The ASME B31 G standard has issued four versions so far, namely the ASME B31G-1984 [

17] standard, the ASME B31G-1991 [

18] standard, the ASME B31 G-2009 [

19] standard, and the ASME B31 G-2012 standard [

20], among which the ASME B31G-1984 standard, also known as the concise evaluation method for the residual strength of corroded pipelines, is one of the most widely used standards in Europe and the United States. The ASME B31G-1991 standard has partially amended and improved the ASME B31G-1984 standard [

18]. Based on many experimental data points, the ASME B31G-2009 standard has significantly changed the ASME B31G-1991 standard. This revision will overcome the conservatism of the ASME B31G-1991 standard. However, Nova Corporation in Alberta, Canada, and Pipeline Company in the UK subsequently demonstrated through research methods such as blasting experiments that the ASME B31G standard still has conservatism in evaluating corrosion defects in pipelines. It is also pointed out that one of the reasons for the conservatism of the ASME B31 G standard is that the impact of single corrosion defects, double corrosion defects, interaction corrosion defects, and corrosion defects with a spiral angle are all evaluated according to the same evaluation method. To solve this problem, ARCO Alaska Co., Ltd. proposed a highly approximate condition for treating discontinuous and multiple corrosion defects as one corrosion defect.

3.2. Calculation of the Risk Score Based on AHP

The AHP method is a set of advantages of qualitative and quantitative analysis [

21], which is a mathematical evaluator’s evaluation thinking process for complex systems and can solve multiple problems simultaneously. Decision makers initially determine the importance ranking of each criterion based on experience and use corresponding algorithmic programs to calculate the weights of each criterion. By using specific weights, the relationship of relative importance between each criterion and another, as well as between a specific criterion and the overall goal, can be accurately expressed, which is especially suitable for structural models with complex standard structures and relatively scarce necessary data [

22].

