Abstract

Proposing a comprehensive evaluation measure of the high-quality development of manufacturing industry (HQDMI), the purpose of this paper is to explore whether the high-quality development of manufacturing industry (HQDMI) promotes the application of industrial robots (AIR). Evidence shows that, first, the index of HQDMI across regions shows an upward trend from 2008 to 2020. Furthermore, the application of industrial robots significantly increases the high-quality development of manufacturing industry. Our heterogeneity analysis further infers that the positive effect of AIR on HQDMI is more pronounced in wealthy and eastern regions. The mechanism analysis shows that the application of industrial robots can generate the “value-added effect of informatization” and the “resource allocation effect”. The findings provide important theoretical support for the use of industrial robots and the promotion of high-quality development.

1. Introduction

A new round of scientific and technological revolution and industrial change is accelerating evolution. The deep integration of new-generation information technology and robotics is gradually changing the way of human production and life. Robotics is the transformation of non-physical knowledge into physical industrial software or digital products, forming a new industrial form [1]. According to the definition of International Federation of Robotics (IFR), the industrial robot is a kind of machine that can be automatically controlled and is reprogrammable and multipurpose. Industrial robots perform various tasks through programmable actions. It is a kind of multi-function manipulator or multi-degree of freedom robot with programming ability. Industrial robots represent the vigorous emergence of a new industrial revolution, which is conducive to improving the labor environment, improving production efficiency and quality, and thereby promoting social and economic development.

China conforms to the times, accelerates technological and industrial change and promotes the deep integration of the real economy and artificial intelligence [2]. However, China, as a large manufacturing country, is currently facing problems such as insufficient innovation, unbalanced industrial structure, and low end of the industrial chain [3]. Artificial intelligence can promote technological progress, which will bring about an increase in production efficiency [4,5,6]. Therefore, can the application of industrial robots (AIR) improve the high-quality development of manufacturing industry (HQDMI) in China? What are the mechanisms by which industrial robots influence the development of manufacturing industry? This paper will attempt to answer these questions.

In order to support the development of industrial robots, countries around the world have introduced many important policies. For example, China introduced the “Robot Industry Development Plan (2016–2020)” in 2016, with the aim of promoting the formation of a comprehensive robot industry system in China within five years. The United States introduced the “National Robotics Plan 2.0” in 2017, with a plan to promote the development and application of collaborative robots. As a result, industrial robots have attracted attention around the world, and more and more AI technologies are being used in their production. Industrial robots are also becoming an important representative of Industry 4.0 [7]. With the optimization of industrial technology and the support of national policies, industrial robots have developed rapidly in recent years [8]. Many studies have noted that AIR can not only effectively boost economic growth but also have a labor substitution effect [9,10]. However, most of the current research focuses on the impact of AIR on the labor market. Very little literature has analyzed the impact of AIR on HQDMI and mechanisms from the perspective of industrial development. Therefore, in order to enrich the research field of AIR, this paper examines the impact of AIR on HQDMI, especially on the high-quality development of China’s manufacturing sector.

China is the largest developing country. The study of AIR in China plays an important role in the sustainable development of the global manufacturing industry. After the reform and opening-up, China has gradually become the second largest economy in the world from a “weak manufacturing country”. On the one hand, cheap labor and abundant natural resources are important reasons for the international competitiveness of China’s manufacturing industry. But, China’s fertility rate and willingness to bear children are low now, and it is unlikely that China can continue to rely on the “demographic dividend” to win an important position in the international manufacturing industry [11]. According to the IFR, the number of robots in China was 550 in 1999. In 2017, the number of industrial robots in China reached 480,000 units, accounting for about 22 percent of the total number of industrial robots in the world, ranking first in the world. China’s AIR market has huge profit and business opportunities. Therefore, studying the impact of China’s AIR on the development of the manufacturing industry can help to improve the way of manufacturing development and accelerate the transformation and upgradation of the global industrial chain. On the other hand, existing studies mainly focus on discussing how the application of industrial robots affects the labor market and economic development in developed economies [7,11,12]. There is still a lack of research on this issue in developing countries. This paper explores the impact of AIR on HQDMI in China, which is conducive to identifying the common problems between AI applications in China and global AI applications. Ultimately, it is useful in advising on the development of AI in both developed and developing countries.

The high-quality development of manufacturing industry is an important manifestation of sustainability. First, the high-quality development of manufacturing industry can achieve environmental sustainability. The high-quality development of manufacturing industry emphasizes the coordinated development of economy and the environment. Manufacturing output must be built within the constraints of ecological and environmental capacity and resource-carrying capacity. And resource consumption and pollution emissions must be reduced in order to achieve the goal of green growth. The high-quality development of manufacturing industry requires that the manufacturing industry must maintain a good natural ecological environment, leading to the fact that the manufacturing industry should reduce the use of high-energy-consuming and high-polluting resources. The manufacturing industry should adopt energy-saving and environmentally friendly measures in production to promote green growth. The high-quality development of manufacturing industry pays attention to the research and application of green technology in order to realize the sustainability of the production process. In addition, in terms of environmental management, the manufacturing industry tends to use environmentally friendly materials and equipment, and actively carries out green procurement to ensure a green and standardized supply chain. Therefore, the manufacturing industry should optimize production processes, improve energy consumption efficiency, reduce production costs, reduce environmental pollution and promote technological research to achieve the goal of high-quality development. It is an important manifestation of sustainable development.

Second, the high-quality development of manufacturing industry can maintain economic sustainability. On the one hand, the high-quality development of manufacturing industry requires balanced development of the manufacturing industry. Regions can improve resource allocation efficiency by converting idle resources into manufacturing means of production through resource integration. The high-quality development of manufacturing industry requires synergistic development of economic growth, scientific and technological innovation, human resources and environmental protection. And regions should formulate sustainable development plans according to local conditions. In addition, the high-quality development of manufacturing industry must maintain a stable economic growth rate and avoid huge fluctuations. Therefore, the high-quality development of manufacturing industry is conducive to the activation of effective investment and potential consumption demand, enhancing the momentum of sustainable development. On the other hand, at the enterprise level, the high-quality development of manufacturing industry means that enterprises need to have a perfect production process, institutional system and risk control system. Enterprises can strengthen internal control and early warning of enterprise risks according to the process system of economic activities. This can lay a good environmental foundation for enterprises to carry out business activities, investment activities and financing activities, thus promoting the high-quality development of enterprises and guaranteeing the sustainability of the economy.

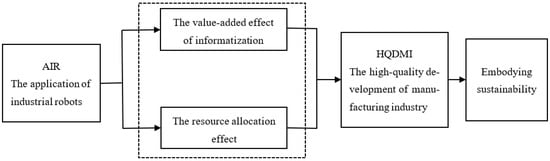

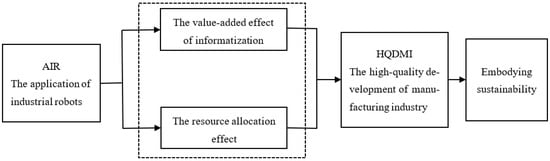

Based on the above, this paper investigates the impact of the application of industrial robots (AIR) on the high-quality development of manufacturing industry (HQDMI) from the overall and heterogeneous perspectives. Firstly, this paper constructs the evaluation index system of HQDMI, and measures the indexes of HQDMI across regions in China from 2008 to 2020. This paper uses the “Bartik instrumental variable” [13] method to measure the installation density of industrial robots as a proxy variable for AIR. Second, it is found that AIR significantly improves HQDMI, and this conclusion still holds under a series of robustness tests such as HQDMI remeasurement, AIR remeasurement and the application of spatial econometric models. Third, the possible endogeneity problem is mitigated by using the first-order lag term of the application of industrial robot (lnAIR_1) as an instrumental variable. The results of the heterogeneity test indicate that AIR contributes more to HQDMI in eastern regions and wealthy regions. Finally, the analysis of the impact mechanism show that AIR generates “value-added informatization effect” and “resource allocation effect”. Intelligent transformation behaviors help the manufacturing industry break through the limitations of time and space and spread the value-added mode of information elements to the important production areas of the manufacturing industry. As a result, it improves the efficiency and quality of manufacturing production. Reasonable resource allocation guarantees a stable supply of factor resources, which is conducive to the development of new business and the extension of the industrial chain in the manufacturing industry, thus promoting HQDMI.

