Environmental and Socio-Economic Assessment of Biomass Pellets Biofuel in Hazara Division, Pakistan

Abstract

:1. Introduction

2. Materials and Methods

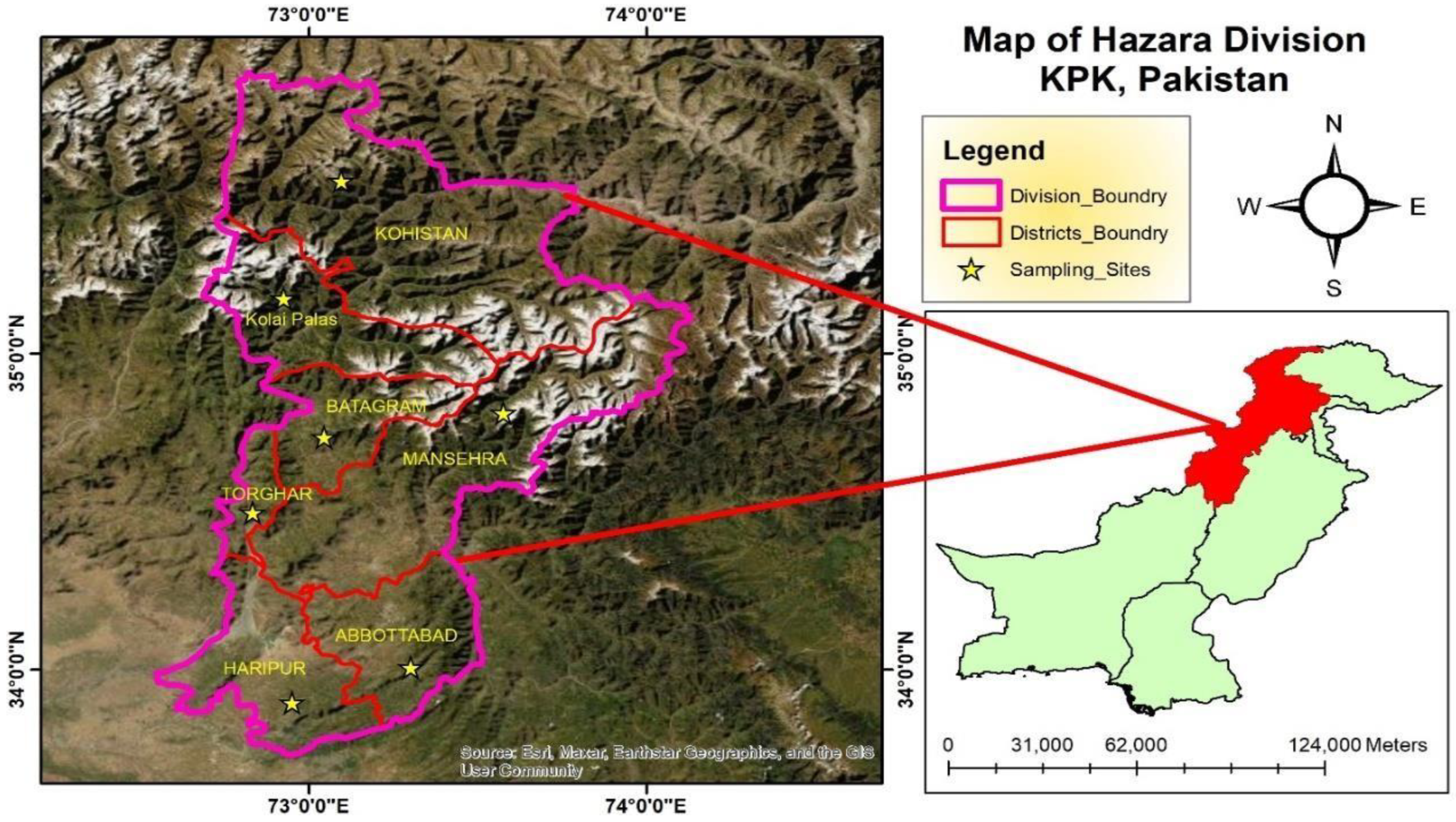

2.1. Description of Study Area

2.2. Climate of the Study Area

2.3. Design of the Research

2.4. Pelletizer Machine Description

2.5. Laboratory Work

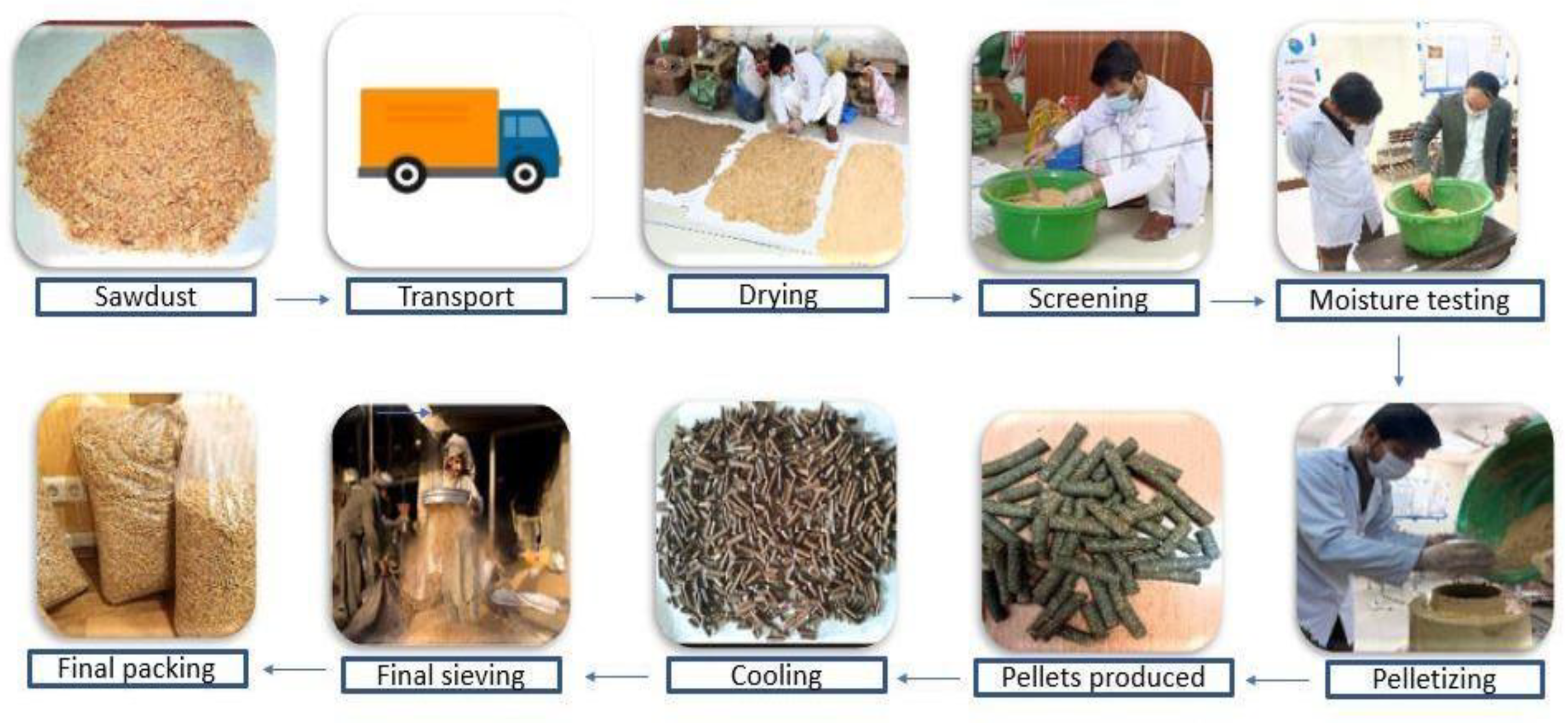

2.6. Production Process of Biomass Pellets

2.6.1. Sample Collection

2.6.2. Grinding

2.6.3. Screening

2.6.4. Additives

2.6.5. Pelleting

2.6.6. Cooling

2.7. Samples Characterization

2.7.1. Determination of Moisture Percentage

2.7.2. Calculation of Pellets Dimension

2.7.3. Calculation of Pellets Ash Content

2.7.4. Bulk Density

2.7.5. Calorific Value

2.7.6. Delong’s Formula

2.7.7. Vendralek Formula

2.7.8. Elemental Analysis

2.8. Socio-Economic Analysis of Biomass Pellets Biofuel

2.9. Life Cycle Assessment (LCA)

2.10. System Boundary

3. Results and Discussion

3.1. Life Cycle Inventory (Lci) of Biomass Pellets

3.2. Wood Pellets Diameter and Length

3.3. Moisture Content, Ash Content, and Bulk Density

3.4. High Heating Value and Low Heating Values

3.5. Nitrogen and Sulfur Content

3.6. Environmental Impact Assessment of Biomass Pellets from Different Species

3.7. Cumulative Energy Demand (CED) of Biomass Pellets from Different Selected Species

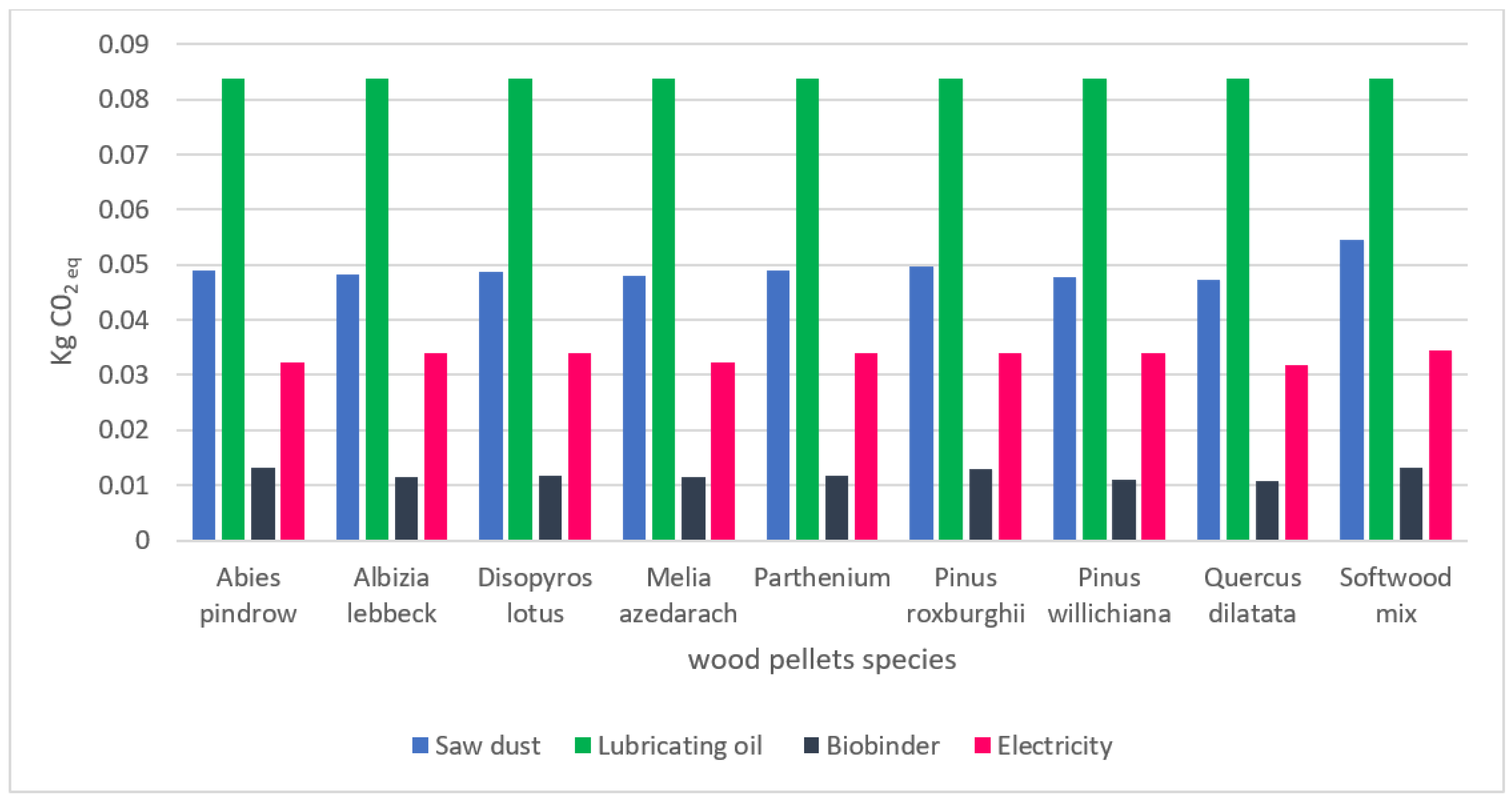

3.8. Carbon Footprint of Biomass Pellets from Different Species

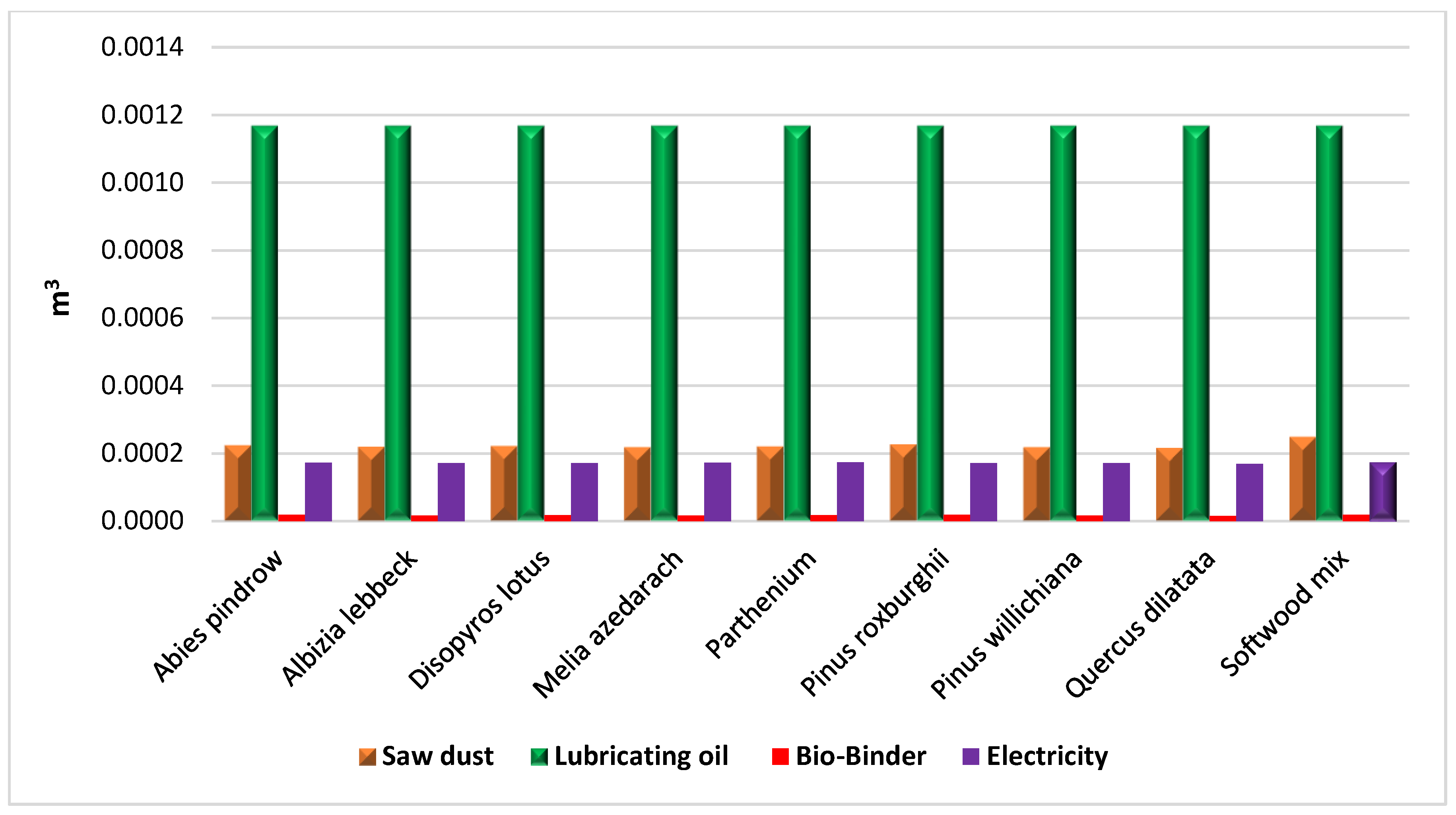

3.9. Water Footprint of Biomass Pellets from Different Selected Species

3.10. Ecological Footprint of Biomass Pellets from Different Species

