Study on Energy Flow Characteristics of Solar–Gas Combined Heating System for Settling Tank of Oilfield

Abstract

1. Introduction

2. Research Method

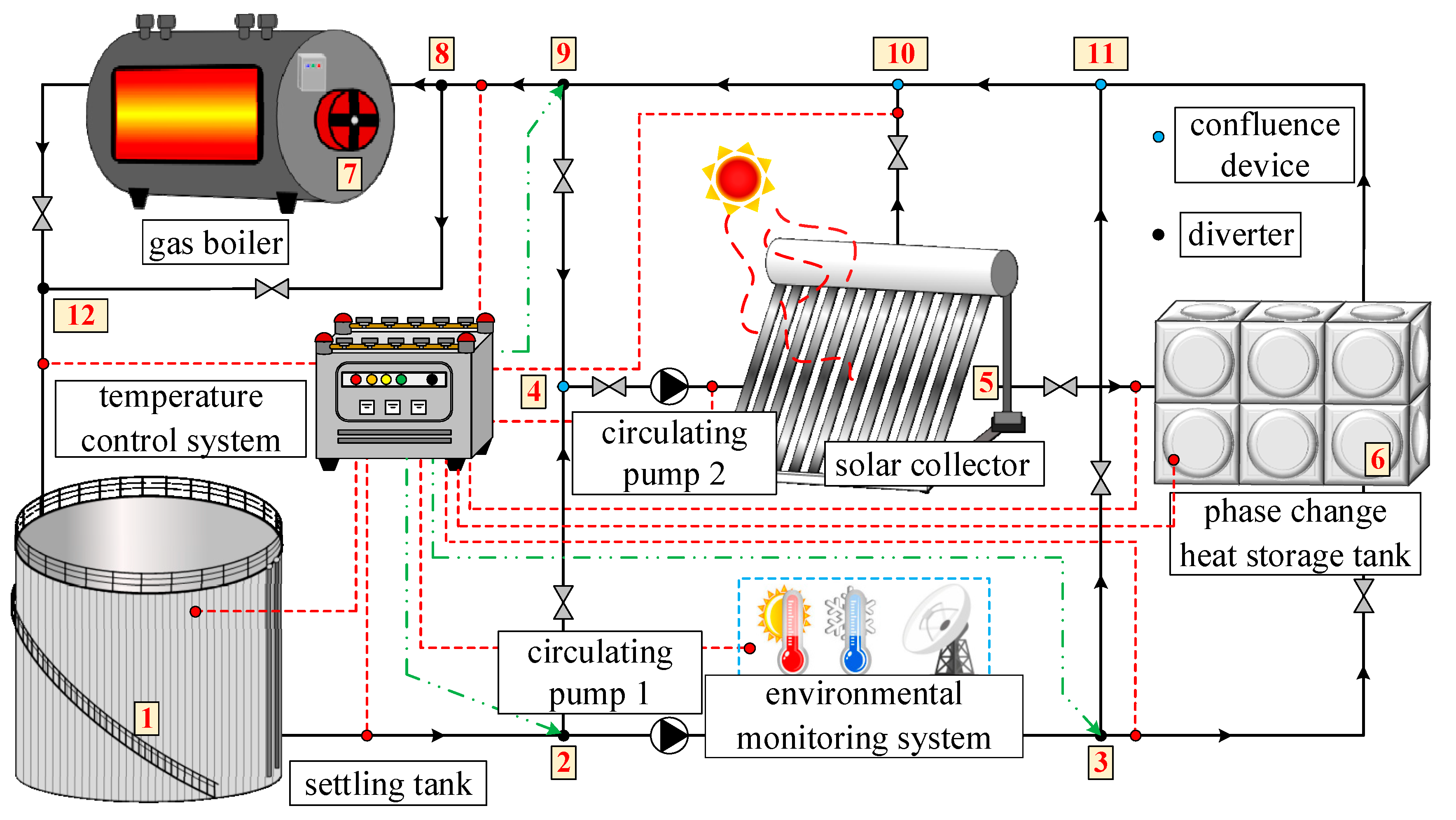

2.1. System Composition and Operating Principles

2.2. System Thermodynamic Model

2.2.1. Solar Collector Model

- Solar radiation model [25]:

- Thermal efficiency of solar collector [26]:

- Heat balance equation of solar collector:

