Recycling of Plastics as a Strategy to Reduce Life Cycle GHG Emission, Microplastics and Resource Depletion

Abstract

1. Introduction

2. Materials and Methods

2.1. Goal and Scope

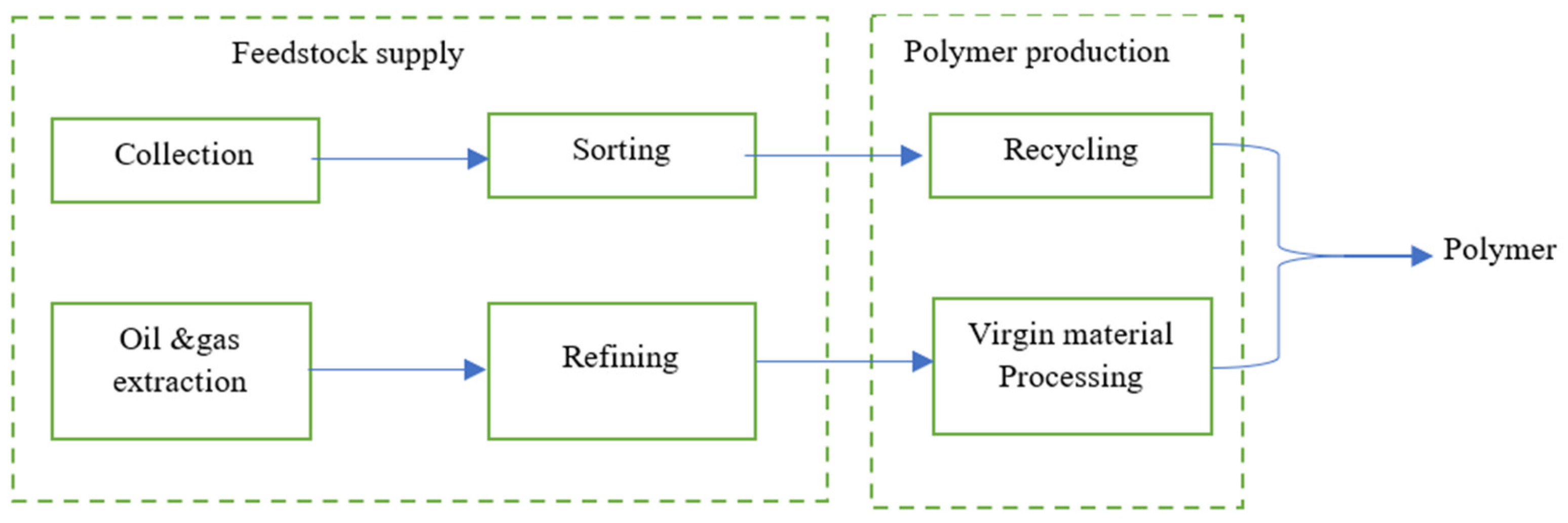

