Experimental Study on Mechanical Properties and Acoustic Emission Characteristics of Dry and Water-Saturated Soft Rocks under Different Dynamic Loadings

Abstract

:1. Introduction

2. Experimental Program and Conditions

2.1. Sample Preparation

2.2. Experimental Equipment

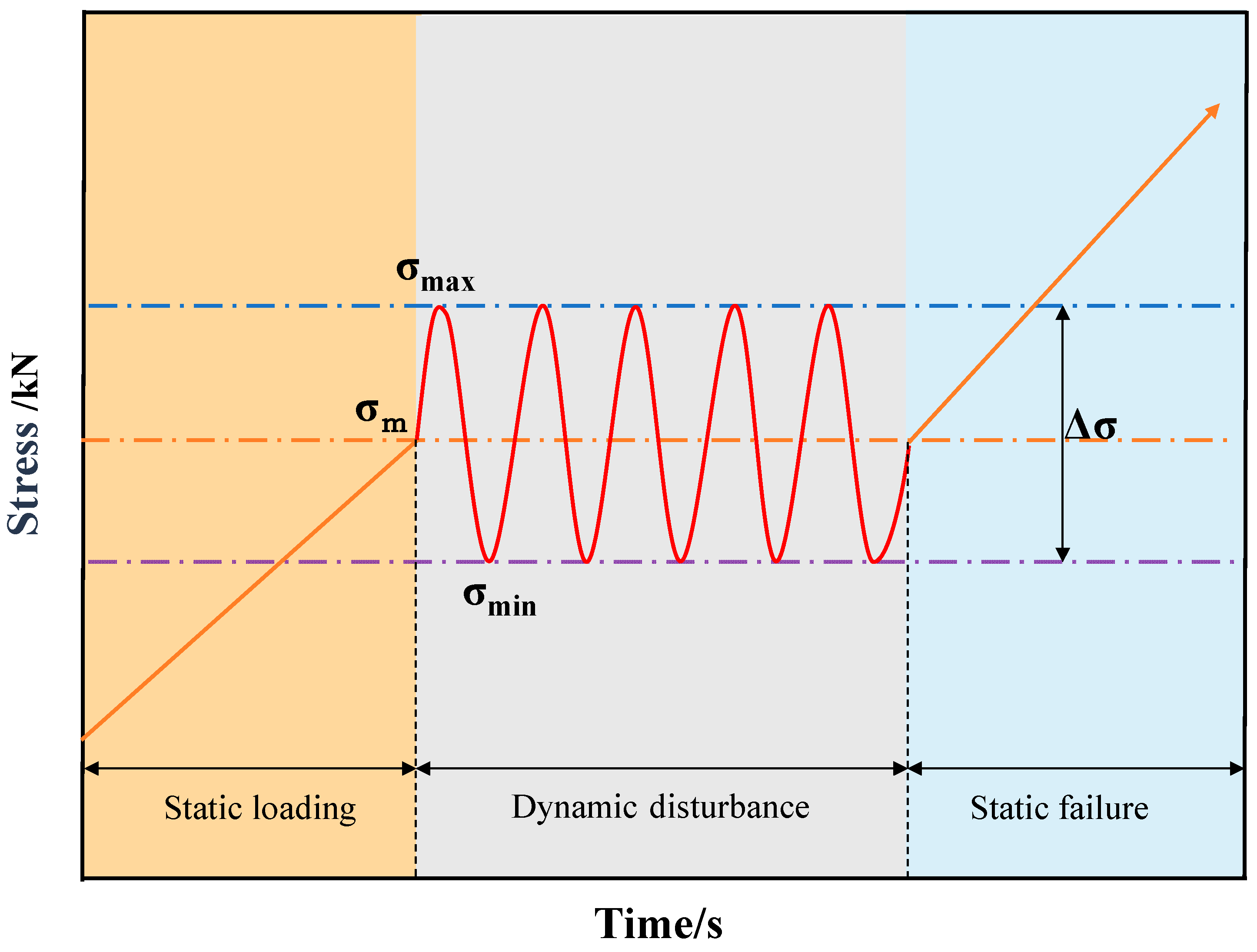

