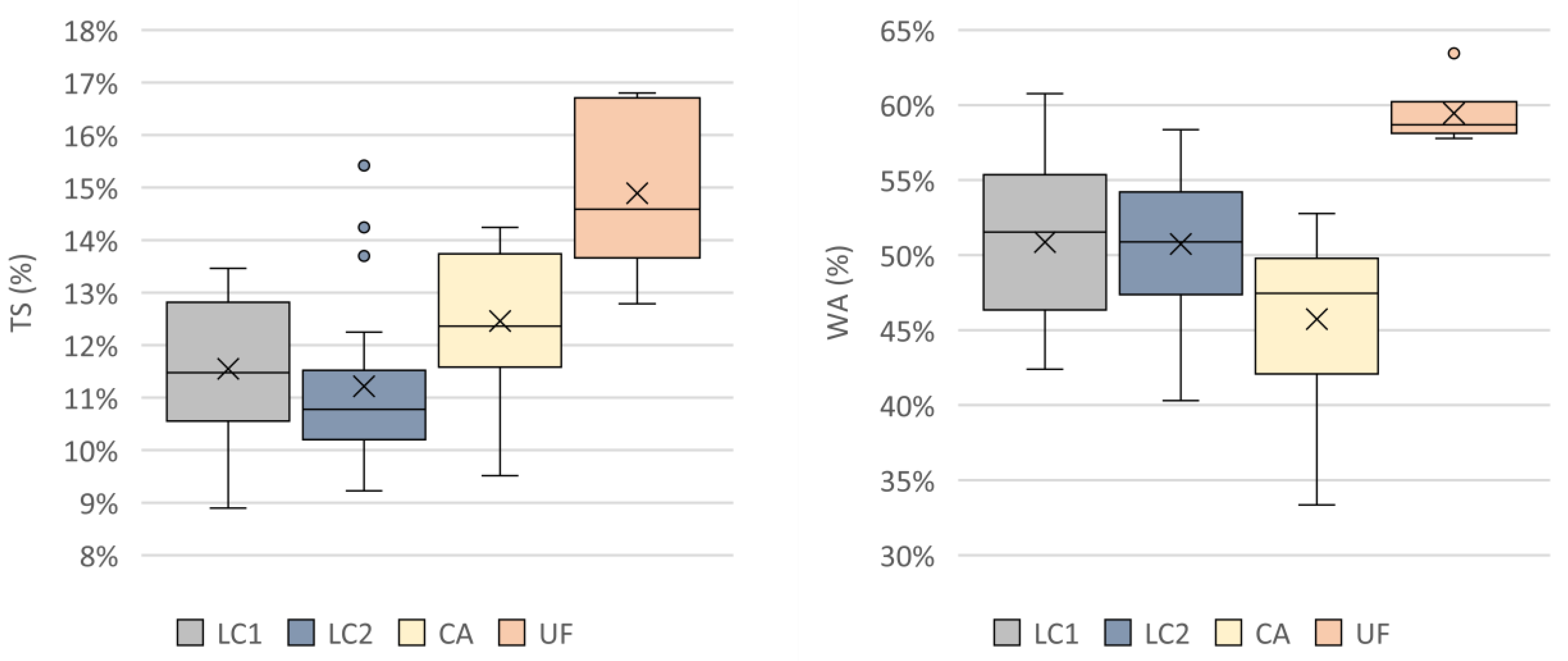

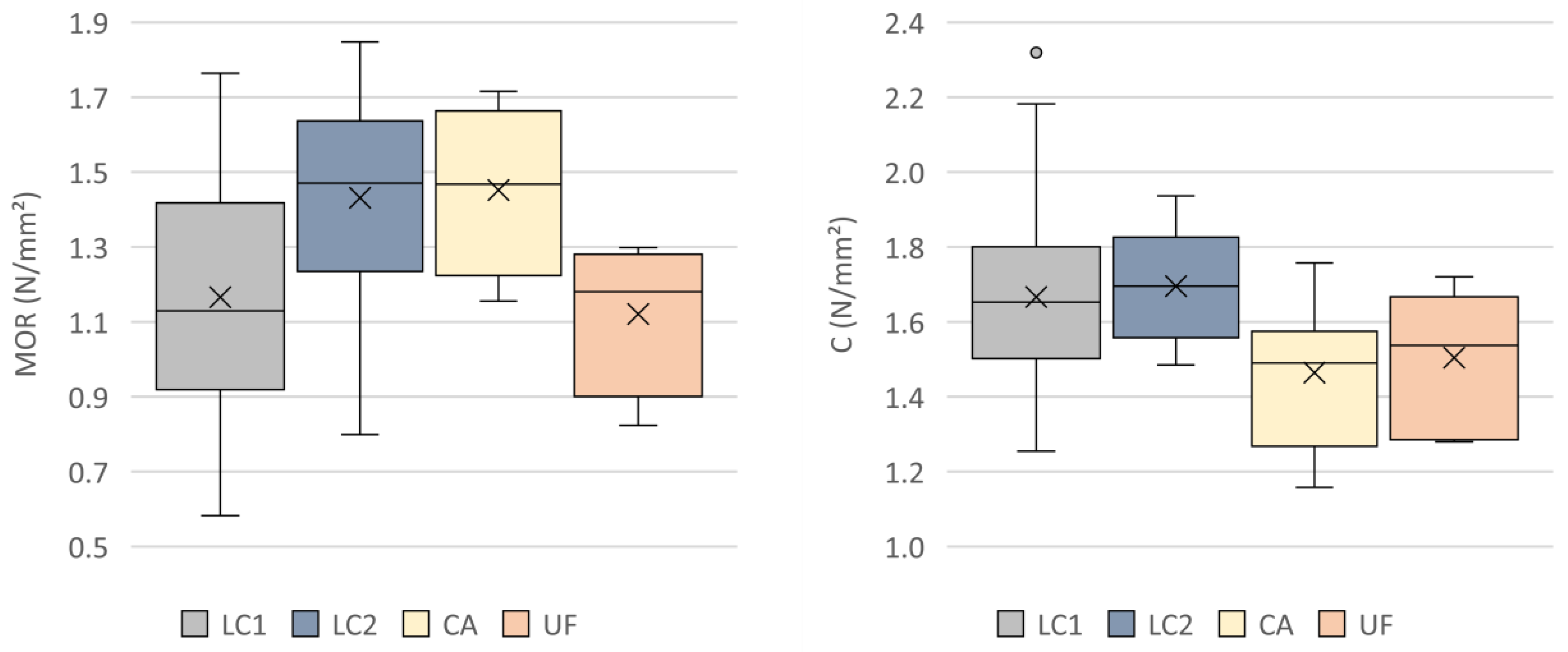

3.2. Physical and Mechanical Properties of the Bark Panels

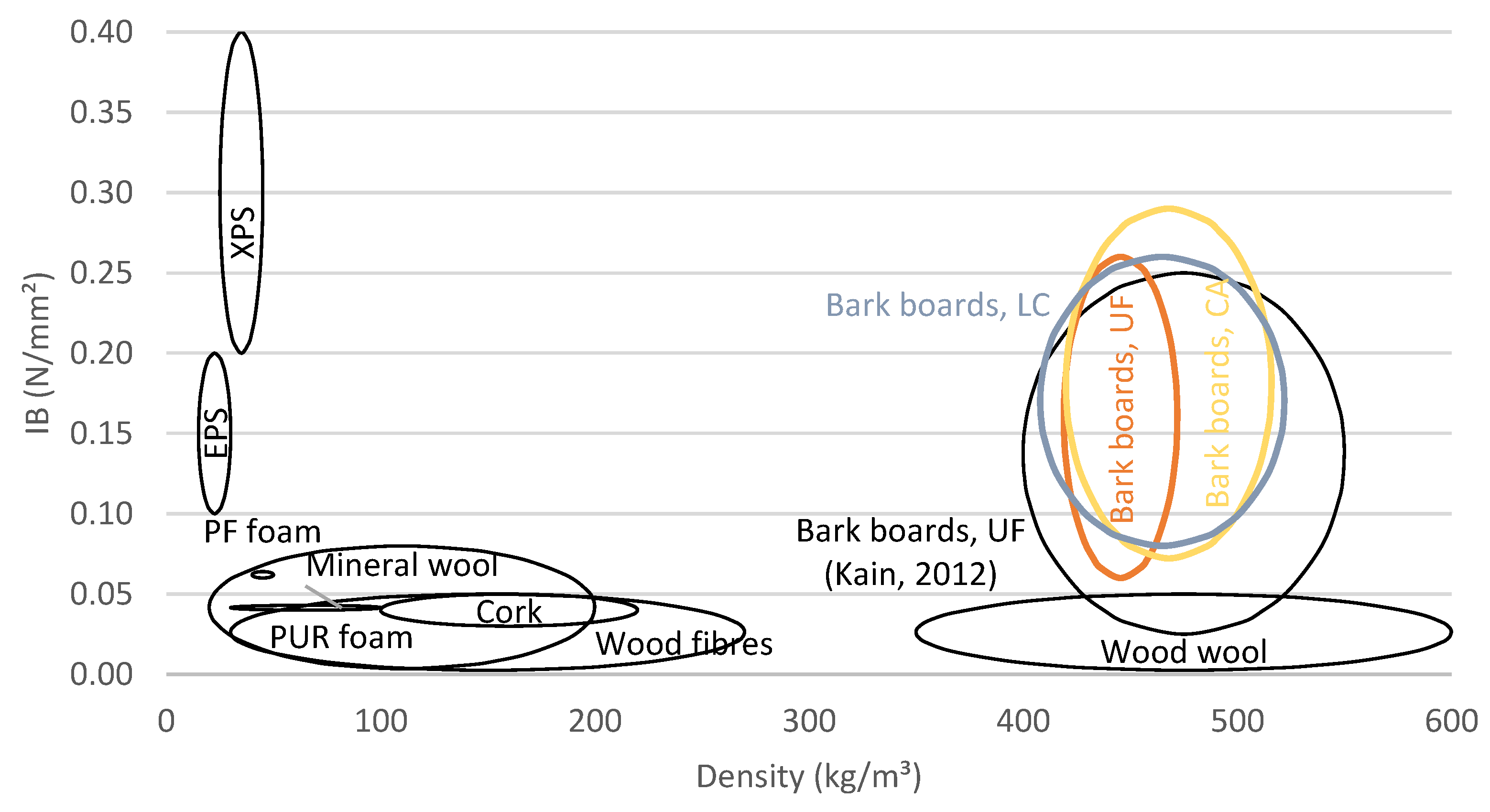

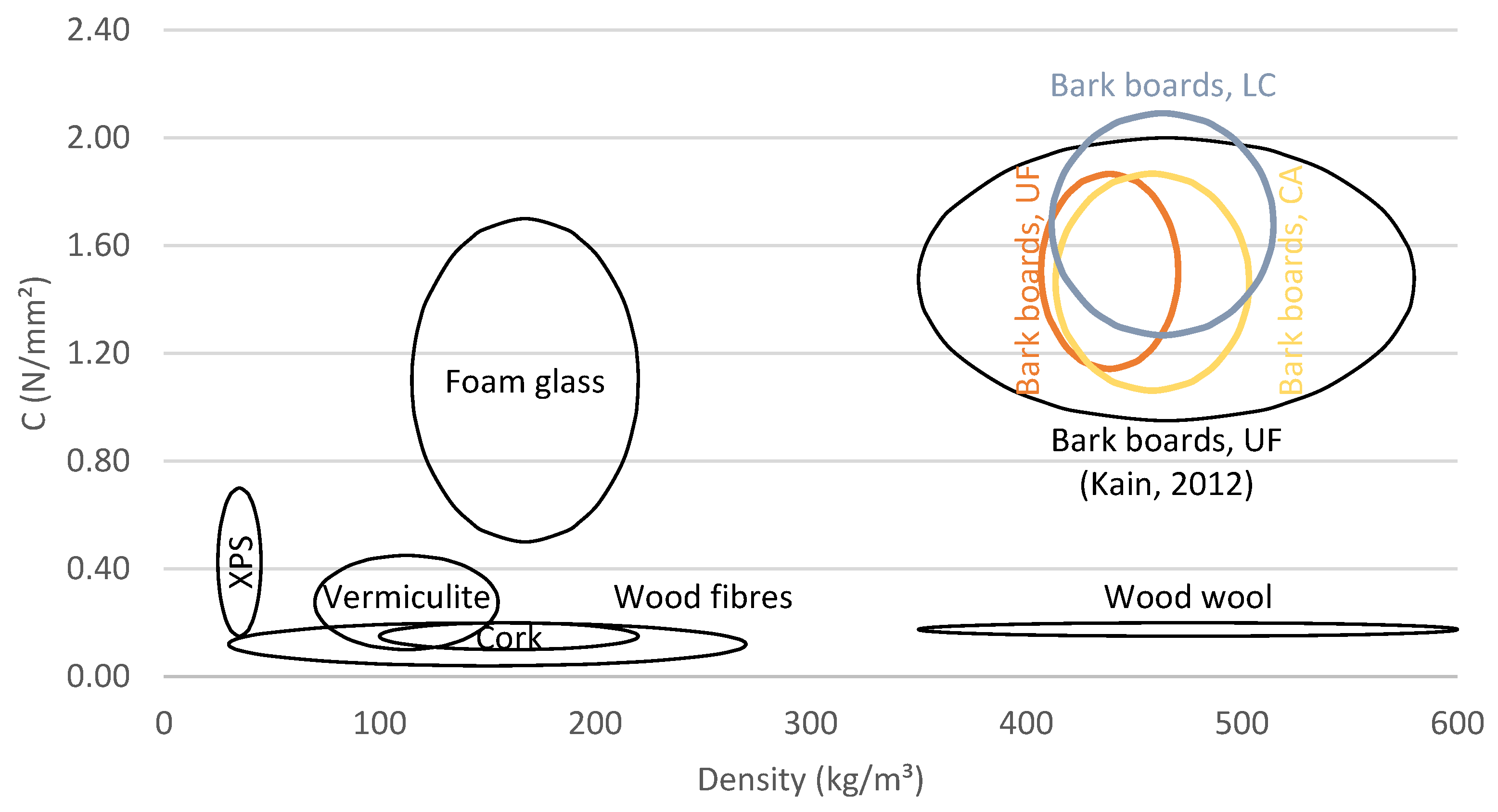

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vaucher, H. Baumrinden: Aussehen, Struktur, Funktion, Eigenschaften; Naturbuch-Verl.: Augsburg, Germany, 1997; ISBN 3894402555. [Google Scholar]

- Kain, G.; Barbu, M.-C.; Teischinger, A.; Musso, M.; Petutschnigg, A. Substantial Bark Use as Insulation Material. For. Prod. J. 2012, 62, 480–487. [Google Scholar] [CrossRef]

- Martin, R.E. Thermal properties of bark. Forest Prod. J. 1963, 419–426. [Google Scholar]

- Volz, K.-R. Herstellung und Eigenschaften von Fichten-, Kiefern- und Buchrindenplatten. Eur. J. Wood Prod. 1973, 31, 221–229. [Google Scholar] [CrossRef]