System Boundary and Assumptions

2.2. Life Cycle Inventory

2.2.1. Virgin Polymer Production

2.2.2. Feedstock Supply

2.2.3. Polymer Production

2.3. Climate Change Effects (GHG Savings) from Plastic Recycling

2.4. Microplastics Emission Reduction

2.5. Resource Depletion Savings

3. Results and Discussion

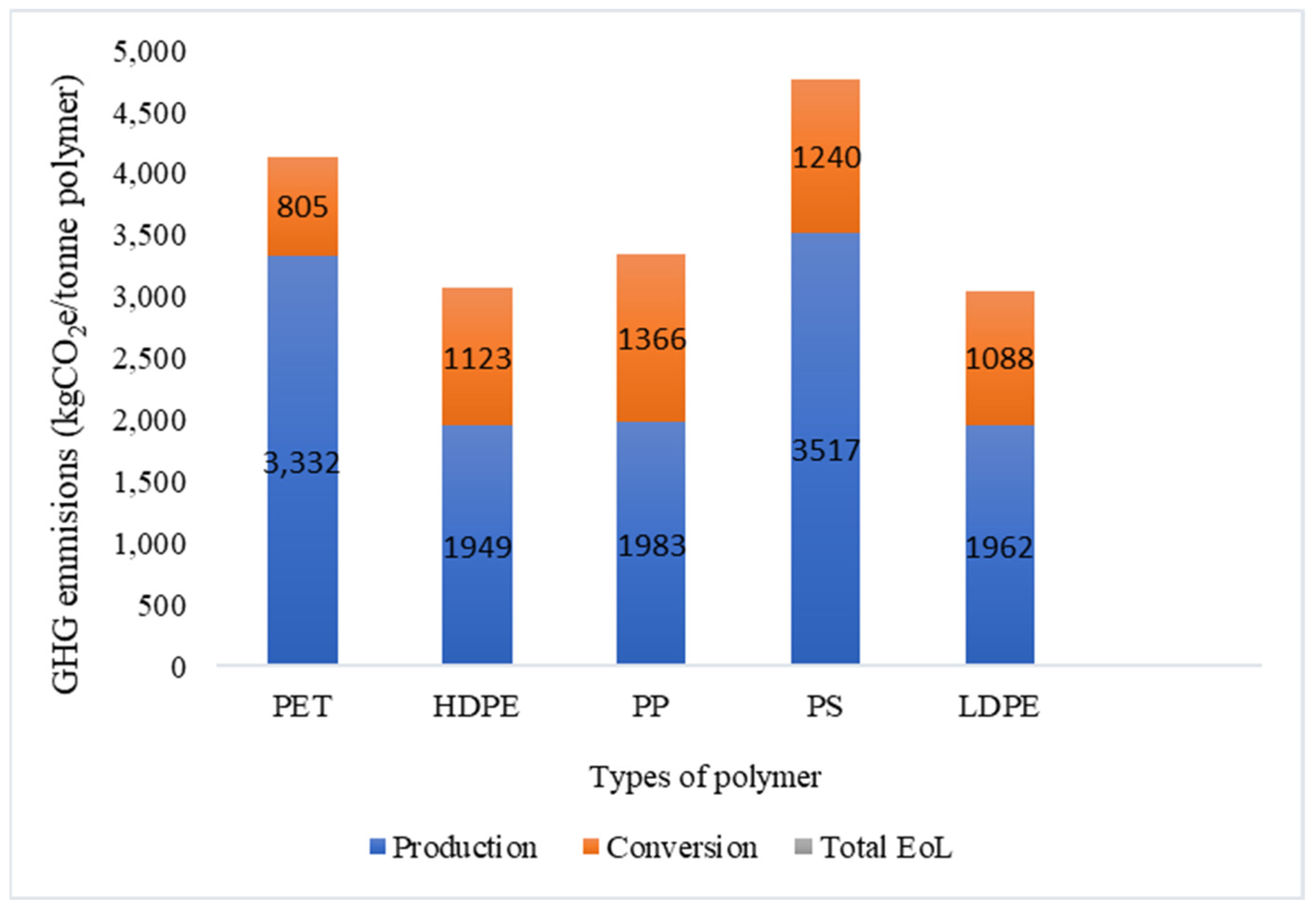

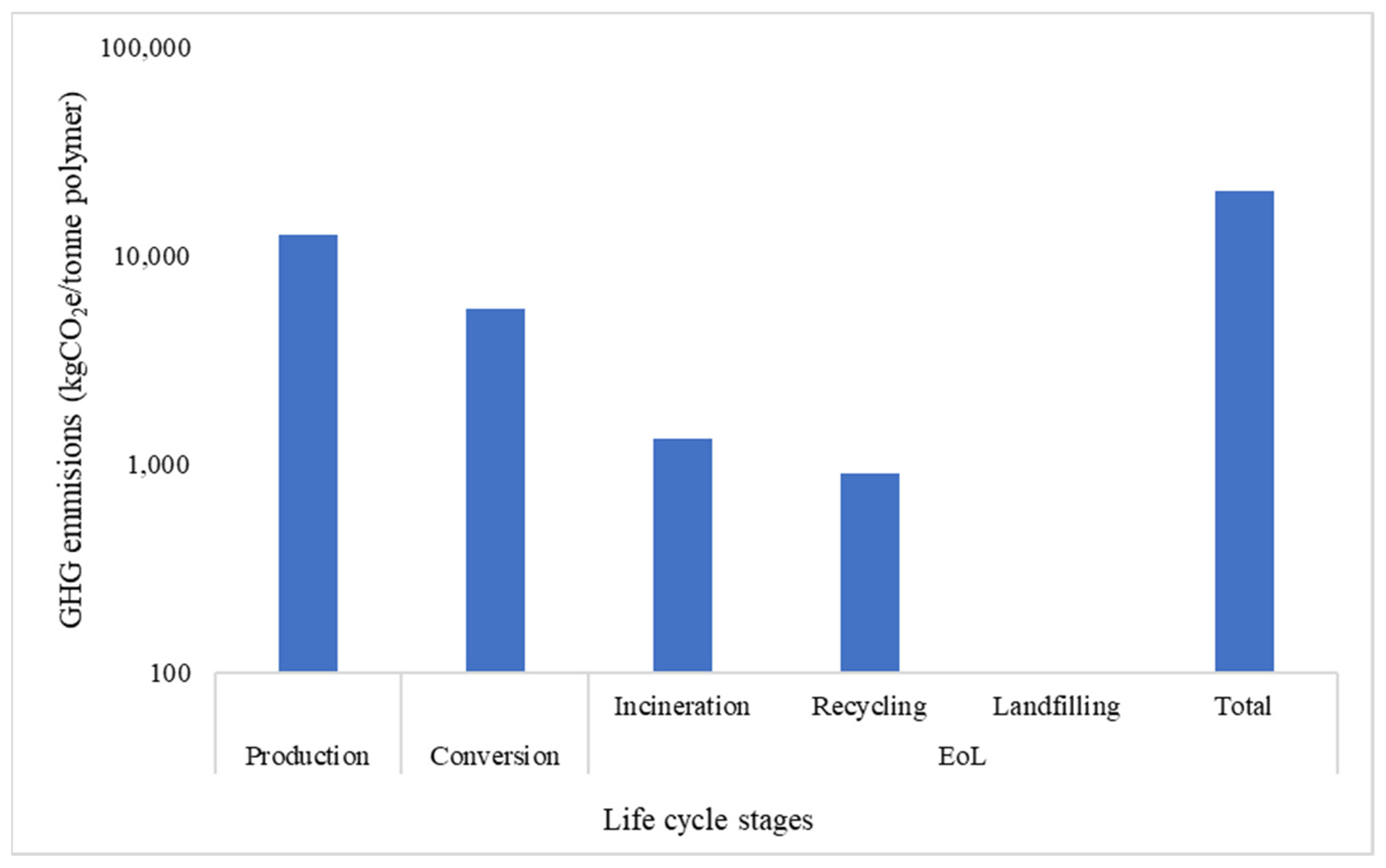

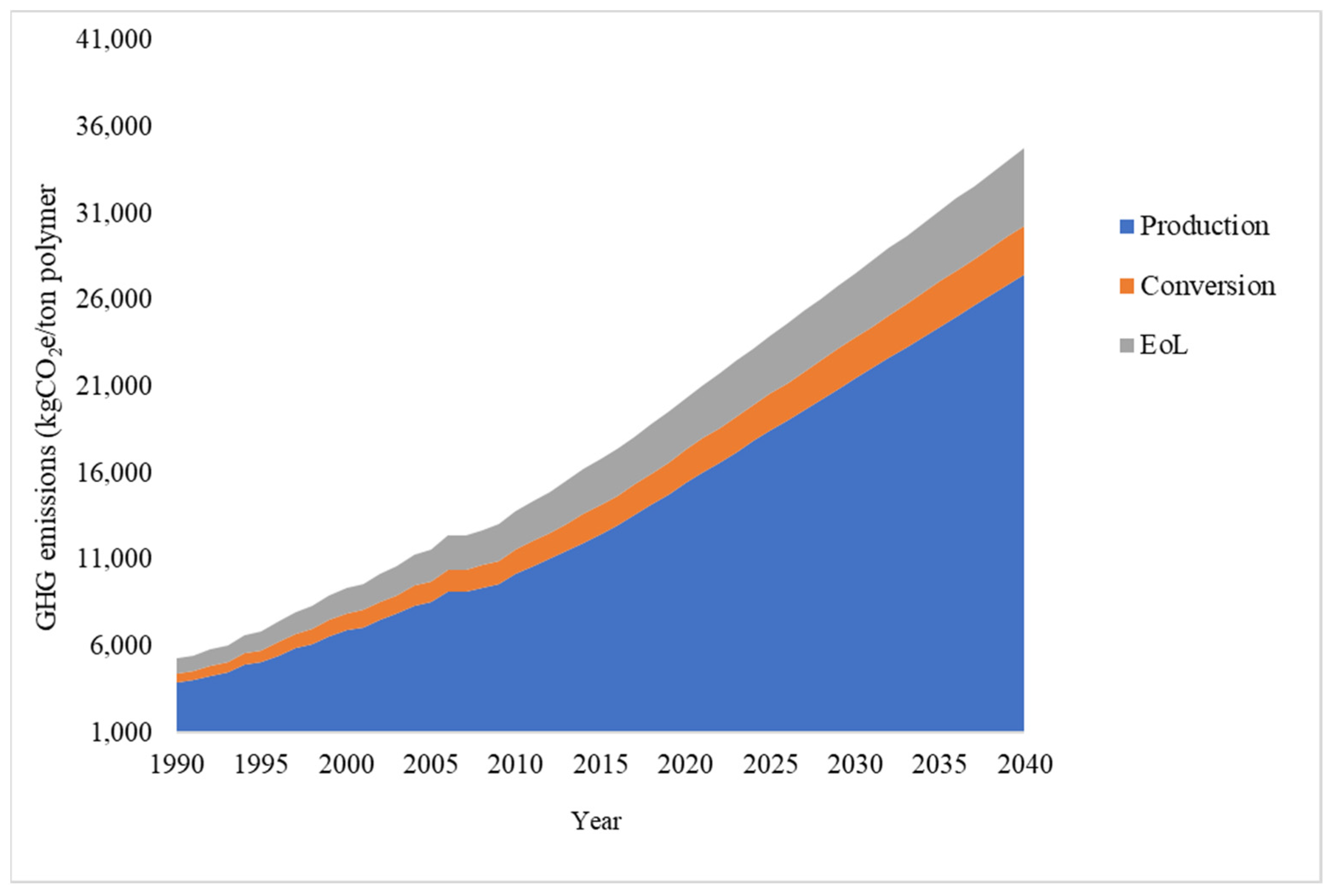

3.1. GHG Emissions Reduction

