Odour Perception Using a Sniffing Team at a Municipal Solid Waste Treatment Plant: A Case Study

Abstract

1. Introduction

2. Materials and Methods

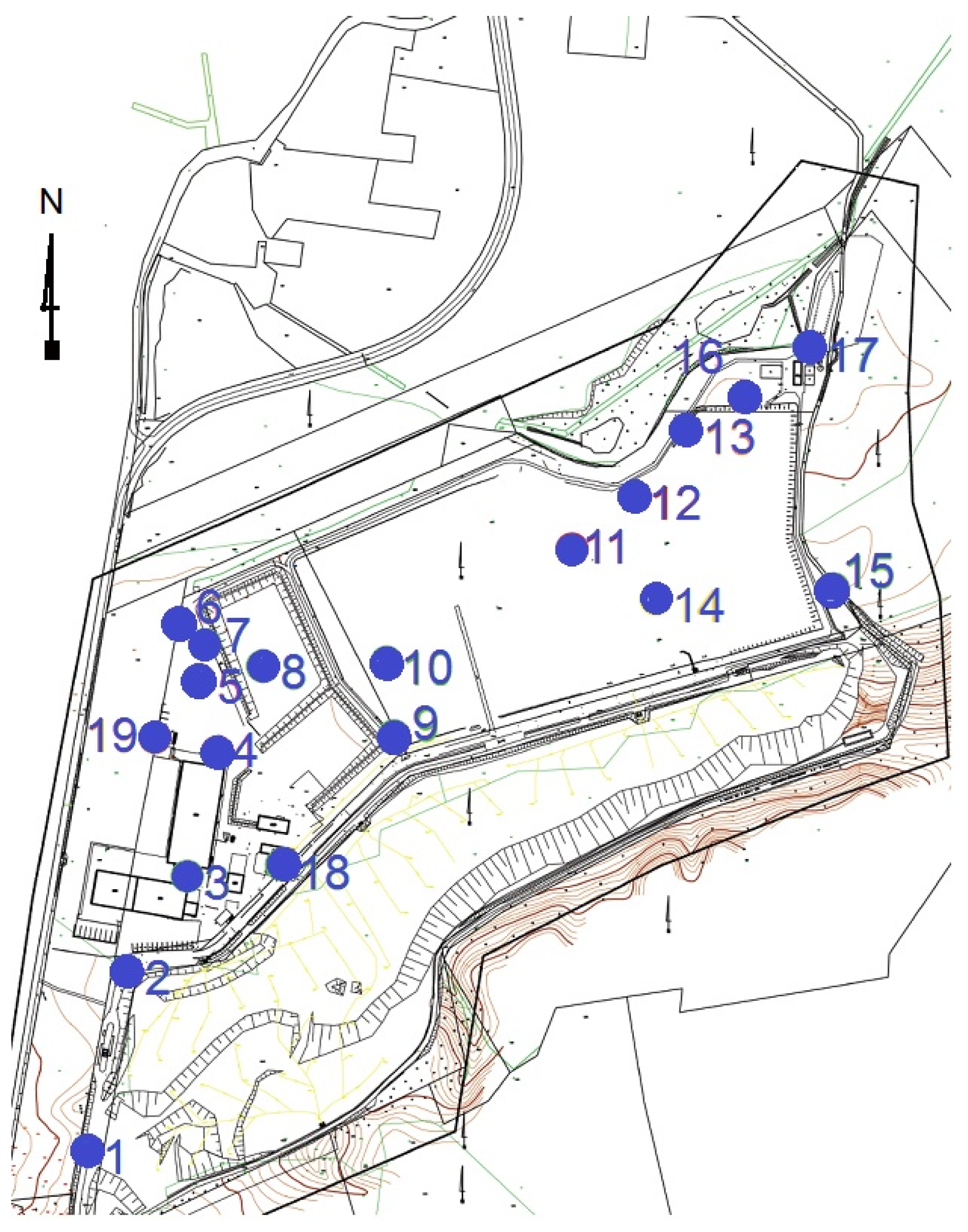

2.1. Site Description

2.2. Methodology and Areas

2.3. Operating Conditions

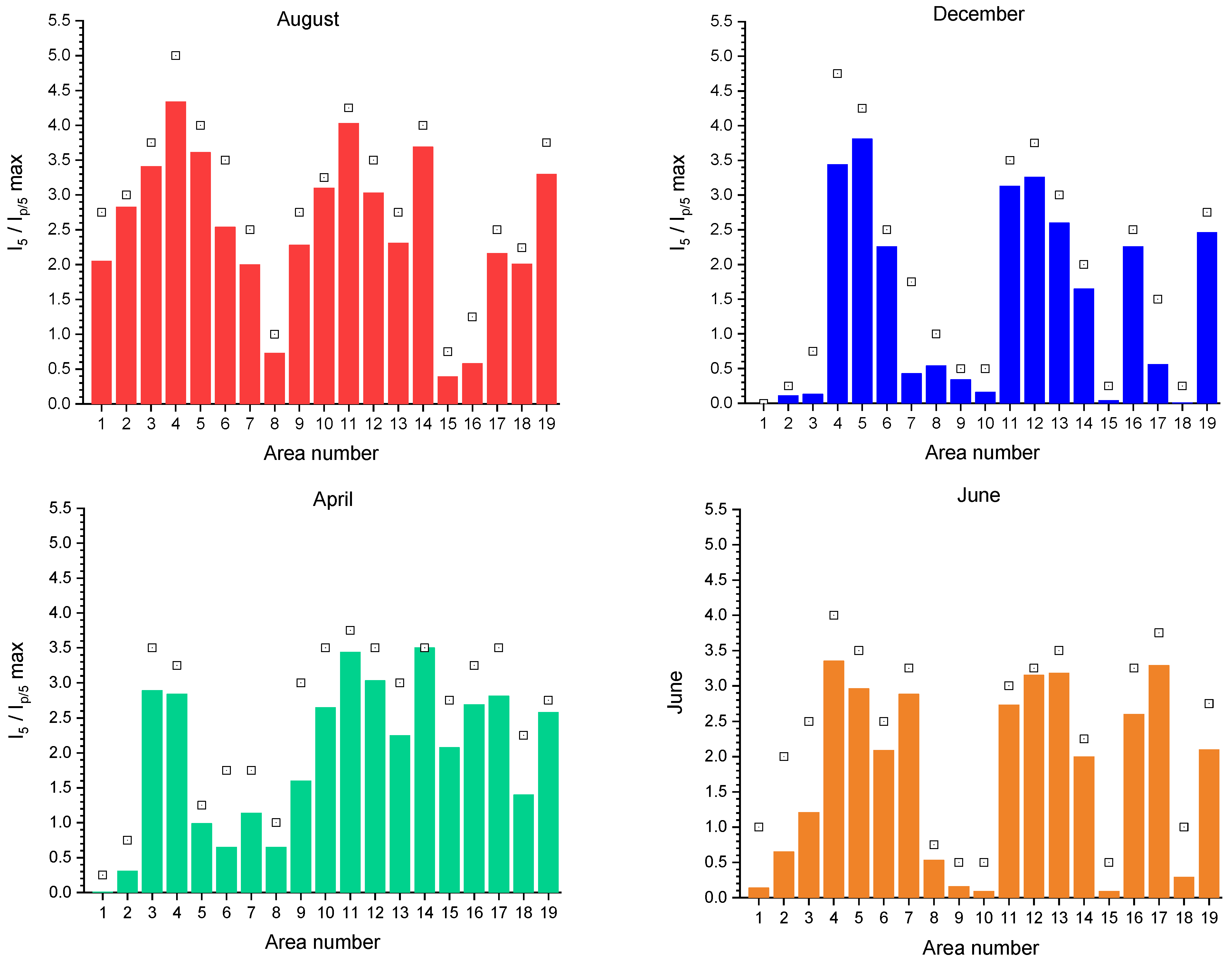

3. Results and Discussion

3.1. Odour Intensity

3.1.1. Road Approaching the Sorting Facility, Areas 1 and 2

3.1.2. Location between Sorting and the CCCF Facility for Mixed Municipal Solid Waste, Area 3

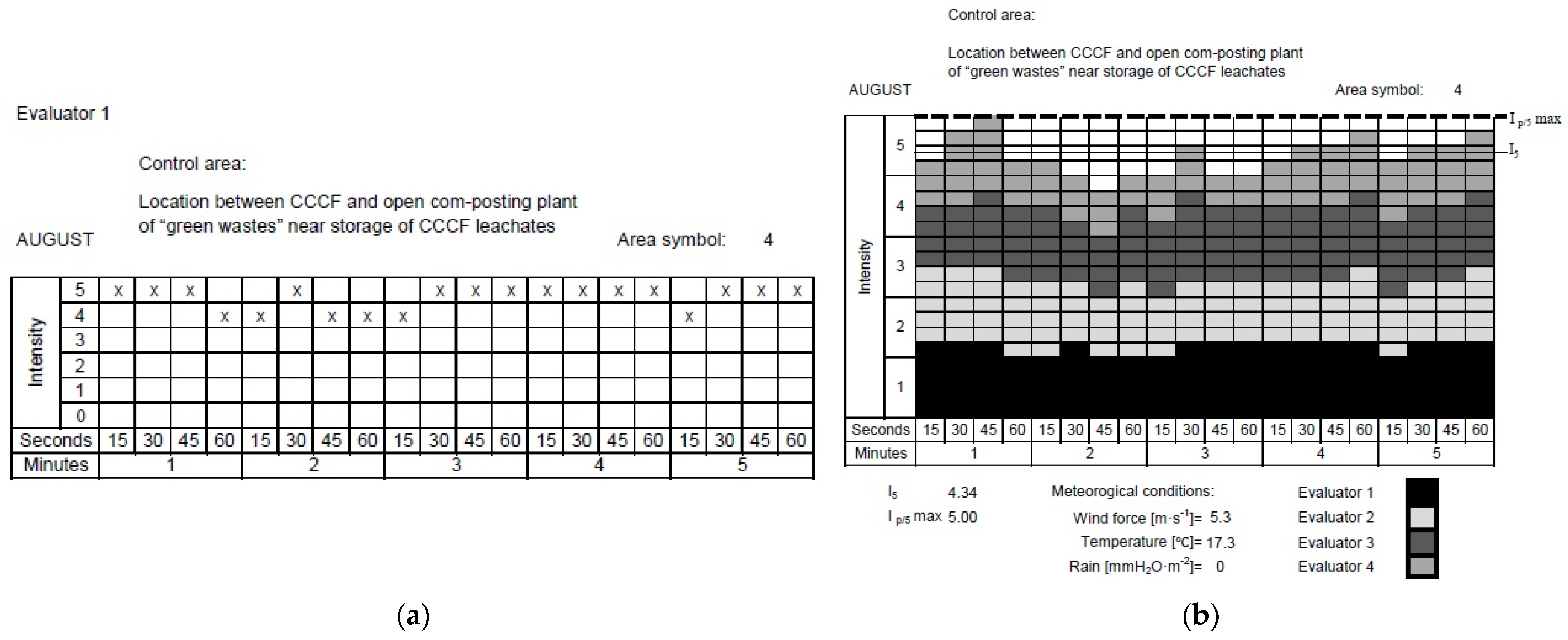

3.1.3. Place between CCCF and the Open Composting Facility for “Green Wastes” near the Storage of CCCF Leachates, Area 4

3.1.4. Open Composting Plant for “Green Wastes”, Areas 5, 6 and 7

3.1.5. Homogenous Waste Dumping Region, Area 8

3.1.6. Landfill Site B1, Areas 9 and 10

3.1.7. Landfill Site B2, Areas 11, 12, 13 and 14

3.1.8. The Road around Landfill Site B2, Areas 15 and 16

3.1.9. Pumping Plant for Wastewater and Landfill Leachates, Area 17

3.1.10. Landfill–Gas Power Station, Area 18

3.1.11. CCCF Biological Filter, Area 19

3.2. Odour Concentrations

- Landfill site B1 (areas 11, 12, and 13);

- The place between the closed-chamber composting facility (CCCF) and the open composting plant for “green wastes” near the storage of CCCF leachates (area 4); this was caused mainly by leachates from the CCCF, and the technological operations associated with the flipping of compost during aeration process;

