1. Introduction

In the face of increasingly severe environmental degradation worldwide, building systems, as human habitation hubs, have a significant impact on the global ecosystem in terms of their sustainability [

1,

2]. As open systems, building systems require the continuous input of materials, energy, information, and other resources, which inevitably lead to changes in the sustainability statuses of building systems [

3,

4]. At the same time, variations in the supply of various building-system components can affect carbon emissions calculations. According to estimations by researchers, carbon emissions from the entire building system account for more than one-third of total carbon emissions [

5,

6]. Therefore, research on the ecological sustainability and carbon emissions of building systems needs to be simultaneously addressed.

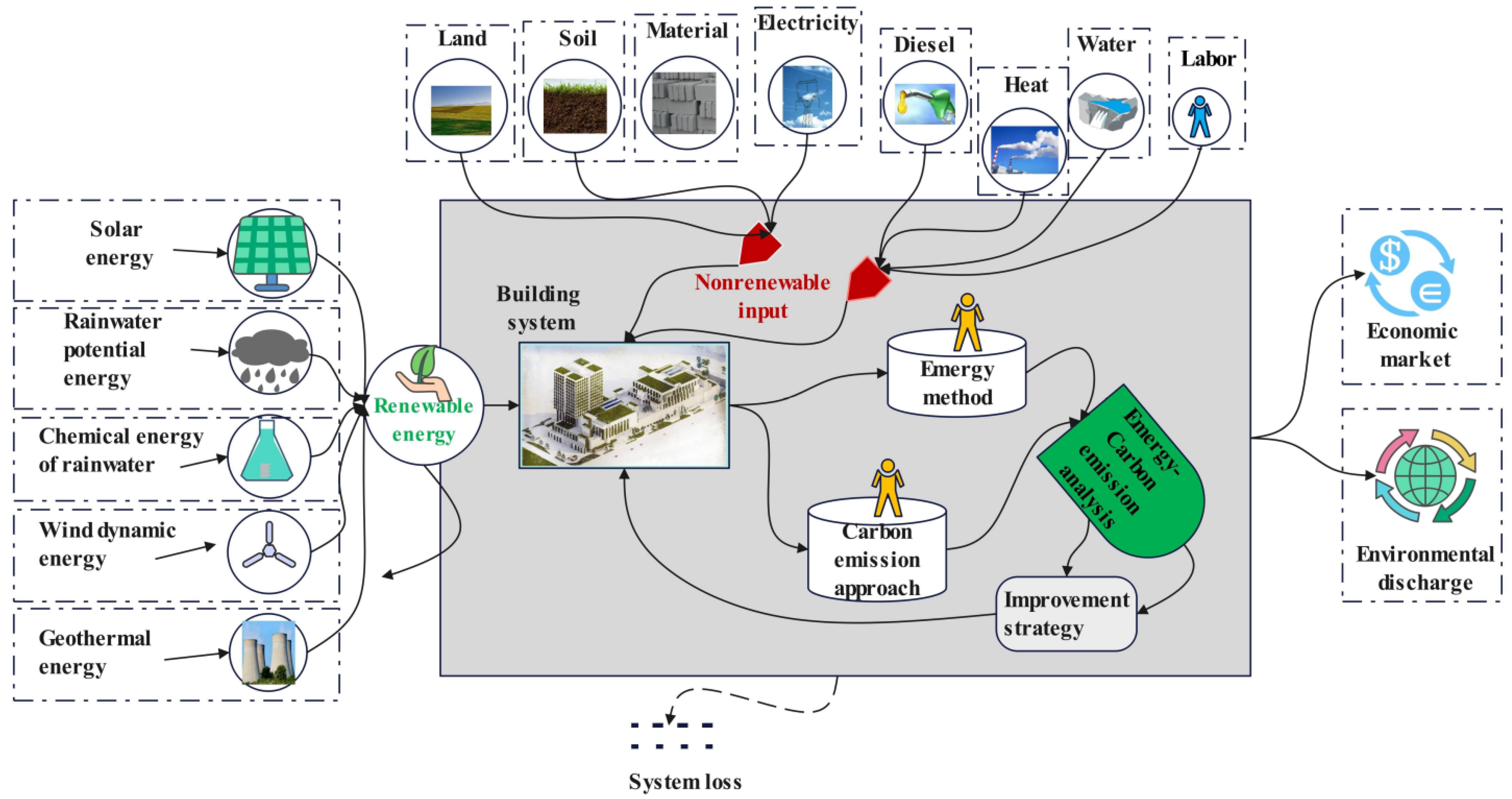

This study applies two methods: ecological emergy analysis and carbon-emission estimation. Emergy analysis is an approach used to analyze systems from an ecological–economic perspective and has been widely applied in various fields, including urban areas [

7], water treatment [

8], industry [

9], materials [

10,

11], ecology [

12], and economics [

13]. Additionally, building systems also constitute an important research area in the field of emergy analysis. However, the focus of research varies among different researchers. Some couple emergy analysis with other methods, such as building information modeling (BIM) technology [

14] or clean energy technologies [

15]. Others have focused on the impact of the emergy embodied in building materials on building systems [

16]. Evaluating green building systems and assessing their sustainability status from the perspective of emergy analysis is also an important research topic [

17]. Moreover, architects can use this method to guide building design, which can help reduce the negative environmental effects of buildings [

18].

As this study involves the emergy analysis of the entire life cycles of building systems, relevant research regarding the relationship between building systems and LCA–emergy methods has been reviewed. Currently, there is limited research in this area, mainly focusing on the emergy analysis of the entire life cycles of building systems [

19], renewal design strategies for building systems [

20], and the impact of the energy embodied in building materials on the sustainability of building systems [

21].

There has been extensive research on carbon emissions from building systems, with different researchers studying and analyzing carbon emissions from various perspectives. For example, the effects of the carbon emissions from different building models have been explored to provide pathways for low-carbon designs [

22]. Starting from the perspective of low-carbon city design, researchers have delved into low-carbon design at the building level, introducing a new way of thinking [

23]. Considering that carbon emissions are dynamic processes, the analysis of the trends in the development of carbon emissions in public buildings has also been a focus of research [

24]. Some researchers have employed system-dynamics methods to analyze and predict carbon emissions in buildings [

25]. The management of carbon emissions in supply chains has also become a research hotspot to ensure the normal operation of building systems [

26]. The integration of low-carbon-design concepts into the renewal design of old buildings is advocated as one of the industry’s approaches [

27]. The low-carbon effects of green space design through the coupling of building and landscape systems have also received attention from multiple scholars [

28]. The analysis of the impact of carbon-emission quotas on the construction industry is a task undertaken by government officials [

29]. The model of zero-carbon buildings, regarded as the optimal model for building systems, has consistently been a focal point of the industry [

30].