2.3. Experimental Program

3. Analysis of Experimental Results

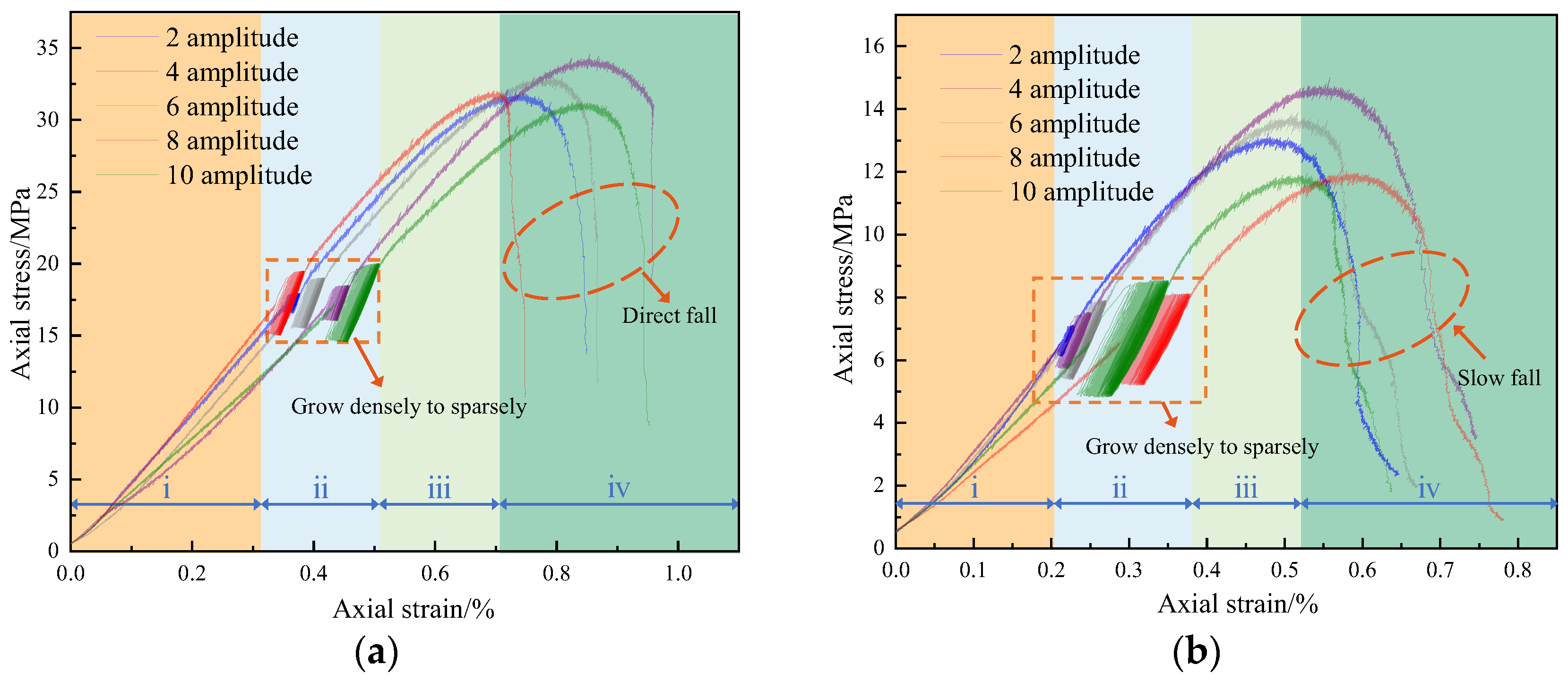

3.1. Stress–Strain Relationships

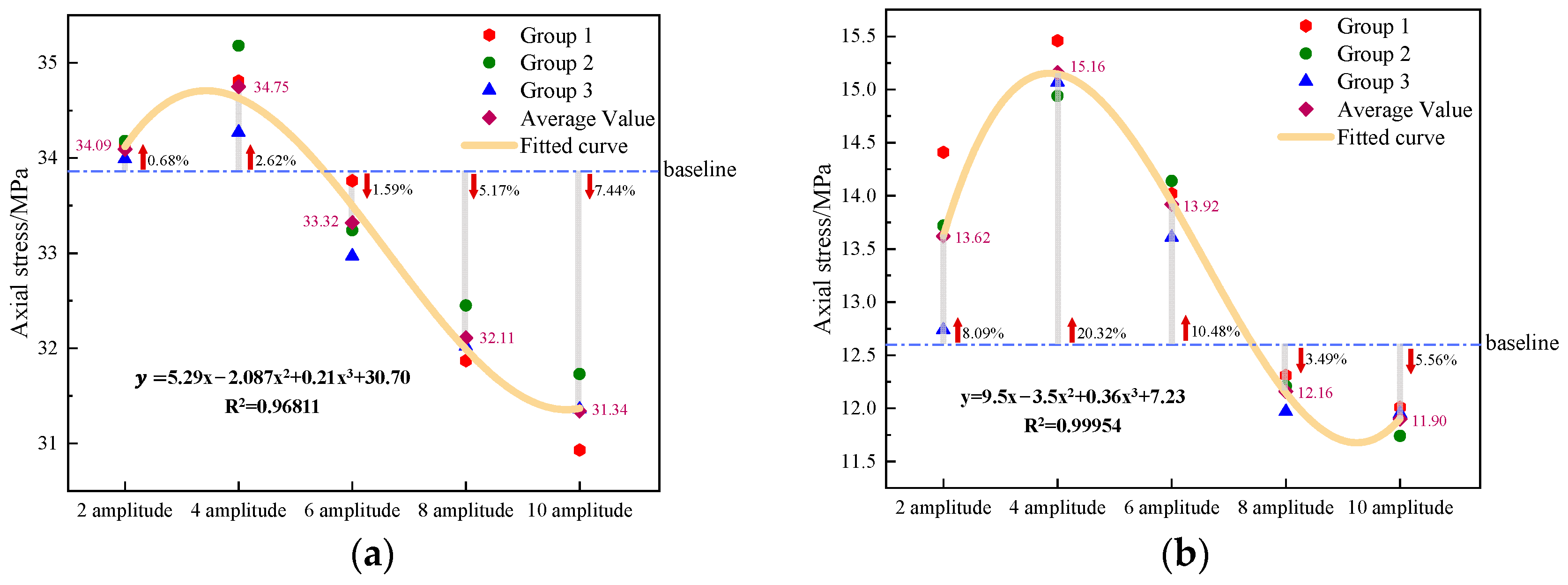

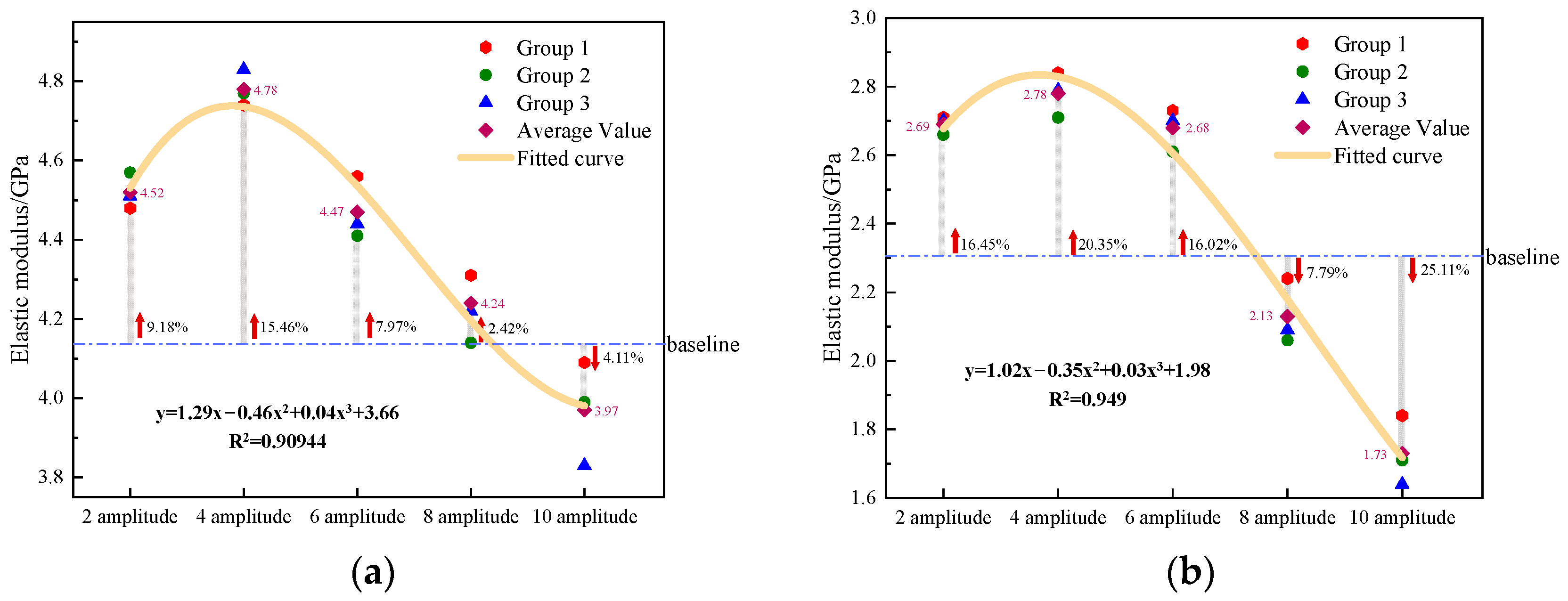

3.2. Change Rule of Mechanical Characteristics

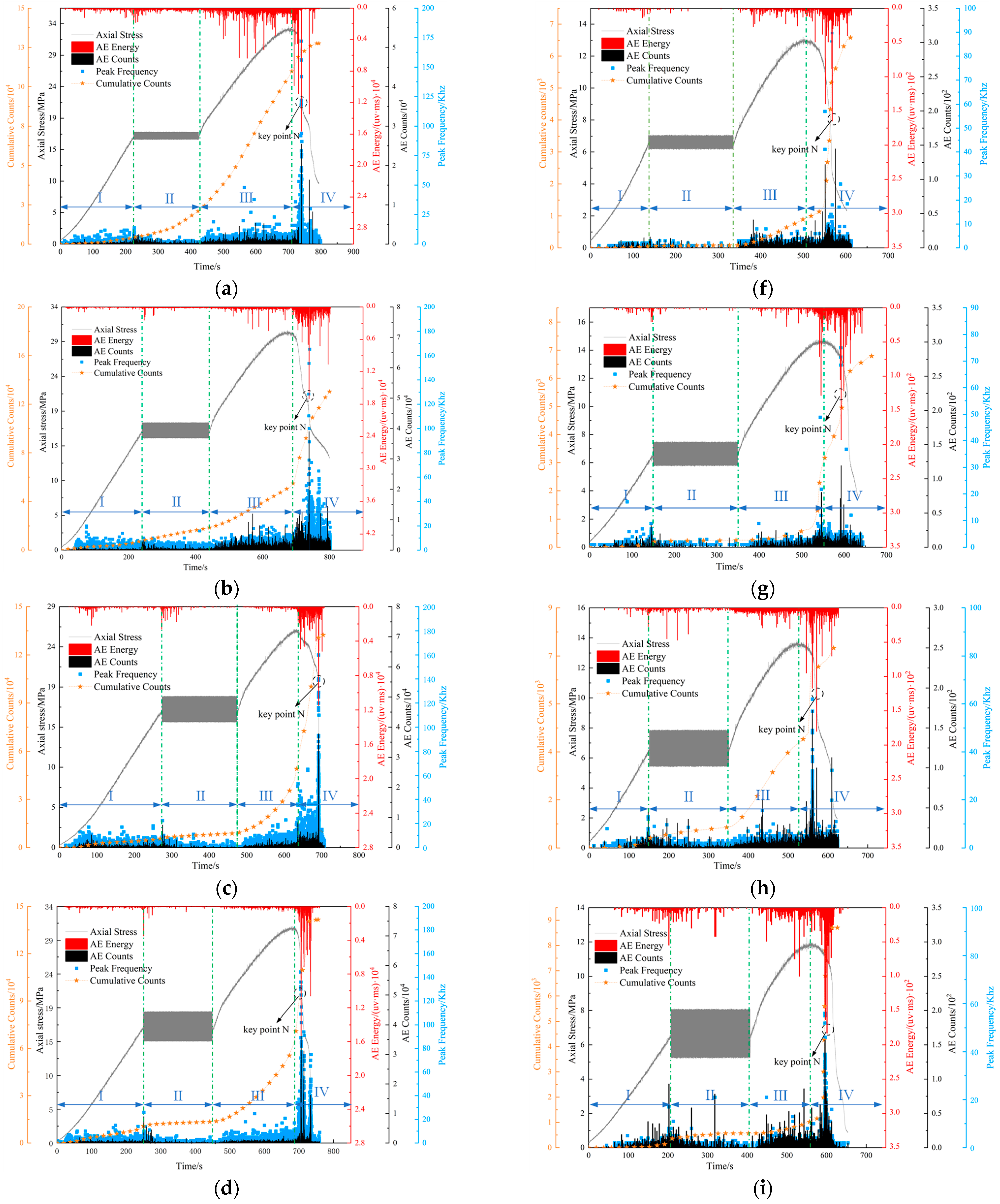

