Decarbonization Potentials for Automotive Supply Chains: Emission-Intensity Pathways of Carbon-Intensive Hotspots of Battery Electric Vehicles

Abstract

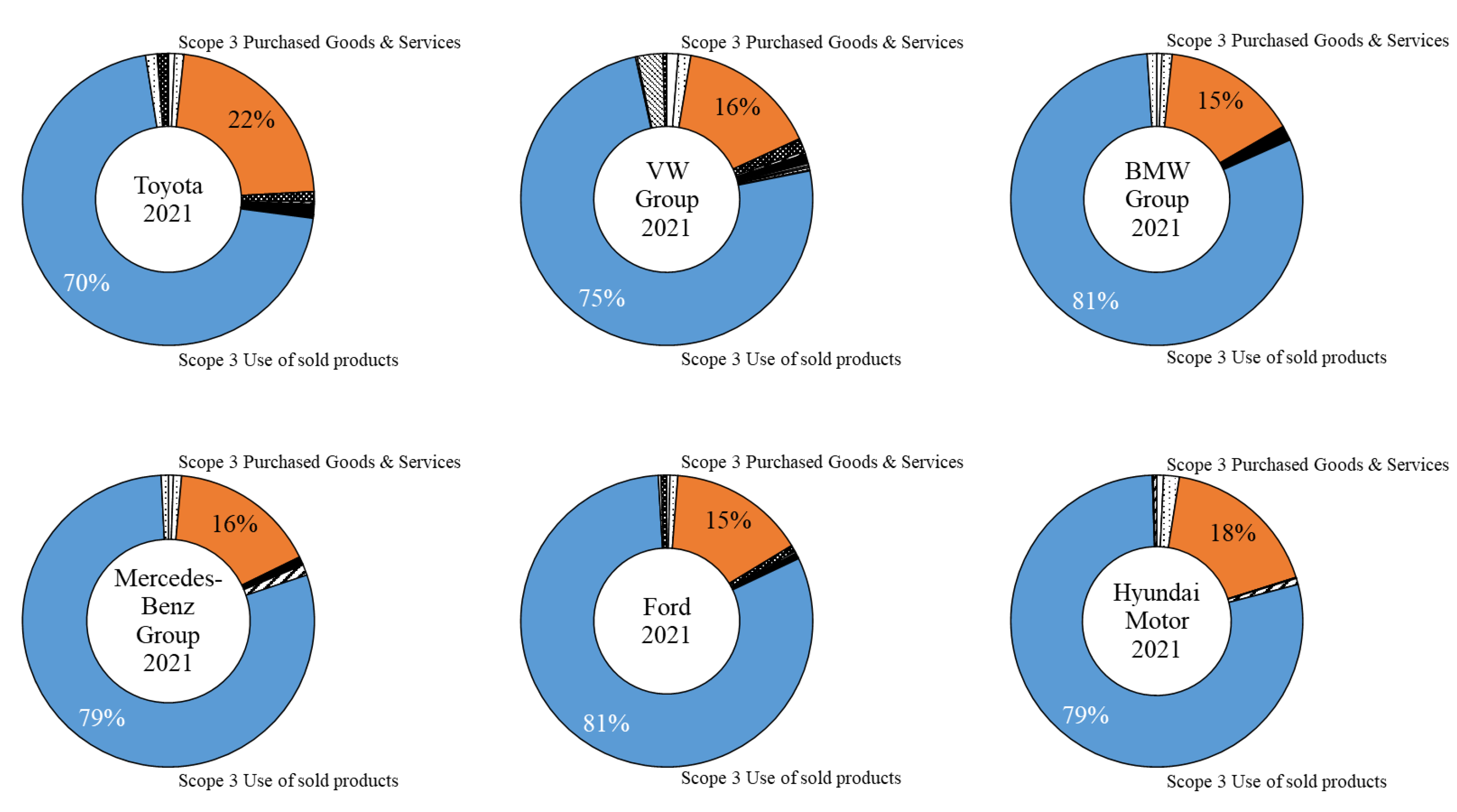

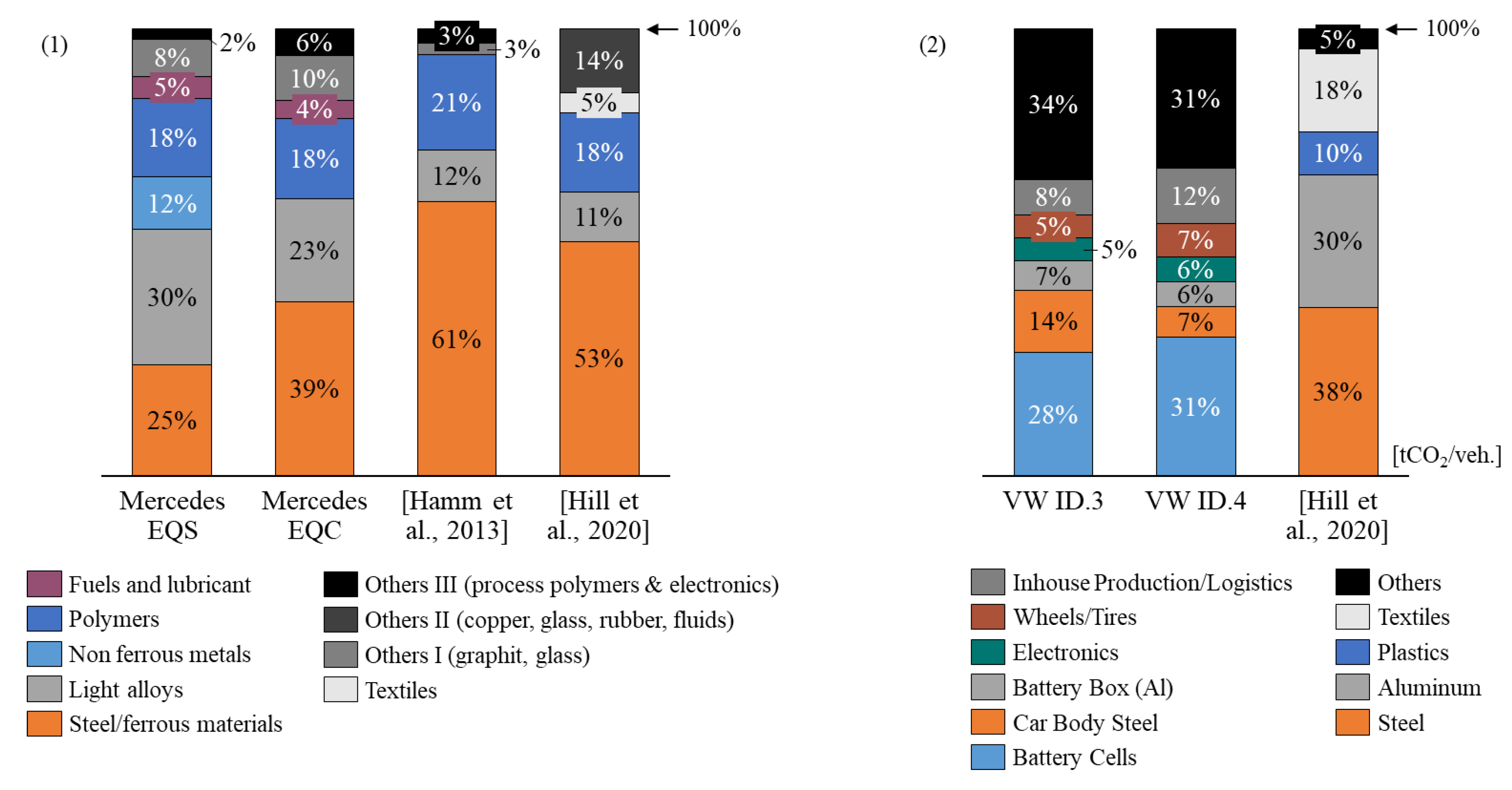

:1. Introduction

- (1)

- to derive emission-intensity pathways for specific materials and components and

- (2)

- to determine the decarbonization impact of the combined levers for extrapolation.

