1. Introduction

Logistics is highly adaptable to evolving demographics, the urban economy, changing purchasing and distribution patterns, and new demands from consumers and businesses [

1]. Amid economic downturns, intense competition, and external environmental and social pressures, numerous freight transport enterprises are committed to elevating their competitiveness and sustainability. This endeavor is particularly significant for those aiming to distinguish themselves within the market [

2].

To achieve this, they aim to increase their efficiency by cutting costs, improving service quality, and reducing their environmental and social footprint through the implementation of sustainable best practices in their logistics operations [

3,

4].

Sustainable logistics is the management of resource processes that combines the logistics system performed by different agents with sustainable initiatives, with a traditional focus on logistics operations through activities such as supplier selection, procurement, manufacturing, warehousing, and delivery in order to reduce a company’s costs, but also with the aim of decreasing its environmental impacts and ameliorating the negative impact it generates on society [

5].

Companies that adopt sustainable logistics practices can stand out in the market, attracting customers and investors who are concerned with environmental and social issues [

6]. Therefore, the implementation of best sustainable logistics practices is a key issue to be overcome for companies in various parts of the world, including Brazil, that envisage becoming more competitive and sustainable in the long term. Thus, the private sector needs to adopt internal actions (solutions and strategies) to achieve sustainability goals [

7].

In Brazil, due to the low investment in logistics, mainly within transportation activity, it has high production costs, since the infrastructure and provision of basic services are precarious [

8]. Due to this bottleneck, freight transportation occurs at about 61% by road, while in other countries of a similar geographical size, this participation is less than 30%, resulting in the high consumption of fossil fuels, with the transportation sector accounting for 35% of consumption and being responsible for 48% of Greenhouse Gas Emissions (GHG) emissions in the country [

9].

It is considered necessary to evaluate the adoption of best practices to promote sustainability in logistics, as Brazil is an emerging (developing) country that makes up the Building Better Global Economic (BRICS) world economic group together with Russia, China, India, and South Africa. It is committed to meeting climate goals in its planning, as evidenced by the Nationally Determined Contribution (NDC), which was first published in September 2016 and updated in December 2020, committing to reducing GHG emissions by 37% concerning a base year of 2005 and target year 2025 [

10].

Thus, this paper aims to map the best practices adopted by Brazilian transportation companies and define the level of maturity of companies regarding their implementation steps, that is, to assess whether the best practices that have been adopted are under adoption or have been planned, as well as to identify and propose implementation actions represented by solutions, strategies, and initiatives undertaken to achieve sustainability objectives and support decision makers in the implementation process, i.e., the adoption of these best practices in transportation.

To fulfill its objectives, in addition to this introductory section, this study is structured as follows:

Section 2 presents a literature review that highlights the importance of sustainable logistics actions for freight transportation, points out some best practices in sustainable logistics and discusses the importance of assessing their degree of maturity;

Section 3 describes the method for proposing the transition to best practices, composed of six easy-to-apply steps;

Section 4 presents the proposal of priority best practices to promote sustainable logistics; and the final considerations are presented in

Section 5.

2. Literature Review

In this section, the importance of sustainable logistics actions for freight transportation is discussed, highlighting the challenges and opportunities faced. In addition, the study analysis is performed on the importance of best practices in this process to reduce GHGs and the excessive consumption of natural resources, improving the efficiency and safety of freight transportation. It also addresses the level of maturity of best practices in freight transportation, pointing out the advances and gaps that still need to be overcome to make sustainable logistics a reality in emerging countries such as Brazil.

2.1. Importance of Sustainable Logistics Actions for Freight Transportation

Logistics consists of planning, implementing, and controlling the movement, handling, warehousing, and storage of goods, associated services, and information, from origin to consumption, to meet customers’ requirements [

11]. According to Wisetjindawat [

12], transport is one of the activities of logistics that embraces resource extraction at the point of origin until its delivery to production unities, wherein it is manufactured into a finished product, which is after transferred to warehouses, stored, then distributed to the stores of the distribution network, and collected after use.

From a broader perspective, the interface between transport and logistics gets closer as a nation advances and expands its productive capacity [

13]. Among the components of the logistics operation system, the freight transport sector has the most significant impact on cost share. Therefore, transport and warehousing activities serve as the primary sources for most logistics operators [

14].

Freight handling in operations such as transfer, distribution, and collection results in about a quarter of all carbon dioxide (CO

2) emissions related to energy use worldwide [

15]. Another factor that corroborates high CO

2 emissions is the consumption of natural resources by the freight transport sector due to fossil fuel combustion and the raw materials used to produce vehicles [

16]. Thus, significant improvements in freight transport would be needed to make it more efficient and sustainable.

2.2. Sustainable Logistics Best Practices

Best practices are actions applied to a wide variety of organizations and can be planned or implemented by private or public companies and public–private partnerships (PPPs) [

17]. Thus, they should be appropriate to a defined topic or relevant issue, based on real experiences or analyses of studies, with positive effects (qualitative and quantitative) on the indicators relevant to logistics activities such as transportation [

18].

Logistics is a critical area for managing the movement of goods and services, ensuring that products are delivered efficiently and cost effectively to their intended destination [

19]. This includes inventory management, which involves tracking and controlling the flow of goods, ensuring that there is a sufficient and optimal level of supplies on hand to meet demand, while minimizing the costs of inventory that can result in resource waste [

20].

