Identifying the Drivers of Circular Food Packaging: A Comprehensive Review for the Current State of the Food Supply Chain to Be Sustainable and Circular

Abstract

:1. Introduction

- RQ1: What is the current state of the food packaging industry in terms of packaging design, materials used, and adopted technologies?

- RQ2: Why is the existing system not enough for the sustainability of the food packaging industry and what possible solutions are there in the literature?

- RQ3: What are the addressed drivers for applying CE principles in the food packaging industry?

2. Comprehensive Review

2.1. Current State of Food Packaging

2.2. Packaging Materials and Design

3. Methodology

4. Analysis

Drivers of Circular Food Packaging

5. Findings

6. Discussion and Implications

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Food Sub-Sectors |

|---|

| Meat: chicken, turkey, pork, beef, sausage, buffalo meat, poultry |

| Fish: tuna, shrimp, sardine, mussel, salmon |

| Dairy: butter, margarine, milk, yoghurt, cheese |

| Bakery: bread, cookie, pasta |

| Milling: wheat, rice, grain |

| Beverages: soft drink and breweries, carbonated soft drink, wine, liquor, tea, coffee |

| Grocery: fruit and vegetables |

| Dried food: seasoning, dressing and spice, fried baked snacks, |

| Oil: sunflower seed oil, olive oil, sesame oil |

| Frozen food: ice manufacturing (frozen) |

| Tea and Coffee: tea, herbal tea, coffee whitener, coffee |

| Other food: snacks, appetizer, syrup, cereal, noodle, popcorn, food-to-go (packaged and processed food) sweets, pet food |

| Sauce: puree, chopped tomato, peeled tomato, marmalade |

| Materials |

|---|

| Plastic: cellophane plastics, film, bag, bottle, styrofoam box, plastic pouch |

| Metal: aluminum foil, steel, tin, iron, zinc, copper, gold, nickel, silver, titanium, zirconium, mica tinplate |

| Paper and board: paper bag, newspaper, magazines, paper foil, recycled paper, disposable paper foil, paperboard, paper box, carton, cardboard, greaseproof paper, kraft paper, sulfite paper, parchment paper |

| Wood: wooden plate, cellulose, timber pallet, wooden boxes |

| Glass: glass bow, cup, jar, bottle |

| Green material: nanomaterial, biodegradable, starch lends, plant-based material, leaves |

| Multimaterial: polymer, composite, polypropylene, polyolefin, bio-nanocomposites multilayer |

| Printing ink: printing inks, adhesives, photoinitiators, solvents, plasticizers, surfactants and pigments, processing aids |

References

- Sijtsema, S.J.; Fogliano, V.; Hageman, M. Tool to Support Citizen Participation and Multidisciplinarity in Food Innovation: Circular Food Design. Front. Sustain. Food Syst. 2020, 4, 58193. [Google Scholar] [CrossRef]

- Chakori, S.; Aziz, A.A.; Smith, C.; Dargusch, P. Untangling the Underlying Drivers of the Use of Single-Use Food Packaging. Ecol. Econ. 2021, 185, 107063. [Google Scholar] [CrossRef]

- Meherishi, L.; Narayana, S.A.; Ranjani, K.S. Sustainable Packaging for Supply Chain Management in the Circular Economy: A Review. J. Clean. Prod. 2019, 237, 117582. [Google Scholar] [CrossRef]

- Smirthers Pira Group. Packaging Material Outlooks—Towards a $1 Trillion Milestone 2020; Smirthers Pira Group: Akron, OH, USA, 2016. [Google Scholar]

- Dixon-Hardy, D.W.; Curran, B.A. Types of Packaging Waste from Secondary Sources (Supermarkets)—The Situation in the UK. Waste Manag. 2009, 29, 1198–1207. [Google Scholar] [CrossRef]

- Gustavo, J.U., Jr.; Pereira, G.M.; Bond, A.J.; Viegas, C.V.; Borchardt, M. Drivers, Opportunities and Barriers for a Retailer in the Pursuit of More Sustainable Packaging Redesign. J. Clean. Prod. 2018, 187, 18–28. [Google Scholar] [CrossRef] [Green Version]

- Grönman, K.; Soukka, R.; Järvi-Kääriäinen, T.; Katajajuuri, J.-M.; Kuisma, M.; Koivupuro, H.-K.; Ollila, M.; Pitkänen, M.; Miettinen, O.; Silvenius, F.; et al. Framework for Sustainable Food Packaging Design. Packag. Technol. Sci. 2012, 26, 187–200. [Google Scholar] [CrossRef]

- Testa, F.; Di Iorio, V.; Cerri, J.; Pretner, G. Five Shades of Plastic in Food: Which Potentially Circular Packaging Solutions Are Italian Consumers More Sensitive To. Resour. Conserv. Recycl. 2021, 173, 105726. [Google Scholar] [CrossRef]

- Hahladakis, J.N. Delineating and Preventing Plastic Waste Leakage in the Marine and Terrestrial Environment. Environ. Sci. Pollut. Res. 2020, 27, 12830–12837. [Google Scholar] [CrossRef] [Green Version]

- Hall, D. Throwaway Culture Has Spread Packaging Waste Worldwide: Here’s What to Do about It. The Guardian, 13 March 2017. [Google Scholar]

- WWF. Solving Plastic Pollution through Accountability 2019. Available online: https://www.worldwildlife.org/publications/solving-plastic-pollution-throughaccountability (accessed on 31 March 2023).