2. Background

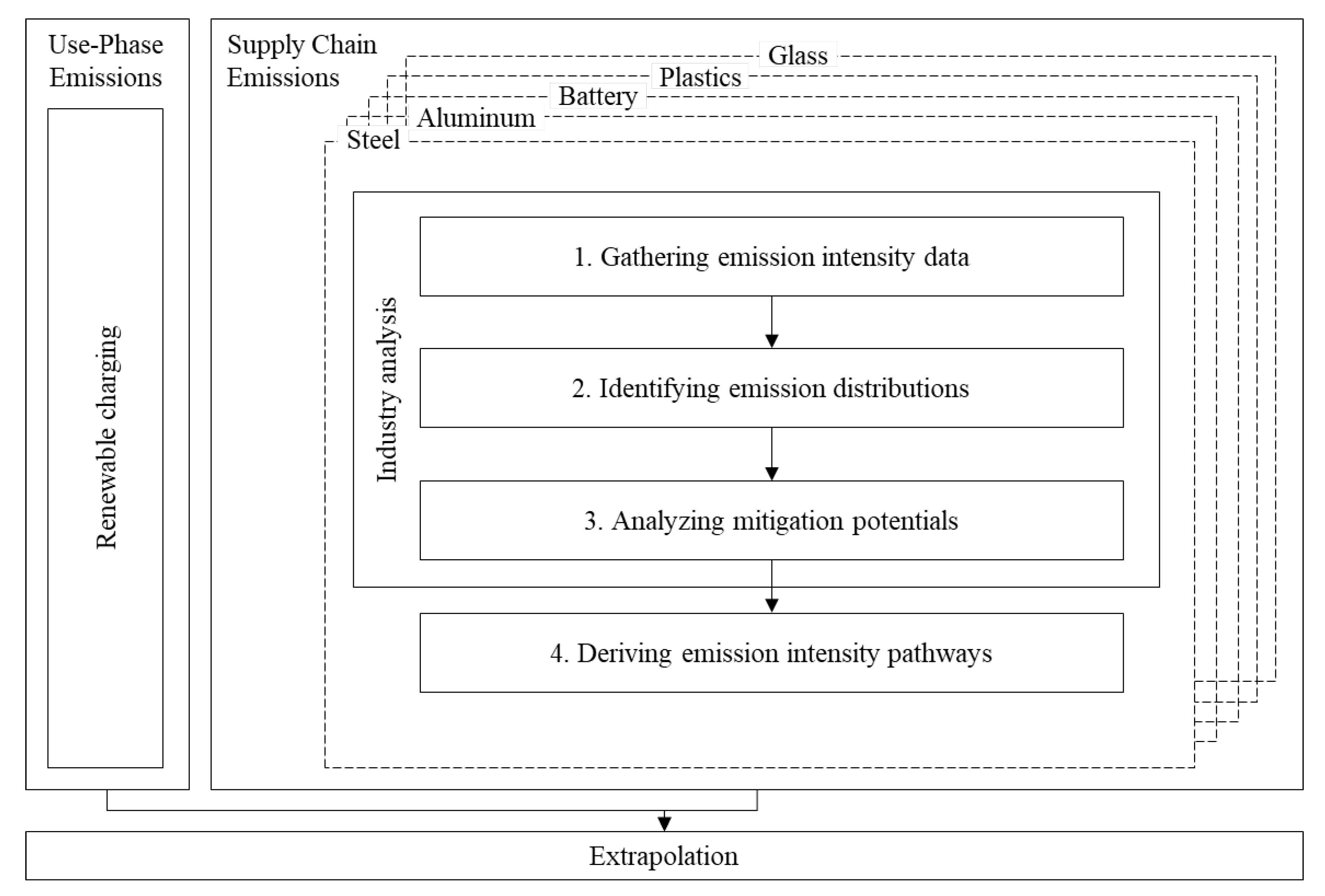

3. Methodology

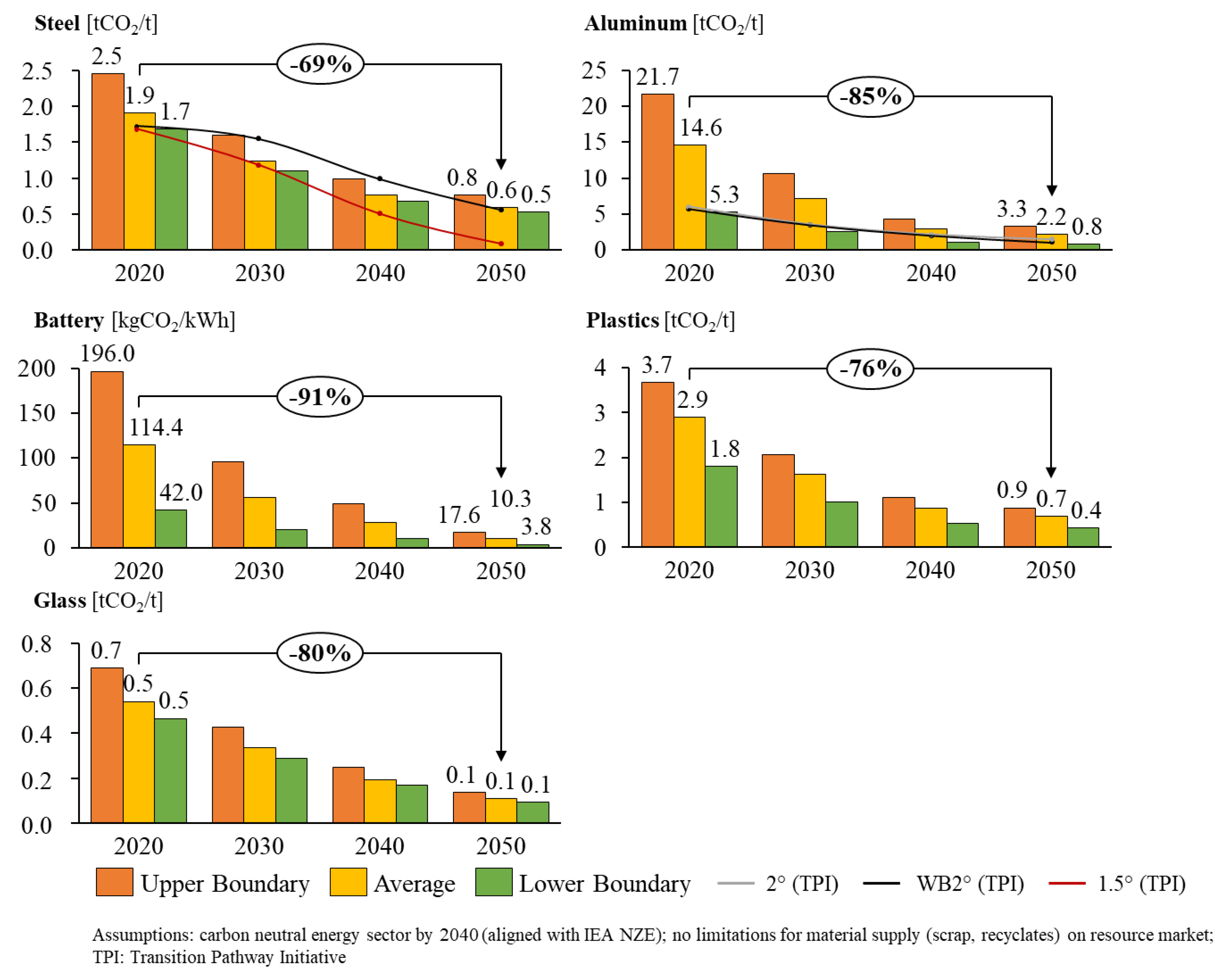

4. Results

4.1. Emission-Intensity Pathways

4.1.1. Steel

4.1.2. Aluminum

4.1.3. Battery

4.1.4. Plastics

4.1.5. Glazing

4.2. Trajectory

4.3. Extrapolation

5. Discussion

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wunderling, N.; Winkelmann, R.; Rockström, J.; Loriani, S.; Armstrong-McKay, D.; Ritchie, P.; Sakschewski, B.; Donges, J. Global Warming Overshoots Increase Risk of Triggering Climate Tipping Points and Cascades; Springer Nature: London, UK, 2022. [Google Scholar]

- IPCC. Climate Change 2023: Synthesis Report: A Report of the Intergovernmental Panel on Climate Change. In Contribution of Working Groups I, II and III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Core Writing Team, Lee, H., Romero, J., Eds.; IPCC: Geneva, Switzerland, 2023. [Google Scholar]

- Weiss, D.; Grüning, C.; van Ackern, P.; Kriege, K.; Buderath, M.; Dovidat, L.; Adelphi; Jungmichel, N.; Aron, M.; Systain Consulting GmbH. Umweltrisiken und—Auswirkungen in Globalen Lieferketten Deutscher Unternehmen—Branchenstudie Automobilindustrie; Umweltbundesamt: Dessau-Roßlau, Germany, 2022. [Google Scholar]

- Canals Casals, L.; Martinez-Laserna, E.; Amante García, B.; Nieto, N. Sustainability analysis of the electric vehicle use in Europe for CO2 emissions reduction. J. Clean. Prod. 2016, 127, 425–437. [Google Scholar] [CrossRef]

- Costa, E.; Wells, P.; Wang, L.; Costa, G. The electric vehicle and renewable energy: Changes in boundary conditions that enhance business model innovations. J. Clean. Prod. 2022, 333, 130034. [Google Scholar] [CrossRef]

- Ahmadi, P. Environmental impacts and behavioral drivers of deep decarbonization for transportation through electric vehicles. J. Clean. Prod. 2019, 225, 1209–1219. [Google Scholar] [CrossRef]

- de Blas, I.; Mediavilla, M.; Capellán-Pérez, I.; Duce, C. The limits of transport decarbonization under the current growth paradigm. Energy Strategy Rev. 2020, 32, 100543. [Google Scholar] [CrossRef]

- World Economic Forum; McKinsey & Company. Forging Ahead: A Material Roadmap for the Zero-Carbon Car; World Economic Forum: Geneva, Switzerland, 2020. [Google Scholar]