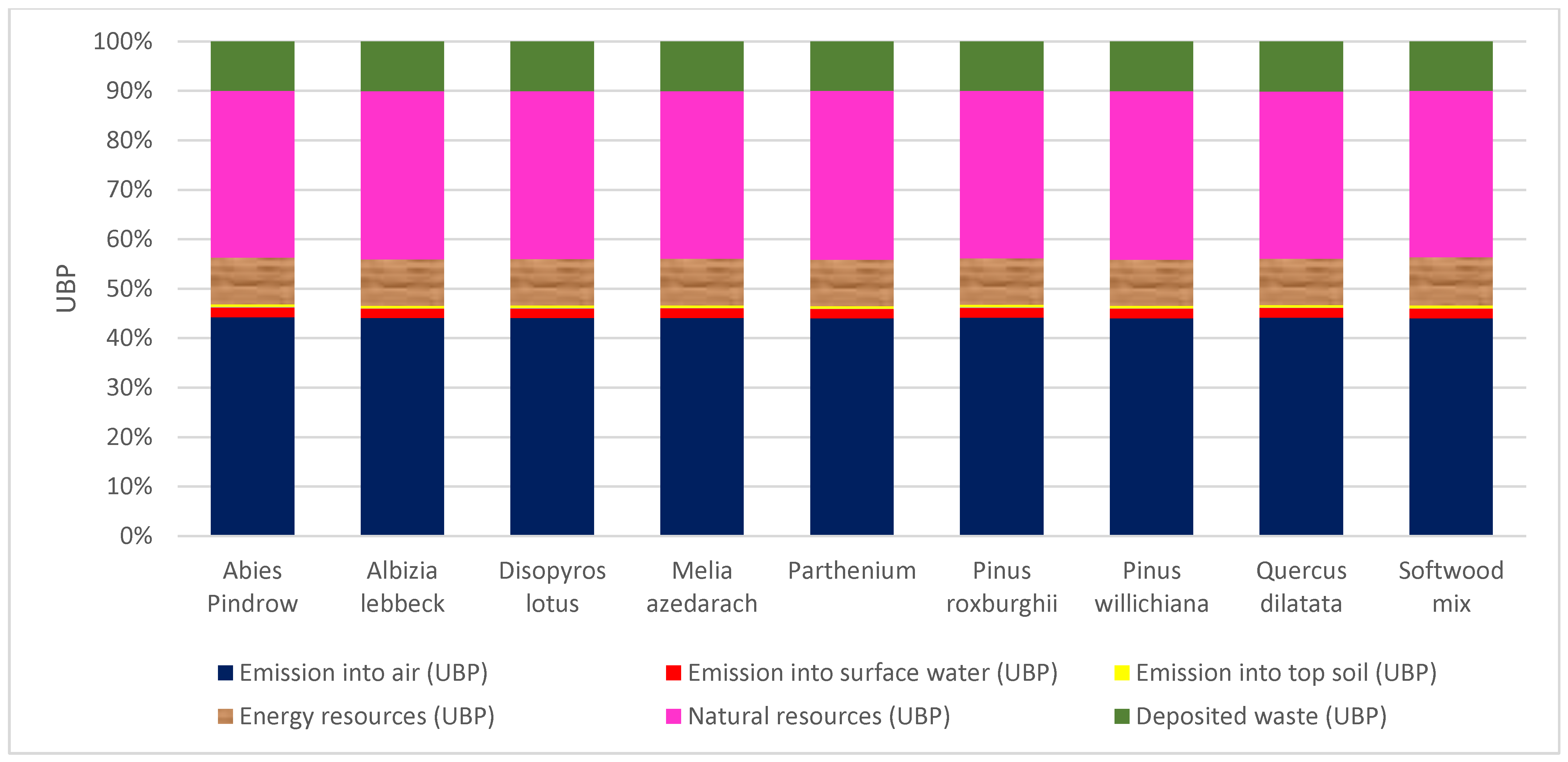

3.11. Various Environmental Impacts Determined through Eco-Indicator (Ei) of Biomass Pellets from Different Species

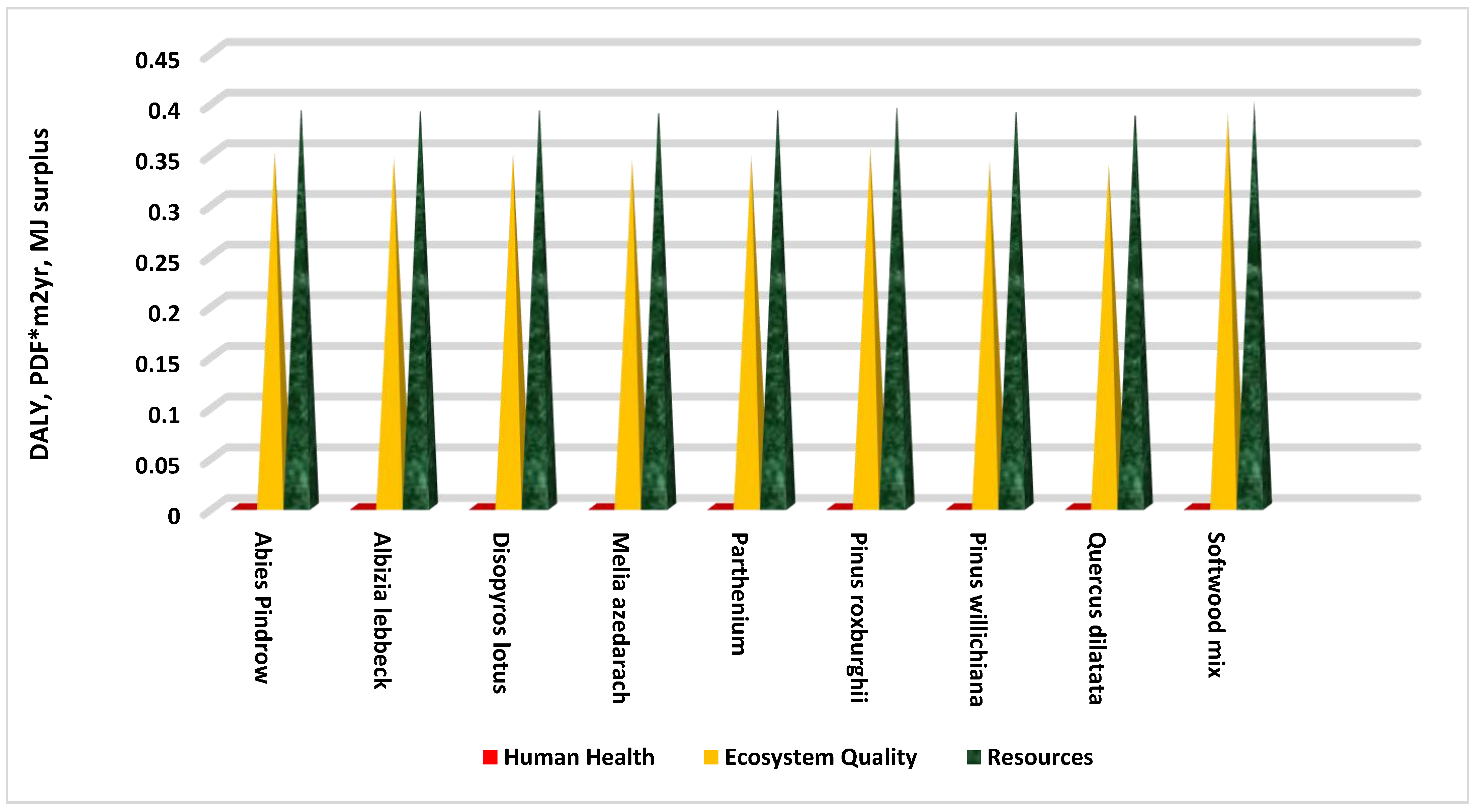

3.12. Damage Assessment of Biomass Pellets from Different Species

3.13. Social Analysis of Biomass Pellets

3.14. Economic Analysis of Biomass Pellets

4. Discussion

5. Conclusions

- Using Melia azedarach as a feedstock to produce wood pellets resulted in smoother and moderately denser wood pellets. The High Heating value was also recorded in the wood pellets of Melia azedarach.

- In the environmental impacts, the highest contribution was shown in the Marin aquatic ecotoxicity by the wood pellets produced from the softwood sawdust.

- It is concluded that lubricating oil should be replaced by an environmentally friendly adhesive to avoid environmental damage.

- In future research, it is recommended to use the needles of Pine trees as it would improve the ignition properties due to the presence of high lignin and resinous contents.

- This study concluded that the highest carbon footprint (0.186 CO2 e) was for Softwood mixed species, while the lowest carbon footprint was recorded (0.173 CO2 e) for Quercus dilatata.

- In the conclusion reported by (Yusuf et al. [74]) it is recommended to use Mbwazirume peel (MP) in future research on wood pellets, as its thermal analysis showed excellent properties.

- The limitations in this study were the unavailability of proper high voltage electricity and binder/adhesive for wood pellets biofuel manufacture.