2.2.2. Phase-Change Heat Storage Tank Model

2.2.3. Circulating Pump Model

2.3. Establishment of Simulation Platform for Solar–Gas Combined Heating System of Settling Tank

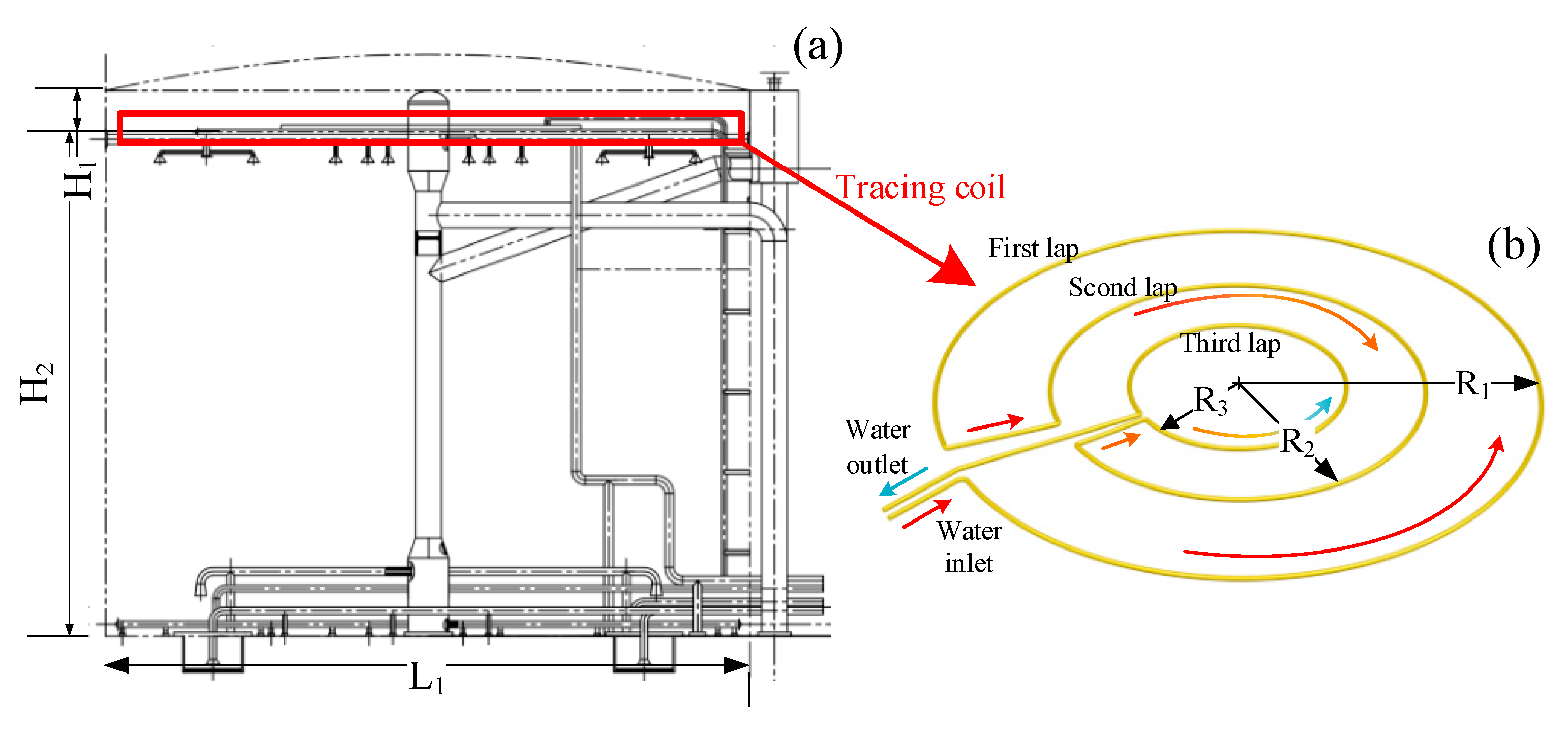

2.3.1. Initial Working Conditions of Settling Tank

- Physical parameters of crude oil

- Initial condition

2.3.2. System Design Parameters

- Main device parameters of the system

- System meteorological parameters

2.4. TRNSYS Simulation Model of the System

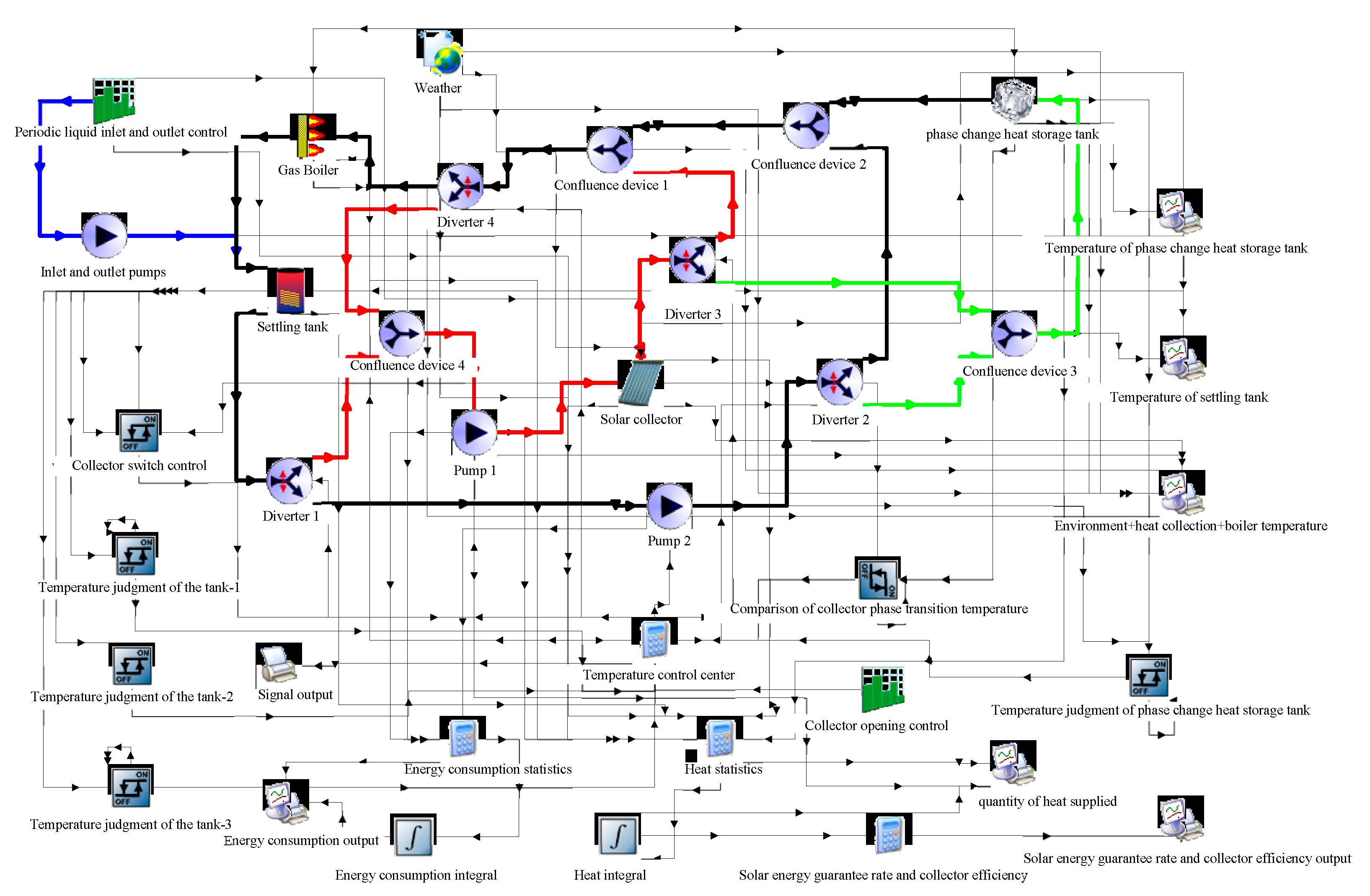

2.4.1. Construction of Model

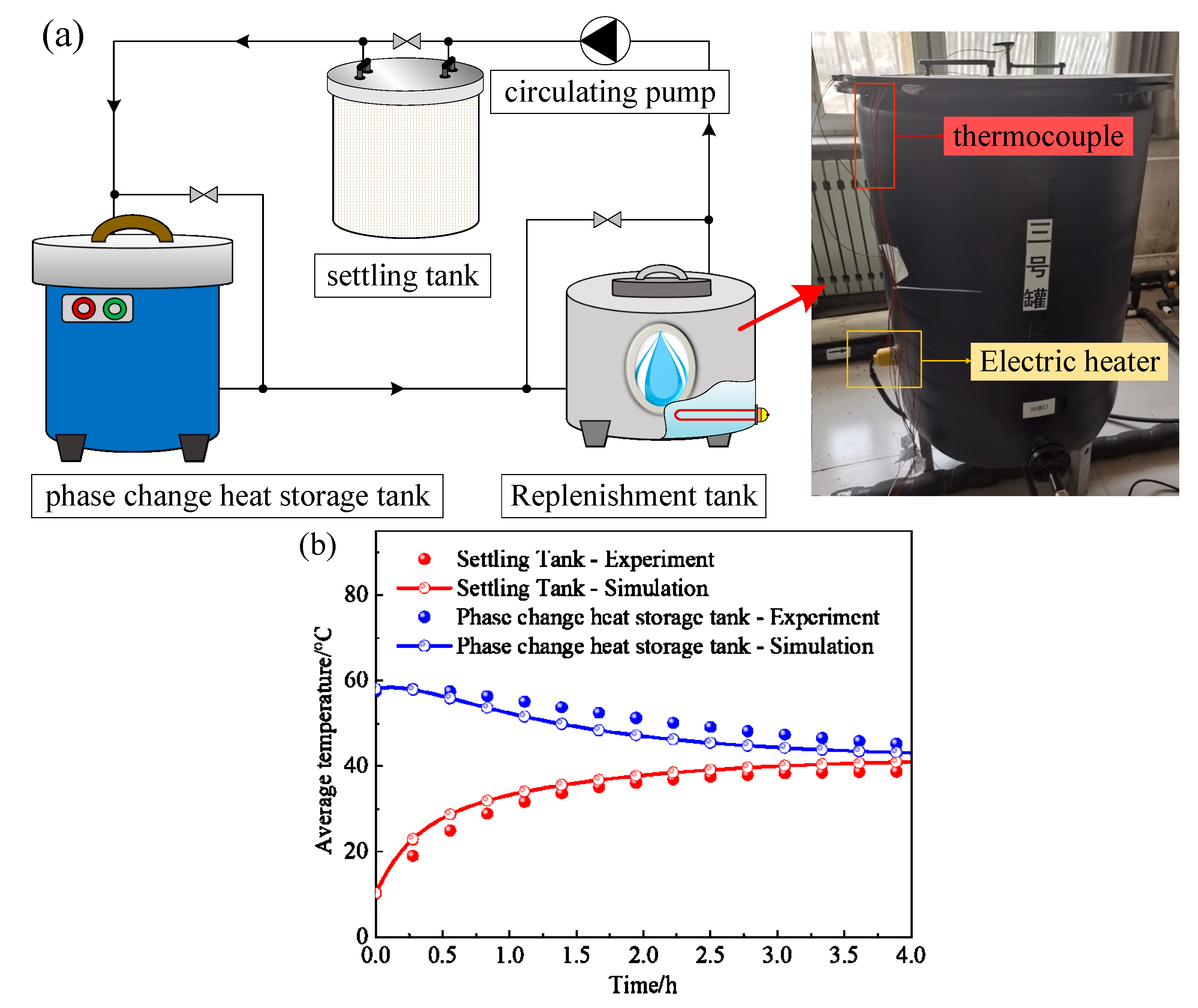

2.4.2. System Model Verification

2.4.3. System Control Mode

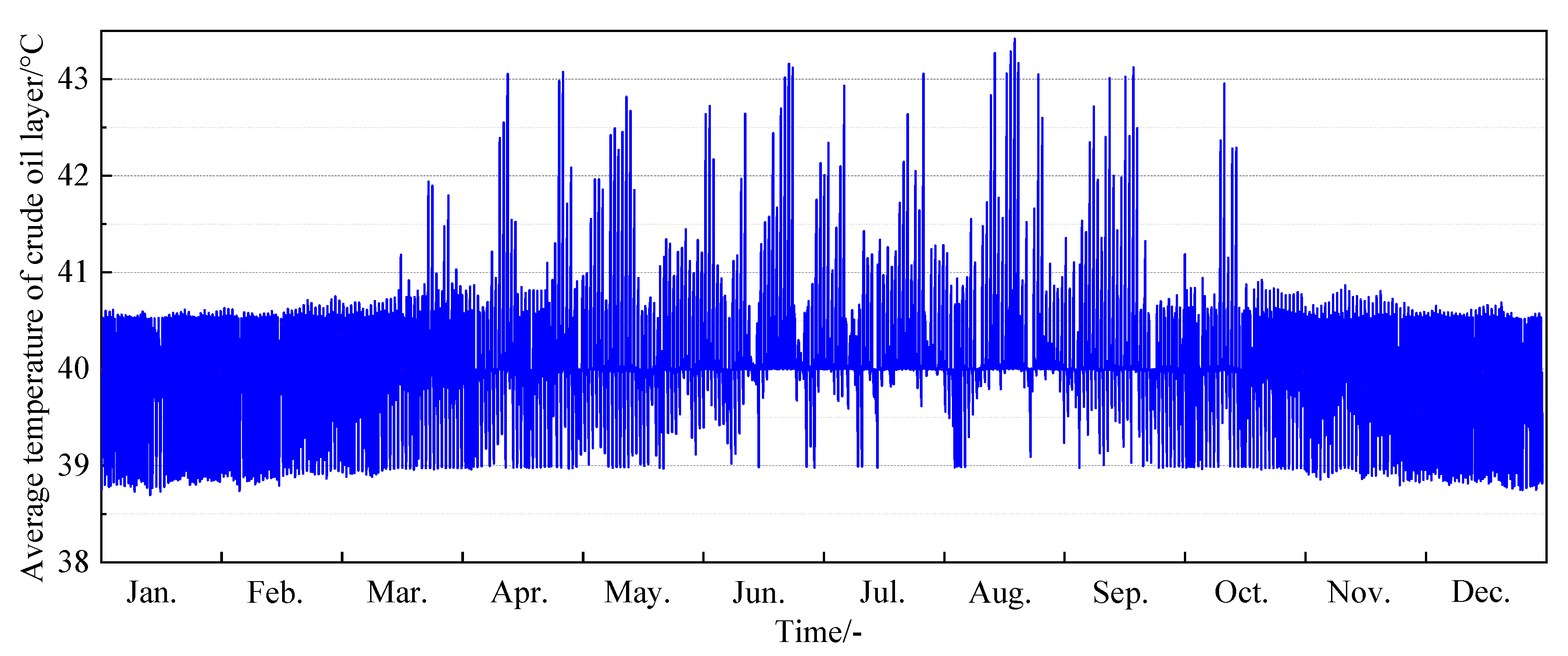

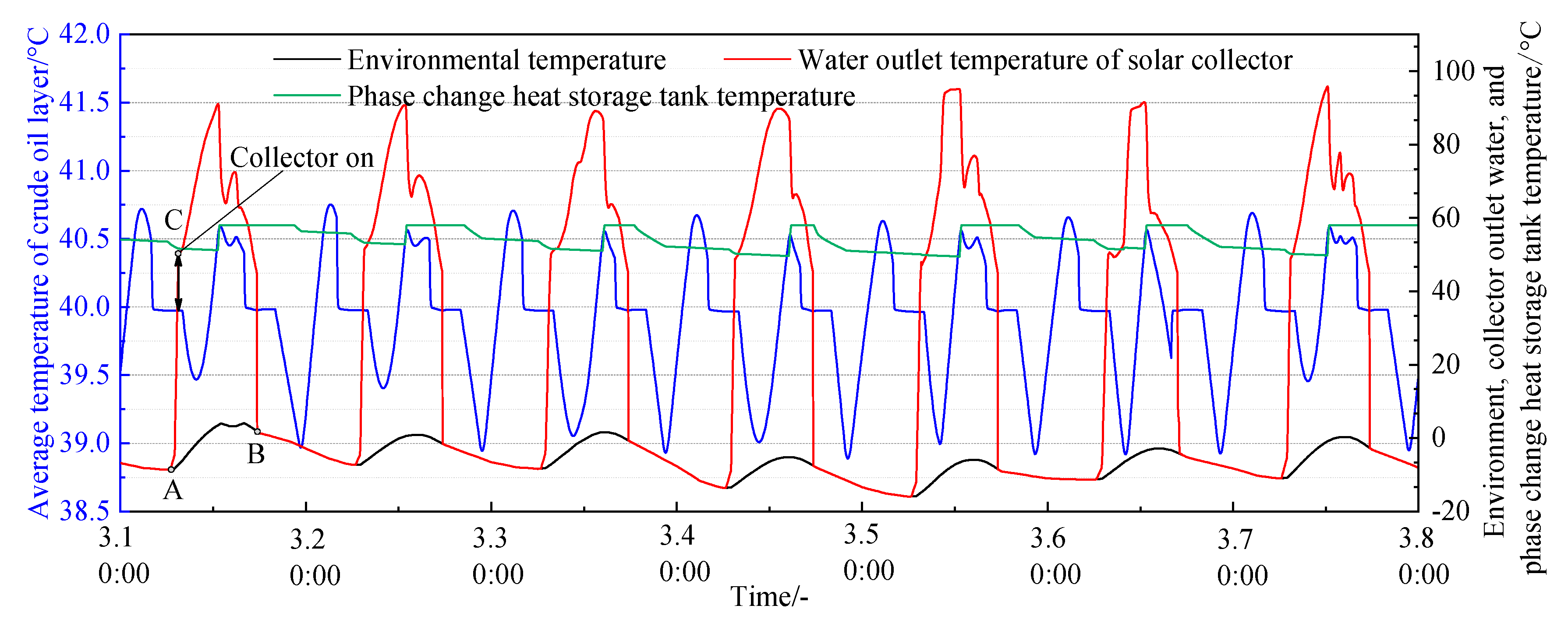

- In order to maintain the appropriate operating temperature of the settling tank, the heat-tracing coil is monitored when the average temperature of the crude oil layer at the top of the tank is lower than 39 °C, and the heating coil is closed when the temperature is higher than 40.5 °C. In order to prevent the temperature of the settling tank from being too high, the heating of the settling tank should be stopped when the temperature of the crude oil layer exceeds 43 °C, and the solar–phase-change heat storage cycle system should be started.

- The collector opening and closing control is coordinated by the collector opening time control and collector temperature difference monitoring. When the daily time is between 6:00 and 18:00, the collector opening time control requirements can be met; when the temperature difference between the heat-transfer fluid at the outlet of the collector and the average temperature difference between the oil layer temperature is more than 10 °C, the collector needs to be started. When the temperature difference is reduced to less than 5 °C, the collector is closed.

- The control of the phase-change heat accumulator is mainly divided into three modes: heat storage, heat release, and by-pass.

- Heat storage mode: In order to ensure that the oil reservoir temperature meets the working requirements, an oil reservoir temperature above 40.5 °C is a necessary prerequisite for the heat storage mode to be opened. When the temperature of the heat-transfer fluid at the outlet of the collector is higher than the temperature of the phase-change heat storage tank, the phase-change heat storage is opened, and when the temperature difference is lower than 8 °C, the phase-change heat storage is closed.