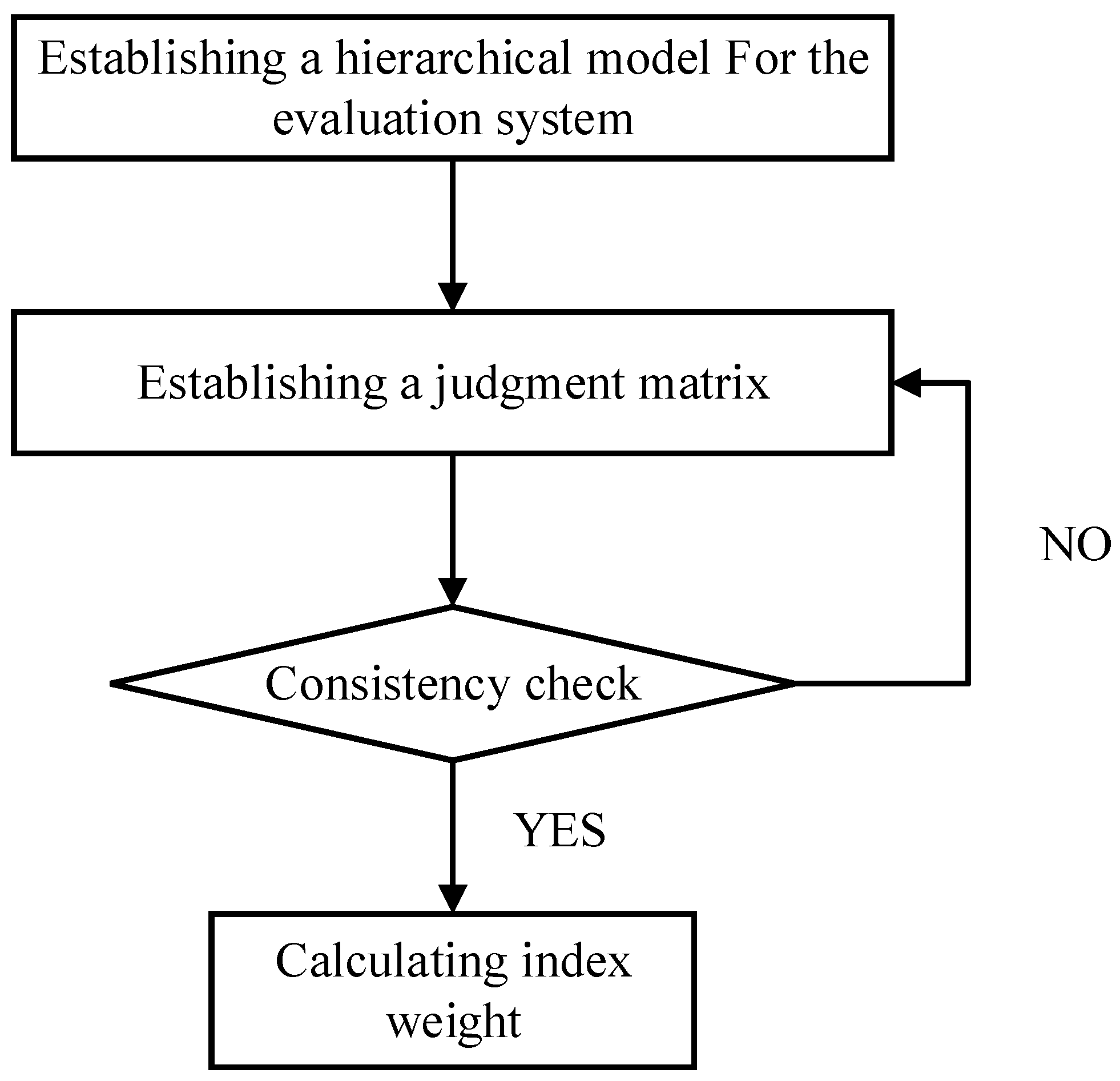

The AHP mainly considers the empirical knowledge and personal preferences of experts. Its basic principle is to compare and judge the evaluation index models at the same level in pairs based on relevant criteria, determine the evaluation matrix, and then conduct consistency testing. The matrix is modified until it passes the consistency test. Finally, the maximum eigenvalue and eigenvector of the judgment matrix are calculated as the subjective weights of the evaluation index. In addition, as the evaluation indicators increase, the order also increases, making it relatively difficult to compare the indicators in pairs and challenging to pass the consistency test. Therefore, 1 to 9 are generally chosen to illustrate their relative importance [

23]. The specific analysis flowchart is shown in

Figure 1.

- (1)