- This study was complicated because there were not enough sawmills near the study site to collect the data easily.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lykidis, C.; Kamperidou, V.; Mantanis, G.I. The Use of Black Pine Bark for Improving the Properties of Wood Pellets. Forests 2023, 14, 1069. [Google Scholar] [CrossRef]

- Varma, A.K.; Thakur, L.S.; Shankar, R.; Mondal, P. Pyrolysis of wood sawdust: Effects of process parameters on products yield and characterization of products. Waste Manag. 2019, 89, 224–235. [Google Scholar] [CrossRef] [PubMed]

- Martins, F.; Felgueiras, C.; Smitkova, M.; Caetano, N. Analysis of fossil fuel energy consumption and environmental impacts in European countries. Energies 2019, 12, 964. [Google Scholar]

- Intergovernmental Panel on Climate Change. IPCC Climate Change; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Malode, S.J.; Prabhu, K.K.; Mascarenhas, R.J.; Shetti, N.P.; Aminabhavi, T.M. Recent advances and viability in biofuel production. Energy Convers. Manag. 2021, 10, 100070. [Google Scholar] [CrossRef]

- Antar, M.; Lyu, D.; Nazari, M.; Shah, A.; Zhou, X.; Smith, D.L. Biomass for a sustainable bio economy: An overview of world biomass production and utilization. Renew. Sustain. Energy Rev. 2021, 139, 110691. [Google Scholar] [CrossRef]

- Perera, F.; Ashrafi, A.; Kinney, P.; Mills, D. Towards a fuller assessment of benefits to children’s health of reducing air pollution and mitigating climate change due to fossil fuel combustion. Environ. Res. 2019, 172, 55–72. [Google Scholar]