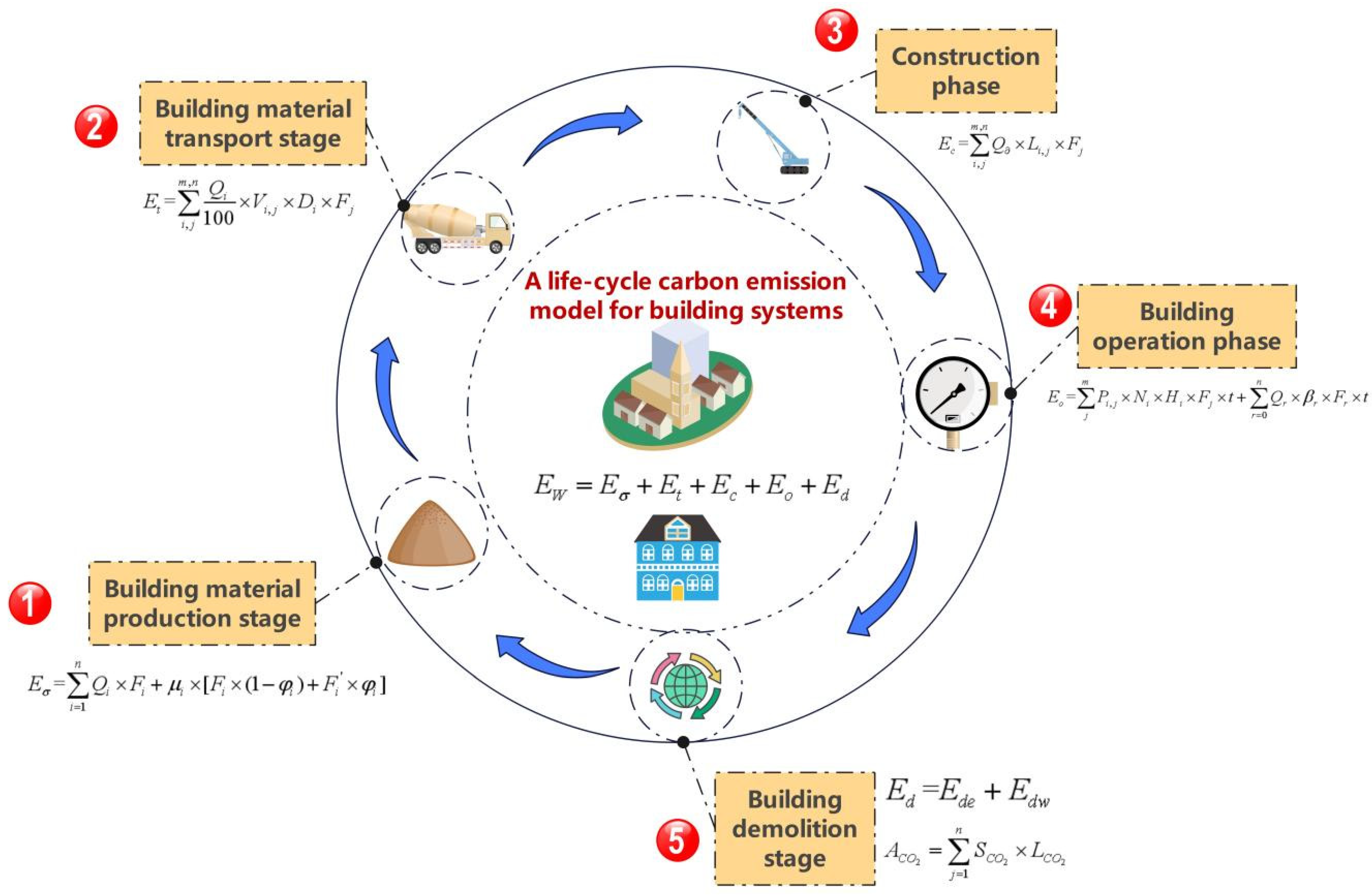

Furthermore, research on the life-cycle carbon emissions of building systems is another major topic. For example, the carbon-emissions intensity and cost of building systems, combined with BIM technology and the LCA method, have been studied and garnered attention [

31]. The economic effects of low-carbon buildings, in conjunction with energy-saving measures, have been analyzed [

32]. Some scholars have explored the environmental and climate effects of low-carbon buildings [

33]. In addition to methodological differences, different types of buildings are also the focus of attention in terms of low-carbon aspects. Topics such as the life-cycle carbon emissions of zero-carbon buildings and the application of carbon capture and storage technologies have been investigated [

34]. Researchers have delved into the carbon emissions of residential houses, rural dwellings, and prefabricated buildings [

35,

36,

37]. Carbon sequestration in concrete materials is an important approach to carbon reduction in building systems. Scholars have conducted research on the chemical reactions between concrete materials and carbon dioxide using a multi-scale thermo-physical model. The findings prove that this is a feasible method for carbon reduction in building systems [

38,

39,

40].

However, at the time of writing, research on the integration of emergy analysis with carbon-emissions analysis in the context of building systems is still in its early stages. As two perspectives for assessing sustainability, are the ecological perspective and carbon emission perspective consistent when it comes to building systems? What are the similarities and differences between the two? Can they provide support for architects and building managers? These are the research focuses of this paper.

The uniqueness of this article lies in its comprehensive study of the sustainability of building systems by coupling emergy theory and carbon emissions methodology. From the perspectives of ecological landscape and carbon emissions, it provides an integrated assessment of the state of buildings, offering novel insights to architects and building managers in approaching sustainable architecture.

3. Case Study

3.1. Case Introduction

The building in question is a renovation project that aims to transform and enhance its functionality. Due to its age of over 25 years, the exterior of the building has deteriorated significantly and no longer meets the requirements for commercial activities. Moreover, the excessive hardscape elements within the complex have disturbed the ecological balance and hindered integration with the surrounding environment. The updated design of the building incorporates the following features: a green coverage ratio of 72%, a building footprint of approximately 14,000 square meters, and a total area of around 56,100 square meters.

