Environmental and Technological Assessment of Operations for Extraction and Concentration of Metals in Electronic Waste

Abstract

:1. Introduction

2. Materials and Methods

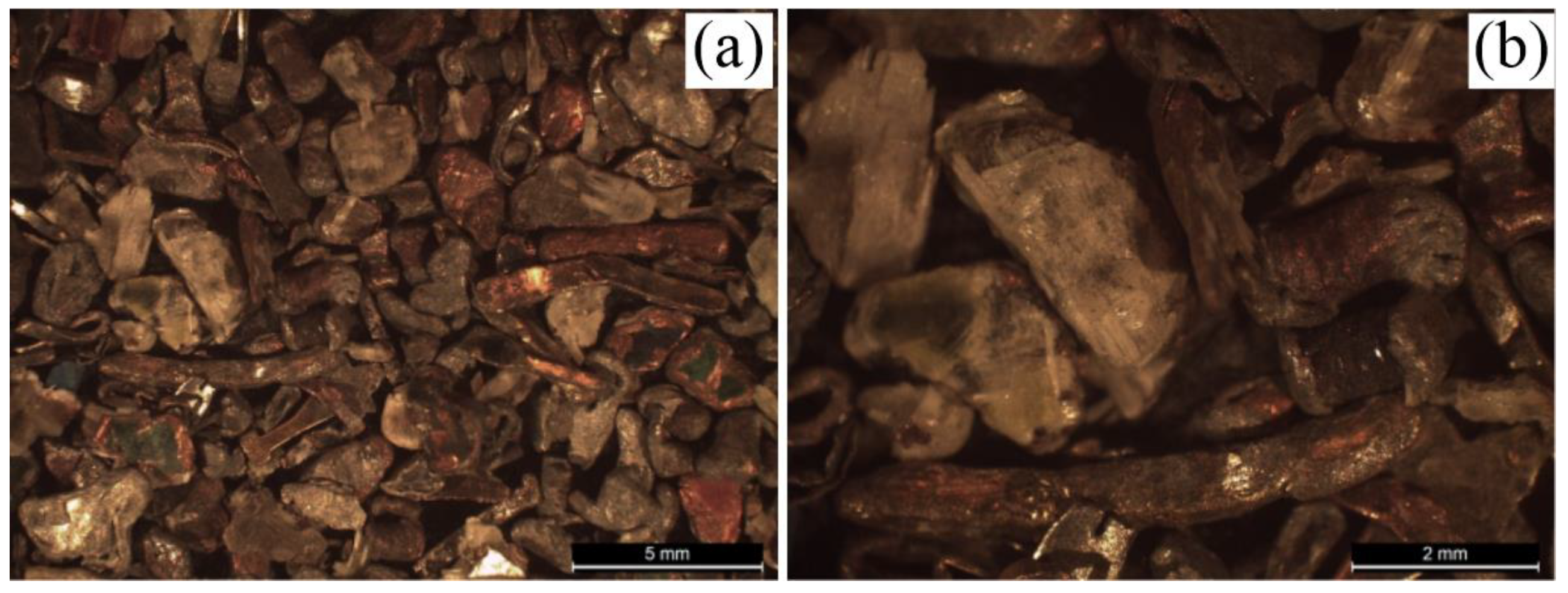

2.1. Materials