Establish a hierarchical model of the evaluation system

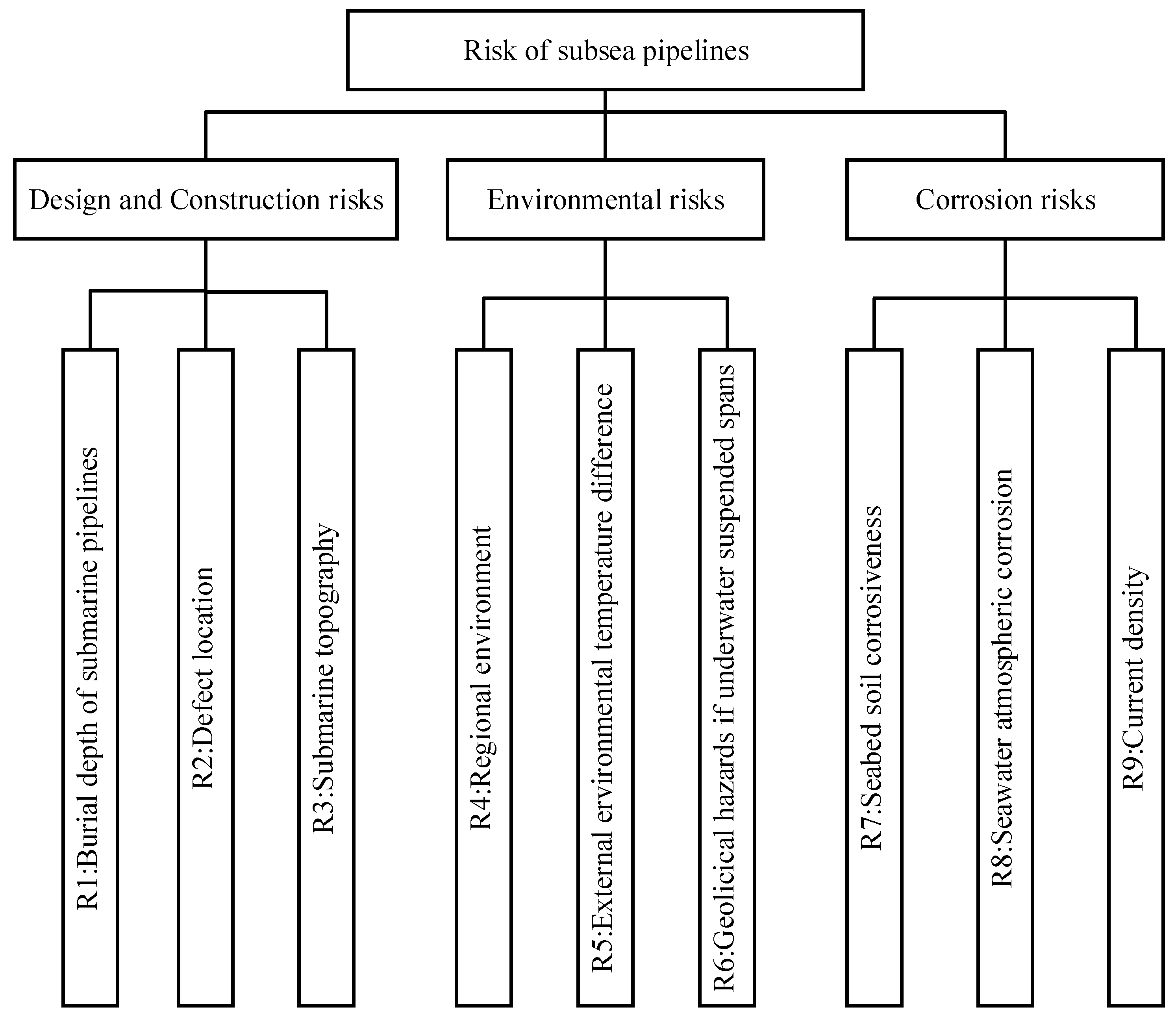

To study the defects contained in pipelines, it is initially necessary to clarify the risk factors related to subsea pipelines. After reviewing relevant literature and analyzing the causes of pipeline accidents both domestically and internationally [

24,

25,

26], based on the applicable standard GB-T 27512-2011 “Risk Assessment Method for Buried Steel Pipelines” [

27] and the actual situation, this article selects a total of nine risk factors from three aspects to develop an evaluation system hierarchical model, as shown in

Figure 2.

For easy reading of subsequent forms, nine risk factors are named from R1 to R9, as shown in

Figure 2.

- (2)

Experts score and establish a judgment matrix

According to the experience and knowledge of experts, the factors of the same layer are compared in pairs to determine the relative importance of the two factors.

Table 2 shows the importance-assigning criteria.

This table adopts a five-level quantitative method for representing the relative importance of one indicator to another. On the contrary, the other indicator is secondary to this indicator, represented by the reciprocal of the corresponding value. At the same time, to improve the accuracy of the judgment matrix, four numbers, 2, 4, 6, and 8, were introduced between 1, 3, 5, 7, and 9, respectively, to construct the judgment matrix. The relative importance of each risk factor is shown in

Table 3.

- (3)

Consistency check of the judgment matrix

To verify whether the calculated results are consistent with the evaluation criteria, determine whether they can be directly used for further analysis of the problem, and prevent irrelevant factors outside the system from interfering with the judgment matrix and causing deviations in the calculation results, it is necessary to verify whether the preliminary calculation results are consistent. Only when the judgment matrix basically meets the consistency test [

28] can the next related operation be carried out, and the consistency test shows that the weight scale assignments in the judgment matrix are reasonable and not contradictory to each other, so that further relevant analysis of the problem can be carried out. The calculation formula for consistency check [

29] is shown in Formula (7):

In the formula, CR is the consistency ratio, and its specific meaning is that when the value of CR is less than 0.10, it indicates that the consistency corresponding to the judgment matrix is within an acceptable range. Otherwise, it is necessary to change the corresponding importance assignment in the judgment matrix, correct it to a value that matches the actual importance, and bring it into the matrix until it finally meets the consistency check.

CI is an indicator of consistency, and the calculation method is shown in Formula (8):

In the formula, the maximum eigenvalue of the judgment matrix is

λmax and the order is

n. In Formula (7),

RI is the average random consistency index related to the order

n, and the corresponding value of

RI can be found in

Table 4.