- The open composting plant of “green wastes” (areas 5, 6 and 7), especially during the flipping of compost in the process of aeration during the summer–autumn period;

- In these locations, the average intensities (I5) and Ip/5max reached a value above 4, which is equivalent to strong intensity. Field tests conducted during August, December, April, and June under different climatic conditions confirm the major sources of odorants. The average intensities for the five-minute period (I5) and the maximum temporary intensity (Ip/5max) achieved in these areas showed the highest values, irrespective of temperature and wind direction;

- A significant increase in the averaged I5 and the maximum temporary intensity (Ip/5max) took place during technological operations, especially those conducted in Area 4 (the flipping of compost during the aeration process). The landfill site B1 was subject to modernization during the performance of the measurements. Uncertainty remains as to how modernization (e.g., the drilling new degasification wells along the landfill edges) will affect the situation in the middle of the deposition point, area 11. The answer could be found through repetition of the tests sometime after landfill modernization. The application of the presented method is limited by changing atmospheric conditions.

4. Conclusions

- action should be taken to degasify landfill site B1, especially near its edges;

- the frequency of compost flipping operations (i.e., intensification of the aeration process) of “green wastes” in open composting plants should be increased in order to avoid rotting.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chukwu, T.M.; Morse, S.; Murphy, R. Poor Air Quality in Urban Settings: A Comparison of Perceptual Indicators, Causes and Management in Two Cities. Sustainability 2022, 14, 1438. [Google Scholar] [CrossRef]

- Perera, F.P. Commentary Multiple Threats to Child Health from Fossil Fuel Combustion: Impacts of Air Pollution and Climate Change. Environ. Health Perspect. 2017, 125, 141–148. [Google Scholar] [CrossRef]

- Schlegelmilch, M.; Streese, J.; Stegmann, R. Odour Management and Treatment Technologies: An Overview. Waste Manag. 2005, 25, 928–939. [Google Scholar] [CrossRef]

- Brattoli, M.; de Gennaro, G.; de Pinto, V.; Loiotile, A.D.; Lovascio, S.; Penza, M. Odour Detection Methods: Olfactometry and Chemical Sensors. Sensors 2011, 11, 5290. [Google Scholar] [CrossRef] [PubMed]

- Brancher, M.; Grif, K.D.; Franco, D.; de Melo, H. A Review of Odour Impact Criteria in Selected Countries around the World. Chemosphere 2017, 168, 1531–1570. [Google Scholar] [CrossRef]

- Mielcarek, P.; Rzeźnik, W. Odor Emission Factors from Livestock Production. Pol. J. Environ. Stud. 2015, 24, 27–35. [Google Scholar] [CrossRef]

- El-Fadel, M.; Findikakis, A.N.; Leckie, J.O. Environmental Impacts of Solid Waste Landfilling. J. Environ. Manag. 1997, 50, 1–25. [Google Scholar] [CrossRef]