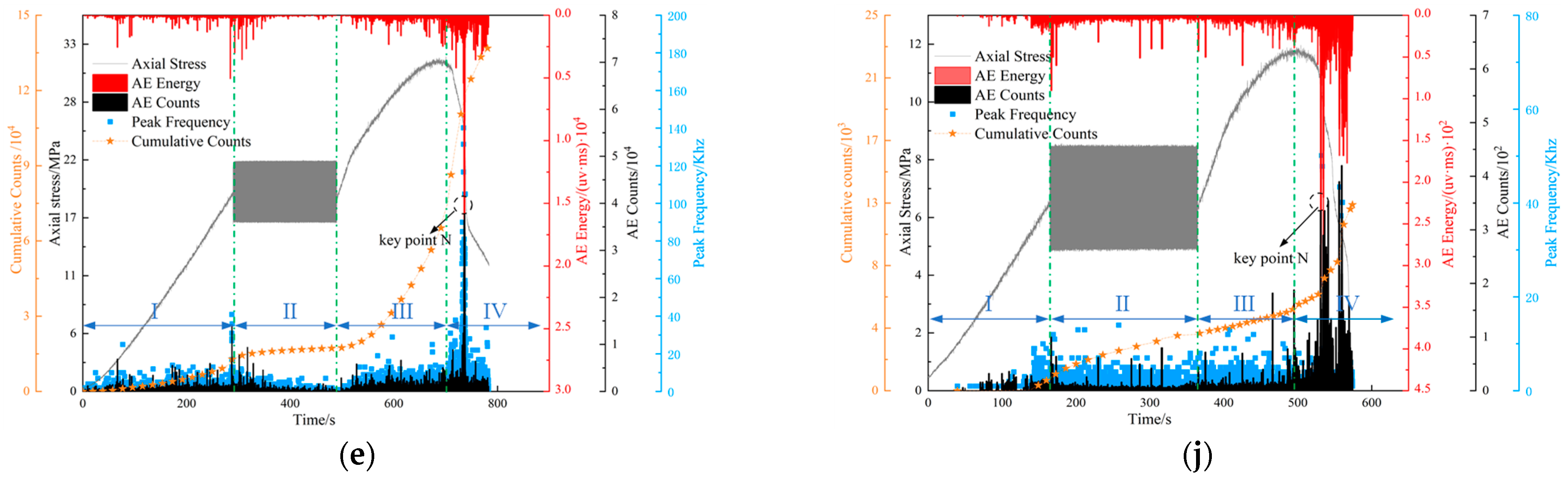

3.3. Acoustic Emission Characterization

- The main frequency eigenvalue of the dry sample decreased gradually with the increase in the perturbation amplitude, and the main frequency range of key point N was between 140 and 172 KHz, with the maximum of 172 KHz at 2 amplitude and the minimum of 140 KHz at an amplitude of 10. The main frequency eigenvalue of the saturated sample changed the rule of law with the dry sample, and the main frequency range of key point N was between 50 and 89 KHz, with the maximum of 89 KHz at 2 amplitude and the minimum of 50 KHz at an amplitude of 10. The smallest amplitude was 50 KHz.