The innovations and marginal contributions of this paper are as follows. First, previous literature focuses more on regional high-quality development [14,15,16]. There are fewer studies on the high-quality development of industries. And most of existing literature is exploring the impact of AIR on the labor market [17,18,19], and less literature discusses the relationship between the application of industrial robots (AIR) and the high-quality development of manufacturing industry (HQDMI). Therefore, this paper examines the impact of AIR on HQDMI from the perspective of industrial development.

Second, in terms of research methodology, this paper constructs a comprehensive evaluation index system of HQDMI based on the coefficient of variation method using six dimensions and 31 indicators. And it uses the first-order lag term of the application of industrial robot (lnAIR_1) as the instrumental variable to alleviate the possible endogenous relationship between AIR and HQDMI.

Thirdly, in terms of the conclusion of the study, this paper analyses in depth the mechanisms of the impact of AIR on HQDMI. The paper infers that AIR has generated “value-added informatization effect” and “resource allocation effect”. AIR can enhance HQDMI by improving the level of regional informatization and optimizing regional resource allocation. Moreover, regional economy and regional location can lead to differences in the impact of AIR on HQDMI. It implies that the impact of AIR on HQDMI is not “localized”, and the effect of AIR is closely related to the policy system, economic development, resource endowment, regional environment and so on.

2. Literature Review and Research Hypothesis

2.1. Literature Review

2.1.1. Literature Review on the Application of Industrial Robots

The existing theoretical and empirical studies on the application of industrial robots (AIR) and the high-quality development of manufacturing industry (HQDMI) can be divided into two categories. The first category is the application effect of industrial robots. The second category is the research on the measurement methods of HQDMI and influencing factors.

With the integration of information technology and production technology, industrial robots have become a product integrating big data, artificial intelligence and cloud computing, becoming the core carrier of the industrial Internet system. The research on industrial robots by scholars at home and abroad mainly focuses on two aspects. On the one hand, scholars have explored the impact of industrial robots on the labor market. At present, there are two different views on whether artificial intelligence will replace the traditional labor force. One view is that industrial robots will replace traditional labor if they can master core skills [20]. If industrial robots can perform the work of traditional laborers, then the bargaining power of employees is reduced, resulting in employees having to accept lower levels of wage. Therefore, industrial robots reduce labor demand and wage levels [11,12,21]. Another viewpoint suggests that industrial robots facilitate the generation of new jobs by creating new work tasks [9]. For example, Bessen (2019) [22] suggests that while the use of computer technology reduces manufacturing jobs, it increases jobs with less-structured work tasks. Furthermore, AIR will increase income inequality between jobs with different skills [17,23,24].

On the other hand, scholars have focused on the impact of industrial robots on productivity. Zeira (1998) [25] proposed a task model, which introduces artificial intelligence factors into the theoretical model of the production function for analyzing economic growth. Aghion et al. (2018) [26] empirically found that the use of robots, automation technology and intelligence technology can effectively alleviate the contradiction between costs of production and slow economic growth. One section of literature has attempted to study the impact of AIR on economic growth, which support the view that AIR will increase total factor productivity and promote economic growth [6,7,27]. AIR will reduce costs of business operations, expand the scale of production, and increase the labor demand for non-automated jobs, thus improving productivity [11,28]. Compared to previous studies, which mainly focus on the labor market and economic growth, there is little analysis of the impact of AIR on the quality of economy. Even fewer studies have directly explored the impact of AIR on HQDMI from the industrial development perspective. Therefore, this paper constructs an analytical framework to discuss the impact of AIR on HQDMI at the level of informatization and resource allocation. The obtained conclusions contribute to the re-conceptualization of AIR, regional informatization development and resource allocation efficiency in HQDMI.

2.1.2. Literature Review on the High-Quality Development of Manufacturing Industry

The manufacturing industry is an important production sector of the national economy. China’s manufacturing sector has a huge volume and a well-developed industrial system. The high-quality development is a new goal for the Chinese economy. As a result, China’s economy is no longer pursuing high-speed growth, but rather focusing on how to achieve high-quality development. High-quality development of the economy means an economy that not only meets real needs but also is competitive in emerging industries. High-quality development requires a complete industrial structure, dynamic innovative individuals and a good supply system, which can meet the people’s needs for a better life [14,29]. The high-quality development of manufacturing industry (HQDMI) is a development paradigm that takes into account the environmental, social and economic benefits throughout all aspects of the manufacturing industry. HQDMI attaches importance to the efficiency of resource allocation of the manufacturing production process, focuses on the combination of quality, efficiency and power, and pays attention to the integration of technological innovation and manufacturing [30].

Regarding the calculation method of high-quality development, scholars use the quality index of economic growth, total factor productivity (TFP), GDP per capita and welfare carbon emission intensity to measure high-quality development [31,32,33]. However, there is a difference between economic growth and high-quality development [31,34]. High-quality development not only includes economic factors but also includes many non-economic factors such as environment, society and so on [30]. Therefore, some scholars have constructed the indicator systems of high-quality development from the dimensions of economic efficiency, innovation capacity, open sharing and green development [35]. Regarding the measurement of manufacturing development, most scholars use the index of industrial development quality, enterprise quality management and export product quality to measure the quality of manufacturing development [3,36]. It can be found that most scholars have constructed macro-level indicators of high-quality development of an economy. Few literatures have studied the high-quality development of the manufacturing industry (HQDMI) at the meso-level. Therefore, this paper constructs a comprehensive evaluation index system of HQDMI using 31 indicators in six dimensions.

In terms of the drivers of high-quality development of the manufacturing industry, this paper discusses them from the macro, industrial and micro perspectives. In the macro perspective, some scholars discuss the impacts of financial aggregation, digital economy, maritime strategy, outward foreign direct investment (OFDI) and green financial policies on the high-quality development of manufacturing [36,37,38,39,40,41,42]. For example, Mathias (2020) [37] found that financial aggregation can promote the high-quality development of manufacturing industry through knowledge spillovers and innovation benefits. In the industrial perspective, scholars have shown that environmental factors and transport accessibility have a significant impact on the industrial development [3,38]. However, financial support has a negative impact on the competitiveness of manufacturing industry [38]. Wu (2011) [39] suggests that industry orientation, industry drive, industry marketability and industry innovativeness are important factors in promoting the development of manufacturing industry. In the micro perspective, scholars have found that digital financial inclusion, innovation and government subsidies can improve the high-quality development of the manufacturing industry [40,41,42]. Some literature has examined the factors affecting the high-quality development of manufacturing industry from the perspective of product quality. For example, the quality of manufacturing products is affected by the affluence of importing and exporting countries, human capital, capital intensity and the type of firm ownership and operation [43,44,45].

With the development of the digital economy, AI technology and industrial robots are important products of the digital economy, and they are important driving factors affecting the high-quality development of the manufacturing industry. The digital economy pushes the manufacturing industry to carry out intelligent transformation. Scholars mainly discuss the impact of industrial robots on the development of the manufacturing industry from the demand side and the supply side. On the demand side, with the development of digitalization in China, some scholars have found that digital transformation can improve the high-quality development of the manufacturing industry by improving innovation, reducing costs, optimizing the human capital structure and promoting industrial integration [46,47]. Changes in the demand-side market accelerate the transformation and upgradation of the manufacturing industry [48]. In the process of manufacturing transformation and upgradation, robotics needs to be applied in order to avoid industrial hollowing out [49]. Robotics can promote the deep integration of the manufacturing industry and the service industry [50]. And robotics technology prompts consumers to create new demands, and heterogeneous demands are the new consumption potential [18]. In order to respond to diverse market demands, the manufacturing industry needs to capture market messages in a timely manner and expand new businesses in a timely manner [51]. Therefore, robotics can promote the high-quality development of manufacturing industry.