- Sundqvist-Andberg, H.; Åkerman, M. Sustainability Governance and Contested Plastic Food Packaging—An Integrative Review. J. Clean. Prod. 2021, 306, 127111. [Google Scholar] [CrossRef]

- Marsh, K.; Bugusu, B. Food Packaging—Roles, Materials, and Environmental Issues. J. Food Sci. 2007, 72, R39–R55. [Google Scholar] [CrossRef] [PubMed]

- Schmidt Rivera, X.C.; Leadley, C.; Potter, L.; Azapagic, A. Aiding the Design of Innovative and Sustainable Food Packaging: Integrating Techno-Environmental and Circular Economy Criteria. Energy Procedia 2019, 161, 190–197. [Google Scholar] [CrossRef]

- Rezaei, J.; Papakonstantinou, A.; Tavasszy, L.; Pesch, U.; Kana, A. Sustainable Product-Package Design in a Food Supply Chain: A Multi-Criteria Life Cycle Approach. Packag. Technol. Sci. 2018, 32, 85–101. [Google Scholar] [CrossRef] [Green Version]

- Rundh, B. The Multi-Faceted Dimension of Packaging. Br. Food J. 2005, 107, 670–684. [Google Scholar] [CrossRef]

- MacArthur, D.E.; Waughray, D.; Stuchtey, M.R. The New Plastics Economy, Rethinking the Future of Plastic; World Economic Forum: Cologny, Switzerland, 2016. [Google Scholar]

- Steenis, N.D.; van Herpen, E.; van der Lans, I.A.; Ligthart, T.N.; van Trijp, H.C.M. Consumer Response to Packaging Design: The Role of Packaging Materials and Graphics in Sustainability Perceptions and Product Evaluations. J. Clean. Prod. 2017, 162, 286–298. [Google Scholar] [CrossRef]

- Glavič, P.; Lukman, R. Review of Sustainability Terms and Their Definitions. J. Clean. Prod. 2007, 15, 1875–1885. [Google Scholar] [CrossRef]

- Batista, L.; Bourlakis, M.; Smart, P.; Maull, R. In search of a circular supply chain archetype—A content-analysis-based literature review. Prod. Plan. Control 2018, 29, 438–451. [Google Scholar] [CrossRef]

- Dervojeda, K.; Verzijl, D.; Rouwmaat, E.; Probst, L.; Frideres, L. Clean Technologies, Circular Supply Chains, Business Innovation Observatory; European Commission: Luxembourg, 2014.

- Zhu, Z.; Chu, F.; Dolgui, A.; Chu, C.; Zhou, W.; Piramuthu, S. Recent Advances and Opportunities in Sustainable Food Supply Chain: A Model-Oriented Review. Int. J. Prod. Res. 2018, 56, 5700–5722. [Google Scholar] [CrossRef] [Green Version]

- Akhtar, P.; Tse, Y.K.; Khan, Z.; Rao-Nicholson, R. Data-Driven and Adaptive Leadership Contributing to Sustainability: Global Agri-Food Supply Chains Connected with Emerging Markets. Int. J. Prod. Econ. 2016, 181, 392–401. [Google Scholar] [CrossRef] [Green Version]

- Glover, J.L.; Champion, D.; Daniels, K.J.; Dainty, A.J.D. An Institutional Theory Perspective on Sustainable Practices across the Dairy Supply Chain. Int. J. Prod. Econ. 2014, 152, 102–111. [Google Scholar] [CrossRef] [Green Version]

- Fearne, A.; María García Álvarez-Coque, J.; López-García Usach Mercedes, T.; García, S. Innovative Firms and the Urban/Rural Divide: The Case of Agro-Food System. Manag. Decis. 2013, 51, 1293–1310. [Google Scholar] [CrossRef]

- Rogoff, M.J. Processing Technologies. In Solid Waste Recycling and Processing; William Andrew: Norwich, NY, USA, 2014; pp. 43–111. [Google Scholar]

- Tiekstra, S.; Dopico-Parada, A.; Koivula, H.; Lahti, J.; Buntinx, M. Holistic Approach to a Successful Market Implementation of Active and Intelligent Food Packaging. Foods 2021, 10, 465. [Google Scholar] [CrossRef] [PubMed]

- Wikström, F.; Verghese, K.; Auras, R.; Olsson, A.; Williams, H.; Wever, R.; Grönman, K.; Kvalvåg Pettersen, M.; Møller, H.; Soukka, R. Packaging Strategies That Save Food: A Research Agenda for 2030. J. Ind. Ecol. 2018, 23, 532–540. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Peponi, L.; López, D.; López, J.; Kenny, J.M. An Overview of Nanoparticles Role in the Improvement of Barrier Properties of Bioplastics for Food Packaging Applications. In Food Packaging; Academic Press: Cambridge, MA, USA, 2017; pp. 391–424. [Google Scholar]

- Zhao, X.; Cornish, K.; Vodovotz, Y. Narrowing the Gap for Bioplastic Use in Food Packaging: An Update. Environ. Sci. Technol. 2020, 54, 4712–4732. [Google Scholar] [CrossRef] [PubMed]

- British Plastics Federation. Oil Consumption. Available online: https://www.bpf.co.uk/press/Oil_Consumption.aspx (accessed on 6 March 2023).

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics Recycling: Challenges and Opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [Green Version]

- Yousefi, H.; Su, H.-M.; Imani, S.M.; Alkhaldi, K.; Filipe, C.D.M.; Didar, T.F. Intelligent Food Packaging: A Review of Smart Sensing Technologies for Monitoring Food Quality. ACS Sens. 2019, 4, 808–821. [Google Scholar] [CrossRef]

- Puligundla, P.; Jung, J.; Ko, S. Carbon Dioxide Sensors for Intelligent Food Packaging Applications. Food Control 2012, 25, 328–333. [Google Scholar] [CrossRef]

- Yam, K.L.; Takhistov, P.T.; Miltz, J. Intelligent Packaging: Concepts and Applications. J. Food Sci. 2005, 70, R1–R10. [Google Scholar] [CrossRef]

- Hong, L.G.; Yuhana, N.Y.; Zawawi, E.Z. Review of Bioplastics as Food Packaging Materials. AIMS Mater. Sci. 2021, 8, 166–184. [Google Scholar] [CrossRef]

- Teck Kim, Y.; Min, B.; Won Kim, K. General Characteristics of Packaging Materials for Food System. In Innovations in Food Packaging; Academic Press: Cambridge, MA, USA, 2014; pp. 13–35. [Google Scholar]

- Beyer, R. Manual on Food Packaging for Small and Medium-Size Enterprises in Samoa; Food and Agriculture Organization of the United Nations Sub-Regional Office for the Pacific Islands: Apia, Samoa, 2012. [Google Scholar]

- Sharma, Y.K.; Mangla, S.K.; Patil, P.P.; Liu, S. When Challenges Impede the Process. Manag. Decis. 2019, 57, 995–1017. [Google Scholar] [CrossRef]

