Optimizing Thermal Management System in Electric Vehicle Battery Packs for Sustainable Transportation

Abstract

:1. Introduction

2. Methodology

2.1. Data Collection and Pre-Processing

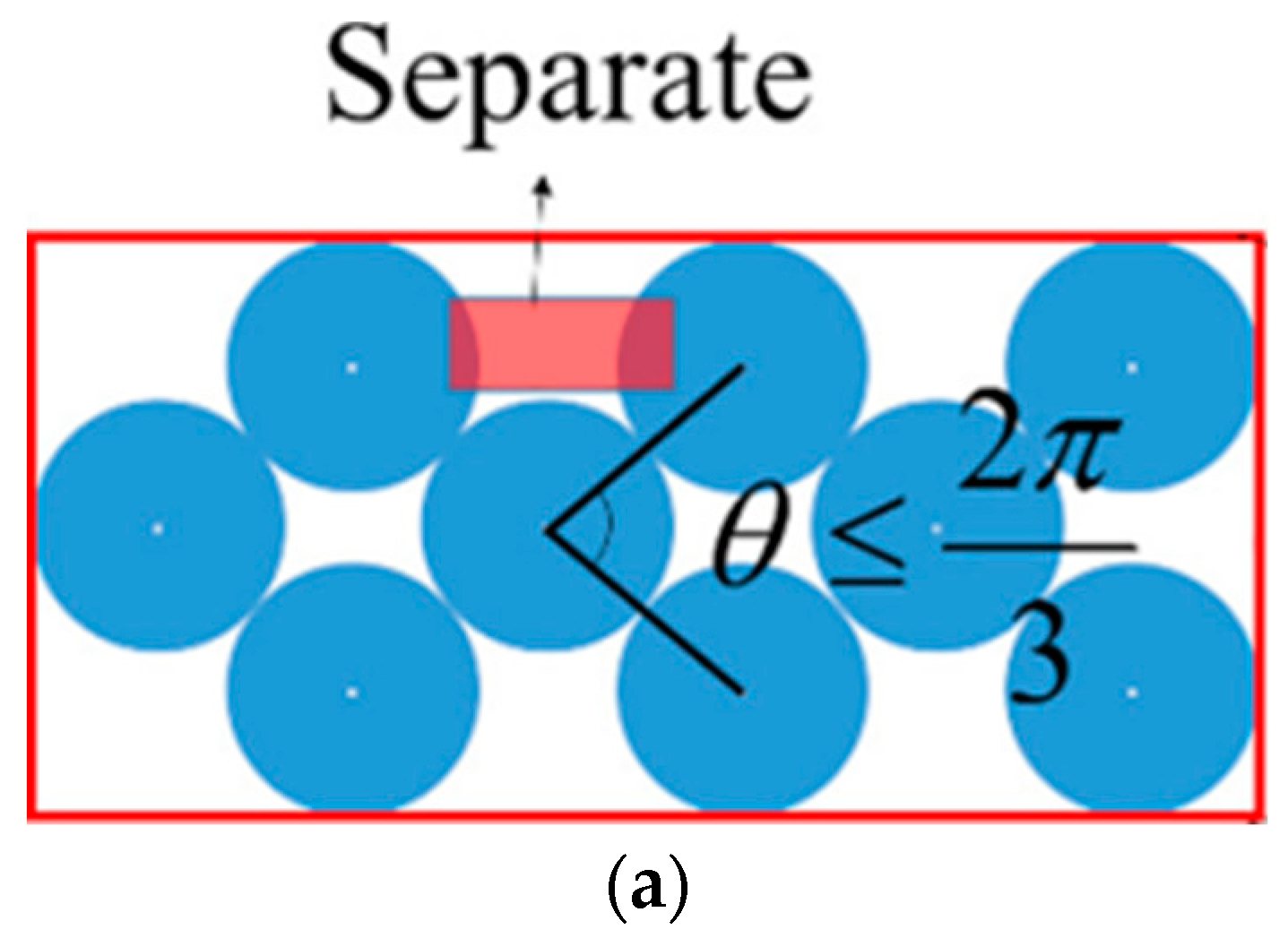