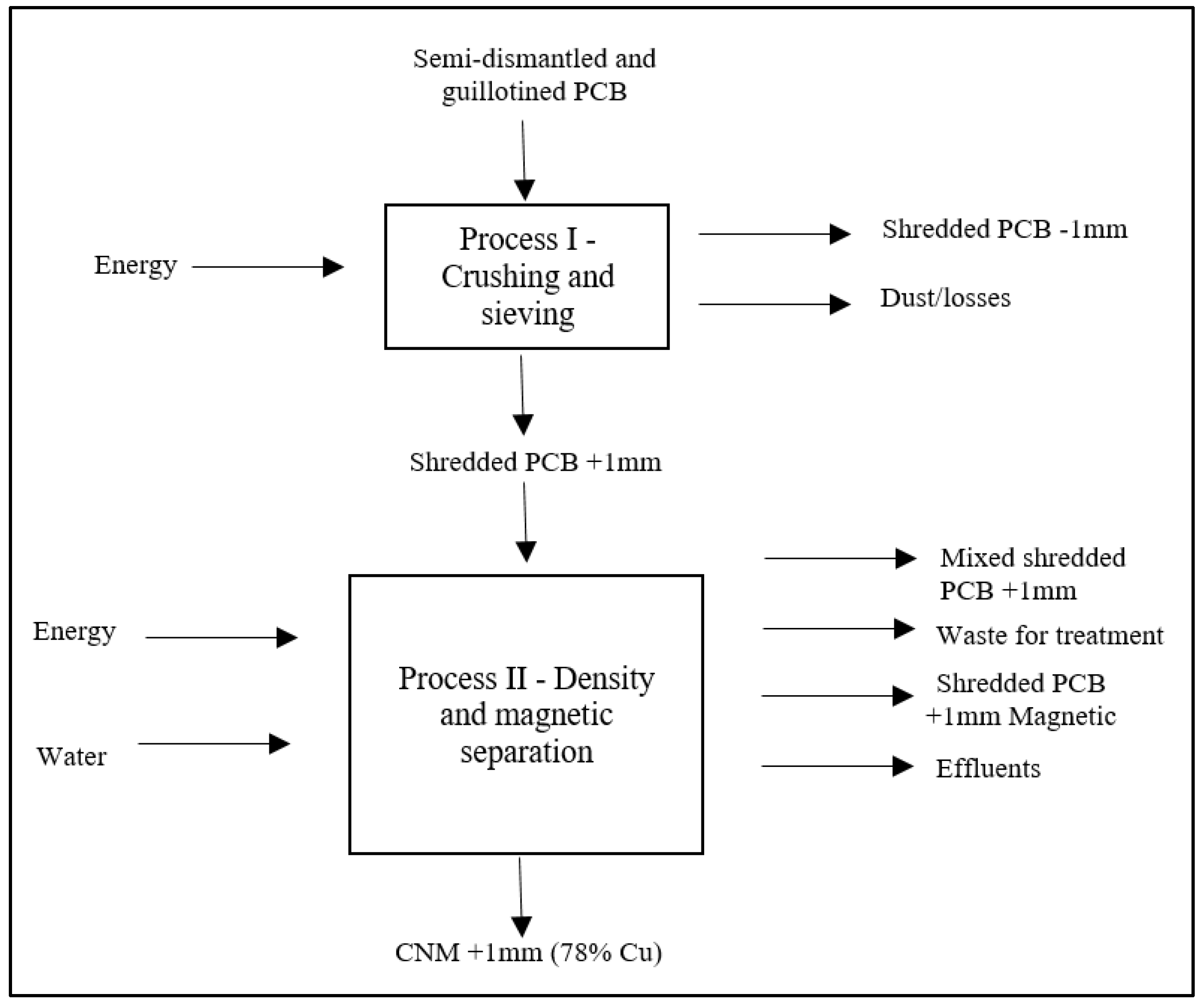

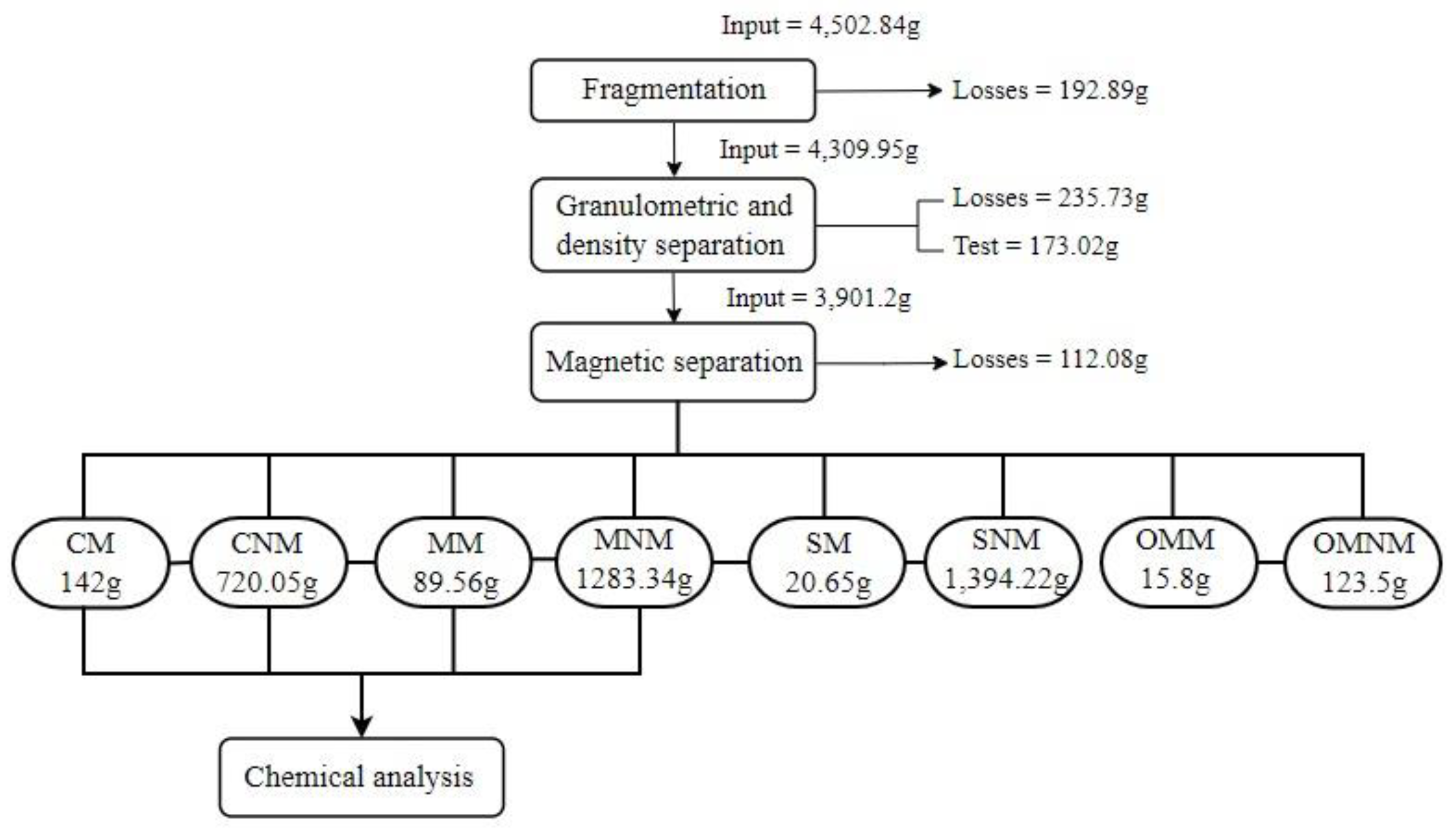

2.2. Physical and Mechanical Processing

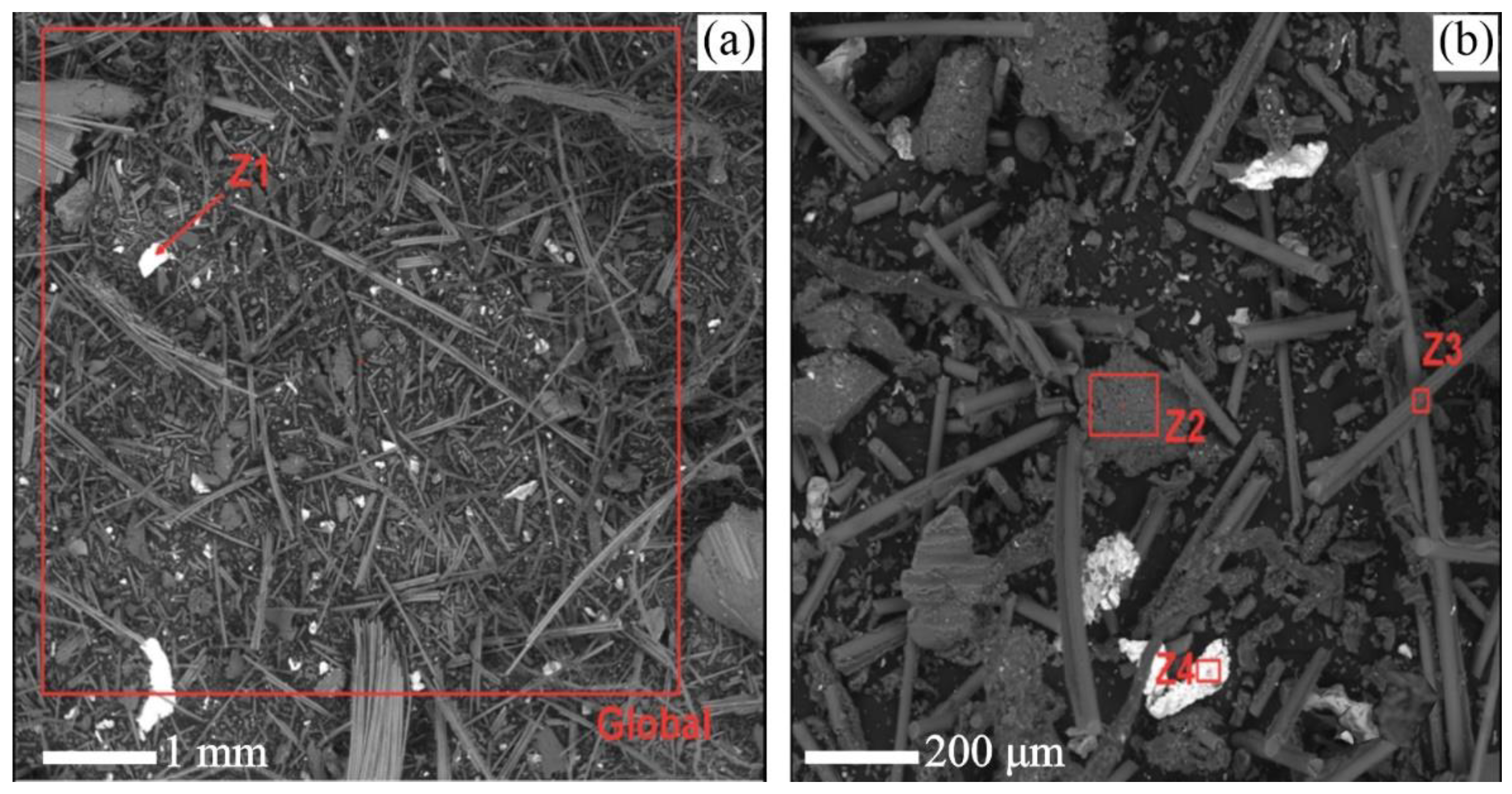

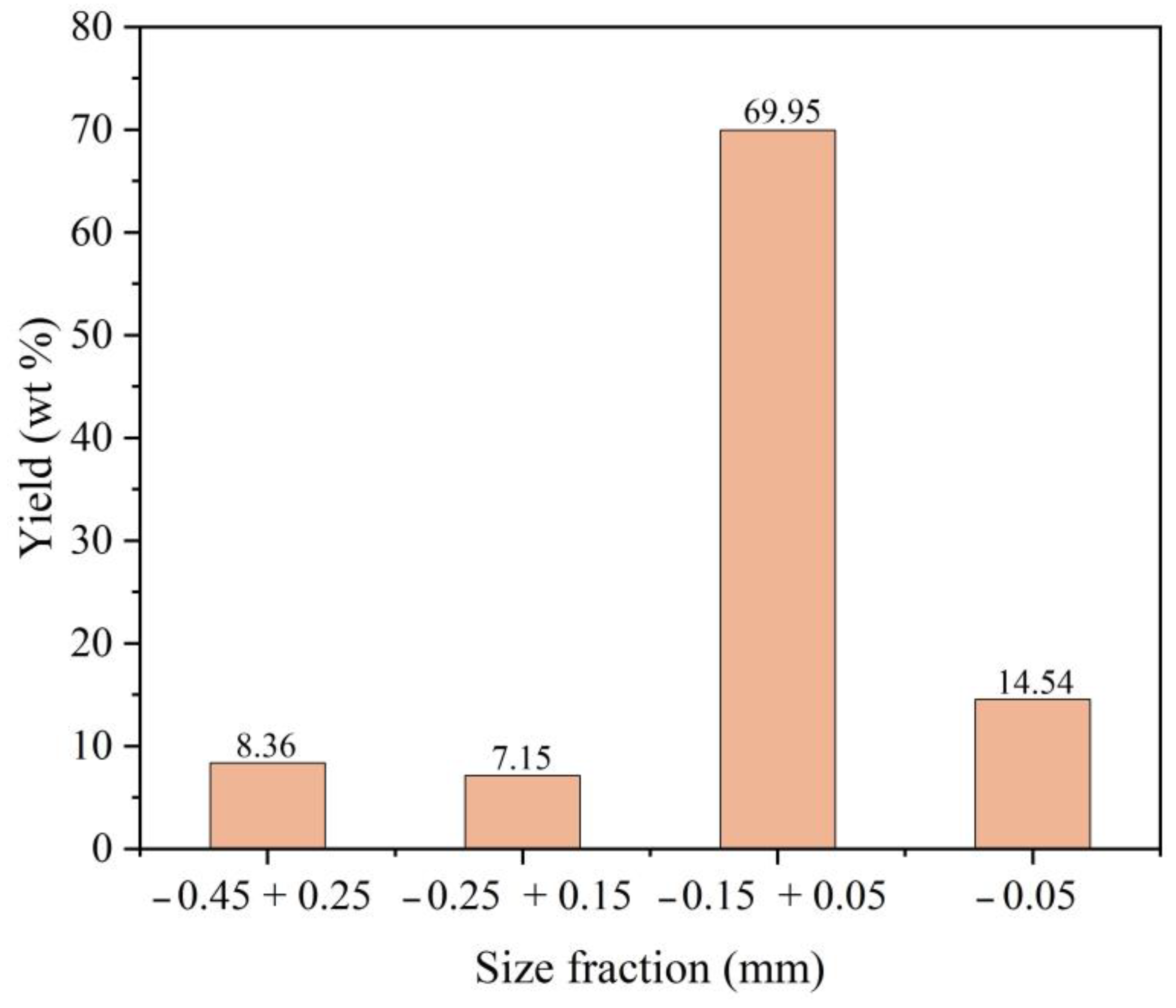

Physical and Chemical Characterization of Waste Printed Circuit Boards Dust