- Heat release mode: The heat release process of the phase-change heat storage tank can be subdivided into daytime and solar collector combined with heating and night heat release. When the temperature of the crude oil layer is lower than 39 °C, and if the daytime collector is opened when the heat-transfer fluid temperature at the collector outlet is lower than 8 °C of the phase-change storage tank, the solar-phase-change joint heating mode is opened. If the collector is closed at night, the temperature of the phase-change heat storage tank should be compared with the temperature of the heat-transfer fluid at the outlet of the settling tank. If the temperature difference between the two is greater than 3 °C, the phase-change heat release mode is on; when the temperature difference is less than 1 °C, the phase-change heat release mode is closed.

- By-pass mode: The by-pass mode is mainly opened when the phase-change heat storage tank cannot meet the requirements of heat storage/release. The purpose of this mode is to ensure that the heat generated by the solar collector can meet the requirements of the settling tank first.

- The opening control of the gas boiler mainly depends on the average temperature of the crude oil layer. When the heat-transfer fluid is heated by the solar collector or the phase-change storage tank, the average temperature of the crude oil layer is still below 39 °C, and at night or under special weather conditions when the solar collector and the phase-change storage tank cannot work, the gas boiler is opened for heating.

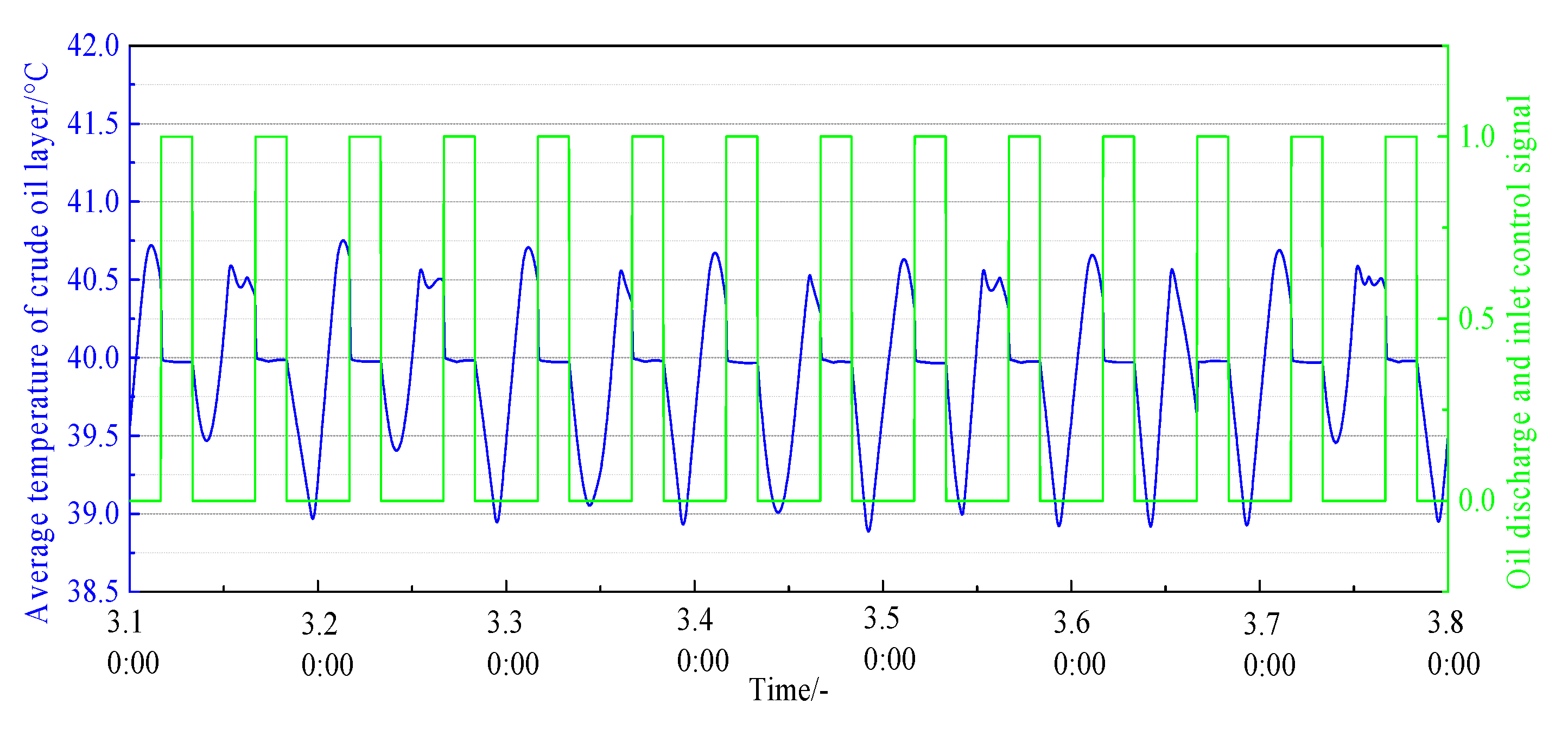

- In order to fit the working process of the actual settling tank, periodic liquid inlet and discharge control have been designed. The settling period of the settling tank is set to 12 h, in which the time of inlet and discharge of liquid is 2 h, and the settling time is 8 h. The tracing coil is closed during the inlet and discharge of the liquid, and the solar–phase-change heat storage circulation system can be operated independently during this period for heat storage.