- The eigenvalues corresponding to the primary frequencies of the dry samples surpassed those of the water-saturated samples.

- An inverse relationship was found between the degree of destruction of the sample and the eigenvalue of the dominant frequency. When the degree of destruction was intense, the eigenvalue of the dominant frequency was small.

3.4. Macro Damage Characteristics

- (1)

- Under the perturbation with an amplitude value of 2, the dry sample experienced the formation of multiple tensile cracks originating from the bottom and propagating towards the middle, leading to destabilization damage of the specimen; the overall performance of tensile damage; the sample from the end face of the development of the main crack and the formation of a shear angle of approximately 65° in the surface of the sample in the 4 amplitude value to 8 amplitude value of the perturbation; the experimental samples damage mode for the laminar surface of the shear slippage along the axial cleavage composite damage in the main cracks around the development of a number of micro-cracks; at 10 amplitude, the tensile cracks developed from the upper end face extending to the middle of the specimen; the right half of the sample had the tendency of peeling off, the macro-cracks increased significantly, and the experimental samples as a whole showed tensile damage.

- (2)

- In water-saturated samples with an amplitude value of 2, damage cracks from the top of the specimen down formed a shear surface, with the increase in stress gradually through the weak surface, and linear single oblique shear damage was formed. With amplitude values of 4 and 6, the conjugate shear damage and cracks in general showed “X”-type damage, and the degree of destruction deepened. At 8 and 10 magnitudes, the damage mode was tensile damage. The crack extension form was significantly affected by the perturbation load, tendency of peeling off on the surface of the samples existed, and the damage degree was further deepened.

4. Discussion

5. Conclusions

- (1)