- Pełka, G.; Jach-Nocoń, M.; Paprocki, M.; Jachimowski, A.; Luboń, W.; Nocoń, A.; Wygoda, M.; Wyczesany, P.; Pachytel, P.; Mirowski, T. Comparison of Emissions and Efficiency of Two Types of Burners When Burning Wood Pellets from Different Suppliers. Energies 2023, 16, 1695. [Google Scholar] [CrossRef]

- Sharma, S.; Kundu, A.; Basu, S.; Shetti, N.P.; Aminabhavi, T.M. Sustainable environmental management and related biofuel technologies. J. Environ. Manag. 2020, 273, 111096. [Google Scholar] [CrossRef]

- Perea-Moreno, M.A.; Samerón-Manzano, E.; Perea-Moreno, A.J. Biomass as renewable energy: Worldwide research trends. Sustainability 2019, 11, 863. [Google Scholar] [CrossRef] [Green Version]

- Visser, L.; Hoefnagels, R.; Junginger, M. Wood pellet supply chain costs—A review and cost optimization analysis. Renew. Sustain. Energy Rev. 2020, 118, 109506. [Google Scholar] [CrossRef]

- Manzano-Agugliaro, F.; Alcayde, A.; Montoya, F.G.; Zapata-Sierra, A.; Gil, C. Scientific production of renewable energies worldwide: An overview. Renew. Sustain. Energy Rev. 2013, 18, 134–143. [Google Scholar] [CrossRef]

- Lazarus, M.; van Asselt, H. Fossil fuel supply and climate policy: Exploring the road less taken. Clim. Chang. 2018, 150, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Arifudin, M.; Annakotapary, D.I.M.; Sariningsih, N.I. Characteristics of wood pellet from sawdust pelletized with the hand meat grinder. IOP Conf. Ser. Earth Environ. Sci. 2021, 753, 012017. [Google Scholar]

- Zadravec, T.; Rajh, B.; Kokalj, F.; Samec, N. The impact of secondary air boundary conditions on CFD results in small-scale wood pellet combustion. Fuel 2022, 324, 124451. [Google Scholar] [CrossRef]

