Performance Improvement Plan towards Energy-Efficient Naturally Ventilated Houses in Tropical Climate Regions

Abstract

1. Introduction

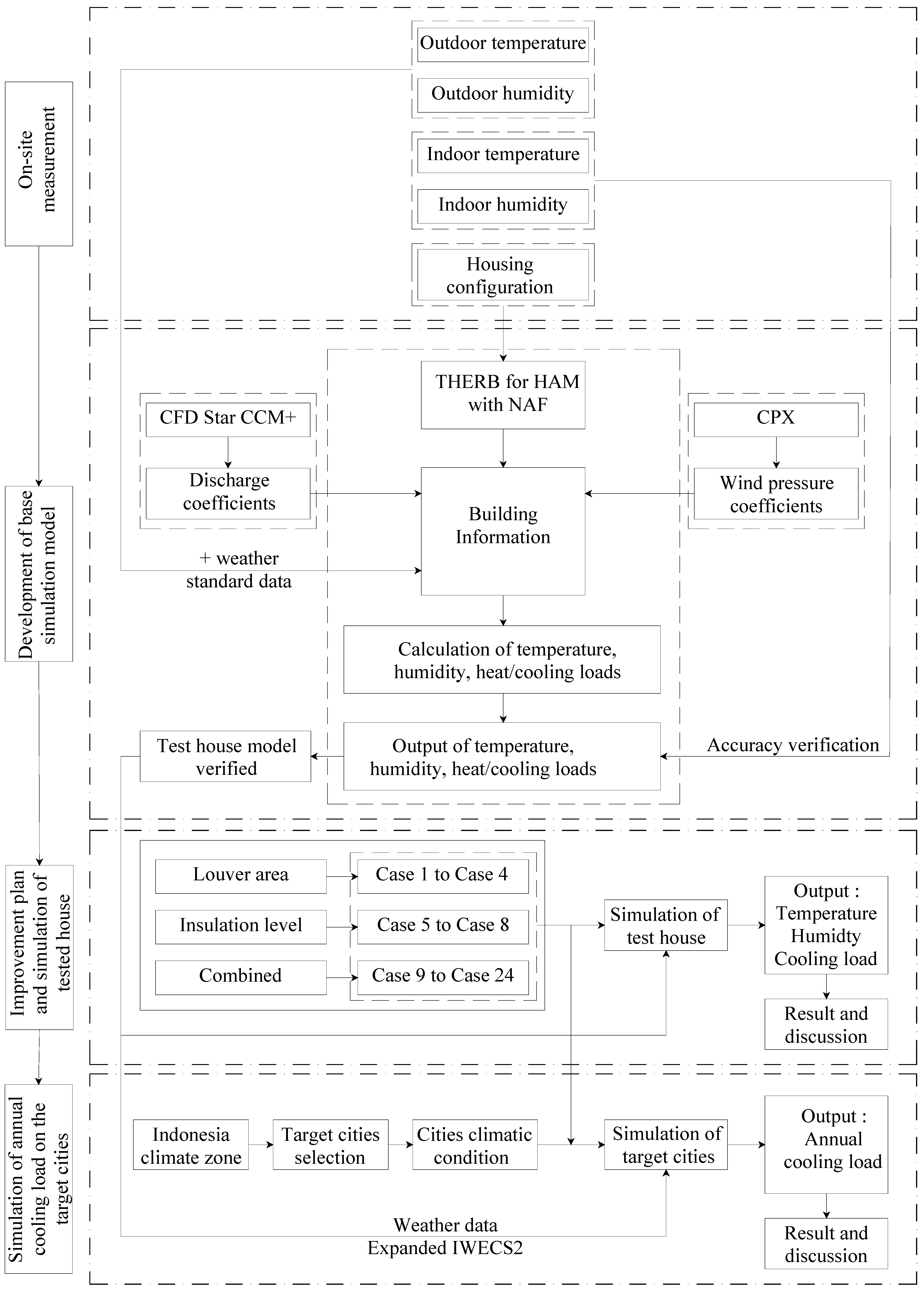

2. Methodology

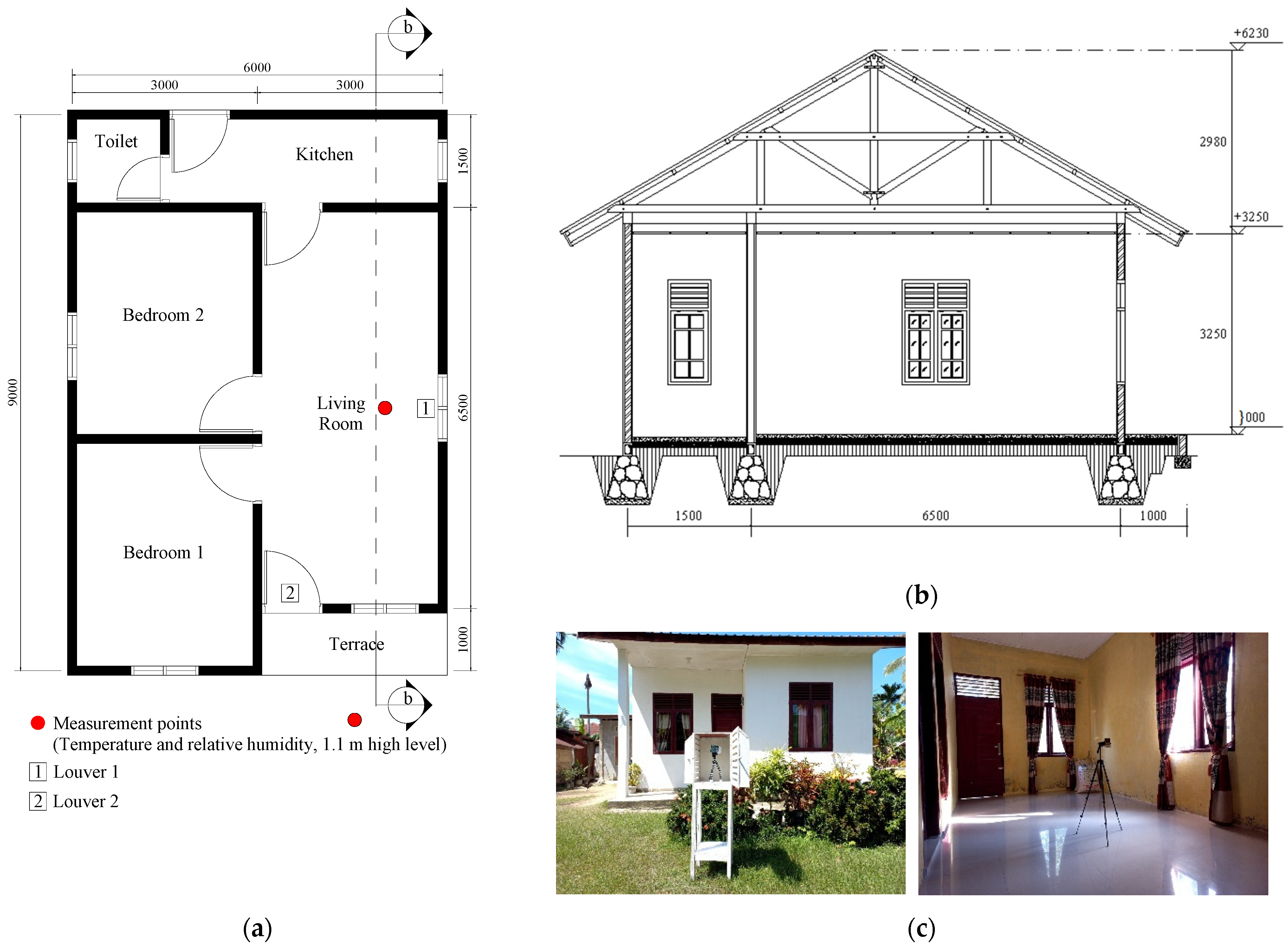

2.1. Overview of the Test House