- Brear, M.J.; Baldick, R.; Cronshaw, I.; Olofsson, M. Sector coupling: Supporting decarbonisation of the global energy system. Electr. J. 2020, 33, 106832. [Google Scholar] [CrossRef]

- Kittner, N.; Tsiropoulos, I.; Tarvydas, D.; Schmidt, O.; Staffell, I.; Kammen, D.M. Electric Vehicles. Technological Learning in the Transition to a Low-Carbon Energy System; Elsevier: Amsterdam, The Netherlands, 2020; pp. 145–163. ISBN 9780128187623. [Google Scholar]

- Hung, C.R.; Völler, S.; Agez, M.; Majeau-Bettez, G.; Strømman, A.H. Regionalized climate footprints of battery electric vehicles in Europe. J. Clean. Prod. 2021, 322, 129052. [Google Scholar] [CrossRef]

- Degen, F.; Schütte, M. Life cycle assessment of the energy consumption and GHG emissions of state-of-the-art automotive battery cell production. J. Clean. Prod. 2022, 330, 129798. [Google Scholar] [CrossRef]

- Pipitone, E.; Caltabellotta, S.; Occhipinti, L. A Life Cycle Environmental Impact Comparison between Traditional, Hybrid, and Electric Vehicles in the European Context. Sustainability 2021, 13, 10992. [Google Scholar] [CrossRef]

- Hill, N.; Amaral, S.; Morgan-Price, S.; Nokes, T.; Bates, J.; Helms, H.; Fehrenbach, H.; Biemann, K.; Abdalla, N.; Jöhrens, J.; et al. Determining the Environmental Impacts of Conventional and Alternatively Fuelled Vehicles through LCA; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Wang, F.; Zhang, S.; Zhao, Y.; Ma, Y.; Zhang, Y.; Hove, A.; Wu, Y. Multisectoral drivers of decarbonizing battery electric vehicles in China. PNAS Nexus 2023, 2, pgad123. [Google Scholar] [CrossRef]

- Fugger, T.; Poligkeit, J.; Herrmann, C. Integration of coupled sectors decarbonization pathways across the value chain into corporate carbon management processes. Procedia CIRP 2023, 116, 1–6. [Google Scholar] [CrossRef]

- World Economic Forum; Accenture Strategy. Raising Ambitions: A New Roadmap for the Automotive Circular Economy: Circular Cars Initiative Business Models Cluster; World Economic Forum: Geneva, Switzerland, 2020. [Google Scholar]

- CDP. Companies Score—The A List 2022: Climate Change. Available online: https://www.cdp.net/en/scores (accessed on 22 May 2023).