- Brosowski, A.; Krause, T.; Mantau, U.; Mahro, B.; Noke, A.; Richter, F.; Raussen, T.; Bischof, R.; Hering, T.; Blanke, C.; et al. How to measure the impact of biogenic residues, wastes and by-products: Development of a national resource monitoring based on the example of Germany. Biomass Bioenergy 2019, 127, 105275. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Song, Y.C.; Li, W.Y.; Feng, J. Ash contents and ash-forming elements of biomass and their significance for solid biofuel combustion. Fuel 2017, 208, 377–409. [Google Scholar] [CrossRef]

- Gündüz, G.; Saraçoğlu, N.; Aydemir, D. Characterization and elemental analysis of wood pellets obtained from low-valued types of wood. Energy Sources Part A Recovery Util. Environ. Eff. 2016, 38, 2211–2216. [Google Scholar] [CrossRef]

- Di Giacomo, G.; Taglieri, L. Renewable energy benefits with conversion of woody residues to pellets. Energy. 2009, 34, 724–731. [Google Scholar] [CrossRef]

- Guo, M.; Song, W.; Buhain, J. Bioenergy and biofuels: History, status, and perspective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Boukherroub, T.; LeBel, L.; Lemieux, S. An integrated wood pellet supply chain development: Selecting among feedstock sources and arange of operating scales. Appl. Energy 2017, 198, 385–400. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. The Pellet Handbook: The Production and Thermal Utilization of Pellets; Routledge: London, UK, 2010. [Google Scholar]

- Kuokkanen, M.; Kuokkanen, T.; Stoor, T.; Niinimäki, J.; Pohjonen, V. Chemical methods in the development of eco-efficient wood-based pellet production. Waste Manag. Res. 2009, 27, 561–571. [Google Scholar] [CrossRef]

- Thomson, H.; Liddell, C. The suitability of wood pellet heating for domestic households: A review of literature. Renew. Sustain. Energy Rev. 2015, 42, 1362–1369. [Google Scholar] [CrossRef]

- Hughes, N.M.; Shahi, C.; Pulkki, R. A review of the wood pellet value chain, modern value/supply chain management approaches, and value/supply chain models. J. Renew. Energy 2014, 2014, 654158. [Google Scholar] [CrossRef] [Green Version]

- Mola-Yudego, B.; Selkimäki, M.; González-Olabarria, J.R. Spatial analysis of the wood pellet production for energy in Europe. Renew. Energy 2014, 63, 76–83. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. Life Cycle Assess; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Demırbas, A. The social, economic, and environmental importance of biofuels in the future. Energy Sources Part B Econ. Plan. Policy 2017, 12, 47–55. [Google Scholar]

- Ji, X.; Long, X. A review of the ecological and socioeconomic effects of biofuel and energy policy recommendations. Renew. Sustain. Energy Rev. 2016, 61, 41–52. [Google Scholar] [CrossRef]

- Yousaf, A.; Hadi, R.; Khan, N.; Ibrahim, F.; Moin, H.; Rahim, S.; Hussain, M. Identification of suitable habitat for Taxus wallichiana and Abies pindrow in moist temperate forest using maxent modelling technique. Saudi J. Biol. Sci. 2022, 29, 103459. [Google Scholar] [CrossRef]

- Shah, G.M.; Khan, M.A. Checklist of medicinal plants of Siran Valley, Mansehra, Pakistan. Ethnobot. Leafl. 2006, 1, 6. [Google Scholar]

- Shah, A.H.; Khan, S.M.; Shah, A.H.; Mehmood, A.; Rahman, I.U.; Ahmad, H. Cultural uses of plants among Basikhel tribe of district Tor Ghar, Khyber Pakhtunkhwa, Pakistan. Pak. J. Bot. 2015, 47, 23–41. [Google Scholar]

- Haq, F. The critically endangered flora and fauna of district Battagram Pakistan. Adv. Life Sci. 2012, 2, 118–123. [Google Scholar] [CrossRef]

- Khayyam, U.; Noureen, S. Assessing the adverse effects of flooding for the livelihood of the poor and the level of external response: A case study of Hazara Division, Pakistan. Environ. Sci. Pollut. Res. 2020, 27, 19638–19649. [Google Scholar] [CrossRef]

- Khan, W.; Ahmad, H.; Haq, F.; Islam, M.; Bibi, F. Present status of moist temperate vegetation of Thandiani forests district Abbottabad Pakistan. Int. J. Biosci. 2012, 10, 80–88. [Google Scholar]

- Brand, M.A.; Rodrigues, T.M.; da Silva, J.P.; de Oliveira, J. Recovery of agricultural and wood wastes: The effect of biomass blends on the quality of pellets. Fuel 2021, 284, 118881. [Google Scholar] [CrossRef]

- Rashedi, A.; Gul, N.; Hussain, M.; Hadi, R.; Khan, N.; Nadeem, S.G.; Khanam, T.; Asyraf, M.R.M.; Kumar, V. Life cycle environmental sustainability and cumulative energy assessment of biomass pellets biofuel derived from agroforest residues. PLoS ONE 2022, 17, e0275005. [Google Scholar] [CrossRef] [PubMed]

- Tiryaki, B.; Yagmur, E.; Banford, A.; Aktas, Z. Comparison of activated carbon produced from natural biomass and equivalent chemical compositions. J. Anal. Appl. Pyrolysis 2014, 105, 276–283. [Google Scholar] [CrossRef]

- Adams, P.; McManus, M. Small-scale biomass gasification CHP utilization in industry: Energy and environmental evaluation. Sustain. Energy Technol. Assess. 2014, 6, 129–140. [Google Scholar]

- Khanam, T.; Khalid, F.; Manzoor, W.; Rashedi, A.; Hadi, R.; Ullah, F.; Rehman, F.; Akhtar, A.; Babu, N.K.; Hussain, M. Environmental sustainability assessment of biodiesel production from Jatropha curcas L. seeds oil in Pakistan. PLoS ONE 2021, 16, e0258409. [Google Scholar] [CrossRef]

- Suh, S.; Lenzen, M.; Treloar, G.J.; Hondo, H.; Horvath, A.; Huppes, G.; Jolliet, O.; Klann, U.; Krewitt, W.; Moriguchi, Y.; et al. System boundary selection in life-cycle inventories using hybrid approaches. Environ. Sci. Technol. 2004, 38, 657–664. [Google Scholar] [CrossRef] [PubMed]

- Padilla-Rivera, A.; Barrette, J.; Blanchet, P.; Thiffault, E. Environmental performance of eastern Canadian wood pellets as measured through life cycle assessment. Forests 2017, 8, 352. [Google Scholar]

- Artemio, C.P.; Maginot, N.H.; Serafín, C.U.; Rahim, F.P.; Guadalupe, R.Q.J.; Fermín, C.M. Physical, mechanical and energy characterization of wood pellets obtained from three common tropical species. PeerJ 2018, 6, e5504. [Google Scholar] [CrossRef] [Green Version]

- Moliner, C.; Lagazzo, A.; Bosio, B.; Botter, R.; Arato, E. Production, characterization, and evaluation of pellets from rice harvest residues. Energies 2020, 13, 479. [Google Scholar] [CrossRef] [Green Version]