- Xing, C.; Deng, J.; Zhang, S.Y.; Riedl, B.; Cloutier, A. Impact of bark content on the properties of medium density fiberboard (MDF) in four species grown in eastern Canada. For. Prod. J. 2006, 56, 64–69. [Google Scholar]

- Kraft, R. Zur Chemisch-Technologischen Verwertung von Gebrauchten Holzwerkstoffen und Holzrinden. Ph.D. Dissertation, Universität Göttingen, Göttingen, Germany, 2007. [Google Scholar]

- Kain, G.; Güttler, V.; Barbu, M.-C.; Petutschnigg, A.; Richter, K.; Tondi, G. Density related properties of bark insulation boards bonded with tannin hexamine resin. Eur. J. Wood Prod. 2014, 72, 417–424. [Google Scholar] [CrossRef]

- Urstöger, J.; Barbu, M.C.; Pacher, T.; Petutschnigg, A.; Jorda, J.; Tudor, E.M. Selected Properties of Cement Bound Spruce and Larch Bark Bio-Aggregates. Polymers 2021, 13, 4438. [Google Scholar] [CrossRef] [PubMed]

- Braungart, M.; McDonough, W. Die nächste industrielle Revolution: Die Cradle to Cradle-Community, 2nd ed.; Europäische Verl.-Anst: Hamburg, Germany, 2008. [Google Scholar]

- Frihart, C.R. Introduction to Special Issue: Wood Adhesives: Past, Present, and Future. For. Prod. J. 2015, 65, 4–8. [Google Scholar] [CrossRef]

- Krug, D.; Tobisch, S. Einsatz von Proteinen als Bindemittel für Holzwerkstoffe. Eur. J. Wood Prod. 2010, 68, 289–301. [Google Scholar] [CrossRef]

- Kain, G.; Güttler, V.; Lienbacher, B.; Barbu, M.C.; Petutschnigg, A.; Richter, K.; Tondi, G. Effects of different Flavonoid Extracts in optimizing Tannin-glued Bark Insulation Boards. Wood Fiber Sci. 2015, 47, 258–269. [Google Scholar]

- Antov, P.; Savov, V.; Neykov, N. Sustainable bio-based adhesives for eco-friendly wood composites a review. Wood Res. 2020, 65, 51–62. [Google Scholar] [CrossRef]

- Pizzi, A.; Stracke, P.; Trosa, A. Industrial tannin/hexamine low-emission exterior particleboards. Eur. J. Wood Prod. 1997, 55, 168. [Google Scholar] [CrossRef]

- Guo, M.; Wang, G. Milk Protein Polymer and Its Application in Environmentally Safe Adhesives. Polymers 2016, 8, 324. [Google Scholar] [CrossRef]

- Solt, P.; Konnerth, J.; Gindl-Altmutter, W.; Kantner, W.; Moser, J.; Mitter, R.; van Herwijnen, H.W. Technological performance of formaldehyde-free adhesive alternatives for particleboard industry. Int. J. Adhes. Adhes. 2019, 94, 99–131. [Google Scholar] [CrossRef]

- Herzog, A.; Kerschbaumer, T.; Schwarzenbrunner, R.; Barbu, M.-C.; Petutschnigg, A.; Tudor, E.M. Efficiency of High-Frequency Pressing of Spruce Laminated Timber Bonded with Casein Adhesives. Polymers 2021, 13, 4237. [Google Scholar] [CrossRef] [PubMed]

- Hussin, M.H.; Abd Latif, N.H.; Hamidon, T.S.; Idris, N.N.; Hashim, R.; Appaturi, J.N.; Brosse, N.; Ziegler-Devin, I.; Chrusiel, L.; Fatriasari, W.; et al. Latest advancements in high-performance bio-based wood adhesives: A critical review. J. Mater. Res. Technol. 2022, 21, 3909–3946. [Google Scholar] [CrossRef]

- Cesprini, E.; Causin, V.; de Iseppi, A.; Zanetti, M.; Marangon, M.; Barbu, M.C.; Tondi, G. Renewable Tannin-Based Adhesive from Quebracho Extract and Furfural for Particleboards. Forests 2022, 13, 1781. [Google Scholar] [CrossRef]