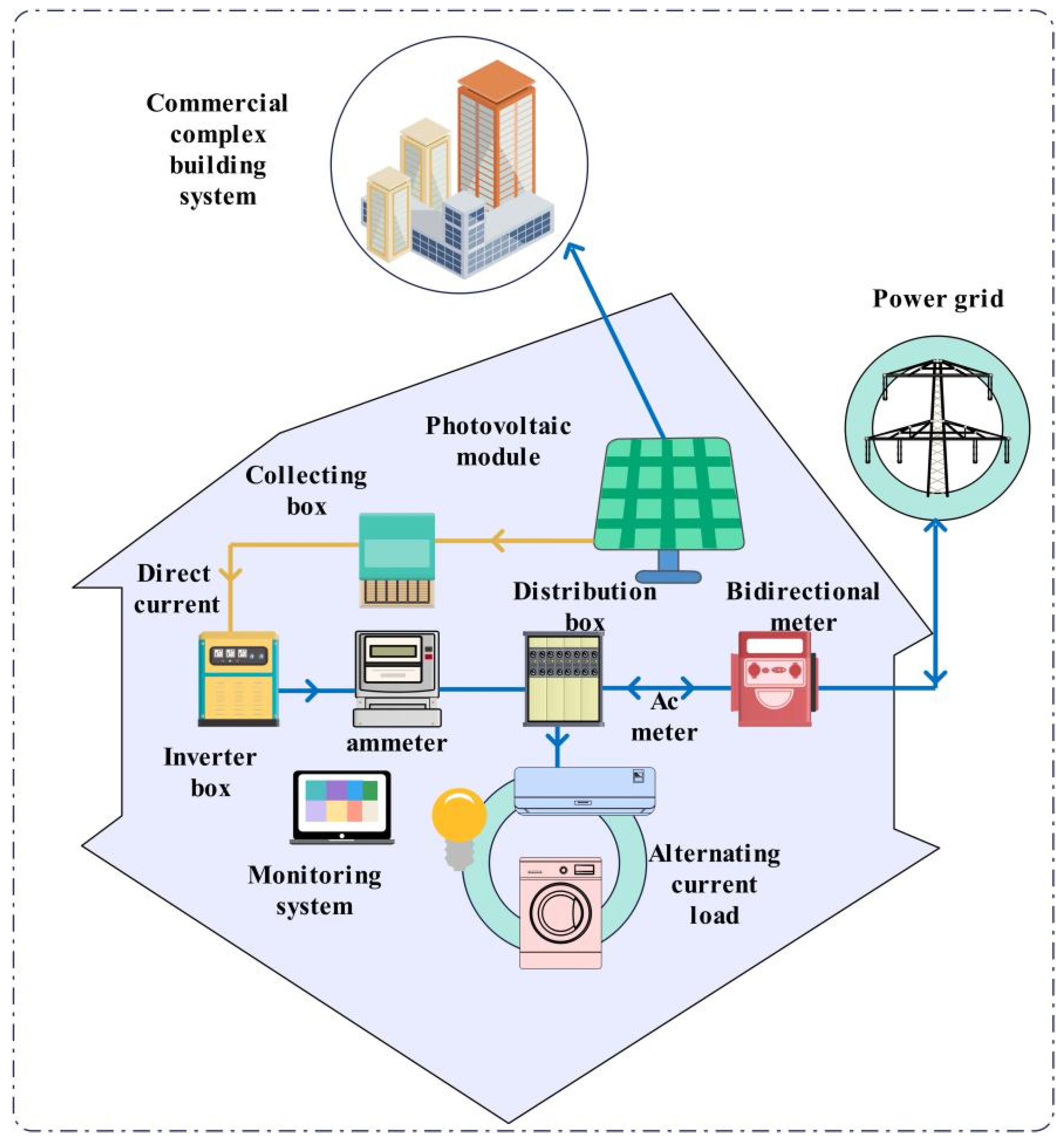

The design concept focuses on creating a sustainable commercial complex that integrates seamlessly with the natural environment and topography. The eastern part of the landscape includes a hotel and commercial terraces, while the southern section, facing a planned residential area, is designed as a terrace to provide an unobstructed view. Considering the blocked view from the northern community center, the commercial floors are connected by corridors that include vertical transportation modules. Additionally, the entire building incorporates eco-friendly design elements such as an ecological curtain wall, rooftop gardens, and sunken ecological plazas (refer to

Figure 3).

3.2. Date Collection

The data required for the entire study can be classified into two categories.

Firstly, the basic data can be obtained from construction manufacturers. These data include material lists, transportation input lists, and labor input data.

Secondly, emergy conversion rates can be found in the relevant research literature, while carbon emission factor data can be obtained from the Intergovernmental Panel on Climate Change (IPCC).

The carbon emission factor is derived from the emission coefficient method, which is widely recognized as one of the most commonly used methods for carbon emission accounting. It quantifies the production of greenhouse gases associated with the consumption per unit of substance. In the construction industry, three types of carbon emission factors are commonly utilized: fossil energy carbon emission factor, electric power carbon emission factor, and building material carbon emission factor.

5. The Comprehensive Analysis Based on LCA–Emergy and LCA–Carbon Emission

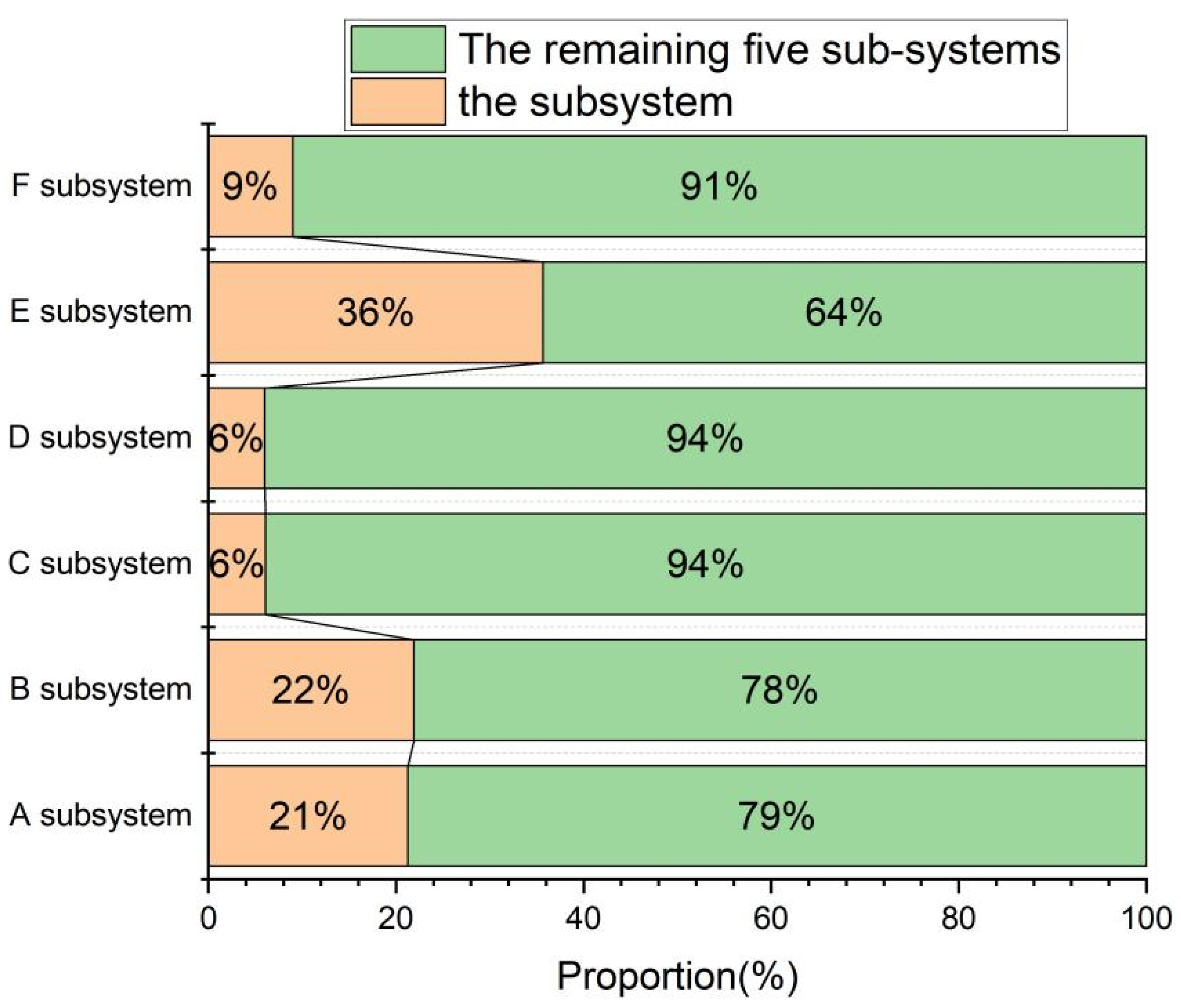

In this chapter, both the emergy and carbon emissions perspectives were analyzed for the same building system to understand their similarities and differences. The findings are as follows:

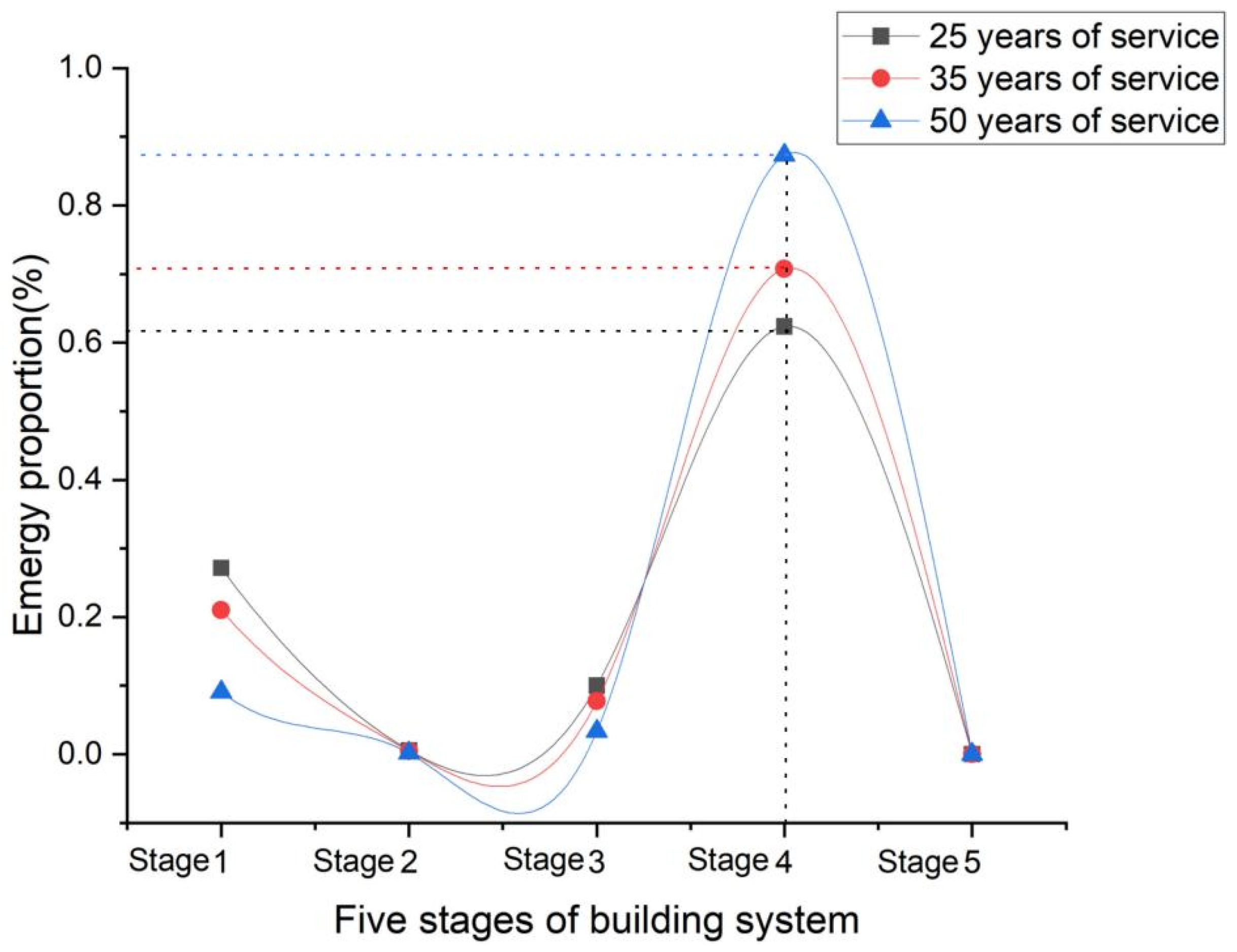

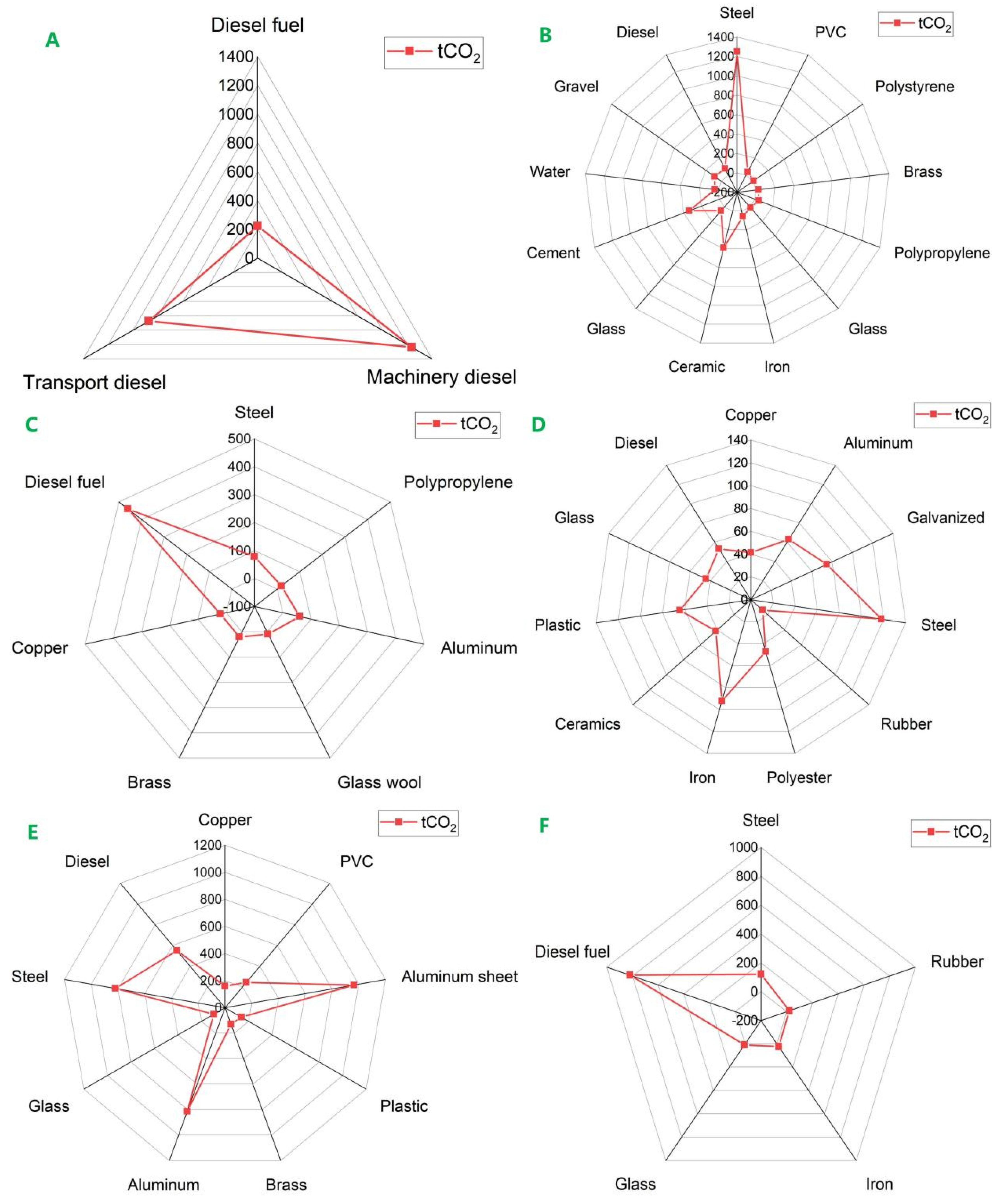

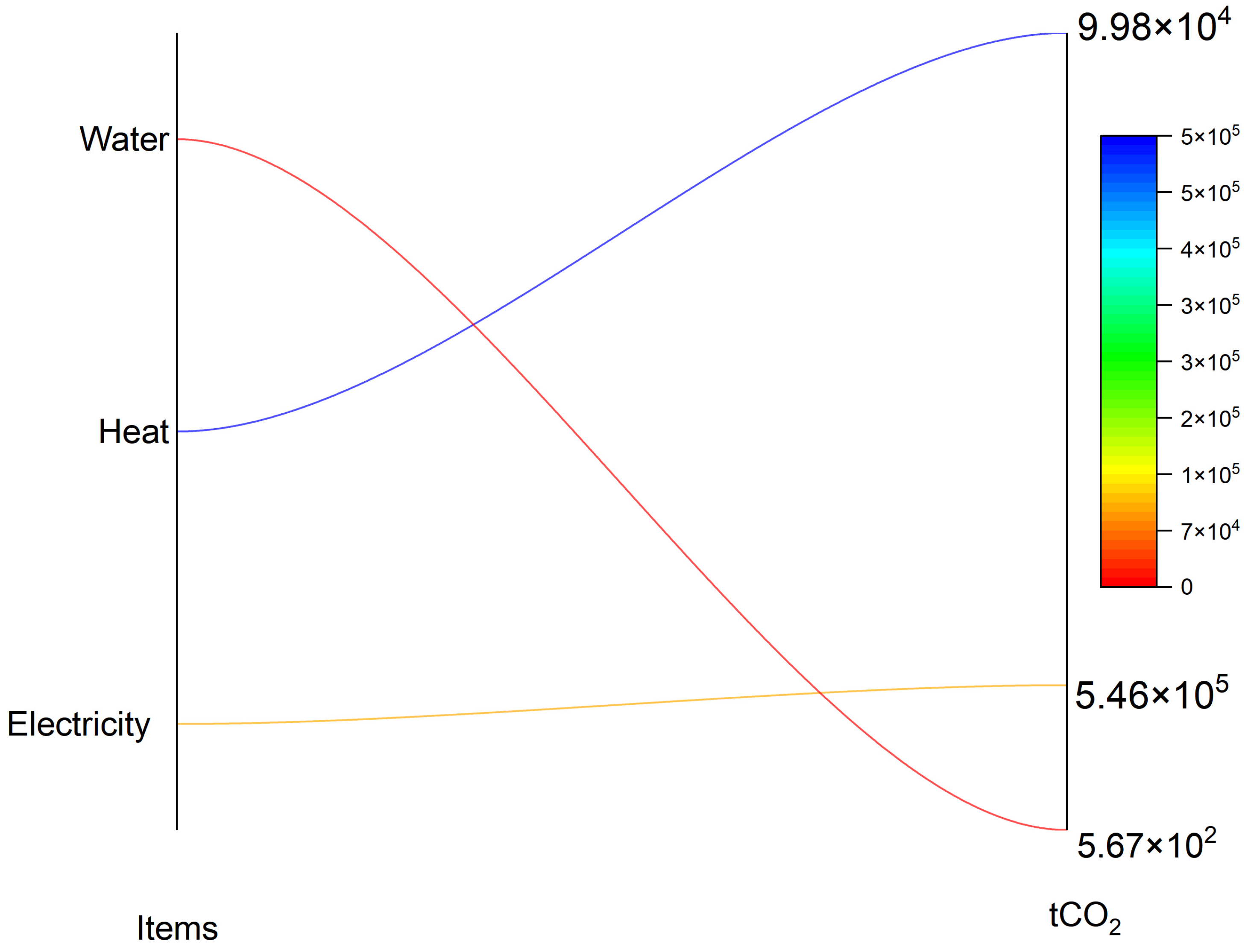

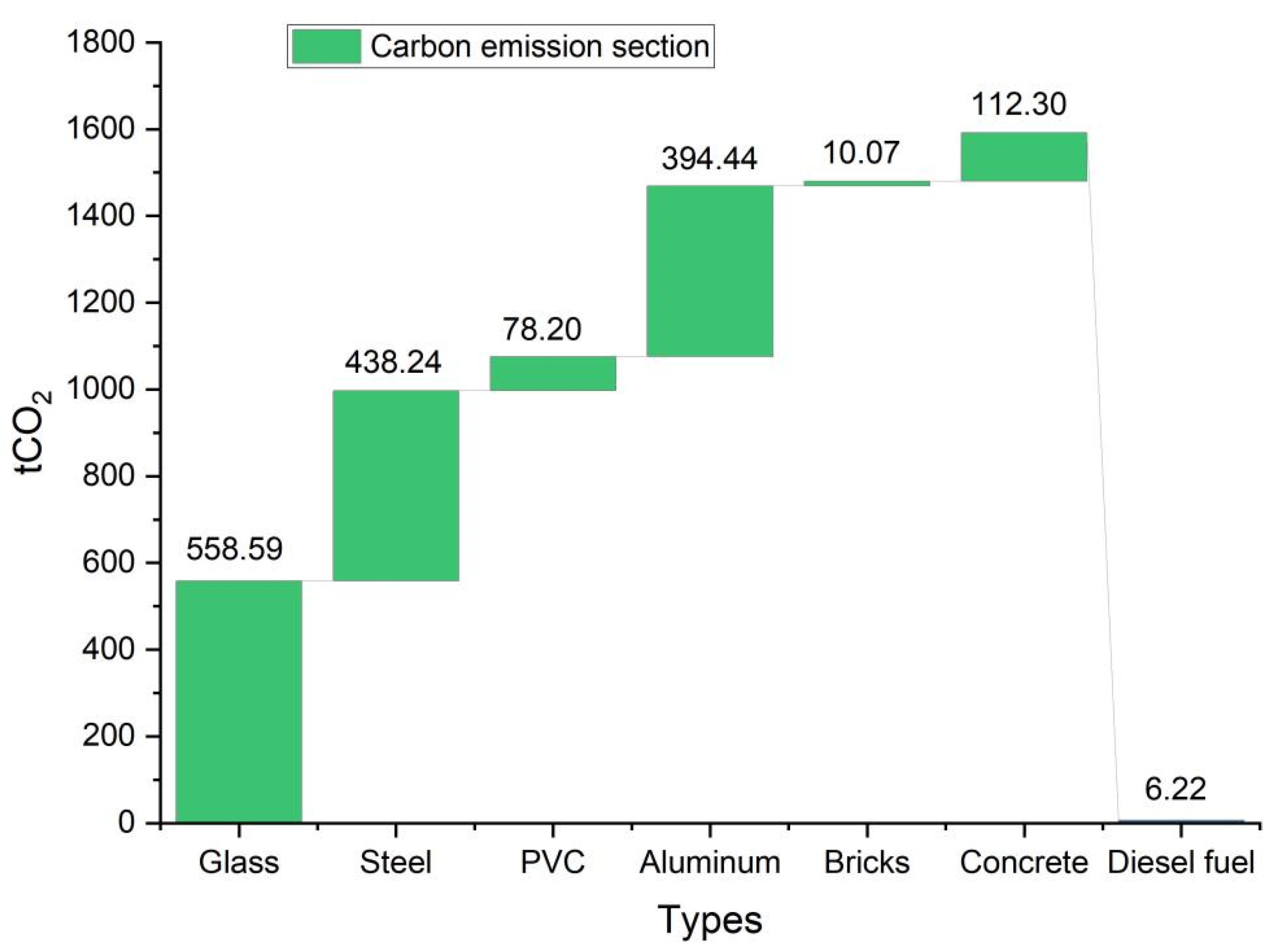

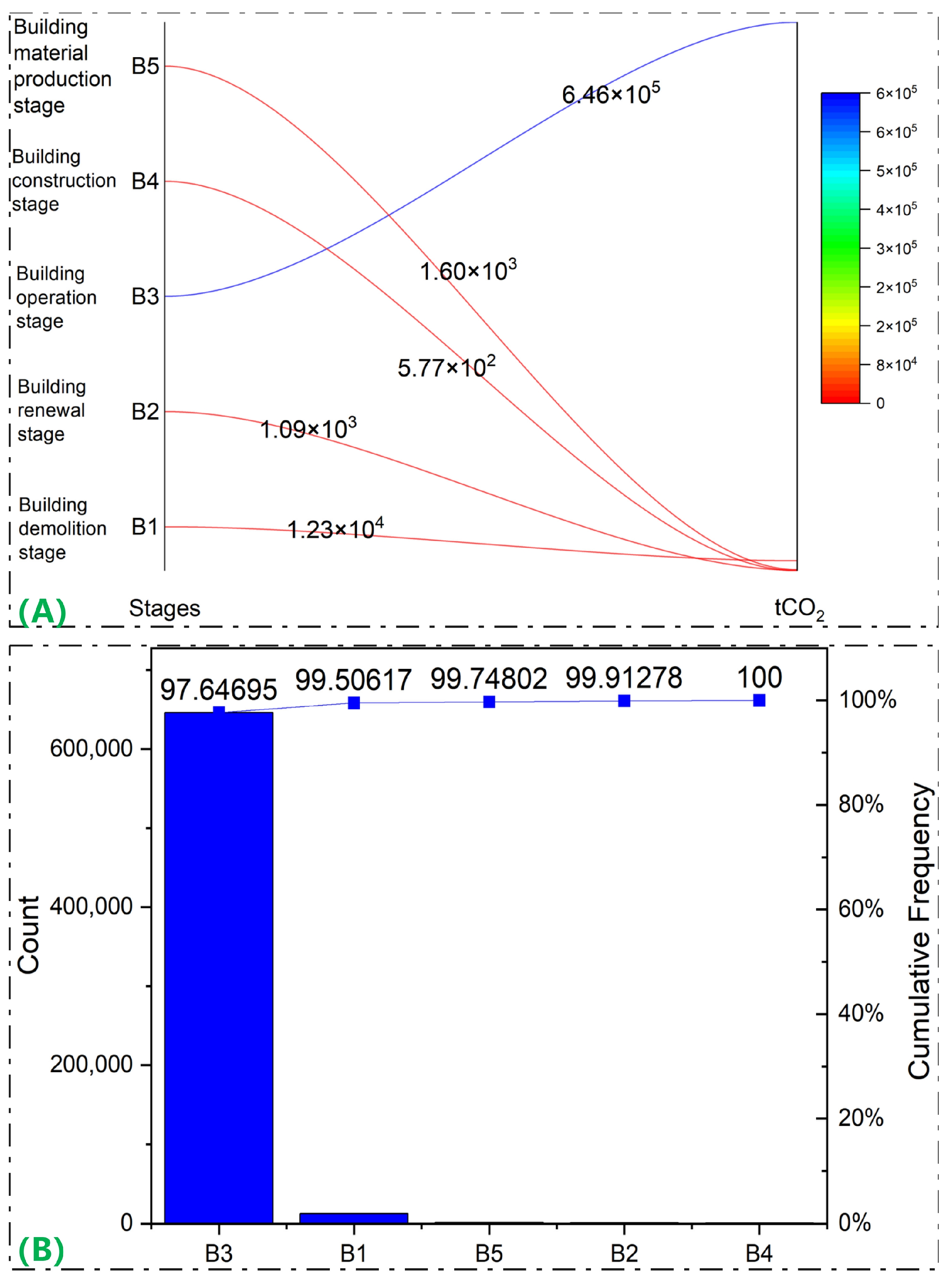

Similar conclusions: Regardless of the perspective, whether it is emergy or carbon emissions, the operational stage of the building system and the building materials production stage are the main controlling factors. These two stages contribute to a significant portion of the emergy consumption and carbon emissions throughout the entire life cycle of the building system and therefore require focused attention and research.

