Experimental Investigation on the Performance of Compressors for Small-Scale Compressed Air Energy Storage in Parallel Mode

Abstract

:1. Introduction

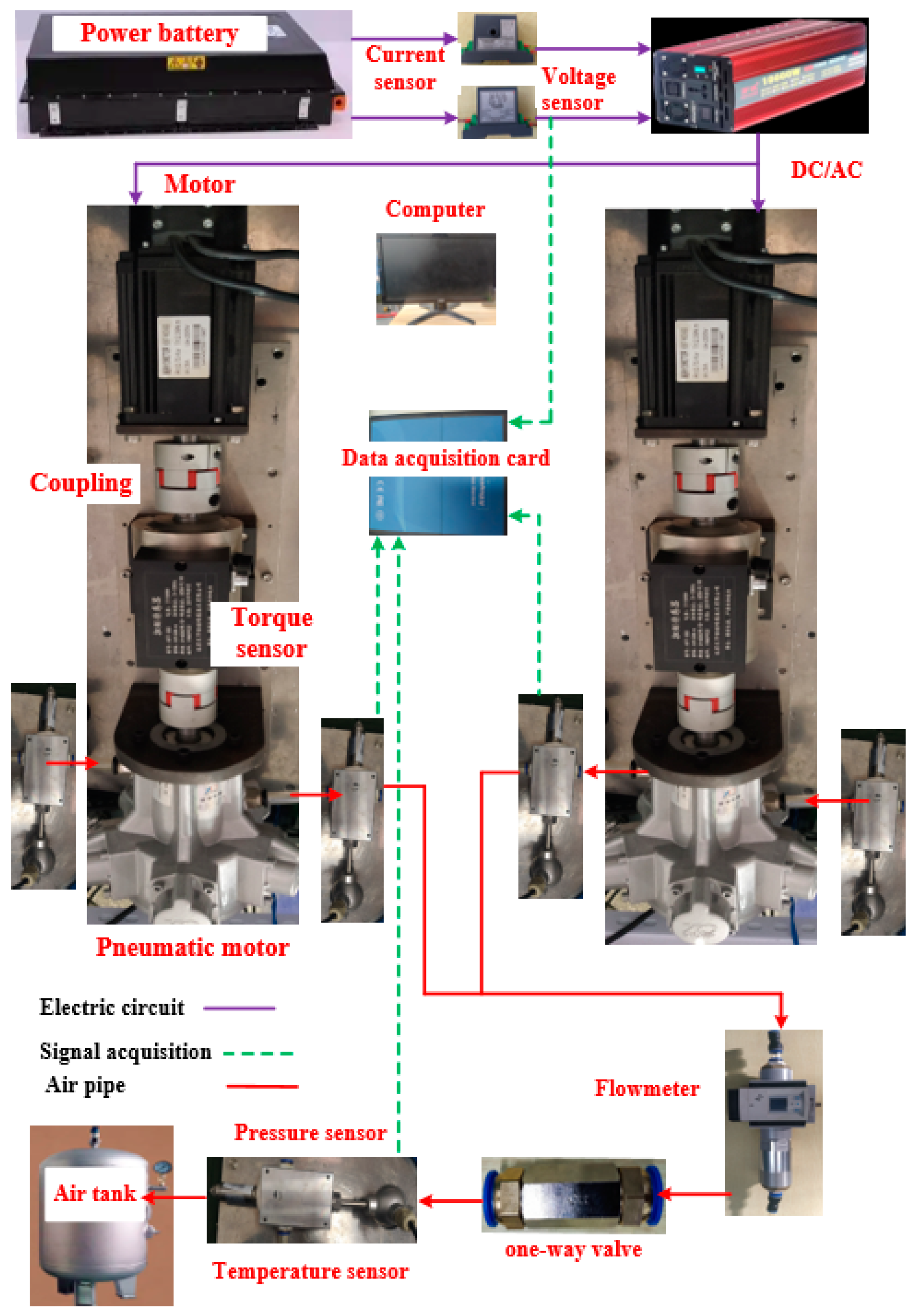

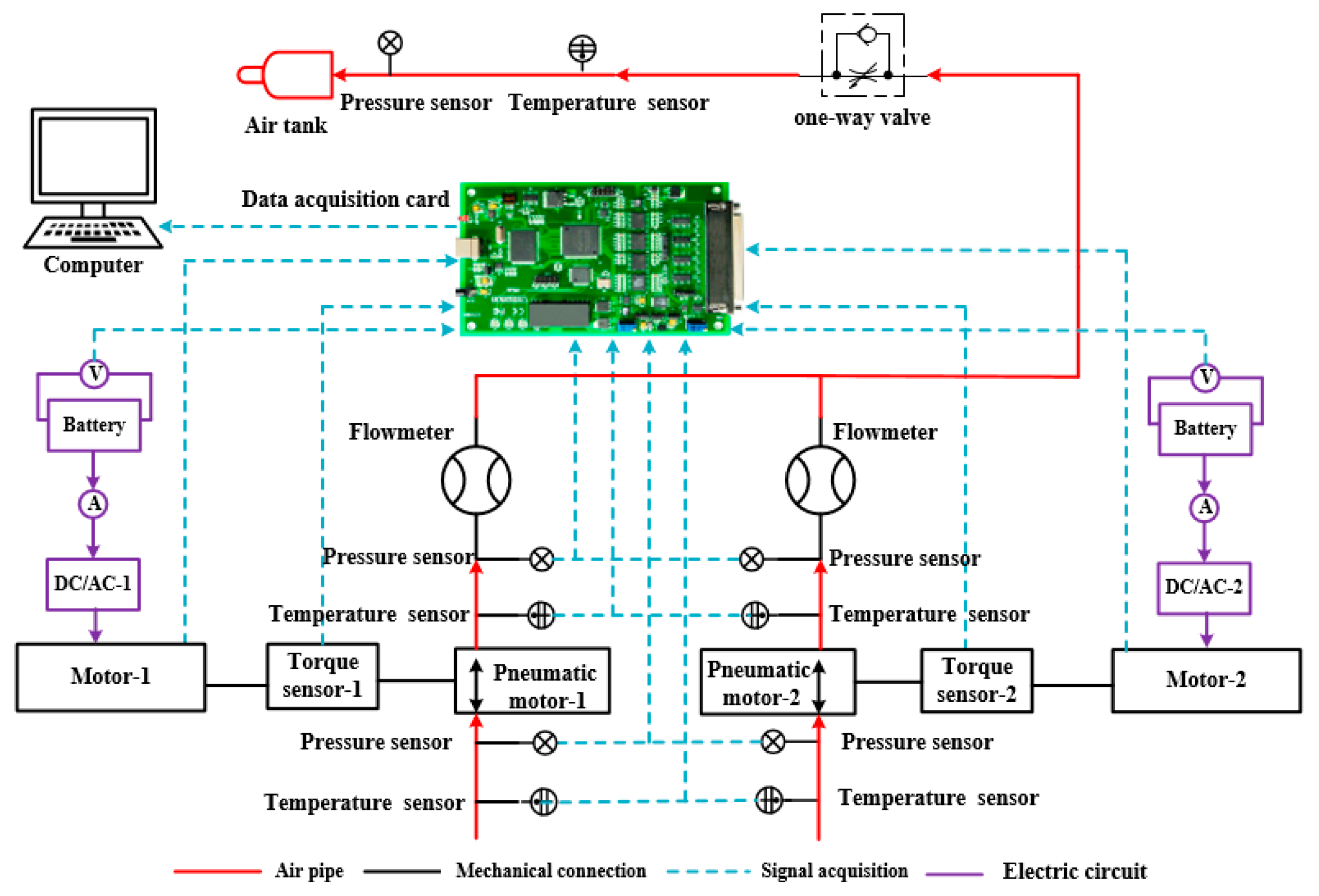

2. Experimental Setup

3. Results and Discussion