2.2. Climates, Target Cities, and Calculation Condition

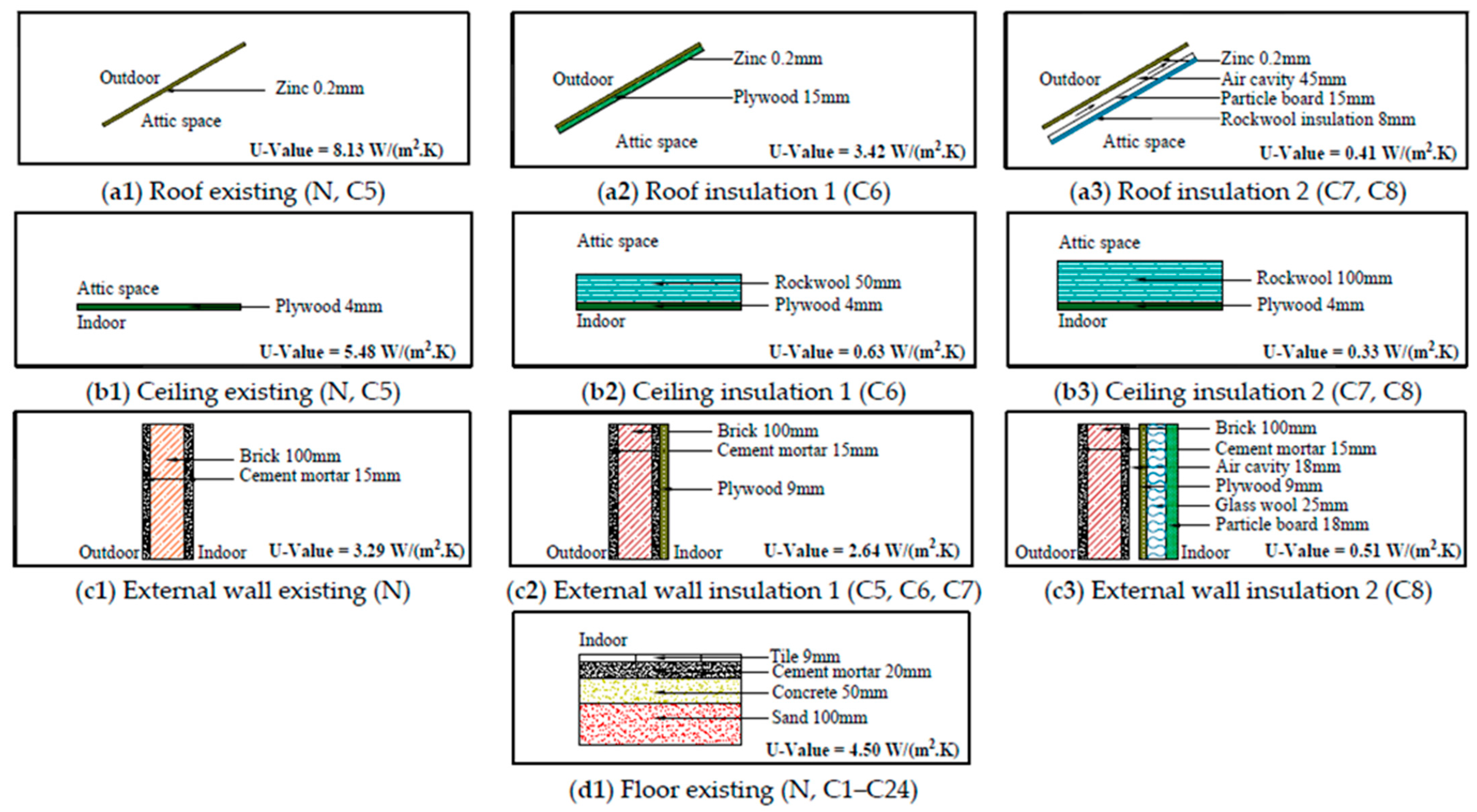

2.3. Improvement Plan

3. Development of the Base Simulation Model

3.1. Discharge Coefficient

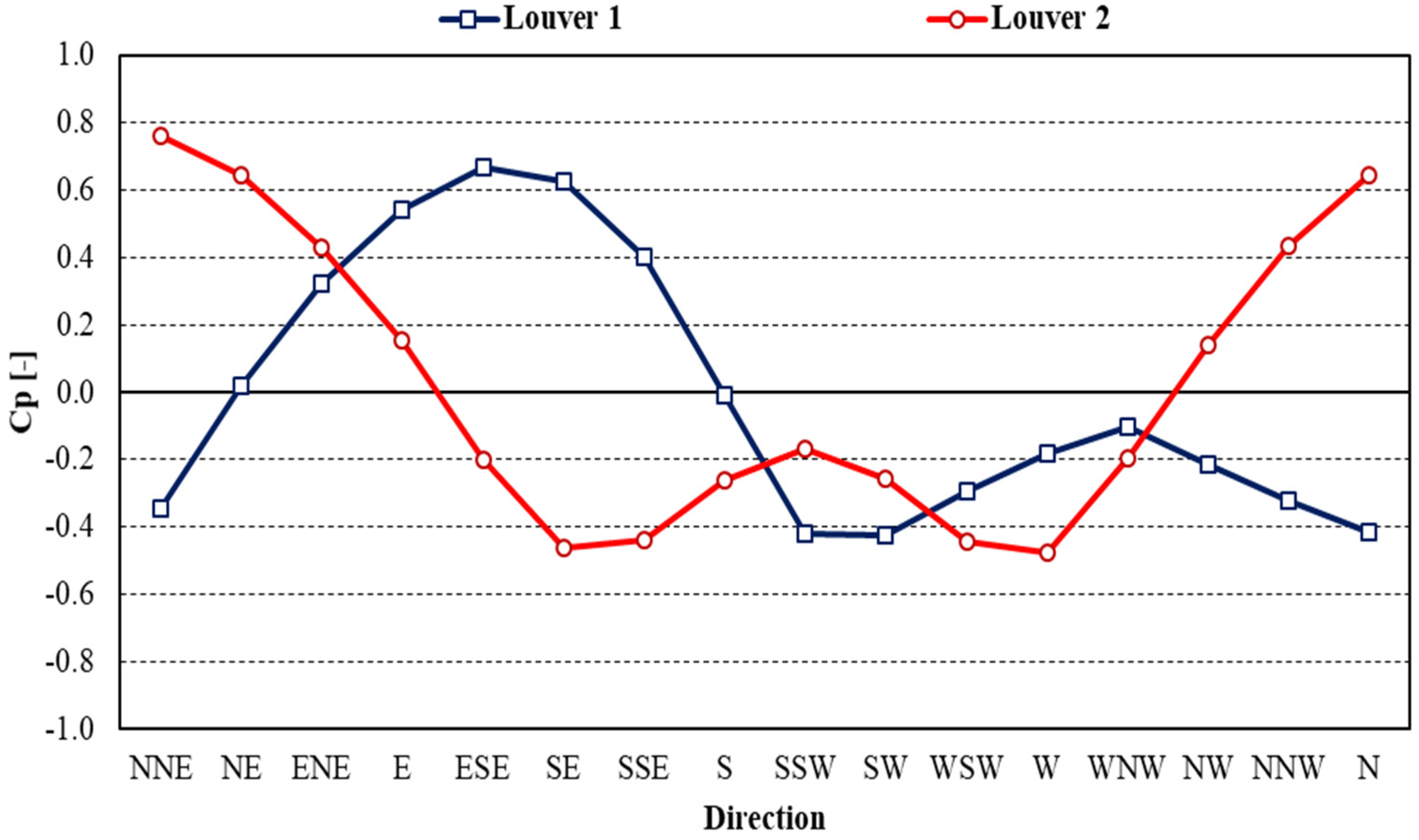

3.2. Wind Pressure Coefficient

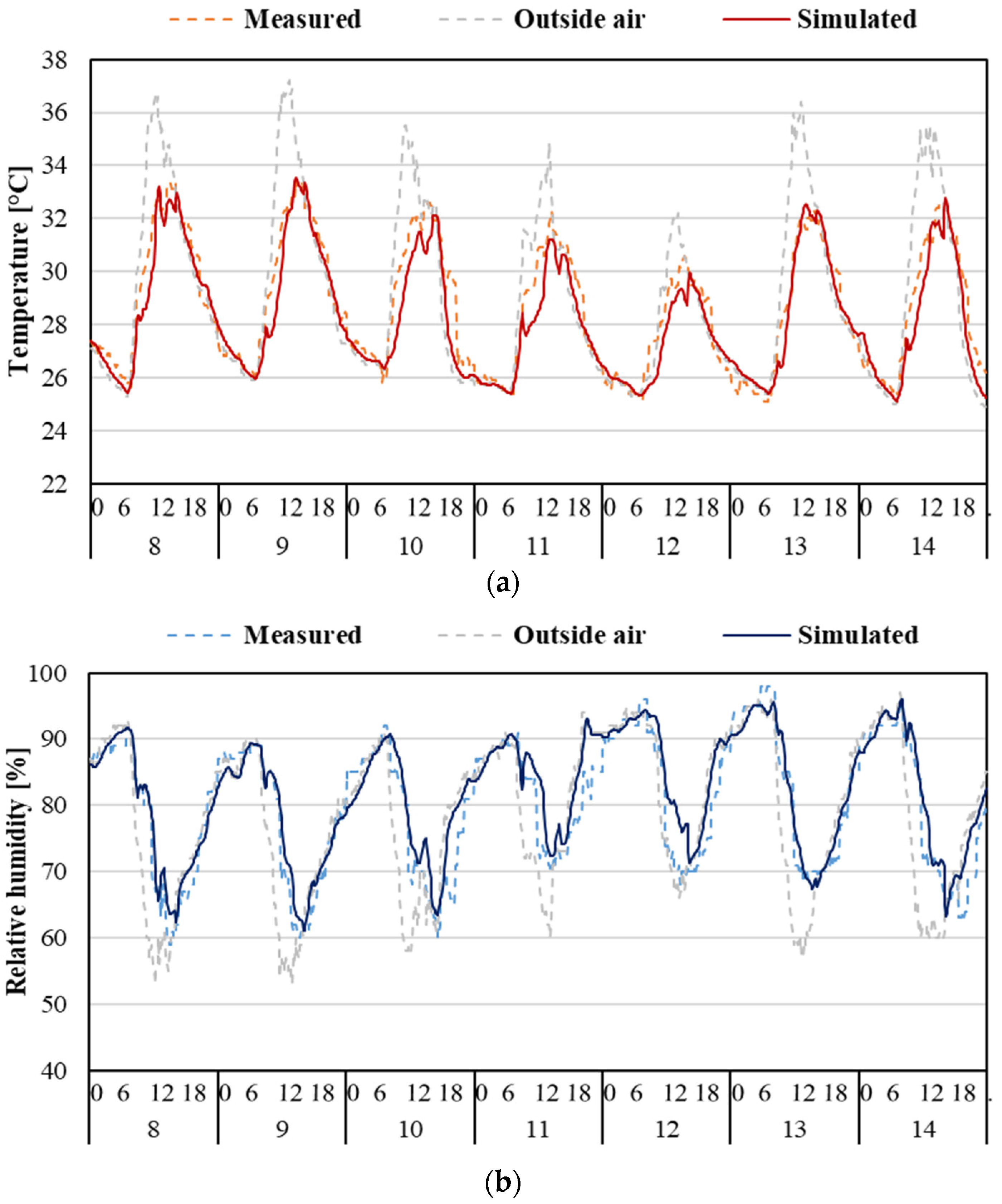