- Scaglia, B.; Orzi, V.; Artola, A.; Font, X.; Davoli, E.; Sanchez, A.; Adani, F. Odours and Volatile Organic Compounds Emitted from Municipal Solid Waste at Different Stage of Decomposition and Relationship with Biological Stability. Bioresour. Technol. 2011, 102, 4638–4645. [Google Scholar] [CrossRef]

- Downey, L.; Van Willigen, M. Environmental Stressors: The Mental Health Impacts of Living near Industrial Activity. J. Health Soc. Behav. 2005, 46, 289–305. [Google Scholar] [CrossRef] [PubMed]

- Fang, J.-J.; Yang, N.; Cen, D.-Y.; Shao, L.-M.; He, P.-J. Odor Compounds from Different Sources of Landfill: Characterization and Source Identification. Waste Manag. 2012, 32, 1401–1410. [Google Scholar] [CrossRef]

- Laor, Y.; Orenstein, P.; Ravid, U.; Baybikov, R.; Hanan, A.; Saadi, I.; Abbou, Y. A Screening Tool for Selection of Field Odor Assessors. J. Air Waste Manag. Assoc. 2011, 61, 1353–1360. [Google Scholar] [CrossRef] [PubMed]

- Moreno, A.I.; Arnáiz, N.; Font, R.; Carratalá, A. Chemical Characterization of Emissions from a Municipal Solid Waste Treatment Plant. Waste Manag. 2014, 34, 2393–2399. [Google Scholar] [CrossRef] [PubMed]

- Lim, J.H.; Cha, J.S.; Kong, B.J.; Baek, S.H. Characterization of Odorous Gases at Landfill Site and in Surrounding Areas. J. Environ. Manag. 2018, 206, 291–303. [Google Scholar] [CrossRef]

- Wang, Y.; Li, L.; Qiu, Z.; Yang, K.; Han, Y.; Chai, F.; Li, P.; Wang, Y. Trace Volatile Compounds in the Air of Domestic Waste Landfill Site: Identification, Olfactory Effect and Cancer Risk. Chemosphere 2021, 272, 129582. [Google Scholar] [CrossRef]

- Roy, S.; Basak, D.; Bose, A.; Chowdhury, I.R. Citizens’ Perception towards Landfill Exposure and Its Associated Health Effects: A PLS-SEM Based Modeling Approach. Environ. Monit. Assess. 2023, 195, 134. [Google Scholar] [CrossRef]

- Szałata, Ł.; Zwoździak, J.; Majrernik, M.; Cierniak-Emerych, A.; Jarossová, M.; Dziuba, S.; Knošková, L.; Drábik, P. Assessment of the Odour Quality of the Air Surrounding a Landfill Site: A Case Study. Sustainability 2021, 13, 1713. [Google Scholar] [CrossRef]

- Belpomme, D.; Irigaray, P.; Hardell, L.; Clapp, R.; Montagnier, L. The Multitude and Diversity of Environmental Carcinogens. Environ. Res. 2007, 105, 414–429. [Google Scholar] [CrossRef]

- Del, R.; Sironi, S.; Capelli, L.; Ce, P.; Il, M. Odour Emission Factors for the Prediction of Odour Emissions from Plants for the Mechanical and Biological Treatment of MSW. Atmos. Environ. 2006, 40, 7632–7643. [Google Scholar] [CrossRef]

- Sironi, S.; Capelli, L.; Céntola, P.; Del Rosso, R.; Il Grande, M. Odour Emission Factors for Assessment and Prediction of Italian MSW Landfills Odour Impact. Atmos. Environ. 2005, 39, 5387–5394. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. The Impact of Technological Processes on Odorant Emissions at Municipal Waste Biogas Plants. Sustainability 2020, 12, 5457. [Google Scholar] [CrossRef]

- Szynkowska, I.; Zwoździak, J. Współczesna Problematyka Odorów; Wydawnictwo Naulowo-Techniczne: Warsaw, Poland, 2010. [Google Scholar]

- Szałata, Ł. Impact of Implementing a Deodorization System on the Functioning of a Waste Management Plant. Sustainability 2020, 13, 5983. [Google Scholar] [CrossRef]

- Pierucci, P.; Porazzi, E.; Martinez, M.P.; Adani, F.; Carati, C.; Rubino, F.M.; Colombi, A.; Calcaterra, E.; Benfenati, E. Volatile Organic Compounds Produced during the Aerobic Biological Processing of Municipal Solid Waste in a Pilot Plant. Chemosphere 2005, 59, 423–430. [Google Scholar] [CrossRef]

- Palmiotto, M.; Fattore, E.; Paiano, V.; Celeste, G.; Colombo, A.; Davoli, E. Influence of a Municipal Solid Waste Landfill in the Surrounding Environment: Toxicological Risk and Odor Nuisance Effects. Environ. Int. 2014, 68, 16–24. [Google Scholar] [CrossRef]