Effective transportation management can help to reduce transportation costs and delivery time and optimize vehicle capacity utilization, all of which can contribute to corporate sustainability by reducing energy consumption, emissions, and waste [

21].

Best sustainable logistics practices include adopting clean and efficient technologies, using recycled and recyclable materials, reducing the consumption of natural resources such as water and energy, and minimizing waste and emissions [

20]. These practices result concomitantly in protecting the environment, improving efficiency, and reducing the operational costs for companies.

Among the previous studies identified in the literature review, we can mention the Center of Excellence for the Sustainable Urban Cargo System (CoE-SUFS), Best Urban Cargo Solutions (BESTUFS), Factory of Good Practices for Cargo Transportation (BESTFACT), Smart Freight Center (SFC), McKinsey Center for Business and Environment, Brazilian Green Logistics Program (PLVB), Transportation Decarbonization Alliance (TDA), and MDS Transmodal, as well as academic studies such as [

12,

22,

23,

24,

25].

Therefore,

Table 1 intricately compiles a range of Best Practices (BP1 to BP22) that hold relevance within this specific context, meticulously curated via an exhaustive analysis of the existing literature.

The practices outlined in

Table 1 have the objective of mitigating the adverse effects of freight transport on the environment and society. These measures have the potential to decrease greenhouse gas (GHG) emissions and other air pollutants, reduce fossil fuel consumption, enhance energy efficiency, and enhance the safety in freight transport. Consequently, it is imperative to implement measures that minimize the negative impacts of freight transport to ensure the sustainability of the transportation sector and aid in addressing climate change while improving the well-being of populations impacted by freight transport.

To this end, the adoption of sustainable practices aims to help a product or service achieve the condition of being socially just and environmentally friendly, but in order to provide a quality transportation service, it must be conducted in an efficient, competitive, and profitable manner, so that traditional logistics strategies have to be improved [

50].

2.3. Sustainable Practices Maturity Level

The need to establish criteria for selecting appropriate sustainable practices becomes evident when considering key factors aligned with an organization’s maturity level, employees, sustainability alternatives, societal demands (such as governments and consumers), implementation feasibility, and other relevant factors.

According to Werner-Lewandowska and Golinska-Dawson [

51], the concept of Sustainable Logistics Maturity Management (SLMM) is utilized to assess the extent to which a company implements modern logistics solutions (management tools and practices) in order to enhance its performance in the economic, environmental, and social dimensions of sustainability. This concept can also be applied to evaluate the performance of logistics service providers.

The logistics maturity model serves as a framework for evaluating a company’s proficiency in logistics management. It identifies the strengths and weaknesses in logistics operations and offers guidance for improvement. Typically, the model includes criteria for assessing performance in various areas such as inventory management, transportation management, and warehouse operations. Zhang et al. [

52] highlighted the importance of incorporating green logistics performance evaluation, which shifts the focus towards sustainable objectives by balancing environmental and economic goals. Consequently, there is an increasing emphasis on low-carbon logistics, driven by organizations and administrative authorities aiming to reduce their energy consumption and CO

2 emissions, making it an inevitable trend in the logistics sector [

53].

Sustainable maturity models assist companies at different stages of transitioning towards sustainability. These models are structured as sequential levels that describe the process of moving towards sustainability in business operations. As sustainable practices are implemented, the evolution of maturity levels can be observed [