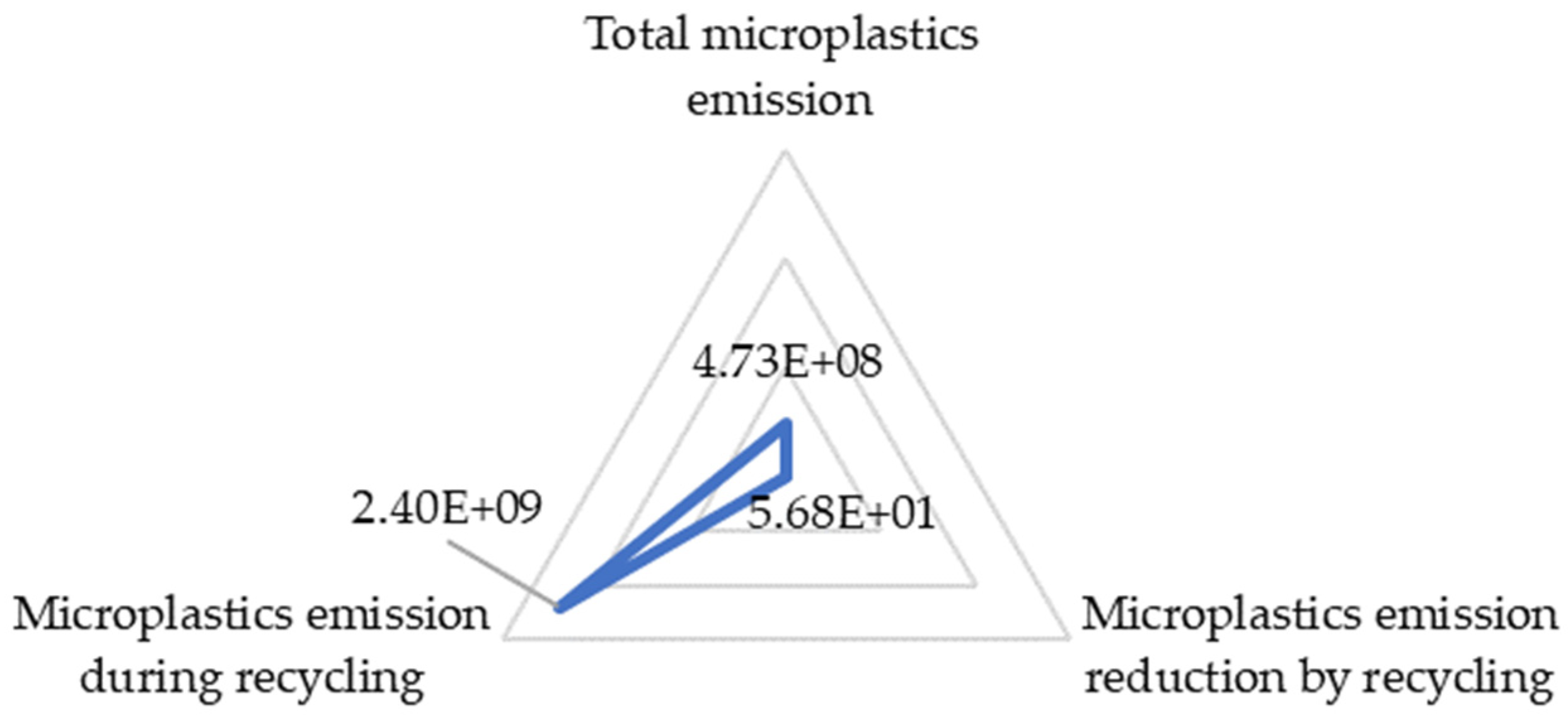

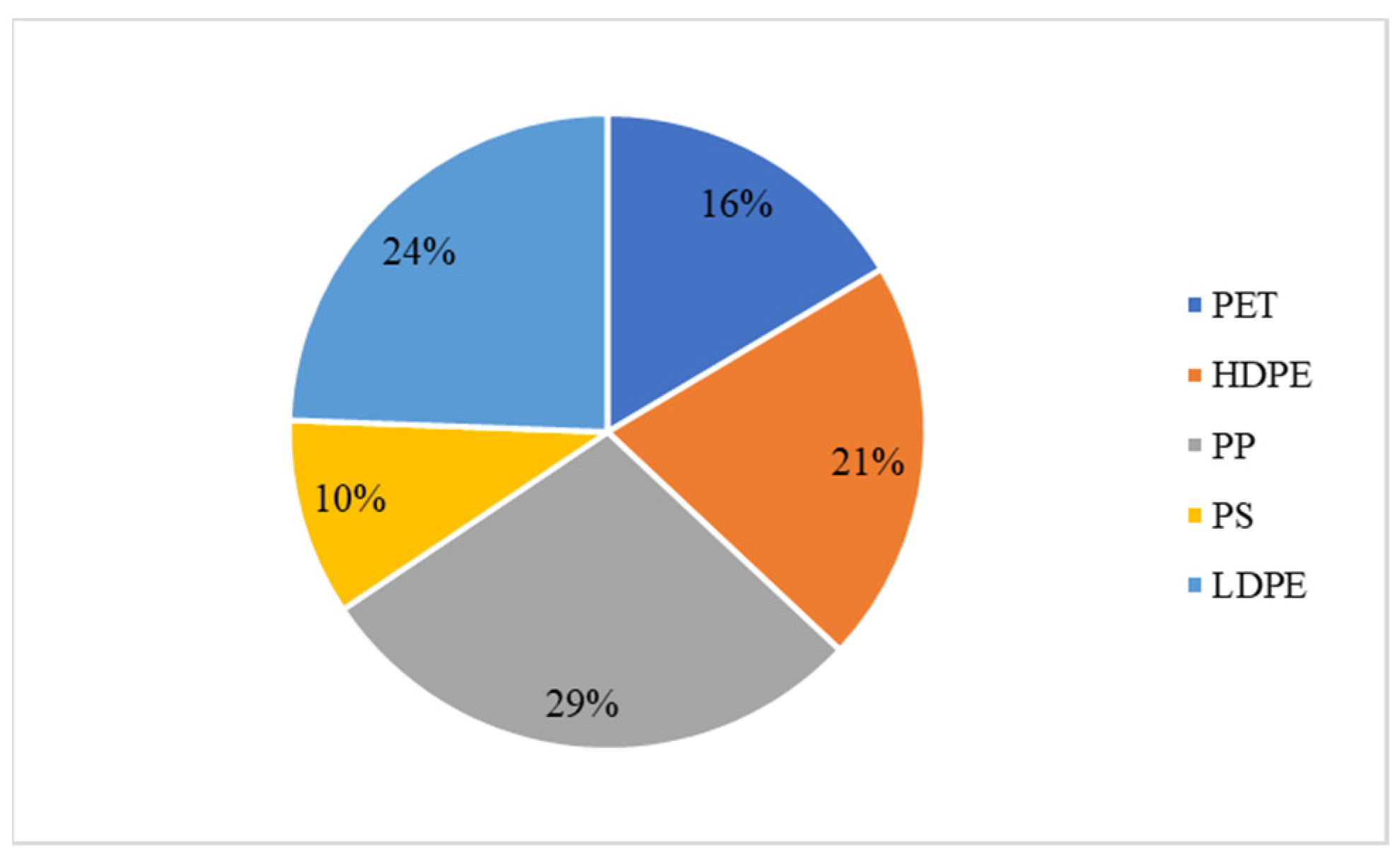

3.2. Microplastics Emissions

3.3. Resource Depletion

4. Perspectives

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thompson, R.C.; Moore, C.J.; Saal, F.S.V.; Swan, S.H. Plastics, the Environment and Human Health: Current Consensus and Future Trends. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2153–2166. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018. [Google Scholar]