- Jorda, J.; Cesprini, E.; Barbu, M.-C.; Tondi, G.; Zanetti, M.; Král, P. Quebracho Tannin Bio-Based Adhesives for Plywood. Polymers 2022, 14, 2257. [Google Scholar] [CrossRef]

- Chen, X.; Pizzi, A.; Zhang, B.; Zhou, X.; Fredon, E.; Gerardin, C.; Du, G. Particleboard bio-adhesive by glyoxalated lignin and oxidized dialdehyde starch crosslinked by urea. Wood Sci. Technol. 2022, 56, 63–85. [Google Scholar] [CrossRef]

- Vitola, L.; Gendelis, S.; Sinka, M.; Pundiene, I.; Bajare, D. Assessment of Plant Origin By-Products as Lightweight Aggregates for Bio-Composite Bounded by Starch Binder. Energies 2022, 15, 5330. [Google Scholar] [CrossRef]

- Gumowska, A.; Kowaluk, G. Physical and Mechanical Properties of High-Density Fiberboard Bonded with Bio-Based Adhesives. Forests 2023, 14, 84. [Google Scholar] [CrossRef]

- Ebnesajjad, S.; Landrock, A.H. (Eds.) Characteristics of Adhesive Materials: Adhesives Technology Handbook; Elsevier: Amsterdam, The Netherlands, 2014; ISBN 9780323356022. [Google Scholar]

- Fay, P.A. History of adhesive bonding. In Adhesive Bonding: Science, Technology and Applications; Adams, R.D., Ed.; CRC Press: Boca Raton, FL, USA; Cambridge, UK, 2005; ISBN 9781855737419. [Google Scholar]

- Kollmann, F. Technologie des Holzes und der Holzwerkstoffe, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 1955. [Google Scholar]

- Sutermeister, E.; Brühl, E. Das Kasein: Chemie und Technische Verwertung; Springer: Berlin/Heidelberg, Germany, 1932. [Google Scholar]

- Habenicht, G. Kleben—Grundlagen, Technologien, Anwendungen, 4th ed.; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Reddy, A.B.; Manjula, B.; Sudhakar, K.; Sivanjineyulu, V.; Jayaramudu, T.; Sadiku, E.R. Polyethylene/Other Biomaterials-based Biocomposites and Bionanocomposites. In Polyethylene-Based Biocomposites and Bionanocomposites; Visakh, P.M., Lüftel, S., Eds.; Wiley & Sons Ltd.: Hoboken, NJ, USA, 2016; pp. 279–314. [Google Scholar]

- Horne, D.S. Casein micelle structure: Models and muddles. Curr. Opin. Colloid Interface Sci. 2006, 11, 148–153. [Google Scholar] [CrossRef]

- McMahon, D.J.; Oommen, B.S. Supramolecular structure of the casein micelle. J. Dairy Sci. 2008, 91, 1709–1721. [Google Scholar] [CrossRef] [PubMed]

- Kain, G.; Tudor, E.M.; Barbu, M.-C. Bark Thermal Insulation Panels: An Explorative Study on the Effects of Bark Species. Polymers 2020, 12, 2140. [Google Scholar] [CrossRef] [PubMed]

- Schwarzenbrunner, R. Development of Sustainable and Waterproof Casein Glue Formulations—Application on Biodegradable Skis. Bachelor Thesis, Salzburg University of Applied Sciences, Kuchl, Austria, 2019. [Google Scholar]

- EN 827:2006; Adhesives—Determination of Conventional Solids Content and Constant Mass Solids Content; European Committee for Standardization: Brussels, Belgium, 2006.

- EN 326-1:2005; Wood-Based Panels—Sampling and Cutting of Test Pieces; European Committee for Standardization: Brussels, Belgium, 2005.