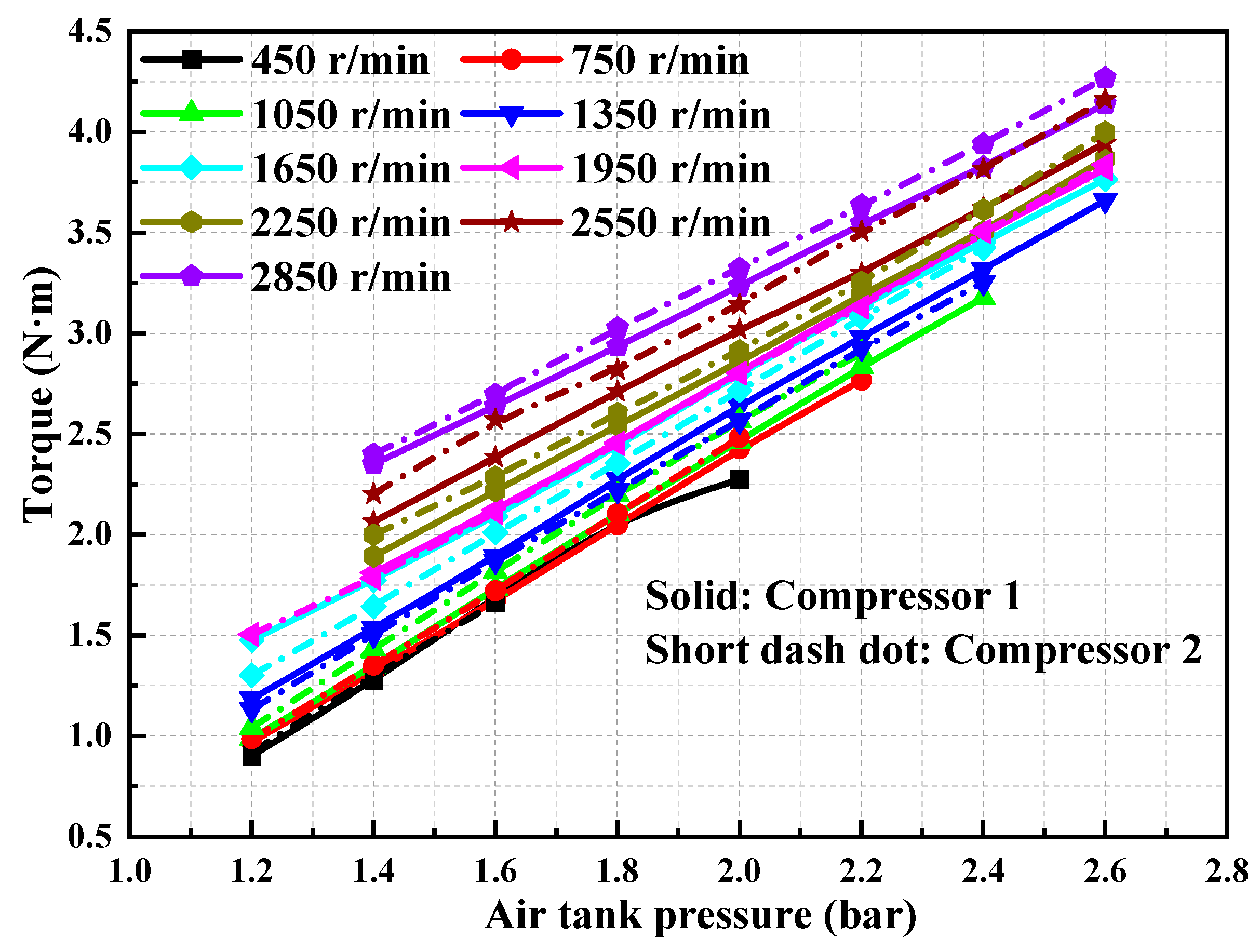

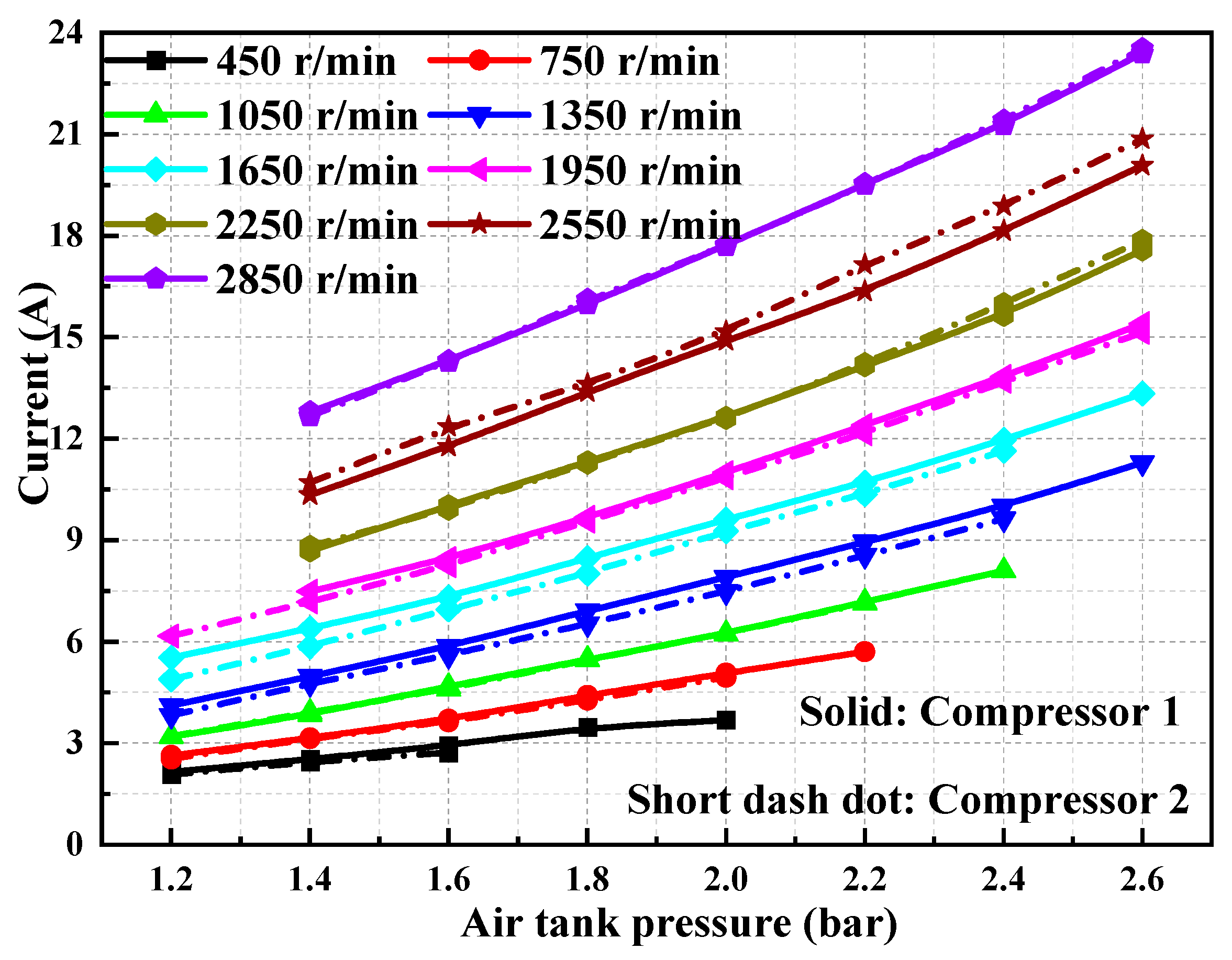

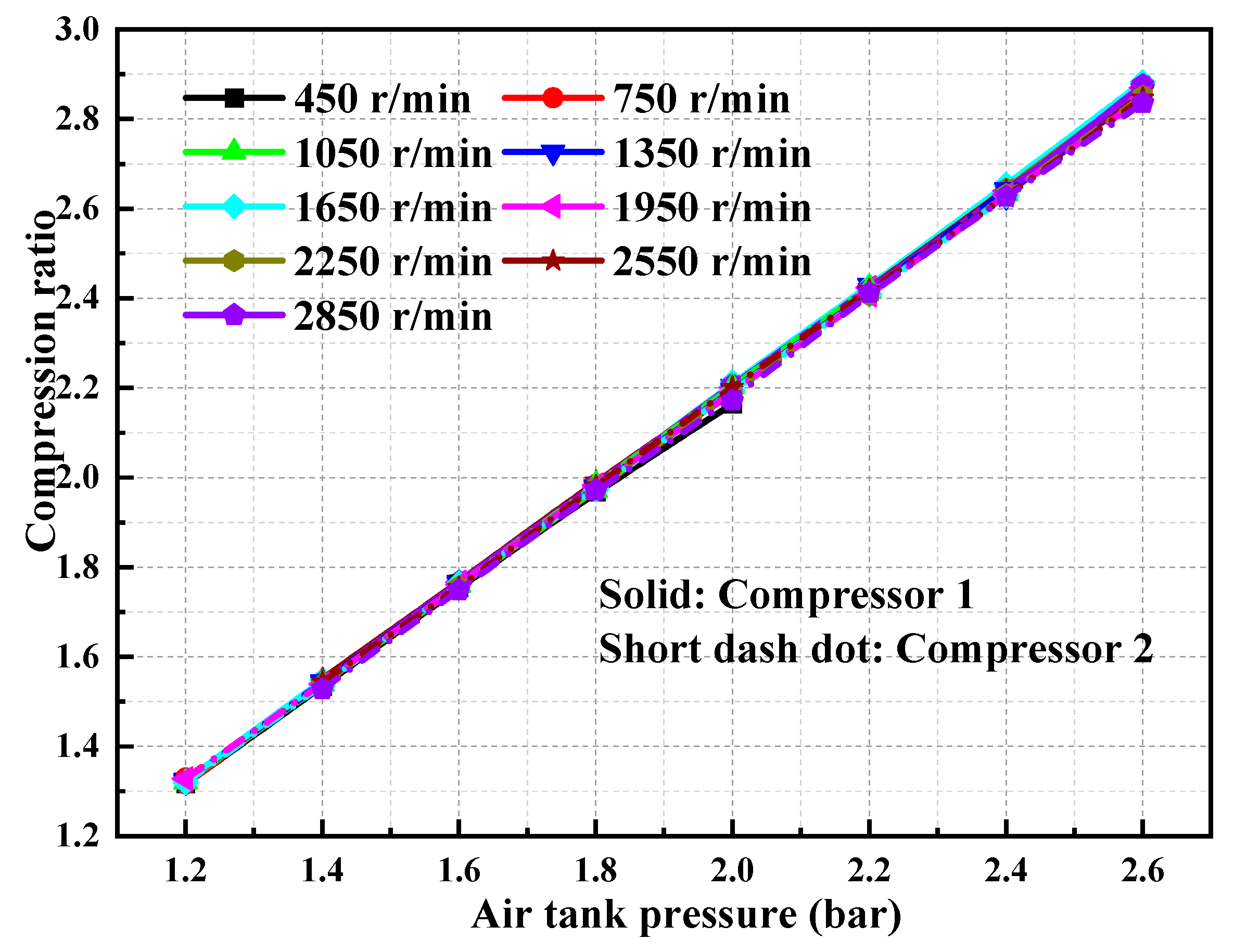

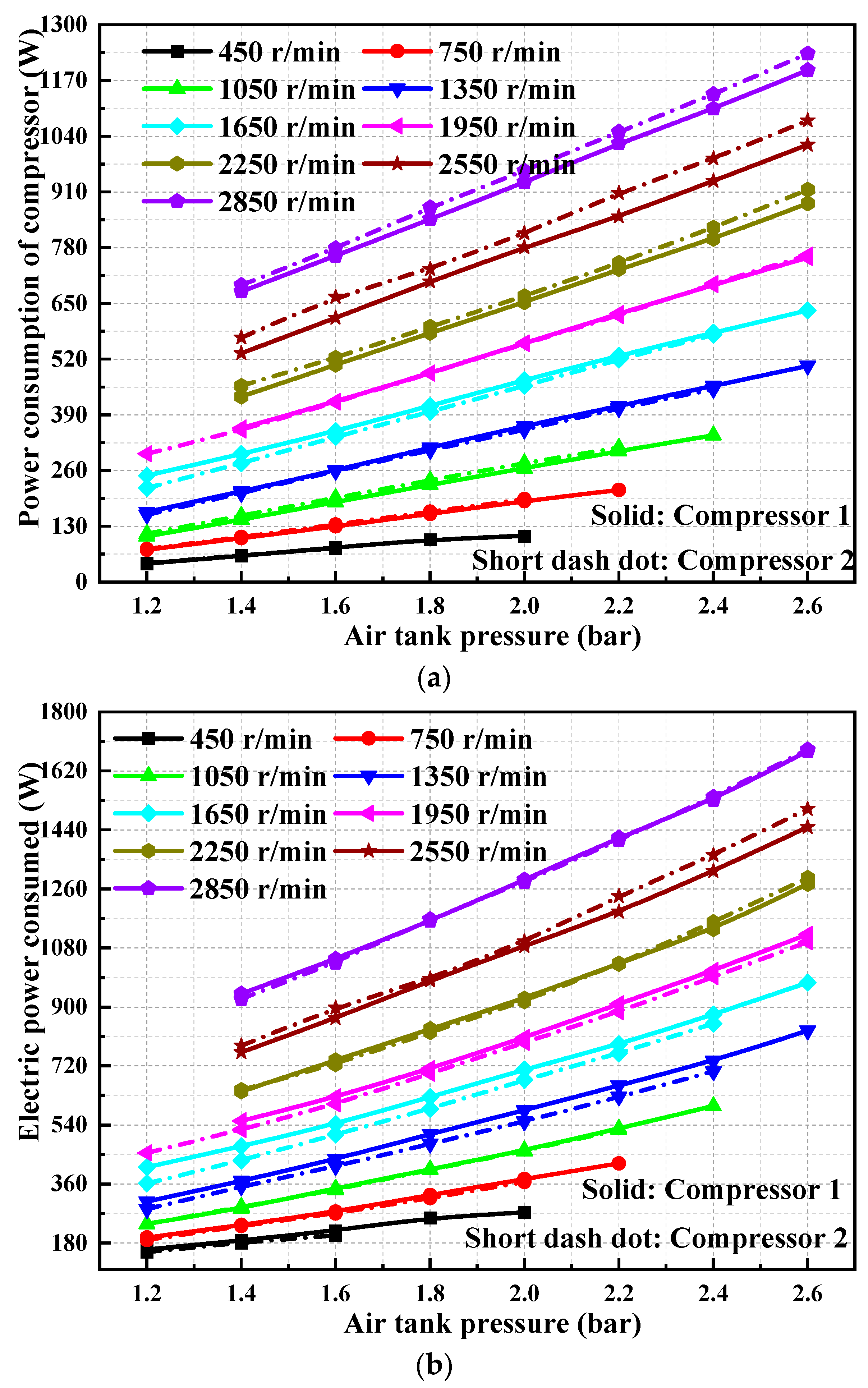

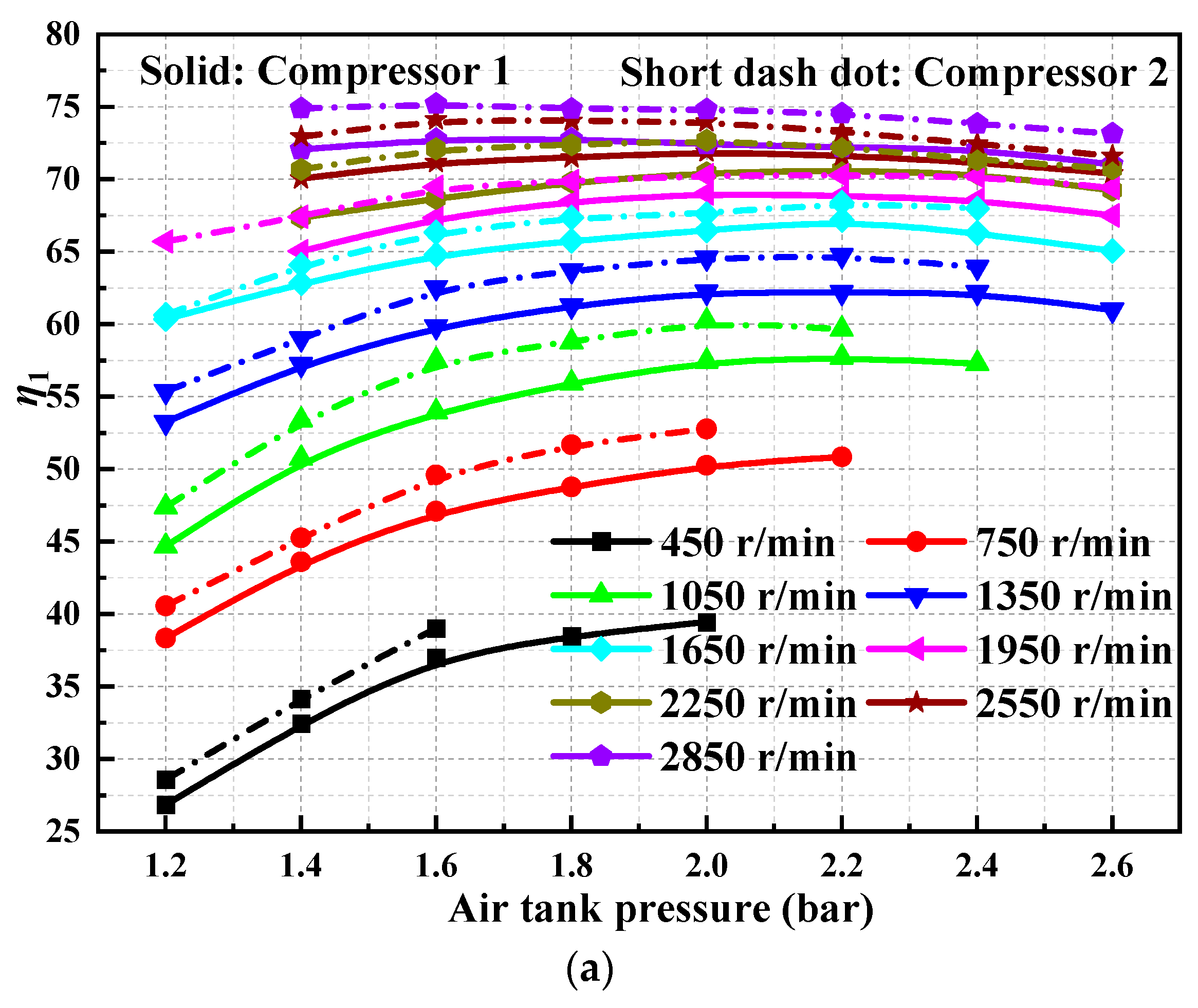

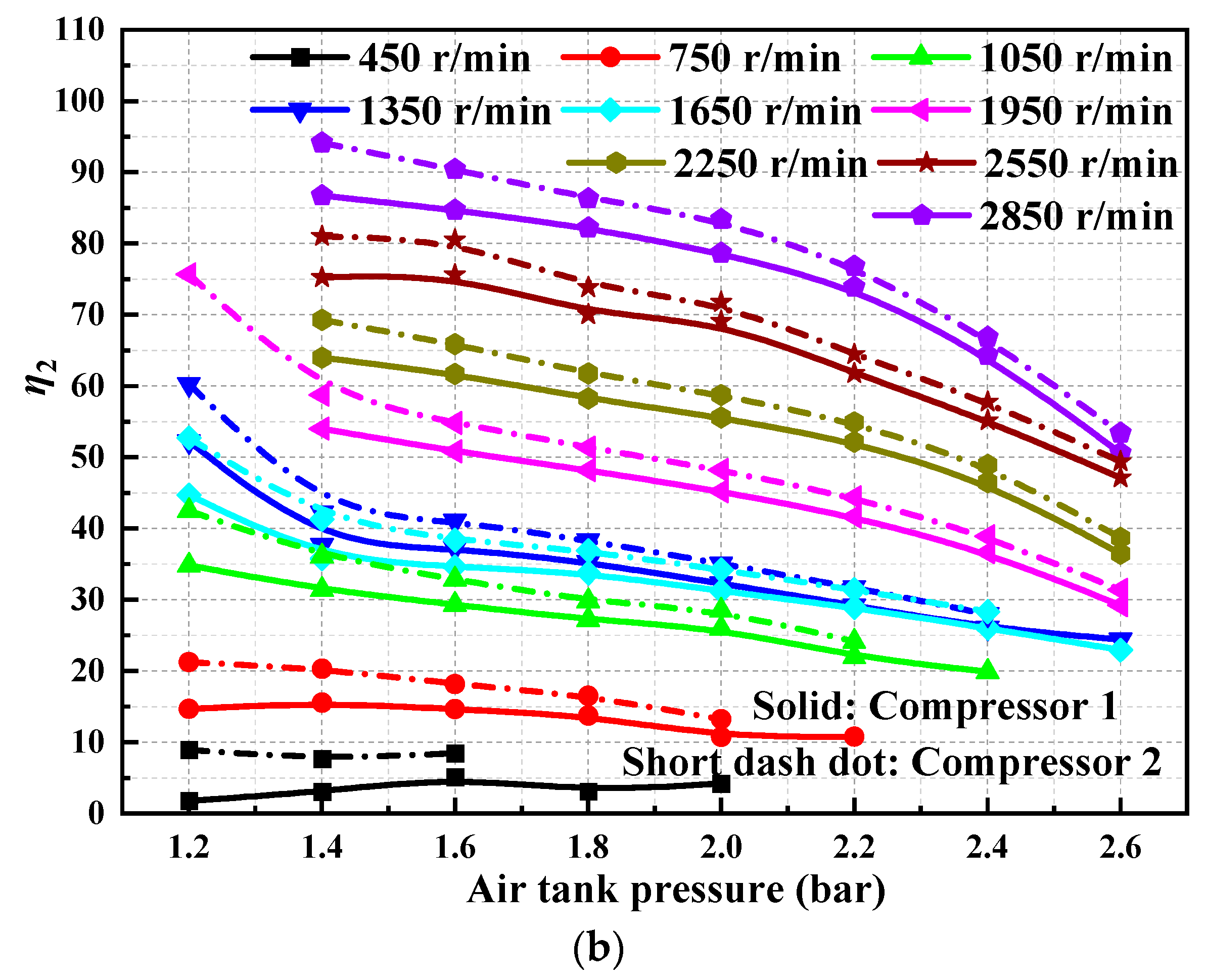

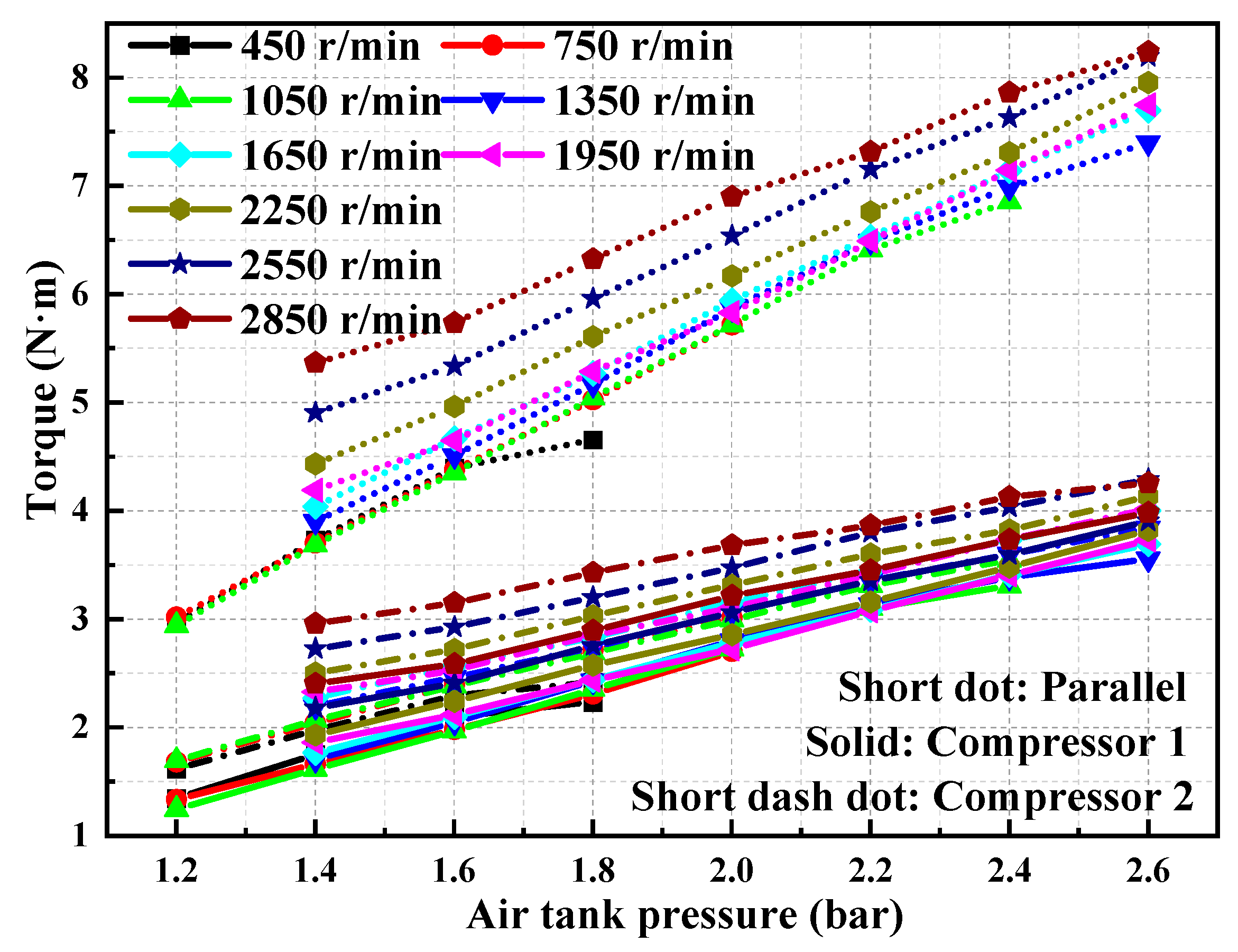

