Data Mining Technology and Its Applications in Coal and Gas Outburst Prediction

Abstract

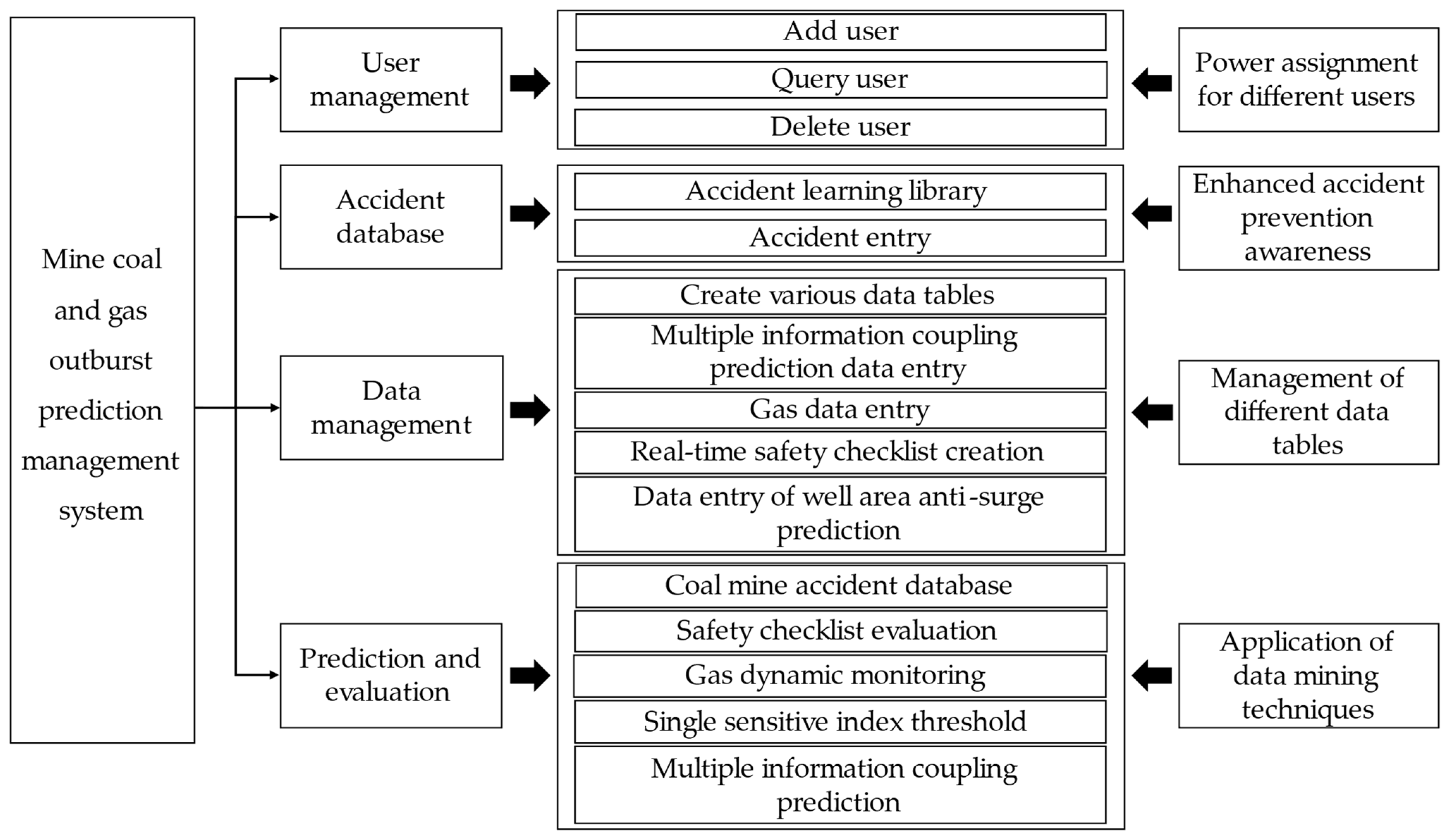

1. Introduction

2. Prediction of Coal and Gas Outburst by Data Mining Technology

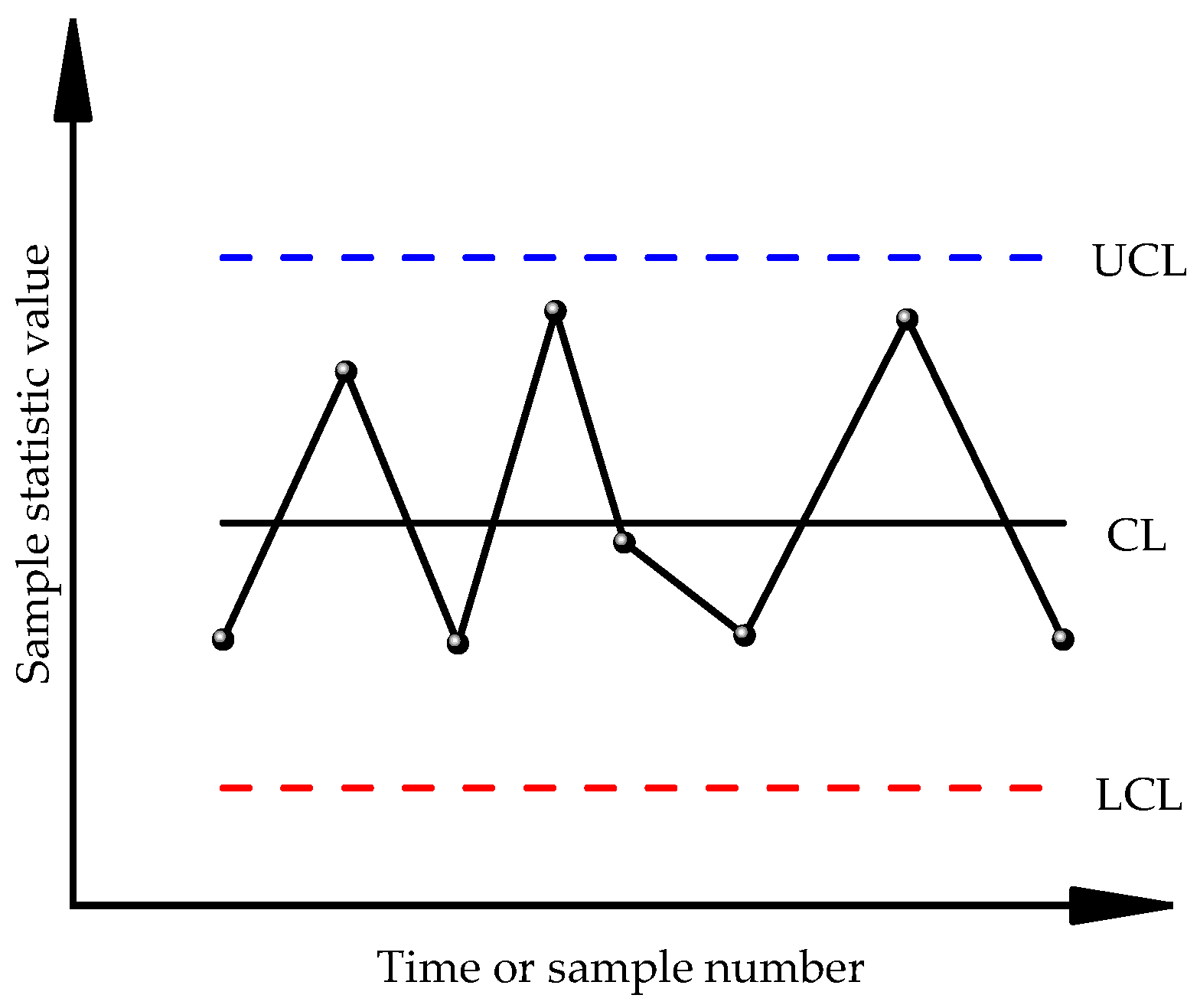

2.1. Determination of the Critical Value of Sensitivity Indexes

2.2. Prediction of Coal and Gas Outburst Risk with Multivariate Information Coupling

2.2.1. Deficiency of the Single-Index Method

- (1)

- Each borehole index is different. In the process of designing the drilling location, owing to the restrictions of the workplace or different experience levels of the practitioner, the drilling location can also be very different. Consequently, the index data obtained from each borehole in the construction are uneven and sometimes contradictory.

- (2)

- Problems with drilling construction quality. In the drilling operation process, whether advance drilling can reach a predetermined depth is greatly affected by the geological conditions of the coal mine and the working attitude of the employees. Sometimes, drilling cannot reach the predetermined depth; sometimes, drilling cannot be constructed according to the design angle, and the drilling deviation is very large. As a result, the coal sample is not representative and the risk ahead cannot be truly verified.

- (3)

- The range of the obtained forecasts is narrow. The prediction of outburst risk by the drilling operation method has a certain limitation: the stress state and gas occurrence in front of the working face change with the distance from the working face, and the drilling cannot reach a considerable depth and breadth.

2.2.2. Multiple-Information Coupling Prediction

2.2.3. Establishment of Logistic Regression Model

- (1)

- When b is positive, the logistic function increases monotonically as x increases. When b is negative, the logistic function decreases monotonically as x increases. Therefore, b reflects the correspondence between the independent variable x and the probability function. Similar to determining the direction of action of the independent variable using the sign of the regression coefficient in multiple linear regression analysis, b also represents the direction of action of the independent variable in the logistic probability function.

- (2)

- a/b is actually the center of the curve, at which point the probability function takes a value of 0.5, which is half the interval between the values of the probability function. The function takes the inflection point (−a/b, 0.5) as the center of symmetry, where the rate of change of the curve is the largest; the farther away from this point, the smaller the rate of change of the curve when approaching the upper or lower limit of the function, and the rate of change of the curve is close to zero.

- (3)

- The greater the absolute value of b, the faster the curve rises or falls to the middle. This implies that the major changes are compressed in the vicinity of the corresponding inflection points on the X-axis.

- Probability of event occurrence: p = p (y = 1).

- Probability of the event not occurring: 1 − p = (y = 0).

- Odds: p/(1 − p) = .