- (4)

Calculate the subjective weight of the evaluation index

Taking the judgment matrix

A as an example, the eigenvectors and eigenvalues of

A are calculated, as shown in Formula (9) [

30]:

The weight of each influencing factor λmax is the characteristic root of the judgment matrix A.

The weight calculation results of each risk factor in the hierarchical model of the evaluation system constructed in this section are shown in

Table 5.

Based on the weight of each risk factor, the establishment of the scoring rules for each indicator can be carried out as follows:

- (1)

Design and construction risks (36 points)

① Burial depth of a submarine pipeline (11 points): If it is a crossing or exposed section, the score is 0 points. If it is a buried pipeline section, the score calculation for the burial depth of non-underwater crossing pipelines is shown in the Formula (10).

In the formula, d is the actual thickness of the overburden layer.

② Defect location (9 points): If it is located in many areas where waterways or rivers intersect, 0 points will be given. If it is located in a mixed area of the waterway, the score is 4.5 points. If it is far from the waterway area, the score will be 9 points.

③ Submarine topography (16 points): 0 points for ocean trenches; 6 points for mid-ocean ridges and ocean basin edges; 10 points for continental slopes and continental uplifts; 16 points for continental shelves, abyssal plains, the middle of ocean basins, etc.

- (2)

Environmental risk (35 points)

① Regional environment (11 points): If there is an area with high tides and dense waterways and the pipeline passes through this area, 4 points will be given. If the pipeline is located in areas with high tides and frequent passage of waterways, 7 points will be given. If the pipeline environment is located at low tide and the waterway is not dense, 9 points will be given. If the pipeline environment is located in a stable tidal and non-navigable area, 11 points will be given.

② External environment temperature difference (9 points): If the average temperature difference between winter and summer in the external environment is greater than 20 degrees, 3 points will be given. If the average temperature difference between winter and summer in the external environment is greater than 15 degrees, 5 points will be given. If the average temperature difference between winter and summer in the external environment is 0–15 degrees, a score of 9 points will be given.

③ Submarine suspended-span geological disasters (15 points): The score is 6 points if a submarine earthquake, seabed movement, ice disaster, and other natural disasters occur frequently; 12 points for occasional submarine earthquakes, seabed movements, ice disasters, and other natural disasters; and 15 points for almost no natural disasters such as submarine earthquakes, seabed movements, and ice disasters.

- (3)

Corrosion risk (29 points)

① Seabed soil corrosiveness (7 points): If the soil resistivity is less than 20 Ω·m, the score is 0 points. If the soil resistivity ∈ [20 Ω·m, 50 Ω·m], then it is 4 points. If the soil resistivity is >50 Ω·m, it is 7 points.

② Seawater atmospheric corrosion (9 points): If the defect is located in the riser section without protection, the score for atmospheric corrosion is 3 points. If no marine atmospheric corrosivity survey has been conducted, 0 points will be given. If it is an offshore riser section with good protection, 6 points will be given. When the defect is located in the seabed section, the score for atmospheric corrosion is 9 points.

③ Current density (13 points): 0 points for current density > 20 μA/mm2; 2 points for current density ∈ (10 μA/mm2, 20 μA/mm2); 6 points for current density ∈ (2 μA/mm2, 10 μA/mm2); 9 points for current density ∈ (0.5 μA/mm2, 2 μA/mm2); 13 points for current density ≤ 0.5 μA/mm2.