- Gao, S.; Zhao, P.; Li, Y.; Hu, J.; Zhou, S.; Zhang, H.; Wu, J.; Jiao, Z.; Wang, S.; Fu, Q.; et al. Characterization and Influence of Odorous Gases on the Working Surface of a Typical Landfill Site: A Case Study in a Chinese Megacity. Atmos. Environ. 2021, 262, 118628. [Google Scholar] [CrossRef]

- Duan, Z.; Scheutz, C.; Kjeldsen, P. Trace Gas Emissions from Municipal Solid Waste Landfills: A Review. Waste Manag. 2021, 119, 39–62. [Google Scholar] [CrossRef] [PubMed]

- Pagans, E.; Font, X.; Sánchez, A. Emission of Volatile Organic Compounds from Composting of Different Solid Wastes: Abatement by Biofiltration. J. Hazard. Mater. 2006, 131, 179–186. [Google Scholar] [CrossRef]

- Young, P.; Parker, A. The Identification and Possible Environmental Impact of Trace Gases and Vapours in Landfill Gas. Waste Manag. Res. 1983, 1, 213–226. [Google Scholar] [CrossRef]

- Romain, A.-C.; Delva, J.; Nicolas, J. Complementary Approaches to Measure Environmental Odours Emitted by Landfill Areas. Sens. Actuators B Chem. 2008, 131, 18–23. [Google Scholar] [CrossRef]

- Duan, Z.; Kjeldsen, P.; Scheutz, C. Trace Gas Composition in Landfill Gas at Danish Landfills Receiving Low-Organic Waste. Waste Manag. 2021, 122, 113–123. [Google Scholar] [CrossRef] [PubMed]

- Capelli, L.; Sironi, S.; Del Rosso, R.; Céntola, P.; Il Grande, M. A Comparative and Critical Evaluation of Odour Assessment Methods on a Landfill Site. Atmos. Environ. 2008, 42, 7050–7058. [Google Scholar] [CrossRef]

- Davoli, E.; Gangai, M.L.; Morselli, L.; Tonelli, D. Characterisation of Odorants Emissions from Landfills by SPME and GC/MS. Chemosphere 2003, 51, 357–368. [Google Scholar] [CrossRef] [PubMed]

- Dincer, F.; Odabasi, M.; Muezzinoglu, A. Chemical Characterization of Odorous Gases at a Landfill Site by Gas Chromatography-Mass Spectrometry. J. Chromatogr. A 2006, 1122, 222–229. [Google Scholar] [CrossRef]

- Senante, E.; Galtier, L.; Békaert, C.; Lambolez-Michael, L.; Budka, A. Odour Management at MSW Landfill Sites: Odours Sources, Odorous Compounds and Control Measures. In Proceedings of the 9th International Waste Management & Landfill Symposium, Pula, Italy, 9–13 October 2003; pp. 1623–1633. [Google Scholar]

- Gostelow, P.; Parsons, S.A.; Stuetz, R.M. Odour Measurements for Sewage Treatment Works. Water Res. 2001, 35, 579–597. [Google Scholar] [CrossRef] [PubMed]

- Stuetz, R.M.; Fenner, R.A.; Engin, G. Assessment of Odours from Sewage Treatment Works by an Electronic Nose, H2S Analysis and Olfactometry. Water Res. 1999, 33, 453–461. [Google Scholar] [CrossRef]

- Turek, P. Recruiting, Training and Managing a Sensory Panel in Odor Nuisance Testing. PLoS ONE 2021, 16, e0258057. [Google Scholar] [CrossRef] [PubMed]

- Capelli, L.; Sironi, S.; Del Rosso, R.; Guillot, J.M. Measuring Odours in the Environment vs. Dispersion Modelling: A Review. Atmos. Environ. 2013, 79, 731–743. [Google Scholar] [CrossRef]

- Hayes, J.E.; Stevenson, R.J.; Stuetz, R.M. The Impact of Malodour on Communities: A Review of Assessment Techniques. Sci. Total Environ. 2014, 500–501, 395–407. [Google Scholar] [CrossRef]

- Muñoz, R.; Sivret, E.C.; Parcsi, G.; Lebrero, R.; Wang, X.; Suffet, I.H.M.; Stuetz, R.M. Monitoring Techniques for Odour Abatement Assessment. Water Res. 2010, 44, 5129–5149. [Google Scholar] [CrossRef]

- Kim, K.H.; Park, S.Y. A Comparative Analysis of Malodor Samples between Direct (Olfactometry) and Indirect (Instrumental) Methods. Atmos. Environ. 2008, 42, 5061–5070. [Google Scholar] [CrossRef]

- Dravnieks, A.; Jarke, F. Odor Threshold Measurement by Dynamic Olfactometry: Significant Operational Variables. J. Air Pollut. Control Assoc. 1980, 30, 1284–1289. [Google Scholar] [CrossRef]

- Kośmider, J.; Krajewska, B. Determining Temporary Odour Concentration under Field Conditions—Comparison of Methods. Pol. J. Environ. Stud. 2007, 16, 215–225. [Google Scholar]

- Jacobson, L.D.; Hetchler, B.P.; Schmidt, D.R.; Nicolai, R.E.; Heber, A.J.; Ni, J.-Q.; Hoff, S.J.; Koziel, J.A.; Zhang, Y.; Beasley, D.B.; et al. Quality Assured Measurements of Animal Building Emissions: Odor Concentrations. J. Air Waste Manag. Assoc. 2008, 58, 806–811. [Google Scholar] [CrossRef] [PubMed]

- Tansel, B.; Inanloo, B. Odor Impact Zones around Landfills: Delineation Based on Atmospheric Conditions and Land Use Characteristics. Waste Manag. 2019, 88, 39–47. [Google Scholar] [CrossRef] [PubMed]

- EN 13725:2003; Air Quality. Determination of Odour Concentration by Dynamic Olfactometry. Slovenski Inštitut za Standardizacijo: Ljubljana, Slovenia, 2003.