2.3. Realization of the System Software Function

3. Application of Data Mining Technology in a Typical Mine

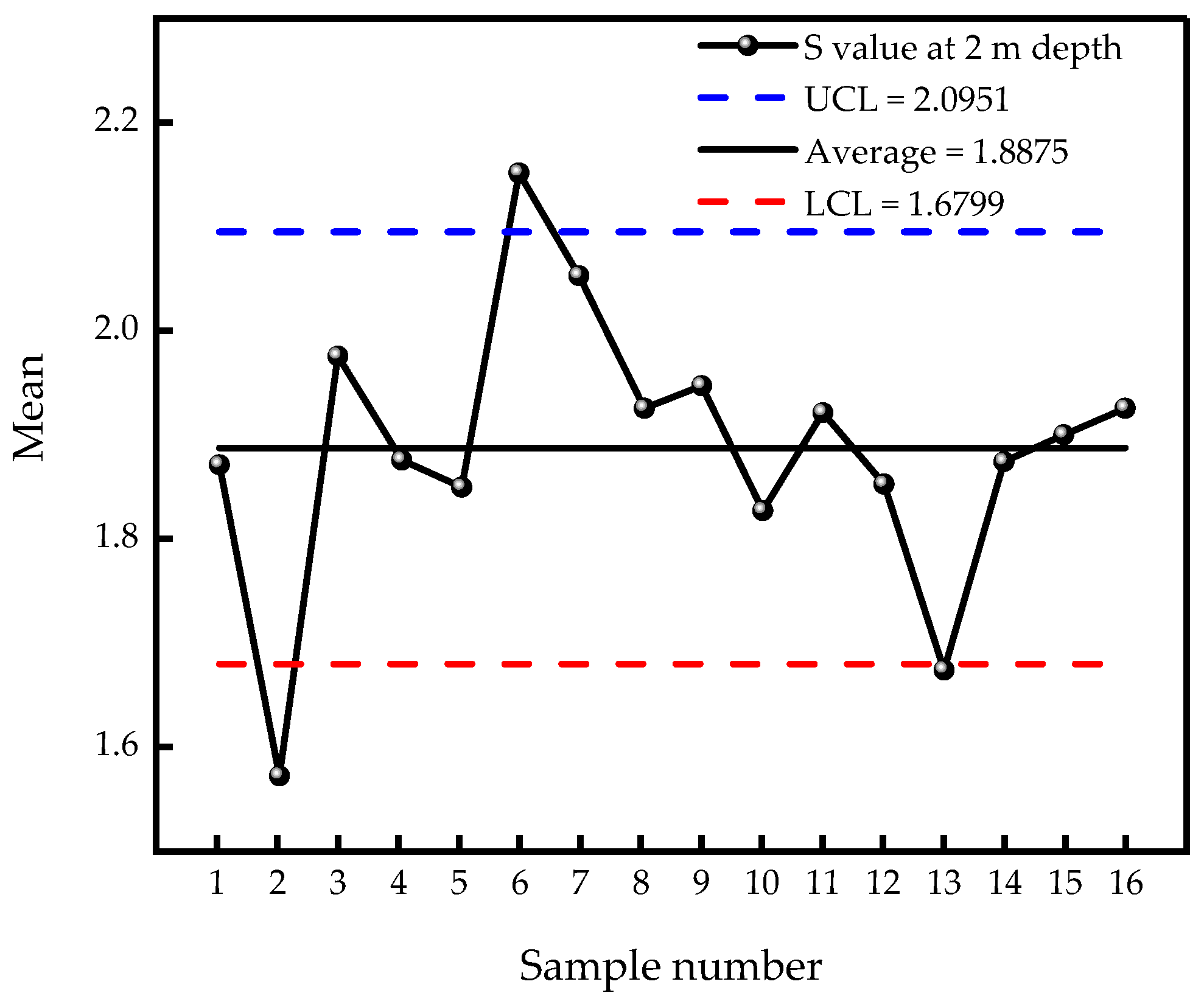

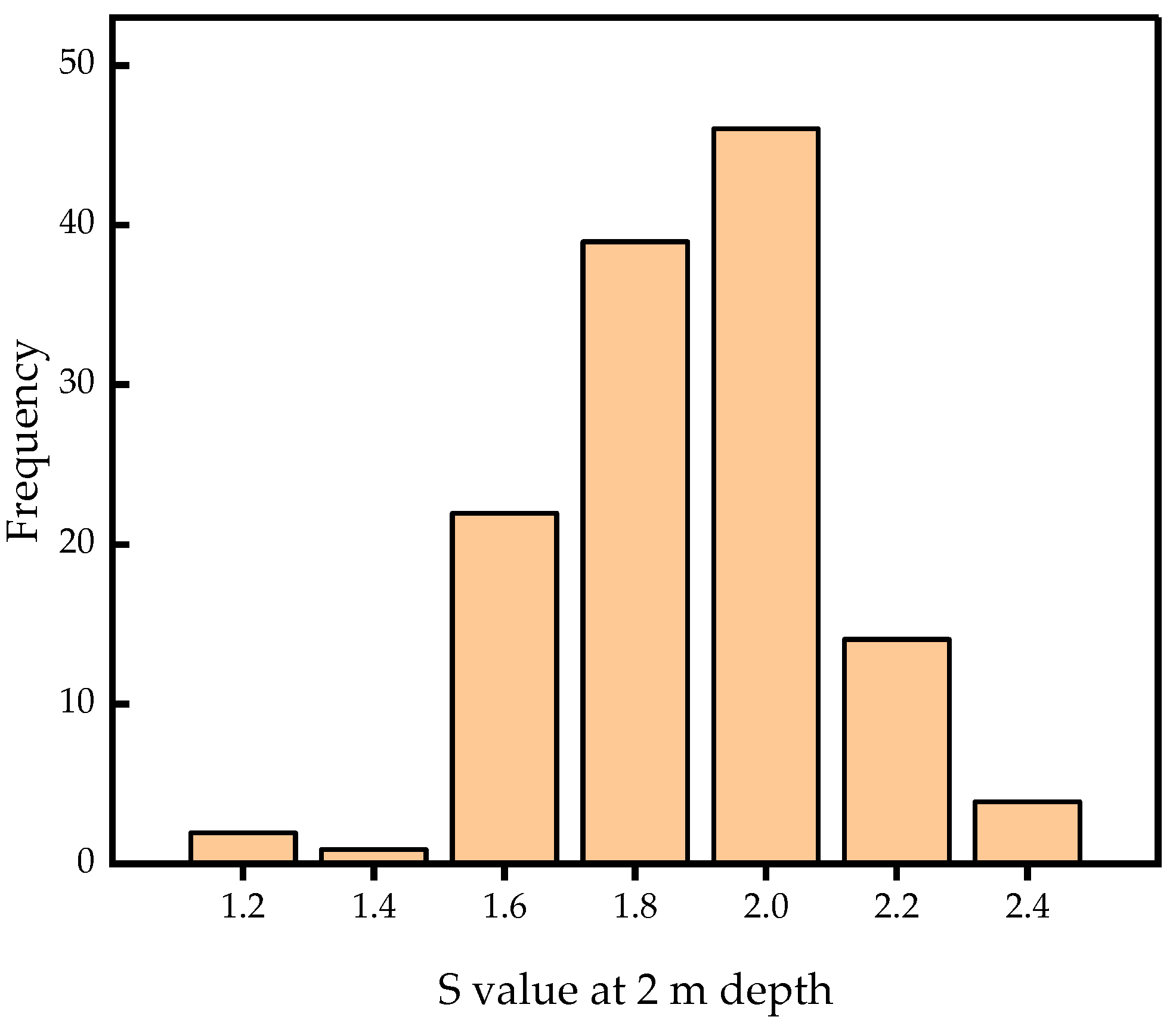