- EN 323:2005; Wood-Based Panels—Determination of Density; European Committee for Standardization: Brussels, Belgium, 2005.

- EN 322:2005; Wood-Based Panels—Determination of Moisture Content; European Committee for Standardization: Brussels, Belgium, 2005.

- EN 317:2005; Particleboards and Fibreboards—Determination of Swelling in Thickness after Immersion in Water; European Committee for Standardization: Brussels, Belgium, 2005.

- EN 319:2005; Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board; European Committee for Standardization: Brussels, Belgium, 2005.

- EN 310:2005; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength; European Committee for Standardization: Brussels, Belgium, 2005.

- EN 29469:2023; Thermal Insulating Products for Building Applications—Determination of Compression Behaviour; European Committee for Standardization: Brussels, Belgium, 2023.

- Backhaus, K.; Erichson, B.; Plinke, W.; Weiber, R. Multivariate Analysemethoden: Eine Anwendungsorientierte Einführung, 13th ed.; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Kuckartz, U.; Rädiker, S.; Ebert, T.; Schehl, J. Statistik: Eine Verständliche Einführung; VS Verlag für Sozialwissenschaften: Wiesbaden, Germany, 2013; ISBN 9783531198903. [Google Scholar]

- EN 10456:2010; Building Materials and Products—Hygrothermal Properties—Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values; European Committee for Standardization: Brussels, Belgium, 2010.

- Schwemmer, R.; Teischinger, A.; Konnerth, J.; Tipplreither, C.; Jutz, W. Entwicklung der Fertigungstechnologie für Rohrkolben-Dämmstoffe; BMVIT: Vienna, Austria, 2010. [Google Scholar]

- Pfundstein, M.; Rodolphi, A.; Spitzner, M.H.; Gellert, R. Dämmstoffe: Grundlagen, Materialien, Anwendungen; Institut f. Internationale Architektur-Dokumentation: München, Germany, 2007; ISBN 9783955530211. [Google Scholar]

- Gößwald, J.; Barbu, M.-C.; Petutschnigg, A.; Tudor, E.M. Binderless Thermal Insulation Panels Made of Spruce Bark Fibres. Polymers 2021, 13, 1799. [Google Scholar] [CrossRef]

| Adhesive | Lean Curd (%) | Lime (%) | Casein (%) | Water (%) | Sodium Silicate (%) | UF (%) |

|---|---|---|---|---|---|---|

| Lean Curd 1 | 69.00 | 31.00 | - | - | - | |

| Lean Curd 2 | 80.00 | 20.00 | - | - | - | |

| Casein reference | - | 16.02 | 23.11 | 58.17 | 2.70 | - |

| UF reference | - | - | - | - | - | 100.00 |

| Adhesive | Abbreviation | Lime Content | Press Temperature (°C) | Press Time (Min) | Panel Count |

|---|---|---|---|---|---|

| Lean Curd 1 | LC1 | 0.31 | 150 | 8 | 2 |

| 180 | 6 | 1 | |||

| 8 | 2 | ||||

| Lean Curd 2 | LC2 | 0.20 | 150 | 8 | 2 |

| 180 | 8 | 2 | |||

| Casein reference | CA | 0.16 | 180 | 8 | 1 |

| UF reference | UF | - | 180 | 7 | 1 |

| Density TS/WA (kg/m3) | TS (%) | WA (%) | Density IB (kg/m3) | IB (N/mm2) | Density MOE/MOR (kg/m3) | MOE (N/mm2) | MOR (N/mm2) | Density C (kg/m3) | C (N/mm2) | |

|---|---|---|---|---|---|---|---|---|---|---|

| LC1 | 466.81 | 11.55 | 50.87 | 458.95 | 0.15 | 464.58 | 284.83 | 1.17 | 457.75 | 1.67 |

| (27.27) | (1.30) | (5.45) | (29.47) | (0.04) | (24.39) | (63.00) | (0.32) | (26.86) | (0.24) | |