- Samuelsson, R.; Larsson, S.H.; Thyrel, M.; Lestander, T.A. Moisture content and storage time influence the binding mechanisms in biofuel wood pellets. Appl. Energy 2012, 99, 109–115. [Google Scholar] [CrossRef]

- Lestander, T.A.; Finell, M.; Samuelsson, R.; Arshadi, M.; Thyrel, M. Industrial scale biofuel pellet production from blends of unbarked softwood and hardwood stems—The effects of raw material composition and moisture content on pellet quality. Fuel Process. Technol. 2012, 95, 73–77. [Google Scholar] [CrossRef]

- Feng, X.; Yu, C.; Shu, Z.; Liu, X.; Yan, W.; Zheng, Q.; Sheng, K.; He, Y. Rapid and non-destructive measurement of biofuel pellet quality indices based on two-dimensional near infrared spectroscopic imaging. Fuel 2018, 228, 197–205. [Google Scholar] [CrossRef]

- Qin, K.; Thunman, H. Diversity of chemical composition and combustion reactivity of various biomass fuels. Fuel 2015, 147, 161–169. [Google Scholar] [CrossRef]

- Alakangas, E. European Standard (EN 14961) for wood chips and hog fuel. For. Bioenergy 2010, 47, 329–340. [Google Scholar]

- Arranz, J.I.; Miranda, M.T.; Montero, I.; Sepúlveda, F.J.; Rojas, C.V. Characterization and combustion behaviour of commercial and experimental wood pellets in South West Europe. Fuel 2015, 142, 199–207. [Google Scholar] [CrossRef]

- Liu, Z.; Mi, B.; Jiang, Z.; Fei, B.; Cai, Z. Improved bulk density of bamboo pellets as biomass for energy production. Renew. Energy 2016, 86, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Graham, S.; Eastwick, C.; Snape, C.; Quick, W. Mechanical degradation of biomass wood pellets during long term stockpile storage. Fuel Process. Technol. 2017, 160, 143–151. [Google Scholar] [CrossRef]

- Acampora, A.; Civitarese, V.; Sperandio, G.; Rezaei, N. Qualitative characterization of the pellet obtained from hazelnut and olive tree pruning. Energies 2021, 14, 4083. [Google Scholar] [CrossRef]

- Shojaeiarani, J.; Bajwa, D.S.; Bajwa, S.G. Properties of densified solid biofuels in relation to chemical composition, moisture content, and bulk density of the biomass. BioResources 2019, 14, 4996–5015. [Google Scholar] [CrossRef]

- Peng, J.; Wang, J.; Bi, X.T.; Lim, C.J.; Sokhansanj, S.; Peng, H.; Jia, D. Effects of thermal treatment on energy density and hardness of torrefied wood pellets. Fuel Process. Technol. 2015, 129, 168–173. [Google Scholar] [CrossRef]

- Peng, J.; Bi, H.; Lim, C.; Sokhansanj, S. Study on density, hardness, and moisture uptake of torrefied wood pellets. Energy Fuels 2013, 27, 967–974. [Google Scholar] [CrossRef]

- Kizuka, R.; Ishii, K.; Sato, M.; Fujiyama, A. Characteristics of wood pellets mixed with torrefied rice straw as a biomass fuel. Int. J. Energy Environ. Eng. 2019, 10, 357–365. [Google Scholar] [CrossRef] [Green Version]

- Hussain, M.; Malik, R.N.; Taylor, A. Carbon footprint as an environmental sustainability indicator for the particleboard produced in Pakistan. Environ. Res. 2017, 155, 385–393. [Google Scholar] [CrossRef] [PubMed]

- Pergola, M.; Gialdini, A.; Celano, G.; Basile, M.; Caniani, D.; Cozzi, M.; Gentilesca, T.; Mancini, I.M.; Pastore, V.; Romano, S.; et al. An environmental and economic analysis of the wood-pellet chain: Two case studies in Southern Italy. Int. J. Life Cycle Assess. 2018, 23, 1675–1684. [Google Scholar] [CrossRef]

- Magelli, F.; Boucher, K.; Bi, H.T.; Melin, S.; Bonoli, A. An environmental impact assessment of exported wood pellets from Canada to Europe. Biomass Bioenergy 2009, 33, 434–441. [Google Scholar] [CrossRef]

- Jović, M.; Laković, M.; Jovčevski, M. A Carbon Footprint from Wood Pellet. In Facta Universitatis. Series: Working and Living Environmental Protection; University of Niš: Niš, Serbia, 2018; pp. 81–88. [Google Scholar]

- Gerbens-Leenes, P.; Hoekstra, A.Y.; Van der Meer, T. The water footprint of energy from biomass: A quantitative assessment and consequences of an increasing share of bio-energy in energy supply. Ecol. Econ. 2009, 68, 1052–1060. [Google Scholar] [CrossRef]

- Schyns, J.F.; Booij, M.J.; Hoekstra, A.Y. The water footprint of wood for lumber, pulp, paper, fuel and firewood. Adv. Water Resour. 2017, 107, 490–501. [Google Scholar] [CrossRef]

- Homdoung, N. Characterization of torrefied biomass pellets from agricultural residues for solid fuels. Agric. Eng. Int.: CIGR J. 2020, 22, 118–128. [Google Scholar]

- Adams, P.; Shirley, J.; McManus, M. Comparative cradle-to-gate life cycle assessment of wood pellet production with torrefaction. Appl. Energy 2015, 138, 367–380. [Google Scholar] [CrossRef] [Green Version]

- Sultana, R.; Rashedi, A.; Khanam, T.; Jeong, B.; Hosseinzadeh-Bandbafha, H.; Hussain, M. Life cycle environmental sustainability and energy assessment of timber wall construction: A comprehensive overview. Sustainability 2022, 14, 4161. [Google Scholar] [CrossRef]

- Hassan, M.; Hussain, M.; Ali, A.; Rehman, F.; Tabassum, A.; Amin, M.; Usman, N.; Bashir, S.; Raza, G.; Yousaf, A.; et al. Economic valuation of selected ecosystem services in Islamabad Capital Territory (ICT), Pakistan. Braz. J. Biol. 2022, 84, e260614. [Google Scholar] [CrossRef]

- Li, X.; Mupondwa, E.; Panigrahi, S.; Tabil, L.; Adapa, P. Life cycle assessment of densified wheat straw pellets in the Canadian Prairies. Int. J. Life Cycle Assess. 2012, 17, 420–431. [Google Scholar] [CrossRef]

- Saosee, P.; Sajjakulnukit, B.; Gheewala, S.H. Environmental externalities of wood pellets from fast-growing and para-rubber trees for sustainable energy production: A case in Thailand. Energy Convers. Manag. 2022, 14, 100183. [Google Scholar]

- Rashedi, A.; Muhammadi, I.U.; Hadi, R.; Nadeem, S.G.; Khan, N.; Ibrahim, F.; Hassan, M.Z.; Khanam, T.; Jeong, B.; Hussain, M. Characterization and life cycle exergo-environmental analysis of wood pellet biofuel produced in Khyber Pakhtunkhwa, Pakistan. Sustainability 2022, 14, 2082. [Google Scholar] [CrossRef]

- Fantozzi, F.; Buratti, C. Life cycle assessment of biomass chains: Wood pellet from short rotation coppice using data measured on a real plant. Biomass Bioenergy 2010, 34, 1796–1804. [Google Scholar] [CrossRef] [Green Version]