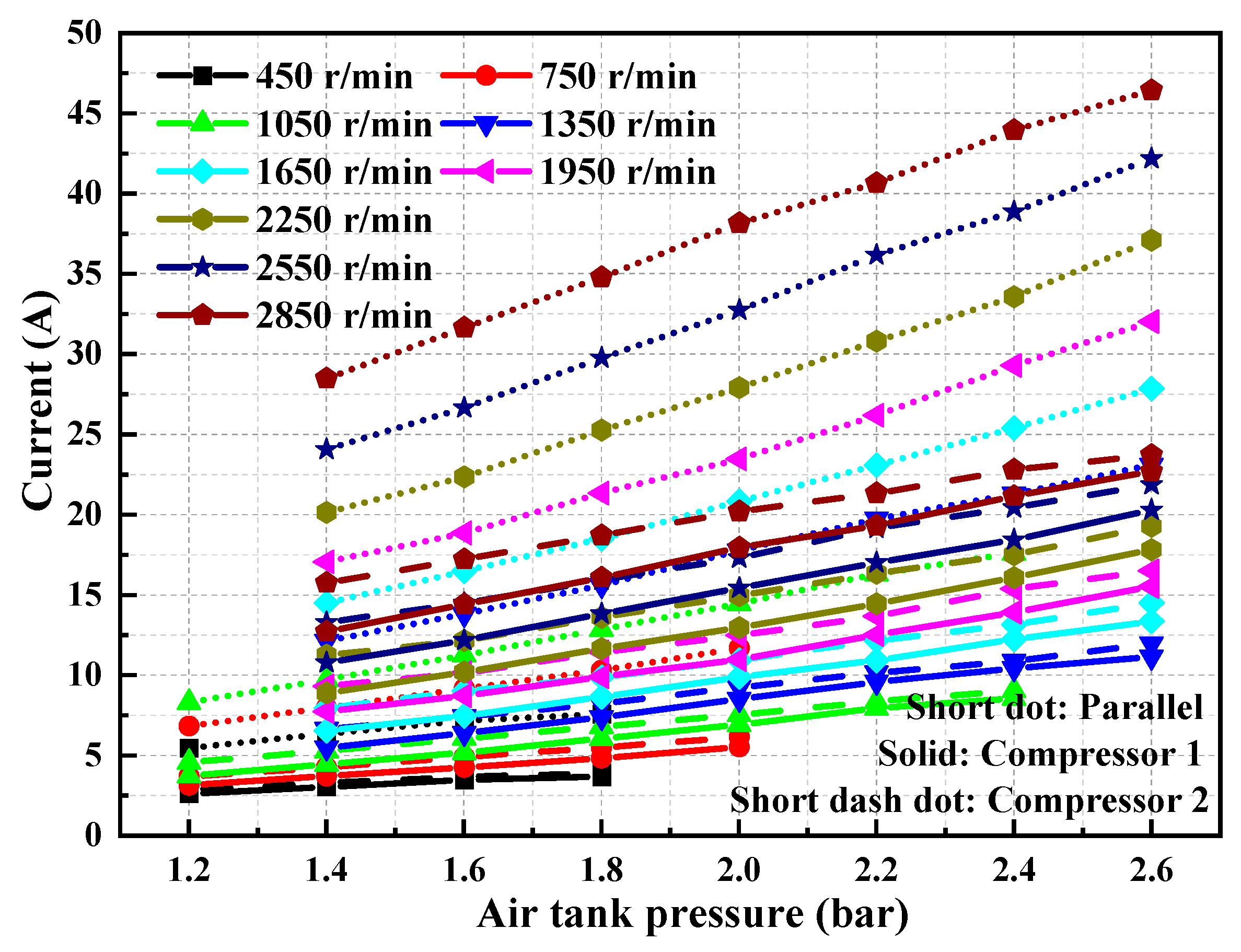

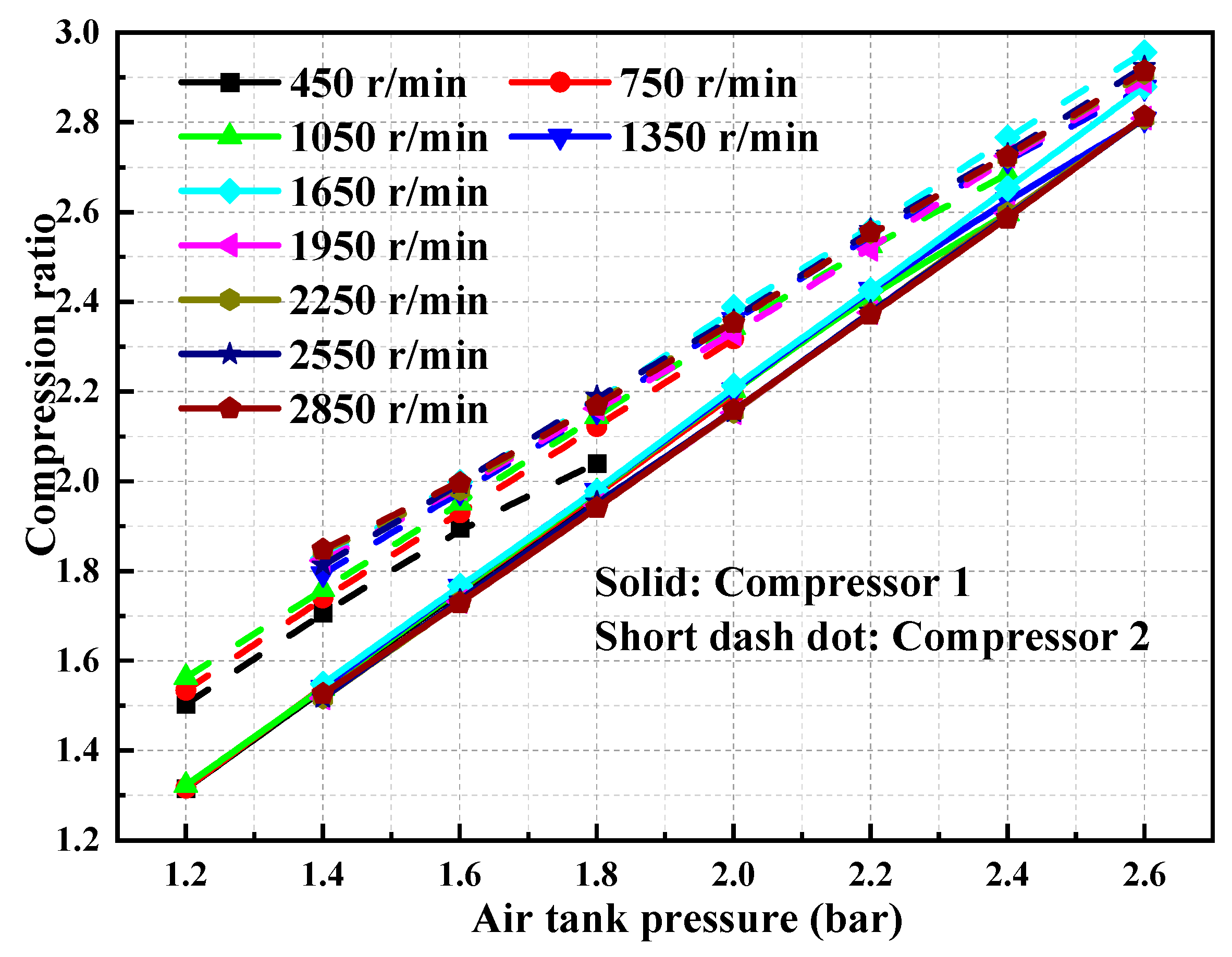

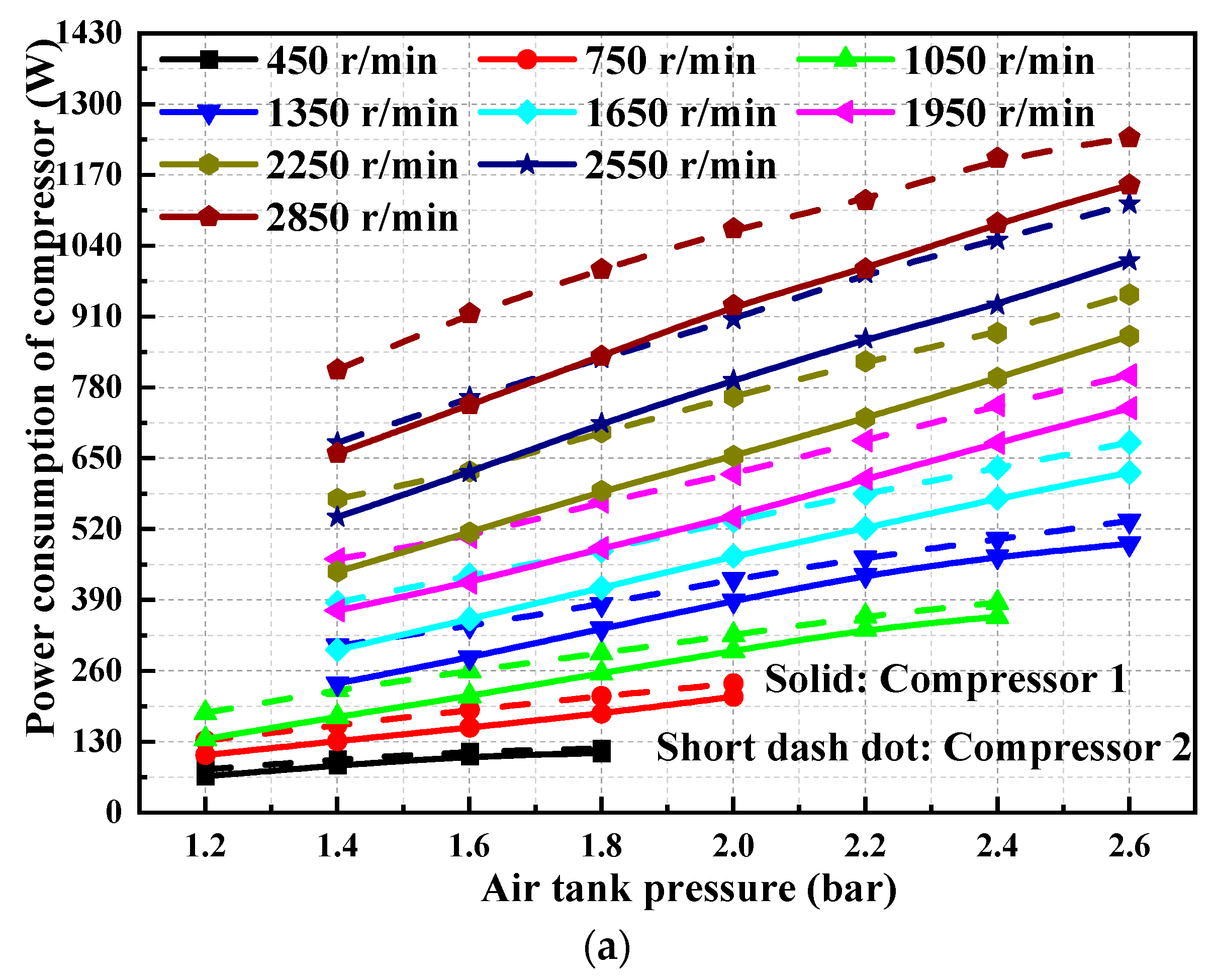

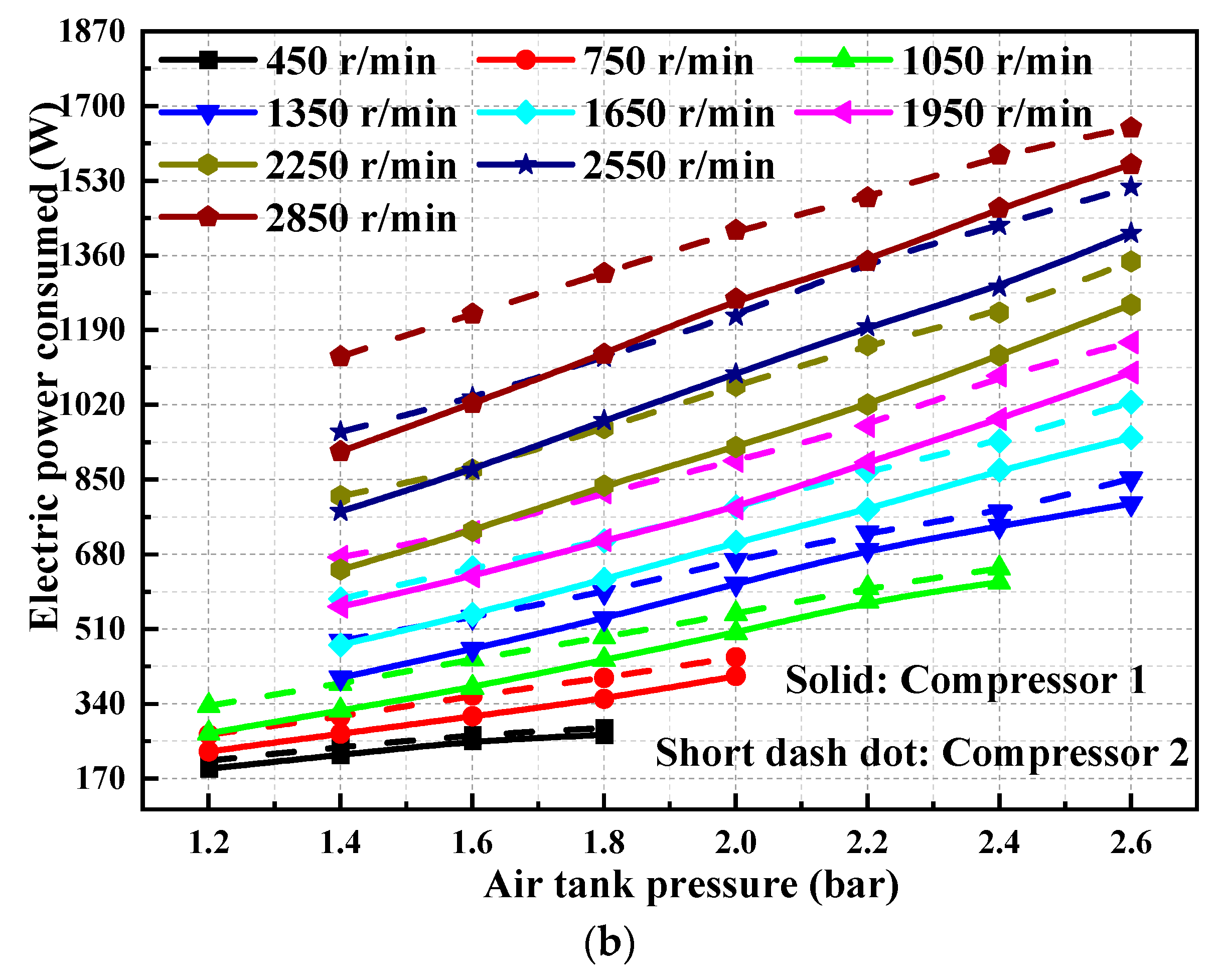

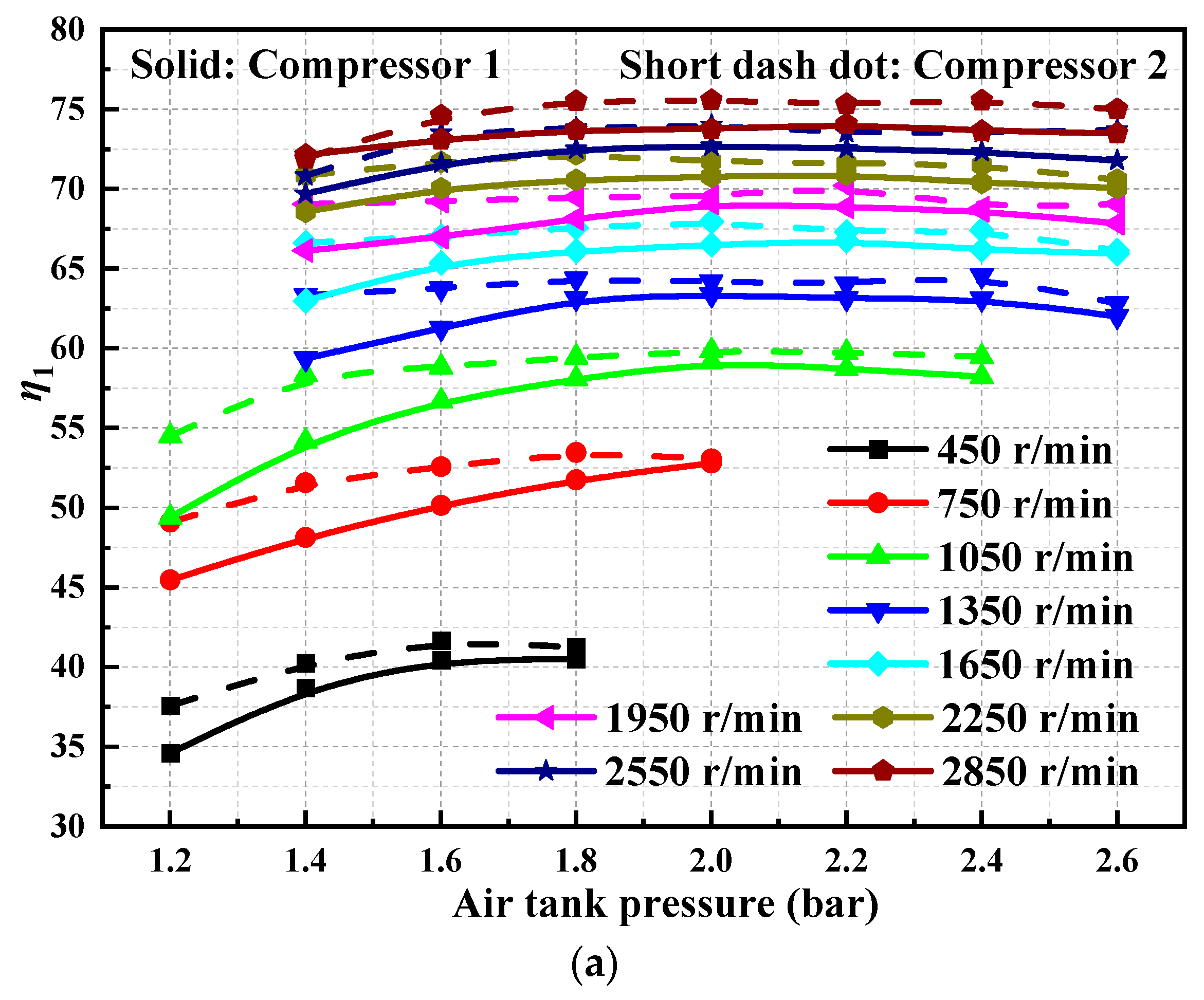

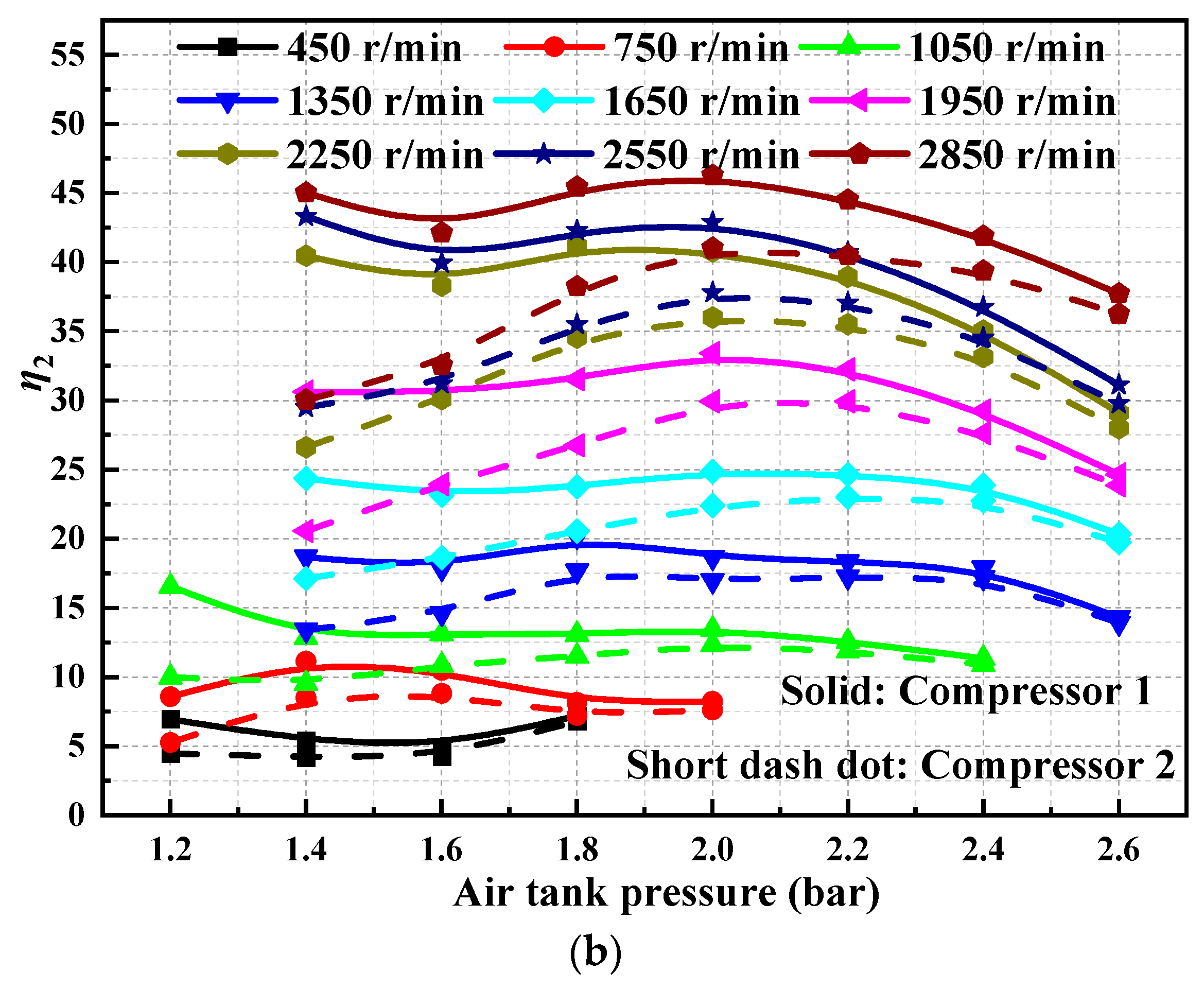

3.1. Influence of Air Tank Pressure on the Performance of the Compressor