2.3. Physical and Chemical Characterization of Waste Printed Circuit Boards

2.4. Life Cycle Assessment—LCA

3. Results and Discussion

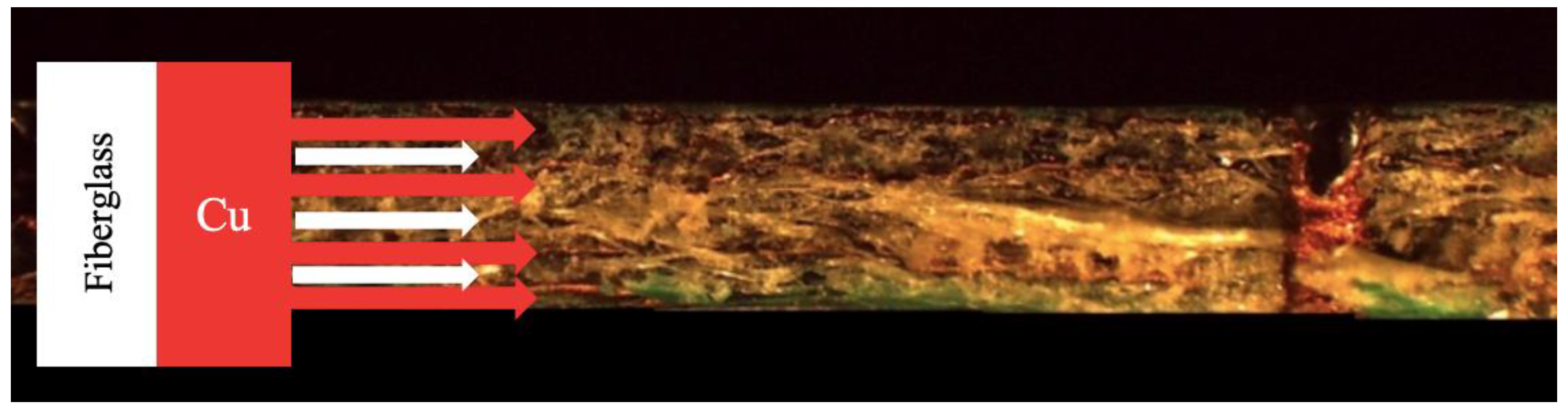

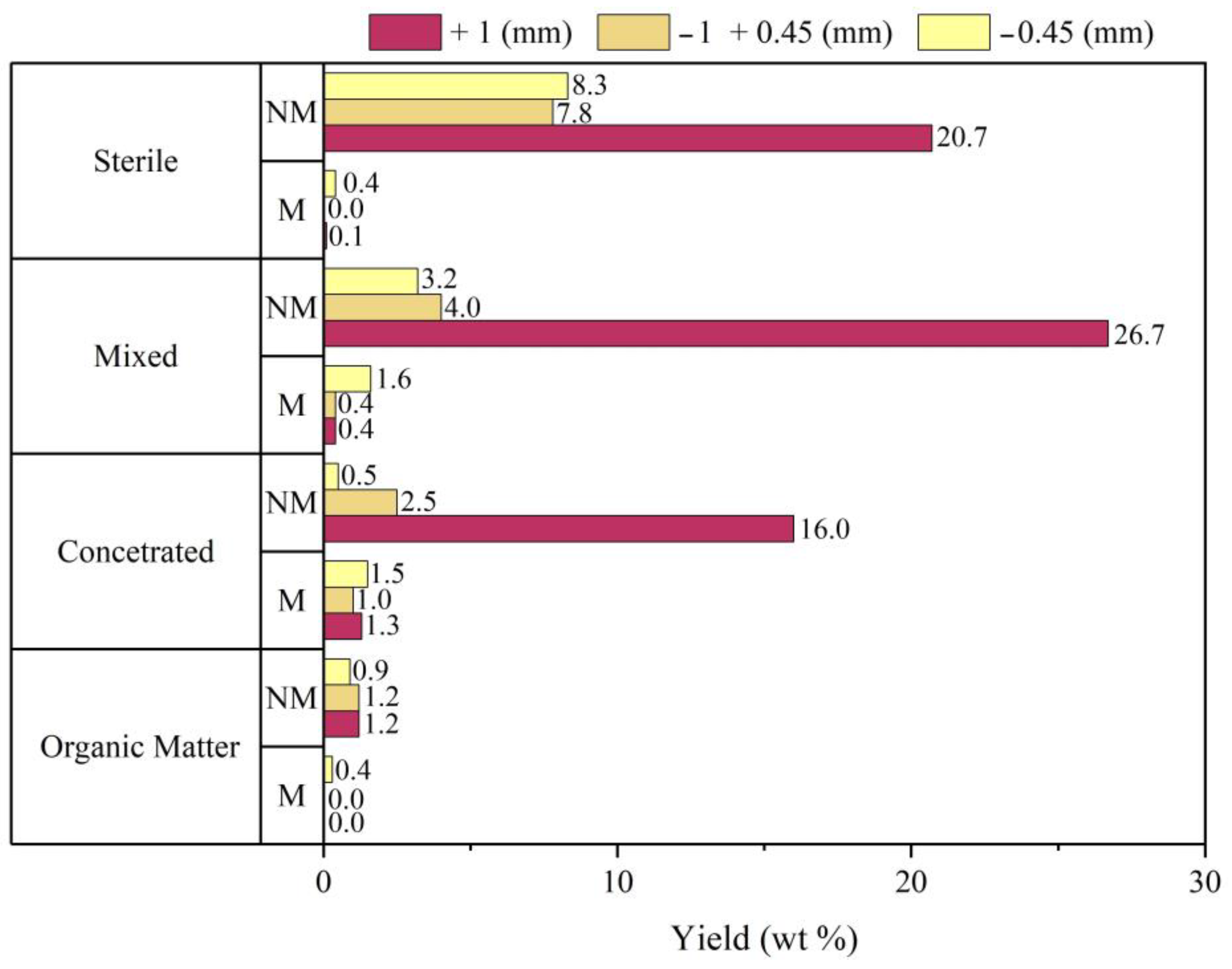