- Izabela, S.; Pawnuk, M.; Miller, U.; Grzelka, A.; Wroniszewska, A.; Bezyk, Y. Assessment of the Odour Impact Range of a Selected Agricultural Processing Plant. Sustainability 2020, 12, 7289. [Google Scholar] [CrossRef]

- Bliss, P.J.; Schultz, T.J.; Senger, T.; Kaye, R.B. Odour Measurement—Factors Affecting Olfactometry Panel Performance. Water Sci. Technol. 1996, 34, 549–556. [Google Scholar] [CrossRef]

- Henry, C.G.; Schulte, D.D.; Hoff, S.J.; Jacobson, L.D.; Parkhurst, A.M. Comparison of Ambient Odor Assessment. Techniques in a Controlled Environment. Trans. ASABE 2011, 54, 1866–1872. [Google Scholar] [CrossRef]

- McGinley, M.; McGinley, C. Comparison of Field Olfactometers in a Controlled Chamber Using Hydrogen Sulfide as the Test Odorant. Water Sci. Technol. 2004, 50, 75–82. [Google Scholar] [CrossRef]

- Rappert, S.; Müller, R. Odor Compounds in Waste Gas Emissions from Agricultural Operations and Food Industries. Waste Manag. 2005, 25, 887–907. [Google Scholar] [CrossRef]

- Szyłak-Szydłowski, M. Odour Samples Degradation During Detention in Tedlar® Bags. Water Air Soil Pollut. 2015, 226, 227. [Google Scholar] [CrossRef][Green Version]

- Szyłak-Szydłowski, M. Comparison of Two Types of Field Olfactometers for Assessing Odours in Laboratory and Field Tests. Chem. Eng. Trans. 2014, 40, 67–72. [Google Scholar] [CrossRef]

- Trabue, S.; Scogging, K.; McConnell, L.; Maghirang, R.; Razote, E.; Hatfield, J. Identifying and Tracking Key Odorants from Cattle Feedlots. Atmos. Environ. 2011, 45, 4243–4251. [Google Scholar] [CrossRef]

- Zhang, Y.; Ning, X.; Li, Y.; Wang, J.; Cui, H.; Meng, J.; Teng, C.; Wang, G.; Shang, X. Impact Assessment of Odor Nuisance, Health Risk and Variation Originating from the Landfill Surface. Waste Manag. 2021, 126, 771–780. [Google Scholar] [CrossRef]

- Lucernoni, F.; Capelli, L.; Sironi, S. Comparison of Different Approaches for the Estimation of Odour Emissions from Landfill Surfaces. Waste Manag. 2016, 63, 345–353. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, W.; Schauberger, G.; Wang, J.; Geng, J.; Wang, G.; Meng, J. Determination of Dose-Response Relationship to Derive Odor Impact Criteria for a Wastewater Treatment Plant. Atmosphere 2021, 12, 371. [Google Scholar] [CrossRef]

- Tagliaferri, F.; Invernizzi, M.; Sironi, S.; Capelli, L. Influence of Modelling Choices on the Results of Landfill Odour Dispersion. Detritus 2020, 12, 92–99. [Google Scholar] [CrossRef]

- Pawnuk, M.; Sówka, I.; Naddeo, V. The Use of Field Olfactometry in the Odor Assessment of a Selected Mechanical–Biological Municipal Waste Treatment Plant within the Boundaries of the Selected Facility—A Case Study. Sustainability 2023, 15, 7163. [Google Scholar] [CrossRef]

- Eyckmans, J.; De Jaeger, S.; Rousseau, S. Hedonic Valuation of Odor Nuisance Using Field Measurements: A Case Study of an Animal Waste Processing Facility in Flanders. Econ. Manag. 2011, 19, 53–75. [Google Scholar] [CrossRef]

- Van Langenhove, H.; Van Broeck, G. Applicability of Sniffing Team Observations: Experience of Field Measurements. Water Sci. Technol. 2001, 44, 65–70. [Google Scholar] [CrossRef]

- Van Elst, T.; Delva, J. The European Standard Pren 16841-2 (Determination of Odour in Ambient Air by Using Field Inspection: Plume Method): A Review of 20 Years Experience with the Method in Belgium. Chem. Eng. Trans. 2016, 54, 175–180. [Google Scholar] [CrossRef]