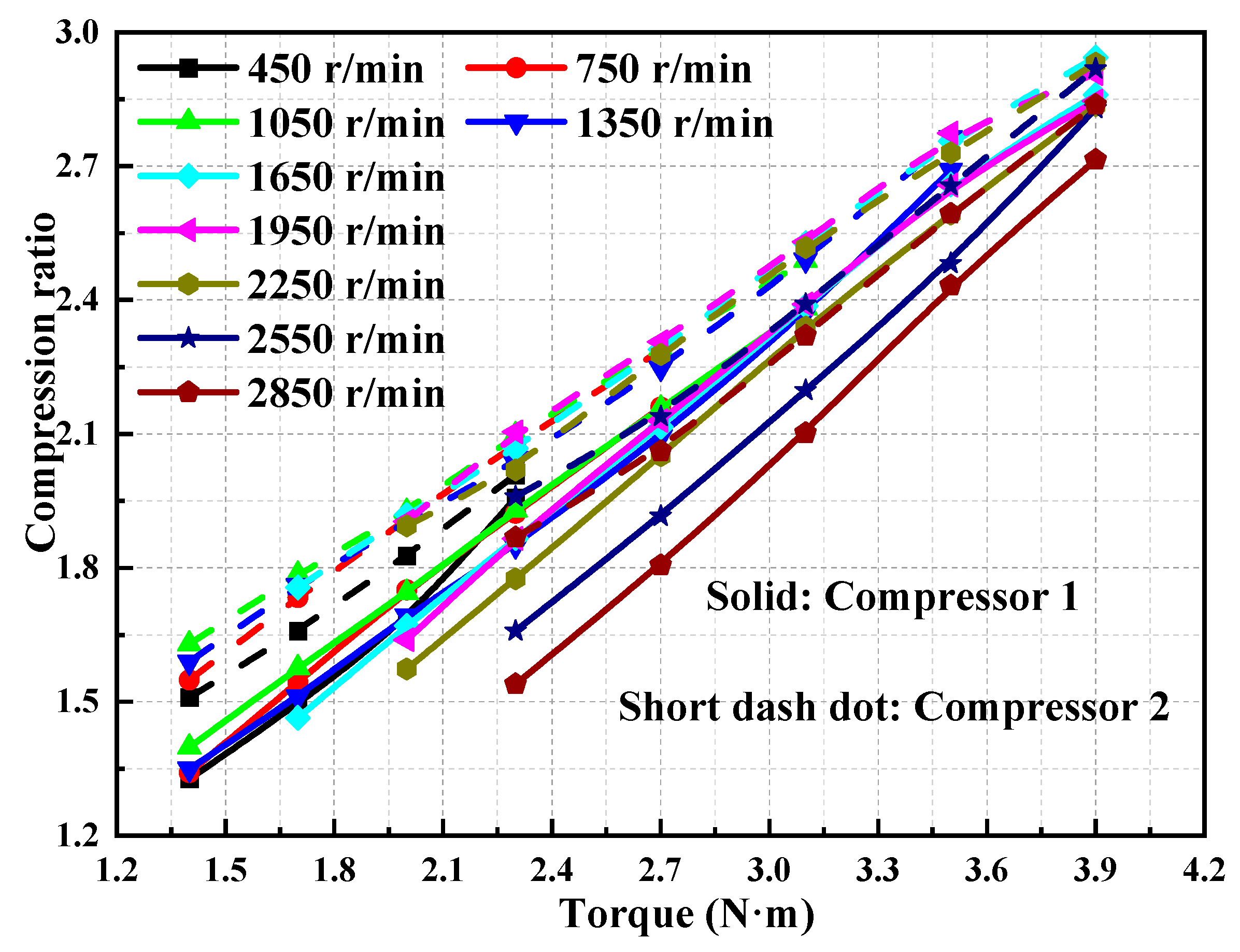

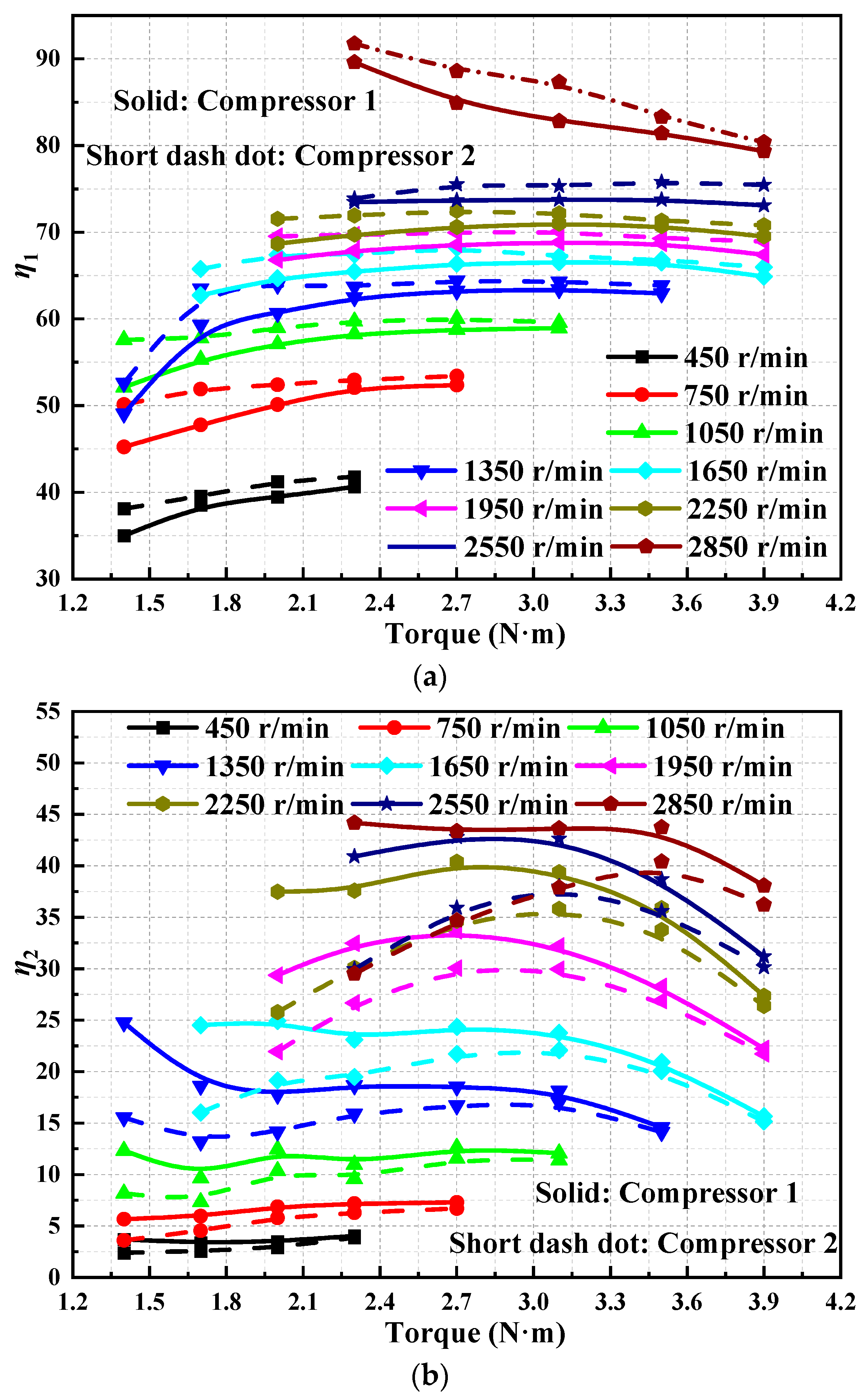

3.2. Influence of Torque on the Performance of the Compressor

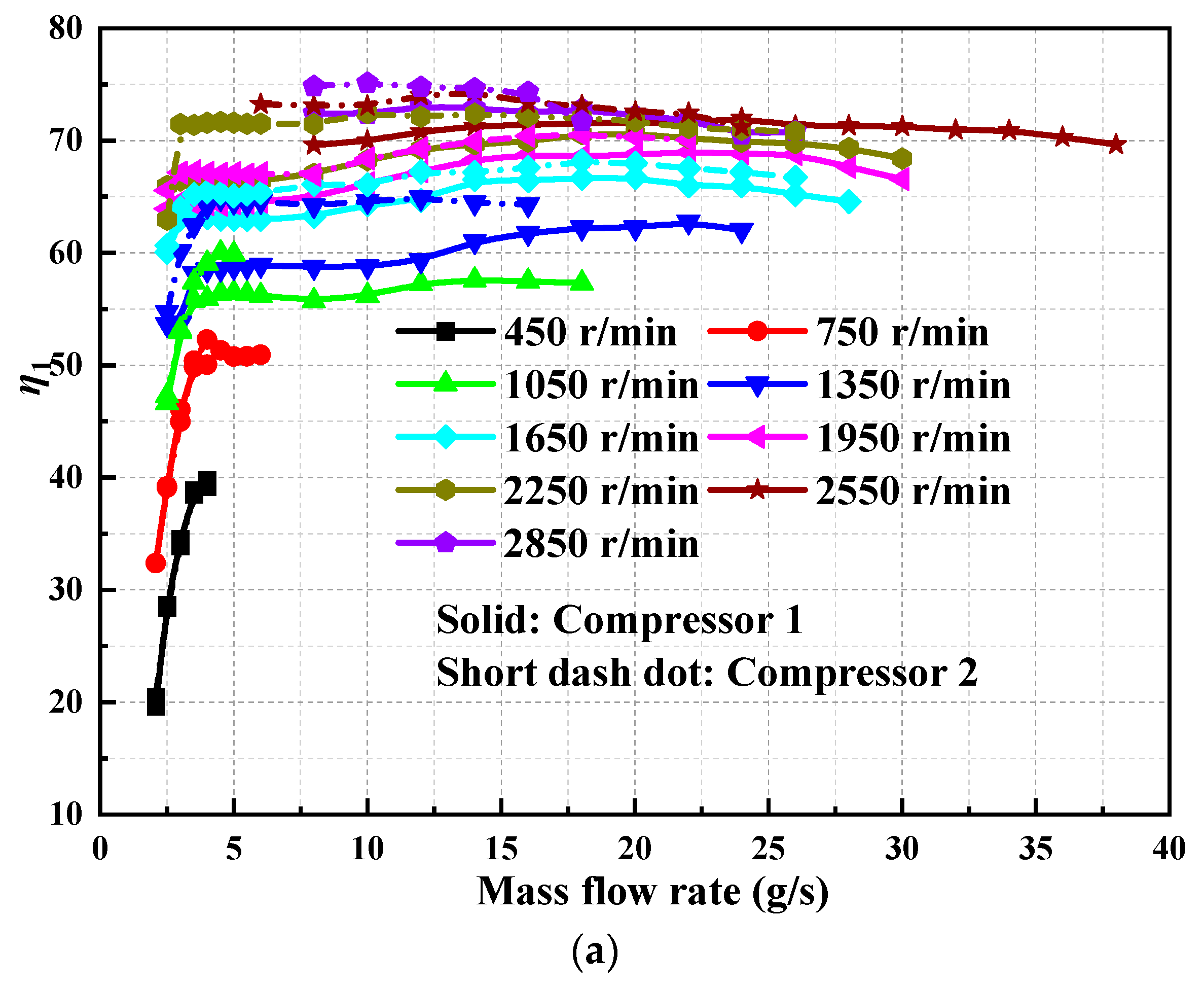

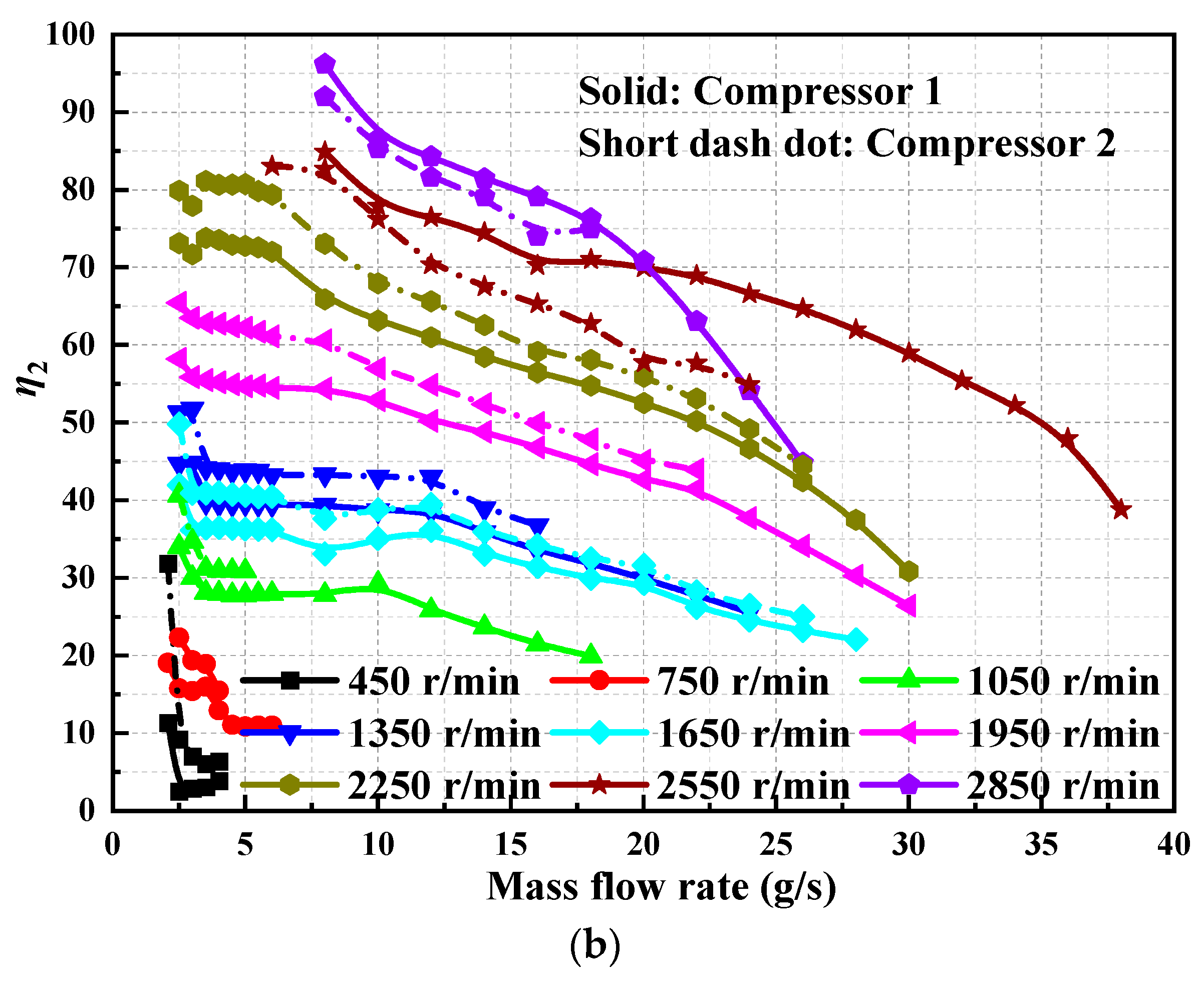

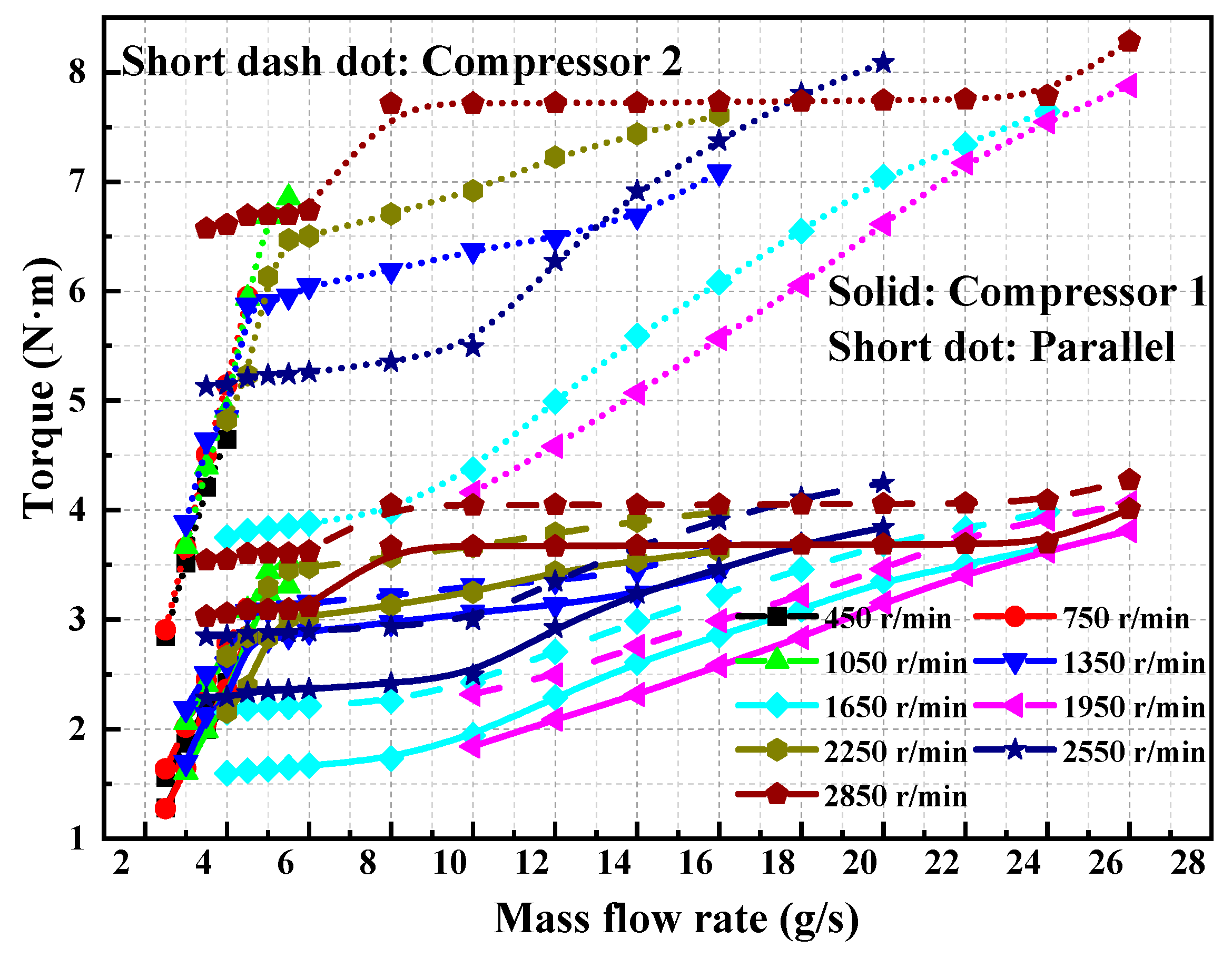