- WBCSD; WRI. Corporate Value Chain (Scope 3) Accounting and Reporting Standard: Supplement to the GHG Protocol Corporate Accounting and Reporting Standard; World Business Council for Sustainable Development (WBCSD): Geneva, Switzerland; World Resources Institute: Washington, DC, USA, 2011. [Google Scholar]

- Mercedes-Benz. The CO2 Balance of the Mercedes Benz EQC—Dependent on Power Generation. Available online: https://www.mercedes-benz.com/en/vehicles/passenger-cars/eqc/the-eqc-is-this-sustainable/ (accessed on 6 August 2021).

- Daimler, A.G. 360° Umweltcheck Mercedes-Benz EQS; Mercedes-Benz AG: Stuttgart, Germany, 2021. [Google Scholar]

- VDA; Volkswagen A.G. CO2-Bilanz von E-Fahrzeugen. Available online: https://www.vdi.de/news/detail/co2-bilanz-von-e-fahrzeugen (accessed on 6 August 2021).

- Volkswagen AG. Sustainability Report 2022; Volkswagen AG: Wolfsburg, Germany, 2023. [Google Scholar]

- Volvo Group. Life Cycle Assessment 2021—Carbon Footprint of Polestar 2 Variants; AB Volvo: Gothenburg, Sweden, 2021. [Google Scholar]

- BMW Group. Environmental Report BMW iX xDrive40; BMW AG: München, Germany, 2021. [Google Scholar]

- Energy Transitions Commission; Material Economics; Breakthrough Energy. Steeling Demand: Mobilising Buyers to Bring Net-Zero Steel to Market Before 2030; Material Economics: Stockholm, Sweden, 2021. [Google Scholar]

- Drive Sustainability; The Responsible Minerals Initiative; The Dragonfly Initiative. Material Change: A Study of Risks and Opportunities for Collective Action in the Materials Supply Chains of the Automotive and Electronics Industries; TDi Sustainability: Cheltenhem, UK, 2018. [Google Scholar]

- Hamm, L.; Peitz, V.; Krautkrämer, B.; Malik, R.; Solfrank, P.; Plank, R. Werkstoffe und Fertigungsverfahren. In Vieweg Handbuch Kraftfahrzeugtechnik; Braess, H.-H., Seiffert, U., Eds.; Springer: Wiesbaden, Germany, 2013; pp. 1039–1131. ISBN 978-3-658-01690-6. [Google Scholar]

- IEA. Net Zero by 2050—A Roadmap for the Global Energy Sector; International Energy Agency: Paris, France, 2021. [Google Scholar]

- International Energy Agency. Iron and Steel Technology Roadmap—Towards More Sustainable Steelmaking; International Energy Agency: Paris, France, 2020. [Google Scholar]

- Napp, T.A.; Gambhir, A.; Hills, T.P.; Florin, N.; Fennell, P.S. A review of the technologies, economics and policy instruments for decarbonising energy-intensive manufacturing industries. Renew. Sustain. Energy Rev. 2014, 30, 616–640. [Google Scholar] [CrossRef]

- Rissman, J.; Bataille, C.; Masanet, E.; Aden, N.; Morrow, W.R.; Zhou, N.; Elliott, N.; Dell, R.; Heeren, N.; Huckestein, B.; et al. Technologies and policies to decarbonize global industry: Review and assessment of mitigation drivers through 2070. Appl. Energy 2020, 266, 114848. [Google Scholar] [CrossRef]

- Draxler, M.; Sormann, A.; Kempken, T.; Hauck, T.; Pierret, J.-C.; Borlee, J.; Di Donato, A.; de Santis, M.; Wang, C. Green Steel for Europe: Technology Assessment and Roadmapping; Green Steel for Europe Consortium: Brussels, Belgium, 2021. [Google Scholar]

- Arens, M.; Worrell, E.; Eichhammer, W.; Hasanbeigi, A.; Zhang, Q. Pathways to a low-carbon iron and steel industry in the medium-term—The case of Germany. J. Clean. Prod. 2017, 163, 84–98. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Arens, M.; Cardenas, J.C.R.; Price, L.; Triolo, R. Comparison of carbon dioxide emissions intensity of steel production in China, Germany, Mexico, and the United States. Resour. Conserv. Recycl. 2016, 113, 127–139. [Google Scholar] [CrossRef] [Green Version]

- Bhaskar, A.; Assadi, M.; Nikpey Somehsaraei, H. Decarbonization of the Iron and Steel Industry with Direct Reduction of Iron Ore with Green Hydrogen. Energies 2020, 13, 758. [Google Scholar] [CrossRef] [Green Version]

- Digiesi, S.; Mummolo, G.; Vitti, M. Minimum Emissions Configuration of a Green Energy–Steel System: An Analytical Model. Energies 2022, 15, 3324. [Google Scholar] [CrossRef]

- Bataille, C.; Åhman, M.; Neuhoff, K.; Nilsson, L.J.; Fischedick, M.; Lechtenböhmer, S.; Solano-Rodriquez, B.; Denis-Ryan, A.; Stiebert, S.; Waisman, H.; et al. A review of technology and policy deep decarbonization pathway options for making energy-intensive industry production consistent with the Paris Agreement. J. Clean. Prod. 2018, 187, 960–973. [Google Scholar] [CrossRef] [Green Version]

- Burchart-Korol, D. Life cycle assessment of steel production in Poland: A case study. J. Clean. Prod. 2013, 54, 235–243. [Google Scholar] [CrossRef]

- Chesnokov, Y.; Lisienko, V.; Lapteva, A. Evaluating the Carbon Footprint from the Production of Steel in an Electric-Arc Furnace. Metallurgist 2014, 57, 774–778. [Google Scholar] [CrossRef]