3. Results and Discussion

3.1. The Influence of Settling Tank Receiving Period on System Operating Characteristics

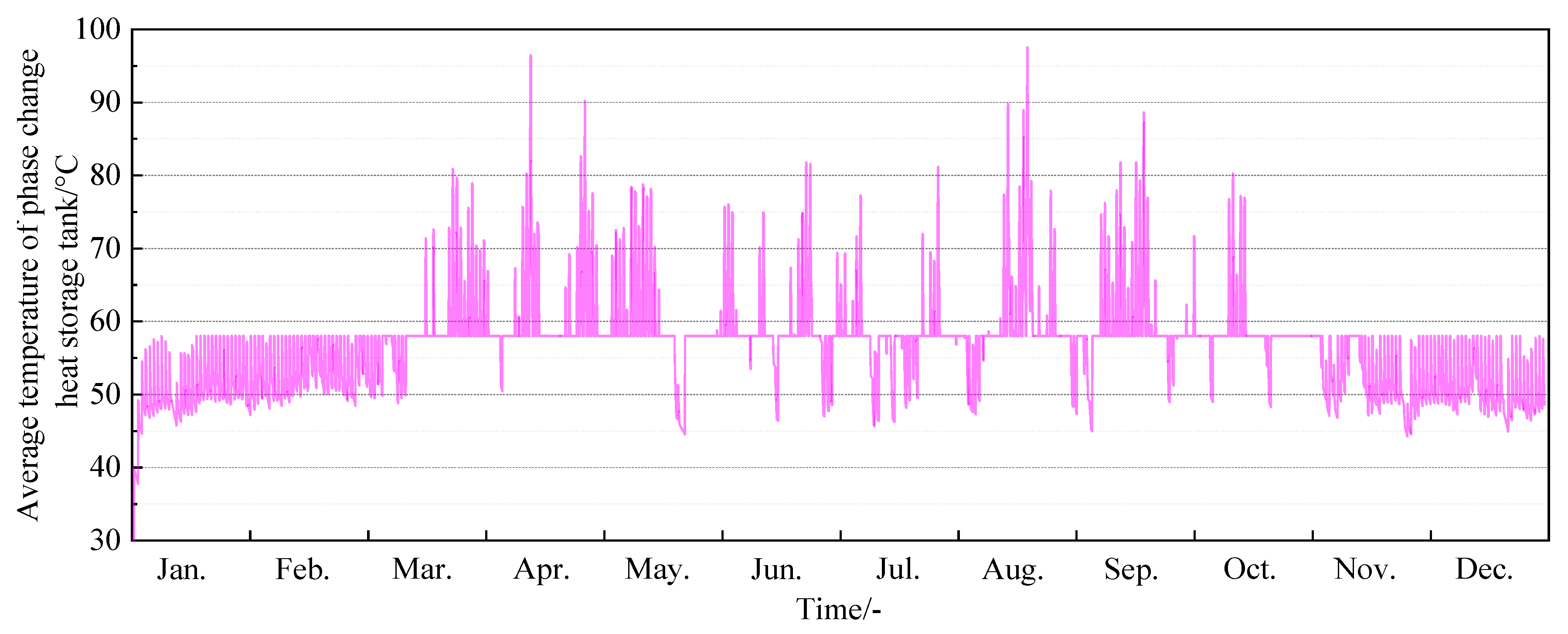

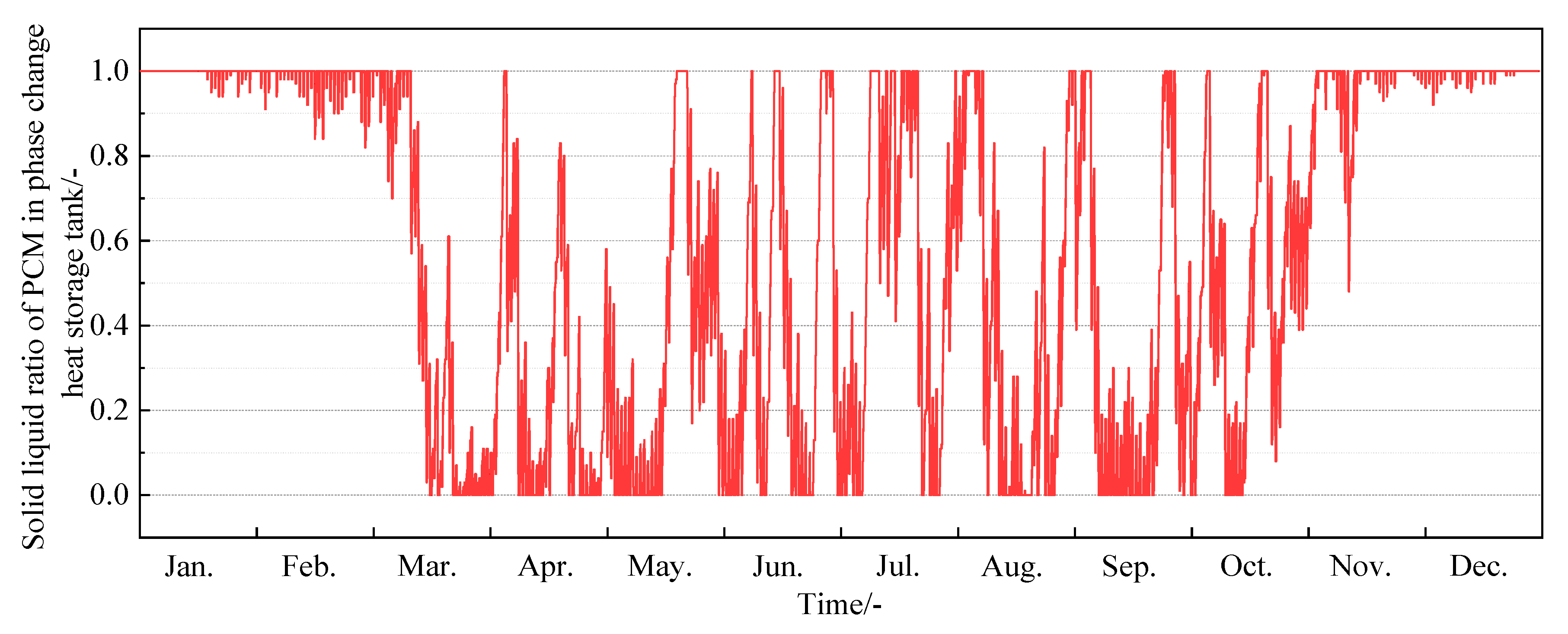

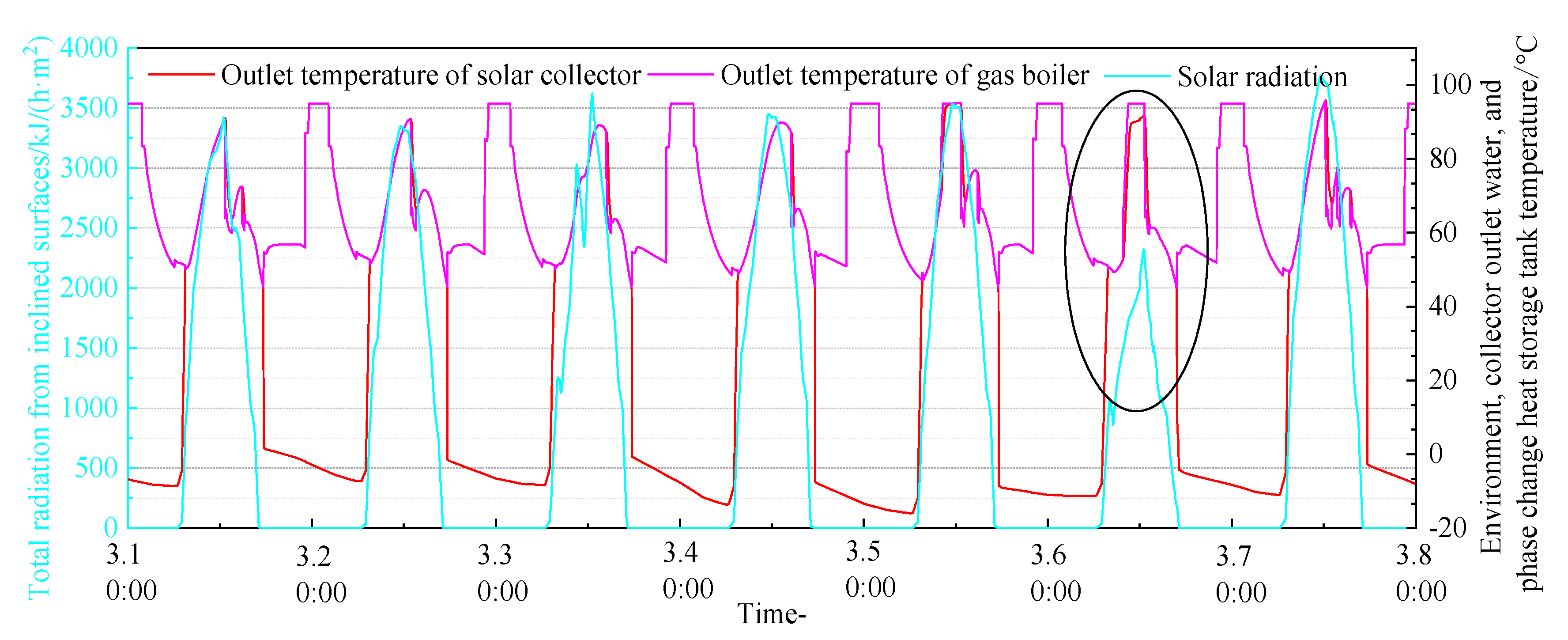

3.2. Analysis of Long Cycle System Operation Characteristics

3.3. Analysis of Short Cycle System Operation Characteristics

3.4. Comprehensive Benefit Analysis

- 1.