- Sówka, I. Metody Identyfikacji Odorotwórczych Gazów Emitowanych z Obiektów Przemysłowych. In Prace Naukowe Instytutu Inżynierii Ochrony Środowiska Politechniki Wrocławskiej; Oficyna Wydawnicza Politechniki Wrocławskiej: Wroclaw, Poland, 2011; pp. 1–90. [Google Scholar]

- Nicolas, J.; Craffe, F.; Romain, A.C. Estimation of Odor Emission Rate from Landfill Areas Using the Sniffing Team Method. Waste Manag. 2006, 26, 1259–1269. [Google Scholar] [CrossRef][Green Version]

- Lebrero, R.; Bouchy, L.; Stuetz, R.; Munoz, R. Odor Assessment and Management in Wastewater Treatment Plants: A Review. Crit. Rev. Environ. Sci. Technol. 2011, 41, 915–950. [Google Scholar] [CrossRef]

- Mazhitov, D.; Ermilova, M.; Altukhova, E.; Maksimova, T.; Zhdanova, O. Development of Technologies and Processes in Environmental Management. E3S Web Conf. 2019, 135, 1–7. [Google Scholar] [CrossRef]

- Kośmider, J.; Krajewska, B. Odor Air Quality Standards and Precision of Odor Intensity Assessments. Pol. J. Environ. Stud. 2004, 13, 87. [Google Scholar]

- Hansen, M.J.; Jonassen, K.E.N.; Marie, M.; Peter, A.; Adamsen, S.; Feilberg, A. Multivariate Prediction of Odor from Pig Production Based on In-Situ Measurement of Odorants. Atmos. Environ. 2016, 135, 50–58. [Google Scholar] [CrossRef]

- Bian, Y.; Gong, H.; Suffet, I.H. The Use of the Odor Profile Method with an “Odor Patrol” Panel to Evaluate an Odor Impacted Site near a Landfill. Atmosphere 2021, 12, 472. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. Olfactometric Testing as a Method for Assessing Odour Nuisance of Biogas Plants Processing Municipal Waste. Arch. Environ. Prot. 2020, 46, 60–68. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. Odour Emissions of Municipal Waste Biogas Plants-Impact of Technological Factors, Air Temperature and Humidity. Appl. Sci. 2020, 10, 1093. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Szyłak-Szydłowski, M. The Air and Sewage Pollutants from Biological Waste Treatment. Processes 2021, 9, 250. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. The Use of Chemical Sensors to Monitor Odour Emissions at Municipal Waste Biogas Plants. Appl. Sci. 2021, 11, 3916. [Google Scholar] [CrossRef]

| Control Area | Area Number | Month | Meteorological Conditions | |

|---|---|---|---|---|

| Wind Speed [m/s] | Temperature [°C] | |||

| Road approaching the sorting facility | 1 | August | 6.7 | 16.5 |

| December | 2.7 | −5.2 | ||

| April | 3.8 | 10 | ||

| June | 4.7 | 21 | ||

| 2 | August | 5.9 | 16.8 | |

| December | 3.5 | −5.2 | ||

| April | 3.9 | 11 | ||

| June | 3.4 | 21 | ||

| Location between sorting and the CCCF of mixed municipal solid waste | 3 | August | 6.3 | 16.7 |

| December | 3.2 | −5.1 | ||

| April | 3.9 | 10 | ||

| June | 4 | 21 | ||

| Location between CCCF and the open composting plant for “green wastes” near the storage of CCCF leachates | 4 | August | 5.3 | 17.3 |