On the supply side, industrial robots can promote the high-quality development of the manufacturing industry by improving manufacturing production efficiency, promoting industrial chain transformation and upgradation, and enhancing enterprise competitiveness [52]. First, industrial robots lead to the recombination of production factors, which can alleviate dependence on scarce resources for the manufacturing industry [26]. For example, the use of information factors accelerates manufacturing production speed [53]. AI technology can effectively handle complex work in manufacturing, saving time and cost and avoiding waste of resources [54], and thus improving the input–output efficiency of manufacturing. Secondly, AI technology promotes the transformation and upgradation of the industrial chain. AI technology requires the use of data elements, which can break the limitations of space and time and promote the flow of production factors in all aspects of the manufacturing industry [55]. The flow of data elements can blur the industrial boundary, thus extending the length of the upstream and downstream supply chain of the manufacturing industry [56]. Moreover, AI technology accelerates the speed of information transfer between manufacturing sectors and extends the layout of industrial chain division of labor [57]. Third, AI technology can enhance the core competitiveness of manufacturing enterprises [57,58]. Enterprises can use AI technology to improve the added value of their products. The application of AI technology can help enterprises to carry out R&D, modelling and product production during the operation process [52,59]. At the same time, AI technology can facilitate enterprises to obtain timely information about consumer demand, which can improve the competitiveness of products and improve enterprises’ performance [26,52,59].

In addition, resource allocation can enhance the productivity of manufacturing industry by improving labor factor allocation, accelerating the development of the Internet, and improving the efficiency of the use of innovation factors [60,61]. However, little literature has analyzed and mined the impact and mechanisms of AIR on HQDMI at the AI level, which this paper attempts to contribute. Therefore, this paper will rigorously demonstrate the impact of AIR on HQDMI based on information technology and resource allocation perspectives.

2.2. Research Hypotheses

Industrial robots are the embodiment of the deep integration of the manufacturing industry and AI technology, which is mainly manifested in the informatization process of design, equipment, production and management [62]. With the development of the digital economy, industrial robots have characteristics of permeability, substitutability and synergism, so they can gradually infiltrate into all aspects of manufacturing production, thus changing the operation mode of the manufacturing industry [59]. First, industrial robots improve production efficiency due to their substitution effect in the manufacturing production process [11]. Compared to traditional labor, industrial robots can operate according to the standardized process in order to improve the accuracy of production steps and ensure product quality [63]. Industrial robots tend to prevent employees from becoming fatigued due to continuous work, and they can work continuously to increase productivity [64]. Industrial robots can replace manual operations in harsh environments, which prevents employee accidents and reduces risks of the production processes. Employees are only responsible for maintenance, and industrial robots can automate production, which saves companies a lot of labor costs. In addition, automation-induced transformation facilitates the manufacturing industry to save production costs as well as operation costs and reduce the price of goods or services, thus enhancing the real performance of the manufacturing industry [11,17,18].

Second, AIR improves the production quality of the manufacturing industry through improving production methods and optimizing the management mode, thus prompting the manufacturing industry to implement energy-saving and emission reduction behaviors to achieve green development [65]. On the one hand, industrial robots can help the manufacturing industry to carry out less-manned or unmanned work in various scenarios. For example, industrial robots can save a large amount of energy such as light and power when operating, which is conducive to reducing energy consumption and improving resource efficiency. Industrial robots can reduce carbon emissions by increasing the use of clean energy, adding pollutant treatment equipment and improving input factors [65,66]. On the other hand, AIR can monitor the production process of the manufacturing industry and achieve the supervision of the pollution emission status in real-time, which is conducive to improving the efficiency and capacity of pollutant treatment of the manufacturing industry [67,68]. Industrial robots promote the manufacturing industry to carry out automation and intelligent transformation, use digital technology to optimize production methods and reduce energy consumption, thus achieving green development.

In addition, industrial robots increase the value of the manufacturing industry by harnessing the innovation effect [62,69]. AIR can break down traditional concepts and promotes technological innovation in the industry. With the concepts of “digital economy” and “AI”, the manufacturing industry will actively apply artificial intelligence (AI) technology to enhance the value and competitiveness of products. The manufacturing industry will apply AI technology to strengthen the research of core technology and scientific innovation activities [52]. Using digital and intelligent technology to improve the organizational structure and management of the manufacturing industry [70]. Efficient use of information technology resources to promote the birth of new technologies, new products, new business forms and new models. Therefore, AIR is conducive in promoting industrial integration, promoting the extension of the manufacturing industry chain and expanding new business areas [55]. For example, industrial robots can not only be applied to traditional manufacturing industries such as automobiles and automotive components, electronics and electrical, machining and manufacturing but also be applied to emerging fields such as meta-universe, cybersecurity and language modelling. Therefore, AIR can have a direct impact on the high-quality development of manufacturing industry (HQDMI) by optimizing human capital, promoting green development and driving technological innovation. Based on this, this paper proposes Hypothesis 1.

Hypothesis 1:

The application of industrial robot (AIR) can improve the high-quality development of manufacturing industry (HQDMI).

This paper further discusses the impact mechanisms of the application of industrial robots (AIR) on the high-quality development of manufacturing industry (HQDMI). We expect that AIR improves HQDMI through the following two mechanisms. First, AIR can improve the level of informatization in the manufacturing industry, which promotes HQDMI. In order to realize the manipulation and management of industrial robots, the manufacturing industry needs to invest advanced and intelligent information elements in the process of R&D, design and manufacturing, and to increase the supply of core basic hardware and software, so as to ensure the smooth operation of industrial robots [71]. Only by improving the level of information technology in the manufacturing industry can we use information transfer, data sharing and data analysis to control the robot and optimize the management process of the robot. AIR accelerates the flow of information elements in all aspects of production and operation, and promotes the sharing of information, thus improving work efficiency [51,72]. The development of information technology can promote the manufacturing industry to establish a perfect information monitoring system in order to grasp the robot operating conditions. It is conducive to the monitoring of production and management risks, and enhances the ability of the upstream and downstream industry chain to work together [51]. In addition, expanding the input of information technology can promote the manufacturing industry to carry out technological innovation [73]. Improving the level of information technology can help the manufacturing industry to overcome the space and time barriers [74]. As a result, it promotes the free dissemination and diffusion of new knowledge and new technology among different regions, which is conducive to the realization of upstream and downstream industrial chain collaborative and integrated innovation. A high level of informatization not only improves input–output efficiency, but also expands new business areas and extends industrial chains, providing new kinetic energy for HQDMI [75]. Therefore, the manufacturing industry can improve the level of informatization through AIR. Achieving the development of informatization in the manufacturing industry is conducive in promoting the circulation of information elements. It also helps to enhance the innovation ability, optimize the intelligent manufacturing mode and develop new business forms. Thus, it enhances the total factor productivity and core competitiveness of the manufacturing industry, and ultimately promotes HQDMI.

Second, AIR can improve HQDMI by optimizing resource allocation. AIR in the production field increases the output contribution of capital factors and promotes the transformation of industries from labor-intensive to capital-intensive, thus realizing industrial upgradation [65]. AIR can replace the high-energy-consuming, high-pollution and low-efficiency production sectors [76]. Through the empowerment effect, AIR spawns new business forms and new production methods, which promotes the redistribution of resource factors. Regional governments meet the demand for automation-induced transformation of the manufacturing industry by controlling and allocating resources to important areas of production, thus avoiding the waste of social resources [77].