- Grimm, J.H.; Hofstetter, J.S.; Sarkis, J. Critical Factors for Sub-Supplier Management: A Sustainable Food Supply Chains Perspective. Int. J. Prod. Econ. 2014, 152, 159–173. [Google Scholar] [CrossRef]

- Bhattacharya, A. Achieving Sustainability in Supply Chain Operations in the Interplay between Circular Economy and Industry 4.0. Prod. Plan. Control 2021, 34, 867–869. [Google Scholar] [CrossRef]

- van der A, J.G.; Sijm, D.T. Risk Governance in the Transition towards Sustainability, the Case of Bio-Based Plastic Food Packaging Materials. J. Risk Res. 2021, 24, 1639–1651. [Google Scholar] [CrossRef]

- National Research Council; Policy and Global Affairs; Board on Sustainable Development; Policy Division. Our Common Journey: A Transition Toward Sustainability. Available online: https://nap.nationalacademies.org/catalog/9690/our-common-journey-a-transitiontoward-sustainability (accessed on 31 March 2023).

- Geng, Y.; Sarkis, J.; Bleischwitz, R. How to Globalize the Circular Economy. Nature 2019, 565, 153–155. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marone, P. Sustainability Transition towards a Bio-Based Economy: New Technologies, New Products, New Policies; MDPI: Basel, Switzerland, 2018. [Google Scholar]

- Johnstone, P.; Newell, P. Sustainability Transitions and the State. Environ. Innov. Soc. Transit. 2018, 27, 72–82. [Google Scholar] [CrossRef]

- Markard, J. Transformation of Infrastructures: Sector Characteristics and Implications for Fundamental Change. J. Infrastruct. Syst. 2011, 17, 107–117. [Google Scholar] [CrossRef]

- Magnier, L.; Crié, D. Communicating Packaging Eco-Friendliness. Int. J. Retail Distrib. Manag. 2015, 43, 350–366. [Google Scholar] [CrossRef]

- Rettie, R.; Brewer, C. The Verbal and Visual Components of Package Design. J. Prod. Brand Manag. 2000, 9, 56–70. [Google Scholar] [CrossRef] [Green Version]

- Underwood, R.L. The Communicative Power of Product Packaging: Creating Brand Identity via Lived and Mediated Experience. J. Mark. Theory Pract. 2003, 11, 62–76. [Google Scholar] [CrossRef]

- Lindh, H.; Williams, H.; Olsson, A.; Wikström, F. Elucidating the Indirect Contributions of Packaging to Sustainable Development: A Terminology of Packaging Functions and Features. Packag. Technol. Sci. 2016, 29, 225–246. [Google Scholar] [CrossRef]

- Siracusa, V.; Rocculi, P.; Romani, S.; Rosa, M.D. Biodegradable Polymers for Food Packaging: A Review. Trends Food Sci. Technol. 2008, 19, 634–643. [Google Scholar] [CrossRef]

- Emblem, A. (Ed.) Packaging Technology: Fundamentals, Materials and Processes; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Nguyen, A.T.; Parker, L.; Brennan, L.; Lockrey, S. A Consumer Definition of Eco-Friendly Packaging. J. Clean. Prod. 2020, 252, 119792. [Google Scholar] [CrossRef]

- Kirwan, M.J.; Plant, S.; Strawbridge, J.W. Plastics in Food Packaging. In Food and Beverage Packaging Technology; Wiley: Hoboken, NJ, USA, 2011; pp. 157–212. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Rother, E.T. Systematic literature review X narrative review. Acta Paul. Enferm. 2007, 20, v–vi. [Google Scholar] [CrossRef] [Green Version]

- Lame, G. Systematic Literature Reviews: An Introduction. Proc. Des. Soc. Int. Conf. Eng. Des. 2019, 1, 1633–1642. [Google Scholar] [CrossRef] [Green Version]

- Thomé, A.M.; Scavarda, L.F.; Scavarda, A.J. Conducting Systematic Literature Review in Operations Management. Prod. Plan. Control 2016, 27, 408–420. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a systematic review. In The Sage Handbook of Organizational Research Methods; Buchanan, D.A., Bryman, A., Eds.; Sage Publications Ltd.: Thousand Oaks, CA, USA, 2009; pp. 671–689. [Google Scholar]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.A.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The Prisma Statement for Reporting Systematic Reviews and Meta-Analyses of Studies That Evaluate Health Care Interventions: Explanation and Elaboration. J. Clin. Epidemiol. 2009, 62, e1–e34. [Google Scholar] [CrossRef] [Green Version]

- Petticrew, M. Systematic Reviews from Astronomy to Zoology: Myths and Misconceptions. BMJ 2001, 322, 98–101. [Google Scholar] [CrossRef] [Green Version]

- Kardung, M.; Cingiz, K.; Costenoble, O.; Delahaye, R.; Heijman, W.; Lovrić, M.; van Leeuwen, M.; M’Barek, R.; van Meijl, H.; Piotrowski, S.; et al. Development of the Circular Bioeconomy: Drivers and Indicators. Sustainability 2021, 13, 413. [Google Scholar] [CrossRef]

- de Jesus, A.; Mendonça, S. Lost in Transition? Drivers and Barriers in the Eco-Innovation Road to the Circular Economy. Ecol. Econ. 2018, 145, 75–89. [Google Scholar] [CrossRef] [Green Version]

- Govindan, K.; Hasanagic, M. A Systematic Review on Drivers, Barriers, and Practices towards Circular Economy: A Supply Chain Perspective. Int. J. Prod. Res. 2018, 56, 278–311. [Google Scholar] [CrossRef]

- Hazen, B.T.; Mollenkopf, D.A.; Wang, Y. Remanufacturing for the Circular Economy: An Examination of Consumer Switching Behavior. Bus. Strategy Environ. 2016, 26, 451–464. [Google Scholar] [CrossRef]

- Quina, M.J.; Soares, M.A.R.; Quinta-Ferreira, R. Applications of Industrial Eggshell as a Valuable Anthropogenic Resource. Resour. Conserv. Recycl. 2017, 123, 176–186. [Google Scholar] [CrossRef]