| December | 3.3 | −5.0 | ||

| April | 3.7 | 10 | ||

| June | 4.0 | 21 | ||

| Open composting plant for “green wastes” | 5 | August | 7.2 | 16.7 |

| December | 3.2 | −4.9 | ||

| April | 3.6 | 11 | ||

| June | 8.9 | 22 | ||

| 6 | August | 6.9 | 16.9 | |

| December | 2.6 | −4.9 | ||

| April | 3.6 | 11 | ||

| June | 7.7 | 22 | ||

| 7 | August | 6.3 | 16.7 | |

| December | 2.4 | −5.0 | ||

| April | 3.6 | 12 | ||

| June | 4.5 | 22 | ||

| Homogenous waste dumping region | 8 | August | 5.5 | 16.6 |

| December | 2.2 | −4.8 | ||

| April | 3.7 | 12 | ||

| June | 4.2 | 22 | ||

| Landfill site B2 | 9 | August | 6.6 | 16.4 |

| December | 2.4 | −4.9 | ||

| April | 3.7 | 12 | ||

| June | 1.1 | 23 | ||

| 10 | August | 6.5 | 16.6 | |

| December | 1.4 | −4.8 | ||

| April | 3.6 | 13 | ||

| June | 4.6 | 22 | ||

| Landfill site B1 | 11 | August | 4.5 | 16.8 |

| December | 2.1 | −4.9 | ||

| April | 3.7 | 13 | ||

| June | 6.2 | 22 | ||

| 12 | August | 5.2 | 16.8 | |

| December | 1.9 | −4.8 | ||

| April | 3.6 | 14 | ||

| June | 7.4 | 23 | ||

| 13 | August | 6.4 | 16.8 | |

| December | 1.9 | −4.7 | ||

| April | 3.5 | 14 | ||

| June | 3.8 | 23 | ||

| 14 | August | 5.5 | 17.1 | |

| December | 1.7 | −4.7 | ||

| April | 3.6 | 15 | ||

| June | 3.8 | 23 | ||

| Road leading to waste deposition, Location B2 | 15 | August | 5.5 | 17.5 |

| December | 1.6 | −4.8 | ||

| April | 3.6 | 15 | ||

| June | 5.9 | 24 | ||

| 16 | August | 4.9 | 17.8 | |

| December | 1.4 | −4.8 | ||

| April | 3.7 | 15 | ||

| June | 5.1 | 23 | ||

| Pumping plant for wastewater and landfill leachates | 17 | August | 4.7 | 17.7 |

| December | 1.2 | −4.8 | ||

| April | 3.5 | 15 | ||

| June | 4.5 | 23 | ||

| Landfill-gas power station | 18 | August | 4.6 | 18.2 |

| December | 0.8 | −4.8 | ||

| April | 3.7 | 15 | ||

| June | 8.5 | 23 | ||

| CCCF biological filter | 19 | August | 6.7 | 17.5 |

| December | 0.4 | −4.6 | ||

| April | 3.7 | 12 | ||

| June | 8.9 | 22 | ||

| Control Area | Area Number | August | December | April | June | ||||

|---|---|---|---|---|---|---|---|---|---|

| Odour Concentration (Cod) [ou/m3] | |||||||||

| Cod 5 | Cod p/5 max | Cod 5 | Cod p/5 max | Cod 5 | Cod p/5 max | Cod 5 | Cod p/5 max | ||

| Road approaching sorting facility | 1 | 63 | 258 | 1 | 1 | 1 | 2 | 1 | 8 |

| 2 | 304 | 428 | 1 | 2 | 2 | 5 | 4 | 57 | |

| Location between sorting and the CCCF of mixed municipal solid waste | 3 | 980 | 1947 | 1 | 5 | 343 | 1175 | 12 | 156 |

| Location between CCCF and the open composting plant for “green wastes” near the storage of CCCF leachates | 4 | 6412 | 24,320 | 1041 | 14,678 | 310 | 709 | 868 | 3227 |

| Open composting plant for “green wastes” | 5 | 1468 | 3227 | 2198 | 5347 | 7 | 12 | 395 | 1175 |

| 6 | 169 | 1175 | 96 | 156 | 4 | 34 | 68 | 156 | |

| 7 | 57 | 156 | 2 | 34 | 10 | 34 | 336 | 709 | |

| Homogenous waste dumpin region | 8 | 4 | 8 | 3 | 8 | 4 | 8 | 3 | 5 |

| Landfill site B1 | 9 | 100 | 258 | 2 | 3 | 25 | 428 | 1 | 3 |

| 10 | 524 | 709 | 1 | 3 | 211 | 1175 | 1 | 3 | |

| Landfill site B2 | 11 | 3428 | 5347 | 557 | 1175 | 1041 | 1947 | 248 | 428 |

| 12 | 455 | 1175 | 724 | 1947 | 455 | 1175 | 580 | 709 | |

| 13 | 106 | 258 | 191 | 428 | 94 | 428 | 616 | 1175 | |

| 14 | 1725 | 3227 | 28 | 57 | 1175 | 1175 | 57 | 94 | |

| Road around landfill site B2 | 15 | 2 | 5 | 1 | 2 | 67 | 258 | 1 | 3 |

| 16 | 3 | 12 | 96 | 156 | 229 | 709 | 191 | 709 | |

| Pumping plant for wastewater and landfill leachates | 17 | 78 | 156 | 3 | 21 | 292 | 1175 | 769 | 1947 |

| Landfill-gas power station | 18 | 58 | 92 | 1 | 2 | 17 | 94 | 2 | 8 |

| CCCF biological filter | 19 | 785 | 1947 | 144 | 258 | 183 | 258 | 70 | 258 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konkol, I.; Tylingo, R.; Mania, S.; Cenian, A. Odour Perception Using a Sniffing Team at a Municipal Solid Waste Treatment Plant: A Case Study. Sustainability 2023, 15, 12203. https://doi.org/10.3390/su151612203

Konkol I, Tylingo R, Mania S, Cenian A. Odour Perception Using a Sniffing Team at a Municipal Solid Waste Treatment Plant: A Case Study. Sustainability. 2023; 15(16):12203. https://doi.org/10.3390/su151612203

Chicago/Turabian StyleKonkol, Izabela, Robert Tylingo, Szymon Mania, and Adam Cenian. 2023. "Odour Perception Using a Sniffing Team at a Municipal Solid Waste Treatment Plant: A Case Study" Sustainability 15, no. 16: 12203. https://doi.org/10.3390/su151612203

APA StyleKonkol, I., Tylingo, R., Mania, S., & Cenian, A. (2023). Odour Perception Using a Sniffing Team at a Municipal Solid Waste Treatment Plant: A Case Study. Sustainability, 15(16), 12203. https://doi.org/10.3390/su151612203