3.3. Simulation Accuracy Verification

4. Simulation Results

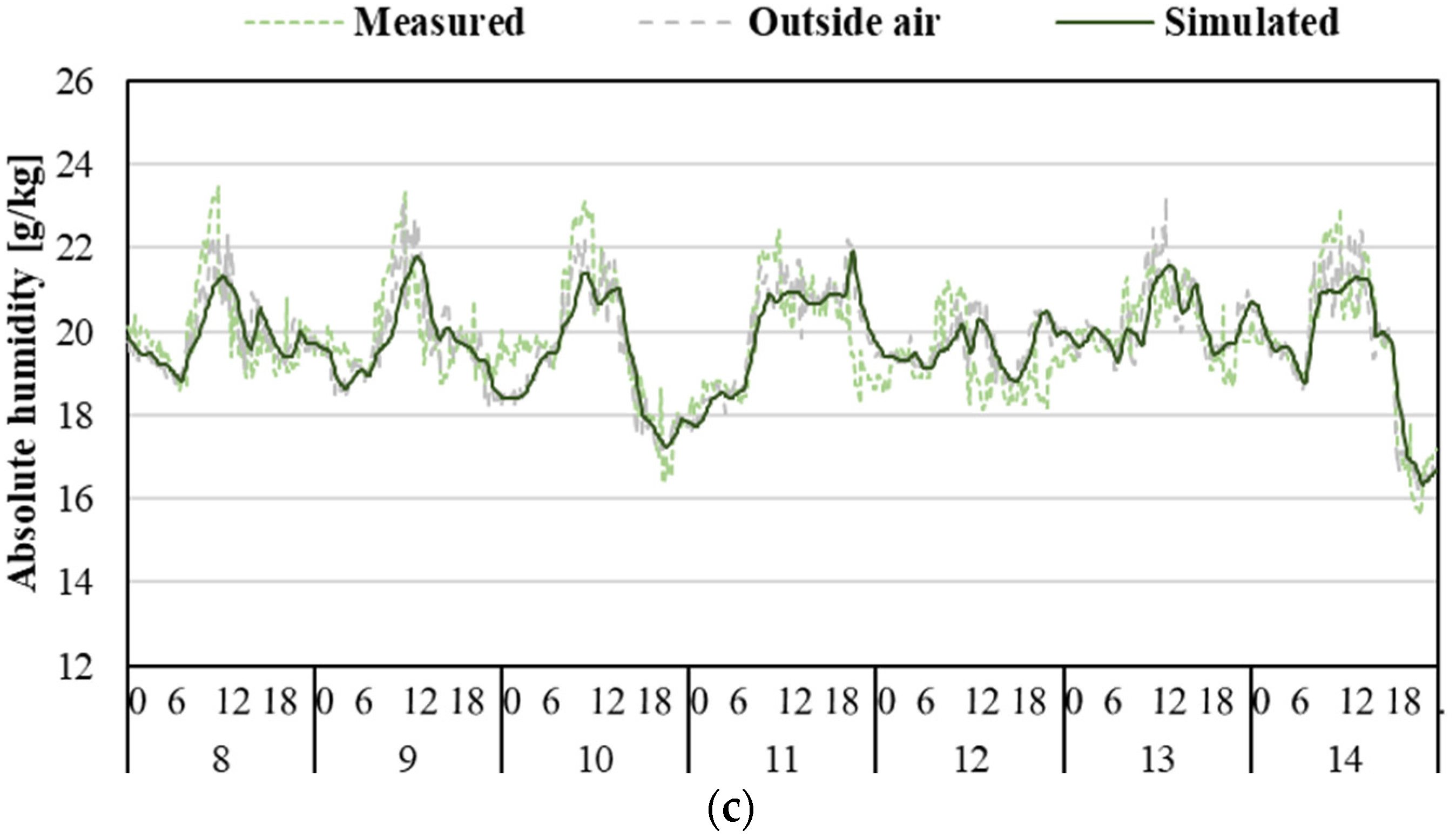

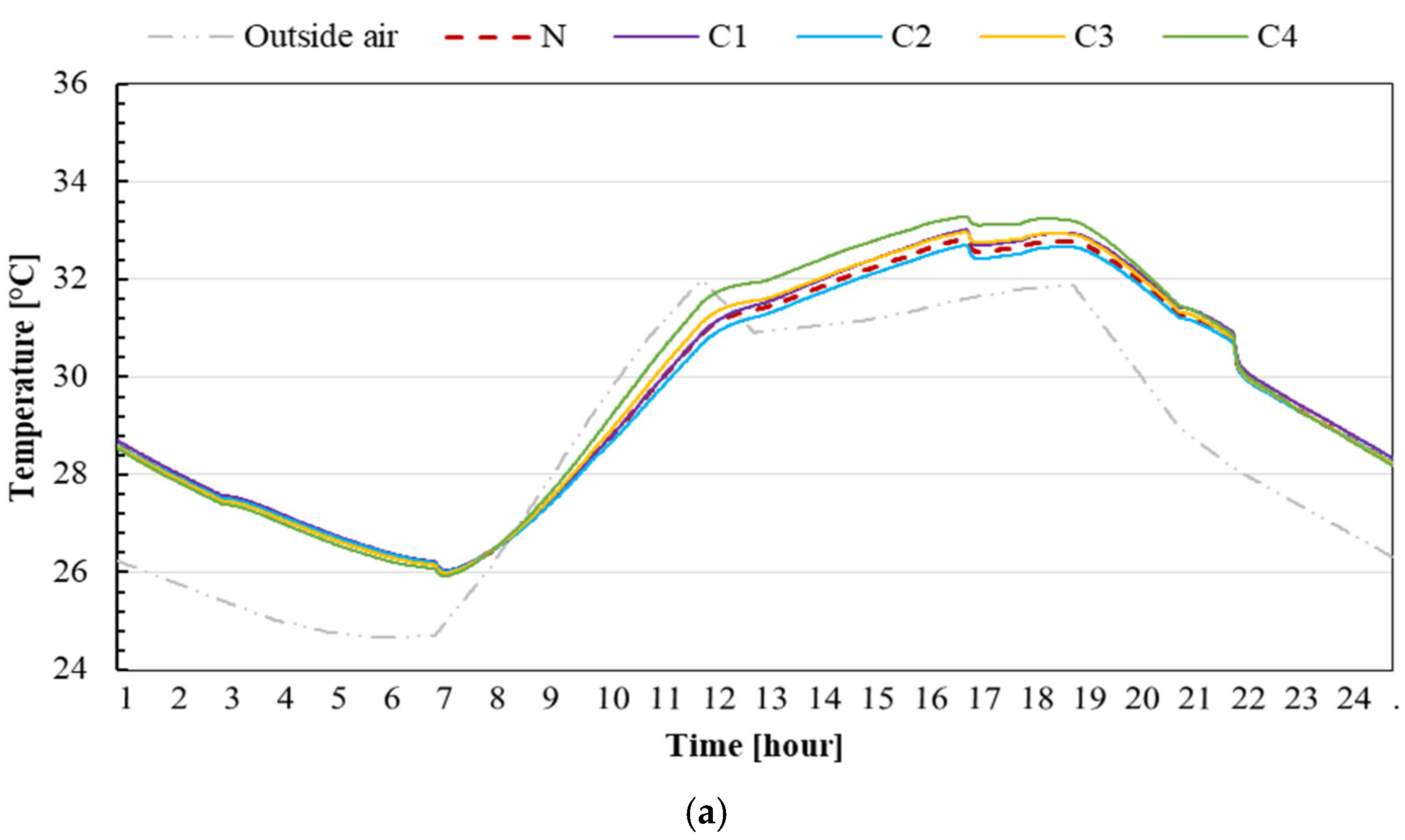

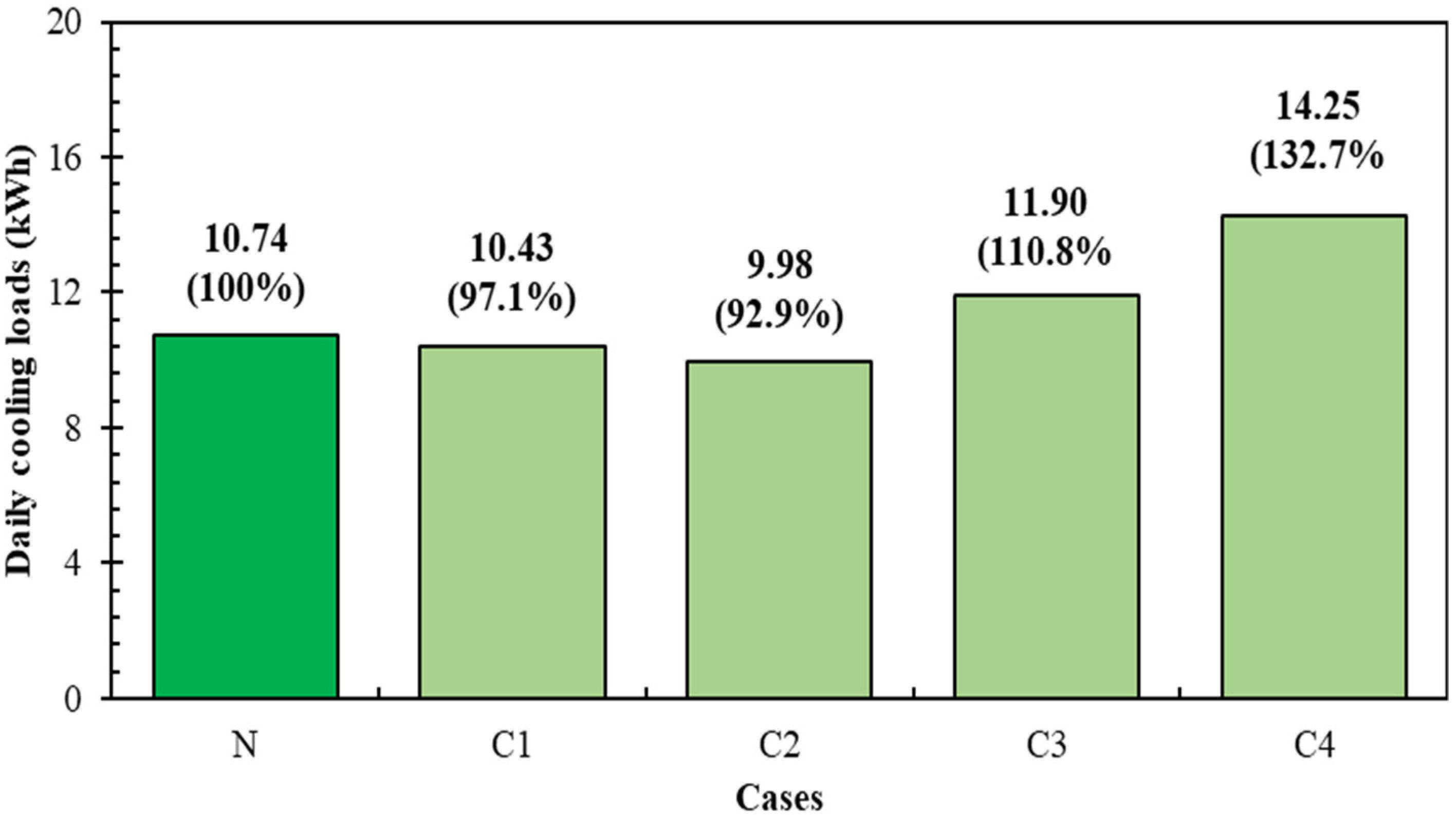

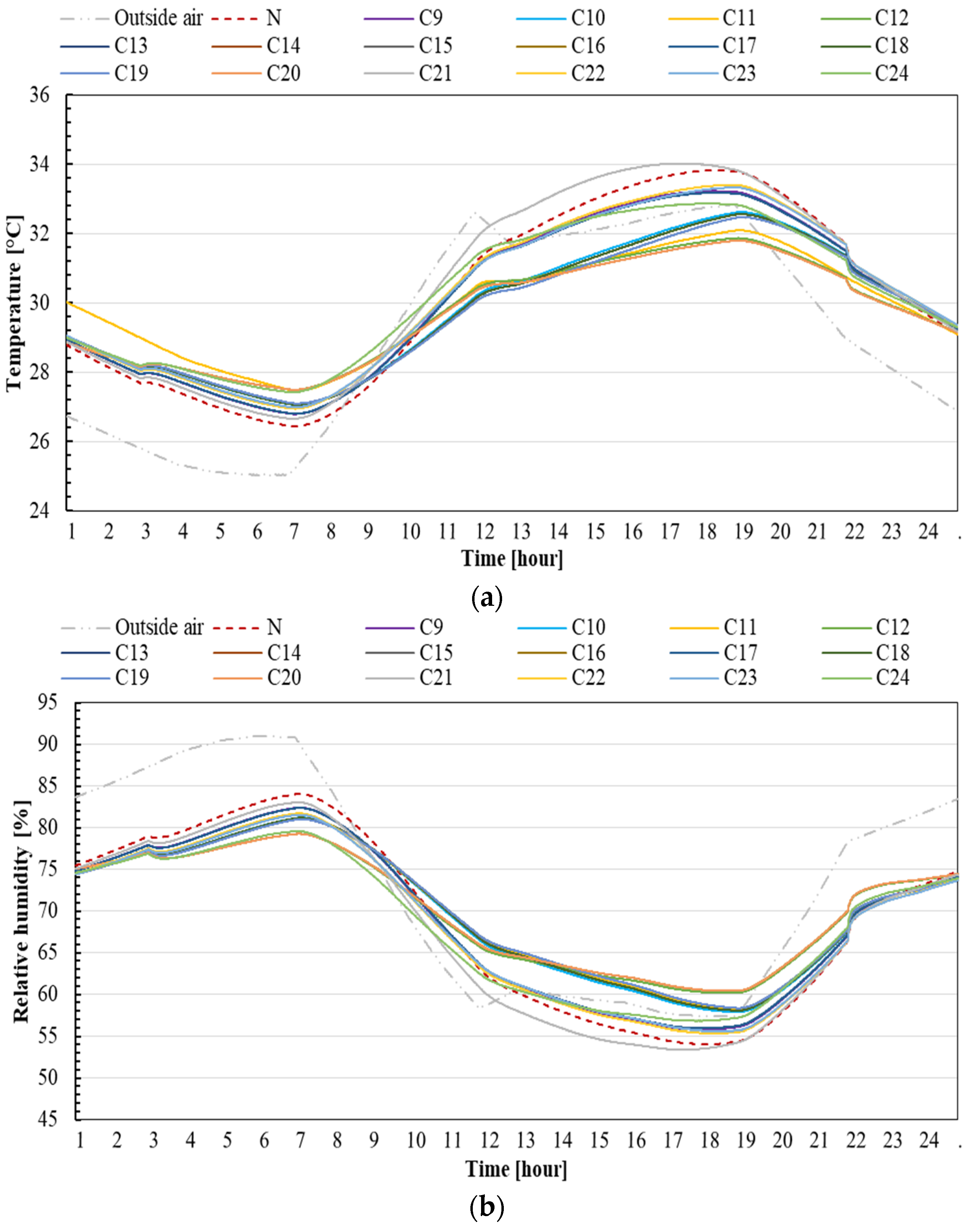

4.1. Louver Improvement

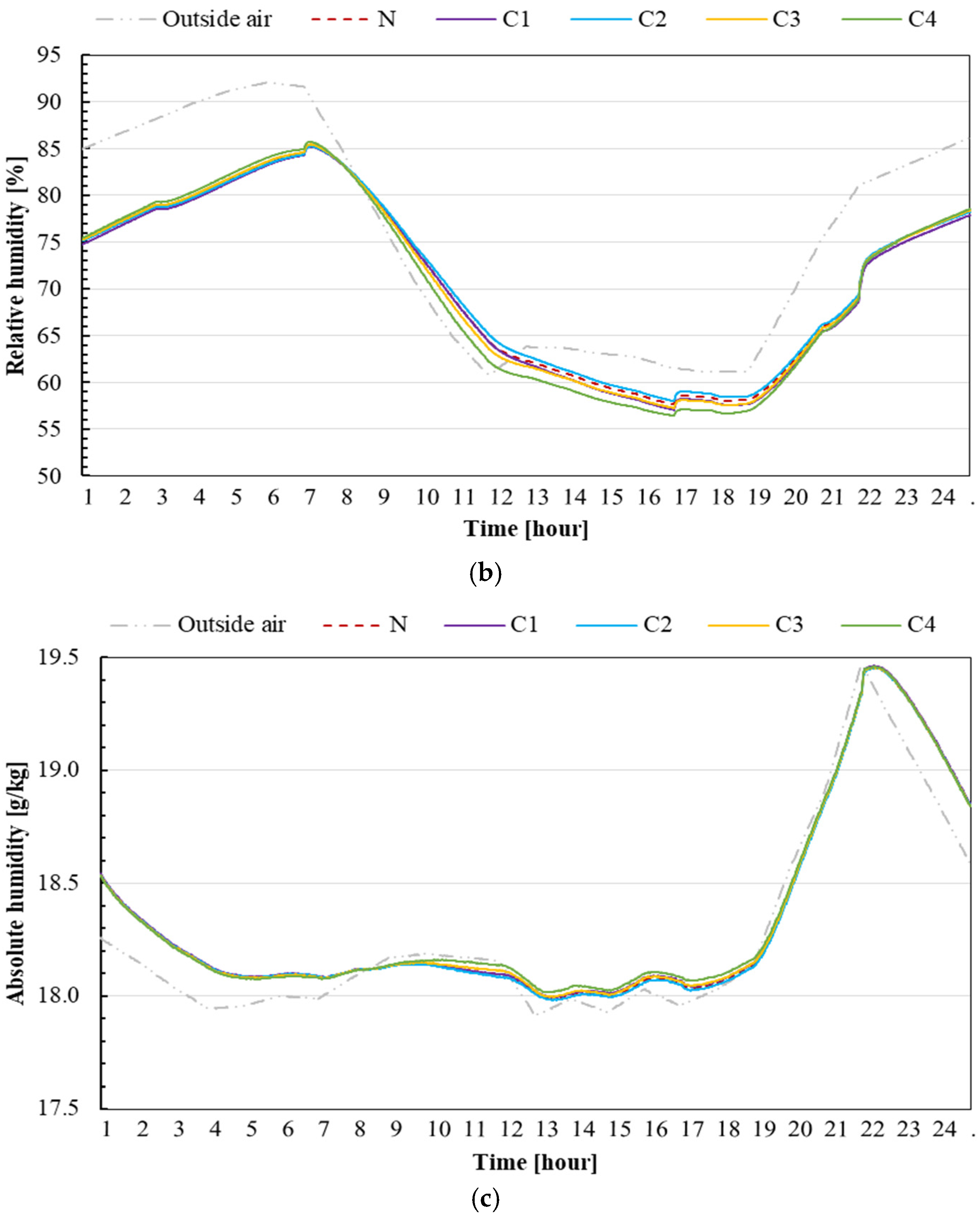