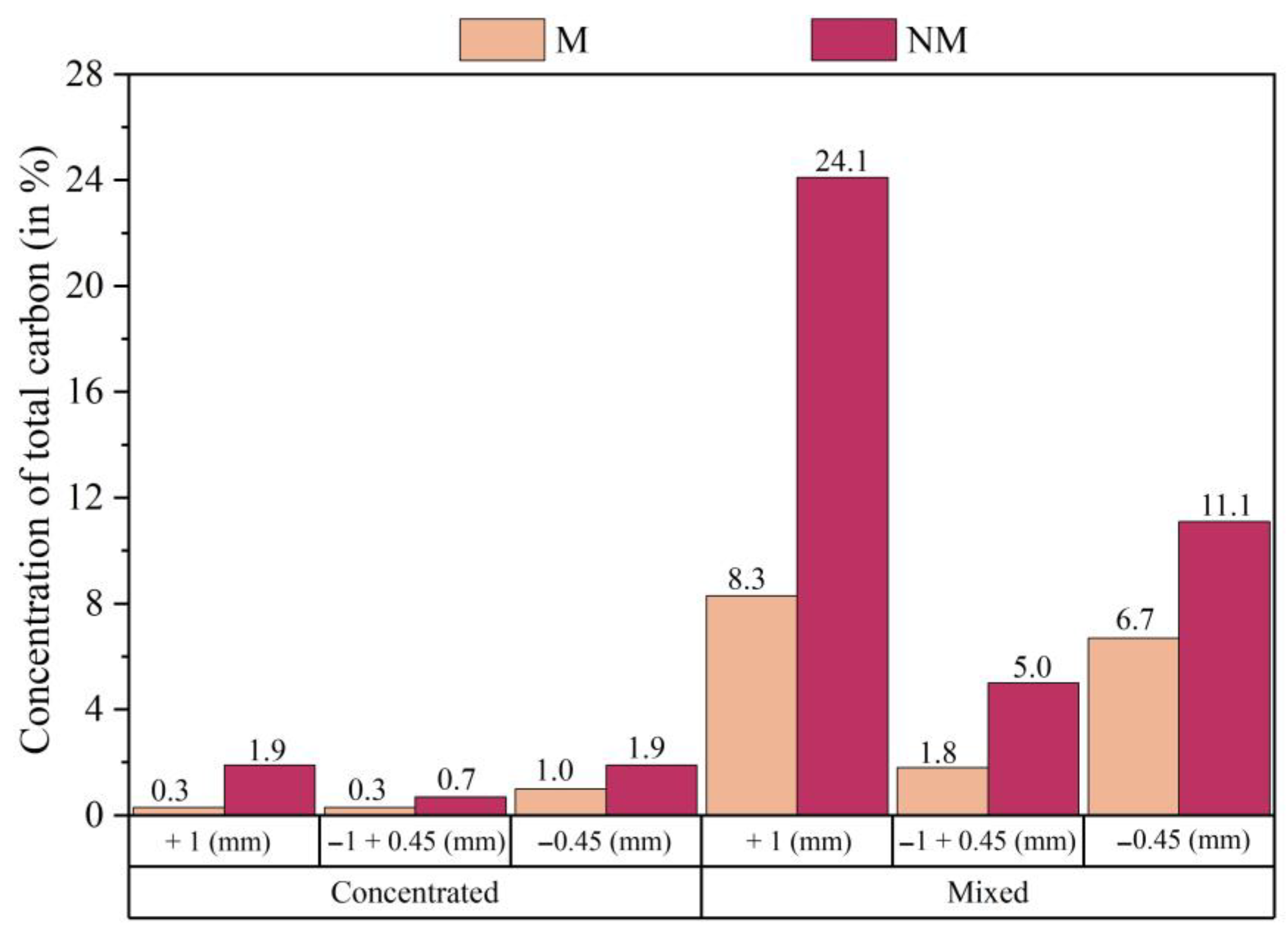

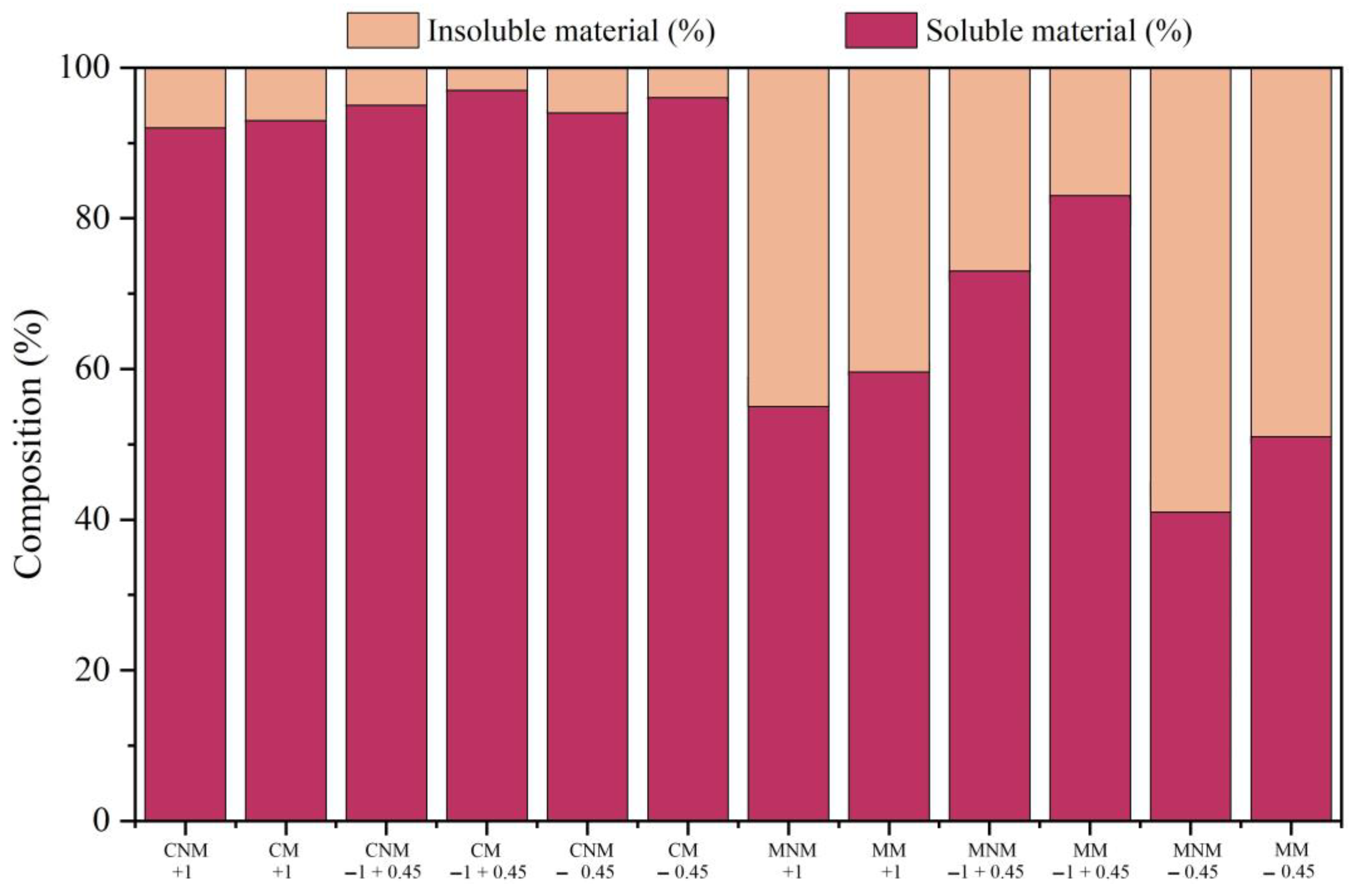

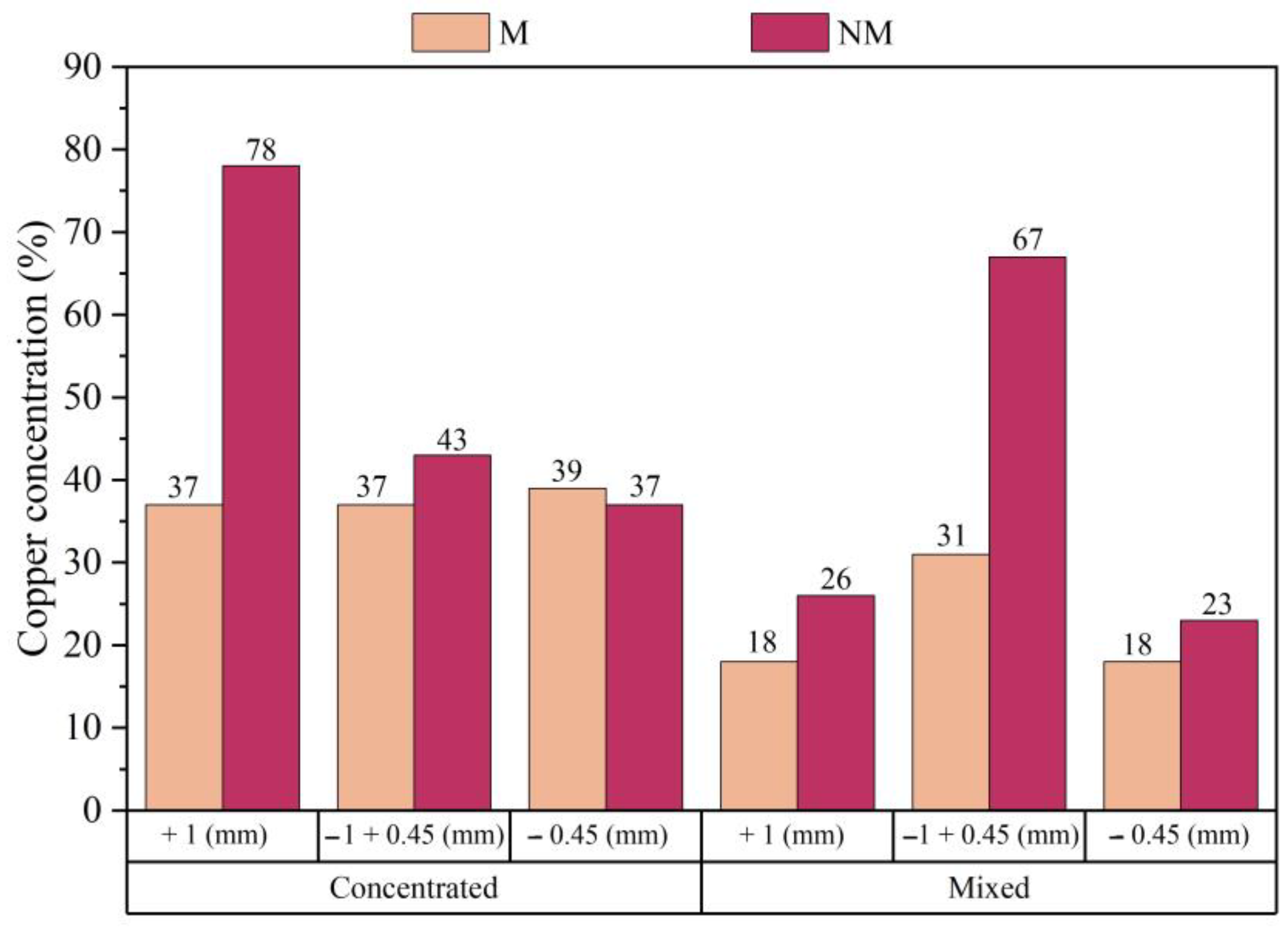

3.1. Physical and Mechanical Processing: Copper Concentration

Analysis of Dust Obtained in the Fragmentation Process

3.2. Life Cycle Assessment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xavier, L.H.; Lins, F.A.F. Mineração Urbana de resíduos eletroeletrônicos: Uma nova fronteira a explorar no Brasil. Bras. Miner. 2018, 379, 22–26. [Google Scholar]