- Hiebel, M. Stahlrecycling Trägt zur Sicherung der Stahlproduktion in Deutschland Bei; Fraunhofer UMSICHT: Oberhausen, Germany, 2016. [Google Scholar]

- Muslemani, H.; Liang, X.; Kaesehage, K.; Ascui, F.; Wilson, J. Opportunities and challenges for decarbonizing steel production by creating markets for ‘green steel’ products. J. Clean. Prod. 2021, 315, 128127. [Google Scholar] [CrossRef]

- Palazzo, J.; Geyer, R. Consequential life cycle assessment of automotive material substitution: Replacing steel with aluminum in production of north American vehicles. Environ. Impact Assess. Rev. 2019, 75, 47–58. [Google Scholar] [CrossRef]

- Somers, J. Technologies to Decarbonise the EU Steel Industry; Publications Office of the European Union: Luxembourg, 2022; ISBN 9789276471479. [Google Scholar]

- Suer, J.; Ahrenhold, F.; Traverso, M. Carbon Footprint and Energy Transformation Analysis of Steel Produced via a Direct Reduction Plant with an Integrated Electric Melting Unit. J. Sustain. Metall. 2022, 8, 1532–1545. [Google Scholar] [CrossRef]

- Suer, J.; Traverso, M.; Ahrenhold, F. Carbon footprint of scenarios towards climate-neutral steel according to ISO 14067. J. Clean. Prod. 2021, 318, 128588. [Google Scholar] [CrossRef]

- Suer, J.; Traverso, M.; Jäger, N. Review of Life Cycle Assessments for Steel and Environmental Analysis of Future Steel Production Scenarios. Sustainability 2022, 14, 14131. [Google Scholar] [CrossRef]

- Das, A.; Kandpal, T.C. Iron and steel manufacturing technologies in India: Estimation of CO2 emission. Int. J. Energy Res. 1997, 21, 1187–1201. [Google Scholar] [CrossRef]

- Hu, C.-Q.; Chen, L.-Y.; Zhang, C.-X.; Qi, Y.-H.; Yin, R.-Y. Emission Mitigation of CO2 in Steel Industry: Current Status and Future Scenarios. J. Iron Steel Res. 2006, 13, 38–42. [Google Scholar] [CrossRef]

- Sakamoto, Y.; Tonooka, Y.; Yanagisawa, Y. Estimation of energy consumption for each process in the Japanese steel industry: A process analysis. Energy Convers. Manag. 1999, 40, 1129–1140. [Google Scholar] [CrossRef]

- Mandova, H.; Patrizio, P.; Leduc, S.; Kjärstad, J.; Wang, C.; Wetterlund, E.; Kraxner, F.; Gale, W. Achieving carbon-neutral iron and steelmaking in Europe through the deployment of bioenergy with carbon capture and storage. J. Clean. Prod. 2019, 218, 118–129. [Google Scholar] [CrossRef]

- Balomenos, E.; Panias, D.; Paspaliaris, I. Energy and Exergy Analysis of the Primary Aluminum Production Processes: A Review on Current and Future Sustainability. Miner. Process. Extr. Metall. Rev. 2011, 32, 69–89. [Google Scholar] [CrossRef]

- Brough, D.; Jouhara, H. The aluminium industry: A review on state-of-the-art technologies, environmental impacts and possibilities for waste heat recovery. Int. J. Thermofluids 2020, 1–2, 100007. [Google Scholar] [CrossRef]

- Hübner, T.; Guminski, A.; Rouyrre, E.; von Roon, S. Energiewende in der Industrie—Potenziale und Wechselwirkungen mit dem Energiesektor: Branchensteckbreif der NE-Metallindustrie; Navigant Energy Germany GmbH: Köln, Germany, 2020. [Google Scholar]

- Hydro. Hydrŏs Roadmap to Zero Emission Aluminium Production; Norsk Hydro ASA: Oslo, Norway, 2022. [Google Scholar]

- Paraskevas, D.; Kellens, K.; van de Voorde, A.; Dewulf, W.; Duflou, J.R. Environmental Impact Analysis of Primary Aluminium Production at Country Level. Procedia CIRP 2016, 40, 209–213. [Google Scholar] [CrossRef] [Green Version]

- Pedneault, J.; Majeau-Bettez, G.; Krey, V.; Margni, M. What future for primary aluminium production in a decarbonizing economy? Glob. Environ. Chang. 2021, 69, 102316. [Google Scholar] [CrossRef]

- Raabe, D.; Ponge, D.; Uggowitzer, P.J.; Roscher, M.; Paolantonio, M.; Liu, C.; Antrekowitsch, H.; Kozeschnik, E.; Seidmann, D.; Gault, B.; et al. Making sustainable aluminum by recycling scrap: The science of “dirty” alloys. Prog. Mater. Sci. 2022, 128, 100947. [Google Scholar] [CrossRef]

- Taberaux, A.T.; Peterson, R.D. Aluminum Production. In Treatise on Process Metallurgy: Industrial Processes; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Saevarsdottir, G.; Magnusson, T.; Kvande, H. Reducing the Carbon Footprint: Primary Production of Aluminum and Silicon with Changing Energy Systems. J. Sustain. Metall. 2021, 7, 848–857. [Google Scholar] [CrossRef]

- Gautam, M.; Pandey, B.; Agrawal, M. Carbon Footprint of Aluminum Production. In Environmental Carbon Footprints; Elsevier: Amsterdam, The Netherlands, 2018; pp. 197–228. ISBN 9780128128497. [Google Scholar]

- Schmidt, J.; Thrane, M. Life Cycle Assessment of Aluminium Production in New Alcoa Smelter in Greenland; Aalborg University: Aalborg, Denmark, 2009. [Google Scholar]

- Steen-Olsen, K. Environmental Assessment of Aluminium Production in Europe: Current Situation and Future Scenarios; Norwegian University of Science and Technology: Trondheim, Norway, 2009. [Google Scholar]

- European Aluminum. Environmental Profile Report for the Aluminium Refining Industry: Life Cycle Inventory data (2017–2019) for the Production of Cast Alloys Ingot from Scrap and Waste; European Aluminium: Brussels, Belgium, 2021. [Google Scholar]

- Hong, J.; Zhou, J.; Hong, J.; Xu, X. Environmental and economic life cycle assessment of aluminum-silicon alloys production: A case study in China. J. Clean. Prod. 2012, 24, 11–19. [Google Scholar] [CrossRef]

- Hao, H.; Geng, Y.; Hang, W. GHG emissions from primary aluminum production in China: Regional disparity and policy implications. Appl. Energy 2016, 166, 264–272. [Google Scholar] [CrossRef]