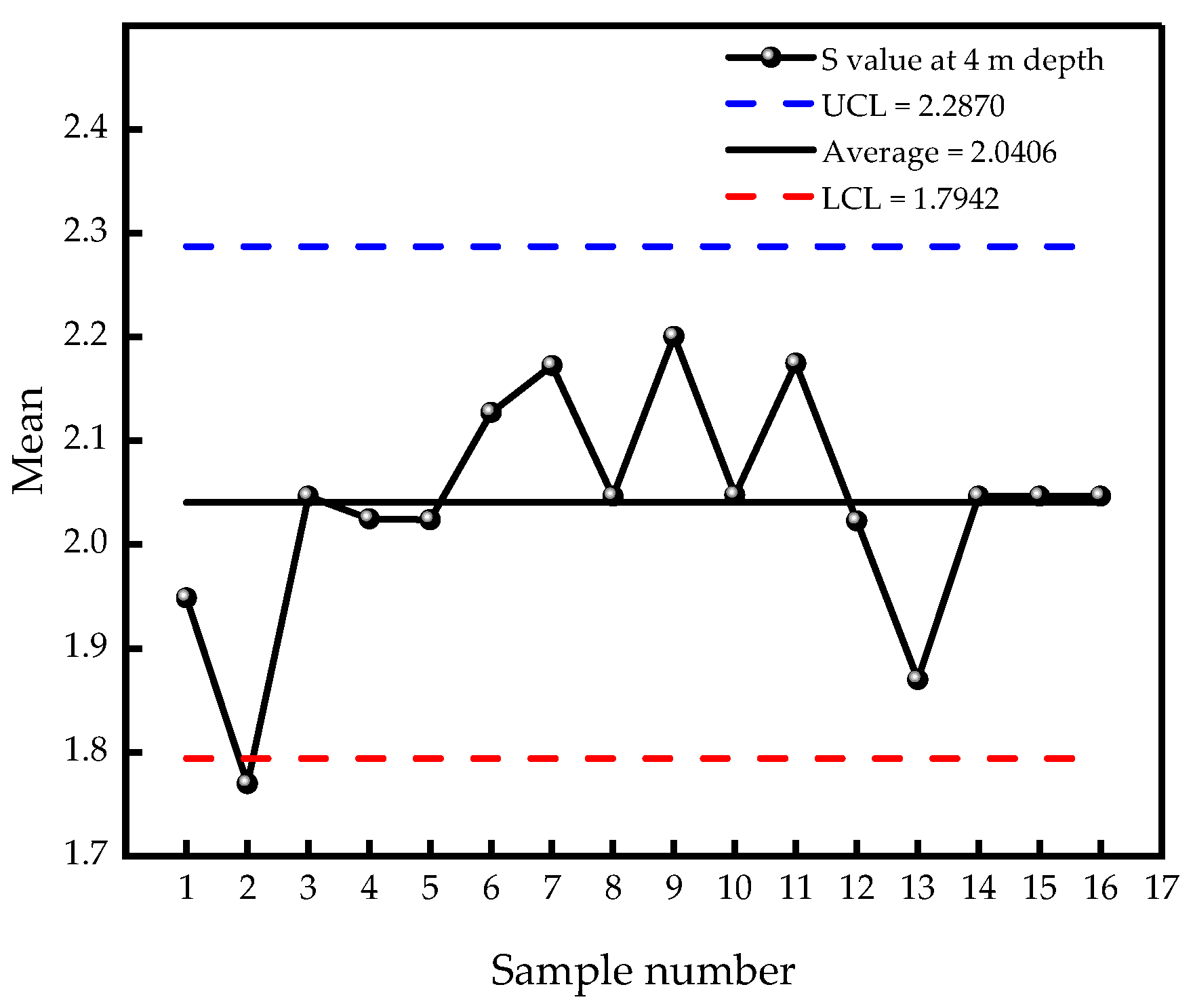

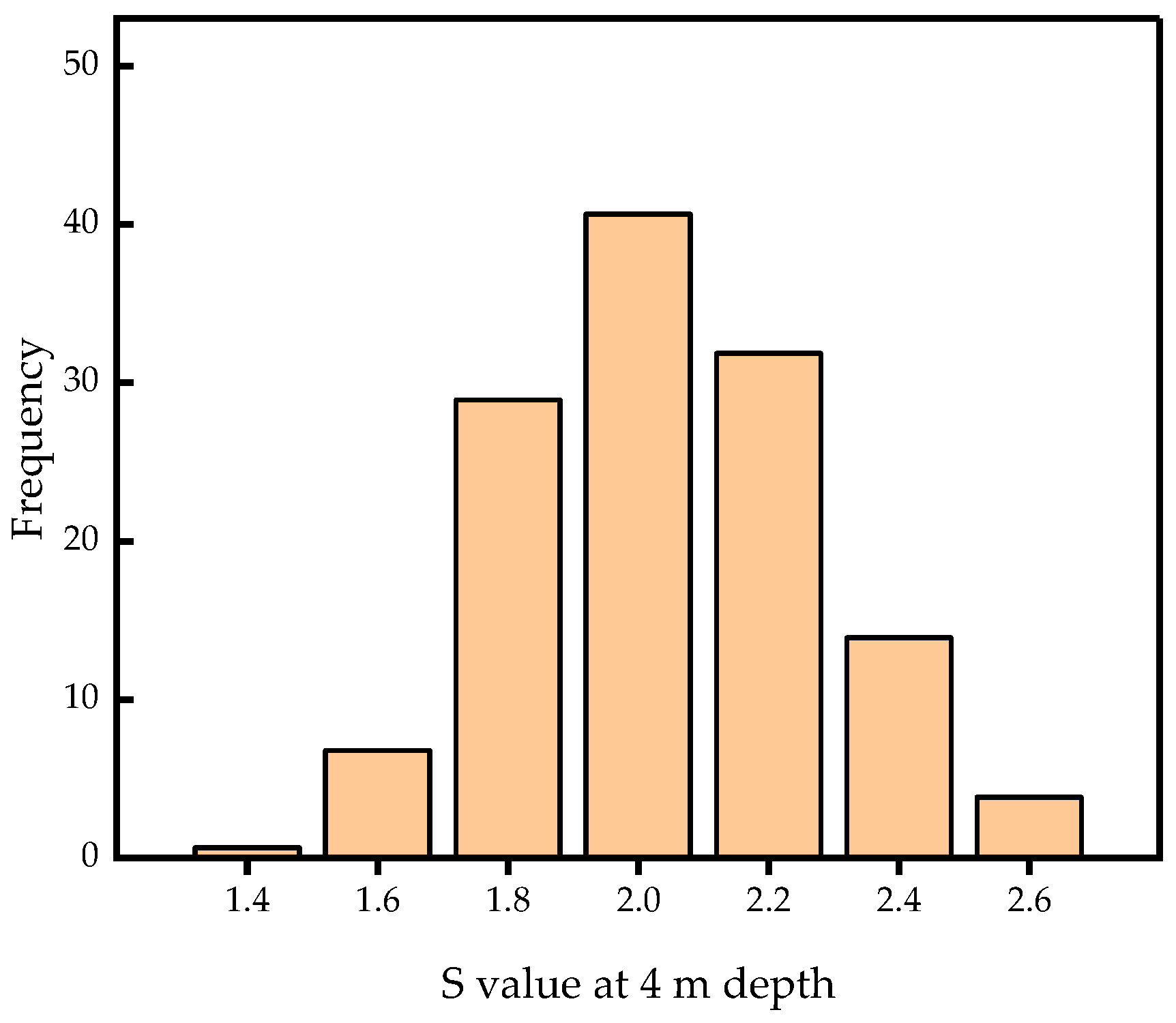