- Leslie, H.A.; Brandsma, S.H.; van Velzen, M.J.M.; Vethaak, A.D. Microplastics En Route: Field Measurements in the Dutch River Delta and Amsterdam Canals, Wastewater Treatment Plants, North Sea Sediments and Biota. Environ. Int. 2017, 101, 133–142. [Google Scholar] [CrossRef]

- Kitahara, K.I.; Nakata, H. Plastic Additives as Tracers of Microplastic Sources in Japanese Road Dusts. Sci. Total Environ. 2020, 736, 139694. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Verma, A.; Shome, A.; Sinha, R.; Sinha, S.; Jha, P.K.; Kumar, R.; Kumar, P.; Shubham; Das, S.; et al. Impacts of Plastic Pollution on Ecosystem Services, Sustainable Development Goals, and Need to Focus on Circular Economy and Policy Interventions. Sustainability 2021, 13, 9963. [Google Scholar] [CrossRef]

- PlasticsEurope. Eco-Profiles of the European Plastics Industry: Polyurethane Rigid Foam. 2020, pp. 58–59. Available online: https://plasticseurope.org/ (accessed on 20 March 2023).

- Popa, C.L.; Dontu, S.I.; Savastru, D.; Carstea, E.M. Role of Citizen Scientists in Environmental Plastic Litter Research—A Systematic Review. Sustainability 2022, 14, 13265. [Google Scholar] [CrossRef]

- Mugilarasan, M.; Karthik, R.; Purvaja, R.; Robin, R.S.; Subbareddy, B.; Hariharan, G.; Rohan, S.; Jinoj, T.P.S.; Anandavelu, I.; Pugalenthi, P.; et al. Spatiotemporal Variations in Anthropogenic Marine Litter Pollution along the Northeast Beaches of India. Environ. Pollut. 2021, 280, 116954. [Google Scholar] [CrossRef]

- Kamalakkannan, S.; Abeynayaka, A.; Kulatunga, A.K.; Singh, R.K.; Tatsuno, M.; Gamaralalage, P.J.D. Life Cycle Assessment of Selected Single-Use Plastic Products towards Evidence-Based Policy Recommendations in Sri Lanka. Sustainability 2022, 14, 14170. [Google Scholar] [CrossRef]

- Nikolaev, A.A. The Physical Characterization and Terminal Velocities of Aluminium, Iron and Plastic Bottle Caps in a Water Environment. Recycling 2022, 7, 28. [Google Scholar] [CrossRef]

- European Commission. European Strategy for Plastics in a Circular Economy; European Commission: Brussels, Belgium, 2019.

- A Roadmap to 2025: The UK Plastics Pact. WRAP, Annual Report. 2020. Available online: https://wrap.org.uk/resources/guide/roadmap-2025-uk-plastics-pact (accessed on 20 March 2023).

- The World Bank. Plastic Waste Material Flow Analysis for Thailand; The World Bank: Washington, DC, USA, 2022. [Google Scholar]

- Mrowiec, B. Plastics in the circular economy (CE). Environ. Prot. Nat. Resour. 2018, 29, 16–19. [Google Scholar] [CrossRef]

- Vanderreydt, I.; Rommens, T.; Tenhunen, A.; Fogh Mortensen, L.; Tange, I. Greenhouse Gas Emissions and Natural Capital Implications of Plastics (Including Biobased Plastics)—Eionet Portal. Flanders, Belgium, 59p. 2021. Available online: https://www.eionet.europa.eu/etcs/etc-wmge/products/etc-wmge-reports/greenhouse-gas-emissions-and-natural-capital-implications-of-plastics-including-biobased-plastics (accessed on 20 March 2023).