54]. Vásquez et al. [

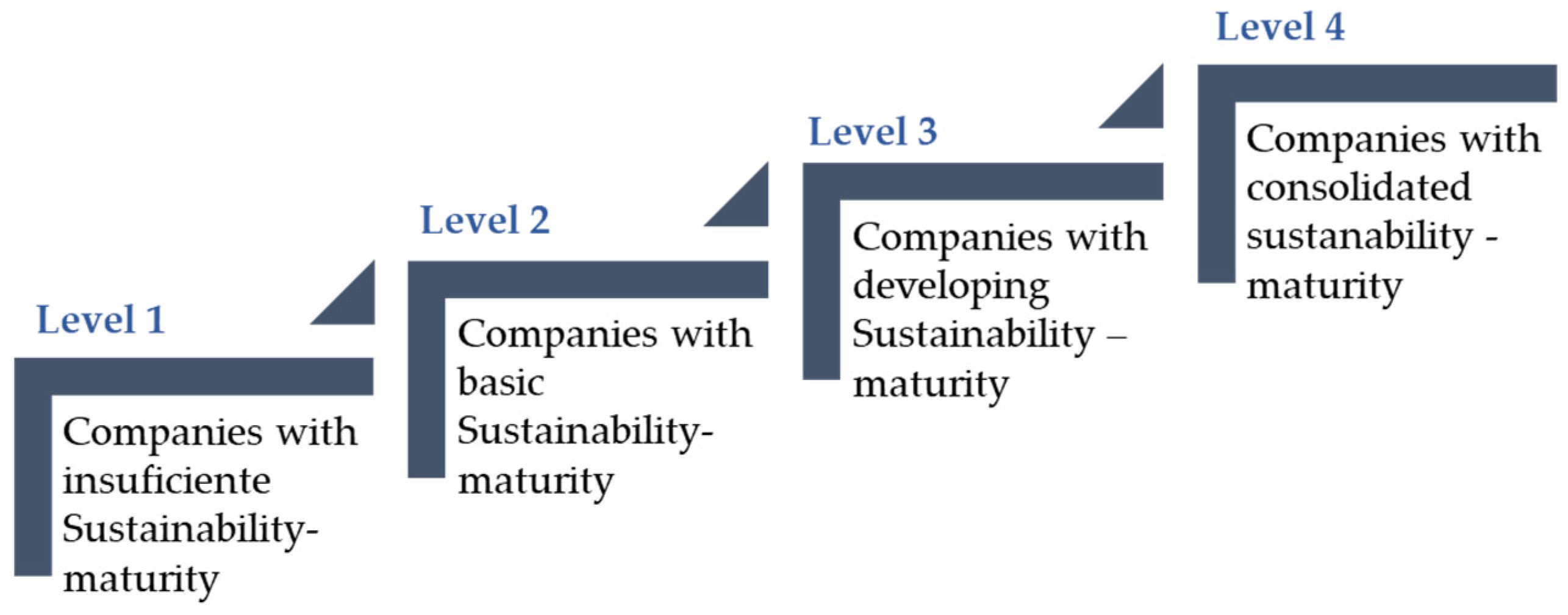

55] proposed that these levels of sustainability maturity in companies are defined based on the fulfillment of specific characteristics, as depicted in

Figure 1.

3. Method for Proposing the Transition from Best Practices

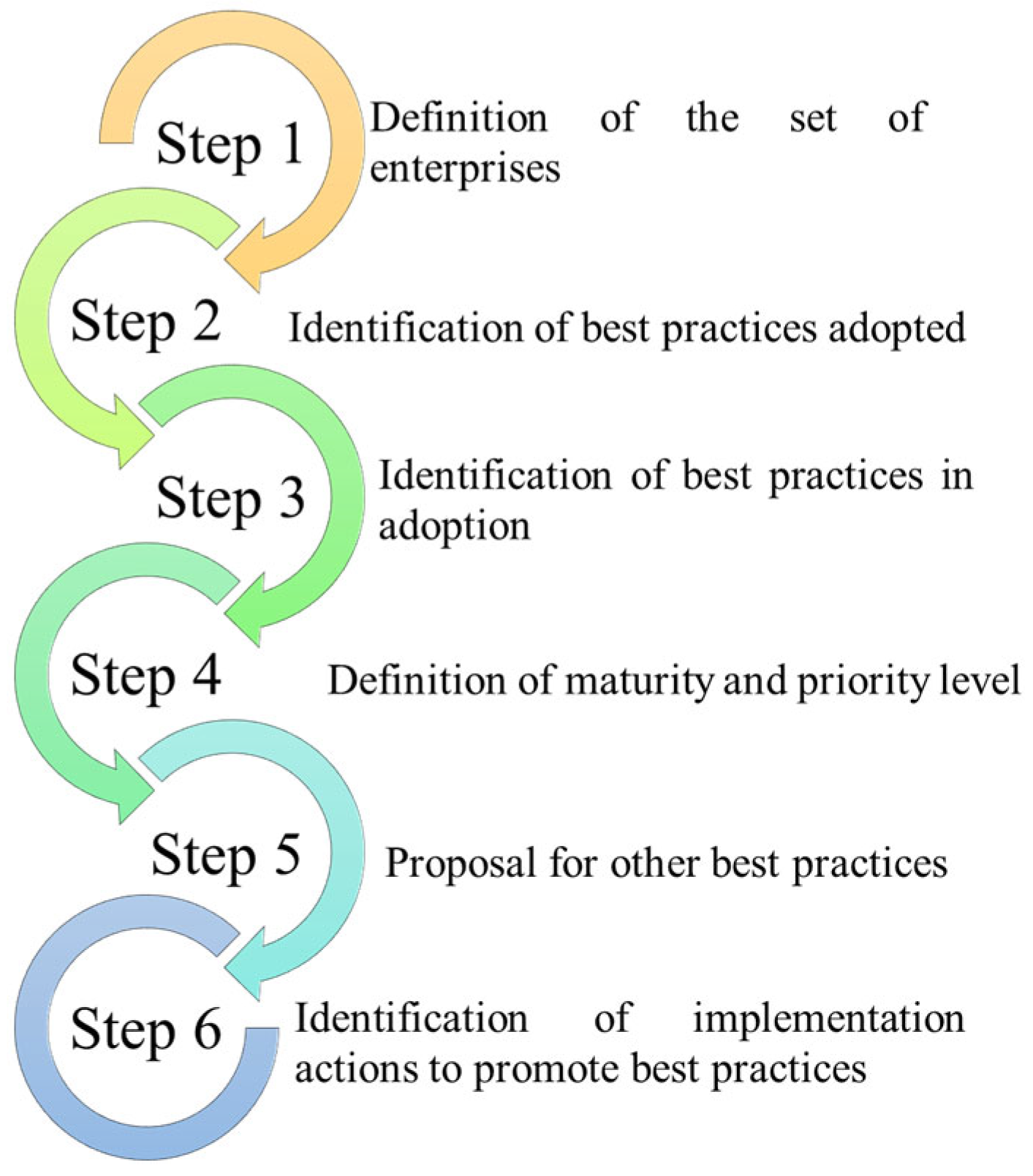

The methodological framework, as visualized in

Figure 2, is an encompassing process that unfolds through five well-defined stages. Its purpose is to provide comprehensive guidance for companies seeking to bolster their sustainable logistics operations. Particularly concentrated within the realms of transportation, warehousing, and procurement (service provision), this methodology aims to usher in a new era of eco-conscious practices. By adopting this approach, businesses can not only optimize their operational efficiency, but also positively contribute to the environment.