- Chen, Q.; Lai, X.; Gu, H.; Tang, X.; Gao, F.; Han, X.; Zheng, Y. Investigating carbon footprint and carbon reduction potential using a cradle-to-cradle LCA approach on lithium-ion batteries for electric vehicles in China. J. Clean. Prod. 2022, 369, 133342. [Google Scholar] [CrossRef]

- Davidsson Kurland, S. Energy use for GWh-scale lithium-ion battery production. Environ. Res. Commun. 2020, 2, 12001. [Google Scholar] [CrossRef]

- Ellingsen, L.A.-W.; Majeau-Bettez, G.; Singh, B.; Srivastava, A.K.; Valøen, L.O.; Strømman, A.H. Life Cycle Assessment of a Lithium-Ion Battery Vehicle Pack. J. Ind. Ecol. 2014, 18, 113–124. [Google Scholar] [CrossRef] [Green Version]

- Ellingsen, L.A.-W.; Hung, C.R.; Strømman, A.H. Identifying key assumptions and differences in life cycle assessment studies of lithium-ion traction batteries with focus on greenhouse gas emissions. Transp. Res. Part D Transp. Environ. 2017, 55, 82–90. [Google Scholar] [CrossRef]

- Erik Emilsson, L.D.; Swedish Energy Agency. Lithium-Ion Vehicle Battery Production; IVL Swedish Environmental Research Institute Ltd.: Stockholm, Sweden, 2019. [Google Scholar]

- McManus, M.C. Environmental consequences of the use of batteries in low carbon systems: The impact of battery production. Appl. Energy 2012, 93, 288–295. [Google Scholar] [CrossRef] [Green Version]

- Melin, H.E.; Transport & Environment. Analysis of the Climate Impact of Lithium-Ion Batteries and How to Measure It; Circular Energy Storage: London, UK, 2019. [Google Scholar]

- Popien, J.-L.; Thies, C.; Barke, A.; Spengler, T.S. Comparative sustainability assessment of lithium-ion, lithium-sulfur, and all-solid-state traction batteries. Int. J. Life Cycle Assess. 2023, 28, 462–477. [Google Scholar] [CrossRef]

- Transport & Environment. Will Future Batteries Be Greener?: The Lifecycle Emissions of Solid State Batteries & Future Supply Chains; Transport & Environment: Brussels, Belgium, 2022. [Google Scholar]

- Xu, C.; Steubing, B.; Hu, M.; Harpprecht, C.; van der Meide, M.; Tukker, A. Future greenhouse gas emissions of automotive lithium-ion battery cell production. Resour. Conserv. Recycl. 2022, 187, 106606. [Google Scholar] [CrossRef]

- Peters, J.F.; Baumann, M.; Zimmermann, B.; Braun, J.; Weil, M. The environmental impact of Li-Ion batteries and the role of key parameters—A review. Renew. Sustain. Energy Rev. 2017, 67, 491–506. [Google Scholar] [CrossRef]

- Temporelli, A.; Carvalho, M.L.; Girardi, P. Life Cycle Assessment of Electric Vehicle Batteries: An Overview of Recent Literature. Energies 2020, 13, 2864. [Google Scholar] [CrossRef]

- Sun, X.; Luo, X.; Zhang, Z.; Meng, F.; Yang, J. Life cycle assessment of lithium nickel cobalt manganese oxide (NCM) batteries for electric passenger vehicles. J. Clean. Prod. 2020, 273, 123006. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J.; Arsenault, R.; Bae, C.; Ahn, S.; Lee, J. Cradle-to-Gate Emissions from a Commercial Electric Vehicle Li-Ion Battery: A Comparative Analysis. Environ. Sci. Technol. 2016, 50, 7715–7722. [Google Scholar] [CrossRef]

- Dai, Q.; Kelly, J.C.; Gaines, L.; Wang, M. Life Cycle Analysis of Lithium-Ion Batteries for Automotive Applications. Batteries 2019, 5, 48. [Google Scholar] [CrossRef] [Green Version]

- Ciez, R.E.; Whitacre, J.F. Examining different recycling processes for lithium-ion batteries. Nat. Sustain. 2019, 2, 148–156. [Google Scholar] [CrossRef]

- Mohr, M.; Peters, J.F.; Baumann, M.; Weil, M. Toward a cell-chemistry specific life cycle assessment of lithium-ion battery recycling processes. J. Ind. Ecol. 2020, 24, 1310–1322. [Google Scholar] [CrossRef]

- Majeau-Bettez, G.; Hawkins, T.R.; Strømman, A.H. Life cycle environmental assessment of lithium-ion and nickel metal hydride batteries for plug-in hybrid and battery electric vehicles. Environ. Sci. Technol. 2011, 45, 4548–4554. [Google Scholar] [CrossRef] [PubMed]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Jeswani, H.; Krüger, C.; Russ, M.; Horlacher, M.; Antony, F.; Hann, S.; Azapagic, A. Life cycle environmental impacts of chemical recycling via pyrolysis of mixed plastic waste in comparison with mechanical recycling and energy recovery. Sci. Total Environ. 2021, 769, 144483. [Google Scholar] [CrossRef] [PubMed]

- Korhonen, M.-R.; Dahlbo, H. Reducing Greenhouse Gas Emissions by Recycling Plastics and Textiles into Products; Finnish Environment Institute: Helsinki, Finland, 2007. [Google Scholar]

- Material Economics; Agora Industry. Europe’s Missing Plastics: Tacking Stock of EU Plastics Circularity; Material Economics Sverige AB.: Stockholm, Sweden, 2021. [Google Scholar]

- Roy, P.; Tadele, D.; Defersha, F.; Misra, M.; Mohanty, A.K. Environmental and economic prospects of biomaterials in the automotive industry. Clean Technol. Environ. Policy 2019, 21, 1535–1548. [Google Scholar] [CrossRef]

- Tonini, D.; Schrijvers, D.; Nessi, S.; Garcia-Gutierrez, P.; Giuntoli, J. Carbon footprint of plastic from biomass and recycled feedstock: Methodological insights. Int. J. Life Cycle Assess. 2021, 26, 221–237. [Google Scholar] [CrossRef]

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Chang. 2019, 9, 374–378. [Google Scholar] [CrossRef]

- Vanderreydt, I.; Rommens, T.; Tenhunen, A.; Mortensen, L.F.; Tange, I. Greenhouse Gas Emissions and Natural Implications of Plastics (Including Biobased Plastics); European Topic Centre on Waste and Materials in a Green Economy: Mol, Belgium, 2021. [Google Scholar]

- Nicholson, S.R.; Rorrer, N.A.; Carpenter, A.C.; Beckham, G.T. Manufacturing energy and greenhouse gas emissions associated with plastics consumption. Joule 2021, 5, 673–686. [Google Scholar] [CrossRef]