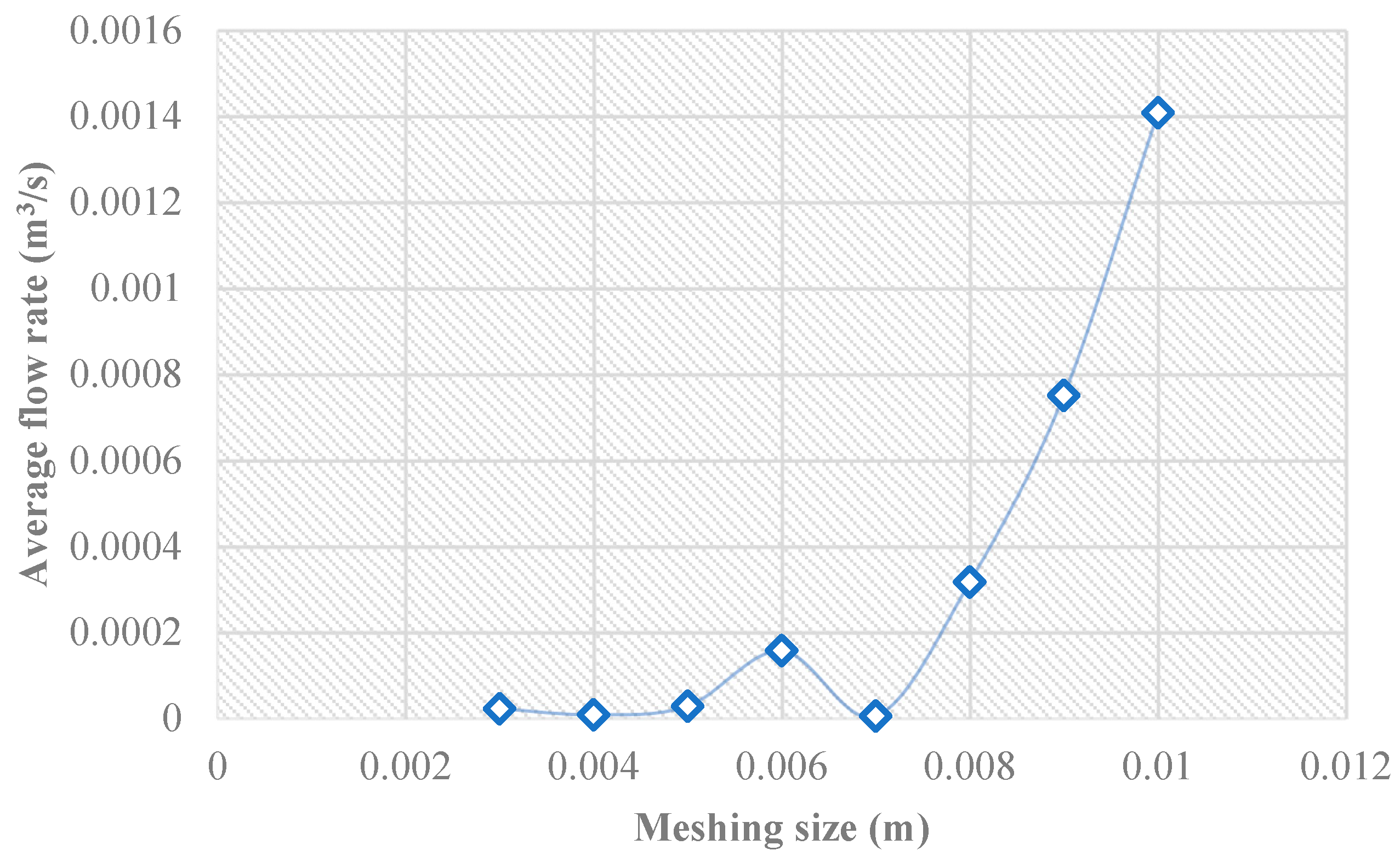

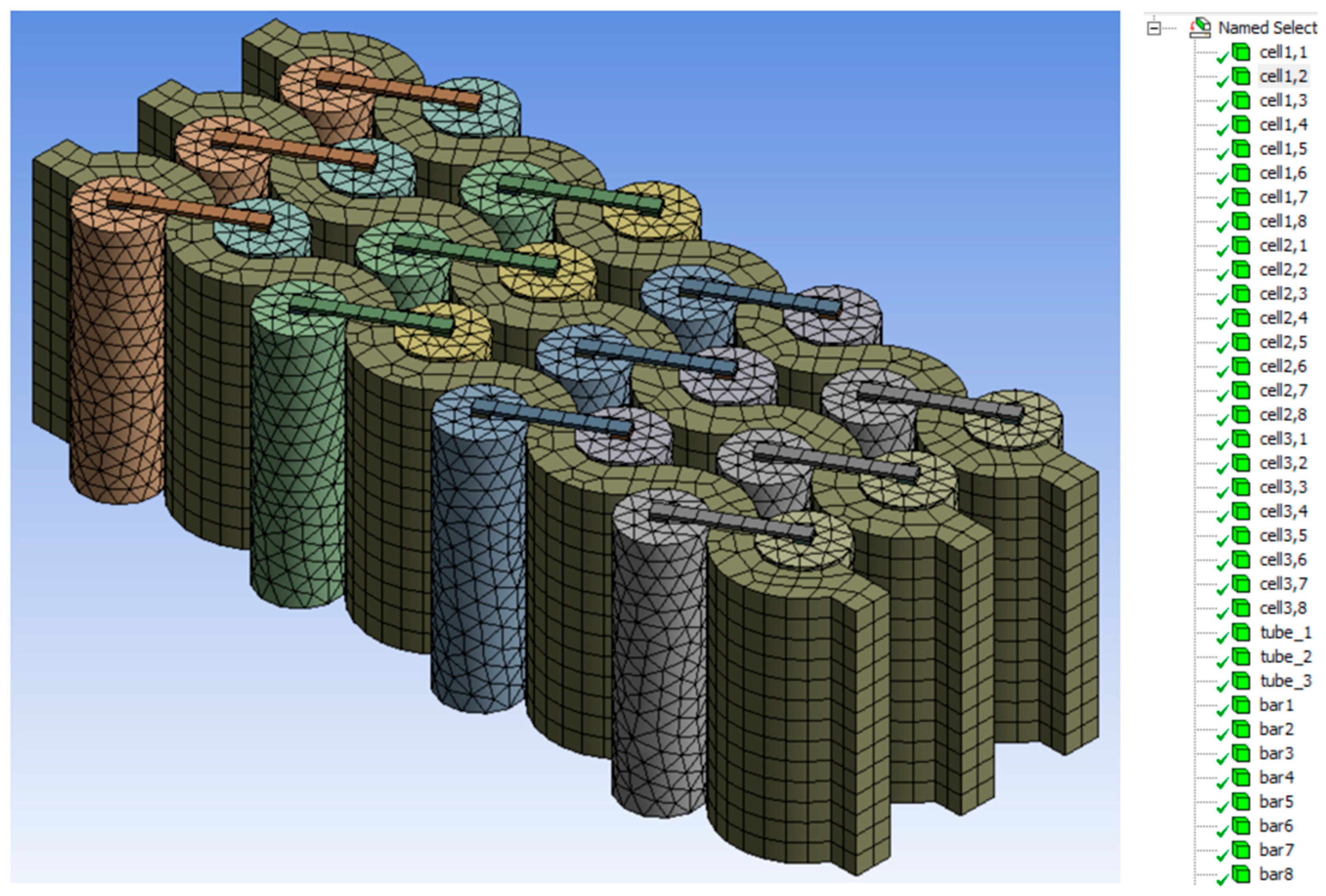

2.2. Multi-Physics Modeling and TMS Design

3. Results and Discussion

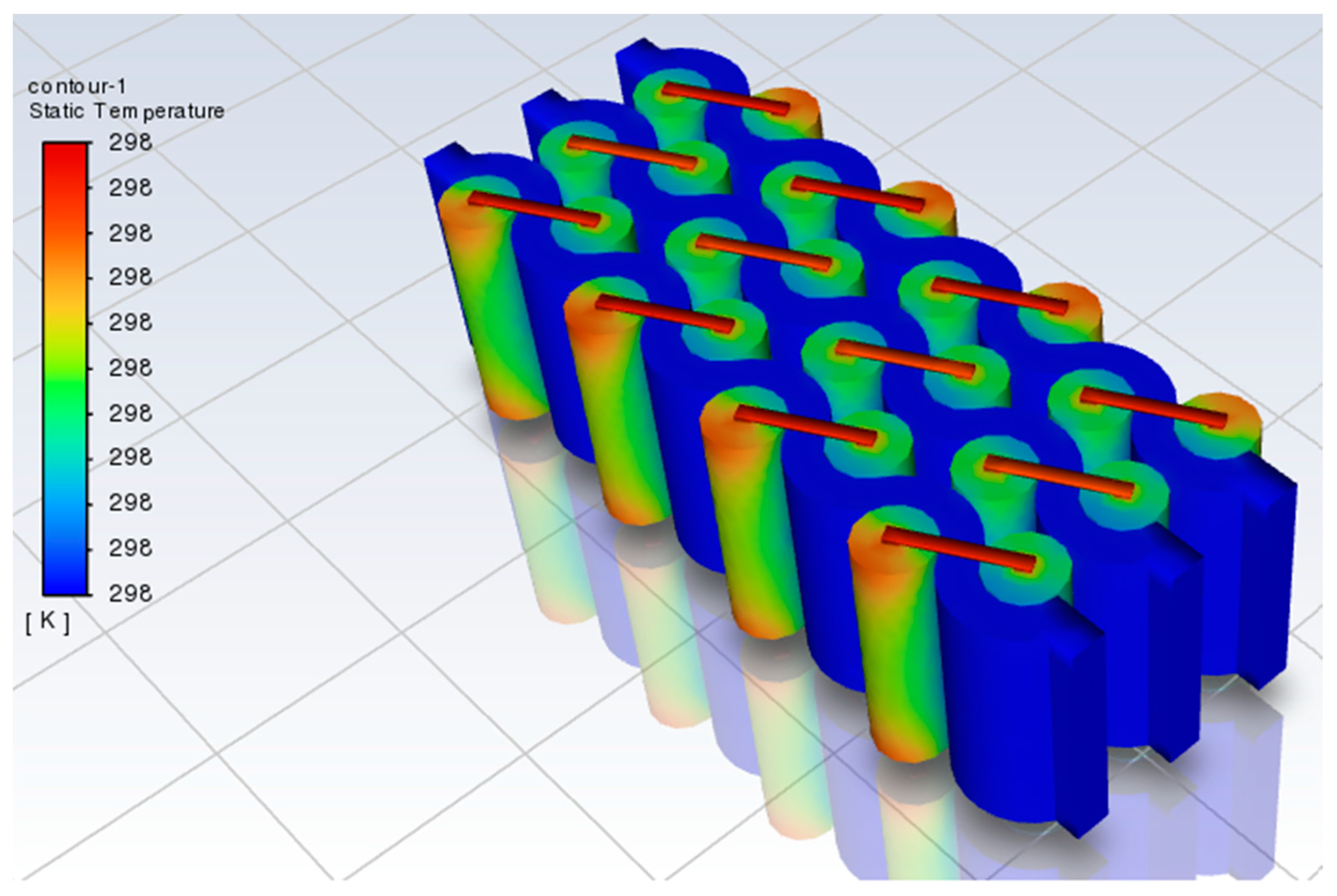

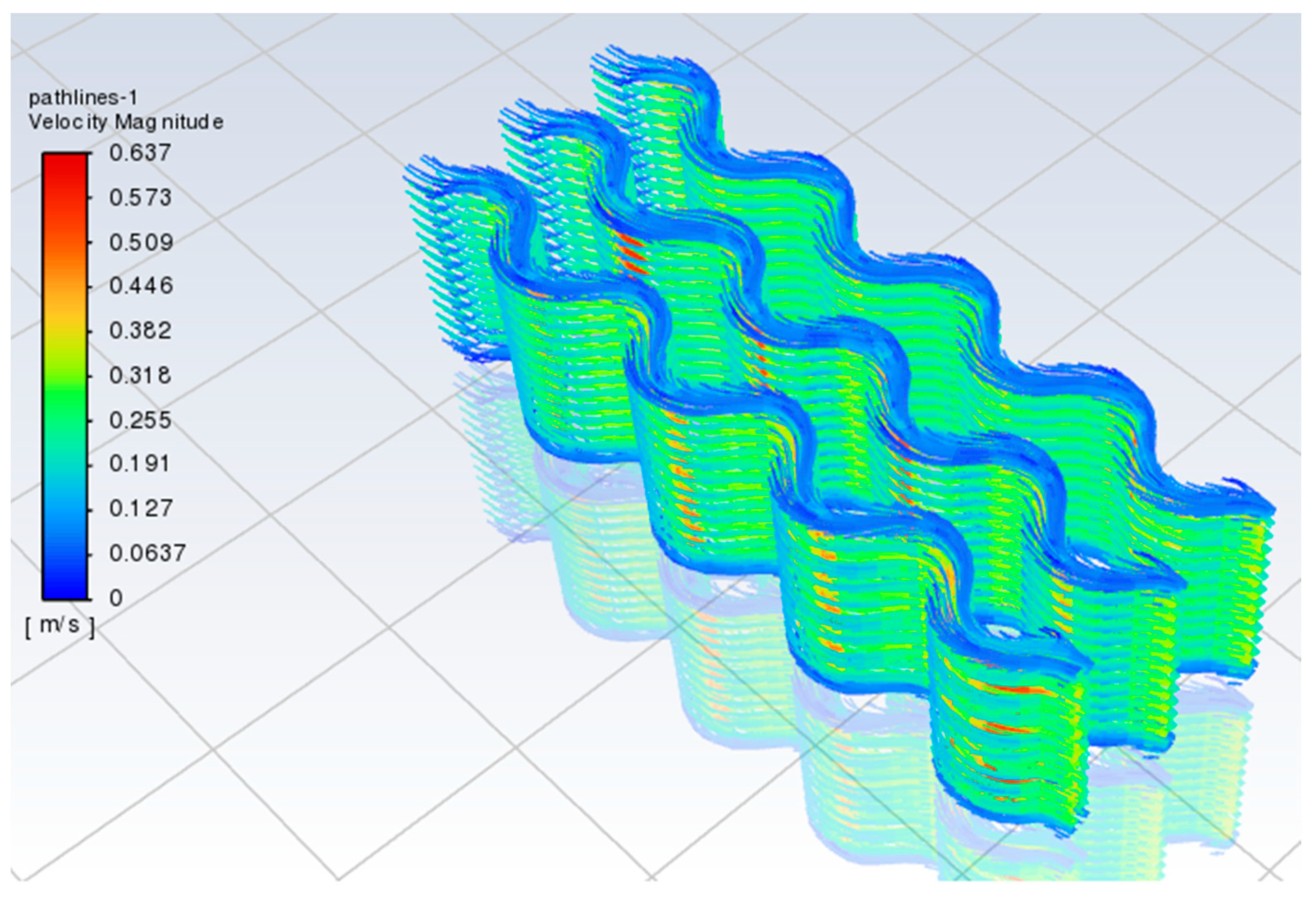