3.3. Influence of Mass Flow Rate on the Performance of the Compressor

3.4. Influence of Air Tank Pressure on the Performance of the Compressor in Parallel Mode

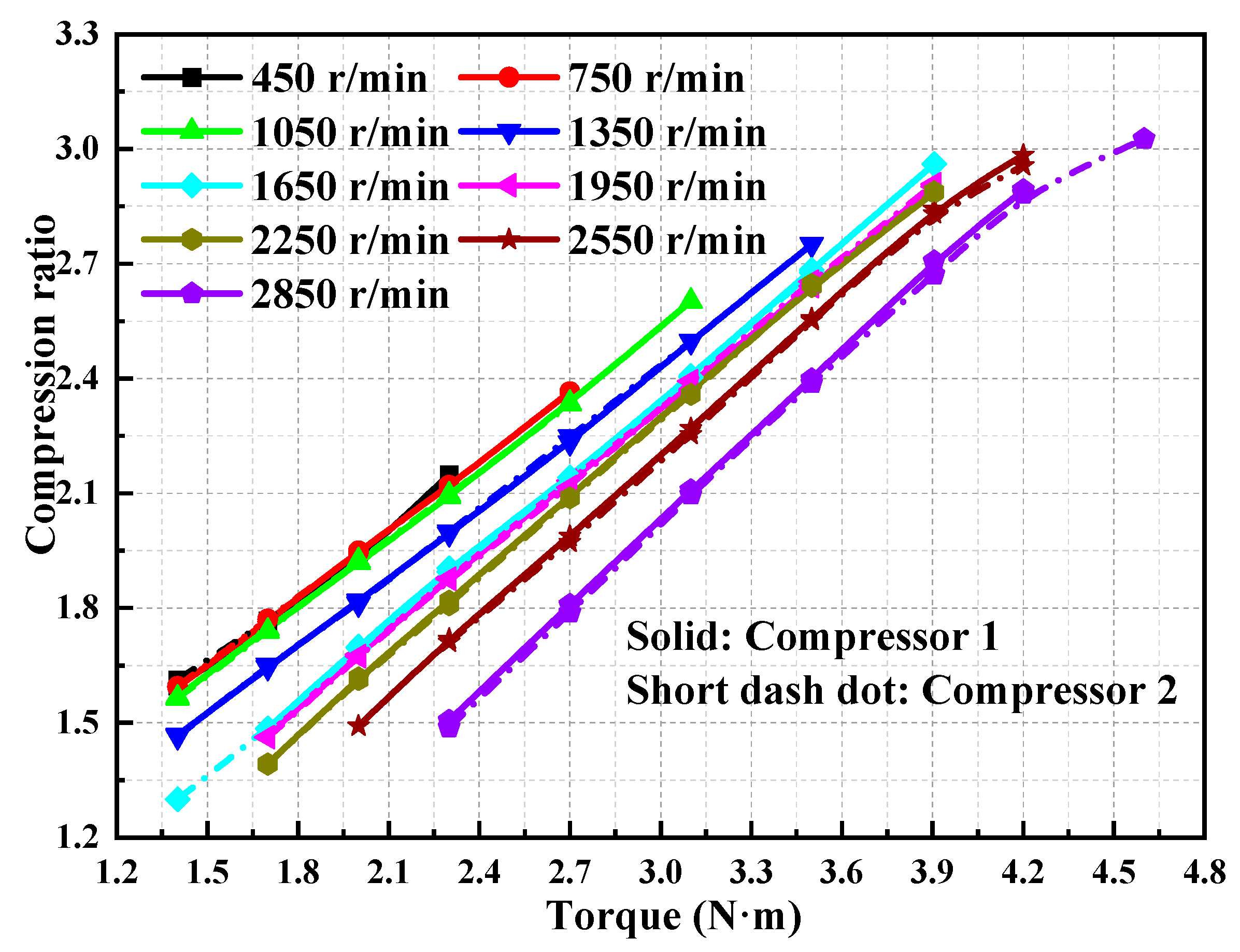

3.5. Influence of Torque on the Performance of the Compressor in Parallel Mode

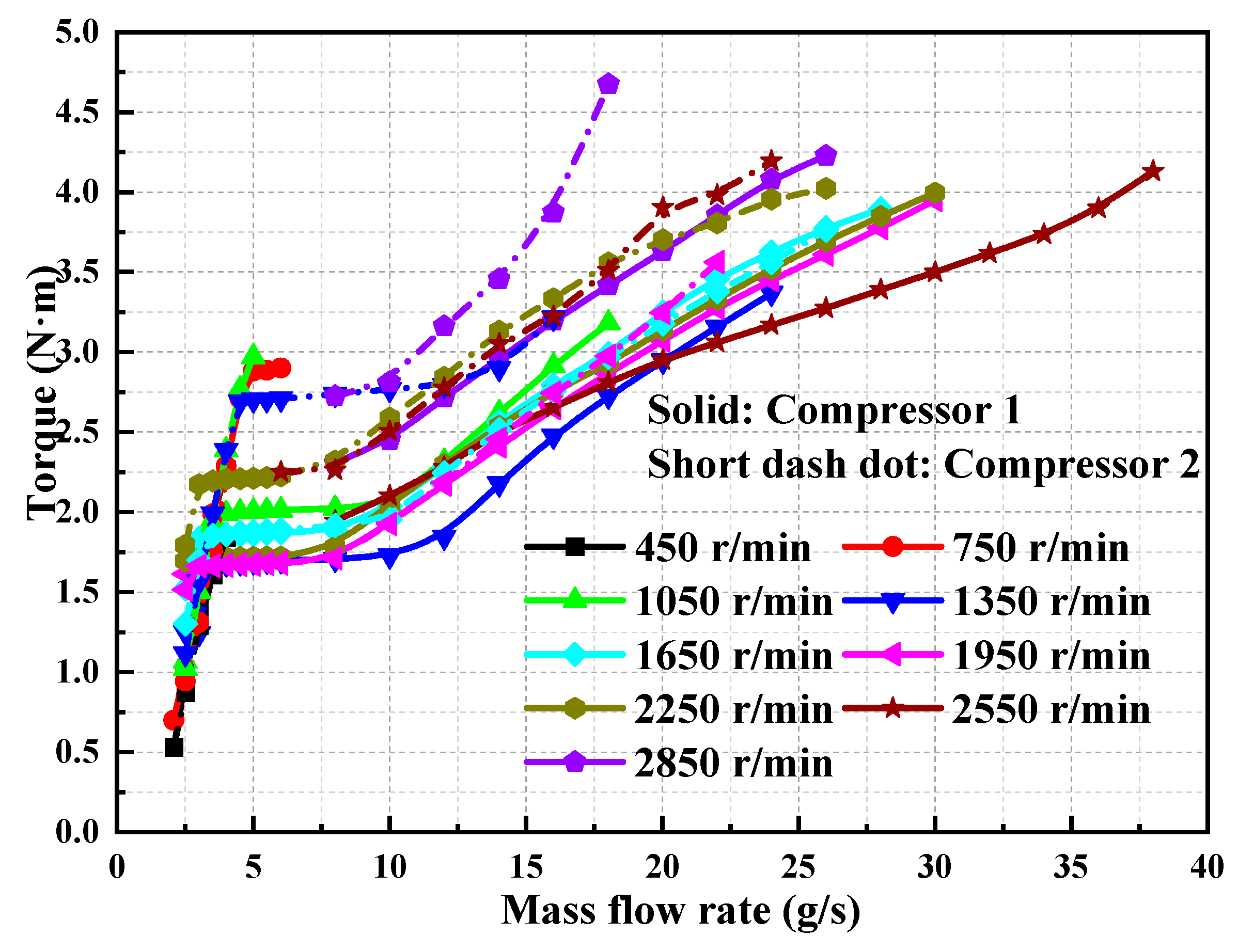