| LC2 | 474.22 | 11.22 | 50.73 | 472.86 | 0.19 | 469.04 | 313.26 | 1.43 | 470.07 | 1.70 |

| (22.05) | (1.53) | (4.40) | (25.37) | (0.04) | (18.73) | (54.27) | (0.27) | (22.87) | (0.15) | |

| CA | 469.93 | 12.46 | 45.73 | 468.02 | 0.18 | 451.78 | 269.46 | 1.45 | 458.48 | 1.46 |

| (18.40) | (1.60) | (6.46) | (23.86) | (0.05) | (20.50) | (40.14) | (0.23) | (22.45) | (0.20) | |

| UF | 448.80 | 14.89 | 59.45 | 445.31 | 0.16 | 438.85 | 248.68 | 1.12 | 438.68 | 1.50 |

| (15.78) | (1.52) | (1.96) | (13.31) | (0.05) | (18.46) | (58.24) | (0.21) | (15.90) | (0.18) |

| MC | TS | WA | IB | MOE | MOR | C | |

|---|---|---|---|---|---|---|---|

| Sample size | 63 | 63 | 63 | 63 | 36 | 36 | 63 |

| Variance homogeneity | 0.005 | 0.028 | 0.391 | 0.448 | 0.504 | 0.560 | 0.598 |

| Density | 0.000 *** | 0.054 | 0.000 *** | 0.000 *** | 0.000 *** | 0.000 *** | 0.000 *** |

| (0.405) | (0.062) | (0.385) | (0.312) | (0.416) | (0.688) | (0.735) | |

| Lime content | 0.000 *** | 0.551 | 0.547 | 0.000 *** | 0.169 | 0.000 *** | 0.023 * |

| (0.291) | (0.006) | (0.006) | (0.276) | (0.060) | (0.339) | (0.086) | |

| Press temperature | 0.064 | 0.337 | 0.503 | 0.404 | 0.159 | 0.062 | 0.296 |

| (0.058) | (0.016) | (0.008) | (0.012) | (0.063) | (0.108) | (0.019) | |

| Lime content x Press temperature | 0.565 | 0.140 | 0.339 | 0.003 ** | 0.960 | 0.145 | 0.000 *** |

| (0.006) | (0.037) | (0.016) | (0.140) | (0.000) | (0.067) | (0.181) |

| MC | TS | WA | IB | MOE | MOR | C | |

|---|---|---|---|---|---|---|---|

| Sample size | 63 | 63 | 63 | 63 | 36 | 36 | 63 |

| Correlation coefficient (R) | 0.667 | −0.246 | −0.608 | 0.580 | 0.618 | 0.762 | 0.822 |

| p-value | 0.000 * | 0.052 | 0.000 * | 0.000 * | 0.000 * | 0.000 * | 0.000 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urstöger, J.; Kain, G.; Prändl, F.; Barbu, M.C.; Kristak, L. Physical-Mechanical Properties of Light Bark Boards Bound with Casein Adhesives. Sustainability 2023, 15, 13530. https://doi.org/10.3390/su151813530

Urstöger J, Kain G, Prändl F, Barbu MC, Kristak L. Physical-Mechanical Properties of Light Bark Boards Bound with Casein Adhesives. Sustainability. 2023; 15(18):13530. https://doi.org/10.3390/su151813530

Chicago/Turabian StyleUrstöger, Johannes, Günther Kain, Felix Prändl, Marius Catalin Barbu, and Lubos Kristak. 2023. "Physical-Mechanical Properties of Light Bark Boards Bound with Casein Adhesives" Sustainability 15, no. 18: 13530. https://doi.org/10.3390/su151813530

APA StyleUrstöger, J., Kain, G., Prändl, F., Barbu, M. C., & Kristak, L. (2023). Physical-Mechanical Properties of Light Bark Boards Bound with Casein Adhesives. Sustainability, 15(18), 13530. https://doi.org/10.3390/su151813530