3.1. Temperature Contour and Velocity Path Line of 3p8s Model with

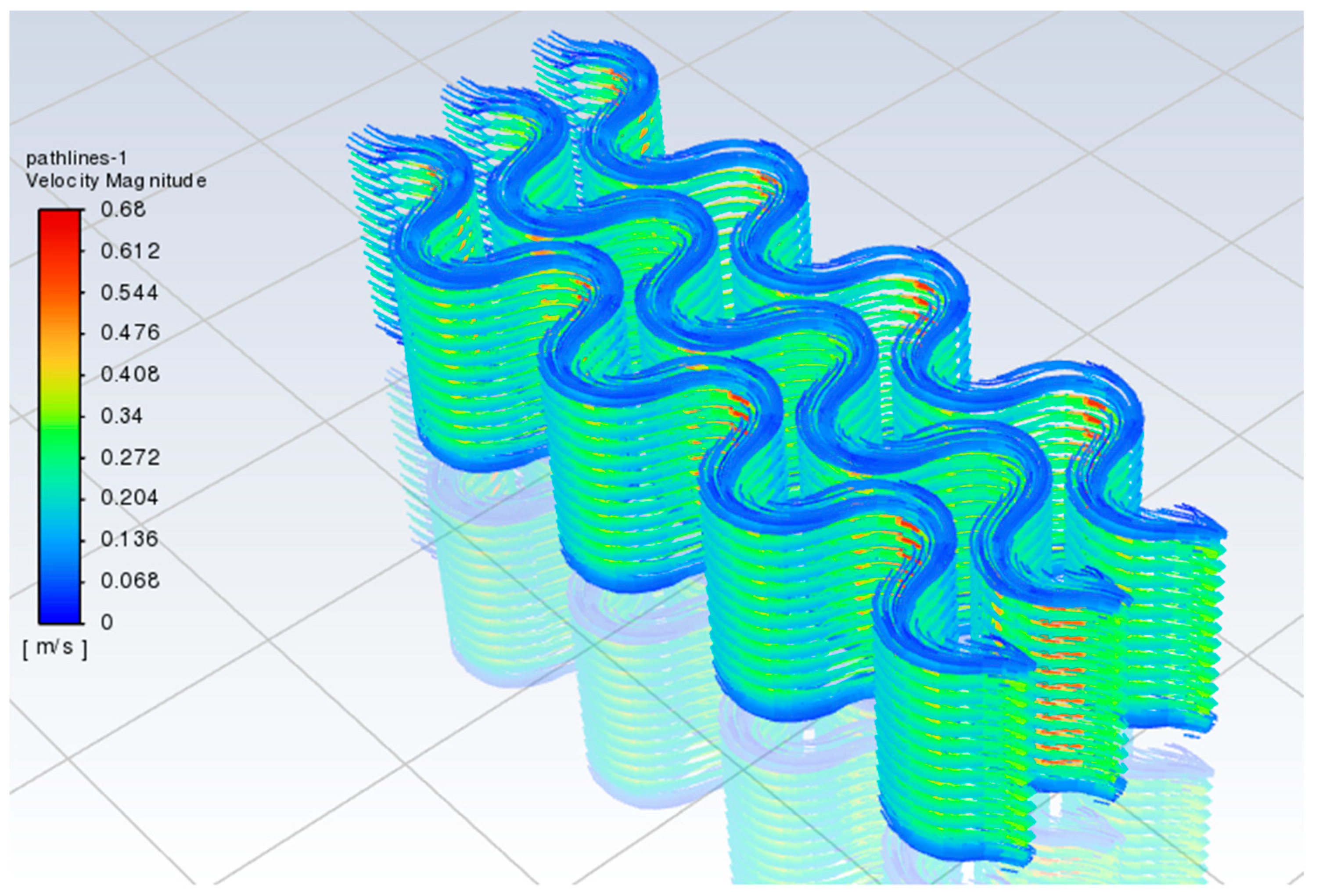

3.2. Temperature Contour and Velocity Path Line of 3p8s model with

3.3. Comparison of Results

- Recognizing the significance of increasing fluid flow velocity to sustain optimal cell temperature;

- As the temperature of a fluid rises, its density decreases and the frictional force against the wall increases at a lower velocity;

- To address the density variation issue, use water with a high specific heat capacity as a coolant;

- Observation that water’s density remains nearly constant as its temperature varies minimally;

- Evidence of uniform and effective heat distribution along the cooling conduit, indicating the design’s viability;