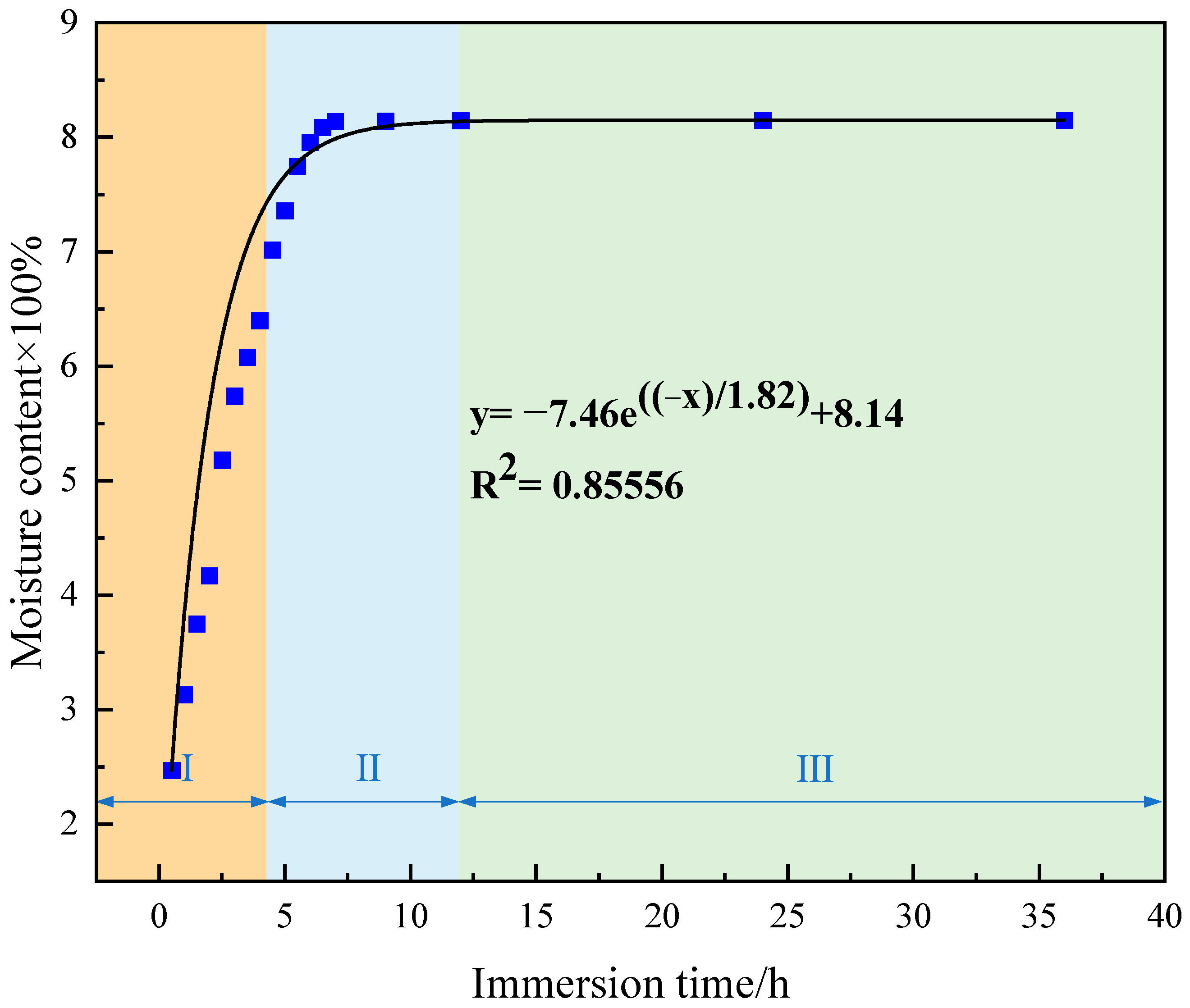

- The muddy sandstone has a saturation water content of 8.148%. In the dynamic perturbation process, the area of the pointed leaf-shaped hysteresis loop is positively linked to the frequency of perturbations. Additionally, this area increases with the perturbation amplitude. Under the same amplitude conditions, the hysteresis loop area of saturated water samples is greater than that of the dry samples.

- (2)

- The peak strength and modulus of elasticity of the samples are nonlinearly related to the amplitude of the perturbation. At 4 amplitude, the strengthening of both samples reaches the maximum, and the water-saturated samples are more sensitive to the effect of the amplitude, and the mechanical characteristic parameters increase or decrease drastically.

- (3)

- The acoustic emission signals of the samples can be divided into four stages according to the characteristics of signal growth. The peak values of the acoustic emission signals of the dry samples are larger than those of the water-saturated samples, and there is a cyclic intensification effect in the fluctuation period (II), which is more obvious as the amplitude increases. The main frequency eigenvalues of the acoustic emission are larger than those of the water-saturated samples when the dry samples are damaged, but the damage degree is reduced.

- (4)

- The damage mode of dry samples varies with amplitude from tensile damage, to tensile–shear composite damage, and finally to tensile damage. The water-saturated samples vary from single-bevel shear damage, to “X”-type conjugate shear damage, and finally to tensile damage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xie, H.P.; Gao, F.; Ju, Y.; Gao, M.Z.; Zhang, R.; Gao, Y.N.; Liu, J.F.; Xie, L.Z. Quantitative definition and investigation of deep mining. J. Chin. Coal. Soc. 2015, 40, 1–10. [Google Scholar]

- Wang, X.F.; Chen, X.Y.; Wang, J.Y.; Chang, Z.C.; Qin, D.D.; Hang, Q.X. Study on creep failure mechanism and control of the deep soft rock roadway in pingdingshan mining area. J. Min. Saf. Eng. 2022, 1–12. [Google Scholar]

- Hang, B.X.; Zhang, N.; Jing, H.W.; Kan, J.G.; Meng, B.; Li, N.; Xie, W.B.; Jiao, J.B. Large deformation theory of rheology and structural instability of the surrounding rock in deep mining roadway. J. Chin. Coal. Soc. 2020, 45, 911–926. [Google Scholar]

- Grgic, D.; Amitrano, D. Creep of a porous rock and associated acoustic emission under different hydrous conditions. J. Geophys. Res. Solid Earth. 2009, 114, 1–19. [Google Scholar] [CrossRef]

- Codeglia, D.; Dixon, N.; Fowmes, G.J.; Marcato, G. Analysis of acoustic emission patterns for monitoring of rock slope deformation mechanisms. Eng. Geol. 2017, 219, 21–31. [Google Scholar] [CrossRef]

- Pham, Q.T.; Vales, F.; Malinsky, L.; Minh, D.N.; Gharbi, H. Effects of desaturation-resaturation on mudstone. Phys. Chem. Earth Parts A/B/C 2007, 32, 646–655. [Google Scholar] [CrossRef]

- Cai, X.; Zhou, Z.L.; Du, X.M. Water-induced variations in dynamic behavior and failure characteristics of sandstone subjected to simulated geo-stress. Int. J. Rock Mech. Min. Sci. 2020, 130, 104339. [Google Scholar] [CrossRef]

- Weng, L.; Wu, Z.J.; Liu, Q.S. Dynamic mechanical properties of dry and water-saturated siltstones under sub-zero temperatures. Rock. Mech. Rock. Eng. 2019, 53, 4381–4401. [Google Scholar] [CrossRef]

- Gao, L.S.; Xu, Y.; Wu, B.B.; Wang, S. Dynamic compression strength of thermal damaged Fangshan marble on dry and saturated conditions. Chin. J. Rock. Mech. Eng. 2018, 37, 3826–3833. [Google Scholar]

- Zhou, Z.L.; Cai, X.; Zhao, Y.; Chen, L.; Xiong, C.; Li, X.B. Strength characteristics of dry and saturated rock at different strain rates. T. Nonferr. Metal. Soc. 2016, 1919–1925. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Liu, S.M.; Jiang, Y.D.; Wang, K.; Hang, Y.Q. Dynamic tensile strength of coal under dry and saturated conditions. Rock. Mech. Rock. Eng. 2016, 49, 1709–1720. [Google Scholar] [CrossRef]