- Yusuf, Y.Y.; Olaberinjo, A.E.; Papadopoulos, T.; Gunasekaran, A.; Subramanian, N.; Sharifi, H. Returnable Transport Packaging in Developing Countries: Drivers, Barriers and Business Performance. Prod. Plan. Control 2017, 28, 629–658. [Google Scholar] [CrossRef]

- Ilić, M.; Nikolić, M. Drivers for Development of Circular Economy—A Case Study of Serbia. Habitat Int. 2016, 56, 191–200. [Google Scholar] [CrossRef]

- Xinan, L.; Yanfu, L. Driving Forces on China’s Circular Economy: From Government’s Perspectives. Energy Procedia 2011, 5, 297–301. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Q.; Geng, Y.; Sarkis, J.; Lai, K.-H. Evaluating Green Supply Chain Management among Chinese Manufacturers from the Ecological Modernization Perspective. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 808–821. [Google Scholar] [CrossRef]

- Park, J.; Sarkis, J.; Wu, Z. Creating Integrated Business and Environmental Value within the Context of China’s Circular Economy and Ecological Modernization. J. Clean. Prod. 2010, 18, 1494–1501. [Google Scholar] [CrossRef]

- Sonneveld, K. What Drives (Food) Packaging Innovation? Packag. Technol. Sci. 2000, 13, 29–35. [Google Scholar] [CrossRef]

- Domenech, T.; Bleischwitz, R.; Doranova, A.; Panayotopoulos, D.; Roman, L. Mapping Industrial Symbiosis Development in Europe_ Typologies of Networks, Characteristics, Performance and Contribution to the Circular Economy. Resour. Conserv. Recycl. 2019, 141, 76–98. [Google Scholar] [CrossRef]

- Lazarevic, D.; Valve, H. Narrating Expectations for the Circular Economy: Towards a Common and Contested European Transition. Energy Res. Soc. Sci. 2017, 31, 60–69. [Google Scholar] [CrossRef]

- Franklin-Johnson, E.; Figge, F.; Canning, L. Resource Duration as a Managerial Indicator for Circular Economy Performance. J. Clean. Prod. 2016, 133, 589–598. [Google Scholar] [CrossRef]

- Olsmats, C.; Kaivo-oja, J. European Packaging Industry Foresight Study—Identifying Global Drivers and Driven Packaging Industry Implications of the Global Megatrends. Eur. J. Futures Res. 2014, 2, 39. [Google Scholar] [CrossRef] [Green Version]

- Geng, Y.; Zhu, Q.; Doberstein, B.; Fujita, T. Implementing China’s Circular Economy Concept at the Regional Level: A Review of Progress in Dalian, China. Waste Manag. 2009, 29, 996–1002. [Google Scholar] [CrossRef] [PubMed]

- Esposito, M.; Tse, T.; Soufani, K. Is the Circular Economy a New Fast-Expanding Market? Thunderbird Int. Bus. Rev. 2015, 59, 9–14. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2015, 140, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Linder, M.; Williander, M. Circular Business Model Innovation: Inherent Uncertainties. Bus. Strategy Environ. 2015, 26, 182–196. [Google Scholar] [CrossRef]

- Dong, L.; Fujita, T.; Dai, M.; Geng, Y.; Ren, J.; Fujii, M.; Wang, Y.; Ohnishi, S. Towards Preventative Eco-Industrial Development: An Industrial and Urban Symbiosis Case in One Typical Industrial City in China. J. Clean. Prod. 2016, 114, 387–400. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Pitt, J.; Heinemeyer, C. Introducing Ideas of a Circular Economy. In Environment, Ethics and Cultures; SensePublishers: Rotterdam, The Netherlands, 2015; pp. 245–260. [Google Scholar]

- Rizos, V.; Behrens, A.; Kafyeke, T.; Hirschnitz-Garbers, M.; Ioannou, A. The circular economy: Barriers and opportunities for SMEs. In CEPS Working Documents; CEPS: Sacramento CA, USA, 2015. [Google Scholar]

- Liu, Y.; Bai, Y. An Exploration of Firms’ Awareness and Behavior of Developing Circular Economy: An Empirical Research in China. Resour. Conserv. Recycl. 2014, 87, 145–152. [Google Scholar] [CrossRef]

- World Economic Forum. Towards the Circular Economy: Accelerating the Scale-Up across Global Supply Chains. Available online: https://www.weforum.org/reports/towards-circular-economy-accelerating-scale-across-global-supply-chains (accessed on 31 March 2023).

- Schulte, U.G. New Business Models for a Radical Change in Resource Efficiency. Environ. Innov. Soc. Transit. 2013, 9, 43–47. [Google Scholar] [CrossRef]

- Andersen, M.S. An Introductory Note on the Environmental Economics of the Circular Economy. Sustain. Sci. 2006, 2, 133–140. [Google Scholar] [CrossRef]

- Witjes, S.; Lozano, R. Towards a More Circular Economy: Proposing a Framework Linking Sustainable Public Procurement and Sustainable Business Models. Resour. Conserv. Recycl. 2016, 112, 37–44. [Google Scholar] [CrossRef] [Green Version]

- Bai, C.; Sarkis, J.; Dou, Y. Corporate Sustainability Development in China: Review and Analysis. Ind. Manag. Data Syst. 2015, 115, 5–40. [Google Scholar] [CrossRef]

- Velis, C.A.; Vrancken, K.C. Which material ownership and responsibility in a circular economy? Waste Manag. Res. 2015, 33, 773–774. [Google Scholar] [CrossRef]

- Yu, C.; de Jong, M.; Dijkema, G.P.J. Process Analysis of Eco-Industrial Park Development—The Case of Tianjin, China. J. Clean. Prod. 2014, 64, 464–477. [Google Scholar] [CrossRef]

- Stahel, W.R. Policy for Material Efficiency—Sustainable Taxation as a Departure from the Throwaway Society. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2013, 371, 20110567. [Google Scholar] [CrossRef] [Green Version]

- Desrochers, P. Cities and industrial symbiosis: Some historical perspectives and policy implications. J. Ind. Ecol. 2001, 5, 29–44. [Google Scholar] [CrossRef]