- Emphasizing that the velocity of water only varies at the peak of the cooling tube, indicating the cooling tube’s practicality;

- Noting that the average flow velocity of this design does not vary exponentially throughout the flow.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Olabi, A.G.; Maghrabie, H.M.; Adhari, O.H.K.; Sayed, E.T.; Yousef, B.A.A.; Salameh, T.; Kamil, M.; Abdelkareem, M.A. Battery thermal management systems: Recent progress and challenges. Int. J. Thermofluids 2022, 15, 100171. [Google Scholar] [CrossRef]

- Yokoyama, A. Thermal Management System for Electric Vehicles. SAE Int. J. Mater. Manuf. 2011, 4, 1277–1285. [Google Scholar] [CrossRef]

- Ling, Z.; Wang, F.; Fang, X.; Gao, X.; Zhang, Z. A hybrid thermal management system for lithium ion batteries combining phase change materials with forced-air cooling. Appl. Energy 2015, 148, 403–409. [Google Scholar] [CrossRef] [Green Version]

- Ritchie, A.; Howard, W. Recent developments and likely advances in lithium-ion batteries. J. Power Sources 2006, 162, 809–812. [Google Scholar] [CrossRef]

- Arfeen, Z.A.; Abdullah, M.P.; Hassan, R.; Othman, B.M.; Siddique, A.; Rehman, A.U.; Sheikh, U.U. Energy storage usages: Engineering reactions, economic-technological values for electric vehicles—A technological outlook. Int. Trans. Electr. Energy Syst. 2020, 30, e12422. [Google Scholar] [CrossRef]

- Ye, Y.; Saw, L.H.; Shi, Y.; Tay, A.A.O. Numerical analyses on optimizing a heat pipe thermal management system for lithium-ion batteries during fast charging. Appl. Therm. Eng. 2015, 86, 281–291. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M. Connecting battery technologies for electric vehicles from battery materials to management. iScience 2022, 25, 103744. [Google Scholar] [CrossRef]

- Wang, S.; Takyi-Aninakwa, P.; Jin, S.; Yu, C.; Fernandez, C.; Stroe, D.-I. An improved feedforward-long short-term memory modeling method for the whole-life-cycle state of charge prediction of lithium-ion batteries considering current-voltage-temperature variation. Energy 2022, 254, 124224. [Google Scholar] [CrossRef]

- Wang, S.; Jin, S.; Bai, D.; Fan, Y.; Shi, H.; Fernandez, C. A critical review of improved deep learning methods for the remaining useful life prediction of lithium-ion batteries. Energy Rep. 2021, 7, 5562–5574. [Google Scholar] [CrossRef]

- Hu, X.; Yuan, H.; Zou, C.; Li, Z.; Zhang, L. Co-Estimation of State of Charge and State of Health for Lithium-Ion Batteries Based on Fractional-Order Calculus. IEEE Trans. Veh. Technol. 2018, 67, 10319–10329. [Google Scholar] [CrossRef]

- She, C.; Zhang, L.; Wang, Z.; Sun, F.; Liu, P.; Song, C. Battery State of Health Estimation Based on Incremental Capacity Analysis Method: Synthesizing from Cell-Level Test to Real-World Application. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 11, 214–223. [Google Scholar] [CrossRef]

- Sharma, S.; Panwar, A.K.; Tripathi, M.M. Storage technologies for electric vehicles. J. Traffic Transp. Eng. Engl. Ed. 2020, 7, 340–361. [Google Scholar] [CrossRef]

- Singirikonda, S.; Obulesu, Y.P. Adaptive secondary loop liquid cooling with refrigerant cabin active thermal management system for electric vehicle. J. Energy Storage 2022, 50, 104624. [Google Scholar] [CrossRef]

- Nazar, M.W.; Iqbal, N.; Ali, M.; Nazir, H.; Amjad, M.Z.B. Thermal management of Li-ion battery by using active and passive cooling method. J. Energy Storage 2023, 61, 106800. [Google Scholar] [CrossRef]

- Jin, L.; Tian, J.; Gao, S.; Xie, P.; Akbarzadeh, M.; Kalogiannis, T.; Berecibar, M.; Lan, Y.; Hu, D.; Ding, Y.; et al. A novel hybrid thermal management approach towards high-voltage battery pack for electric vehicles. Energy Convers. Manag. 2021, 247, 114676. [Google Scholar] [CrossRef]

- Xia, Q.; Wang, Z.; Ren, Y.; Sun, B.; Yang, D.; Feng, Q. A reliability design method for a lithium-ion battery pack considering the thermal disequilibrium in electric vehicles. J. Power Sources 2018, 386, 10–20. [Google Scholar] [CrossRef]

- Rao, Z.; Huo, Y.; Liu, X. Experimental study of an OHP-cooled thermal management system for electric vehicle power battery. Exp. Therm. Fluid Sci. 2014, 57, 20–26. [Google Scholar] [CrossRef]