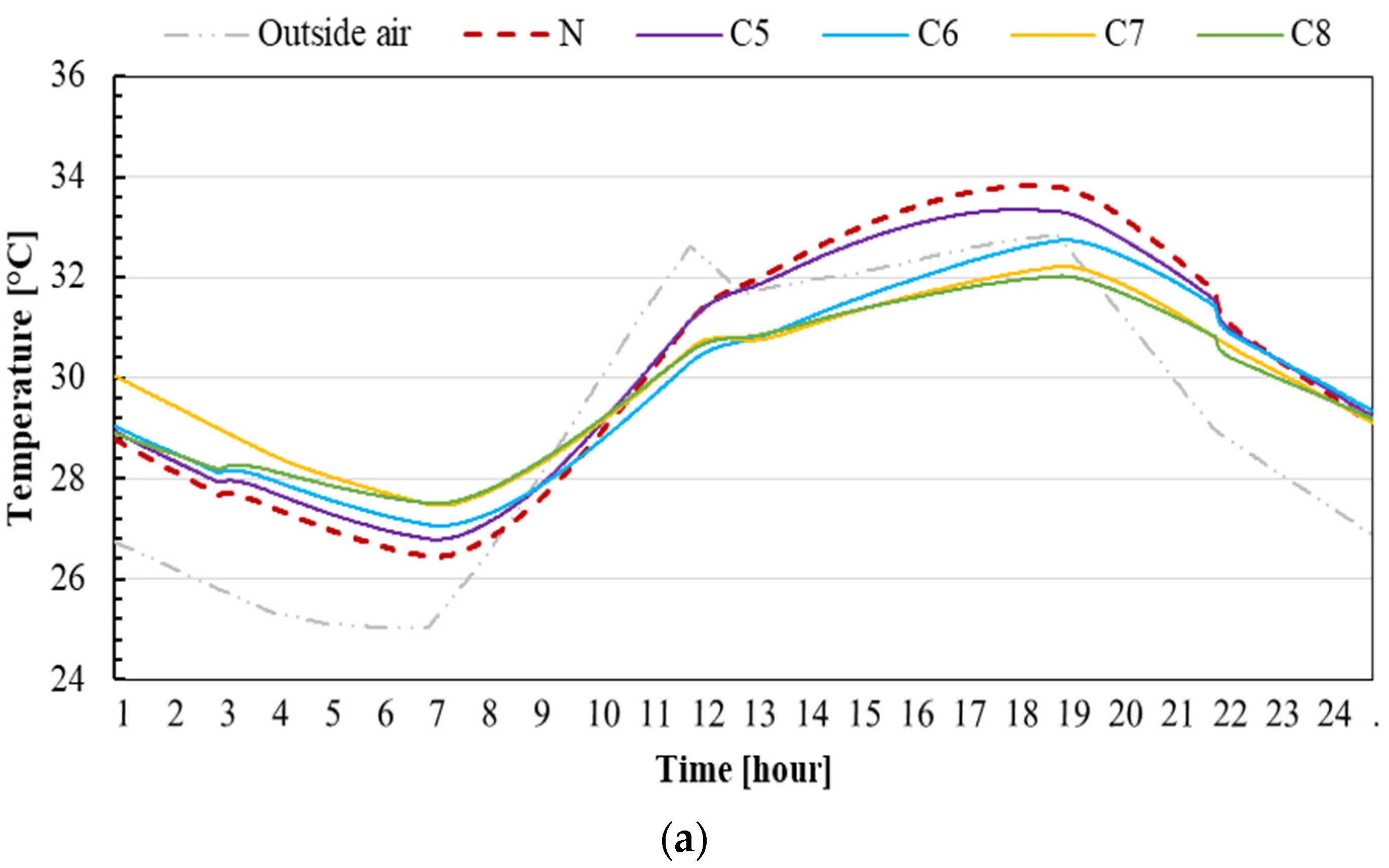

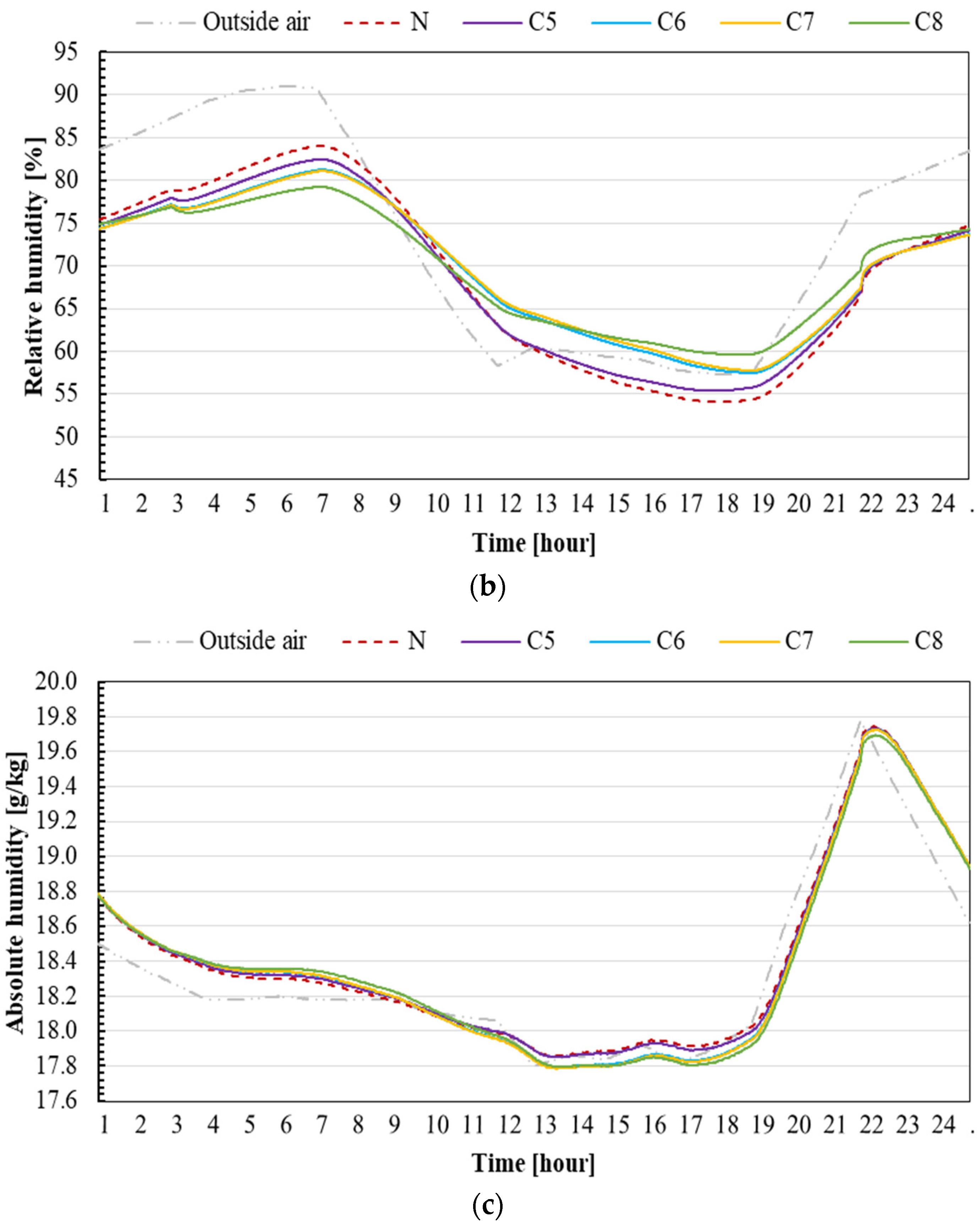

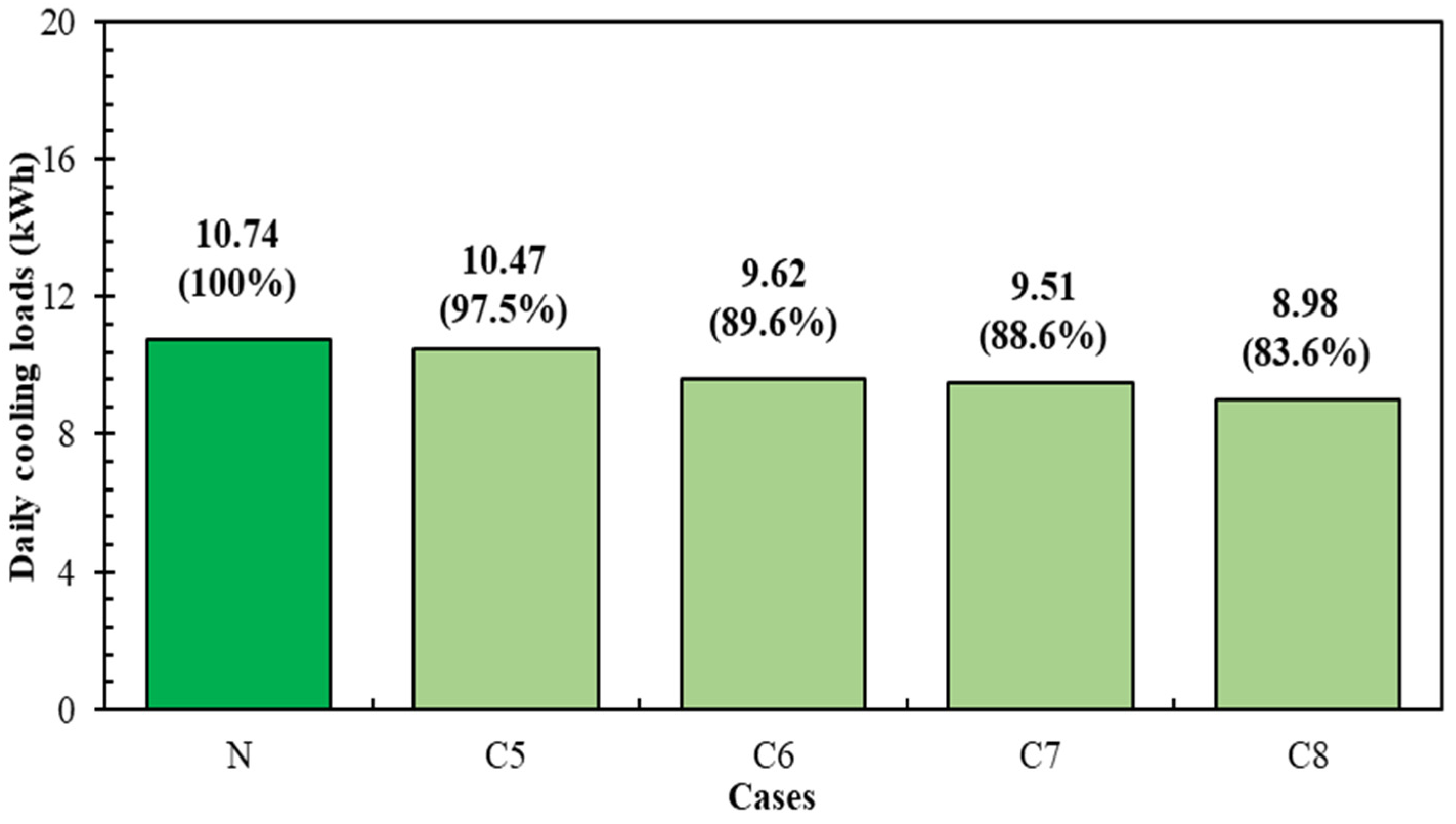

4.2. Insulation Improvement

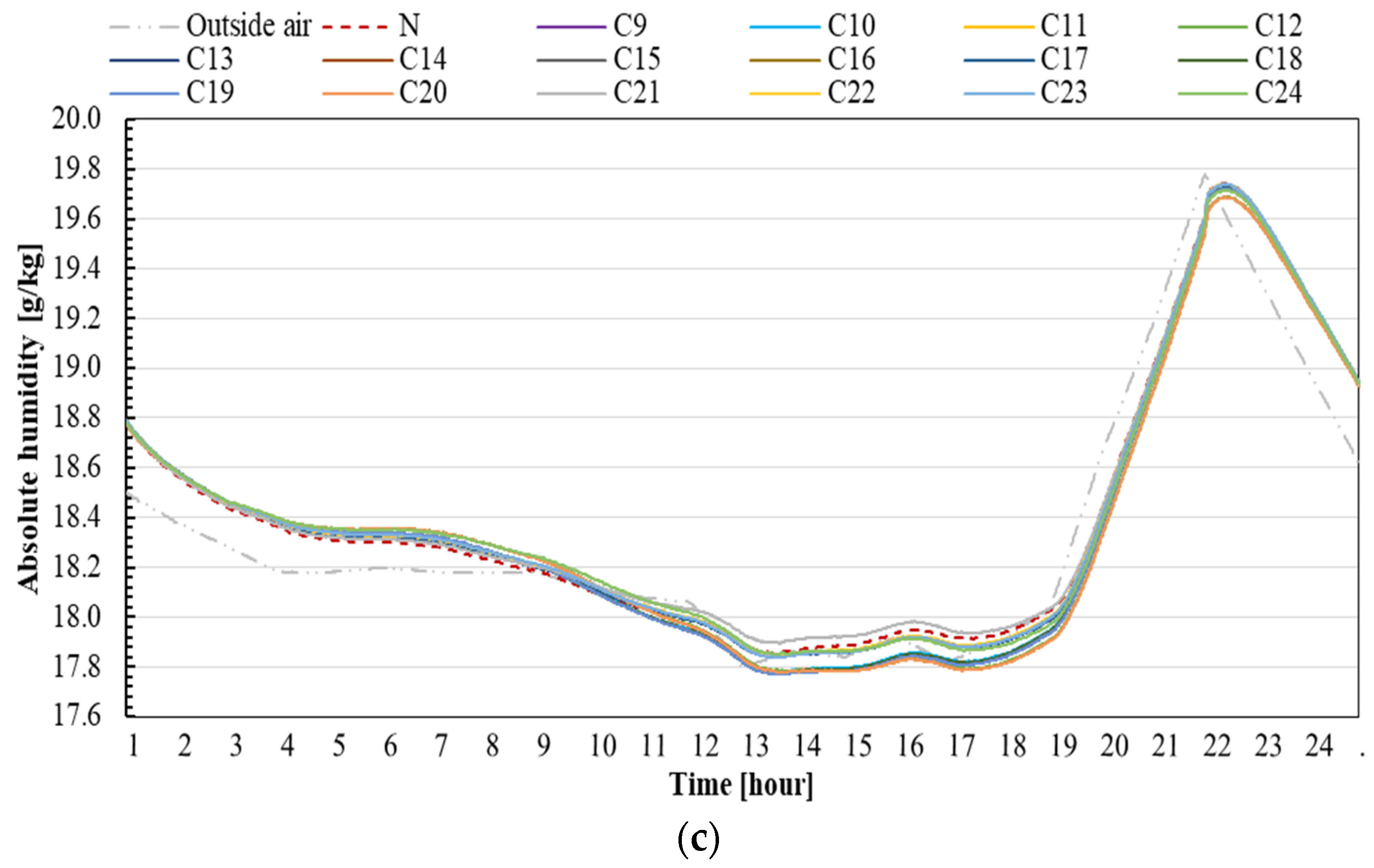

4.3. Combined Model

4.4. Annual Cooling Loads on the Target Cities

5. Conclusions

- Louver openings affect indoor conditions, where the larger the louver opening area, the higher the indoor temperature during daytime, and the lower the relative humidity. However, the situation was sharply reversed at night, when the temperature slightly decreased for a larger louver compared with the existing case.