- Clark, J.H.; Farmer, T.J.; Herrero-Davila, L.; Sherwood, J. Circular Economy Design Considerations for Research and Process Development in the Chemical Sciences. Green Chem. 2016, 18, 3914–3934. [Google Scholar] [CrossRef] [Green Version]

- Magnier, L.; Schoormans, J.; Mugge, R. Judging a Product by Its Cover: Packaging Sustainability and Perceptions of Quality in Food Products. Food Qual. Prefer. 2016, 53, 132–142. [Google Scholar] [CrossRef]

- Pringle, T.; Barwood, M.; Rahimifard, S. The Challenges in Achieving a Circular Economy within Leather Recycling. Procedia CIRP 2016, 48, 544–549. [Google Scholar] [CrossRef] [Green Version]

- Thyberg, K.L.; Tonjes, D.J. Drivers of Food Waste and Their Implications for Sustainable Policy Development. Resour. Conserv. Recycl. 2016, 106, 110–123. [Google Scholar] [CrossRef]

- Matthes, J.; Wonneberger, A.; Schmuck, D. Consumers’ Green Involvement and the Persuasive Effects of Emotional versus Functional Ads. J. Bus. Res. 2014, 67, 1885–1893. [Google Scholar] [CrossRef]

- Schiller, G.; Müller, F.; Ortlepp, R. Mapping the Anthropogenic Stock in Germany: Metabolic Evidence for a Circular Economy. Resour. Conserv. Recycl. 2017, 123, 93–107. [Google Scholar] [CrossRef]

- van den Oever, M.; Molenveld, K.; van der Zee, M.; Harriëtte, B. Bio-Based and Biodegradable Plastics: Facts and Figures: Focus on Food Packaging in The Netherlands; Wageningen Food & Biobased Research: Wageningen, The Netherlands, 2017. [Google Scholar]

- Dilkes-Hoffman, L.; Ashworth, P.; Laycock, B.; Pratt, S.; Lant, P. Public Attitudes towards Bioplastics—Knowledge, Perception and End-of-Life Management. Resour. Conserv. Recycl. 2019, 151, 104479. [Google Scholar] [CrossRef]

- Jurgilevich, A.; Birge, T.; Kentala-Lehtonen, J.; Korhonen-Kurki, K.; Pietikäinen, J.; Saikku, L.; Schösler, H. Transition towards Circular Economy in the Food System. Sustainability 2016, 8, 69. [Google Scholar] [CrossRef] [Green Version]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and Its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Korhonen, J.; Nuur, C.; Feldmann, A.; Birkie, S.E. Circular Economy as an Essentially Contested Concept. J. Clean. Prod. 2018, 175, 544–552. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A. How Do Scholars Approach the Circular Economy? A Systematic Literature Review. J. Clean. Prod. 2018, 178, 703–722. [Google Scholar] [CrossRef]

- Yadav, S.; Mehrotra, G.K.; Bhartiya, P.; Singh, A.; Dutta, P.K. Preparation, Physicochemical and Biological Evaluation of Quercetin Based Chitosan-Gelatin Film for Food Packaging. Carbohydr. Polym. 2020, 227, 115348. [Google Scholar] [CrossRef]

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.C.L. Sustainable Supply Chain Management and the Transition towards a Circular Economy: Evidence and Some Applications. Omega 2017, 66, 344–357. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards Circular Economy Implementation: A Comprehensive Review in Context of Manufacturing Industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Bramble, T. Book Reviews: The Machine That Changed the World. J. Ind. Relat. 1992, 34, 182–183. [Google Scholar] [CrossRef]

- Tencati, A.; Pogutz, S.; Moda, B.; Brambilla, M.; Cacia, C. Prevention Policies Addressing Packaging and Packaging Waste: Some Emerging Trends. Waste Manag. 2016, 56, 35–45. [Google Scholar] [CrossRef]

- Andersson, C.; Stage, J. Direct and Indirect Effects of Waste Management Policies on Household Waste Behaviour: The Case of Sweden. Waste Manag. 2018, 76, 19–27. [Google Scholar] [CrossRef] [Green Version]

- Hickel, J.; Kallis, G. Is Green Growth Possible? New Political Econ. 2019, 25, 469–486. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Fan, Y.V.; Jiang, P. Plastics: Friends or Foes? the Circularity and Plastic Waste Footprint. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 43, 1549–1565. [Google Scholar] [CrossRef]

- Aarnio, T.; Hämäläinen, A. Challenges in Packaging Waste Management in the Fast Food Industry. Resour. Conserv. Recycl. 2008, 52, 612–621. [Google Scholar] [CrossRef]

- Massoud, M.A.; Fayad, R.; El-Fadel, M.; Kamleh, R. Drivers, Barriers and Incentives to Implementing Environmental Management Systems in the Food Industry: A Case of Lebanon. J. Clean. Prod. 2010, 18, 200–209. [Google Scholar] [CrossRef]

- Van Berkum, S.; Dengerink, J.; Ruben, R. The Food Systems Approach: Sustainable Solutions for a Sufficient Supply of Healthy Food; Wageningen Food & Biobased Research: Wageningen, The Netherlands, 2018. [Google Scholar]

- Timmer, C.P. Managing structural transformation: A political economy approach. In Proceedings of the WIDER Annual Lecture 18, New York, NY, USA, 18 November 2014. [Google Scholar]

- Food and Agriculture Organizatin (FAO) The Future of Food and Agriculture—Trends and and Challenges. 2017. Available online: https://www.fao.org/global-perspectives-studies/resources/detail/en/c/458158/ (accessed on 23 December 2022).

- Kroyer, G.T. Impact of Food Processing on the Environment—An Overview. LWT-Food Sci. Technol. 1995, 28, 547–552. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Davoudpour, Y.; Saurabh, C.K.; Hossain, M.S.; Adnan, A.S.; Dungani, R.; Paridah, M.T.; Islam Sarker, M.Z.; Fazita, M.R.N.; Syakir, M.I.; et al. A Review on Nanocellulosic Fibres as New Material for Sustainable Packaging: Process and Applications. Renew. Sustain. Energy Rev. 2016, 64, 823–836. [Google Scholar] [CrossRef]

- Pauer, E.; Wohner, B.; Heinrich, V.; Tacker, M. Assessing the Environmental Sustainability of Food Packaging: An Extended Life Cycle Assessment Including Packaging-Related Food Losses and Waste and Circularity Assessment. Sustainability 2019, 11, 925. [Google Scholar] [CrossRef] [Green Version]

- European Commission. A European Strategy for Plastics in a Circular Economy. 2018. Available online: https://www.switch-asia.eu/resource/a-european-strategy-for-plastics-in-a-circular-economy/ (accessed on 8 March 2023).