- Wang, Z.; Song, C.; Zhang, L.; Zhao, Y.; Liu, P.; Dorrell, D.G. A Data-Driven Method for Battery Charging Capacity Abnormality Diagnosis in Electric Vehicle Applications. IEEE Trans. Transp. Electrif. 2022, 8, 990–999. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, S.; Wu, M.; Lin, Z.; Li, F. Experimental investigation on thermal management of electric vehicle battery with heat pipe. Energy Convers. Manag. 2013, 65, 92–97. [Google Scholar] [CrossRef]

- Panchal, S.; Dincer, I.; Agelin-Chaab, M.; Fowler, M.; Fraser, R. Uneven temperature and voltage distributions due to rapid discharge rates and different boundary conditions for series-connected LiFePO4 batteries. Int. Commun. Heat Mass Transf. 2017, 81, 210–217. [Google Scholar] [CrossRef]

- Xiong, R.; Li, Z.; Yang, R.; Shen, W.; Ma, S.; Sun, F. Fast self-heating battery with anti-aging awareness for freezing climates application. Appl. Energy 2022, 324, 119762. [Google Scholar] [CrossRef]

- Jin, L.W.; Lee, P.S.; Kong, X.X.; Fan, Y.; Chou, S.K. Ultra-thin minichannel LCP for EV battery thermal management. Appl. Energy 2014, 113, 1786–1794. [Google Scholar] [CrossRef]

- Tousi, M.; Sarchami, A.; Kiani, M.; Najafi, M.; Houshfar, E. Numerical study of novel liquid-cooled thermal management system for cylindrical Li-ion battery packs under high discharge rate based on AgO nanofluid and copper sheath. J. Energy Storage 2021, 41, 102910. [Google Scholar] [CrossRef]

- Sheng, L.; Zhang, H.; Su, L.; Zhang, Z.; Zhang, H.; Li, K.; Fang, Y.; Ye, W. Effect analysis on thermal profile management of a cylindrical lithium-ion battery utilizing a cellular liquid cooling jacket. Energy 2021, 220, 119725. [Google Scholar] [CrossRef]

- Park, H. A design of air flow configuration for cooling lithium ion battery in hybrid electric vehicles. J. Power Sources 2013, 239, 30–36. [Google Scholar] [CrossRef]

- Bisht, A.S.; Bisht, V.S.; Bhandari, P.; Rawat, K.S.; Alam, T.; Blecich, P. The Use of a Vortex Generator for the Efficient Cooling of Lithium-Ion Batteries in Hybrid Electric Vehicles. Processes 2023, 11, 500. [Google Scholar] [CrossRef]

- Lin, C.; Xu, S.; Chang, G.; Liu, J. Experiment and simulation of a LiFePO4 battery pack with a passive thermal management system using composite phase change material and graphite sheets. J. Power Sources 2015, 275, 742–749. [Google Scholar] [CrossRef]

- Lamrani, B.; Lebrouhi, B.E.; Khattari, Y.; Kousksou, T. A simplified thermal model for a lithium-ion battery pack with phase change material thermal management system. J. Energy Storage 2021, 44, 103377. [Google Scholar] [CrossRef]

- Liu, H.; Wen, C.; Yuen, A.C.Y.; Han, Y.; Cheung, S.C.-P.; Kook, S.; Yeoh, G.H. A novel thermal management system for battery packs in hybrid electrical vehicles utilising waste heat recovery. Int. J. Heat Mass Transf. 2022, 195, 123199. [Google Scholar] [CrossRef]

- Sankaran, G.; Venkatesan, S. Standardization of electric vehicle battery pack geometry form factors for passenger car segments in India. J. Power Sources 2021, 502, 230008. [Google Scholar] [CrossRef]

- Waldmann, T.; Scurtu, R.-G.; Richter, K.; Wohlfahrt-Mehrens, M. 18650 vs. 21700 Li-ion cells—A direct comparison of electrochemical, thermal, and geometrical properties. J. Power Sources 2020, 472, 228614. [Google Scholar] [CrossRef]

- Zülke, A.; Li, Y.; Keil, P.; Burrell, R.; Belaisch, S.; Nagarathinam, M.; Mercer, M.P.; Hoster, H.E. High-Energy Nickel-Cobalt-Aluminium Oxide (NCA) Cells on Idle: Anode- versus Cathode-Driven Side Reactions. Batter. Supercaps 2021, 4, 934–947. [Google Scholar] [CrossRef]