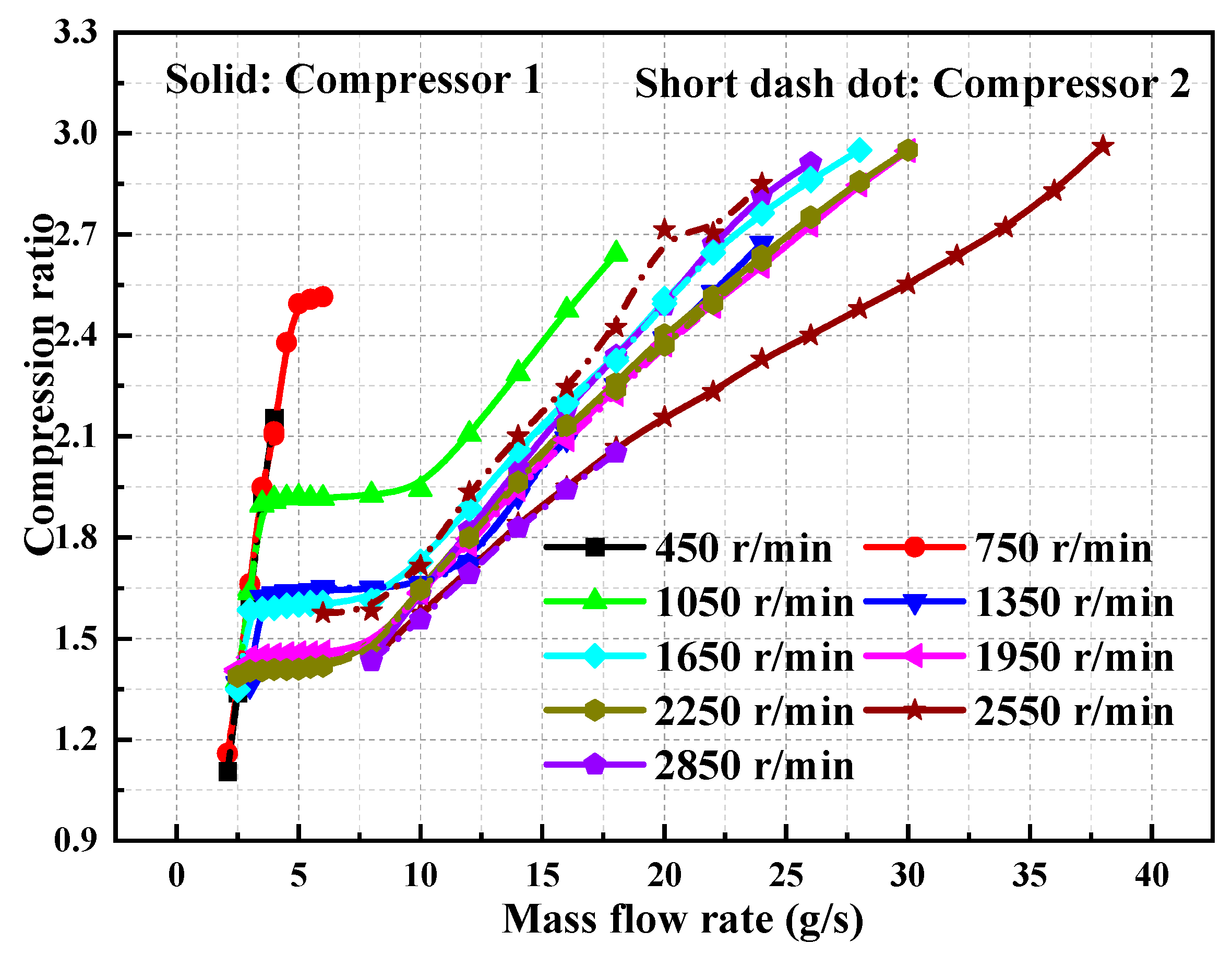

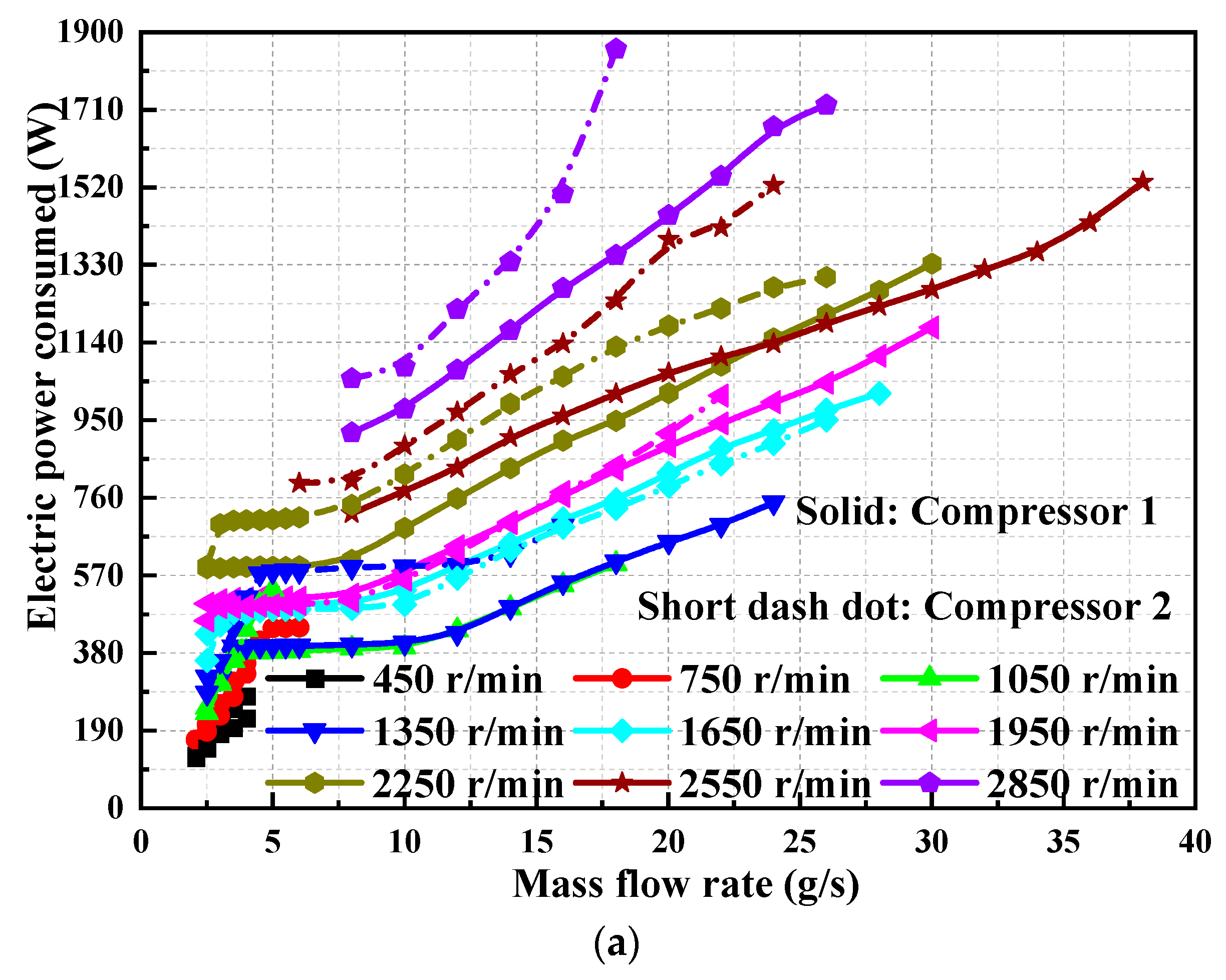

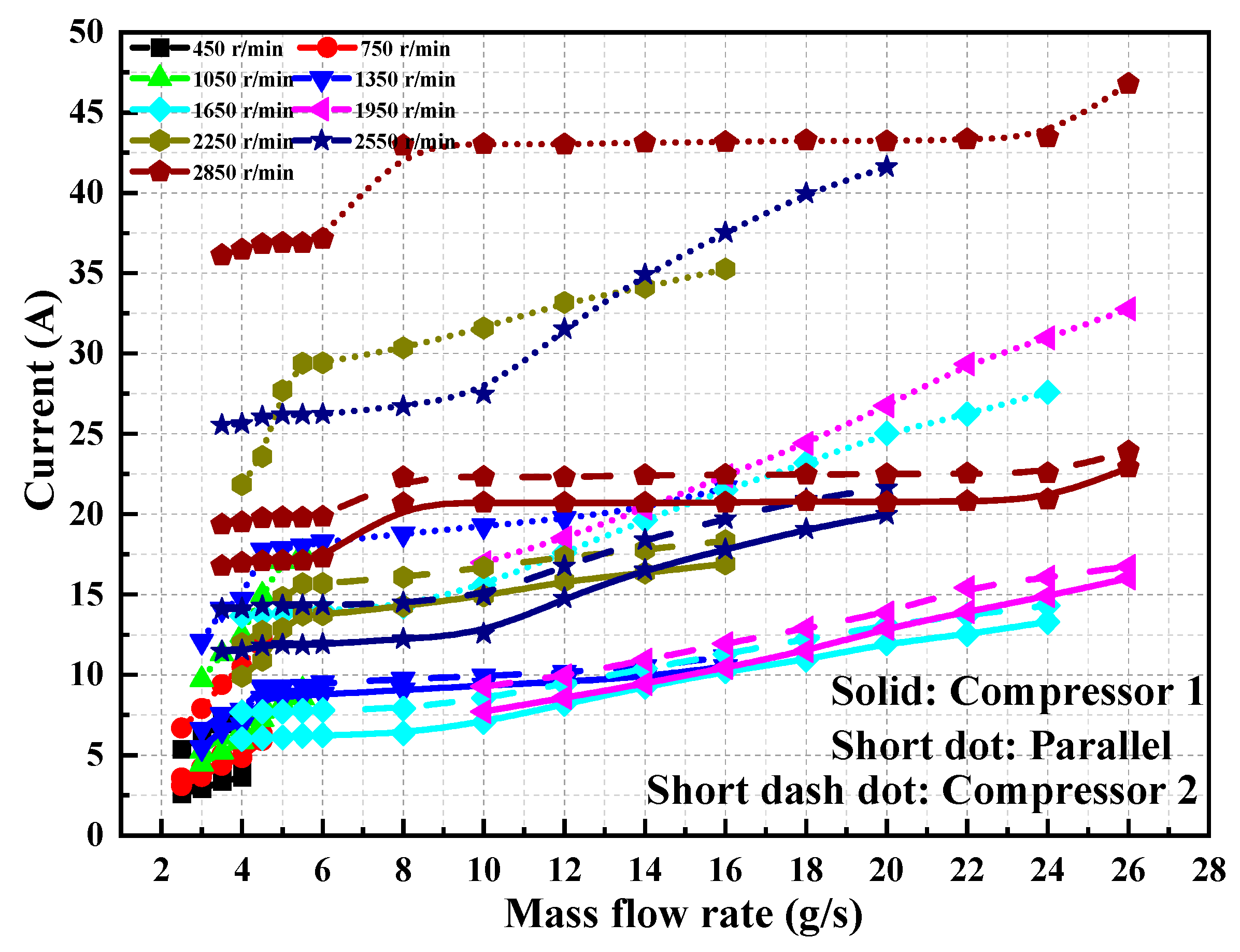

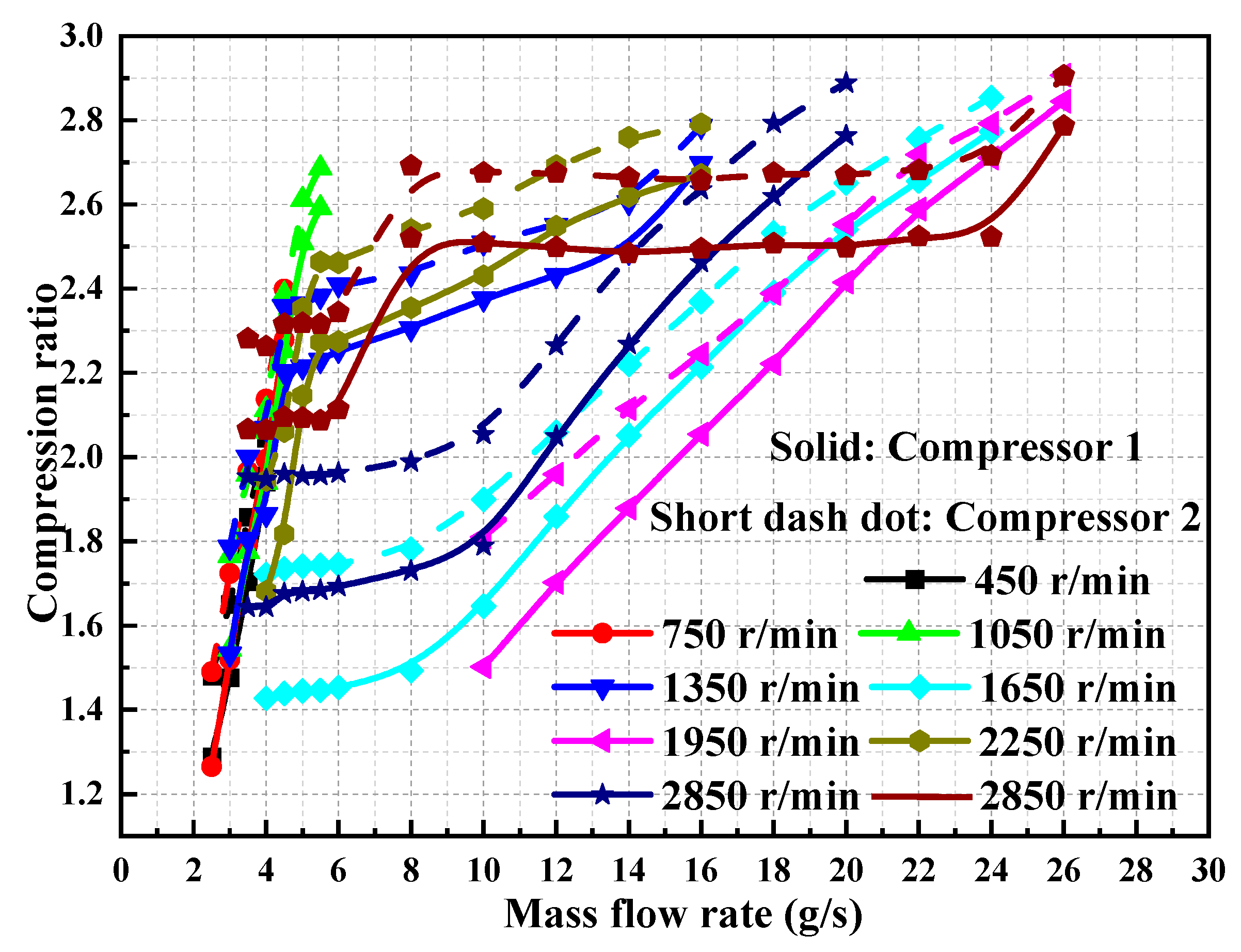

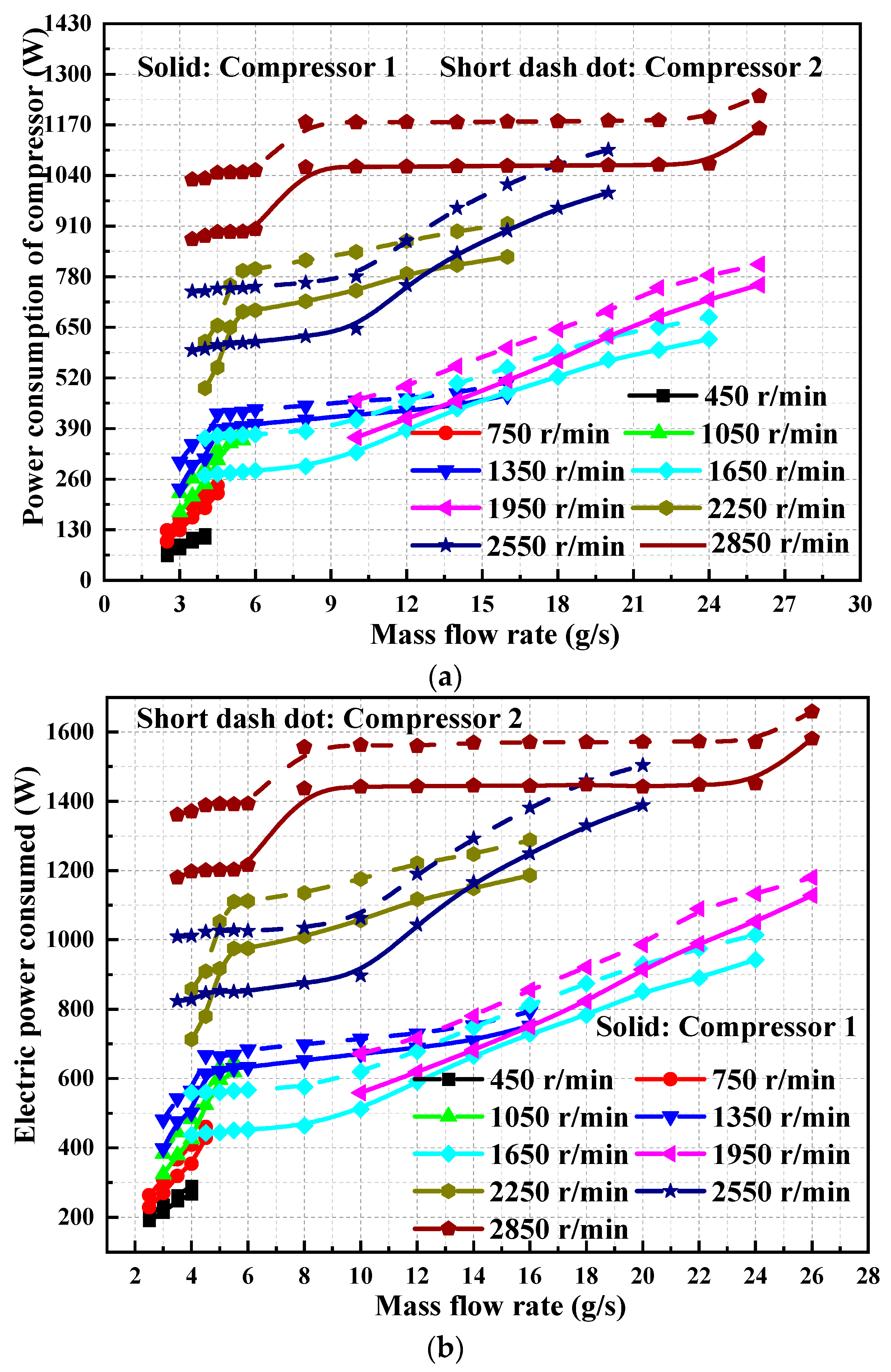

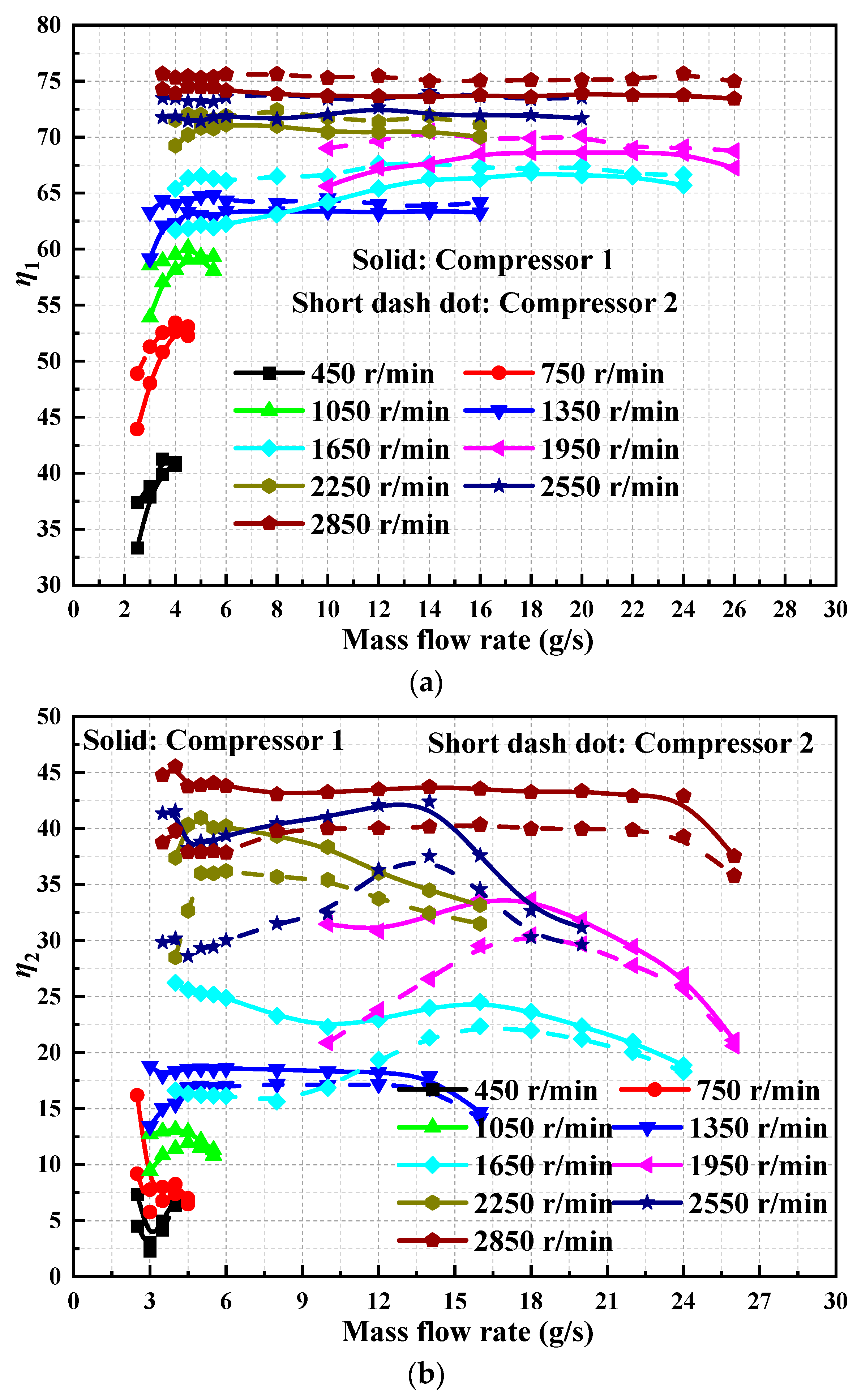

3.6. Influence of Mass Flow Rate on the Performance of the Compressor in Parallel Mode

3.7. Uncertainty Analysis

4. Summary and Conclusions

- (1)

- The torque, pressure ratio, and power consumption of the compressor increase linearly with the increase in the air tank pressure. The maximum value of power consumption is approximately 1233.1 W.