- Chuck Bennett. SB: Reducing Material Use through Packaging Innovation: Aveda’s Journey. 2013. Available online: https://sustainablebrands.com/read/waste-not/reducing-material-use-through-packaging-innovation-aveda-s-journey (accessed on 31 March 2023).

- Oude Ophuis, P.A.M.; Van Dam, Y.K.; Lamers, A.M.J. Relative importance of health aspects and environmental issues for food consumption: Product attributes of lettuce. In Proceedings of the 21st EMAC Conference Marketing for Europe: Marketing for the Future, Aarhus, Denmark, 26–29 May 1992. [Google Scholar]

- Bohlen, G.; Schlegelmilch, B.B.; Diamantopoulos, A. Measuring Ecological Concern: A Multi-Construct Perspective. J. Mark. Manag. 1993, 9, 415–430. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Winans, K.; Kendall, A.; Deng, H. The History and Current Applications of the Circular Economy Concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Loiseau, E.; Saikku, L.; Antikainen, R.; Droste, N.; Hansjürgens, B.; Pitkänen, K.; Leskinen, P.; Kuikman, P.; Thomsen, M. Green Economy and Related Concepts: An Overview. J. Clean. Prod. 2016, 139, 361–371. [Google Scholar] [CrossRef]

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The next Generation of Sustainable Food Packaging to Preserve Our Environment in a Circular Economy Context. Front. Nutr. 2018, 5, 121. [Google Scholar] [CrossRef] [Green Version]

- Tan, J.; Tan, F.J.; Ramakrishna, S. Transitioning to a Circular Economy: A Systematic Review of Its Drivers and Barriers. Sustainability 2022, 14, 1757. [Google Scholar] [CrossRef]

- Gusmerotti, N.M.; Testa, F.; Corsini, F.; Pretner, G.; Iraldo, F. Drivers and Approaches to the Circular Economy in Manufacturing Firms. J. Clean. Prod. 2019, 230, 314–327. [Google Scholar] [CrossRef]

- Franz, R.; Welle, F. Recycling of Post-Consumer Packaging Materials into New Food Packaging Applications—Critical Review of the European Approach and Future Perspectives. Sustainability 2022, 14, 824. [Google Scholar] [CrossRef]

- Harnkarnsujarit, N.; Wongphan, P.; Chatkitanan, T.; Laorenza, Y.; Srisa, A. Bioplastic for Sustainable Food Packaging. In Sustainable Food Processing and Engineering Challenges; Academic Press: Cambridge, MA, USA, 2021; pp. 203–277. [Google Scholar]

- Niaounakis, M. Definitions of Terms and Types of Biopolymers. In Biopolymers: Applications and Trends; Academic Press: Cambridge, MA, USA, 2015; pp. 1–90. [Google Scholar]

- Mishra, A.; Mohite, A.M.; Sharma, N. Influence of particle size on physical, mechanical, thermal, and morphological properties of tamarind-fenugreek mucilage biodegradable films. Polym. Bull. 2023, 80, 3119–3133. [Google Scholar] [CrossRef]

- Mohite, A.M.; Sharma, N.; Aggarwal, S.; Sharma, S. Effect of Tamarindus Coating on Post-Harvest Quality of Apples and Pears Stored at Different Conditions. Carpathian J. Food Sci. Technol. 2018, 10, 17–25. [Google Scholar]