In the methodology, Step 1 involves the meticulous delineation and comprehensive description of a cohort comprising both domestic and multinational enterprises engaged in operations within Brazil. This select group is characterized by the successful integration or continuous adoption of best practices, many of them aimed at advancing the principles of corporate sustainability.

Once the set of companies to be evaluated is determined, Step 2 involves identifying the best practices that have already been implemented in the logistics operations of these companies. These practices are defined as strategies that have been put into effect or are currently being developed by the organization.

Moreover, Step 3 is dedicated to the precise identification of paramount practices within the adoption continuum. These practices manifest as tangible strategic initiatives, subject to rigorous examination and evaluation, poised for potential assimilation within the organizational framework.

In Step 4, after identifying the best practices adopted and being adopted, the requirements are defined for classifying these best practices according to the level of maturity and degree of priority established for the promotion of sustainable logistics in the business environment.

Step 5 culminates in the formulation of a comprehensive array of best practices, as delineated by the participating companies. Subsequently, Step 6 engages in the categorization of these best practices based on their degree of priority, followed by a presentation of their implementation actions. These encompass the strategic deployment of sustainable initiatives that have been meticulously planned or already set in motion by an organization, thus facilitating the seamless progression of the transitional process.

4. Proposal of Priority Best Practices to Promote Sustainable Logistic

This section presents the application of the steps of the proposed methodology for building the transition to sustainable operation in logistics.

4.1. Definition of the Set of Companies

The study focuses on a specific group of companies that provide transportation services to various economic sectors within Brazil. These companies are part of the Brazilian Green Logistics Program (in Portuguese Programa de Logística Verde Brasil—PLVB), which was established in 2016. The PLVB is a strategic initiative that demonstrates the commitment of a group of 32 private companies (referred to as Member Companies) to social and environmental responsibility. As of the first quarter of 2023, these Member Companies consist of 19 carriers and 13 shippers [

56].

Based on this composition, the criterion adopted is the selection of companies that have been certified by the so-called PLVB Green Seal, which corresponds to a formal declaration that signals the approval of a request for certification as a member company, characterizing a set of 95% of the member carrier’s companies. In the application, the company declares its commitment to valuing sustainability in its logistical activities by proving the set of best practices adopted and under adoption, as well as its implementation actions. This form is used by the program to map the best practices and their respective implementation actions, with the aim of understanding the degree of maturity of the companies and verifying their compliance with the commitment to their responsibility for sustainability.

This group of companies, defined in this study as C1 to C18, attend the most diverse customers, including a variety of economic segments such as agribusiness, food and beverage, chemical, consumer goods, fuel, energy, and automotive, etc., as well as different activities in the supply chain such as transferring, distribution, collection, and last mile. It is important to highlight that

Appendix A provides a detailed description of the companies included in the study analysis.

4.2. Adopted Best Practices

For the identification of the adopted best practices, as presented in

Table 2, a documentary evaluation was conducted based on a request that included a list of 22 pre-established best practices according to a literature review. Additionally, the companies were given the option to include other best practices, indicating which actions or strategies had been implemented and were currently in the development phase by the company.

4.3. Best Practices under Adoption

For the identification of the best practices under adoption, as presented in

Table 2, a documentary evaluation was conducted based on a request that included a list of 22 pre-established best practices according to a literature review. Additionally, the companies were given the option to include other practices, indicating which strategies had been planned and were currently in the testing phase for future implementation, as well as the inclusion of other best practices defined by the companies on an optional basis, with the indication of which strategies had already been planned and were being tested for future implementation.