- Ribeiro, P.P.M.; Santos, I.D.; Achilles Dutra, A.J.B. Copper and metals concentration from printed circuit boards using a zig-zag classifier. J. Mater. Res. Technol. 2019, 8, 513–520. [Google Scholar] [CrossRef]

- Zhou, Y.; Qiu, K. A new technology for recycling materials from waste printed circuit boards. J. Hazard. Mater. 2010, 175, 823–828. [Google Scholar] [CrossRef] [PubMed]

- Kasper, A.C.; Veit, H.M. Gold recovery from printed circuit boards of mobile phones scraps using a leaching solution alternative to cyanide. Braz. J. Chem. Eng. 2018, 35, 931–942. [Google Scholar] [CrossRef]

- Gu, F.; Summers, P.A.; Hall, P. Recovering materials from waste mobile phones: Recent technological developments. J. Clean. Prod. 2019, 136, 657–663. [Google Scholar] [CrossRef]

- Ghosh, B.; Ghosh, M.K.; Parhi, P.; Mukherjee, P.S.; Mishra, B.K. Waste Printed Circuit Boards Recycling: An Extensive Assessment of Current Status. J. Clean. Prod. 2015, 94, 5–19. [Google Scholar] [CrossRef]

- Kaya, M. Waste printed circuit board (WPCB) recycling technology: Disassembly and desoldering approach. In Reference Module in Materials Science and Materials Engineering/Encyclopedia of Renewable and Sustainable Materials Volume; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Kumar, V.; Lee, J.; Jeong, J.; Kumar, M.; Kim, B. Recycling of printed circuit boards (PCBs) to generate enriched rare metal concentrate. J. Ind. Eng. Chem. 2015, 21, 805–813. [Google Scholar] [CrossRef]

- Nekouei, R.K.; Pahlevani, F.; Rajarao, R.; Golmohammadzadeh, R.; Sahajwalla, V. Two-step pre-processing enrichment of waste printed circuit boards: Mechanical milling and physical separation. J. Clean. Prod. 2018, 184, 1113–1124. [Google Scholar] [CrossRef]

- Silvas, F.P.C. Utilização de Hidrometalurgia e Biohidrometalurgia para Reciclagem de Placas de Circuito Impresso/F.P.C. Silvas.—Tese (Doutorado)—Escola Politécnica da Universidade de São Paulo; Departamento de Engenharia Química: São Paulo, Brazil, 2014. [Google Scholar]

- Işıldar, A.; Rene, E.R.; van Hullebusch, E.D.; Lens, P.N.L. Electronic waste as a secondary source of critical metals: Management and recovery technologies. Resour. Conserv. Recycl. 2018, 135, 296–312. [Google Scholar] [CrossRef]

- Suresh, S.S.; Bonda, S.; Mohanty, S.; Nayak, S.K. A review on computer waste with its special insight to toxic elements, segregation and recycling techniques. Process Saf. Environ. Prot. 2018, 116, 477–493. [Google Scholar] [CrossRef]

- Liu, R.; Shieh, R.; Yeh, R.Y.; Lin, C. The general utilization of scrapped PC board. Waste Manag. 2009, 29, 2842–2845. [Google Scholar] [CrossRef]

- Dias, J.; Xavier, G.; Azevedo, A.; Alexandre, J.; Colorado, H.; Vieira, C.M. Eco-friendly ceramic bricks: A comparative study of life cycle impact methods. Environ. Sci. Pollut. Res. 2022, 29, 76202–76215. [Google Scholar] [CrossRef]

- ISO 11466:1995; Soil Quality—Extraction of Trace Metals Soluble in Aqua Regia. ISO: Geneva, Switzerland, 1995.

- EN 13137: 2001; Characterization of Waste-Determination of Total Organic Carbon (TOC) in Waste, Sludges and Sediments. EN: Berlin, Germany, 2001.

- ISO 14040: 2006/Amd 1:2020; Environmental Management Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- Silvas, F.P.C.; Jiménez, M.M.C.; Caldas, M.P.K.; De Moraes, V.T.; Espinosa, D.C.R.; Tenório, J.A.S. Printed circuit board recycling: Physical processing and copper extraction by selective leaching. Waste Manag. 2015, 46, 503–510. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Huisman, J.; Meskers, C.E.M.; Schluep, M.; Stevels, A.; Hagelüken, C. The Best-of-2-Worlds philosophy: Developing local dismantling and global infrastructure network for sustainable e-waste treatment in emerging economies. Waste Manag. 2012, 32, 2134–2146. [Google Scholar] [CrossRef] [PubMed]