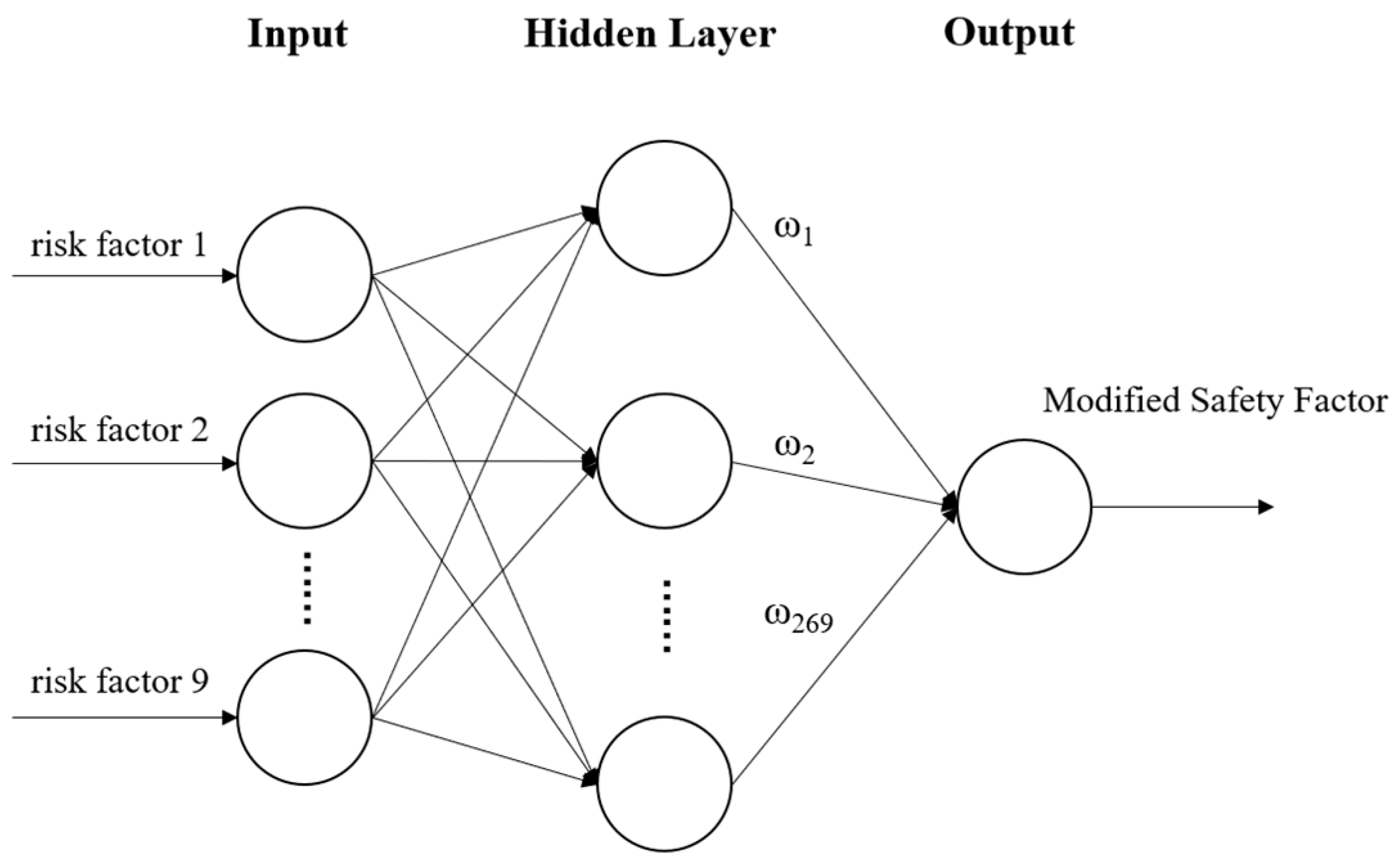

3.3. Safety Factor Correction

The submarine pipeline system includes many business departments, and the system’s efficient operation depends on the unity and cooperation of various departments. The shared platform for achieving mutual communication and correlation, which uses the Geographic Information System (GIS) for collecting different business information, is based entirely on the spatial distribution characteristics of data and resources within the pipeline transportation system. The combination of electronic maps and pipeline transportation makes it possible to comprehensively and intuitively reflect the current status, distribution, and technical characteristics of transportation objects, transportation tools, and their related information. Therefore, it maximizes the sharing of information and data, providing a reference basis and auxiliary decision-making support for the operation and management of pipeline transportation.

The data used in this article are all from the monitoring and recording of a submarine pipeline using the Pipeline Geographic Information System. The pipeline adopts X60 pipe steel with a diameter of 660 mm and a designed working pressure of 6.4 MPa. The collected data includes relevant data on defects as well as attribute data such as the burial depth of the submarine pipeline at the defect location, seabed terrain, external environmental temperature difference, soil corrosion properties, and current density.

Normalize the risk scores at the defect points of each submarine pipeline using a self-designed program, and then modify the safety factor based on the regional level. The correction formula is shown in Formula (11):

In this formula, SF1 is the revised safety factor; SF0 is the safety factor based on the regional level; and x is the risk score.