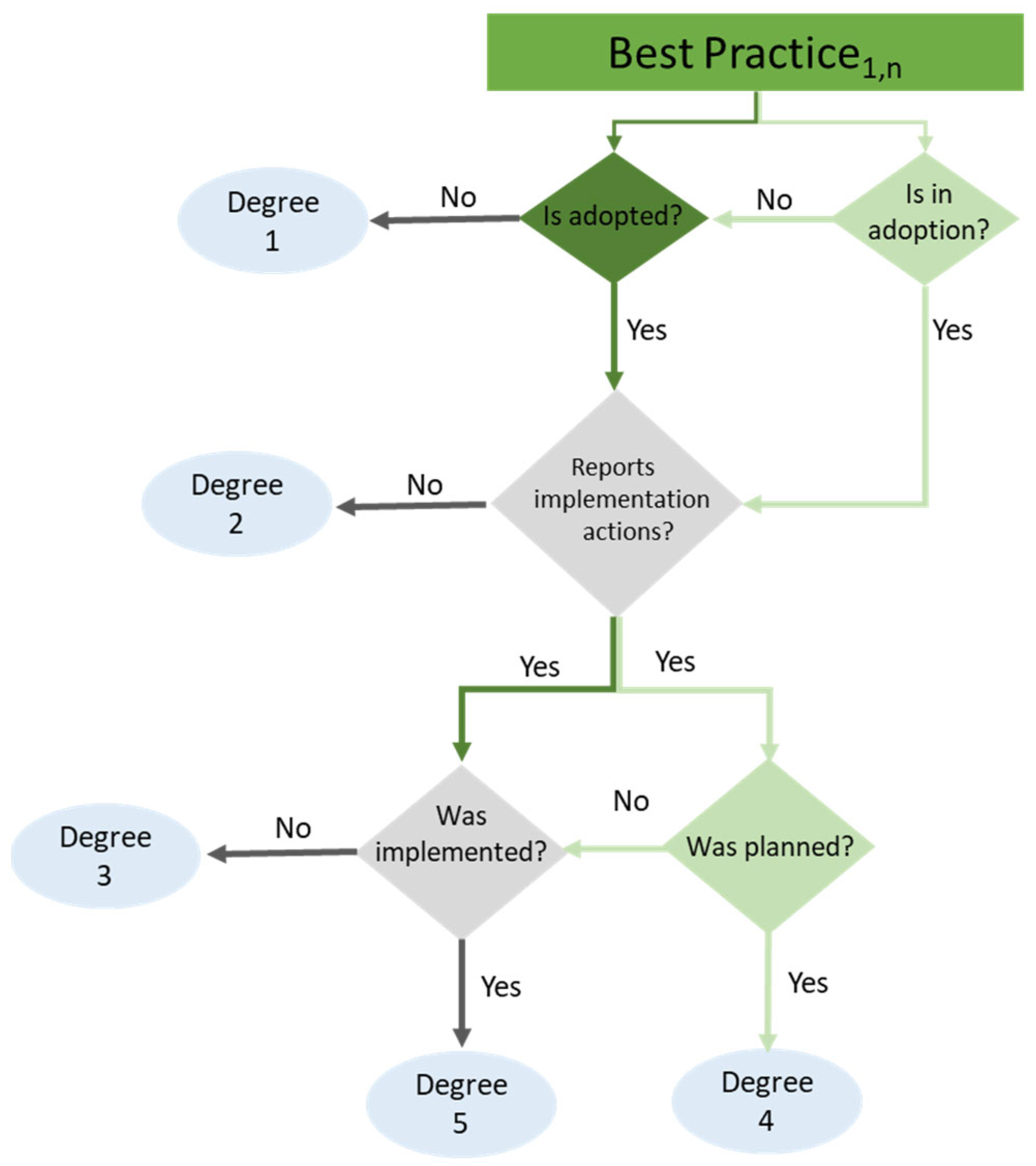

4.4. Maturity and Priority Level

In order to map the best practices and define their level of priority, a set of rules was established in this study to determine the maturity level of the practices based on material evidence and the criteria established for evaluation, adapted from the model by Vásquez et al. [

55] and described in

Figure 3.

Where, (i) degree 1 is defined by non-compliance with the requirement, indicating that the practices have not been adopted and are not in the process of adoption; (ii) degree 2 represents cases where companies claim to adopt or be in the process of adopting the practice, but do not provide implementation actions that prove this adoption or planning for implementation of the practices, partially fulfilling the requirement; (iii) degree 3 is defined by the presentation of implementation actions, but without implementation and the planning of practices, partially fulfilling the requirement; (iv) degree 4 represents cases where companies are in the process of adopting practices and they have been planned, partially fulfilling the requirement; and (v) degree 5 corresponds to the fulfillment of the entire set of established rules, where practices are adopted, implementation actions are presented, and these practices have been implemented.

Therefore, in order to comply with the rules defined in

Figure 3, in

Table 2, the relationship between the adopted practices, practices under adoption, and practices with presented implementation actions are shown, based on the companies’ responses.

Based on the definition and evaluation of the requirements, the corresponding maturity level for each company and average maturity level of the best practices were calculated, as shown in

Table 3.