| Process I | ||

|---|---|---|

| Description | Value | Unit |

| Inputs (materials and energy) | ||

| WPCB | 7.16 | kg |

| Energy | 29.5 | kWh |

| Output | ||

| Shredded PCB + 1 mm | 4.33 | kg |

| Shredded PCB − 1 mm | 2.51 | kg |

| Waste for treatments—Dust/losses | 0.32 | kg |

| Process II | ||

|---|---|---|

| Description | Value | Unit |

| Inputs (materials and energy) | ||

| Shredded PCB + 1 mm | 4.33 | kg |

| Energy | 0.36 | kWh |

| Water | 0.33 | m3 |

| Output | ||

| CNM + 1 mm (78% Cu) | 1 | kg |

| Shredded PCB + 1 mm M | 0.08 | kg |

| Mixed shredded PCB + 1 mm | 2.99 | kg |

| Waste for treatment | 0.25 | kg |

| Effluents | 0.32 | m3 |

| Particle Size Fraction | Yield (wt%) |

|---|---|

| +1 mm | 63.27 |

| −1 mm + 0.71 mm | 7.38 |

| −0.71 mm + 0.45 mm | 9.24 |

| −0.45 mm + 0.25 mm | 5.42 |

| −0.25 mm + 0.15 mm | 3.67 |

| −0.15 mm + 0.05 mm | 5.93 |

| −0.05 mm | 5.09 |

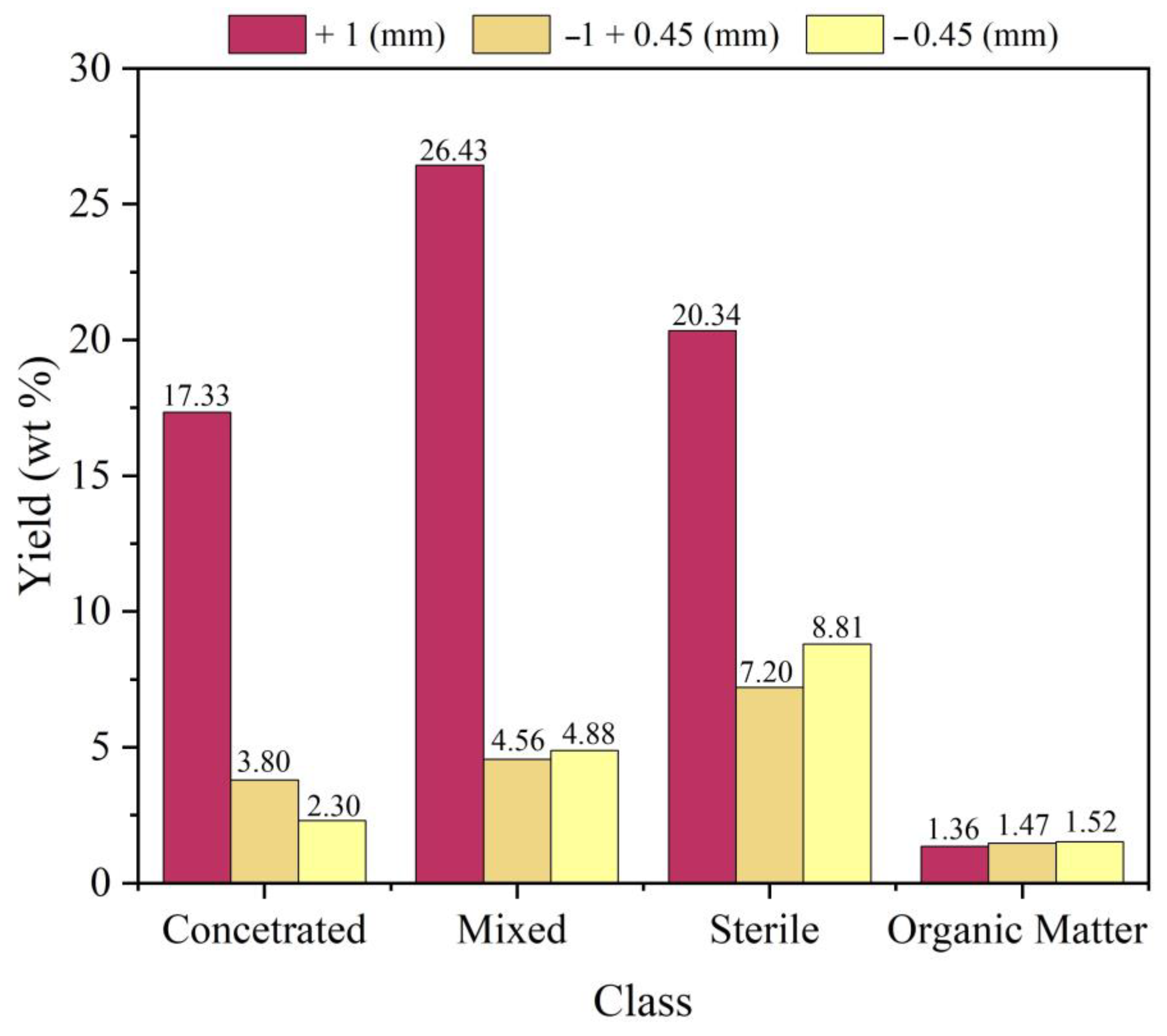

| Classes | Yield (wt%) |

|---|---|

| Concentrated | 24 |

| Mixed | 36 |

| Sterile | 36 |

| Organic matter | 4 |

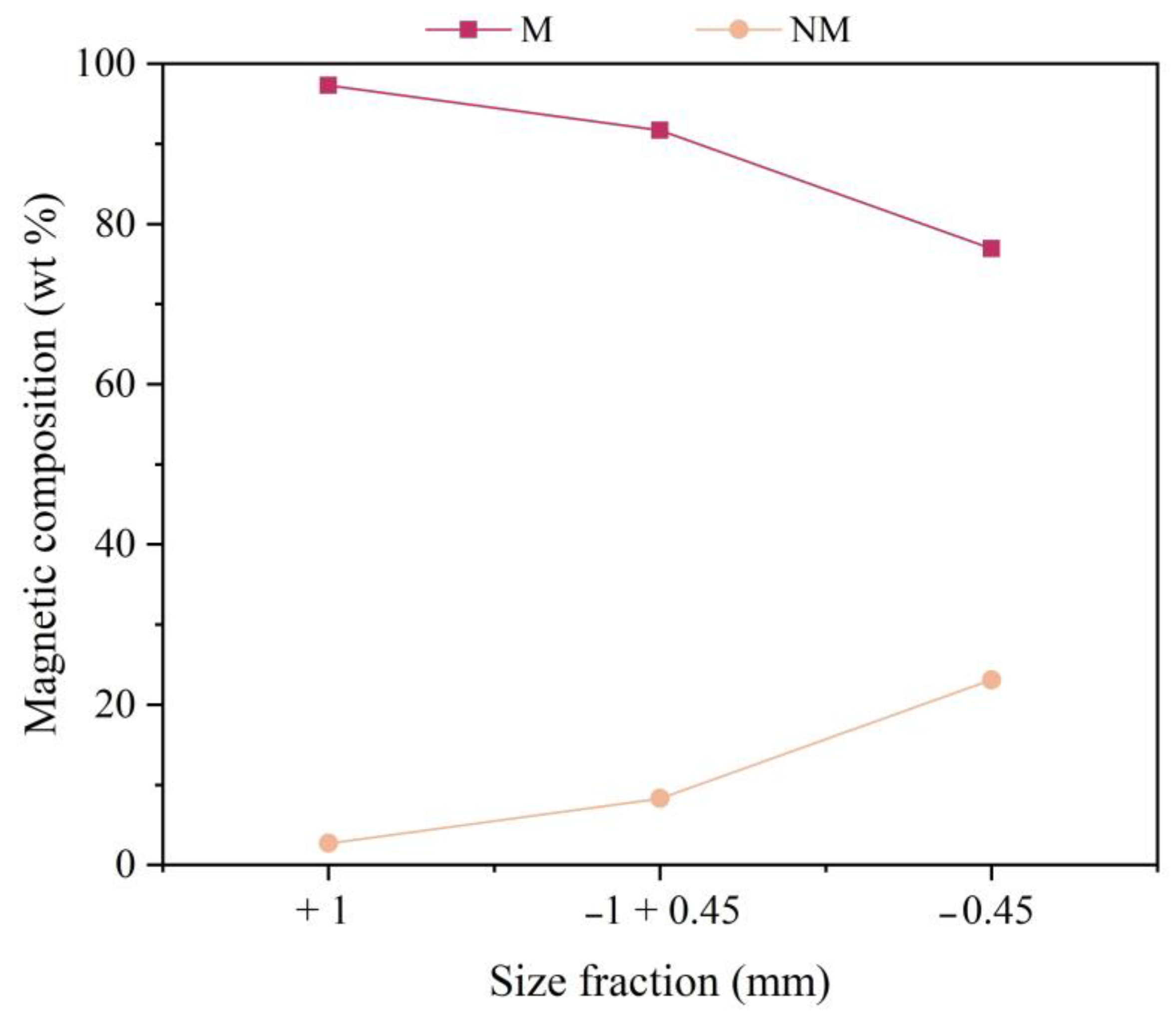

| Size Fraction | Concentrated (g) | Mixed (g) | Sterile (g) | Organic Matter (g) | ||||