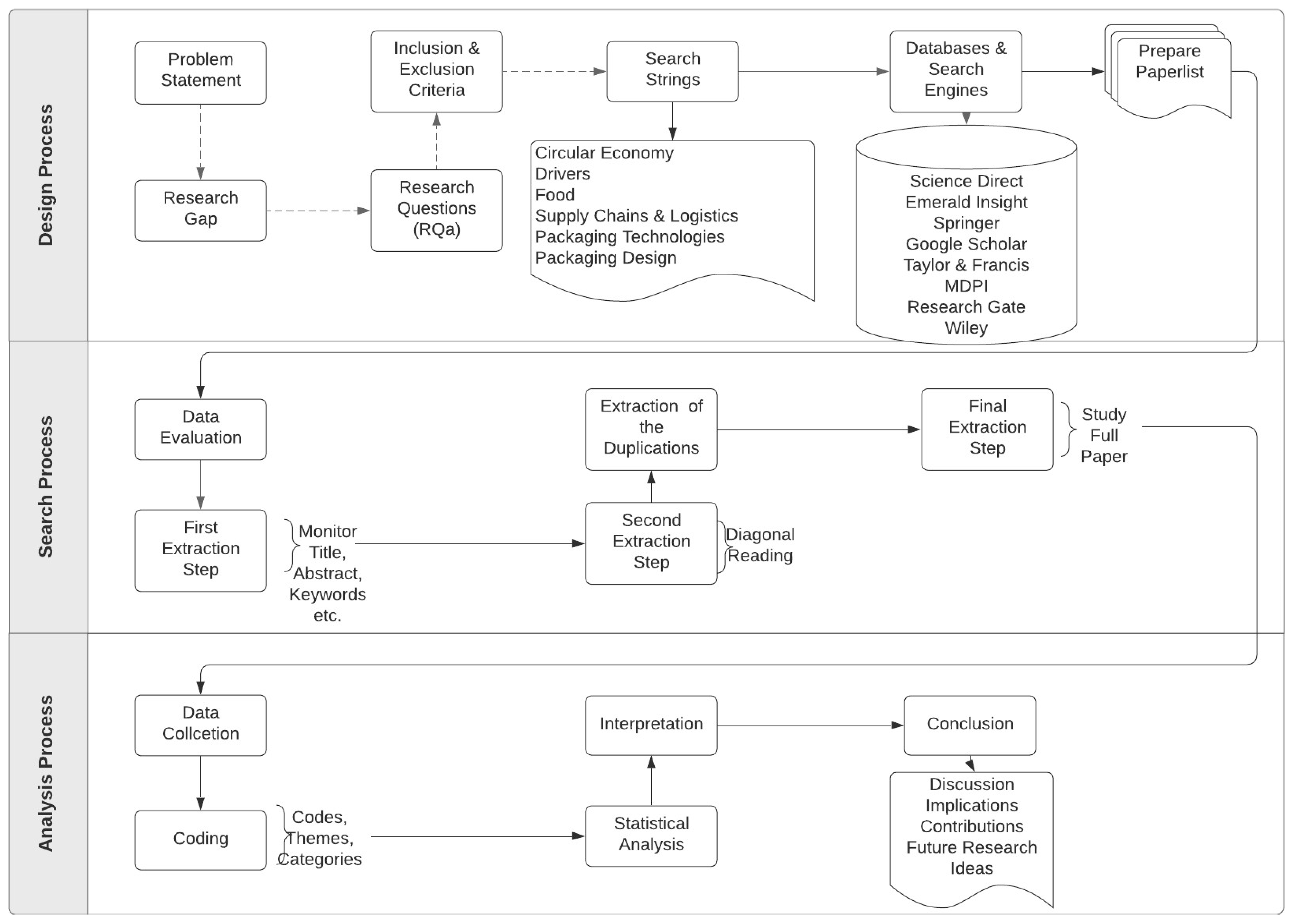

| Steps of Systematic Literature Review | Sub-Steps of Systematic Literature Review | Description of the Layers | Adaptation of SLR into This Study | ||||

|---|---|---|---|---|---|---|---|

| Step 1: Systematic Research Design of the Review (Design Process) | Sub-step 1: Problem Statement |

|

| ||||

| Sub-step 2: Research Gap |

|

| |||||

| Sub-step 3: Research Questions (RQs) |

|

| |||||

| Sub-step 4: Inclusion and Exclusion Criteria |

| Inclusion Criteria: Language: English; Search Timeline: 2022–1990 | Exclusion Criteria: Language: Publication not in English; Type: book, white paper, workshop | ||||

| Sub-step 5: Search String |

|

| |||||

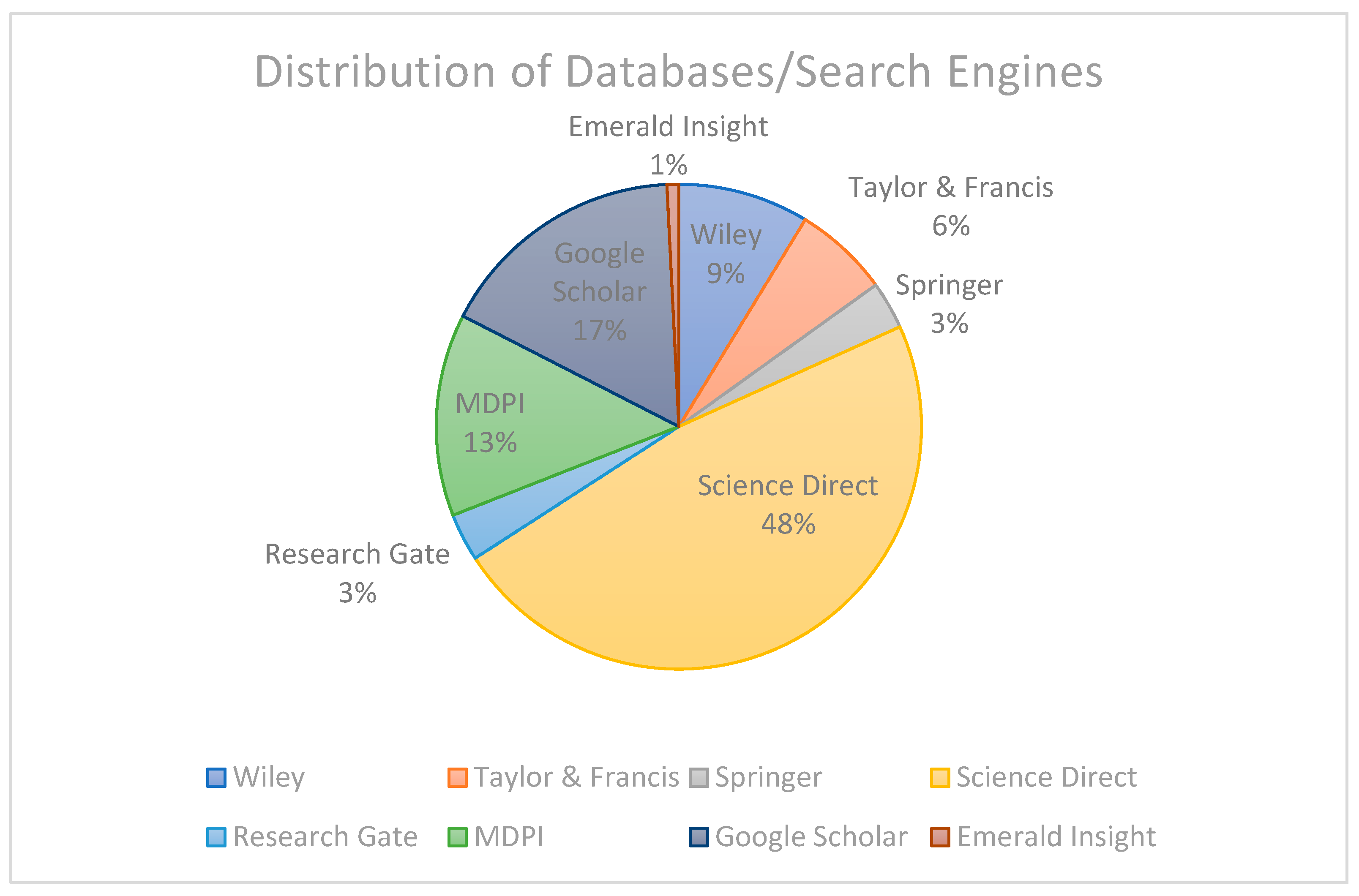

| Sub-step 6: Database and Search Engines |

|

| |||||

| Step 2: Initial Step for Searching Publications (Search Process) | Sub-step 1: Data Evaluation |