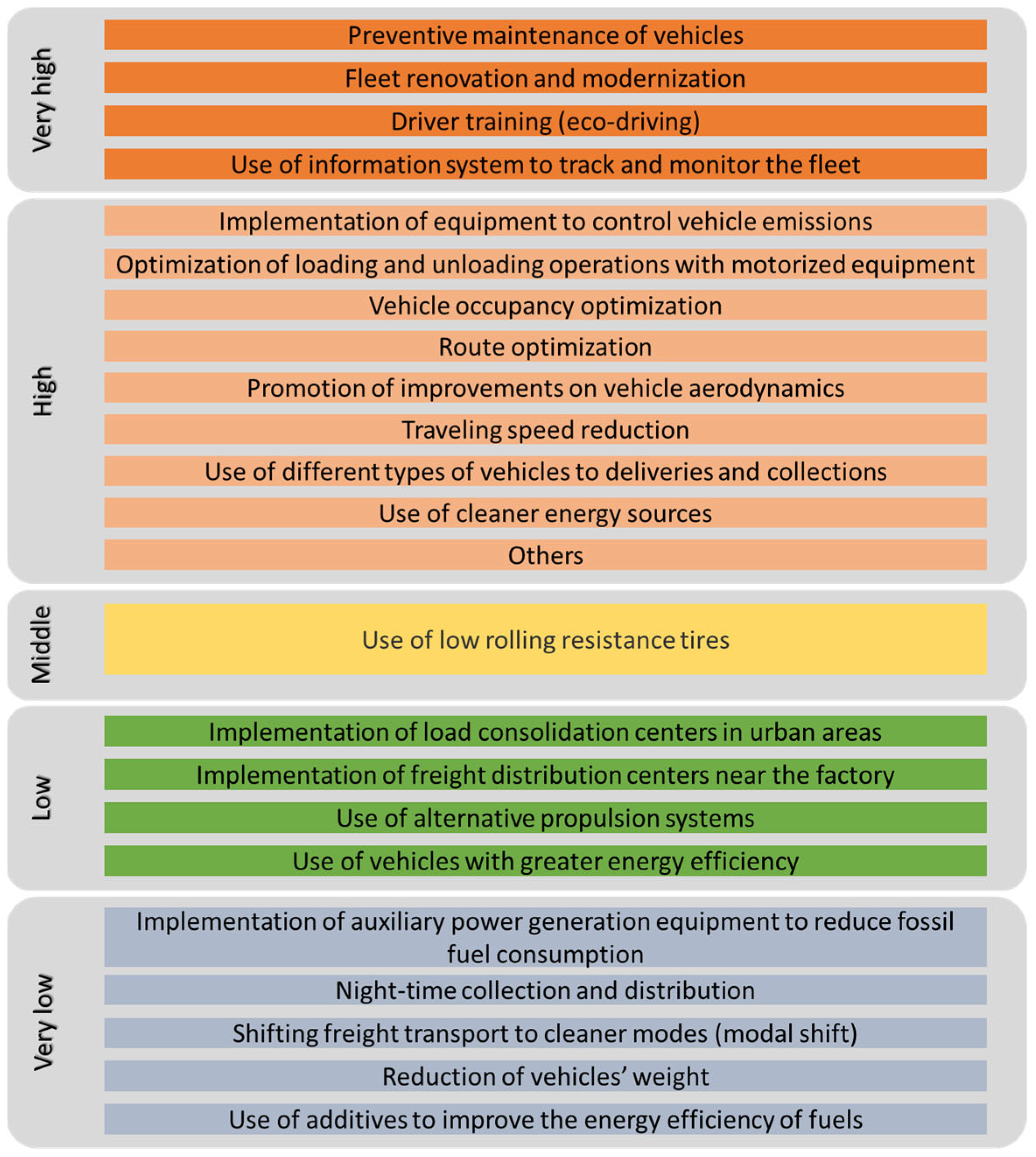

Based on this evaluation, the corresponding range for the priority scale of the best practices was defined as follows: (i) Level 1 corresponds to very-low-priority best practices; (ii) Level 2 represents low-priority best practices; (iii) Level 3 denotes medium-priority best practices; (iv) Level 4 corresponds to high-priority best practices; and (v) Level 5 represents very-high-priority best practices. Then, the maturity scores were defined based on the class interval and divided into five groups, between the average value with the lower limit and the average value with the upper limit, according to the rule presented in

Table 4.

Thus, the evaluation results can be observed in

Figure 4, which presents the priority level of each best practice.

In this context, the evaluation highlights the highest level of maturity among the companies in terms of their adoption of best practices related to preventive vehicle maintenance, fleet renewal and modernization, driver training, and the use of information systems to track and monitor a fleet. These practices have the advantage of a low implementation complexity, as more than 50% of the evaluated transportation companies had already adopted these implementation actions in managing their cargo transportation fleets. These practices, either individually or in combination, can reduce the operational costs associated with fuel consumption and lead to up to a 30% reduction in GHG emissions [

57].

4.5. Other Best Practices Proposed

The remaining best practices, also categorized as high priority, were identified through insights provided by the assessed companies. These practices encompass diverse realms, including water consumption, waste management, and reutilization, among others. Consequently, the delineation and elucidation of these other best practices within this study adhered to the established norms and categories found in widely recognized sustainability reports, such as those by the Sustainability Accounting Standards Board (SASB) and the Global Reporting Initiative (GRI), as meticulously outlined in

Table 5. These practices, highlighted by the surveyed companies, underscore the multi-faceted approach needed to achieve sustainable logistics. They span an array of crucial areas, including water resource management, waste reduction strategies, and innovative approaches to resource reuse.

Therefore, among the other best practices mentioned in this group, the practices adopted by the evaluated companies stand out, as presented in

Table 6. It is noteworthy that there is an absence of best practices in the adoption process.