- Trømborg, E.; Ranta, T.; Schweinle, J.; Solberg, B.; Skjevrak, G.; Tiffany, D.G. Economic sustainability for wood pellets production—A comparative study between Finland, Germany, Norway, Sweden and the US. Biomass Bioenergy 2013, 57, 68–77. [Google Scholar] [CrossRef]

- Saosee, P.; Sajjakulnukit, B.; Gheewala, S.H. Environmental and Socio-economic Assessment of Wood pellet Production from Fast growing trees in Thailand. IOP Conf. Ser. Earth Environ. Sci. 2020, 463, 012049. [Google Scholar] [CrossRef]

- Yusuf, A.A. Production, Evaluation and Testing of Bioethanol from Matooke Peels Species as an Alternative Fuel for Spark Ignition Engine: A Case Study of Uganda. Ph.D. Thesis, University of KwaZulu-Natal, Durban, South Africa, 2020. [Google Scholar]

| Species | Sawdust | Bio Binder | Lubricating Oil | Water | Electricity Consumed |

|---|---|---|---|---|---|

| Unit | g | g | g | L | kWh |

| Parthenium hysterophorus | 1065 | 180 | 50 | 0.555 | 0.056 |

| Pinus wallichiana | 1050 | 170 | 50 | 0.521 | 0.055 |

| Quercus dilatata | 1040 | 165 | 50 | 0.498 | 0.054 |

| Pinus roxburghii | 1090 | 200 | 50 | 0.601 | 0.055 |

| Abies pindrow | 1080 | 200 | 50 | 0.594 | 0.053 |

| Melia azedarach | 1055 | 175 | 50 | 0.411 | 0.055 |

| Diospyros Lotus | 1070 | 180 | 50 | 0.541 | 0.056 |

| Albizia lebbeck | 1060 | 175 | 50 | 0.529 | 0.054 |

| Softwood mixed | 1045 | 170 | 50 | 0.499 | 0.054 |

| Italian Standard | 6 ± 0.5–8 | ≤10 |

|---|---|---|

| Pellets | Diameter Average (mm) | Length Average (mm) |

| Parthenium hysterophorus | 10.3 | 36.4 |

| Pinus wallichiana | 10.3 | 37.8 |

| Quercus dilatata | 10.3 | 38.2 |

| Pinus roxburghii | 10.3 | 43.9 |

| Abies pindrow | 10.3 | 33.8 |

| Melia azedarach | 10.3 | 41.2 |

| Diospyros Lotus | 10.3 | 43.3 |

| Albizia lebbeck | 10.3 | 40.2 |

| Softwood mix | 10.3 | 27.6 |

| Italian Standard | ≤10 | ≤0.7 | 620–720 |

|---|---|---|---|

| Pellets | Moisture Content, % | Ash Content, % | Bulk Density, kg/m³ |

| Parthenium hysterophorus | 5.14 | 4.58 | 650 |

| Pinus wallichiana | 5.14 | 7 | 680 |

| Quercus dilatata | 5.29 | 4.99 | 810 |

| Pinus roxburghii | 9.97 | 0.61 | 500 |

| Abies pindrow | 7.94 | 0.31 | 930 |

| Melia azedarach | 8.76 | 3.15 | 710 |

| Diospyros Lotus | 9.01 | 3.98 | 640 |

| Albizia lebbeck | 7.36 | 0.68 | 720 |

| Softwood mix | 7.22 | 4.75 | 700 |

| Italian Standard for HHV of Wood Pellets (≥16.91 MJ/kg) | ||

|---|---|---|

| Pellets | HHV, (MJ/kg) | LHV, (MJ/kg) |

| Parthenium hysterophorus | 22.23 | 20.26 |

| Pinus wallichiana | 23.39 | 21.65 |

| Quercus dilatata | 22.83 | 20.98 |

| Pinus roxburghii | 23.01 | 21.19 |

| Abies pindrow | 22.21 | 20.24 |

| Melia azedarach | 24.79 | 23.33 |

| Diospyros Lotus | 23.25 | 21.49 |

| Albizia lebbeck | 22.68 | 20.80 |

| Softwood mixed | 23.84 | 22.19 |

| Italian Standard | ≤0.3 | ≤0.5 |

|---|---|---|

| Wood Pellets | Nitrogen % | Sulfur % |

| Parthenium hysterophorus | 1.03 | 0.03 |

| Pinus wallichiana | 1.20 | Not detected. |

| Quercus dilatata | 1.04 | Not detected. |

| Pinus roxburghii | 0.49 | Not detected. |

| Abies pindrow | 0.69 | Not detected. |

| Melia azedarach | 0.61 | Not detected. |

| Diospyros Lotus | 0.56 | Not detected. |

| Albizia lebbeck | 0.72 | 0.05. |

| Softwood mix | 0.64 | Not detected. |

| Impact Category | Unit | Abies pindrow | Albizia lebbeck | Diospyros lotus | Melia azedarach | Parthenium | Pinus roxburghi | Pinus wallichiana | Quercus dilatata | Softwood Mixed |

|---|---|---|---|---|---|---|---|---|---|---|

| Abiotic depletion | kg Sb eq | 0.00239 | 0.00239 | 0.00239 | 0.00237 | 0.00240 | 0.00241 | 0.00238 | 0.00235 | 0.00244 |

| Acidification | kg SO2 eq | 0.00090 | 0.00089 | 0.00089 | 0.00088 | 0.00089 | 0.00091 | 0.00088 | 0.00086 | 0.00090 |

| Eutrophication | kg PO4-eq | 0.00035 | 0.00035 | 0.00036 | 0.00035 | 0.00036 | 0.00036 | 0.00035 | 0.00034 | 0.00036 |

| Global warming | kg CO2 eq | 0.17666 | 0.17573 | 0.17651 | 0.17388 | 0.17689 | 0.17873 | 0.17494 | 0.17197 | 0.18440 |

| Ozone layer depletion | CFC-11 eq | 4.4 × 10−8 | 4.44 × 10−8 | 4.45 × 10−8 | 4.438 × 10−8 | 4.454 × 10−8 | 4.47 × 10−8 | 4.438 × 10−8 | 4.42 × 10−8 | 4.58 × 10−8 |

| Human toxicity | kg 1,4-DB eq | 0.1589 | 0.1570 | 0.1576 | 0.1568 | 0.1579 | 0.1593 | 0.1564 | 0.1553 | 0.1643 |

| Freshwater aquatic ecotoxicity | kg 1,4-DB eq | 0.0690 | 0.0695 | 0.0696 | 0.0686 | 0.0700 | 0.0699 | 0.0694 | 0.0680 | 0.0709 |

| Marine aquatic ecotoxicity | kg 1,4-DB eq | 145.4711 | 146.5664 | 146.8872 | 144.1382 | 147.5428 | 147.9535 | 146.2456 | 142.8842 | 149.8558 |

| Terrestrial ecotoxicity | kg 1,4-DB eq | 0.0008 | 0.0008 | 0.0008 | 0.0008 | 0.0008 | 0.0008 | 0.0008 | 0.0008 | 0.0008 |

| Photochemical oxidation | kg C2H4 eq | 6.923 × 10−5 | 6.812 × 10−5 | 6.856 × 10−5 | 6.771 × 10−5 | 6.852 × 10−5 | 6.977 × 10−5 | 6.769 × 10−5 | 6.688 × 10−5 | 7.272 × 10−5 |

| Impact Category | Unit | Abies pindrow | Albizia lebbeck | Diospyros lotus | Melia azedarach | Parthenium | Pinus roxburghii | Pinus wallichiana | Quercus dilatata | Softwood Mix |