- (2)

- With the increase in mass flow rate, the pressure ratio and power consumption first present a linear increasing trend, then tends to be flat, and finally shows an increasing trend again.

- (3)

- Parallel mode could extend the current and torque working conditions almost twice as much as single mode.

- (4)

- In parallel mode, DC/AC conversion efficiency and isotropic efficiency have improved significantly. The isotropic efficiency curve has a bell shape with a wide peak.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| m | Mass (kg) |

| n | Rotation speed (r/min) |

| pin | Intake pressure (bar) |

| pout | Exhaust back pressure (bar) |

| Pc | Power consumption of compressor (W) |

| Pt | Power output of battery (W) |

| Tr | Torque (N·m) |

| Greek letters | |

| ε | Expansion ratio |

| η | Efficiency |

| Acronyms | |

| CAES | Compressed air energy storage |

References

- Wang, W.; Yuan, B.Q.; Sun, Q.; Ronald, W. Application of energy storage in integrated energy systems—A solution to fluctuation and uncertainty of renewable energy. J. Energy Storage 2022, 52, 104812. [Google Scholar] [CrossRef]

- Yu, X.L.; Jiang, R.C.; Li, Z.; Qian, G.; Wang, B.Z.; Wang, L.; Huang, R. Synergistic improvement of melting rate and heat storage capacity by a rotation-based method for shell-and-tube latent thermal energy storage. Appl. Therm. Eng. 2023, 219, 11948. [Google Scholar] [CrossRef]

- Zhou, Q.; Du, D.M.; Lu, C.; He, Q.; Liu, W.Y. A review of thermal energy storage in compressed air energy storage system. Energy 2019, 188, 115993. [Google Scholar] [CrossRef]

- Taleb, A.L.; Barfuß, C.; Sapin, P.; White, A.J.; Fabris, D.; Markides, C.N. Simulation of thermally induced thermodynamic losses in reciprocating compressors and expanders: Influence of real-gas effects. Appl. Therm. Eng. 2022, 217, 118738. [Google Scholar] [CrossRef]

- El, M.G.; Thibault, N.; Mustapha, B.; Fan, Y.L.; Albert, S. Experimental and numerical investigation on the flow and heat transfer behaviors during a compression–cooling–expansion cycle using a liquid piston for compressed air energy storage. Energy 2023, 277, 127622. [Google Scholar]

- Chen, H.; Peng, Y.H.; Wang, Y.L.; Zhang, J. Thermodynamic analysis of an open type isothermal compressed air energy storage system based on hydraulic pump/turbine and spray cooling. Energy Convers. Manag. 2020, 204, 112293. [Google Scholar] [CrossRef]

- Li, P. Isothermal Compressed Air Energy Storage (i-CAES) System. Encycl. Energy Storage 2022, 2, 204–217. [Google Scholar]

- Chen, L.X.; Zhang, L.G.; Yang, H.P.; Xie, M.N.; Ye, K. Dynamic simulation of a Re-compressed adiabatic compressed air energy storage (RA-CAES) system. Energy 2022, 261, 125351. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Z.; Xie, D.S.; Wu, H.W. Unsteady characteristic and flow mechanism of a scroll compressor in small-scale compressed air energy storage system. J. Energy Storage 2022, 51, 104368. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, C.H.; Li, K. Hybrid modeling and efficiency analysis of the scroll compressor used in micro compressed air energy storage system. Appl. Therm. Eng. 2019, 161, 114139. [Google Scholar] [CrossRef]

- Song, X.F.; Wu, Y.T.; Shen, L.L.; Wang, W.; Lei, B.; Zhi, R.P.; Ma, C.F. Comparative experimental analysis of the effect of lubricant viscosity on the performance of a single-screw expander with different structures. J. Energy Storage 2022, 52, 10495. [Google Scholar] [CrossRef]

- Mahbod, H.; David, P.; Martin, K.P. Physical design, techno-economic analysis and optimization of distributed compressed air energy storage for renewable energy integration. J. Energy Storage 2021, 35, 10226. [Google Scholar]

- Guo, W.B.; Zuo, Z.T.; Sun, J.T.; Hou, H.C.; Liang, Q.; Chen, H.S. Experimental investigation on off-design performance and adjustment strategies of the centrifugal compressor in compressed air energy storage system. J. Energy Storage 2021, 38, 10251. [Google Scholar] [CrossRef]

- Lin, Z.H.; Zuo, Z.T.; Guo, W.B.; Sun, J.T.; Liang, Q.; Chen, H.S. Experimental study on effects of adjustable vaned diffusers on impeller backside cavity of centrifugal compressor in CAES. Energies 2021, 14, 6187. [Google Scholar] [CrossRef]

- Lin, Z.H.; Zuo, Z.T.; Sun, J.T.; Zhou, X.; Zhang, D.; Chen, H.S. Flow characteristics of impeller backside cavity and its effects on the centrifugal compressor for compressed air energy storage. J. Energy Storage 2022, 49, 104024. [Google Scholar] [CrossRef]

- Lin, Z.; Zuo, Z.; Li, W.; Sun, J.; Zhou, X.; Chen, H.; Zhou, X. Experimental and Numerical Analysis of the Impeller Backside Cavity in a Centrifugal Compressor for CAES. Energies 2022, 15, 420. [Google Scholar] [CrossRef]

- Meng, C.; Zuo, Z.; Guo, W.; Sun, J.T.; Zhou, X.; Chen, H.S. Experimental and numerical investigation on off-design performance of a high-pressure centrifugal compressor in compressed air energy storage system. J. Energy Storage 2022, 53, 105081. [Google Scholar] [CrossRef]

- Xue, X.; Wang, T. Experimental study on inducement and development of flow instabilities in a centrifugal compressor with different diffuser types. J. Therm. Sci. 2020, 29, 435–444. [Google Scholar] [CrossRef]

- He, Y.; Chen, H.S.; Xu, Y.J.; Deng, J.Q. Compression performance optimization considering variable charge pressure in an adiabatic compressed air energy storage system. Energy 2018, 165, 349–359. [Google Scholar] [CrossRef]

- Cao, Z.; Zhou, S.H.; He, Y.; Xu, Y.J.; Chen, H.S.; Deng, J.Q. Numerical study on adiabatic compressed air energy storage system with only one ejector alongside final stage compression. Appl. Therm. Eng. 2022, 216, 119071. [Google Scholar] [CrossRef]

- Patil, V.C.; Ro, P.I. Experimental study of heat transfer enhancement in liquid piston compressor using aqueous foam. Appl. Therm. Eng. 2020, 164, 114441. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, L.X.; Zhang, C.; He, X.B.; Zhang, Y.P.; Yang, T. Performance analysis of an adiabatic compressed air energy storage system with a pressure regulation inverter-driven compressor. J. Energy Storage 2021, 43, 103197. [Google Scholar] [CrossRef]

- Khaljani, M.; Harrison, J.; Surplus, D.; Murphy, A.; Sapin, P.; Markides, C.N.; Mahmoudi, Y. A combined experimental and modelling investigation of an overground compressed-air energy storage system with a reversible liquid-piston gas compressor/expander. Energy Convers. Manag. 2021, 245, 114536. [Google Scholar] [CrossRef]

- Khaljani, M.; Vennard, A.; Harrison, J.; Surplus, D.; Murphy, A.; Mahmoudi, Y. Experimental and modelling analysis of efficiency enhancement in a liquid piston gas compressor using metal plate inserts for compressed air energy storage application. J. Energy Storage 2021, 43, 10324. [Google Scholar] [CrossRef]

- Rice, A.T.; Li, P.Y.; Sanckens, C.J. Optimal efficiency-power tradeoff for an air compressor/expander. J. Dyn. Syst. Meas. Control 2018, 140, 021011. [Google Scholar] [CrossRef]

- Li, R.X.; Tao, R.; Yao, E.T.; Zhang, H.R.; Niu, Y.L.; Ling, L.N.; Yan, A.; Wang, H.R. Decoupling heat-pressure potential energy of compressed air energy storage system: Using near-isothermal compressing and thermal energy storage. J. Energy Storage 2023, 63, 10701. [Google Scholar] [CrossRef]

- Wieberdink, J.; Li, P.Y.; Simon, T.W.; Van de Ven, J.D. Effects of porous media insert on the efficiency and power density of a high pressure (210 bar) liquid piston air compressor/expander—An experimental study. Appl. Energy 2018, 212, 1025–1037. [Google Scholar] [CrossRef]

- Li, P.Y.; Saadat, M. An approach to reduce the flow requirement for a liquid piston near-isothermal air compressor/expander in a compressed air energy storage system. IET Renew. Power Gener. 2016, 10, 1506–1514. [Google Scholar] [CrossRef]

- Hu, S.W.; Xu, W.Q.; Cai, M.L.; Jia, G.W. Energy efficiency and power density analysis of a tube array liquid piston air compressor/expander for compressed air energy storage. J. Energy Storage 2022, 55, 105674. [Google Scholar] [CrossRef]

- He, Q.; Li, G.Q.; Lu, C.; Du, D.M.; Liu, W.Y. A compressed air energy storage system with variable pressure ratio and its operation control. Energy 2019, 169, 881–894. [Google Scholar] [CrossRef]

- Srivatsa, A.; Li, P.Y. How moisture content affects the performance of a liquid piston air compressor/expander. J. Energy Storage 2018, 18, 121–132. [Google Scholar] [CrossRef]

- Patil, V.C.; Liu, J.; Ro, P.I. Efficiency improvement of liquid piston compressor using metal wire mesh for near-isothermal compressed air energy storage application. J. Energy Storage 2020, 28, 101226. [Google Scholar] [CrossRef]

- Xu, Y.H.; Zhang, H.G.; Yang, F.B.; Tong, L.; Yang, Y.F.; Yan, D.; Wang, C.Y.; Ren, J.; Wu, Y.T. Experimental study on small power generation energy storage device based on pneumatic motor and compressed air. Energy Convers. Manag. 2021, 234, 113949. [Google Scholar] [CrossRef]

- Xu, Y.H.; Zhang, H.G.; Yang, F.B.; Tong, L.; Yan, D.; Yang, Y.F.; Wang, Y.; Wu, Y.T. Experimental investigation of pneumatic motor for transport application. Renew. Energy 2021, 179, 517–527. [Google Scholar] [CrossRef]

- Huang, X.; Li, K.; Xie, Y.; Liu, B.; Liu, J.Y.; Liu, Z.M.; Mou, L.J. A novel multistage constant compressor speed control strategy of electric vehicle air conditioning system based on genetic algorithm. Energy 2022, 241, 122903. [Google Scholar] [CrossRef]

- Abadeh, A.; Sardarabadi, M.; Abedi, M.; Pourramezan, M.; Passandideh-Fard, M.; Maghrebi, M.J. Experimental characterization of magnetic field effects on heat transfer coefficient and pressure drop for a ferrofluid flow in a circular tube. J. Mol. Liq. 2020, 299, 112206. [Google Scholar] [CrossRef]

- Wang, Z.; Shen, Y.F.; Wang, Z.B.; Wang, J.; Jiang, W.C.; Li, Q. Theoretical research and optimization analysis for the injection process of the single screw refrigeration compressor. Int. J. Refrig. 2018, 88, 91–101. [Google Scholar] [CrossRef]

| Type | Rated Rotation Speed | Rated Power | Rated Torque |

|---|---|---|---|

| QMH050A | 2000 r/min | 485 W | 7.0 N·m |

| 80ST-M02430 | 3000 r/min | 750 W | 2.39 N·m |

| Name | Measuring Range | Tolerances |

|---|---|---|

| Pressure sensors | 0~15 bar | ±0.2% FS |

| Temperature sensor | −20~100 °C | ±0.5% FS |

| Torque sensor | 0~20 N·m | ±0.5% FS |

| Speed sensor | 0~6000 r/min | ±0.5% FS |

| Flowmeter | 0~5000 L/min | ±0.5% FS |

| Voltage sensor | 0~250 V | ±0.5% FS |

| Current sensor | 0~30 A | ±0.5% FS |

| Parameters | Measuring Range | Accuracy | Relative Uncertainty |

|---|---|---|---|

| pin, pout | 0–15 bar | ±0.2% FS | 0.4% |

| Tin, Tout | −20–100 °C | ±0.5% FS | 2.5% |

| Torque | 0–20 N·m | ±0.5% FS | 1.67% |

| Rotation speed | 0–6000 r/min | ±0.5% FS | 1.5% |

| Volume flow rate | 0–5000 L/min | ±0.5% FS | 1.56% |

| Current | 0–30 A | ±0.5% FS | 1.67% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Xu, Y.; Zhang, H.; Zhang, J.; Yang, F.; Wang, Y.; Wu, Y. Experimental Investigation on the Performance of Compressors for Small-Scale Compressed Air Energy Storage in Parallel Mode. Sustainability 2023, 15, 13164. https://doi.org/10.3390/su151713164

Yang H, Xu Y, Zhang H, Zhang J, Yang F, Wang Y, Wu Y. Experimental Investigation on the Performance of Compressors for Small-Scale Compressed Air Energy Storage in Parallel Mode. Sustainability. 2023; 15(17):13164. https://doi.org/10.3390/su151713164

Chicago/Turabian StyleYang, Hailong, Yonghong Xu, Hongguang Zhang, Jian Zhang, Fubin Yang, Yan Wang, and Yuting Wu. 2023. "Experimental Investigation on the Performance of Compressors for Small-Scale Compressed Air Energy Storage in Parallel Mode" Sustainability 15, no. 17: 13164. https://doi.org/10.3390/su151713164

APA StyleYang, H., Xu, Y., Zhang, H., Zhang, J., Yang, F., Wang, Y., & Wu, Y. (2023). Experimental Investigation on the Performance of Compressors for Small-Scale Compressed Air Energy Storage in Parallel Mode. Sustainability, 15(17), 13164. https://doi.org/10.3390/su151713164