- Garcia-Gutierrez, P.; Amadei, A.M.; Klenert, D.; Nessi, S.; Tonini, D.; Tosches, D.; Ardente, F.; Saveyn, H. Environmental and Economic Assessment of Plastic Waste Recycling a Comparison of Mechanical, Physical, Chemical Recycling and Energy Recovery of Plastic Waste; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar]

- Leisin, M. Energiewende in der Industrie—Potenziale und Wechselwirkungen mit dem Energiesektor: Branchensteckbrief der Glasindustrie; Navigant Energy Germany GmbH: Köln, Germany, 2020. [Google Scholar]

- Zier, M.; Stenzel, P.; Kotzur, L.; Stolten, D. A review of decarbonization options for the glass industry. Energy Convers. Manag. X 2021, 10, 100083. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. U.S. Flat Glass Industry Carbon Intensities (2019); United States Environmental Protection Agency: Washington, DC, USA, 2022.

- EuRIC AISBL. Fakten Metallrecycling: Bridging Circular Economy & Climate Policy. Available online: https://www.bvse.de/dateien2020/2-PDF/06-Publikationen/04-Broschueren/0608-EuRIC_Metal_Recycling_Factsheet_GER_002.pdf (accessed on 2 January 2023).

- Mulvaney, D.; Richards, R.M.; Bazilian, M.D.; Hensley, E.; Clough, G.; Sridhar, S. Progress towards a circular economy in materials to decarbonize electricity and mobility. Renew. Sustain. Energy Rev. 2021, 137, 110604. [Google Scholar] [CrossRef]

- de Souza, J.F.T.; Pacca, S.A. Carbon reduction potential and costs through circular bioeconomy in the Brazilian steel industry. Resour. Conserv. Recycl. 2021, 169, 105517. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Completing the Picture: How the Circular Economy Tackles Climate Change; Ellen MacArthur Foundation: Isle of Wight, UK, 2019. [Google Scholar]

- Gielen, D.; Saygin, D.; Taibi, E.; Birat, J.-P. Renewables-based decarbonization and relocation of iron and steel making: A case study. J. Ind. Ecol. 2020, 24, 1113–1125. [Google Scholar] [CrossRef]

- Chisalita, D.-A.; Petrescu, L.; Cobden, P.; van Dijk, H.A.J.; Cormos, A.-M.; Cormos, C.-C. Assessing the environmental impact of an integrated steel mill with post-combustion CO2 capture and storage using the LCA methodology. J. Clean. Prod. 2019, 211, 1015–1025. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, Z.; Xu, G.; Zeng, X.; Hu, W.; Matsubae, K. Wrought and cast aluminum flows in China in the context of electric vehicle diffusion and automotive lightweighting. Resour. Conserv. Recycl. 2023, 191, 106877. [Google Scholar] [CrossRef]

- Liu, G.; Bangs, C.E.; Müller, D.B. Unearthing potentials for decarbonizing the U.S. aluminum cycle. Environ. Sci. Technol. 2011, 45, 9515–9522. [Google Scholar] [CrossRef]

- Reinsch, W.A.; Benson, E. Decarbonizing Aluminum: Rollin Out a More Sustainable Sector; Center for Strategic & International Studies: Washington, DC, USA, 2022. [Google Scholar]

- World Economic Forum; Accenture. Closing the Gap for Aluminium Emissions: Technologies to Accelerate Deep Decarbonization of Direct Emissions; World Economic Forum: Geneva, Switzerland, 2021. [Google Scholar]

- Sai Krishna, P.; Andrey, S.Y.; Peter, V.P. Progress of Inert Anodes in Aluminium Industry: Review. J. Sib. Fed. Univ. Chem. 2018, 11, 18–30. [Google Scholar] [CrossRef] [Green Version]

- Obaidat, M.; Al-Ghandoor, A.; Phelan, P.; Villalobos, R.; Alkhalidi, A. Energy and Exergy Analyses of Different Aluminum Reduction Technologies. Sustainability 2018, 10, 1216. [Google Scholar] [CrossRef] [Green Version]

- Halmann, M.; Frei, A.; Steinfeld, A. Carbothermal reduction of alumina: Thermochemical equilibrium calculations and experimental investigation. Energy 2007, 32, 2420–2427. [Google Scholar] [CrossRef]

- Lai, X.; Chen, Q.; Tang, X.; Zhou, Y.; Gao, F.; Guo, Y.; Bhagat, R.; Zheng, Y. Critical review of life cycle assessment of lithium-ion batteries for electric vehicles: A lifespan perspective. eTransportation 2022, 12, 100169. [Google Scholar] [CrossRef]

- Lai, X.; Meng, Z.; Wang, S.; Han, X.; Zhou, L.; Sun, T.; Li, X.; Wang, X.; Ma, Y.; Zheng, Y. Global parametric sensitivity analysis of equivalent circuit model based on Sobol’ method for lithium-ion batteries in electric vehicles. J. Clean. Prod. 2021, 294, 126246. [Google Scholar] [CrossRef]

- Andre, D.; Kim, S.-J.; Lamp, P.; Lux, S.F.; Maglia, F.; Paschos, O.; Stiaszny, B. Future generations of cathode materials: An automotive industry perspective. J. Mater. Chem. A 2015, 3, 6709–6732. [Google Scholar] [CrossRef]

- Dunn, J.; Slattery, M.; Kendall, A.; Ambrose, H.; Shen, S. Circularity of Lithium-Ion Battery Materials in Electric Vehicles. Environ. Sci. Technol. 2021, 55, 5189–5198. [Google Scholar] [CrossRef] [PubMed]

- Ellingsen, L.A.-W.; Singh, B.; Strømman, A.H. The size and range effect: Lifecycle greenhouse gas emissions of electric vehicles. Environ. Res. Lett. 2016, 11, 54010. [Google Scholar] [CrossRef]

- Liang, Y.; Su, J.; Xi, B.; Yu, Y.; Ji, D.; Sun, Y.; Cui, C.; Zhu, J. Life cycle assessment of lithium-ion batteries for greenhouse gas emissions. Resour. Conserv. Recycl. 2017, 117, 285–293. [Google Scholar] [CrossRef]

- Hammond, G.P.; Hazeldine, T. Indicative energy technology assessment of advanced rechargeable batteries. Appl. Energy 2015, 138, 559–571. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Gu, F.; Guo, J. Environmental feasibility of secondary use of electric vehicle lithium-ion batteries in communication base stations. Resour. Conserv. Recycl. 2020, 156, 104713. [Google Scholar] [CrossRef]