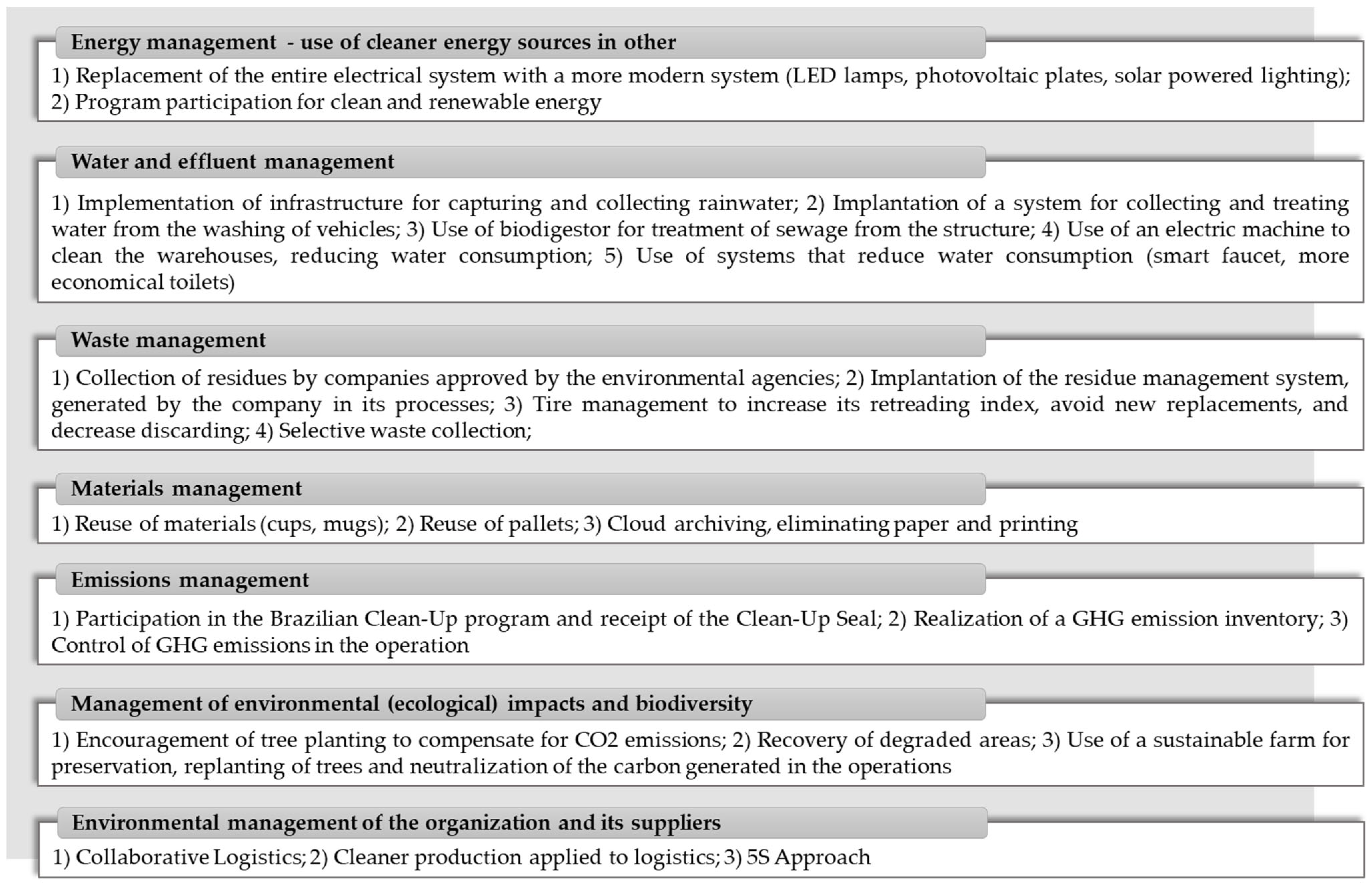

Thus, based on the evaluation, a decreasing implementation of best practices can be observed in the areas of water and effluent management, energy management, waste management, emissions management, materials management, the management of environmental (ecological) impacts and biodiversity, and the environmental management of an organization and its suppliers.

5. Implementation Actions

The implementation actions refer to the solutions, strategies, or initiatives adopted and implemented by companies to make the transition from conventional to sustainable operations. In this way, the solutions, strategies, or initiatives taken by a company have the function of helping companies to achieve their sustainability objectives, improve their overall performance, mitigate their environmental impacts, and comply with regulations when carrying out operational activities related to logistics.

Some examples of implementation actions include the adoption of energy-efficient technologies, the implementation of waste management and recycling programs, the provision of employee training and awareness campaigns on sustainability practices, the establishment of partnerships with sustainable suppliers, and the utilization of eco-friendly transportation methods. The selection and implementation of appropriate implementation actions are contingent upon the unique needs, goals, and circumstances of each company, as shown in

Figure 5.

5.1. Best Practices with Very High Priority

Therefore, in this case, it can be observed that implementation actions are carried out through contracts with concessionaires and manufacturers in order to provide preventive maintenance services, driver training, and fleet renewal plans. These actions have the opportunity to benefit from government fiscal incentives to encourage the adoption of innovative technologies in vehicles, such as trucks with stricter limits on atmospheric pollutants (AP) and greenhouse gas emissions (GHG), such as the Euro 6 category. Additionally, the adoption of fleet management programs provided by manufacturers, such as the Scania Fleet application, the implementation of computerized systems, internal control, and manufacturer guidelines for monitoring preventive and corrective fleet maintenance contribute to the practice of preventive maintenance. Software and hardware programs such as Global Star for fleet tracking systems and driver training provided by manufacturers, the company itself, and other organizations also support these actions.

5.2. Best Practices with High Priority

Regarding this category, the implementation actions observed included solutions directly related to the use of equipment for reducing the pollution generated by a fleet on a periodic basis, fleet monitoring through telematics, vehicles with catalytic converters, and the use of AdBlue (Arla 32) to decrease air pollutants by treating emitted gases such as nitrogen oxides, as well as the adoption of operational planning that focuses on maximizing vehicle occupancy to optimize the operational efficiency of a fleet, including assistance with speed control. Additionally, choosing the most suitable vehicle based on its operational characteristics and using cleaner energy sources help to reduce the energy intensity that would otherwise be consumed by larger and empty vehicles with higher emission factors.

For the specific details of other best practices, these are presented in

Figure 6.