|---|---|---|---|---|---|---|---|---|

| M | NM | M | NM | M | NM | M | NM | |

| +1 mm | 49.84 | 604.47 | 15.34 | 1009.81 | 2.13 | 785.06 | - | 44.04 |

| −1 mm + 0.45 mm | 37 | 95.83 | 14.49 | 151.28 | 1.87 | 294.99 | - | 45.9 |

| −0.45 mm | 55.16 | 19.75 | 59.73 | 122.25 | 16.65 | 314.17 | 15.8 | 33.56 |

| Total | 142 | 720.05 | 89.56 | 1283.34 | 20.65 | 1394.22 | 15.8 | 123.5 |

| Class | Size Fraction (mm) | Product i | Magnetic Properties | wt (g) |

|---|---|---|---|---|

| Concentrated | +1 mm | 1 | NM | 604.47 |

| 2 | M | 49.84 | ||

| −1 mm + 0.45 mm | 3 | NM | 95.83 | |

| 4 | M | 37.00 | ||

| –0.45 mm | 5 | NM | 19.75 | |

| 6 | M | 55.16 | ||

| Mixed | +1 mm | 7 | NM | 1009.81 |

| 8 | M | 15.34 | ||

| −1 mm + 0.45 mm | 9 | NM | 151.28 | |

| 10 | M | 14.49 | ||

| –0.45 mm | 11 | NM | 122.25 | |

| 12 | M | 59.73 |

| Class and Size Fraction | Cu (%) | Zn (%) | Mn (%) | Au (%) | Fe (%) | Ag (%) | Ni (%) | Others (%) |

|---|---|---|---|---|---|---|---|---|

| CNM + 1 mm | 78.48 | 15.00 | 0.008 | 0.01 | 0.04 | 0.02 | 0.21 | 6.23 |

| CM + 1 mm | 37.46 | 3.1 | 0.13 | 0.02 | 44.9 | 0.02 | 3.7 | 10.67 |

| CNM – 1 mm + 0.45 mm | 42.34 | 8.07 | 0.01 | 0.02 | 0.04 | 0.02 | 0.12 | 49.38 |

| CM – 1 mm + 0.45 mm | 37.30 | 0.35 | 0.09 | 0.05 | 31.6 | 0.01 | 2.83 | 27.77 |

| CNM − 0.45 mm | 37.36 | 1.46 | 0.03 | 0.07 | 0.06 | 0.02 | 0.14 | 60.86 |

| CM − 0.45 mm | 39.02 | 0.3241 | 0.11 | 0.07 | 55.3 | 0.04 | 1.16 | 3.97 |

| Class | Size Fraction (mm) | Magnetic Fraction | Product (i) | Metallic Fraction (%) | Cu Fraction (%) | Fraction Weight (g) | Metallic Fraction (g) | Cu Fraction (g) |

|---|---|---|---|---|---|---|---|---|

| Concentrated | +1 mm | NM | 1 | 92 | 78 | 604.47 | 556.11 | 433.76 |

| M | 2 | 93 | 37 | 49.84 | 46.35 | 17.15 | ||

| −1 mm + 0.45 mm | NM | 3 | 95 | 43 | 95.83 | 91.04 | 39.15 | |

| M | 4 | 97 | 37 | 37.00 | 35.89 | 13.28 | ||

| –0.45 mm | NM | 5 | 94 | 37 | 19.75 | 18.56 | 6.87 | |

| M | 6 | 96 | 39 | 55.16 | 52.95 | 20.65 | ||

| Mixed | +1 mm | NM | 7 | 55 | 26 | 1009.81 | 555.39 | 144.40 |

| M | 8 | 59 | 18 | 15.34 | 9.05 | 1.63 | ||

| −1 mm + 0.45 mm | NM | 9 | 73 | 67 | 151.28 | 110.43 | 73.99 | |

| M | 10 | 83 | 31 | 14.49 | 12.03 | 3.73 | ||

| –0.45 mm | NM | 11 | 41 | 23 | 122.25 | 50.12 | 11.52 | |

| M | 12 | 51 | 18 | 59.73 | 30.46 | 5.48 | ||

| Total Fraction | 2234.95 | 1568.38 | 771.61 |

| Impact Category | Unit | Total | Crushing and Sieving | Density and Magnetic Separation |

|---|---|---|---|---|

| Climate change | kg CO2 eq | 15.4 | 15.1 | 0.236 |

| Fossil depletion | kg oil eq | 4.1 | 4.04 | 0.0613 |

| Occupation of agricultural land | m2a | 3.77 | 3.04 | 0.2 |

| Human toxicity | kg 1.4-DB eq | 3.24 | 3.04 | 0.2 |

| Ionizing radiation | kBq U235 eq | 3.24 | 3.04 | 0.2 |

| Metal depletion | kg Fe eq | 0.246 | 0.216 | 0.03 |

| Ecotoxicity in fresh water | kg 1.4-DB eq | 0.0979 | 0.0781 | 0.0198 |

| Terrestrial ecotoxicity | kg 1.4-DB eq | 0.000695 | 0.000676 | 1.89 × 10−5 |

| Ozone depletion | kg CFC-11 eq | 1.2 × 10−6 | 1.19 × 10−6 | 1.71 × 10−8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dias, J.; Silva, A.G.P.; de Holanda, J.N.F.; Delatorre, F.M.; da Conceição, A.O.; de Miranda Júnior, G.M.; Futuro, A.; Pinho, S.C. Environmental and Technological Assessment of Operations for Extraction and Concentration of Metals in Electronic Waste. Sustainability 2023, 15, 13175. https://doi.org/10.3390/su151713175

Dias J, Silva AGP, de Holanda JNF, Delatorre FM, da Conceição AO, de Miranda Júnior GM, Futuro A, Pinho SC. Environmental and Technological Assessment of Operations for Extraction and Concentration of Metals in Electronic Waste. Sustainability. 2023; 15(17):13175. https://doi.org/10.3390/su151713175

Chicago/Turabian StyleDias, Josinaldo, Angelus Giuseppe Pereira Silva, José Nilson França de Holanda, Fabíola Martins Delatorre, Amanda Oliveira da Conceição, Gilson Mendonça de Miranda Júnior, Aurora Futuro, and Sílvia Cardinal Pinho. 2023. "Environmental and Technological Assessment of Operations for Extraction and Concentration of Metals in Electronic Waste" Sustainability 15, no. 17: 13175. https://doi.org/10.3390/su151713175

APA StyleDias, J., Silva, A. G. P., de Holanda, J. N. F., Delatorre, F. M., da Conceição, A. O., de Miranda Júnior, G. M., Futuro, A., & Pinho, S. C. (2023). Environmental and Technological Assessment of Operations for Extraction and Concentration of Metals in Electronic Waste. Sustainability, 15(17), 13175. https://doi.org/10.3390/su151713175