- Proper insulation effectively reduced indoor temperatures and controlled relative humidity. Compared to the existing model, level 4 insulation could reduce the indoor temperature and relative humidity by 2.10 °C and 7% at peak conditions.

- The combination cases improved between various louver openings, and insulation could reduce the indoor temperature to 2.2 °C at peak conditions, and the relative humidity was stable at 60% and 78% during the day and at night.

- Daily cooling loads of the test house in the selected area present a significant decrease in energy consumption by applying the most improved case of approximately 25.09% compared with the existing case.

- The annual cooling load of each city declined by over 3.33 GJ/year. Therefore, the total annual cooling employing the optimizing cases was 155.30 GJ/year, which could save the annual cooling load of 46.63 GJ/year (23.09%) compared with the existing case.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Xing, Y.; Hewitt, N.; Griffiths, P. Zero carbon buildings refurbishment––A Hierarchical pathway. Renew. Sustain. Energy Rev. 2011, 15, 3229–3236. [Google Scholar] [CrossRef]

- Sambodo, M.T.; Novandra, R. The state of energy poverty in Indonesia and its impact on welfare. Energy Policy 2019, 132, 113–121. [Google Scholar] [CrossRef]

- Choi, Y.; Song, D.; Ozaki, A.; Lee, H.; Park, S. Do energy subsidies affect the indoor temperature and heating energy consumption in low-income households? Energy Build. 2022, 256, 111678. [Google Scholar] [CrossRef]

- Grey, C.N.B.; Schmieder-Gaite, T.; Jiang, S.; Nascimento, C.; Poortinga, W. Cold homes, fuel poverty and energy efficiency improvements: A longitudinal focus group approach. Indoor Built Environ. 2017, 26, 902–913. [Google Scholar] [CrossRef] [PubMed]

- Liddell, C.; Morris, C. Fuel poverty and human health: A review of recent evidence. Energy Policy 2010, 38, 2987–2997. [Google Scholar] [CrossRef]

- Oreszczyn, T.; Hong, S.H.; Ridley, I.; Wilkinson, P. Determinants of winter indoor temperatures in low income households in England. Energy Build. 2006, 38, 245–252. [Google Scholar] [CrossRef]

- Paravantis, J.A.; Santamouris, M. An analysis of indoor temperature measurements in low- and very-low-income housing in Athens, Greece. Adv. Build. Energy Res. 2016, 10, 20–45. [Google Scholar] [CrossRef]

- Rudge, J.; Gilchrist, R. Measuring the health impact of temperatures in dwellings: Investigating excess winter morbidity and cold homes in the London Borough of Newham. Energy Build. 2007, 39, 847–858. [Google Scholar] [CrossRef]

- Santamouris, M.; Alevizos, S.; Aslanoglou, L.; Mantzios, D.; Milonas, P.; Sarelli, I.; Karatasou, S.; Cartalis, K.; Paravantis, J. Freezing the poor—Indoor environmental quality in low and very low income households during the winter period in Athens. Energy Build. 2014, 70, 61–70. [Google Scholar] [CrossRef]

- Bardhan, R.; Debnath, R.; Jana, A.; Norford, L.K. Investigating the association of healthcare-seeking behavior with the freshness of indoor spaces in low-income tenement housing in Mumbai. Habitat Int. 2018, 71, 156–168. [Google Scholar] [CrossRef]

- Jevons, R.; Carmichael, C.; Crossley, A.; Bone, A. Minimum indoor temperature threshold recommendations for English homes in winter – A systematic review. Public Health 2016, 136, 4–12. [Google Scholar] [CrossRef]

- Webb, E.; Blane, D.; de Vries, R. Housing and respiratory health at older ages. J. Epidemiol. Community Health 2013, 67, 280–285. [Google Scholar] [CrossRef] [PubMed]

- BRR. Monthly Report; Pusdatin BRR, NAD NIAS: Banda Aceh, Indonesia, 2008. [Google Scholar]

- Sari, L.H.; Hasan, I.; Irwansyah, M.; Meutia, E. An Environmental Assessment of Vernacular Housing in Banda Aceh, Indonesia. Tesa Arsit. 2017, 15, 1–12. [Google Scholar] [CrossRef]

- Tong, S.; Wen, J.; Wong, N.H.; Tan, E. Impact of façade design on indoor air temperatures and cooling loads in residential buildings in the tropical climate. Energy Build. 2021, 243, 110972. [Google Scholar] [CrossRef]

- Prianto, E.; Depecker, P. Optimization of architectural design elements in tropical humid region with thermal comfort approach. Energy Build. 2003, 35, 273–280. [Google Scholar] [CrossRef]

- Putra, I.D.G.A.; Nimiya, H.; Sopaheluwakan, A.; Kubota, T.; Lee, H.S.; Pradana, R.P.; Alfata, M.N.F.; Perdana, R.B.; Permana, D.S.; Riama, N.F. Development of climate zones for passive cooling techniques in the hot and humid climate of Indonesia. Build. Environ. 2022, 226, 109698. [Google Scholar] [CrossRef]

- Gong, X.; Akashi, Y.; Sumiyoshi, D. Optimization of passive design measures for residential buildings in different Chinese areas. Build. Environ. 2012, 58, 46–57. [Google Scholar] [CrossRef]

- Huang, H.; Zhou, Y.; Huang, R.; Wu, H.; Sun, Y.; Huang, G.; Xu, T. Optimum insulation thicknesses and energy conservation of building thermal insulation materials in Chinese zone of humid subtropical climate. Sustain. Cities Soc. 2020, 52, 101840. [Google Scholar] [CrossRef]

- Sana, S.; Hayati, A.; Salmanzadeh, M. Optimization of Window-to-Wall Ratio for Buildings Located in. Energies 2021, 14, 1974. [Google Scholar]

- Ahmadi, F.; Wilkinson, S.; Rezazadeh, H.; Keawsawasvong, S.; Najafi, Q.; Masoumi, A. Energy efficient glazing: A comparison of microalgae photobioreactor and Iranian Orosi window designs. Build. Environ. 2023, 233, 109942. [Google Scholar] [CrossRef]

- Ashouri, M.; Astaraei, F.; Ghasempour, R.; Ahmadi, M.; Feidt, M. Optimum insulation thickness determination of a building wall using exergetic life cycle assessment. Appl. Therm. Eng. 2016, 106, 307–315. [Google Scholar] [CrossRef]

- Ozaki, A.; Tsujimaru, T. Prediction of hygrothermal environment of buildings based upon combined simulation of heat and moisture transfer and airflow. In Proceedings of the Building Simulation, Montreal, QC, Canada, 15–18 August 2005; pp. 899–906. [Google Scholar]

- Etheridge, D. Natural Ventilation of Buildings: Theory, Measurement and Design; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2011. [Google Scholar] [CrossRef]

- Heiselberg, P.; Svidt, K.; Nielsen, P.V. Characteristics of airflow from open windows. Build Environ. 2001, 36, 859–869. [Google Scholar] [CrossRef]

- Iqbal, A.; Afshari, A.; Wigö, H.; Heiselberg, P. Discharge coefficient of centre-pivot roof windows. Build. Environ. 2015, 92, 635–643. [Google Scholar] [CrossRef]

- AIJ. AIJ Recommendations for Loads on Buildings (2015); Architectural Institute of Japan: Tokyo, Japan, 2019; Available online: https://www.aij.or.jp/ (accessed on 15 March 2023).

- Cóstola, D.; Blocken, B.; Hensen, J. Overview of pressure coefficient data in building energy simulation and airflow network programs. Build. Environ. 2009, 44, 2027–2036. [Google Scholar] [CrossRef]

- Maruta, E.; Sawachl, T.; Sato, K.-I.; Takahashi, Y.; Nishizawa, S. Wind Pressure Coefficient Database for Natural Ventilation Design; Building Research Institute, National Research and Development Agency: Tokyo, Japan, 2018; Available online: https://www.kenken.go.jp/japanese/contents/publications/data/189/all.pdf (accessed on 28 February 2023).

- ASHRAE 14. Measurement of Energy, Demand, and Water Savings; ASHRAE Guideline 14-2014; ASHRAE: Atlanta, GA, USA, 2014; Volume 4, pp. 1–150. Available online: www.ashrae.org%0Awww.ashrae.org/technology (accessed on 20 March 2023).

- U. S. Department of Energy–Federal Energy Management Program. M&V Guidelines: Measurement and Verification for Performance-Based Contracts—Version 4.0; U.S. Department of Energy: Washington, DC, USA, 2015; Volume 3, pp. 1–108. [Google Scholar]

- Efficiency Valuation Organization. International Performance Measurement & Verification Protocol, Handbook of Financing Energy Projects; National Technical Information Service: Springfield, VA, USA, 2016; Volume I, 122p. [Google Scholar]

- Mustafaraj, G.; Marini, D.; Costa, A.; Keane, M. Model calibration for building energy efficiency simulation. Appl. Energy 2014, 130, 72–85. [Google Scholar] [CrossRef]

- Royapoor, M.; Roskilly, T. Building model calibration using energy and environmental data. Energy Build. 2015, 94, 109–120. [Google Scholar] [CrossRef]