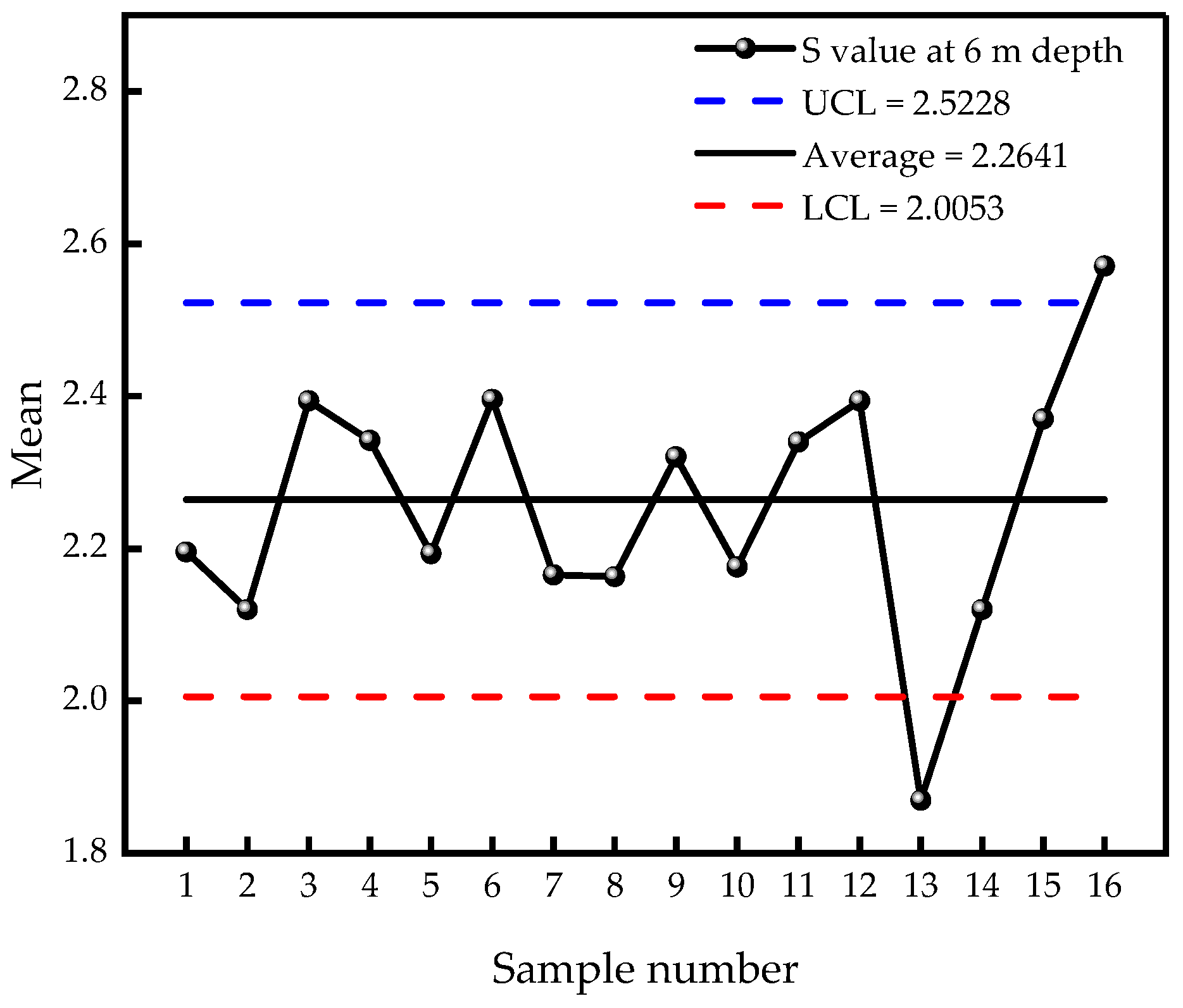

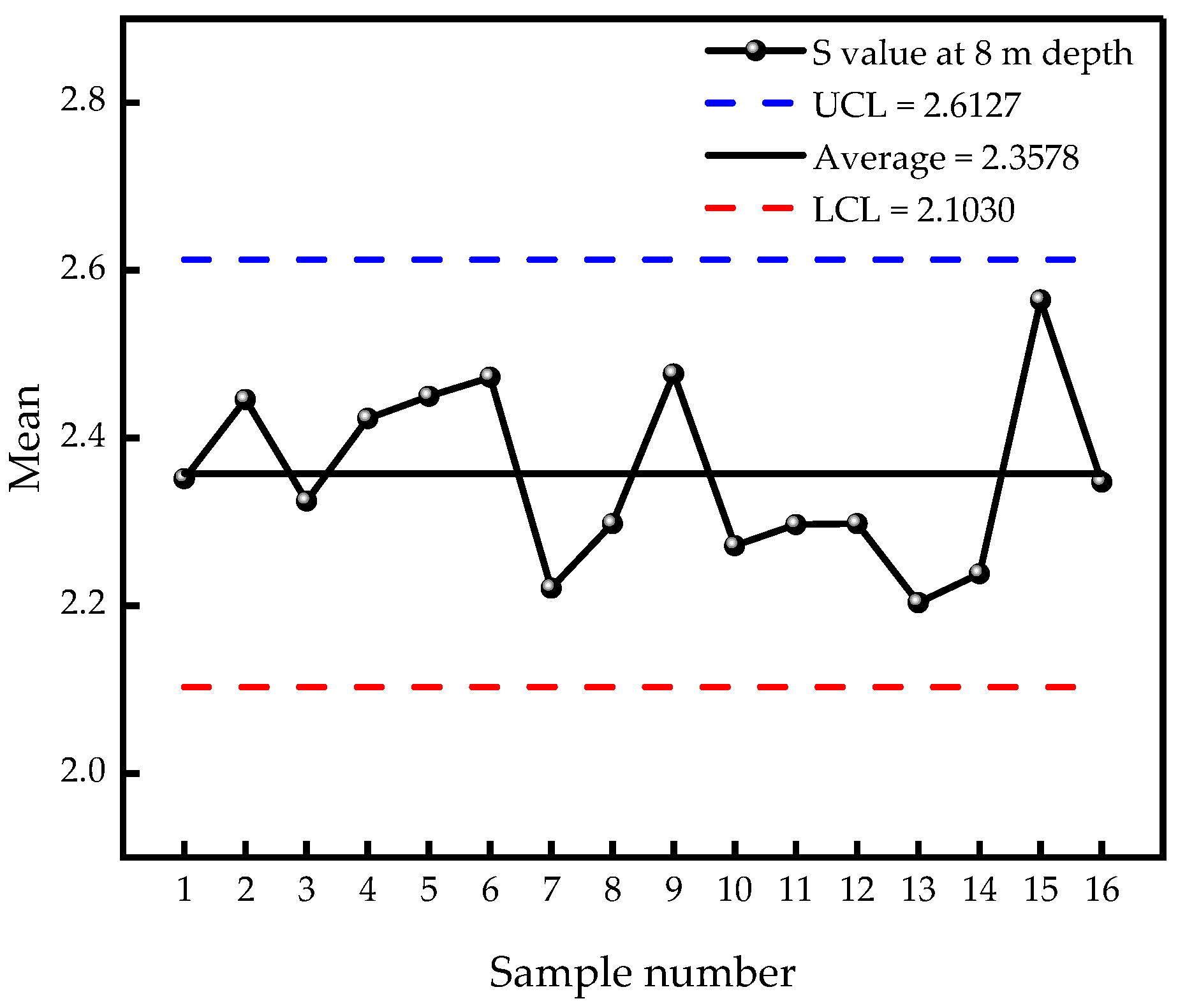