In addition, AIR can increase the opportunities for innovative subjects to use application scenarios, which accelerates the convergence of resource elements such as talents, technologies, data, algorithms, etc., and promotes the deep integration of innovation and industrial chain [51]. Regions can increase the supply of resource elements by creating the resource-sharing platform, establishing the data resource protection system, providing financial support and cultivating the high-quality workforce, thus promoting the development of industrial integration. Reasonable resource allocation ensures that the regional economic structure, industrial structure and enterprise structure are in a balanced state. The productivity structure of the manufacturing industry meet the needs of high-quality development [78]. Therefore, AIR optimizes resource allocation through industrial upgradation, eliminating backward industrial sectors and promoting integrated development. Ultimately, it promotes HQDMI. Based on the above, this paper proposes Hypothesis 2.

Hypothesis 2:

AIR generates the “value-added effect of informatization” and the “resource allocation effect”, thus improving HQDMI (Figure 1).

Figure 1.

Theoretical model.

3. Data and Methodology

3.1. Sample Selection and Variable Description

3.1.1. Sample Selection

This paper selects 30 regions in China from 2008 to 2020 as the research sample (Tibet is disregarded due to missing data) (the data for the study were obtained from China Environmental Statistics Yearbook, China Science and Technology Statistics Yearbook, China Statistics Yearbook and China Electronic Information Industry Statistics Yearbook). Specifically, the explained variable of this paper is the high-quality development of manufacturing industry, which is measured by the index of high-quality development of manufacturing industry. The explanatory variable is industrial robot application, which is measured by the density of robot installation in each region (industrial robot installation data from the International Federation of Robotics (IFR)). The details of industrial robot application are shown in Equation (1). Based on Wang and Chen (2022) [78], government investment, government intervention, quality of labor, infrastructure, servicing rate and urbanization level were chosen as control variables.

3.1.2. Construction of Variables

The explained variable is the index of high-quality development of manufacturing industry, which measures the level of high-quality development of manufacturing industry in each region. The core explanatory variable is industrial robot application. With the arrival of the machine revolution in recent years, industrial production has undergone dramatic changes. The application of intelligent, digital and automation technologies has gradually replaced manual labor, which is not only an important manifestation of technological progress but also improves the productivity of manufacturing industry and creates more new manufacturing development businesses [11]. Based on Wang and Dong (2020) and Yan et al. (2020) [11,17], this paper adopts Bartik’s instrumental variable method [13] in order to measure the installed density of industrial robot across regions in China. The specific approach is as follows. Firstly, the global sub-industry industrial robot data provided by the International Federation of Robotics (IFR) (with a total of 14 manufacturing industry classifications) were matched with 31 manufacturing sub-industries of China to obtain manufacturing sub-industry industrial robot data. Secondly, the number of employees by industry from the China Labor Statistics Yearbook and the China Industrial Statistics Yearbook were matched according to the two-digit code of manufacturing industries to obtain data on the employment of employees in the industry. Finally, calculations are performed according to the following formula.

where denotes the robot installation density in region i in year t. denotes the number of employees employed in region i in year t. denotes the total number of employees employed in region i in year t. denotes the number of industrial robots installed in industry n in year t. denotes the number of employees employed in industry n in year t. is an instrumental variable for the Bartik calculation method, where denotes the number of industrial robots installed in the United States in year t, and denotes total employment of manufacturing industry in the United States in 2006.

The important variables in this paper are specified in Table 1.

Table 1.

Definitions of variables.

3.2. Model Setting

This paper investigates the impact of the application of industrial robot (AIR) on the high-quality development for manufacturing industry (HQDMI) and the mediating effect played by development of information technology and resource allocation in the transmission process. The econometric model is as follows.

where is the explained variable. is the core explanatory variable. are control variables. i is the region. t is the year. And is the estimated coefficient value of the variable.

3.3. Construction of the Indicators System for the High-Quality Development of Manufacturing Industry

3.3.1. Indicators System for High-Quality Development Index of Manufacturing Industry

Based on the methods of Song and Zhang (2019), Ning (2020) and Qu et al. (2021) [30,32,79], the index system for the high-quality development of the manufacturing industry is divided into six evaluation dimensions with a total of 31 evaluation indicators. Refer Table 2 for details.

Table 2.

System of indicators for the high-quality development index of manufacturing industry.

Six dimensions include innovative development, product regulation, industrial development, green development, opening to the outside world and regional resource sharing. Innovative development is the core driver of sustainable development, implying that the manufacturing industry should adhere to innovation to enhance competitiveness. Product regulation embodies the necessary conditions for sustainability. Good products are screened out through government supervision and review, and poor-quality products are eliminated to avoid wasting resources. Industrial development embodies the economic characteristics of sustainable development. The manufacturing industry can achieve sustainability if it has market efficiency. Green development is the main goal of sustainable development. The manufacturing industry needs to achieve a balance between corporate revenue and environmental friendliness, and improve environmental management and resource utilization. Opening to the outside world reflects the sustainable market environment, only by making full use of the domestic market and foreign markets can we promote the high-end development of manufacturing industry. Regional resource sharing reflects the basic environment for sustainable development. The government needs to establish a sound infrastructure and provide abundant public resources for the manufacturing industry.

3.3.2. The Method of Measuring the High-Quality Development Index of Manufacturing Industry

This paper adopts the coefficient of variation method to measure the index of high-quality development of manufacturing industry. First, we standardized the indicators separately.

where j represents the evaluation factor of high-quality development of manufacturing industry. i denotes the region, and t denotes the year. and represent the dimensionless method of positive and negative indicators, respectively. denotes the initial value. and represent the maximum and minimum values of this indicator in each region in the t year. Then, we assign the value of to .

Second, this paper uses the coefficient of variation method to calculate the weights of indicators. Specifically, the formula for calculating the weights is as follows.

where represents the weight of the evaluation factor i of the high-quality development of manufacturing industry in the t year. represents the coefficient of variation of the high-quality development of manufacturing industry. represents the standard deviation of the indexes after dimensionless quantification. represents the mean value of the indexes for the evaluation of high-quality development of manufacturing industry after dimensionless quantification.

Finally, a weighted composite index of the high-quality development of manufacturing industry is calculated.

where calculated in Equation (5) is the weighted composite index of the high-quality development of manufacturing industry across regions. The index is between 0 and 1. The larger the index, the higher the level of high-quality development of manufacturing industry in the region.

3.3.3. The results of Measuring the Level of High-Quality Development of Manufacturing Industry across Regions

As shown in Table 3, the mean value of index of the high-quality development of manufacturing industry (HQDMI) in the eastern region is about 0.3278. The mean value of index of HQDMI in the central region and in the western region are 0.1687 and 0.1243, respectively. Mean values of indexes of HQDMI in the eastern regions range from 0.0933 to 0.6479. Mean values of indexes of HQDMI in the central and western regions range from 0.1234 to 0.2478 and from 0.0413 to 0.2624, respectively. On the whole, indexes of HQDMI in the eastern regions are generally higher than that in the central and western regions, indicating a higher level of manufacturing industry development in the eastern regions. It is worth noting that indexes of HQDMI of Guangdong Province and Beijing are significantly higher than those of other regions. In addition, from 2008 to 2020, the index of HQDMI across regions shows an upward trend, indicating that regions have gradually begun to focus on the transformation of the manufacturing industry from “quantitative development” to “quality development”.

Table 3.

The index of HQDMI by region, 2008–2020.