- Yatim, A.N.M.; Latif, M.T.; Sofwan, N.M.; Ahamad, F.; Khan, M.F.; Mahiyuddin, W.R.W.; Sahani, M. The association between temperature and cause-specific mortality in the Klang Valley, Malaysia. Environ. Sci. Pollut. Res. 2021, 28, 60209–60220. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Zhang, J.; Zhang, C.; Xu, J. Mechanical integrity of 18650 lithium-ion battery module: Packing density and packing mode. Eng. Fail. Anal. 2018, 91, 315–326. [Google Scholar] [CrossRef] [Green Version]

- Ali, N.; Addali, A.; Amaral Teixeira, J. Effect of Water Temperature, pH Value, and Film Thickness on the Wettability Behaviour of Copper Surfaces Coated with Copper Using EB-PVD Technique. J. Nano Res. 2019, 60, 124–141. [Google Scholar] [CrossRef]

| Parameter Type | Parameters | Value |

|---|---|---|

| Dimension of cell/mm | Diameter | 21 |

| Height | 70 | |

| Thickness of components/μm | Positive electrode | 125 |

| Negative electrode | 126 | |

| Separator | 16 | |

| Aluminium foil | 20 | |

| Copper foil | 16 | |

| Electronic properties of cell | Nominal Voltage/V | 3.6 |

| Maximum Voltage/V | 4.2 | |

| Minimum Voltage/V | 2.75 | |

| Nominal capacity/Ah | 5.0 | |

| Internal resistance/mΩ | 15 | |

| Thermal properties of cell | Density/kg m−3 | 2615 |

| Specific heat capacity/J kg−1 K−1 | 1605 | |

| Thermal conductivity/W m−1 K−1 | 3 |

| Type | Boundary Condition |

|---|---|

| Cooling condition | Liquid cooling |

| Fluid dynamic conditions | Turbulence |

| Inlet | Velocity inlet |

| Outlet | Pressure outlet |

| Fluid temperature/K | 298 |

| Ambient temperature/K | 298 |

| Outlet pressure/Pa | 101,325 |

| Ambient pressure/Pa | 101,325 |

| Flow rate/m s−1 | 0.5 |

| Parameters | NCR18500BF | NCR21700A |

|---|---|---|

| Pack Energy | 113.4 kWh | 113.4 kWh |

| Final Pack Energy | 126 kWh | 126 kWh |

| Energy Required in 1 Module | 7.9 kWh | 7.9 kWh |

| Total V in 8 Series Cells | 28.8 V | 28.8 V |

| Total Capacity of Parallel Cells | 274.7 Ah (82 Parallel) | 275.0 Ah (55 Parallel) |

| Energy Produced by 1 Module | 7.91 kWh | 7.9 kWh |

| Energy Produced by 1 Battery Pack | 126.56 kWh | 126.0 kWh |

| Current Across Module | 399.75 A | 825.0 A |

| Current Across Pack | 6369 A | 13,200 A |

| Total Power of System | 184.2 kW | 380.2 kW |

| No. of Cells Per Module | 656 Cells | 440 Cells |

| No. of Cells Per Pack | 10496 Cells | 7040 Cells |

| Manipulated Variables | Responding Variables | |||||

|---|---|---|---|---|---|---|

| Cell’s Arrangement | Angle (Radian) | Max. Cell’s Temperature (K) | Average Cell’s Temperature (K) | Cell’s Potential (V) | Avg. Fluid Velocity (m/s) | Model Size (mm) |

| 3p8s | 298.130 | 298.024 | 28.825–32.943 | 0.492 | 103.0 (w) × 268.0 (l) × 74 (h) | |

| 3p8s | 298.157 | 298.040 | 28.826–32.943 | 0.508 | 98.5 (w) × 238.9 (l) × 74 (h) | |

| 3p5s [16] | 298.143 | 298.032 | 16.471–20.590 | 0.500 | 104.4 (w) × 176 (l) × 74 (h) | |

| 3p5s [16] | 298.301 | 298.119 | 16.467–20.590 | 0.500 | 99.5 (w) × 158.4 (l) × 74 (h) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chan, C.K.; Chung, C.H.; Raman, J. Optimizing Thermal Management System in Electric Vehicle Battery Packs for Sustainable Transportation. Sustainability 2023, 15, 11822. https://doi.org/10.3390/su151511822

Chan CK, Chung CH, Raman J. Optimizing Thermal Management System in Electric Vehicle Battery Packs for Sustainable Transportation. Sustainability. 2023; 15(15):11822. https://doi.org/10.3390/su151511822

Chicago/Turabian StyleChan, Choon Kit, Chi Hong Chung, and Jeyagopi Raman. 2023. "Optimizing Thermal Management System in Electric Vehicle Battery Packs for Sustainable Transportation" Sustainability 15, no. 15: 11822. https://doi.org/10.3390/su151511822

APA StyleChan, C. K., Chung, C. H., & Raman, J. (2023). Optimizing Thermal Management System in Electric Vehicle Battery Packs for Sustainable Transportation. Sustainability, 15(15), 11822. https://doi.org/10.3390/su151511822