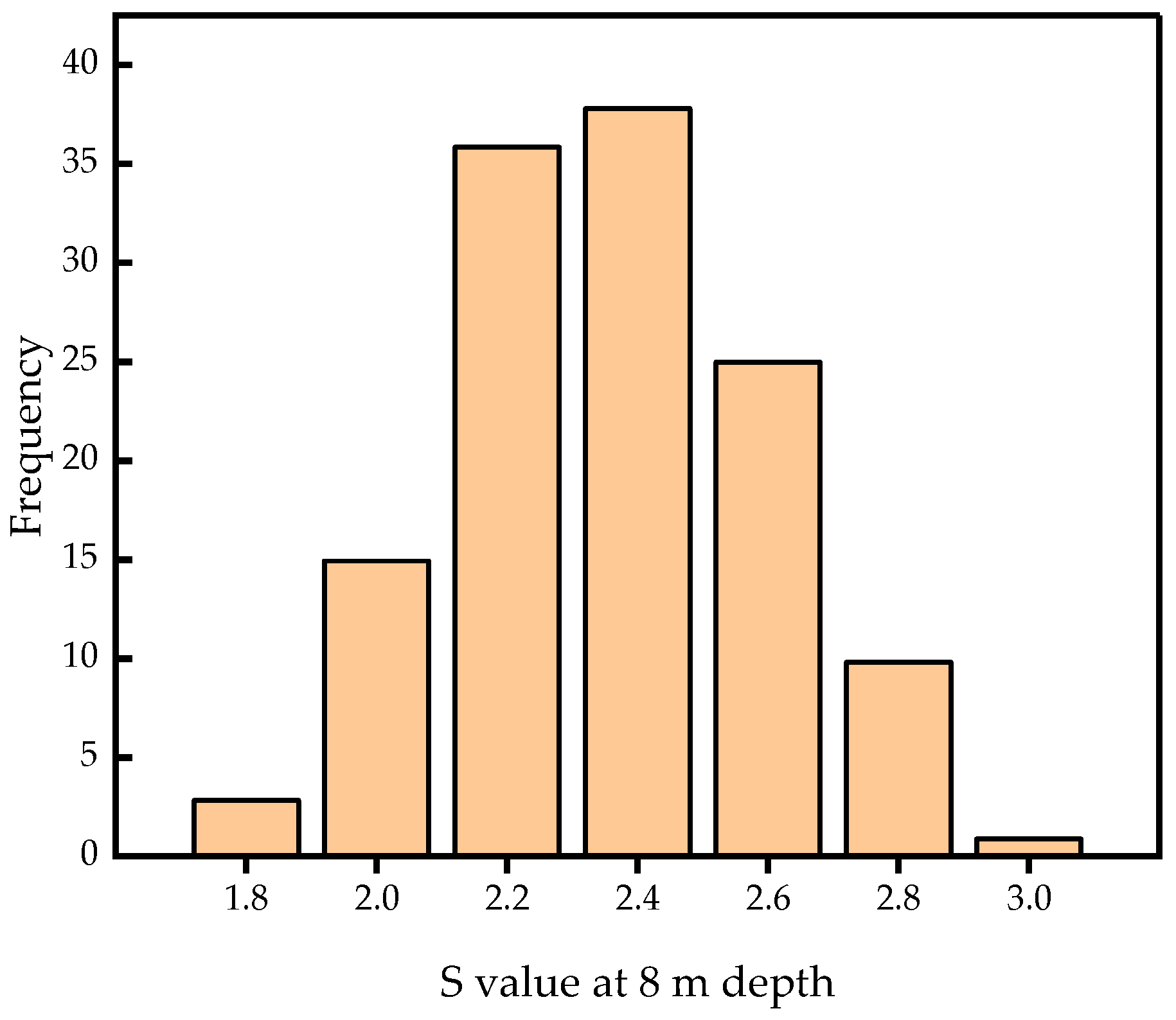

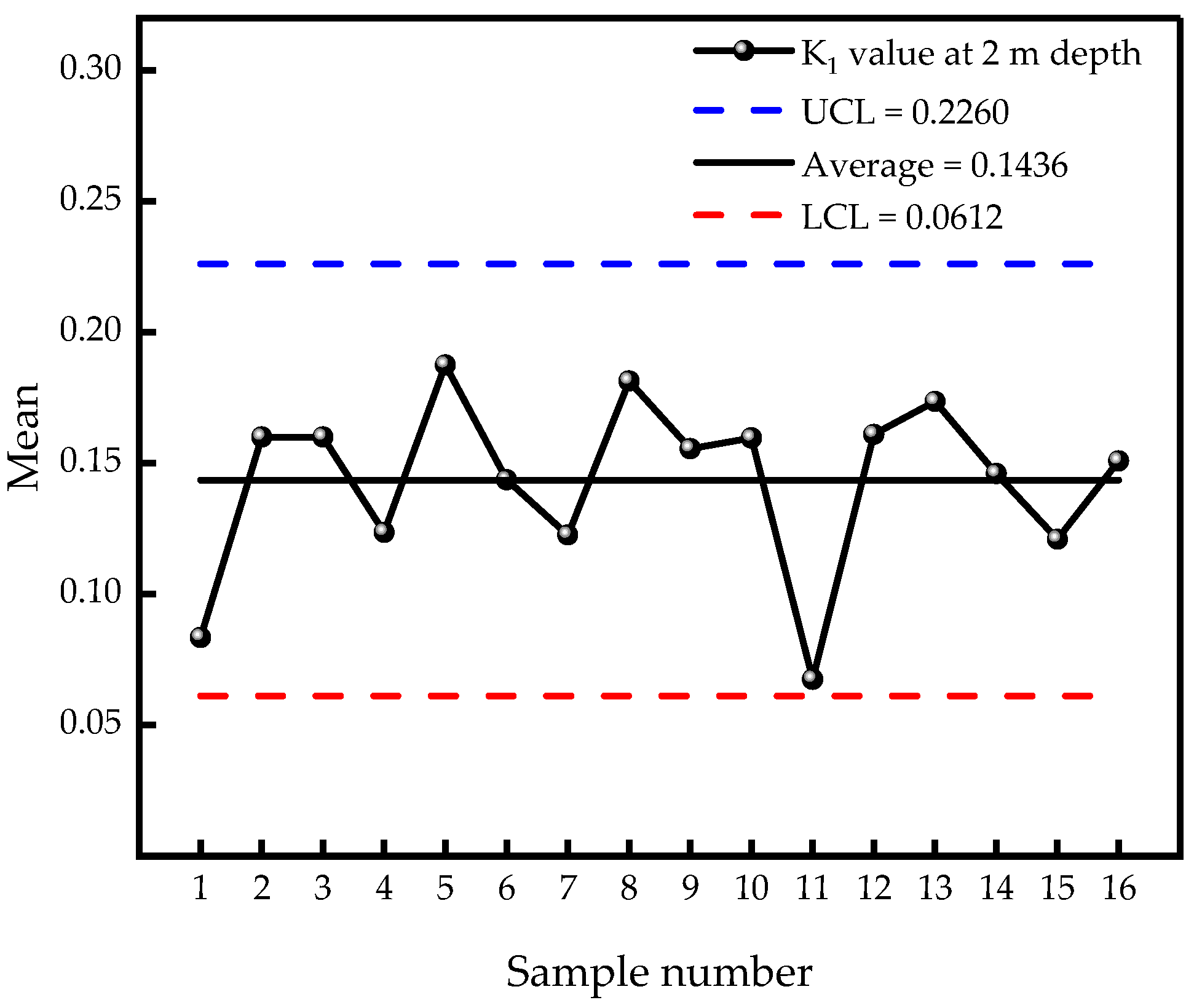