4. Empirical Results

4.1. Descriptive Statistics

The results of descriptive statistics are shown in Table 4. As can be observed in Table 4, the mean value of the high-quality development of manufacturing industry (HQDMI) is 0.2190, and the standard deviation is 0.1528, indicating that the high-quality development of China’s regional manufacturing industry is uneven. The variable with the largest standard deviation is the level of development of AI, with a standard deviation of 8.5334, which indicates that there is a large difference in the level of AI development across regions. The mean value of the level of resource allocation is 8.8187, with a standard deviation of 1.4427, indicating that the level of resource allocation varies greatly across regions. The least fluctuating is the quality of labor, with a mean value of 0.0192 and a standard deviation of 0.0056. Government investment has a mean value of 0.8281 and a standard deviation of 0.2955. Government intervention has a mean value of 0.2538 and a standard deviation of 0.1115. Infrastructure has a mean value of 0.0715 and a standard deviation of 0.0578. Servicing rate has a mean value of 0.4208 and a standard deviation of 0.0827. The mean of the level of urbanization is 0.5691 with a standard deviation of 0.1322, implying that there are regional differences in government investment, government intervention, infrastructure, servicing rate and the level of urbanization.

Table 4.

Descriptive statistics.

4.2. Results of the Baseline Models

To test Hypothesis 1, Table 5 reports the effect of the application of industrial robots (AIR) on the high-quality development of manufacturing industry (HQDMI) under the baseline models, Equation (2). Model (1) examines the basic direction of the effect of AIR on HQDMI. Without adding any control variables, the estimated coefficient of lnAIR is 0.1031, which is significantly positive at least at the 1% level, indicating that AIR improves HQDMI greatly. Control variables are added gradually in models (2)–(7), and model (7) is the model that includes all the control variables. In models (2)–(7), the estimated coefficients of lnAIR are still significant and positive, suggesting that the effect of AIR on HQDMI is significant and stable, and the application of industrial robots can promote the high-quality development of manufacturing industry.

Table 5.

Regression results of the baseline model.

Among the control variables, first, lninvestment can promote lnHQDMI. The reason is that the government investment is an important factor in driving the economy, and the development of the manufacturing industry needs the support of social capital. Infrastructure represents the transport situation across regions, and lnInfrastructure has a positive impact on HQDMI. Because a well-developed transport system promotes the circulation of raw materials and the economic and trade exchanges of manufacturing goods. Servicing rate (lnservicing) reflects the level of servicing across regions, which can greatly promote HQDMI. Because a high level of servicing is conducive to the vertical extension and horizontal expansion of the manufacturing industry chain, which can enhance the core competitiveness of the manufacturing industry. The level urbanization (lnurban) is an important indicator of regional development, which can promote HQDMI. Because the higher the level of urbanization represents the stronger ability of the region to progress, which is conducive to the avoidance of risks in the development of manufacturing industry. And when the level of urbanization is high, it means that the region can provide production factors for the transformation and development of the manufacturing industry, and alleviate the problem of uneven distribution of resources. The lnlabor measures the quality of the population. The lnlabor has a positive impact on HQDMI. Because when the population quality of a region is high, it means that it can provide high-quality labor for the manufacturing process, which can ensure the promotion and application of AI technology. The demographic dividend can also promote the transfer of low-end industry chain to high-end intelligence, which promotes the high-quality development of manufacturing industry.

Table 6 reports the regression results of the application of industrial robots (AIR) on each subcomponent of the high-quality development of manufacturing industry (HQDMI). The results show that AIR has an enhancing effect on all six dimensions, indicating that AIR can improve HQDMI through the path of innovation, product regulation, industrial development, green development, opening to the outside world and resource sharing. In fact, whether AIR will have a positive effect on HQDMI has been a hot topic among academics at home and abroad in recent years. Scholars are now in agreement that AIR is the embodiment of technological innovation [59,75]. Due to the productivity effect and job creation effect, AIR is conducive in promoting the optimization of industrial structure and expanding the industrial chain. In addition, AIR promotes the circulation of production factors and enhances the trade exchange of products. AIR can effectively utilize regional resource advantages and increase energy-saving and emission reduction activities. Optimizing regional resource allocation and improving green production processes can enhance HQDMI effectively.

Table 6.

Results of sub-regression for the overall sample.

4.3. Robustness Tests

4.3.1. Re-Measurement of the High-Quality Development of Manufacturing Industry (HQDMI)

There is a lack of consistent measurement methodology for calculating HQDMI. Based on the methodology of Ning (2020) [79], total factor productivity of manufacturing industry (TFPMI) can be regarded as another comprehensive indicator for measuring the high-quality development of manufacturing industry, which includes factors such as scientific and technological innovation, green development, and resource utilization efficiency. The explained variable HQDMI is replaced with TFPMI and new regression results are obtained. Table 7 reports the robustness results after replacing the explained variable. The results of model (1) and model (2) in Table 7 show that the coefficients of AIR are both significantly positive at least at the 1% level, which indicates that AIR can significantly accelerate the rate of high-quality development of manufacturing industry. Therefore, the benchmark regression results are robust.

Table 7.

Robustness tests.

4.3.2. Re-Measurement of the Application of Industrial Robots (AIR)

The baseline regression measures the application of industrial robot using the density of robot installations across regions. In order to test the robustness of the baseline regression results, this paper uses the level of industrial artificial intelligence development (AI) as another indicator indicating the application of industrial robot. The method of Sun and Hou (2019) [2] is referred to construct the evaluation index system of AI. AI is measured by principal component analysis, which includes four dimensions such as information technology service capacity, software popularization and application capacity, the scale of use of AI technology and embedded system software application capacity (the data is from “China Statistical Yearbook” and “China Electronic Information Industry Statistical Yearbook”). Models (3) and (4) in Table 7 report the robustness results with replacement of explanatory variables. The results of model (3) and model (4) in Table 7 show that the coefficient of lnAI is significantly positive at the 1% level, indicating that the results of the positive impact of industrial robot application on HQDMI are very robust.

4.3.3. Application of Spatial Econometrics Models

Because resource elements will flow between spaces, the impact of AIR on HQDMI may be affected by spatial geography. Referring to the approach of Sun and Hou (2019) [2], we apply the SDM and SEM spatial econometrics models to mitigate the possible spatial dependence and spatial correlation problems (the SDM model contains spatial lag operators for both the explained and explanatory variables, allowing for the simultaneous analysis of spatial spillovers of both the explained and explanatory variables in a region. The SEM model assumes that inter-region interactions are realized through the error term. And spatial spillovers are the result of stochastic shocks). The geographic matrices and economic matrices are used in the spatial econometrics models for regression analyses, respectively. Table 8 reports the regression results by using the spatial econometrics models. The results in Table 8 show that after using different spatial weighting matrices in the models, AIR still has a positive effect on HQDMI. Therefore, the results of the spatial econometric model illustrate the robustness of the baseline regression results.

Table 8.

Robustness test of the spatial matrix.

4.4. Addressing Endogeneity

In order to prevent the regression results from being affected by endogeneity issues, this paper uses the instrumental variable method to deal with endogeneity issues. This paper uses the lagged values of the application of industrial robot as the instrumental variable. In general, the application of industrial robot in the previous period can affect the application of industrial robot in the current period. However, the high-quality development of manufacturing industry in the current period is difficult to influence the application of industrial robot in the previous period. Therefore, this paper uses the first-order lag term of the application of industrial robot (lnAIR_1) as the instrumental variable for regression.

The results in Table 9 show that the LM statistic of lnAIR_1 significantly rejects the original hypothesis that the instrumental variable is not identifiable. The statistic of Cragg–Donald Wald F significantly rejects the original hypothesis that the instrumental variable is weak. And the statistic of Anderson–Rubin Wald strongly rejects the original hypothesis that the sum of endogenous regression coefficients is equal to zero. It is further verified that there is a strong correlation between lnAIR_1 and endogenous variables. Therefore, lnAIR_1 is appropriate as an instrumental variable.

Table 9.

Regression results of instrumental variables.