In this category, implementation actions associated with transportation activities, other logistics activities, and facility infrastructure are observed. Cleaner energy sources, such as solar energy, modern lighting systems such as LED lamps, and the use of photovoltaic panels, are utilized. In terms of water treatment, the adoption of rainwater collection systems and the use of recycled water for vehicle washing are mentioned, as well as the use of biodigesters for the sewage treatment of the waste generated by employees and facility operations. To reduce the acquisition of new materials, practices such as material reuse, such as pallets, and the adoption of modern systems such as cloud-based file storage to eliminate printing activities are implemented.

Furthermore, the importance of participating in national programs, such as DESPOLUIR, to improve the quality of life for transporters and engage in socio-environmental responsibility actions, conducting emissions inventories to account for the emissions generated by transportation operations, and implementing emission control mechanisms are emphasized. Based on this knowledge, companies also aim to offset their CO2 emissions through tree planting and the regeneration of degraded areas.

Regarding management systems, companies claim to adopt practices of collaborative logistics, aiming to collaborate with other organizations to increase their chances of making their operations more sustainable. The other approaches mentioned include making logistics activities cleaner and promoting the 5S approach, which encompasses the principles of utilization, organization, cleanliness, standardization, and self-discipline (Seiri, Seiton, Seiso, Seiketsu, and Shitsuke).

5.3. Best Practices with Middle Priority

For the best practices with medium priority, implementation actions associated with vehicle technological modifications to promote fuel consumption reduction through improved tire resistance can be observed. To achieve this, companies adopt measures such as the use of advanced technology materials such as rubber compounds, low-rolling resistance tires, and appropriate tire selection based on the characteristics of each vehicle type, as presented in the previous analysis. Additionally, the implementation of vehicle tracking systems, telematics, and driver behavior monitoring tools are utilized to optimize route planning, minimize idling time, and promote eco-driving practices. Furthermore, the adoption of engine optimization techniques, such as the use of fuel additives and regular maintenance programs, is emphasized to enhance fuel efficiency. These actions aim to reduce the fuel consumption and emissions associated with transportation operations, contributing to environmental sustainability.

5.4. Best Practices with Low Priority

For the low-priority level, more complex best practices involve the construction of new infrastructure and technology replacement. Thus, as actions, infrastructure such as transit points, distribution centers, support points, and hubs have been implemented. Additionally, strategic locations near customers, such as the headquarters of high-consumption contracted companies, have been adopted. In terms of vehicle technology change, implementation actions include the purchase of vehicles with 100% electric propulsion systems and advanced onboard technology such as Euro 5 and high-tech features to increase vehicle energy efficiency.

5.5. Best Practices with Very Low Priority

In this context, there was an absence or lower incidence of reports on the use of implementation actions for or planning of the best practices presented. Therefore, in this classification, the following are observed: the planning of night transportation to serve branches, the use of transport modes with larger vehicles for transfers, the adoption of lighter parts and accessories to reduce vehicle weight, and the use of fuels with additives supplied directly by manufacturers to ensure origin.

6. Conclusions

The objectives of this article were to map the adopted BPs by Brazilian transport companies, define their priority levels based on the maturity degree of the BP implementation and planning, and present implementation actions applied to logistics. The article was aimed at assisting transport companies that are interested in becoming sustainable but do not know where to start.

Furthermore, through the research conducted with transport companies, BPs associated with other topics such as material management, water and effluent management, waste management, and environmental management, among others, were identified. This contributed to the presentation of implementation actions that could be adopted or planned for the implementation of BPs in a broader context.

One limitation of the study is that it focused on the Brazilian scenario, evaluating companies that are members of the national PLVB program. However, these companies are large-scale transporters serving a wide range of economic sectors.

A model was developed to assess the level of priority of the best practices adopted by the transportation companies. This model took into consideration various criteria, such as the maturity level of the best practices implementation, the evaluation of requirements, environmental impacts, and implementation complexity.

Firstly, the necessary requirements for each best practice were defined, considering the guidelines established by recognized organizations such as the Sustainability Accounting Standards Board (SASB) and Global Reporting Initiative (GRI). Based on these requirements, an assessment was made of the maturity level of each company regarding their implementation of best practices.

Next, the average maturity levels of the best practices were calculated, taking into account the performances of the evaluated companies. This allowed for determining the range corresponding to the priority scale, classifying the best practices into different levels of priority, from level 1 (very low priority) to level 5 (very high priority).

The model also considered the environmental impact of the best practices and the complexity of their implementation. The best practices with a higher environmental impact and lower complexity were classified as being higher priority, while those with a lower environmental impact and higher complexity received a lower-priority classification.

Based on this model, it was possible to evaluate and classify the best practices adopted by transportation companies, providing a clear view of which practices are considered as priorities and which can be more easily implemented. This helps interested companies in adopting sustainable best practices to allocate their efforts and resources more efficiently.

For future studies, it is suggested to evaluate the level of priority of the best practices adopted by Brazilian shipping companies in order to map the maturity level and actions implemented by them. Additionally, it is considered important to conduct a study that encompasses other logistical activities such as warehousing, material handling, packaging, and more. It is also suggested to perform an economic analysis of these best practices, including investment and benefit analyses, as well as measuring performance indicators to assist in the decision-making process. By expanding the scope of research, a more comprehensive understanding of the sustainable practices within the logistics industry can be achieved.