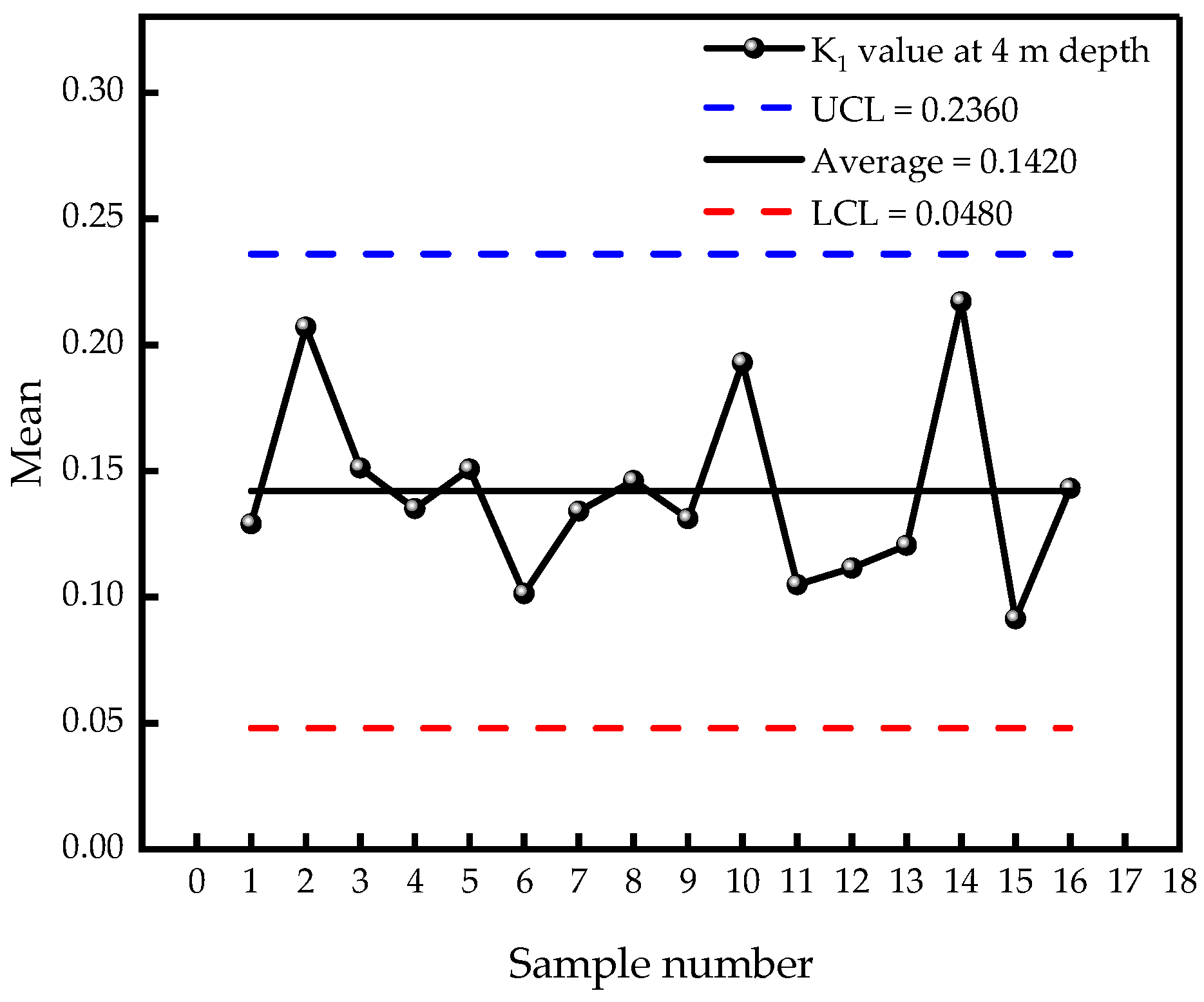

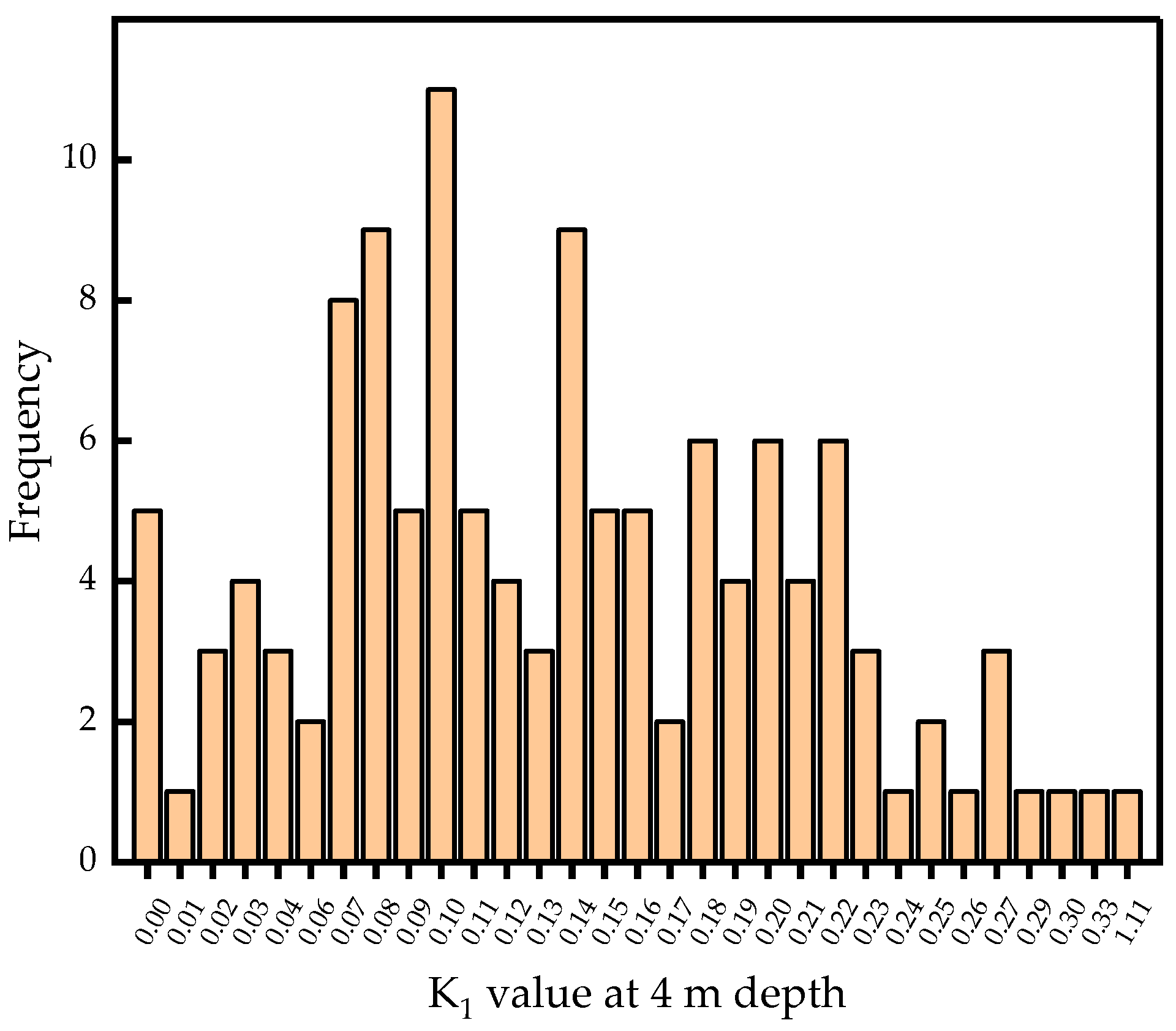