In this paper, the two-stage least squares method has been applied to deal with the endogeneity issues. Table 9 reports the estimation results of the instrumental variable method. The first-stage estimation results show a significant positive correlation between the first-order lag term of the application of industrial robot (lnAIR_1) and the high-quality development of manufacturing industry, suggesting that lnAIR_1 satisfies the correlation requirement. In the second-stage regression results, the estimated coefficient of the application of industrial robot is significantly positive, indicating that the application of industrial robot has an enhancing effect on the high-quality development of manufacturing industry.

4.5. Heterogeneity Analyses

4.5.1. Level of Economic Development

A conditional test on GDP per capita is conducted to examine whether the impact of the application of industrial robots (AIR) on the high-quality development of manufacturing industry (HQDMI) in wealthy regions is different from that in less-wealthy regions. First, based on the median of GDP per capita across regions from 2008 to 2020, we divide the sample into wealthy regions and less-wealthy regions. Second, using these two subsamples, we run the baseline regression, Equation (2), and report the results under columns (1) and (2) of Table 10. As a result, the coefficients of AIR on HQDMI in wealthy and less-wealthy regions are both significantly positive, but the regression coefficient of AIR in less-wealthy regions is smaller than that in wealthy regions. It implies that the effects of AIR are stronger in wealthy regions. Because wealthy regions have the advantages of advanced production technology, solid industrial foundation, open trade market, favorable business environment and powerful government policies. Therefore, the manufacturing industry in these regions can make full use of intelligent and digital resources to complete the transformation of automated production. Moreover, the favorable development environment is conducive to improving the input and output efficiency of the manufacturing industry, and it is more convenient to obtain innovative technologies. A solid foundation for HQDMI has been laid through reasonable resource allocation and information flow channels.

Table 10.

Regression results of heterogeneity analysis.

4.5.2. Geographical Locations

Now, we attempt to examine whether the impact of the application of industrial robots (AIR) on the high-quality development of manufacturing industry (HQDMI) varies across geographical locations. First, all regions are divided into three groups, eastern, central and western regions (the eastern regions include Beijing, Tianjin, Hebei, Liaoning, Shanghai, Jiangsu, Zhejiang, Fujian, Shandong, Guangdong and Hainan; the central regions include Heilongjiang, Jilin, Shanxi, Anhui, Jiangxi, Henan, Hubei and Hunan; and the western regions include Sichuan, Chongqing, Guizhou, Yunnan, Shaanxi, Gansu, Qinghai, Ningxia, Xinjiang, Guangxi and Neimenggu), based on the geographical locations. Second, employing these three subsamples, we estimate the baseline regression, Equation (2), and report the results of location heterogeneity under columns (3), (4) and (5) of Table 10, respectively. Evidence shows that the coefficients on AIR in eastern, central and western regions are significantly positive, while the regression coefficients of AIR in eastern regions are bigger than those in central and western regions. The results clearly confirm our belief that the impact of the implementation of AIR on HQDMI in eastern regions is stronger than those in central and western regions. Because of the higher level of information technology in the eastern regions, it is conducive in promoting the transformation of manufacturing automation. Resources can effectively flow into the key links of manufacturing production in the eastern regions, so as to achieve the reasonable allocation of production factors. The central region is in an important position of “taking the east and starting the west”, with rich resource endowment. With the development of information technology and the construction of transport networks, the central regions have overcome the barriers to the flow of raw materials and commodities. It has accelerated the integration of the manufacturing industry and other industries, and improved the quality of manufacturing development. The western regions are dominated by the heavy industrial economy, with a strong dependence on high-emission and high-pollution resources. The productivity of the manufacturing industry in the western regions is low. And it is limited by geographic location and digital technology, the level of informatization and the efficiency of resource allocation in the western regions are low, resulting in insufficient impetus for the high-quality development of manufacturing industry.

4.6. Channels Analysis

The empirical analysis in this paper concludes that the application of industrial robots (AIR) can improve the high-quality development of manufacturing industry (HQDMI). What is the mechanism of AIR to promote the development of HQDMI? This paper selects two variables, the level of information development (lninfor) and the level of resource allocation (lnallocation), to investigate the impact mechanisms. This paper constructs the following models to test whether AIR generates the “value-added effect of informatization” and the “resource allocation effect”.

where are the mechanism variables for conducting channel analysis. If both and are significant, it means that AIR can influence HQDMI through the development of informatization and resource allocation.

4.6.1. Test the Value-Added Effect of Informatization

With the development of informatization, the manufacturing industry will invest automation and digital information elements into the R&D, design and production processes to improve the core competitiveness of products. Therefore, information elements can increase the value of manufacturing products and create new value growth points for the manufacturing industry. This paper uses a composite index of informatization development (based on the methodology of Du et al. (2017) [80], this paper selects four indicators to construct the composite index of the development of informatization, including the Internet penetration rate, per capita telecommunication output, the number of mobile phones per 100 households in rural areas and the average number of computers per 100 households in rural households) to measure the value-added effect of informatization. Firstly, in Table 11, Column (1) shows the regression result of Equation (6). The regression coefficient on AIR is significantly positive, indicating that AIR significantly increases HQDMI. Column (2) shows the regression results of Equation (7). The coefficient on AIR is positive at the 1% level, indicating that AIR significantly promotes the development of informatization (lninfor). Column (3) shows the regression results for Equation (8). The coefficients on AIR and the development of informatization are also positive. However, the estimated coefficient of AIR decreases compared to column (1), indicating that the value-added effect of informatization exists. AIR can improve HQDMI through the development of informatization. A possible scenario is that first AIR attracts R&D. Moreover, R&D can encourage technological innovations and improve energy efficiency, which generates more investment opportunities and further stimulates HQDMI. The possible reasons for the above are as follows. On the one hand, AIR improves the input–output efficiency of information elements. Changes and improvements in the elements structure can effectively reduce the use of high-energy-consumption and high-pollution elements in the manufacturing industry, which are conducive to energy conservation, emission reduction and green development in the manufacturing industry. It also promotes the integration of the manufacturing industry with other industries and improves the core competitiveness of the manufacturing industry. On the other hand, the increase in information elements can promote the manufacturing industry to actively carry out technological innovation. The use of innovative technology to further expand new business areas and extend the industrial chain. Ultimately, it ensures the value-added and quantity-keeping development of the manufacturing industry.

Table 11.

Results of mechanism testing.

4.6.2. Test the Resource Allocation Effect

The resource allocation status can reflect the support of regional social and economic resources to the manufacturing industry. According to the law of market supply and demand and the development requirements of the economy and society to dictate and grasp the flow of resources and consumption intensity. Reasonable resource allocation is conducive to the development of the manufacturing industry [78]. This paper uses the comprehensive index of resource allocation (referring to the study of Li et al. (2019) [81], this paper uses four indicators, including employment resources, medical resources, education resources and living resources to assess the status of regional resource allocation. The gross product per unit province area is used to indicate the quality of employment resources. The number of practicing physicians is used to indicate the quality of medical resources. The number of students in regular higher education institutions is used to indicate the quality of education resources. The total retail sales of social commodities are used to indicate the quality of living resources. The four indicators can reflect the regional resource allocation situation from different levels. Then, based on the standardized four indicators, this paper adopts the linear weighting method to measure the comprehensive index of resource allocation) to reflect the efficiency of resource allocation. Concerning the effect of resource allocation, the results are shown in Column (4)–(6) in Table 11. The results in Column (4) remain unchanged, while the coefficient on AIR in Column (5) is significantly positive at the 1% level, indicating that AIR improves the efficiency of resource allocation. In Column (6), the coefficients on AIR and the resource allocation are also significantly positive, supporting the existence of the resource allocation effect. It means that AIR can promote HQDMI by improving the efficiency of resource allocation. The reason is that AIR has attracted the attention of regional governments, which pushes the governments to allocate social resources to important manufacturing production areas or emerging fields. And the reasonable resource allocation ensures that the regional economic structure, industrial structure and enterprise structure are in a balanced state. It leads to the manufacturing productivity in line with the requirements of high-quality development. Ultimately, it promotes the optimization and upgrading of industries and improves HQDMI.