- Annual energy saving of the settling tank solar–gas combined heating system [31] is calculated as follows:where Jn is the total annual solar radiation on the inclined surface of the collector, MJ/m2.

- 2.

- Total energy-saving cost of solar–gas combined heating system of the settling tank during the total life SAV [31]:where P is the discount coefficient considering bank interest rate and fuel price fluctuation comprehensively; CC is the heating price of conventional energy, CNY/MJ; Sin is the total additional investment in the system, CNY; Da is the percentage of the total additional investment spent annually on system maintenance. Among them, P can be calculated as follows:where d is the annual market discount rate, which can be calculated as the bank loan interest rate; e is the annual fuel price increase rate; n is the calculation period.

- 3.

- 4.

- CO2 emission reduction in the settling tank solar–gas combined heating system during the total life [31]:where n is the system life, which is calculated as 15 years; W is the calorific value of standard coal, which is 29.308 MJ/kg; Em is the efficiency of a conventional energy water-heating device; FCO2 is a carbon emission factor.

4. Conclusions

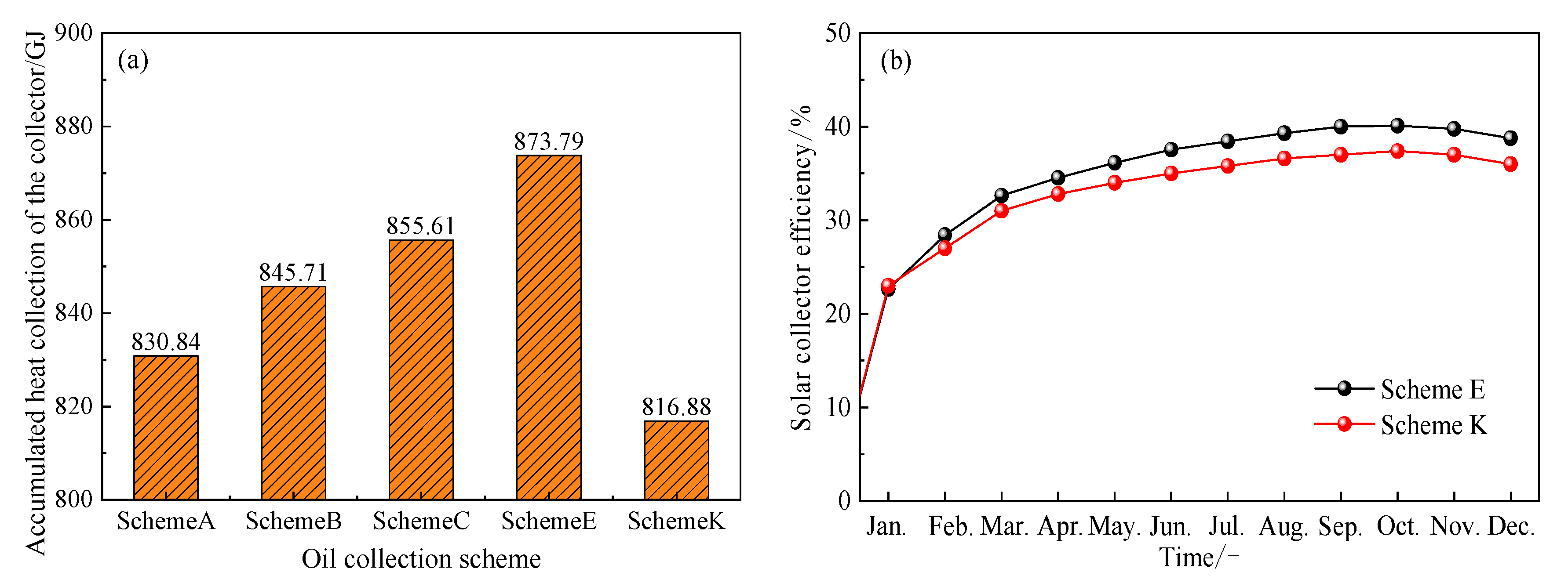

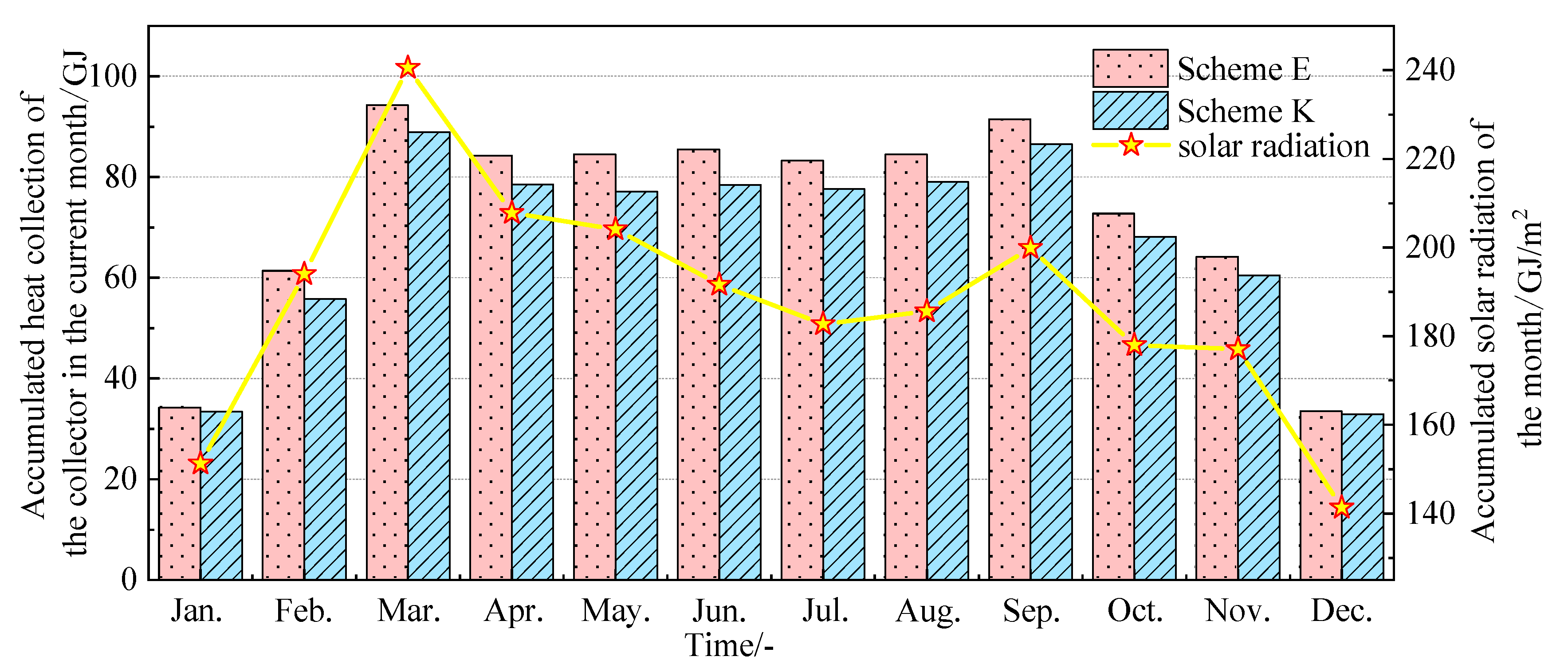

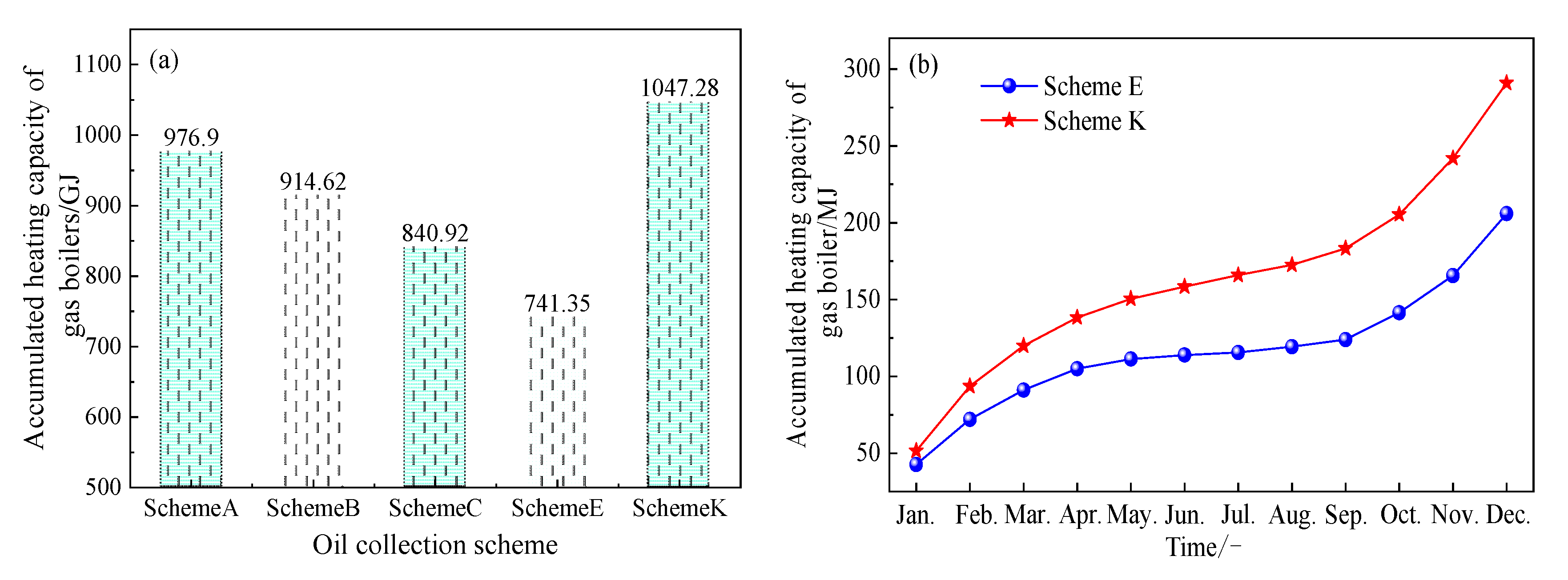

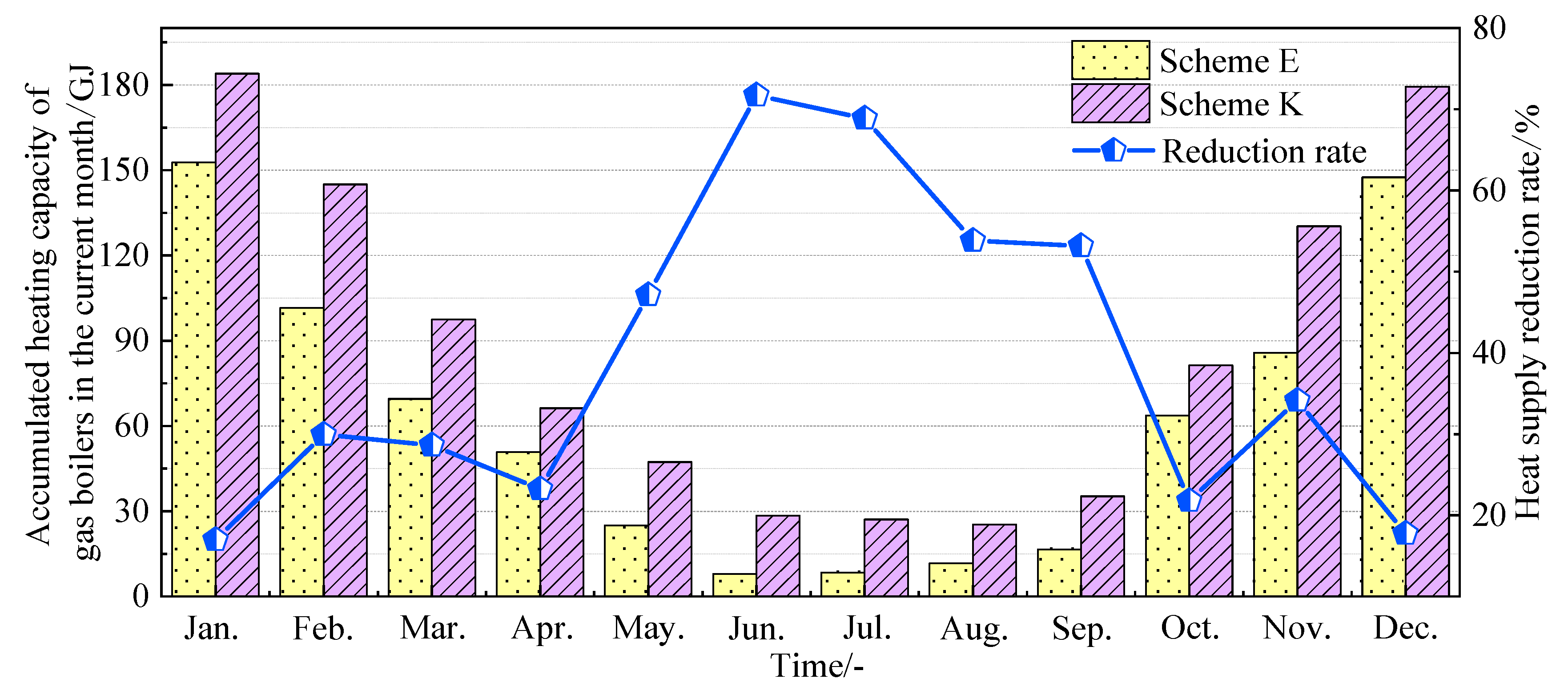

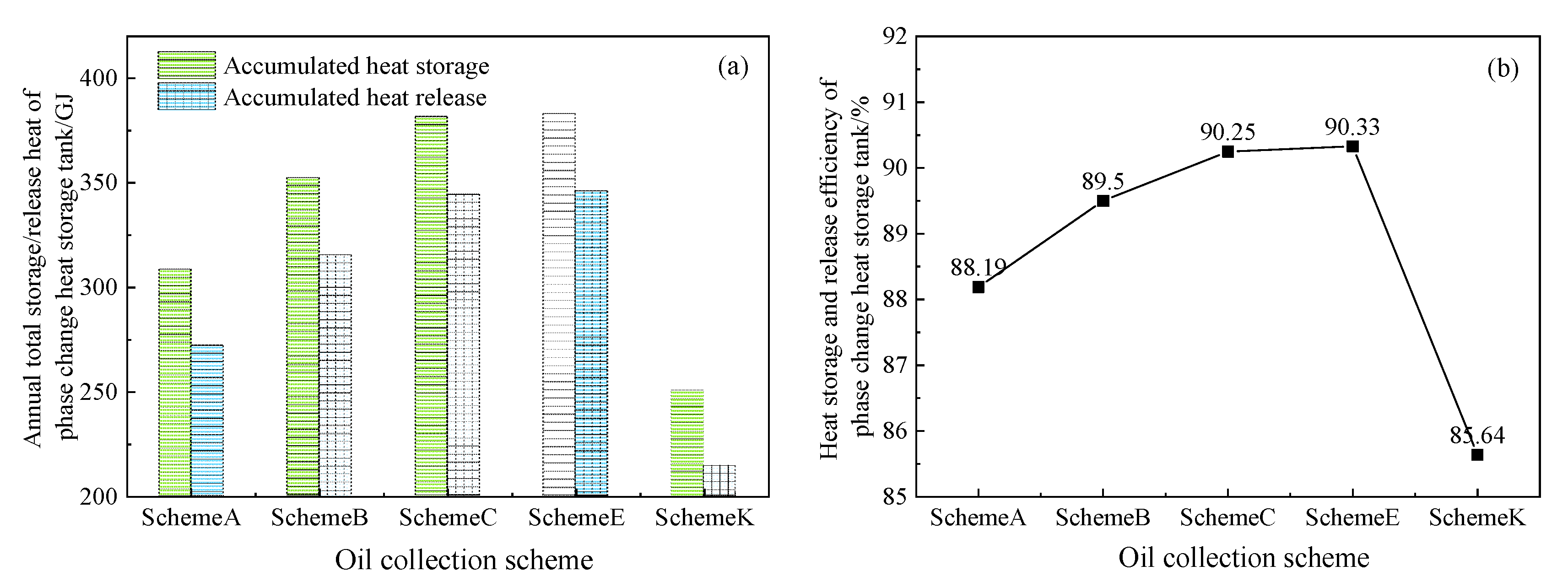

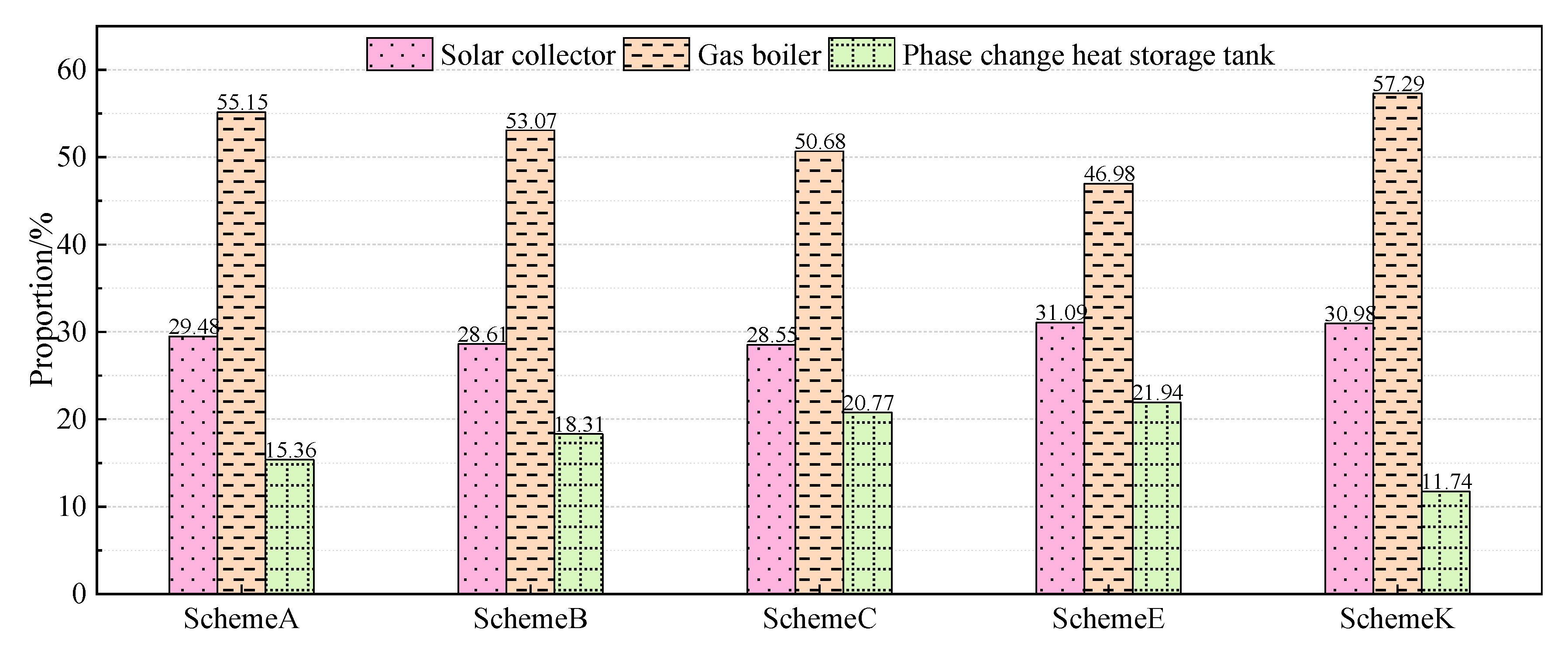

- The optimal solution for the oil-collection period of the settling tank is E (4:00–8:00). This solution results in the highest annual cumulative heat collection by the collector, the lowest annual total heat supply by the gas boiler, and the highest heat storage and release efficiency of the phase-change heat storage tank. Compared to the most adverse plan K (10:00–14:00), the annual cumulative heat collection of the collector can be increased by 6.7% (56.91 GJ), the annual total heat supply of the gas boiler can be reduced by 29.2% (305.93 GJ), and the heat storage and release efficiency of the phase-change heat storage tank can be improved by 4.69%.

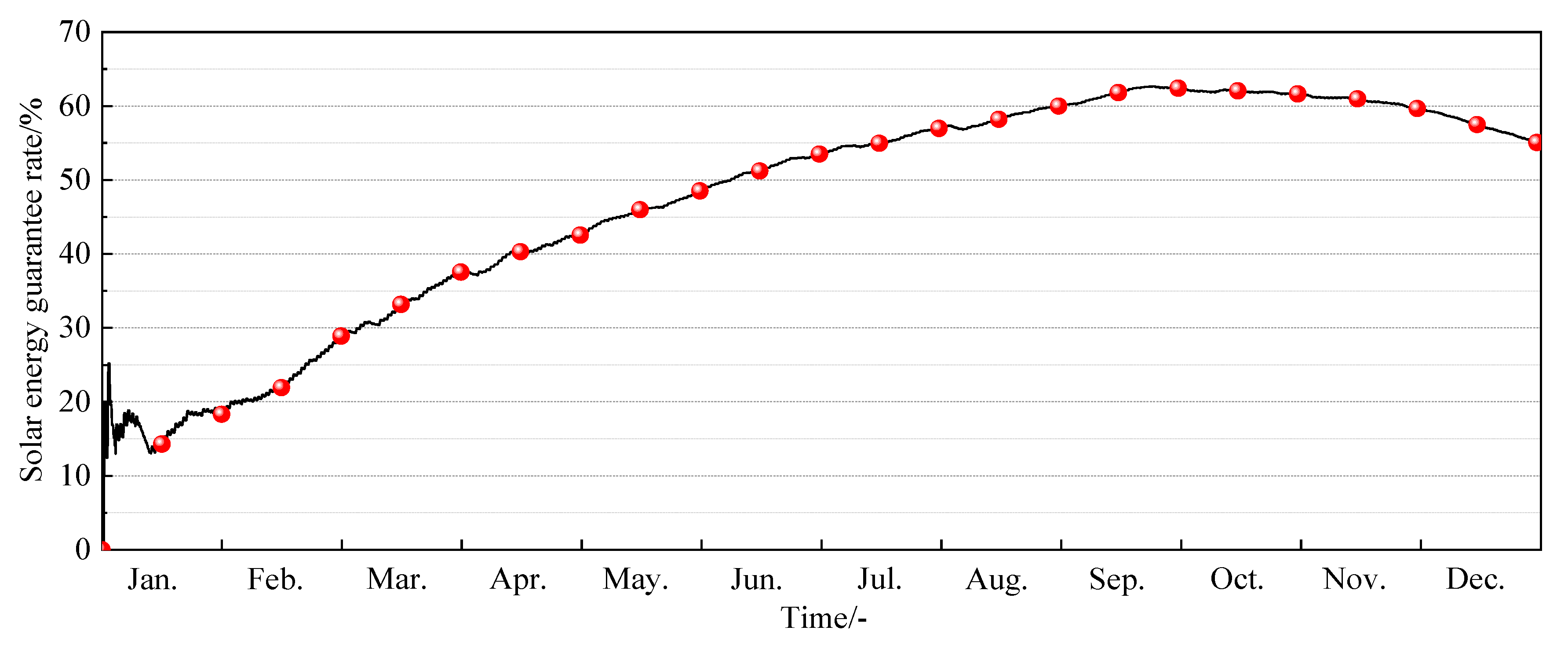

- The average crude oil temperature is maintained above 39 °C throughout the year, thereby meeting the requirements of the settling tanks. The solar–gas combined heating system of the settling tank achieves the highest solar guarantee rate (about 62.7%) in September and October Approximately 65% of the year, the latent heat of PCM melting can be effectively utilized, fully leveraging the advantages of the heat storage and release advantages of phase-change materials.

- The service life of the settling tank solar–gas combined heating system is calculated as 15 years, and its annual energy saving, total energy-saving cost, dynamic payback period, and CO2 emission reduction are 727,988.69 MJ, CNY 397,007, 9.14 years, and 753,069.8 kg, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ding, P.; Dang, W.; Wang, L.; Liu, J. Current Status and Prospects of Oilfield Produced Water Reinjection Treatment Technology. Mod. Chem. Ind. 2019, 39, 21–25. [Google Scholar]

- Bao, Z. Methods for Improving the Quality of Oil and Water Treatment in Joint Stations. China Pet. Chem. Stand. Qual. 2022, 42, 25–27. [Google Scholar]

- Wang, X. Research on Heat Transfer Characteristics and Structural Stress Influencing Factors of Heat Tracing Coils in Sewage Settlement Tanks. Ph.D. Thesis, Northeast Petroleum University, Daqing, China, 2022. [Google Scholar]

- Liu, X.; Chen, D.; Zhang, W.; Qin, W.; Zhou, W.; Qiu, T.; Zhu, B. An assessment of the energy-saving potential in China’s petroleum refining industry from a technical perspective. Energy 2013, 59, 38–49. [Google Scholar] [CrossRef]