- Özbek, A. Investigation of the effects of wetting-drying and freezing-thawing cycles on some physical and mechanical properties of selected ignimbrites. Bull. Eng. Geol. Environ. 2014, 73, 595–609. [Google Scholar] [CrossRef]

- Khanlari, G.; Abdilor, Y. Influence of wet-dry, freeze-thaw, and heat-cool cycles on the physical and mechanical properties of Upper Red sandstones in central Iran. Bull. Eng. Geol. Environ. 2015, 74, 1287–1300. [Google Scholar] [CrossRef]

- Ren, S.; Li, K.X.; Zhang, P. Mechanical properties and failure characteristics of sandstone under combined effect of dynamic disturbance and high temperature. J. Cent. South. Univ. (Sci. Technol.) 2023, 3, 1087–1097. [Google Scholar]

- Zhang, P.; Ren, S.; Zhang, C.; Wu, F.; Long, N.Z.; Li, K.X. Rockburst tendency and failure characteristics of sandstone under cyclic disturbance and high temperature. Rock. Soil. Mech. 2023, 3, 771–783. [Google Scholar]

- Wang, Y.; Zhou, Z.; Ling, K.; Guo, Y.P. Study on Acoustic Emission Characteristics of Sandstone Impact Rockburst under Different Disturbance Frequencies. Coal. Tech. 2022, 12, 27–31. [Google Scholar]

- Feng, F.; Chen, S.J.; Wang, Q.; Rostami, J.; Khoreshok, A.; Sheng, S.Q.; Bian, Z.; Ding, Y.S. Experimental study on failure characteristics of natural and saturated sandstone under true triaxial unloading and dynamic disturbance condition. Chin. J. Rock. Mech. Eng. 2022, 11, 2240–2253. [Google Scholar]

- Yang, K.; Zhang, Z.N.; Chi, X.L.; Lü, X.; Wei, Z.; Liu, W.J. Experimental study on crack evolution and damage characteristics of water bearing sandstone under cyclic loading. Rock. Soil. Mech. 2022, 7, 1791–1802. [Google Scholar]

- Zhang, Q.X.; Ge, X.R.; Hang, M.; Sun, H. Testing study on fatigue deformation law of Red-sandstone under triaxial compression with cyclic loading. Chin. J. Rock. Mech. Eng. 2006, 25, 473–478. [Google Scholar]

- Xiao, J.Q.; Ding, D.X.; Xu, G.; Jiang, F.L. Deformation characteristics of rock under constant amplitude cyclic loading. J. Cent. South. Univ. Sci. Technol. 2010, 41, 685–691. [Google Scholar]

- Li, S.C.; Xu, J.; Tao, Y.Q.; Tang, X.J.; Yang, H.W. Low cycle fatigue damage model and damage variable expression of rock. Rock. Soil. Mech. 2009, 30, 1611–1615. [Google Scholar]

- Guo, Y.T.; Zhao, K.L.; Sun, G.H.; Yang, C.H.; Ma, H.L.; Zhang, G.M. Experimental study of fatigue deformation and damage characteristics of salt rock under cyclic loading. Rock. Soil. Mech. 2011, 32, 1353–1358. [Google Scholar]

- Sun, X.M.; Jiang, M.; Wang, X.B.; Zang, J.C.; Gao, X.; Miao, C.Y. Experimental study on creep mechanical properties of sandstone with different water content in Wanfu Coal Mine. Rock. Soil. Mech. 2023, 44, 624–636. [Google Scholar]

- Sun, X.M.; Wang, D.; Feng, J.L.; Zhang, C.; Chen, Y.W. Deformation Control of Asymmetric Floor Heave in Deep Rock Roadway: A Case Study. Int. J. Min. Sci. Technol. 2014, 24, 799–804. [Google Scholar] [CrossRef]

- Erguler, Z.A.; Ulusay, R. Water-induced variations in mechanical properties of clay-bearing rocks. Int. J. Rock Mech. Min. Sci. 2009, 46, 355–370. [Google Scholar] [CrossRef]

- Roy, D.G.; Singh, T.N.; Kodikara, J.; Das, R. Effect of Water Saturation on the Fracture and Mechanical Properties of Sedimentary Rocks. Rock. Mech. Rock. Eng. 2017, 50, 2585–2600. [Google Scholar]

- Yu, C.; Tang, S.; Tang, C.A.; Duan, D.; Zhang, Y.; Liang, Z.; Ma, K.; Ma, T. The effect of water on the creep behavior of red sandstone. Eng. Geol. 2019, 253, 64–74. [Google Scholar] [CrossRef]

- Tang, S.B.; Yu, C.Y.; Heap, M.J.; Chen, P.Z.; Ren, Y.G. The Influence of Water Saturation on the Short- and Long-Term Mechanical Behavior of Red Sandstone. Rock. Mech. Rock. Eng. 2018, 51, 2669–2687. [Google Scholar] [CrossRef]