|---|---|---|---|---|---|---|---|---|---|---|

| Nonrenewable fossil | MJ | 5.0412 | 5.0285 | 5.0407 | 4.9989 | 5.0446 | 5.0745 | 5.0163 | 4.9711 | 5.1648 |

| Non-renewable biomass | MJ | 0.0017 | 0.0016 | 0.0016 | 0.0016 | 0.0016 | 0.0017 | 0.0016 | 0.0016 | 0.0018 |

| Renewable biomass | MJ | 21.7855 | 21.3861 | 21.5861 | 21.2856 | 21.4865 | 21.986 | 21.1861 | 20.9852 | 24.1862 |

| Renewable water | MJ | 0.0005 | 0.003 | 0.0029 | 0.0008 | 0.0035 | 0.0026 | 0.0031 | 0.0005 | 0.0019 |

| Impact Categories | Unit | Abies pindrow | Albizia lebbeck | Diospyros lotus | Melia azedarach | Parthenium | Pinus roxburghii | Pinus wallichiana | Quercus dilatata | Softwood Mix |

|---|---|---|---|---|---|---|---|---|---|---|

| Carcinogens | DALY | 6.383 × 10−8 | 6.409 × 10−8 | 6.414 × 10−8 | 6.368 × 10−8 | 6.442 × 10−8 | 6.426 × 10−8 | 6.404 × 10−8 | 6.331 × 10−8 | 6.504 × 10−8 |

| Respiratory organics | DALY | 1.680 × 10−9 | 1.675 × 10−9 | 1.677 × 10−9 | 1.674 × 10−9 | 1.676 × 10−9 | 1.682 × 10−9 | 1.673 × 10−9 | 1.671 × 10−9 | 1.700 × 10−9 |

| Respiratory inorganics | DALY | 2.663 × 10−7 | 2.668 × 10−7 | 2.680 × 10−7 | 2.614 × 10−7 | 2.689 × 10−7 | 2.720 × 10−7 | 2.656 × 10−7 | 2.581 × 10−7 | 2.780 × 10−7 |

| Climate change | DALY | 3.695 × 10−8 | 3.676 × 10−8 | 3.692 × 10−8 | 3.637 × 10−8 | 3.700 × 10−8 | 3.739 × 10−8 | 3.659 × 10−8 | 3.597 × 10−8 | 3.857 × 10−8 |

| Radiation | DALY | 2.945 × 10−10 | 2.988 × 10−10 | 2.989 × 10−10 | 2.940 × 10−10 | 3.009 × 10−10 | 2.993 × 10−10 | 2.986 × 10−10 | 2.910 × 10−10 | 3.030 × 10−10 |

| Ozone layer | DALY | 4.687 × 10−11 | 4.672 × 10−11 | 4.682 × 10−11 | 4.663 × 10−11 | 4.680 × 10−11 | 4.701 × 10−11 | 4.662 × 10−11 | 4.640 × 10−11 | 4.812 × 10−11 |

| Ecotoxicity | PAF*m2yr | 8.204 × 10−2 | 8.131 × 10−2 | 8.154 × 10−2 | 8.145 × 10−2 | 8.185 × 10−2 | 8.202 × 10−2 | 8.108 × 10−2 | 8.000 × 10−2 | 8.400 × 10−2 |

| Acidification | PDF*m2yr | 3.931 × 10−3 | 3.843 × 10−3 | 3.870 × 10−3 | 3.825 × 10−3 | 3.872 × 10−3 | 3.955 × 10−3 | 3.815 × 10−3 | 3.700 × 10−3 | 4.000 × 10−3 |

| Land use | PAF*m2yr | 3.393 × 10−1 | 3.331 × 10−1 | 3.362 × 10−1 | 3.315 × 10−1 | 3.347 × 10−1 | 3.425 × 10−1 | 3.300 × 10−1 | 3.200 × 10−1 | 3.700 × 10−1 |

| Minerals | MJ surplus | 4.222 × 10−3 | 4.155 × 10−3 | 4.161 × 10−3 | 4.207 × 10−3 | 4.168 × 10−3 | 4.173 × 10−3 | 4.149 × 10−3 | 4.187 × 10−3 | 4.240 × 10−3 |

| Fossil fuels | MJ surplus | 3.869 × 10−1 | 3.858 × 10−1 | 3.868 × 10−1 | 3.837 × 10−1 | 3.870 × 10−1 | 3.893 × 10−1 | 3.849 × 10−1 | 3.816 × 10−1 | 3.963 × 10−1 |

| Species | Unit | Sawdust | Bio Binder | Lubricating Oil | Electricity | Labor | Transport | Packing | Total |

|---|---|---|---|---|---|---|---|---|---|

| Abies pindrow | PKR | 3 | 10 | 3 | 2 | 2 | 3 | 2 | 25 |

| Pinus roxburghii | PKR | 3 | 10 | 3 | 2 | 2 | 3 | 2 | 25 |

| Pinus wallichiana | PKR | 4 | 8 | 3 | 2 | 2 | 3 | 2 | 24 |

| Quercus dilatata | PKR | 4 | 8 | 3 | 2 | 2 | 3 | 2 | 24 |

| Melia azedarach | PKR | 4 | 8 | 3 | 2 | 2 | 3 | 2 | 24 |

| Albizia lebbeck | PKR | 5 | 8 | 3 | 2 | 2 | 3 | 2 | 25 |

| Diospyros Lotus | PKR | 5 | 9 | 3 | 2 | 2 | 3 | 2 | 26 |

| Softwood mix | PKR | 3 | 8 | 3 | 2 | 2 | 2 | 2 | 22 |

| Parthenium hysterophorus | PKR | 6 | 9 | 3 | 2 | 2 | 2 | 2 | 26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassan, M.; Usman, N.; Hussain, M.; Yousaf, A.; Khattak, M.A.; Yousaf, S.; Mishr, R.S.; Ahmad, S.; Rehman, F.; Rashedi, A. Environmental and Socio-Economic Assessment of Biomass Pellets Biofuel in Hazara Division, Pakistan. Sustainability 2023, 15, 12089. https://doi.org/10.3390/su151512089

Hassan M, Usman N, Hussain M, Yousaf A, Khattak MA, Yousaf S, Mishr RS, Ahmad S, Rehman F, Rashedi A. Environmental and Socio-Economic Assessment of Biomass Pellets Biofuel in Hazara Division, Pakistan. Sustainability. 2023; 15(15):12089. https://doi.org/10.3390/su151512089

Chicago/Turabian StyleHassan, Maaz, Naveed Usman, Majid Hussain, Adnan Yousaf, Muhammad Aamad Khattak, Sidra Yousaf, Rankeshwarnath Sanjay Mishr, Sana Ahmad, Fariha Rehman, and Ahmad Rashedi. 2023. "Environmental and Socio-Economic Assessment of Biomass Pellets Biofuel in Hazara Division, Pakistan" Sustainability 15, no. 15: 12089. https://doi.org/10.3390/su151512089

APA StyleHassan, M., Usman, N., Hussain, M., Yousaf, A., Khattak, M. A., Yousaf, S., Mishr, R. S., Ahmad, S., Rehman, F., & Rashedi, A. (2023). Environmental and Socio-Economic Assessment of Biomass Pellets Biofuel in Hazara Division, Pakistan. Sustainability, 15(15), 12089. https://doi.org/10.3390/su151512089