- Zou, C.; He, D.; Jia, C.; Xiong, B.; Zhao, Q.; Pan, S. Connotation and pathway of world energy transition and its significance for carbon neutral. Acta Pet. Sin. 2021, 42, 233–247. [Google Scholar]

- Helman, C. Oil From The Sun. Forbes 2011, 187, 86–89. [Google Scholar]

- BrightSource Energy Delivers World’s Largest Solar-to-Steam Facility for Enhanced Oil Recovery to Chevron. [EB/OL]. Available online: http://www.businesswire.com/news/home/20111003006187/en/BrightSourceEnergyDelivers-World%E2%80%99s-Largest-Solarto-Steam-Facility (accessed on 1 March 2023).

- Moritis, G. Chevron starts California demo of solar-to-steam enhanced recovery. Oil Gas J. 2011, 109, 87–88. [Google Scholar]

- Yao, Z. Research on the Technology of Using Concentrated Solar Energy to Generate Steam Injection for Oil Production. Energy Conserv. Emiss. Reduct. Pet. Petrochem. Ind. 2013, 3, 1–6. [Google Scholar]

- Bierman, B.; Treynor, C.; O’donnell, J.; Lawrence, M.; Chandra, M.; Farver, A.; Von Behrens, P.; Lindsay, W. Performance of an enclosed trough EOR system in South Oman. Energy Procedia 2014, 49, 1269–1278. [Google Scholar] [CrossRef]

- Luo, W.; Zhao, R.; Xia, X.; Yao, T.; Xiao, A. Feasibility Analysis of the Application of Solar Energy Closed Cell Heavy Oil Thermal Recovery Technology in Xinjiang Oilfield. J. Xi’an Pet. Univ. (Nat. Sci. Ed.) 2015, 30, 64–68. [Google Scholar]

- Du, M.; Jing, Q.; Zhang, Z.; Li, J.; Yin, R. Key Technologies for Heavy Oil Thermal Recovery through Solar Photothermal Conversion. Energy Storage Sci. Technol. 2020, 9, 62–69. [Google Scholar]

- Qian, J.; Wang, Q. Development on solar—Assisted sewage source heat pump system for crude oil heating. J. Harbin Univ. Commer. (Nat. Sci. Ed.) 2017, 33, 477–481. [Google Scholar]