- Wang, D.; Jiang, Y.; Sun, X.; Luan, H.; Zhang, H. Nonlinear Large Deformation Mechanism and Stability Control of Deep Soft Rock Roadway: A Case Study in China. Sustainability 2019, 11, 6243. [Google Scholar] [CrossRef]

- Dong, L.; Wang, D.; Sun, X.; Jiang, Y.; Luan, H.; Xu, H.; Li, B.; Cai, F. Large-Deformation Failure Mechanism and Stability Control of a Swelling Soft Rock Roadway in a Sea Area: A Case Study in Eastern China. Sustainability 2023, 15, 5323. [Google Scholar] [CrossRef]

- Liu, H.; Yang, G.S.; Shen, Y.J.; Ye, W.J.; Xi, J.M.; Jin, L.; Wei, Y.; Li, B.R.; Liu, S. CT visual quantitative characterization of meso-damage evolution of sandstone under freeze-thaw-loading synergistic effect. Chin. J. Rock. Mech. Eng. 2023, 42, 1136–1149. [Google Scholar]

- Liu, S.X.; Xing, J.; Zheng, X.; Chen, S.J. Zonal damage information and critical failure identification of CT images of rock under triaxial compression. Chin. J. Geotech. 2021, 3, 432–438. [Google Scholar]

| State of Rock Sample | No. of Samples | Average Water Content (%) | Average Compressive Strength (MPa) | Average Modulus of Elasticity (GPa) |

|---|---|---|---|---|

| Dryness | 3 | 0.000 | 33.86 | 4.14 |

| Saturation | 3 | 8.148 | 12.60 | 2.31 |

| State of Rock Sample | Sample Group | No. of Samples | Average Water Content (%) | σm (MPa) | Disturbance Frequency (Hz) | Amplitude (kN) |

|---|---|---|---|---|---|---|

| Dryness | DS-2 | 3 | 0.000 | 16.93 | 5 | 2 |

| Dryness | DS-4 | 3 | 0.000 | 16.93 | 5 | 4 |

| Dryness | DS-6 | 3 | 0.000 | 16.93 | 5 | 6 |

| Dryness | DS-8 | 3 | 0.000 | 16.93 | 5 | 8 |

| Dryness | DS-10 | 3 | 0.000 | 16.93 | 5 | 10 |

| Saturation | SS-2 | 3 | 8.148 | 6.30 | 5 | 2 |

| Saturation | SS-4 | 3 | 8.148 | 6.30 | 5 | 4 |

| Saturation | SS-6 | 3 | 8.148 | 6.30 | 5 | 6 |

| Saturation | SS-8 | 3 | 8.148 | 6.30 | 5 | 8 |

| Saturation | SS-10 | 3 | 8.148 | 6.30 | 5 | 10 |

| State of Rock Sample | Sample Group | No. of Samples | Average Water Content (%) | Average Compressive Strength (MPa) | Average Modulus of Elasticity (GPa) |

|---|---|---|---|---|---|

| Dryness | DS-2 | 3 | 0.000 | 34.09 | 4.52 |

| Dryness | DS-4 | 3 | 0.000 | 34.75 | 4.78 |

| Dryness | DS-6 | 3 | 0.000 | 33.32 | 4.47 |

| Dryness | DS-8 | 3 | 0.000 | 32.11 | 4.24 |

| Dryness | DS-10 | 3 | 0.000 | 31.34 | 3.97 |

| Saturation | SS-2 | 3 | 8.148 | 13.62 | 2.69 |

| Saturation | SS-4 | 3 | 8.148 | 15.16 | 2.78 |

| Saturation | SS-6 | 3 | 8.148 | 13.92 | 2.68 |

| Saturation | SS-8 | 3 | 8.148 | 12.16 | 2.13 |

| Saturation | SS-10 | 3 | 8.148 | 11.90 | 1.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Wang, D.; Jiang, Y.; Luan, H.; Zhang, G.; Liang, B. Experimental Study on Mechanical Properties and Acoustic Emission Characteristics of Dry and Water-Saturated Soft Rocks under Different Dynamic Loadings. Sustainability 2023, 15, 13201. https://doi.org/10.3390/su151713201

Chen L, Wang D, Jiang Y, Luan H, Zhang G, Liang B. Experimental Study on Mechanical Properties and Acoustic Emission Characteristics of Dry and Water-Saturated Soft Rocks under Different Dynamic Loadings. Sustainability. 2023; 15(17):13201. https://doi.org/10.3390/su151713201

Chicago/Turabian StyleChen, Lugen, Dong Wang, Yujing Jiang, Hengjie Luan, Guangchao Zhang, and Bin Liang. 2023. "Experimental Study on Mechanical Properties and Acoustic Emission Characteristics of Dry and Water-Saturated Soft Rocks under Different Dynamic Loadings" Sustainability 15, no. 17: 13201. https://doi.org/10.3390/su151713201

APA StyleChen, L., Wang, D., Jiang, Y., Luan, H., Zhang, G., & Liang, B. (2023). Experimental Study on Mechanical Properties and Acoustic Emission Characteristics of Dry and Water-Saturated Soft Rocks under Different Dynamic Loadings. Sustainability, 15(17), 13201. https://doi.org/10.3390/su151713201