A self-designed program calculates the predicted circumferential failure stress (

SF) mentioned in this article and combines it with the pipeline’s design pressure and safety factor to determine whether the defect is acceptable.

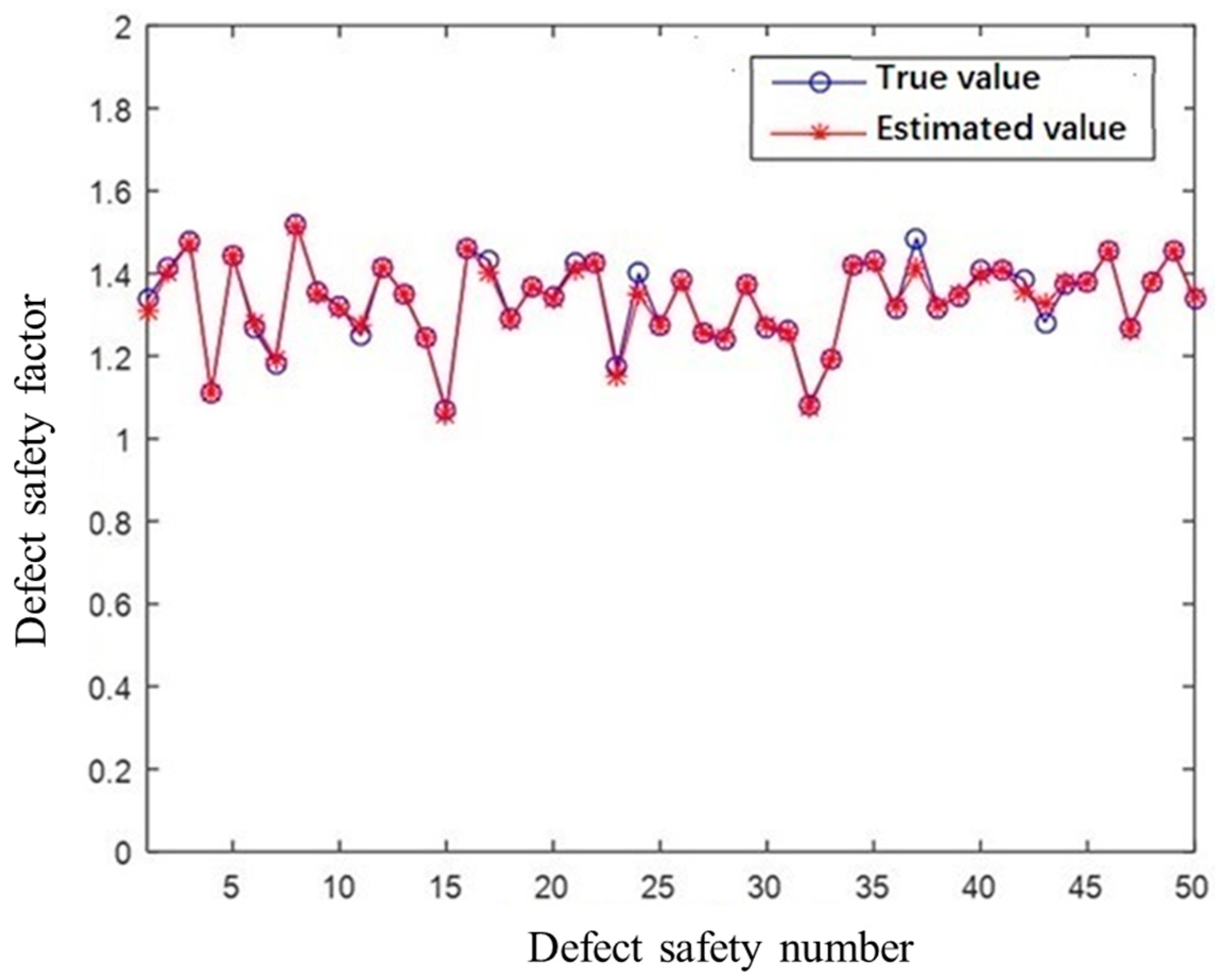

Table 6 compares the evaluation results based on the original and modified safety factors for some submarine pipeline defects.

It can be seen from the above table that after considering the correction of various risk factors at the defect zone, the problem of the original evaluation results being too conservative has been improved, providing a new theoretical basis for the safety evaluation of submarine pipelines.