- Choi, Y.; Cho, W.; Ozaki, A.; Lee, H. Influence of the moisture driving force of moisture adsorption and desorption on indoor hygrothermal environment and building thermal load. Energy Build. 2021, 253, 111501. [Google Scholar] [CrossRef]

| Category | Layer | Thickness | Thermal | Specific Heat | Specific | Moisture | Moisture |

|---|---|---|---|---|---|---|---|

| Conductivity | Gravity | Conductivity | Capacity | ||||

| [m] | [W/(m·K)] | [J/(kg·K)] | [kg/m3] | [kg/(m·s·Pa)] | [kg/(m3(kJ/kg)] | ||

| Roof (U-Value = 8.13 W/(m2·K)) | Zinc plate | 0.0002 | 110 | 896 | 2800 | - | - |

| Ceiling (U-Value = 5.48 W/(m2·K)) | Plywood | 0.004 | 0.120 | 1880.0 | 556.0 | 5.670 × 10−13 | 2.200 × 10−1 |

| Exterior wall (U-Value = 2.90 W/(m2·K)) | Cement mortar | 0.03 | 1.910 | 917.0 | 2009.0 | 4.570 × 10−12 | 1.830 × 10−1 |

| Brickwork | 0.1 | 0.807 | 880.0 | 1792.0 | 2.600 × 10−11 | 1.072 × 10−2 | |

| Floor (U-Value = 4.50 W/(m2·K)) | Sand | 0.1 | 1.910 | 840.0 | 1764.0 | 0.000 | 0.000 |

| Concrete | 0.05 | 1.619 | 890.0 | 2206.0 | 1.020 × 10−12 | 1.881 | |

| Cement mortar | 0.02 | 1.910 | 917.0 | 2009.0 | 4.570 × 10−12 | 1.830 × 10−1 | |

| Concrete tile | 0.009 | 1.1 | 837 | 2100 | - | - |

| Description | Specification |

|---|---|

| Measures temperature range | −40 °C to +60 °C |

| Measures humidity range | 1%RH–99%RH |

| Temperature accuracy | ±1 °C under 0–50 °C |

| Humidity accuracy | ±4% under 20–80% |

| Logging interval | 8 s to 4 h |

| Condition | |

|---|---|

| Calculation periods | January 1 to December 31 |

| Calculation interval | 3600 s |

| Calculation target | Living room |

| Indoor set-point of temperature and RH | Temperature: 24 °C |

| RH: 60% | |

| Space conditioning time | 6–9, 12–13, 17–22 (Living schedule of a family) |

| Weather data | Expanded IWEC2 Weather data |

| City | Temperature [°C] | Relative Humidity [%] | Wind Velocity [m/s] | Solar Radiation [w/m2] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Average | Min | Max | Average | Min | Max | Average | Min | Max | Average | |

| Lhokseumawe | 18.60 | 37.90 | 26.98 | 44 | 100 | 81.58 | 0 | 30.80 | 1.68 | 0 | 1134 | 111.01 |

| Banda Aceh | 19.10 | 36.90 | 26.94 | 34 | 100 | 80.07 | 0 | 25.70 | 1.74 | 0 | 1149 | 162.29 |

| Kerinci | 9.50 | 30.70 | 22.70 | 32 | 100 | 82.62 | 0 | 27.80 | 1.50 | 0 | 925 | 147.15 |

| Wamena | 6.70 | 28.60 | 19.58 | 26 | 100 | 80.46 | 0 | 15.40 | 2.21 | 0 | 897 | 114.37 |

| Cilacap | 2.50 | 55.60 | 26.36 | 18 | 100 | 82.65 | 0 | 48.30 | 2.03 | 0 | 1250 | 111.58 |

| Sumbawa Besar | 18.30 | 38.80 | 26.86 | 24 | 100 | 78.21 | 0 | 15.40 | 1.62 | 0 | 874 | 136.34 |

| Waingapu | 12.10 | 39.00 | 26.84 | 24 | 100 | 76.95 | 0 | 12.90 | 2.13 | 0 | 922 | 150.67 |

| Surabaya | 19.00 | 37.70 | 27.93 | 16 | 100 | 75.10 | 0 | 20.60 | 2.70 | 0 | 889 | 187.55 |

| Balikpapan | 22.00 | 37.00 | 27.49 | 50 | 100 | 85.36 | 0 | 30.80 | 2.19 | 0 | 887 | 178.51 |

| Maluku Utara | 21.00 | 34.40 | 26.78 | 41 | 100 | 86.01 | 0 | 11.30 | 1.17 | 0 | 868 | 135.64 |

| Semarang | 14.30 | 37.40 | 28.16 | 22 | 100 | 74.26 | 0 | 29.90 | 2.77 | 0 | 940 | 202.51 |

| Gorontalo | 20.70 | 34.60 | 27.16 | 41 | 100 | 82.33 | 0 | 27.80 | 1.49 | 0 | 917 | 218.44 |

| Bima | 18.20 | 36.30 | 27.51 | 25 | 100 | 78.49 | 0 | 25.70 | 2.20 | 0 | 943 | 271.95 |

| Madura | 21.20 | 34.10 | 27.76 | 47 | 100 | 81.10 | 0 | 39.10 | 3.86 | 0 | 955 | 205.40 |

| Cases | Louver Area | Insulation Level | Remarks | |||||

|---|---|---|---|---|---|---|---|---|

| Louver 1 [m2] | Louver 2 [m2] | No Ins. | Ins. 1 | Ins. 2 | Ins. 3 | Ins. 4 | ||

| N | 0.32 | 0.19 | √ | Existing test house | ||||

| C1 | 0.16 | 0.095 | √ | Reduce louver area (louver area of existing × 0.5) | ||||

| C2 | 0.08 | 0.048 | √ | Reduce louver area (louver area of existing × 0.25) | ||||

| C3 | 0.64 | 0.38 | √ | Enlarge louver area (louver area of existing × 2) | ||||

| C4 | 1.28 | 0.76 | √ | Enlarge louver area (louver area of existing × 4) | ||||

| C5 | 0.32 | 0.19 | √ | Insulation 1 (a1, b1, c2, d1) | ||||

| C6 | 0.32 | 0.19 | √ | Insulation 2 (a2, b2, c2, d1) | ||||

| C7 | 0.32 | 0.19 | √ | Insulation 3 (a3, b3, c2, d1) | ||||

| C8 | 0.32 | 0.19 | √ | Insulation 4 (a3, b3, c3, d1) | ||||

| C9 | 0.16 | 0.095 | √ | Combined 1 (c1 and c5) | ||||

| C10 | 0.16 | 0.095 | √ | Combined 2 (c1 and c6) | ||||

| C11 | 0.16 | 0.095 | √ | Combined 3 (c1 and c7) | ||||

| C12 | 0.16 | 0.095 | √ | Combined 4 (c1 and c8) | ||||

| C13 | 0.08 | 0.048 | √ | Combined 5 (c2 and c5) | ||||

| C14 | 0.08 | 0.048 | √ | Combined 6 (c2 and c6) | ||||

| C15 | 0.08 | 0.048 | √ | Combined 7 (c2 and c7) | ||||

| C16 | 0.08 | 0.048 | √ | Combined 8 (c2 and c8) | ||||

| C17 | 0.64 | 0.38 | √ | Combined 9 (c3 and c5) | ||||

| C18 | 0.64 | 0.38 | √ | Combined 10 (c3 and c6) | ||||

| C19 | 0.64 | 0.38 | √ | Combined 11 (c3 and c7) | ||||

| C20 | 0.64 | 0.38 | √ | Combined 12 (c3 and c8) | ||||

| C21 | 1.28 | 0.76 | √ | Combined 13 (c4 and c5) | ||||

| C22 | 1.28 | 0.76 | √ | Combined 14 (c4 and c6) | ||||

| C23 | 1.28 | 0.76 | √ | Combined 15 (c4 and c7) | ||||

| C24 | 1.28 | 0.76 | √ | Combined 16 (c4 and c8) | ||||

| Ground Surface Roughness Classification | Ⅰ | Ⅱ | Ⅲ | Ⅳ | Ⅴ |

|---|---|---|---|---|---|

| Zg (sky wind altitude) | 250 | 350 | 450 | 550 | 650 |

| α | 0.1 | 0.15 | 0.2 | 0.27 | 0.35 |

| Content | Detail |

|---|---|

| Analysis software | STAR-CCM+ (v12.04B) |

| Analysis domain | 50 m (x) × 90 m (y) × 25 m (z) |

| Number of meshes | 3,300,000 |

| Inflow boundary condition | 1/5 power law |

| Outflow boundary condition | Gradient 0 at the outflow boundary |

| Air/Side Boundary Conditions | Slip |

| Wall conditions | Floor surface: wall boundary condition based on wall function |

| Target building: wall boundary condition based on wall function | |

| Calculation algorithm | SIMPLE method |

| Turbulence model | Realizable k-ε model |

| Indicator | Prediction Error | Standard | ||||

|---|---|---|---|---|---|---|

| Temperature | RH | Abs. Humidity | ASHRAE | IPMVP | FEMP | |

| MBE | 2.06% | 3.05% | 3.22% | ±10% | ±10% | ±5% |

| CV (RMSE) | 2.69% | 3.97% | 4.01% | <30% | <30% | <20% |

| Cases | Parameters | Daily Cooling Loads | |

|---|---|---|---|

| kWh | % | ||

| N | Existing Model | 10.74 | 100.00 |

| C1 | Reduce louvre 1 | 10.43 | 97.18 |

| C2 | Reduce louvre 2 | 9.98 | 92.98 |

| C3 | Enlarge louvre 1 | 11.90 | 110.88 |

| C4 | Enlarge louvre 2 | 14.25 | 132.77 |

| C5 | Insulation 1 | 10.47 | 97.53 |

| C6 | Insulation 2 | 9.63 | 89.67 |

| C7 | Insulation 3 | 9.51 | 88.60 |

| C8 | Insulation 4 | 8.98 | 83.67 |

| C9 | C1 + C5 | 9.94 | 92.57 |

| C10 | C1 + C6 | 9.08 | 84.54 |

| C11 | C1 + C7 | 8.94 | 83.24 |

| C12 | C1 + C8 | 8.36 | 77.88 |

| C13 | C2 + C5 | 9.68 | 90.21 |

| C14 | C2 + C6 | 8.75 | 81.48 |

| C15 | C2 + C7 | 8.63 | 80.41 |

| C16 | C2 + C8 | 8.04 | 74.91 |

| C17 | C3 + C5 | 11.70 | 108.97 |

| C18 | C3 + C6 | 10.93 | 101.79 |

| C19 | C3 + C7 | 10.80 | 100.60 |

| C20 | C3 + C8 | 10.32 | 96.13 |

| C21 | C4 + C5 | 14.05 | 130.89 |

| C22 | C4 + C6 | 13.35 | 124.39 |

| C23 | C4 + C7 | 13.27 | 123.64 |

| C24 | C4 + C8 | 12.88 | 120.01 |

| Cases | Parameters | Annual Thermal Load per Unit of Living Room (63.37 m³) for Each City ((GJ/year) and (%)) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lhok-Seumawe | Banda Aceh | Kerinci | Wamena | Cilacap | Sumbawa Besar | Waingapu | Surabaya | Balikpapan | Maluku Utara | Semarang | Gorontalo | Bima | Madura | ||

| N | Existing Model | 14.11 | 12.69 | 1.64 | −0.07 | 11.45 | 15.35 | 6.28 | 22.93 | 18.04 | 14.52 | 24.93 | 14.97 | 22.58 | 22.50 |

| (100%) | (100%) | (100%) | (100%) | (100%) | (100%) | (100%) | (100%) | (100%) | (100%) | (100%) | (100%) | (100%) | (100%) | ||

| Case 1 | Reduce louvre 1 | 13.71 | 12.42 | 1.60 | −0.07 | 11.05 | 14.48 | 6.15 | 22.08 | 17.71 | 14.06 | 23.45 | 14.26 | 20.50 | 20.38 |

| (97%) | (98%) | (97%) | (102%) | (97%) | (94%) | (98%) | (96%) | (98%) | (97%) | (94%) | (95%) | (91%) | (91%) | ||

| Case 2 | Reduce louvre 2 | 13.12 | 11.83 | 1.43 | −0.07 | 10.54 | 13.66 | 5.83 | 21.24 | 17.14 | 13.54 | 22.27 | 13.48 | 19.36 | 19.43 |