- Li, W.; Wu, Y.; Hu, J.; Zhao, X. Application of solar photovoltaic integration technology in crude oil heating system. Energy Conserv. Pet. Petrochem. Ind. 2021, 11, 13–16. [Google Scholar]

- Pei, J.; Chen, G. Application of solar energy and heat pump technology in crude oil heating systems. Oil Gas Storage Transp. 2012, 31, 289–291. [Google Scholar]

- Xu, X.; Xiao, Y.; Xu, Y. On site application of crude oil heating energy-saving technology in Ansai Oilfield. Petrochem. Equip. 2019, 48, 69–72. [Google Scholar]

- Hao, Y.; Lv, S.; Li, H. Research on the Application of Solar Photovoltaic Photothermal Systems in Crude Oil Gathering and Transportation. Pet. Petrochem. Green Low Carbon 2020, 5, 69–72+77. [Google Scholar]

- Mammadov, F.; Samadova, U.; Salamov, O. Experimental results of using a parabolic trough solar collector for thermal treatment of crude oil. J. Energy South. Afr. 2008, 19, 70–76. [Google Scholar] [CrossRef]

- Lasich, J.; Kaila, N. Helitherm-solar power throughput enhancement and heat tracing for heavy oil pipelines. In SPE International Thermal Operations and Heavy Oil Symposium; SPE: New Orleans, LA, USA, 2001. [Google Scholar]

- Wang, X.; Ye, C. Energy saving application of solar photothermal technology in oil and gas fields. Pet. Petrochem. Energy Conserv. 2013, 3, 22–25. [Google Scholar]

- Hou, L.; Zhang, X.; Zhou, W. The application of solar energy in surface engineering of oil and gas fields. Appl. Energy Technol. 2011, 1, 40–43. [Google Scholar]

- He, Z. Application of solar heating system for raw petroleum during its piping transport. Energy Procedia 2014, 48, 1173–1180. [Google Scholar] [CrossRef]

- Fu, Z.; Gao, H.; Zhang, T.; Zhu, Z. Calculation of Heat Load Matching for Solar Heating Crude Oil Storage and Transportation System. Oil Gas Storage Transp. 2019, 38, 1306–1310. [Google Scholar]

- Ai, L. Research on the area calculation of collectors and heat exchange coils in oil storage tanks using solar indirect heating systems. Sol. Energy 2012, 16, 56–58. [Google Scholar]

- Li, S.; Lin, W.; Gong, X.; Sun, Y.; Ma, Z. Corrugated transpired solar collectors: Mathematical modeling, experimental investigation, and performance analysis. Sol. Energy 2023, 262, 111839. [Google Scholar]

- Al-Rabeeah, A.Y.; Seres, I.; Farkas, I. Experimental investigation of parabolic trough solar collector thermal efficiency enhanced with different absorber coatings. Int. J. Thermofluids 2023, 19, 100386. [Google Scholar]

- Zhao, J.; Dong, H.; Fu, X.; Lei, Q. Cooling gelation behavior of waxy crude oil in floating roof tanks during static storage. J. Chem. Eng. 2017, 68, 4882–4891. [Google Scholar]

- Li, D.; Wu, Y.; Liu, C.; Yang, R.; Arıcı, M. Thermal Analysis of Crude Oil in Floating Roof Tank Equipped with Horizontal Heating Finned Tube Bundles. ES Energy Environ. 2021, 13, 65–76. [Google Scholar]

- GB 50495-2019; Solar Heating Engineering Technical Standard. China Architecture Publishing House: Beijing, China, 2019.

- GB 50364-2018; Civil Building Solar Water Heating System Application Technical Standard. China Architecture Publishing House: Beijing, China, 2018.

- Zheng, R. Engineering Technical Manual of Solar Water Heating System for Civil Buildings; Chemical Industry Press: Beijing, China, 2011. [Google Scholar]

| Material | Thermal Conductivity W/(m·°C) | Specific Heat J/(kg·°C) | Density kg/m3 | Viscosity Pa·s |

|---|---|---|---|---|

| Steel plates | 40 | 460 | 7800 | - |

| Thermal insulation material | 0.035 | 800 | 60 | - |

| Asphalt sand | 0.5 | 1000 | 1400 | - |

| Sand | 0.56 | 837 | 1500 | - |

| Backfill soil | 0.93 | 1062 | 1750 | - |

| Water | 0.636 | 4174 | 992.2 | 0.0006533 |

| Material | Density kg/m3 | Specific Heat J/(kg·°C) | Thermal Conductivity W/(m·°C) |

|---|---|---|---|

| Glycol solution | 1064 | 3358 | 0.394 |

| Material | Density kg/m3 | Specific Heat J/(kg·°C) | Thermal Conductivity W/(m·°C) | Phase Transition Temperature °C | Latent Heat of Phase Transition kJ/kg |

|---|---|---|---|---|---|

| 58# Phase-change wax | 818 (s)/760 (l) | 2520 (s)/2690 (l) | 0.15 | 58 | 186 |

| Rated Heating Capacity MW | Rated Pressure MPa | Outgoing/Incoming Water Temperature °C | Boiler Efficiency % | Maximum Gas Consumption m3/h | Boiler Size m |

|---|---|---|---|---|---|

| 0.35 | 0.7–20 | 95/70 | 90.3 | 37.3 | 2.9 × 1.59 × 1.86 |

| Model | Flow m3/h | Head of Delivery m | Suction Range m | Power kW |

|---|---|---|---|---|

| IRG50-125A-1.1 | 10.5 | 16 | 7 | 1.1 |

| IRG50-125(I)A-2.2 | 22.3 | 16 | 7 | 2.2 |

| Illumination Condition | Time | Oil Collection Scheme | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | ||

| No light | 0:00–1:00 | 1 | 1 | 1 | 1 | ||||||||

| 1:00–2:00 | 1 | 1 | 1 | 1 | |||||||||

| 2:00–3:00 | 1 | 1 | 1 | 1 | |||||||||

| 3:00–4:00 | 1 | 1 | 1 | 1 | |||||||||

| 4:00–5:00 | 1 | 1 | 1 | 1 | |||||||||

| 5:00–6:00 | 1 | 1 | 1 | 1 | |||||||||

| Weak light | 6:00–7:00 | 1 | 1 | 1 | 1 | ||||||||

| Stronger light | 7:00–8:00 | 1 | 1 | 1 | 1 | ||||||||

| 8:00–9:00 | 1 | 1 | 1 | 1 | |||||||||

| 9:00–10:00 | 1 | 1 | 1 | 1 | |||||||||

| 10:00–11:00 | 1 | 1 | 1 | 1 | |||||||||

| Strong light | 11:00–12:00 | 1 | 1 | 1 | 1 | ||||||||

| 12:00–13:00 | 1 | 1 | 1 | 1 | |||||||||

| Stronger light | 13:00–14:00 | 1 | 1 | 1 | 1 | ||||||||

| 14:00–15:00 | 1 | 1 | 1 | 1 | |||||||||

| 15:00–16:00 | 1 | 1 | 1 | 1 | |||||||||

| 16:00–17:00 | 1 | 1 | 1 | 1 | |||||||||

| Weak light | 17:00–18:00 | 1 | 1 | 1 | 1 | ||||||||

| No light | 18:00–19:00 | 1 | 1 | 1 | 1 | ||||||||

| 19:00–20:00 | 1 | 1 | 1 | 1 | |||||||||

| 20:00–21:00 | 1 | 1 | 1 | 1 | |||||||||

| 21:00–22:00 | 1 | 1 | 1 | 1 | |||||||||

| 22:00–23:00 | 1 | 1 | 1 | 1 | |||||||||

| 23:00–24:00 | 1 | 1 | 1 | 1 | |||||||||

| Materials and Equipment | Price | |

|---|---|---|

| Settling tank modification | Retrofit of heat-tracing coil | CNY 260,200 (total) |

| Phase-change heat storage tank | Phase-change material | CNY 15/kg |

| CNY 306,750 (total) | ||

| Solar collector | Vacuum tube collector | CNY 1550/series |

| Collector bracket | CNY 450/series | |

| 90,000 (total) | ||

| Pumps and valves, etc. | IRG50-125A-1.1 | CNY 740 per |

| IRG50-125(I)A-2.2 | CNY 980 per | |

| Valves and tees, etc | CNY 8000 (total) | |

| CNY 9720 (total) | ||

| Initial total investment | CNY 666,670 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, F.; Yu, Y.; Wu, Y.; Li, D.; Zhao, X.; Meng, L.; Wang, Z. Study on Energy Flow Characteristics of Solar–Gas Combined Heating System for Settling Tank of Oilfield. Sustainability 2023, 15, 12229. https://doi.org/10.3390/su151612229

Meng F, Yu Y, Wu Y, Li D, Zhao X, Meng L, Wang Z. Study on Energy Flow Characteristics of Solar–Gas Combined Heating System for Settling Tank of Oilfield. Sustainability. 2023; 15(16):12229. https://doi.org/10.3390/su151612229

Chicago/Turabian StyleMeng, Fanbin, Yang Yu, Yangyang Wu, Dong Li, Xuefeng Zhao, Lan Meng, and Zhihua Wang. 2023. "Study on Energy Flow Characteristics of Solar–Gas Combined Heating System for Settling Tank of Oilfield" Sustainability 15, no. 16: 12229. https://doi.org/10.3390/su151612229

APA StyleMeng, F., Yu, Y., Wu, Y., Li, D., Zhao, X., Meng, L., & Wang, Z. (2023). Study on Energy Flow Characteristics of Solar–Gas Combined Heating System for Settling Tank of Oilfield. Sustainability, 15(16), 12229. https://doi.org/10.3390/su151612229