- IPCC. Climate Change 2022, Mitigation of Climate Change Summary for Policymakers (SPM); IPCC: Geneva, Switzerland, 2022; ISBN 9781107415416. [Google Scholar]

- Agarski, B.; Budak, I.; Micunovic, M.I.; Vukelic, D. Life Cycle Assessment of Injection Moulding Tools and Multicomponent Plastic Cap Production. J. Clean. Prod. 2023, 413, 137450. [Google Scholar] [CrossRef]

- Zhang, K.; Hamidian, A.H.; Tubić, A.; Zhang, Y.; Fang, J.K.H.; Wu, C.; Lam, P.K.S. Understanding Plastic Degradation and Microplastic Formation in the Environment: A Review. Environ. Pollut. 2021, 274, 116554. [Google Scholar] [CrossRef]

- Seltenrich, N. New Link in the Food Chain? Marine Plastic Pollution and Seafood Safety. Environ. Health Perspect. 2015, 123, A34–A41. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Z.; Nag, R.; Cummins, E. Human Health Concerns Regarding Microplastics in the Aquatic Environment—From Marine to Food Systems. Sci. Total Environ. 2022, 823, 153730. [Google Scholar] [CrossRef] [PubMed]

- Pinto Da Costa, J.; Rocha Santos, T.; Duarte, A. The Environmental Impacts of Plastics and Micro-Plastics Use, Waste and Pollution: EU and National Measures; European Union: Brussels, Belgium; Luxembourg, 2020; pp. 10–62. [Google Scholar]

- World Economic Forum (WEF). Rethinking the Future of Plastics—The New Plastics Economy: Rethinking the Future of Plastics; World Economic Forum: Cologny, Switzerland, 2016. [Google Scholar]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and Chemical Recycling of Solid Plastic Waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Serranti, S.; Bonifazi, G. Techniques for Separation of Plastic Wastes. In Use of Recycled Plastics in Eco-Efficient Concrete; Elsevier: Amsterdam, The Netherlands, 2018; pp. 9–37. ISBN 9780081026762. [Google Scholar]

- Kangal, M.O.; Üçerler, Z. Recycling of Virgin and Post-Consumer Polypropylene and High Density Polyethylene. Int. Polym. Process. 2018, 33, 268–275. [Google Scholar] [CrossRef]

- Rigamonti, L.; Falbo, A.; Grosso, M. Improving Integrated Waste Management at the Regional Level: The Case of Lombardia. Waste Manag. Res. 2013, 31, 946–953. [Google Scholar] [CrossRef] [PubMed]

- Franklin Associates. Life Cycle Impacts of Plastic Packaging Compared To Substitutes in the United States and Canada; Franklin Associates: Baton Rouge, LA, USA, 2018; pp. 1–160. [Google Scholar]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of Post-Consumer Plastic Packaging Waste in EU: Process Efficiencies, Material Flows, and Barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef] [PubMed]

- Rigamonti, L.; Falbo, A.; Zampori, L.; Sala, S. Supporting a Transition towards Sustainable Circular Economy: Sensitivity Analysis for the Interpretation of LCA for the Recovery of Electric and Electronic Waste. Int. J. Life Cycle Assess. 2017, 22, 1278–1287. [Google Scholar] [CrossRef]

- Ecoinvent: Ecoinvent 3.9.1 Dataset Documentation “Polyethylene Terephthalate Production, Granulate, Bottle Grade, Recycled-GLO”. Available online: https://v391.ecoquery.ecoinvent.org/Details/UPR/514a0bcb-315a-48e6-a0db-c066f9c92d3e/8b738ea0-f89e-4627-8679-433616064e82 (accessed on 15 May 2023).

- Ecoinvent: Ecoinvent 3.9.1 Dataset Documentation “Polyethylene Production, High Density, Granulate, Recycled-GLO”. Available online: https://v391.ecoquery.ecoinvent.org/Details/UPR/6ef2a207-2712-4809-8469-835fc8a66830/8b738ea0-f89e-4627-8679-433616064e82 (accessed on 15 May 2023).