5. Conclusions and Inspirations

Developing a composite index to quantify the high-quality development of manufacturing industry (HQDMI) and measuring the density of industrial robot installations to represent the application of industrial robots (AIR), this paper employs data from 2008 to 2020 to examine the impacts of AIR on HQDMI. The evidence shows that, first, AIR increases HQDMI. Second, the effects of AIR are robust to a variety of tests applying alternative proxies for major variables, re-measuring the HQDMI, re-measuring the AIR and using the spatial measurement models. Third, this paper uses the first-order lag term of the application of industrial robot (lnAIR_1) as an instrumental variable to deal with the possible endogeneity problems. Fourth, heterogeneity tests show that the effects of AIR on HQDMI are stronger in wealthy regions and in eastern regions.

Finally, the economic mechanisms behind the effects of AIR on HQDMI are observed. The level of informatization development (lninfor) and the resource allocation (lnallocation) play vital roles in linking AIR to HQDMI. For example, AIR encourages the manufacturing industry to accelerate the development of information technology. Informatization transformation promotes the manufacturing industry to apply information elements to important production processes, thus improving the production efficiency and quality of the manufacturing industry. In addition, AIR facilitates the manufacturing industry to optimize resource allocation, thus guaranteeing stable production and supply of factor resources, and facilitating the manufacturing industry to develop new business fields and extend the industrial chain. Ultimately, it promotes the high-quality development of manufacturing industry.

Based on the observed empirical results, the insights of this paper are as follows. There are a total of three recommendations for manufacturing firms. First, manufacturing enterprises should enhance the application of industrial robots to improve the level of intelligence. Enterprises should not only increase the number of industrial robots but also use them effectively. Enterprises should combine industrial robots with artificial intelligence, image processing, voice recognition and other technologies in order to improve the level of intelligence, thereby promoting the high-quality development of the manufacturing industry. Second, we need to promote the development of the deep integration of artificial intelligence and the manufacturing industry. On the one hand, we should encourage enterprises to use production intelligent decision-making, flexible manufacturing, equipment intelligent operation and maintenance, energy consumption optimization and other technologies in order to improve the efficiency of resource allocation. On the other hand, we should expand the demand for application scenarios of industrial robots in the manufacturing industry, such as intelligent agriculture, intelligent logistics, intelligent building, intelligent transport, intelligent medical care, virtual simulation training, intelligent biology and so on. We should strengthen the development of artificial intelligence industries such as smart robots, smart cars, intelligent security and smart homes. Third, enterprises should strengthen cooperation with domestic and foreign AI teams and establish an effective communication platform. It aids in keeping abreast with the latest developments in the field of AI and helping the manufacturing industry uncover potential development opportunities.

At the regional level, regions should provide full opportunity to intelligent technology for promoting the high-quality development of manufacturing industry. Regions should make use of industrial robots, artificial intelligence and big data to improve the efficiency of resource factor allocation and promote productivity enhancement, thereby promoting the high-quality development of manufacturing industry. Second, regions should strengthen the application of robotics in the manufacturing industry and use robotics to maintain the stability and security of the industrial chain. Regions should use AI technology to identify the weak links in the industrial chain, overcome the key technological bottlenecks and then enhance the independent innovation capability of the industrial chain. In addition, regions need to promote the collaborative innovation and development both upstream and downstream of the industrial chain to enhance the added value of products and extend the industrial chain. Third, regions need to implement differentiated industrial policies based on the development characteristics and environmental differences of the manufacturing industry and AI industries. The government uses industrial robotics to optimize the governance model and improve service and regulatory efficiency. The government should build a system of standards and norms for the application of AI technology in the manufacturing industry. It is conducive in promoting the high-quality development of the manufacturing industry through AI technology.

Author Contributions

Conceptualization, Q.G. and Z.S.; methodology, Q.G. and Z.S.; validation, Q.G. and Z.S.; formal analysis, Q.G.; investigation, Q.G.; writing and editing, Q.G. and Z.S.; project management and review, Z.S.; Project funding support, Z.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets used during the current study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rojko, A. Industry 4.0 concept: Background and overview. Int. J. Interact. Mob. Technol. 2017, 11. [Google Scholar] [CrossRef]

- Sun, Z.; Hou, Y.L. How industrial intelligence reshapes the labour force employment structure. China Ind. Econ. 2019, 5, 61–79. (In Chinese) [Google Scholar]

- He, Z.C.; Cao, D.; Wu, Y. The interactive path of China’s manufacturing development quality and international competitiveness. Contemp. Financ. Econ. 2018, 11, 88–99. (In Chinese) [Google Scholar]

- Leontief, W. National Perspective: The Definition of Problems and Opportunities. In The Long-Term Impact of Technology on Employment and Unemployment; Academic press: Cambridge, MA, USA, 1983; pp. 3–7. [Google Scholar]

- Frey, C.B.; Osborne, M.A. The future of employment: How susceptible are jobs to computerisation? Technol. Forecast. Soc. Chang. 2017, 114, 254–280. [Google Scholar] [CrossRef]

- Graetz, G.; Michaels, G. Is modern technology responsible for jobless recoveries? Am. Econ. Rev. 2017, 107, 168–173. [Google Scholar] [CrossRef]

- Graetz, G.; Michaels, G. Robots at work. Rev. Econ. Stat. 2018, 100, 753–768. [Google Scholar] [CrossRef]

- Cheng, H.; Jia, R.; Li, D.; Li, H. The rise of robots in China. J. Econ. Perspect. 2019, 33, 71–88. [Google Scholar] [CrossRef]

- Acemoglu, D.; Restrepo, P. Secular stagnation? The effect of aging on economic growth in the age of automation. Am. Econ. Rev. 2017, 107, 174–179. [Google Scholar] [CrossRef]

- Acemoglu, D.; Restrepo, P. Automation and new tasks: How technology displaces and reinstates labor. J. Econ. Perspect. 2019, 33, 3–30. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Dong, W. How does the rise of robots affect China’s labor market?—Evidence from listed manufacturing companies. Econ. Res. 2020, 55, 159–175. (In Chinese) [Google Scholar]

- Acemoglu, D.; Restrepo, P. Robots and jobs: Evidence from US labor markets. J. Political Econ. 2020, 128, 2188–2244. [Google Scholar] [CrossRef]

- Bartik, T.J. Who Benefits from State and Local Economic Development Policies? W.E. Upjohn Institute: New York, NY, USA, 1991. [Google Scholar]

- Jin, B. Economic research on “high-quality development”. China Ind. Econ. 2018, 4, 5–18. (In Chinese) [Google Scholar]

- Gao, P.Y. Understanding, grasping and promoting high-quality economic development. Econ. Dyn. 2019, 8, 3–9. (In Chinese) [Google Scholar]

- Yang, Y.W.; Zang, P. Logic, measurement and governance of China’s high-quality economic development. Econ. Res. 2021, 56, 26–42. (In Chinese) [Google Scholar]

- Yan, X.L.; Zhu, B.K.; Ma, C. Industrial robot use and manufacturing employment: Evidence from China. Stat. Res. 2020, 37, 74–87. (In Chinese) [Google Scholar]

- Yang, G.; Hou, Y. The use of industrial robots, technology upgrading and economic growth. China Ind. Econ. 2020, 10, 138–156. (In Chinese) [Google Scholar]

- Kong, G.W.; Liu, S.S.; Kong, D.M. Robotics and employment-an exploratory analysis based on industry and regional heterogeneity. China Ind. Econ. 2022, 8, 80–98. (In Chinese) [Google Scholar]