|

| ||||

| Sub-step 2: First Extraction Step |

|

| |||||

| Sub-step 3: Second Extraction Step |

|

| |||||

| Sub-step 4: | Duplication Extraction |

| Duplicated |

| |||

| Sub-step 5: Final Extraction Step |

|

| |||||

| Step 3: Developing Analysis Framework (Analysis Process) | an | Sub-step 1: Data Collection |

|

| |||

| Sub-step 2: Coding |

|

| |||||

| Sub-step 3: Statistical Analysis |

|

| |||||

| Sub-step 4: Interpretation |

|

| |||||

| Sub-step 5: Conclusion |

|

| |||||

| Circular Economy | “circular economy” OR “sustainable design” OR “circular design” OR “circular product design” OR “circular product design” OR “close the loop” OR “sustainable packaging strategy” OR “package design for sustainability” OR “redesign” OR “reuse” OR “remanufacture” OR “repurpose” OR “refurbish” OR “recycle” OR “circular design” OR “modular design” OR “cradle to cradle” OR “closed loop” OR “green design” OR “reversible design” OR “transition to circular economy” |

| AND | |

| Drivers | “drivers” OR “enablers” OR “facilitators” OR “success factors” OR “promoters” |

| AND | |

| Food | “seafood” OR “meat” OR “perishable” OR “food” OR “dairy” OR “food loss” OR “food waste” OR “dried food” OR “durable goods packaging” OR “groceries” OR “groceries packaging” OR “dried food packaging” OR “aquaculture” OR “fishing” OR “aquaculture packaging” OR “fish packaging” OR “cold chain packaging” OR “liquid” OR “cooking oil” |

| AND | |

| Supply Chain and Logistics | “supply chain in retail” OR “circular food supply chain” OR “meat supply chain” OR “food supply chain” OR “dairy supply chain” OR “reverse logistics” OR “closed loop supply chain” OR “wholesale supply chain” OR “intermediate supply chain” OR “perishable supply chain” OR “durable goods supply chain” OR “groceries supply chain” OR “dried food supply chain” OR “aquaculture supply chain” OR “fishing supply chain” OR “frozen food supply chain” OR “cold chain supply chain” OR “closed loop food supply chain” |

| AND | |

| Packaging Technologies | “bioactive packaging techniques” OR “active packaging” OR “absorbers” OR “ethylene removers” OR “carbon dioxide emitters/absorbers” OR “multi-layer barrier packaging” OR “modified atmosphere packaging (MAP)” OR “edible coatings” OR “ethylene scavengers” OR “oxygen scavengers” OR “moisture absorbers” OR “Aseptic packaging” OR “nanotechnology” OR “bio and smart packaging technologies” OR “vacuum packaging” OR “barcodes” OR “RFID tags” OR “biodegradable packaging” OR “smart packaging” |

| AND | |

| Package Design | “life-cycle design” OR “package design” OR “design for life-cycle” OR “sustainable product service system (SPSS)” OR “zero packaging” OR “package free” OR “zero-level packaging” OR “packaging material” |

| Dimensions of Drivers | Number | Drivers | References |

|---|---|---|---|

| Legal Drivers | D1 | Strict waste management laws and legislations | [63,64,65,66,67,68,69,70,71,72,73]. |

| D2 | Global and Regional EU and National Policies | [63,64,68]. | |

| D3 | Supportive institutional/regulatory environmental policies | [64,65,74,75]. | |

| Financial Drivers | D4 | Economic and green growth potential | [65,69,76,77,78]. |

| D5 | Cost efficiency | [74,79,80,81,82,83,84,85,86,87,88,89]. | |

| D6 | Supportive funds, incentive, and taxation | [64,69,82,90,91,92,93,94,95]. | |

| Environmental Drivers | D7 | Global environmental issues and concerns | [8,14,63,65,66,67,69,77,96,97,98,99,100]. |

| D8 | Renewable energy demand | [65,96,101,102]. | |

| D9 | Pollution concerns | [8,63,99,103,104]. | |

| D10 | Increased amount of carbon footprint | [102,105,106,107]. | |

| Social Drivers | D11 | Shifting consumer behaviors, prevailing attitudes, and social norms | [28,64,77,99]. |

| D12 | Potential job creation in supply chain | [45,65,69,74,79,101]. | |

| D13 | Consumers’ environmental awareness, sensitivity, and pressure | [28,64,65,69,102]. | |

| D14 | Building a brand image and reputational gains | [64,108,109,110]. | |

| Technical, Technology, and Innovation-Related Drivers | D15 | Rise of new technologies and technological innovations | [63,64,69,74,77,82,90,91,92,93,94,95]. |

| D16 | Technical know-how and capabilities | [64,111]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ada, E.; Kazancoglu, Y.; Lafcı, Ç.; Ekren, B.Y.; Çimitay Çelik, C. Identifying the Drivers of Circular Food Packaging: A Comprehensive Review for the Current State of the Food Supply Chain to Be Sustainable and Circular. Sustainability 2023, 15, 11703. https://doi.org/10.3390/su151511703

Ada E, Kazancoglu Y, Lafcı Ç, Ekren BY, Çimitay Çelik C. Identifying the Drivers of Circular Food Packaging: A Comprehensive Review for the Current State of the Food Supply Chain to Be Sustainable and Circular. Sustainability. 2023; 15(15):11703. https://doi.org/10.3390/su151511703

Chicago/Turabian StyleAda, Erhan, Yigit Kazancoglu, Çisem Lafcı, Banu Y. Ekren, and Cansu Çimitay Çelik. 2023. "Identifying the Drivers of Circular Food Packaging: A Comprehensive Review for the Current State of the Food Supply Chain to Be Sustainable and Circular" Sustainability 15, no. 15: 11703. https://doi.org/10.3390/su151511703

APA StyleAda, E., Kazancoglu, Y., Lafcı, Ç., Ekren, B. Y., & Çimitay Çelik, C. (2023). Identifying the Drivers of Circular Food Packaging: A Comprehensive Review for the Current State of the Food Supply Chain to Be Sustainable and Circular. Sustainability, 15(15), 11703. https://doi.org/10.3390/su151511703