- Nessi, S.; Sinkko, T.; Bulgheroni, C.; Garcia-Gutierrez, P.; Giuntoli, J.; Konti, A.; Sanye-Mengual, E.; Tonini, D.; Pant, R.; Marelli, L.; et al. Life Cycle Assessment (LCA) of Alternative Feedstocks for Plastics Production Part 1: The Plastics LCA Method; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics Recycling: Challenges and Opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Nessi, S.; Rigamonti, L.; Grosso, M. Packaging Waste Prevention Activities: A Life Cycle Assessment of the Effects on a Regional Waste Management System. Waste Manag. Res. 2015, 33, 833–849. [Google Scholar] [CrossRef]

- Littlefield, J.; Rai, S.; Skone, T.J. Life Cycle GHG Perspective on U.S. Natural Gas Delivery Pathways. Environ. Sci. Technol. 2022, 56, 16033–16042. [Google Scholar] [CrossRef] [PubMed]

- Textile Exchange. Preferred Fiber & Materials Market Report 2021; Textile Exchange: Lamesa, TX, USA, 2021. [Google Scholar]

- Zink, T.; Geyer, R. Material Recycling and the Myth of Landfill Diversion. J. Ind. Ecol. 2019, 23, 541–548. [Google Scholar] [CrossRef]

- Guran, S. Options to Feed Plastic Waste Back into the Manufacturing Industry to Achieve a Circular Carbon Economy. AIMS Environ. Sci. 2019, 6, 341–355. [Google Scholar] [CrossRef]

- Suzuki, G.; Uchida, N.; Tuyen, L.H.; Tanaka, K.; Matsukami, H.; Kunisue, T.; Takahashi, S.; Viet, P.H.; Kuramochi, H.; Osako, M. Mechanical Recycling of Plastic Waste as a Point Source of Microplastic Pollution. Environ. Pollut. 2022, 303, 119114. [Google Scholar] [CrossRef] [PubMed]

- Astrup, T.; Fruergaard, T.; Christensen, T.H. Recycling of Plastic: Accounting of Greenhouse Gases and Global Warming Contributions. Waste Manag. Res. 2009, 27, 763–772. [Google Scholar] [CrossRef] [PubMed]

- Gala, A.B.; Raugei, M.; Fullana-i-Palmer, P. Introducing a New Method for Calculating the Environmental Credits of End-of-Life Material Recovery in Attributional LCA. Int. J. Life Cycle Assess. 2015, 20, 645–654. [Google Scholar] [CrossRef]

- Enfrin, M.; Myszka, R.; Giustozzi, F. Paving Roads with Recycled Plastics: Microplastic Pollution or Eco-Friendly Solution? J. Hazard. Mater. 2022, 437, 129334. [Google Scholar] [CrossRef]

- Zhan, L.; Zhang, Q.; Bulati, A.; Wang, R.; Xu, Z. Characteristics of Microplastics and the Role for Complex Pollution in E-Waste Recycling Base of Shanghai, China. Environ. Int. 2022, 169, 107515. [Google Scholar] [CrossRef]

| Polymer Type | Recycling Dataset | Rate of Sorting | Rate of Recycling | Substitution Factor |

|---|---|---|---|---|

| PET | EF | 91% | 12% | 0.9 |

| HDPE | EI | 91% | 12% | 0.9 |

| LDPE | EF | 73% | 12% | 0.75 |

| PP | EF | 79% | 12% | 0.9 |

| PS | EF | 65% | 12% | 0.9 |

| Polymer Type | Primary Plastic Production (Mt) | Waste Generated (Mt) |

|---|---|---|

| PE | 33 | 32 |

| HDPE | 52 | 40 |

| PP | 68 | 55 |

| PS | 25 | 17 |

| LDPE | 64 | 57 |

| Total | 242 | 201 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gabisa, E.W.; Ratanatamskul, C.; Gheewala, S.H. Recycling of Plastics as a Strategy to Reduce Life Cycle GHG Emission, Microplastics and Resource Depletion. Sustainability 2023, 15, 11529. https://doi.org/10.3390/su151511529

Gabisa EW, Ratanatamskul C, Gheewala SH. Recycling of Plastics as a Strategy to Reduce Life Cycle GHG Emission, Microplastics and Resource Depletion. Sustainability. 2023; 15(15):11529. https://doi.org/10.3390/su151511529

Chicago/Turabian StyleGabisa, Elias W., Chavalit Ratanatamskul, and Shabbir H. Gheewala. 2023. "Recycling of Plastics as a Strategy to Reduce Life Cycle GHG Emission, Microplastics and Resource Depletion" Sustainability 15, no. 15: 11529. https://doi.org/10.3390/su151511529

APA StyleGabisa, E. W., Ratanatamskul, C., & Gheewala, S. H. (2023). Recycling of Plastics as a Strategy to Reduce Life Cycle GHG Emission, Microplastics and Resource Depletion. Sustainability, 15(15), 11529. https://doi.org/10.3390/su151511529