- Agrawal, A.; Gans, J.S.; Goldfarb, A. Artificial intelligence: The ambiguous labor market impact of automating prediction. J. Econ. Perspect. 2019, 33, 31–50. [Google Scholar] [CrossRef]

- Autor, D.H.; Levy, F.; Murnane, R.J. The skill content of recent technological change: An empirical exploration. Q. J. Econ. 2003, 118, 1279–1333. [Google Scholar] [CrossRef]

- Bessen, J. Automation and jobs: When technology boosts employment. Econ. Policy 2019, 34, 589–626. [Google Scholar] [CrossRef]

- Acemoglu, D.; Autor, D. What does human capital do? A review of Goldin and Katz’s The race between education and technology. J. Econ. Lit. 2012, 50, 426–463. [Google Scholar] [CrossRef]

- Dauth, W.; Findeisen, S.; Südekum, J.; Woessner, N. German Robots-The Impact of Industrial Robots on Workers; CEPR Press: London, UK, 2017. [Google Scholar]

- Zeira, J. Workers, machines, and economic growth. Q. J. Econ. 1998, 113, 1091–1117. [Google Scholar] [CrossRef]

- Aghion, P.; Jones, B.F.; Jones, C.I. Artificial intelligence and economic growth. In The Economics of Artificial Intelligence: An Agenda; University of Chicago Press: Chicago, IL, USA, 2018; pp. 237–282. [Google Scholar]

- Brynjolfsson, E.; Hitt, L.M. Computing productivity: Firm-level evidence. Rev. Econ. Stat. 2003, 85, 793–808. [Google Scholar] [CrossRef]

- Herrendorf, B.; Rogerson, R.; Valentinyi, A. Two perspectives on preferences and structural transformation. Am. Econ. Rev. 2013, 103, 2752–2789. [Google Scholar] [CrossRef]

- Zhang, J.K.; Hou, Y.Z.; Liu, P.L. Target requirements and strategic path of high-quality development. Manag. World 2019, 35, 1–7. (In Chinese) [Google Scholar]

- Qu, L.; Wang, L.; Ji, H.Y. Analysis on the measurement of high-quality development of regional manufacturing industry in China. Res. Quant. Tech. Econ. 2021, 38, 45–61. (In Chinese) [Google Scholar]

- Mlachila, M.; Tapsoba, R.; Tapsoba, S.J. A quality of growth index for developing countries: A proposal. Soc. Indic. Res. 2017, 134, 675–710. [Google Scholar] [CrossRef]

- Song, X.N.; Zhang, F. Research on quality measurement and trend of industrial development under high-quality development. Soft Sci. 2019, 33, 36–41. (In Chinese) [Google Scholar]

- Li, J.C.; Shi, L.M.; Xu, A.T. Discussion on the evaluation index system of high-quality development. Stat. Res. 2019, 36, 4–14. (In Chinese) [Google Scholar]

- Barro, R.J. Quantity and Quality of Economic Growth; Banco Central de Chile: Santiago, Chile, 2002. [Google Scholar]

- Guo, Y.; Fan, B.N.; Long, N. Research on the actual measurement and spatio-temporal evolution characteristics of China’s regional high-quality development. Res. Quant. Technol. Econ. 2020, 37, 118–132. (In Chinese) [Google Scholar]

- Bernard, A.B.; Jensen, J.B.; Schott, P.K. Trade costs, firms and productivity. J. Monet. Econ. 2006, 53, 917–937. [Google Scholar] [CrossRef]

- Mathias, B.D.; Mc Cann, B.T.; Whitman, D.S. A meta-analysis of agglomeration and venture performance: Firm-level evidence. Strateg. Entrep. J. 2021, 15, 430–453. [Google Scholar] [CrossRef]

- Yu, H.W.; Hu, D.Z. Measurement of quality competitiveness of Chinese regional manufacturing industry and analysis of influencing factors. J. Manag. 2015, 12, 1703–1709. [Google Scholar]

- Wu, Y. Evaluation and Selection of Strategic Emerging Industries. Sci. Res. 2011, 29, 678–683+721. [Google Scholar]

- Lee, C.C.; Tang, M.; Lee, C.C. Reaping digital dividends: Digital inclusive finance and high-quality development of enterprises in China. Telecommun. Policy 2023, 47, 102484. [Google Scholar] [CrossRef]

- Huang, H.; Qi, B.; Chen, L. Innovation and High-Quality Development of Enterprises—Also on the Effect of Innovation Driving the Transformation of China’s Economic Development Model. Sustainability 2022, 14, 8440. [Google Scholar] [CrossRef]

- Lin, B.; Zhang, A. Government subsidies, market competition and the TFP of new energy enterprises. Renew. Energy 2023, 216, 119090. [Google Scholar] [CrossRef]

- Hallk, J.C. Product Quality and the Direction of Trade. J. Int. Econ. 2006, 68, 238–265. [Google Scholar] [CrossRef]

- Schott, P.K. Across-Product versus Within-Product Specialization in International Trade. Q. J. Econ. 2004, 119, 647–678. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, W.P.; Zhai, F.X. Has the quality of China’s export products improved? Econ. Res. 2014, 10, 46–59. (In Chinese) [Google Scholar]

- Zhao, C.Y.; Wang, W.C.; Li, X.S. How digital transformation affects enterprise total factor productivity. Financ. Trade Econ. 2021, 42, 114–129. (In Chinese) [Google Scholar]

- Wang, H.; Cao, W.; Wang, F. Digital transformation and manufacturing firm performance: Evidence from China. Sustainability 2022, 14, 10212. [Google Scholar] [CrossRef]

- Xiao, L. Co-ordination of Supply Side Structural Reform and Demand Side Management. In New Supply Side Economics: The Structural Reform on Supply Side and Sustainable Growth; Springer: Berlin/Heidelberg, Germany, 2017; pp. 251–282. [Google Scholar]

- Olszewski, M. Modern industrial robotics. Pomiary Autom. Robot. 2020, 24, 5–20. [Google Scholar] [CrossRef]

- Ahmad, N.; Ribarsky, J. Towards a framework for measuring the digital economy. In Proceedings of the 16th Conference of the International Association of Official Statisticians, Paris, France, 19–21 September 2018; pp. 1–33. [Google Scholar]

- Goel, R.; Gupta, P. Robotics and industry 4.0. A Roadmap to Industry 4.0: Smart Production. In Sharp Business and Sustainable Development; Springer: Berlin/Heidelberg, Germany, 2020; pp. 157–169. [Google Scholar]

- Li, B.H.; Hou, B.C.; Yu, W.T.; Lu, X.B.; Yang, C.W. Applications of artificial intelligence in intelligent manufacturing: A review. Front. Inf. Technol. Electron. Eng. 2017, 18, 86–96. [Google Scholar] [CrossRef]

- Saniee, I.; Kamat, S.; Prakash, S.; Weldon, M. Will productivity growth return in the new digital era. Bell Labs Tech. J. 2017, 22, 1–18. [Google Scholar] [CrossRef]

- De Soto, B.G.; Agustí-Juan, I.; Hunhevicz, J.; Joss, S.; Graser, K.; Habert, G.; Adey, B.T. Productivity of digital fabrication in construction: Cost and time analysis of a robotically built wall. Autom. Constr. 2018, 92, 297–311. [Google Scholar] [CrossRef]

- Martínez-Caro, E.; Cegarra-Navarro, J.G.; Alfonso-Ruiz, F.J. Digital technologies and firm performance: The role of digital organisational culture. Technol. Forecast. Soc. Chang. 2020, 154, 119962. [Google Scholar] [CrossRef]

- Li, C.F.; Li, D.D.; Zhou, C. The role mechanism of digital economy driving the transformation and upgrading of manufacturing industry-analysis based on the perspective of industrial chain. Bus. Res. 2020, 2, 73–82. [Google Scholar]