| (93%) | (93%) | (87%) | (101%) | (92%) | (89%) | (93%) | (93%) | (95%) | (93%) | (89%) | (90%) | (86%) | (86%) | ||

| Case 3 | Enlarge louvre 1 | 15.64 | 13.94 | 1.98 | −0.08 | 13.19 | 17.73 | 7.07 | 25.67 | 19.49 | 16.10 | 29.43 | 17.28 | 26.33 | 26.78 |

| (111%) | (110%) | (120%) | (114%) | (115%) | (115%) | (113%) | (112%) | (108%) | (111%) | (118%) | (115%) | (117%) | (119%) | ||

| Case 4 | Enlarge louvre 2 | 18.73 | 16.63 | 2.58 | −0.17 | 16.28 | 22.35 | 8.61 | 30.99 | 22.60 | 19.40 | 37.12 | 21.40 | 32.96 | 33.36 |

| (133%) | (131%) | (157%) | (237%) | (142%) | (146%) | (137%) | (135%) | (125%) | (134%) | (149%) | (143%) | (146%) | (148%) | ||

| Case 5 | Insulation 1 | 13.76 | 12.31 | 1.51 | −0.09 | 11.26 | 15.07 | 6.17 | 22.51 | 17.73 | 14.20 | 24.67 | 14.58 | 22.08 | 22.28 |

| (98%) | (97%) | (92%) | (125%) | (98%) | (98%) | (98%) | (98%) | (98%) | (98%) | (99%) | (97%) | (98%) | (99%) | ||

| Case 6 | Insulation 2 | 12.65 | 11.37 | 1.32 | −0.09 | 10.38 | 14.12 | 5.70 | 21.48 | 16.91 | 13.50 | 23.60 | 13.32 | 20.55 | 21.16 |

| (90%) | (90%) | (81%) | (124%) | (91%) | (92%) | (91%) | (94%) | (94%) | (93%) | (95%) | (89%) | (91%) | (94%) | ||

| Case 7 | Insulation 3 | 12.50 | 11.24 | 1.22 | −0.10 | 10.32 | 14.01 | 5.66 | 21.26 | 16.65 | 13.44 | 23.42 | 13.08 | 20.38 | 21.00 |

| (89%) | (89%) | (74%) | (134%) | (90%) | (91%) | (90%) | (93%) | (92%) | (93%) | (94%) | (87%) | (90%) | (93%) | ||

| Case 8 | Insulation 4 | 11.80 | 10.56 | 1.13 | −0.09 | 9.82 | 13.44 | 5.38 | 20.60 | 16.02 | 12.92 | 22.76 | 12.45 | 19.54 | 20.38 |

| (84%) | (83%) | (69%) | (117%) | (86%) | (88%) | (86%) | (90%) | (89%) | (89%) | (91%) | (83%) | (87%) | (91%) | ||

| Case 9 | C1 + C5 | 13.06 | 11.75 | 1.35 | −0.08 | 10.62 | 13.91 | 5.87 | 21.42 | 17.12 | 13.51 | 22.88 | 13.58 | 19.68 | 20.00 |

| (93%) | (93%) | (82%) | (105%) | (93%) | (91%) | (93%) | (93%) | (95%) | (93%) | (92%) | (91%) | (87%) | (89%) | ||

| Case 10 | C1 + C6 | 11.93 | 10.70 | 1.18 | −0.08 | 9.93 | 12.94 | 5.37 | 20.23 | 16.18 | 12.78 | 21.74 | 12.41 | 18.05 | 18.80 |

| (85%) | (84%) | (72%) | (107%) | (87%) | (84%) | (86%) | (88%) | (90%) | (88%) | (87%) | (83%) | (80%) | (84%) | ||

| Case 11 | C1 + C7 | 11.74 | 10.59 | 1.13 | −0.08 | 9.63 | 12.81 | 5.33 | 20.10 | 15.91 | 12.72 | 21.55 | 12.03 | 17.86 | 18.65 |

| (83%) | (83%) | (69%) | (107%) | (84%) | (83%) | (85%) | (88%) | (88%) | (88%) | (86%) | (80%) | (79%) | (83%) | ||

| Case 12 | C1 + C8 | 10.99 | 9.87 | 0.96 | −0.08 | 9.12 | 12.20 | 5.02 | 19.39 | 15.26 | 12.17 | 20.84 | 11.33 | 16.98 | 17.98 |

| (78%) | (78%) | (58%) | (109%) | (80%) | (79%) | (80%) | (85%) | (85%) | (84%) | (84%) | (76%) | (75%) | (80%) | ||

| Case 13 | C2 + C5 | 12.73 | 11.50 | 1.33 | −0.07 | 10.29 | 13.32 | 5.70 | 20.90 | 16.77 | 13.23 | 21.98 | 13.08 | 18.90 | 19.22 |

| (90%) | (91%) | (81%) | (96%) | (90%) | (87%) | (91%) | (91%) | (93%) | (91%) | (88%) | (87%) | (84%) | (85%) | ||

| Case 14 | C2 + C6 | 11.49 | 10.44 | 1.12 | −0.07 | 9.45 | 12.31 | 5.22 | 19.71 | 15.77 | 12.70 | 20.79 | 11.72 | 17.24 | 18.01 |

| (81%) | (82%) | (68%) | (100%) | (82%) | (80%) | (83%) | (86%) | (87%) | (87%) | (83%) | (78%) | (76%) | (80%) | ||

| Case 15 | C2 + C7 | 11.34 | 10.27 | 1.04 | −0.07 | 9.26 | 12.21 | 5.17 | 19.52 | 15.54 | 12.37 | 20.60 | 11.50 | 16.96 | 17.82 |

| (80%) | (81%) | (63%) | (100%) | (81%) | (80%) | (82%) | (85%) | (86%) | (85%) | (83%) | (77%) | (75%) | (79%) | ||

| Case 16 | C2 + C8 | 10.57 | 9.53 | 0.92 | −0.07 | 8.69 | 11.57 | 4.85 | 18.79 | 14.87 | 11.81 | 19.85 | 10.78 | 16.03 | 17.12 |

| (75%) | (75%) | (56%) | (96%) | (76%) | (75%) | (77%) | (82%) | (82%) | (81%) | (80%) | (72%) | (71%) | (76%) | ||

| Case 17 | C3 + C5 | 15.37 | 13.60 | 1.87 | −0.08 | 13.00 | 17.51 | 6.94 | 25.38 | 19.21 | 15.82 | 29.15 | 17.19 | 25.85 | 26.51 |

| (109%) | (107%) | (114%) | (115%) | (113%) | (114%) | (111%) | (111%) | (106%) | (109%) | (117%) | (115%) | (115%) | (118%) | ||

| Case 18 | C3 + C6 | 14.36 | 12.85 | 1.66 | −0.08 | 12.40 | 16.60 | 6.49 | 24.48 | 18.33 | 15.46 | 28.23 | 16.01 | 24.46 | 25.51 |

| (102%) | (101%) | (101%) | (107%) | (108%) | (108%) | (103%) | (107%) | (102%) | (106%) | (113%) | (107%) | (108%) | (113%) | ||

| Case 19 | C3 + C7 | 14.19 | 12.64 | 1.61 | −0.08 | 12.13 | 16.50 | 6.46 | 24.20 | 18.26 | 15.13 | 28.03 | 15.68 | 24.31 | 25.39 |

| (101%) | (100%) | (98%) | (107%) | (106%) | (107%) | (103%) | (106%) | (101%) | (104%) | (112%) | (105%) | (108%) | (113%) | ||

| Case 20 | C3 + C8 | 13.56 | 12.03 | 1.49 | −0.08 | 11.70 | 16.01 | 6.21 | 23.62 | 17.68 | 14.65 | 27.45 | 15.11 | 23.56 | 24.83 |

| (96%) | (95%) | (91%) | (110%) | (102%) | (104%) | (99%) | (103%) | (98%) | (101%) | (110%) | (101%) | (104%) | (110%) | ||

| Case 21 | C4 + C5 | 18.46 | 16.34 | 2.45 | −0.17 | 16.04 | 22.11 | 8.49 | 30.80 | 22.27 | 19.13 | 36.97 | 21.21 | 32.55 | 33.16 |

| (131%) | (129%) | (149%) | (235%) | (140%) | (144%) | (135%) | (134%) | (123%) | (132%) | (148%) | (142%) | (144%) | (147%) | ||

| Case 22 | C4 + C6 | 17.55 | 15.58 | 2.27 | −0.18 | 15.48 | 21.39 | 8.10 | 29.92 | 21.50 | 18.79 | 36.13 | 19.99 | 31.43 | 32.30 |

| (124%) | (123%) | (138%) | (247%) | (135%) | (139%) | (129%) | (131%) | (119%) | (129%) | (145%) | (134%) | (139%) | (144%) | ||

| Case 23 | C4 + C7 | 17.44 | 15.47 | 2.20 | −0.16 | 15.34 | 21.28 | 8.06 | 29.79 | 21.44 | 18.56 | 36.02 | 19.90 | 31.17 | 32.16 |

| (124%) | (122%) | (134%) | (225%) | (134%) | (139%) | (128%) | (130%) | (119%) | (128%) | (145%) | (133%) | (138%) | (143%) | ||

| Case 24 | C4 + C8 | 16.93 | 14.99 | 2.07 | −0.18 | 15.01 | 20.87 | 7.87 | 29.32 | 20.99 | 18.18 | 35.56 | 19.50 | 30.61 | 31.75 |

| (120%) | (118%) | (126%) | (246%) | (131%) | (136%) | (125%) | (128%) | (116%) | (125%) | (143%) | (130%) | (136%) | (141%) | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iqbal, M.; Ozaki, A.; Choi, Y.; Arima, Y. Performance Improvement Plan towards Energy-Efficient Naturally Ventilated Houses in Tropical Climate Regions. Sustainability 2023, 15, 12173. https://doi.org/10.3390/su151612173

Iqbal M, Ozaki A, Choi Y, Arima Y. Performance Improvement Plan towards Energy-Efficient Naturally Ventilated Houses in Tropical Climate Regions. Sustainability. 2023; 15(16):12173. https://doi.org/10.3390/su151612173

Chicago/Turabian StyleIqbal, Muhammad, Akihito Ozaki, Younhee Choi, and Yusuke Arima. 2023. "Performance Improvement Plan towards Energy-Efficient Naturally Ventilated Houses in Tropical Climate Regions" Sustainability 15, no. 16: 12173. https://doi.org/10.3390/su151612173

APA StyleIqbal, M., Ozaki, A., Choi, Y., & Arima, Y. (2023). Performance Improvement Plan towards Energy-Efficient Naturally Ventilated Houses in Tropical Climate Regions. Sustainability, 15(16), 12173. https://doi.org/10.3390/su151612173