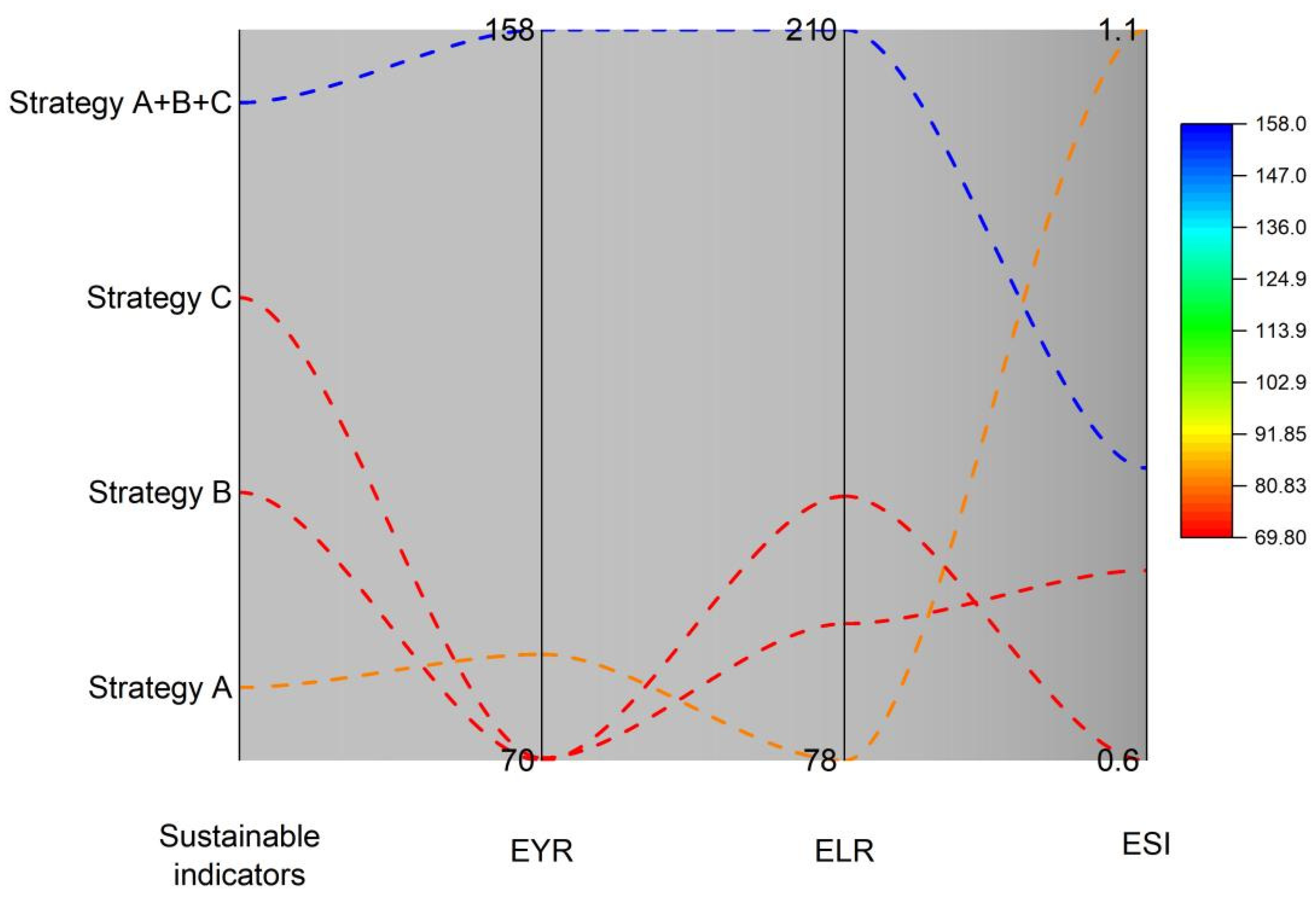

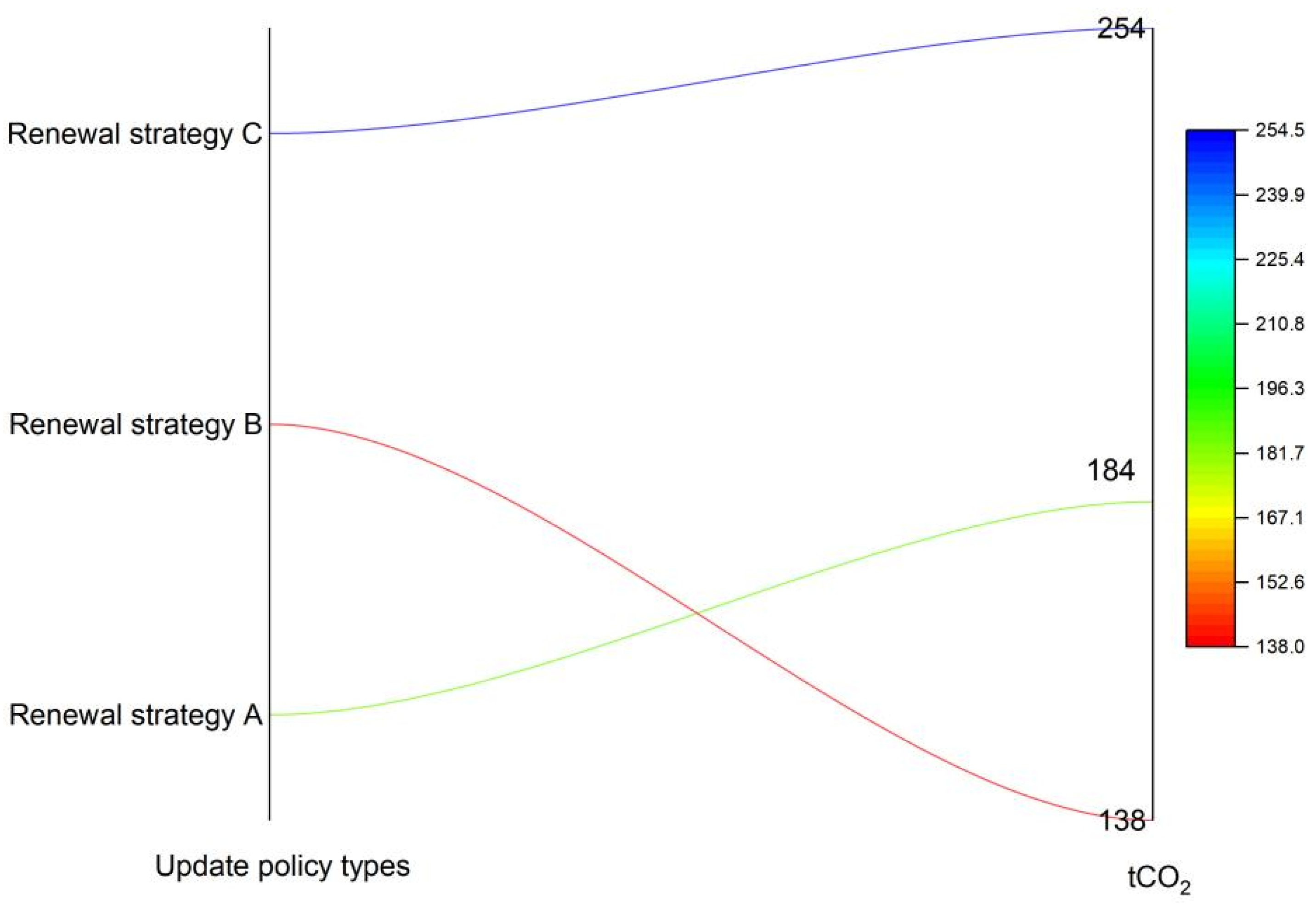

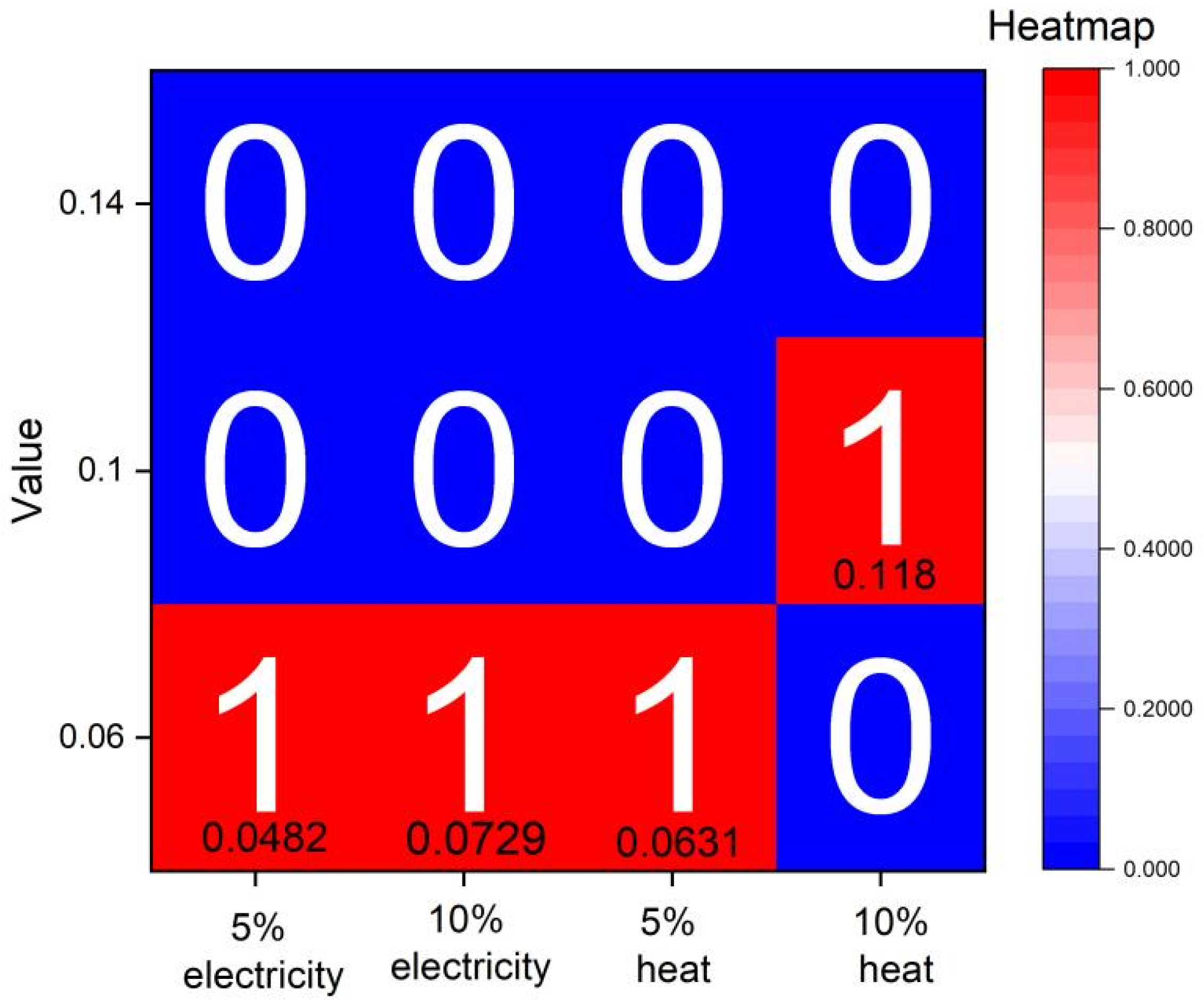

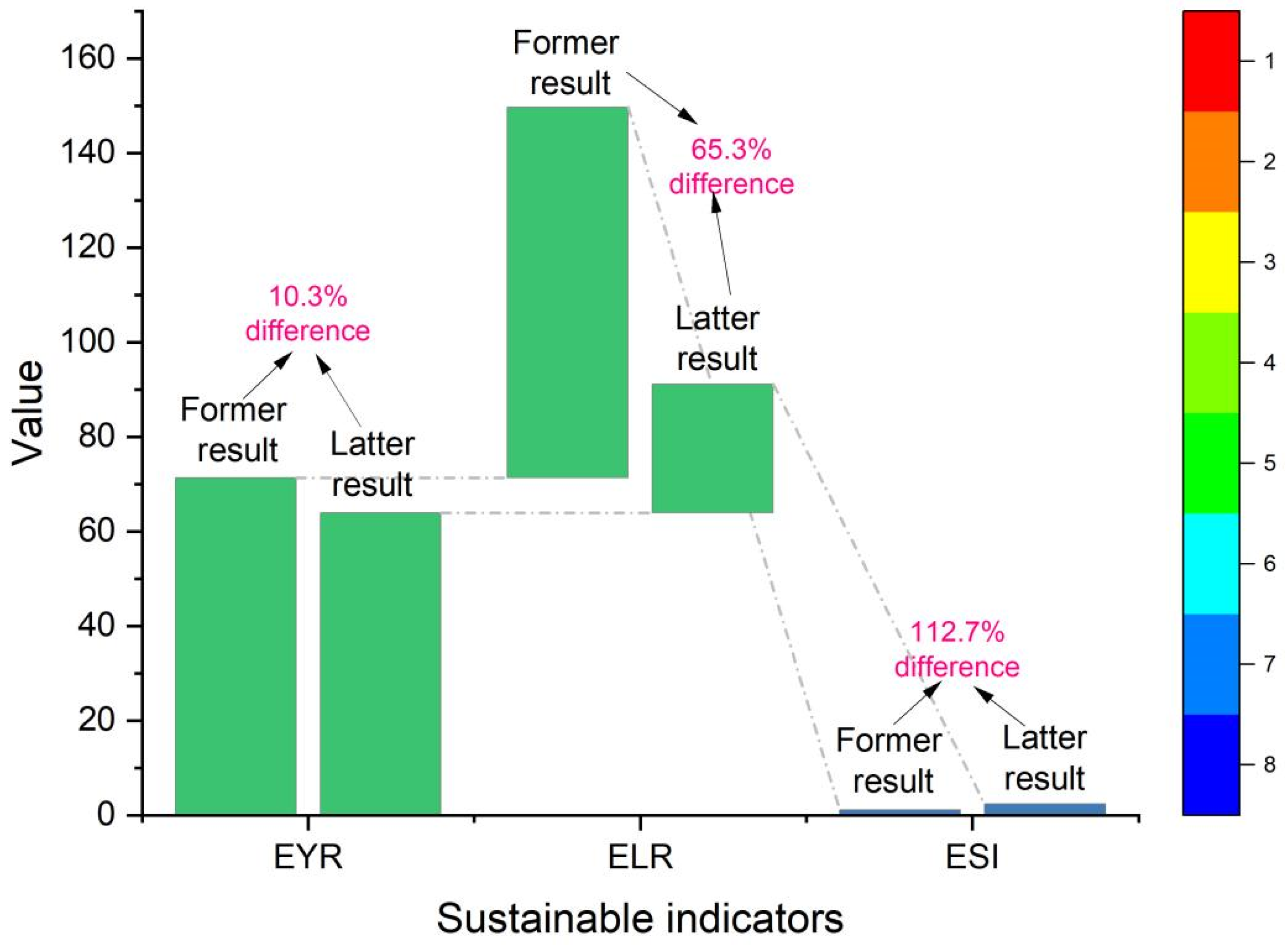

Differences: Taking the building retrofit stage as an example, three different retrofit design strategies were evaluated from the perspective of emergy sustainability. Design strategy A was found to be the most optimal, followed by design strategy B and design strategy C. Based on common predictions, the order of carbon emissions would be A < B < C (which is incorrect). However, in reality, the order is B < A < C (which is the actual result). This explains that analyzing from a single perspective may lead to discrepancies. This has positive implications for architects and building managers.

7. Conclusions

As a complex system, the definition of sustainability in the context of architecture is diverse. While readers often associate sustainable architecture with green buildings, the sustainable perspective of building systems can be much broader. This paper introduces two interconnected perspectives (emergy and carbon emission) for analyzing the sustainability of building systems, providing readers with new directions to consider.

The LCA–Emergy analysis and the LCA–Carbon emission perspective revealed that the operational stage and the building materials production stage are critical stages throughout the entire life cycle. Retrofit design strategies help enhance the sustainability performance of the building system, and the extent of improvement depends on the choice of design strategies. However, there are differences between the two perspectives. For instance, the integration of solar clean energy sources enhances the sustainability of the building system from an emergy perspective, but it also increases the overall carbon emissions of the building system from a carbon emissions perspective, thereby having a negative impact on the environment to some extent. Therefore, comprehensive analysis and judgment are required by considering both perspectives.

To conduct a more comprehensive sustainable analysis, future work will focus on the dynamic monitoring and prediction of emergy performance and carbon emissions. This will involve utilizing theoretical models related to artificial intelligence and machine learning for analysis. This area will be the primary focus of future research.