- Wu, X.; Markir, A.; Xu, Y.; Zhang, C.; Leonard, D.P.; Shin, W.; Ji, X. A Rechargeable Battery with an Iron Metal Anode. Adv. Funct. Mater. 2019, 29, 1900911. [Google Scholar] [CrossRef]

- Shu, X.; Guo, Y.; Yang, W.; Wei, K.; Zhu, G. Life-cycle assessment of the environmental impact of the batteries used in pure electric passenger cars. Energy Rep. 2021, 7, 2302–2315. [Google Scholar] [CrossRef]

- Smith, L.; Ibn-Mohammed, T.; Astudillo, D.; Brown, S.; Reaney, I.M.; Koh, S.C.L. The Role of Cycle Life on the Environmental Impact of Li6.4La3Zr1.4Ta0.6O12 based Solid-State Batteries. Adv. Sustain. Syst. 2021, 5, 2000241. [Google Scholar] [CrossRef]

- Duffner, F.; Kronemeyer, N.; Tübke, J.; Leker, J.; Winter, M.; Schmuch, R. Post-lithium-ion battery cell production and its compatibility with lithium-ion cell production infrastructure. Nat. Energy 2021, 6, 123–134. [Google Scholar] [CrossRef]

- Randau, S.; Weber, D.A.; Kötz, O.; Koerver, R.; Braun, P.; Weber, A.; Ivers-Tiffée, E.; Adermann, T.; Kulisch, J.; Zeier, W.G.; et al. Benchmarking the performance of all-solid-state lithium batteries. Nat. Energy 2020, 5, 259–270. [Google Scholar] [CrossRef]

- Bauer, F.; Tilsted, J.P.; Pfister, S.; Oberschelp, C.; Kulionis, V. Mapping GHG emissions and prospects for renewable energy in the chemical industry. Curr. Opin. Chem. Eng. 2023, 39, 100881. [Google Scholar] [CrossRef]

- Alhazmi, H.; Almansour, F.H.; Aldhafeeri, Z. Plastic Waste Management: A Review of Existing Life Cycle Assessment Studies. Sustainability 2021, 13, 5340. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- McDougall, F.R.; White, P.R.; Franke, M.; Hindle, P.; Procter & Gamble. Integrated Solid Waste Management: A Life Cycle Inventory. Int. J. LCA 2001, 6, 320. [Google Scholar] [CrossRef]

- Meys, R.; Kätelhön, A.; Bachmann, M.; Winter, B.; Zibunas, C.; Suh, S.; Bardow, A. Achieving net-zero greenhouse gas emission plastics by a circular carbon economy. Science 2021, 374, 71–76. [Google Scholar] [CrossRef]

- European Climate, Infrastructure and Environment Executive Agency. How LIFE Is Reducing Emissions from Glass Production: Two Consecutive LIFE Projects Have Improved the Energy Efficiency of the Glass-Melting Process; European Climate, Infrastructure and Environment Executive Agency: Brussels, Belgium, 2022. [Google Scholar]

- The International Journal of Science. Glass is the hidden gem in a carbon-neutral future. Nature 2021, 599, 7–8. [Google Scholar] [CrossRef]

- Pisciotta, M.; Pilorgé, H.; Feldmann, J.; Jacobson, R.; Davids, J.; Swett, S.; Sasso, Z.; Wilcox, J. Current state of industrial heating and opportunities for decarbonization. Prog. Energy Combust. Sci. 2022, 91, 100982. [Google Scholar] [CrossRef]

- Gerres, T.; Chaves Ávila, J.P.; Llamas, P.L.; San Román, T.G. A review of cross-sector decarbonisation potentials in the European energy intensive industry. J. Clean. Prod. 2019, 210, 585–601. [Google Scholar] [CrossRef]

- Transition Pathway Initiative. TPI Online Tool: Carbon Perfomance. Available online: https://www.transitionpathwayinitiative.org/sectors (accessed on 28 June 2023).

- SBTi. SBTi Corporate Net-Zero Standard: Version 1.1; Science-Based Target Initiative: London, UK, 2023. [Google Scholar]

- Grenz, J.; Cerdas, F.; Herrmann, C. LCA based analysis of product portfolios—Towards decarbonization. Procedia CIRP 2022, 105, 519–524. [Google Scholar] [CrossRef]

- Poschmann, J.; Bach, V.; Finkbeiner, M. Deriving decarbonization targets and pathways—A case study for the automotive industry. J. Clean. Prod. 2023, 409, 137256. [Google Scholar] [CrossRef]

- Poschmann, J.; Bach, V.; Finkbeiner, M. Are the EU climate ambitions reflected on member-state level for greenhouse gas reductions and renewable energy consumption shares? Energy Strategy Rev. 2022, 43, 100936. [Google Scholar] [CrossRef]

- European Parliament. Making Batteries More Sustainable, More Durable and Better-Performing; European Parliament: Strasbourg, France, 2023. [Google Scholar]

- Mauler, L.; Duffner, F.; Zeier, W.G.; Leker, J. Battery cost forecasting: A review of methods and results with an outlook to 2050. Energy Environ. Sci. 2021, 14, 4712–4739. [Google Scholar] [CrossRef]

- Bildirici, M.; Ersin, Ö.Ö. Nexus between Industry 4.0 and environmental sustainability: A Fourier panel bootstrap cointegration and causality analysis. J. Clean. Prod. 2023, 386, 135786. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poschmann, J.; Bach, V.; Finkbeiner, M. Decarbonization Potentials for Automotive Supply Chains: Emission-Intensity Pathways of Carbon-Intensive Hotspots of Battery Electric Vehicles. Sustainability 2023, 15, 11795. https://doi.org/10.3390/su151511795

Poschmann J, Bach V, Finkbeiner M. Decarbonization Potentials for Automotive Supply Chains: Emission-Intensity Pathways of Carbon-Intensive Hotspots of Battery Electric Vehicles. Sustainability. 2023; 15(15):11795. https://doi.org/10.3390/su151511795

Chicago/Turabian StylePoschmann, Justus, Vanessa Bach, and Matthias Finkbeiner. 2023. "Decarbonization Potentials for Automotive Supply Chains: Emission-Intensity Pathways of Carbon-Intensive Hotspots of Battery Electric Vehicles" Sustainability 15, no. 15: 11795. https://doi.org/10.3390/su151511795

APA StylePoschmann, J., Bach, V., & Finkbeiner, M. (2023). Decarbonization Potentials for Automotive Supply Chains: Emission-Intensity Pathways of Carbon-Intensive Hotspots of Battery Electric Vehicles. Sustainability, 15(15), 11795. https://doi.org/10.3390/su151511795