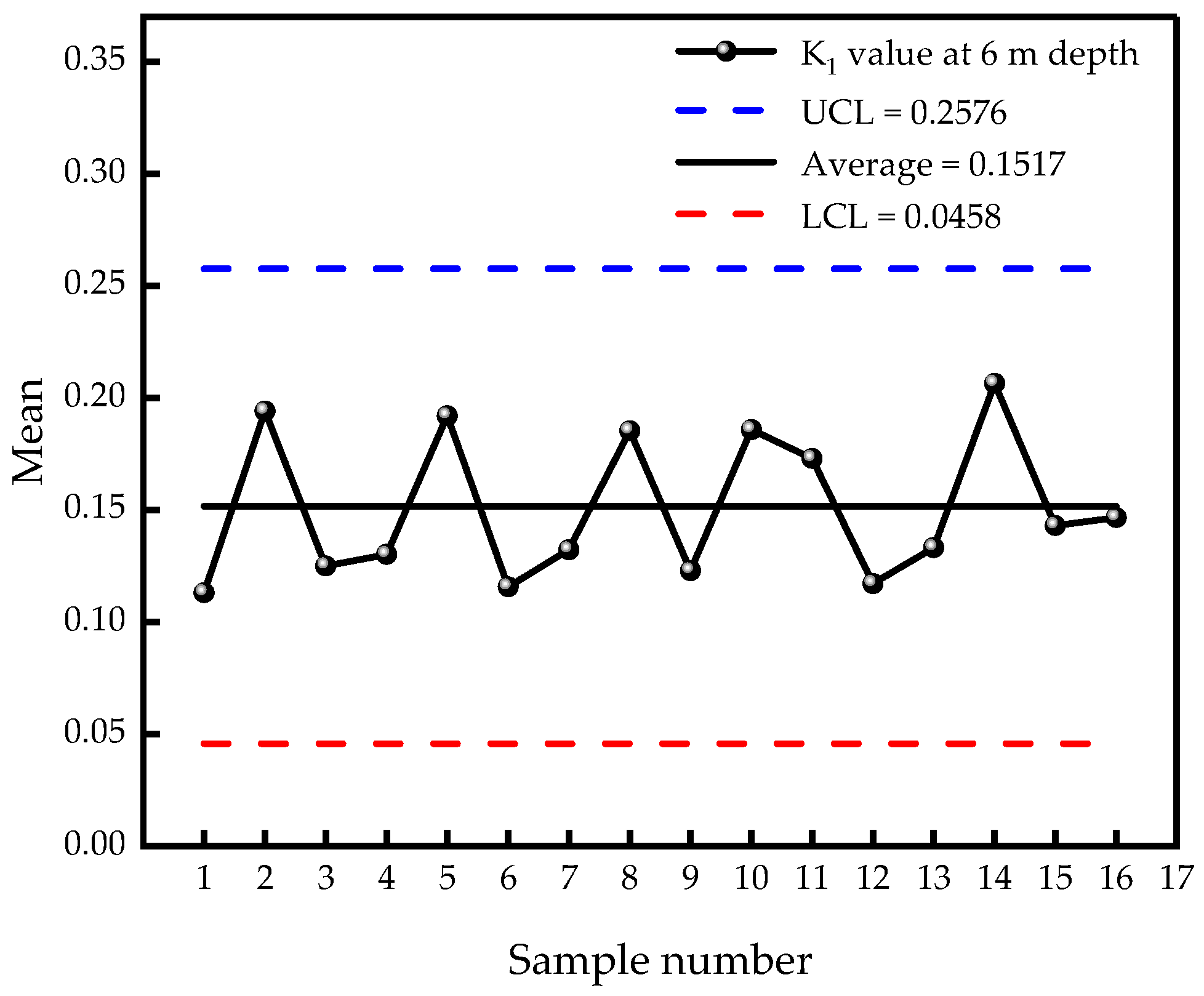

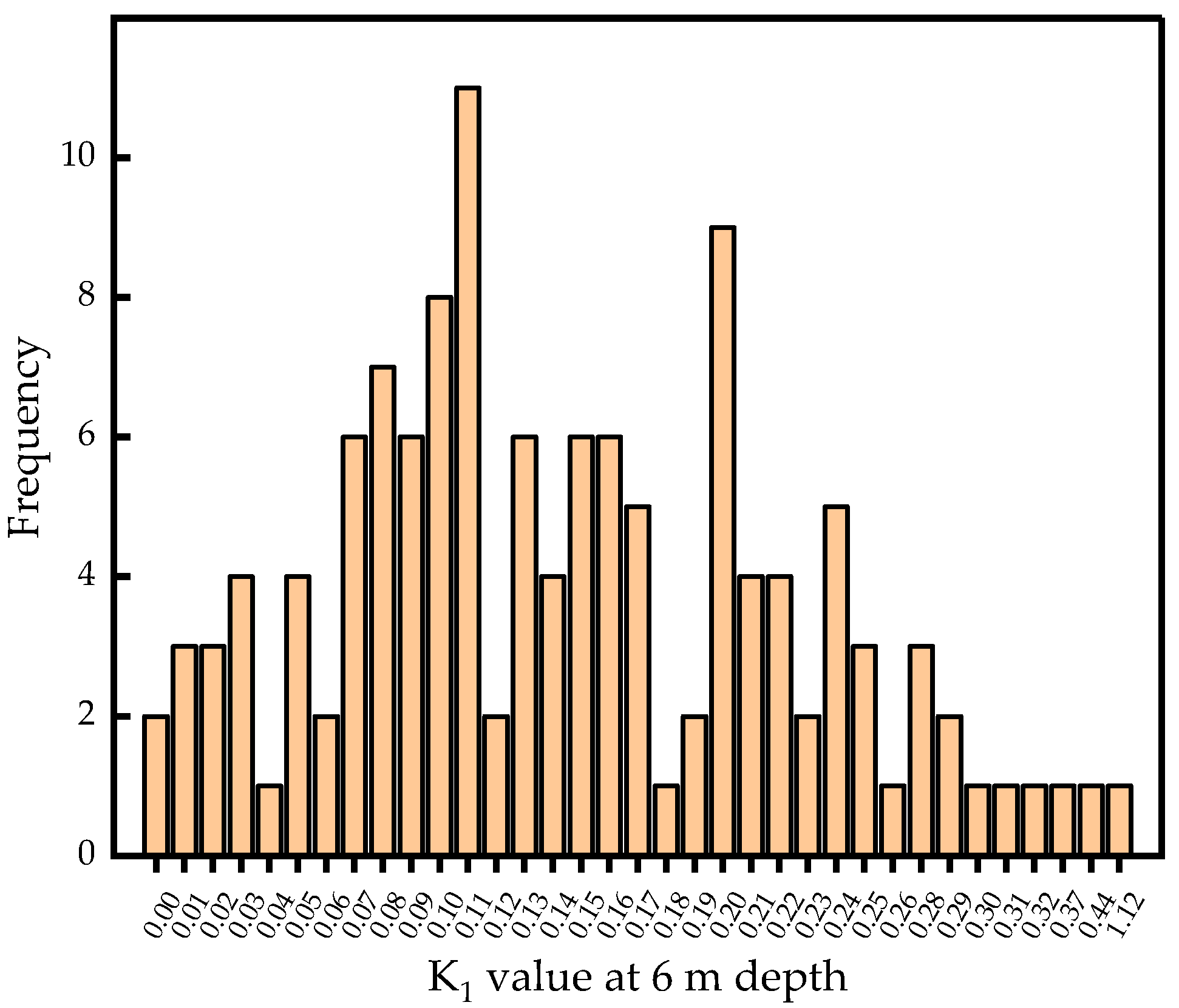

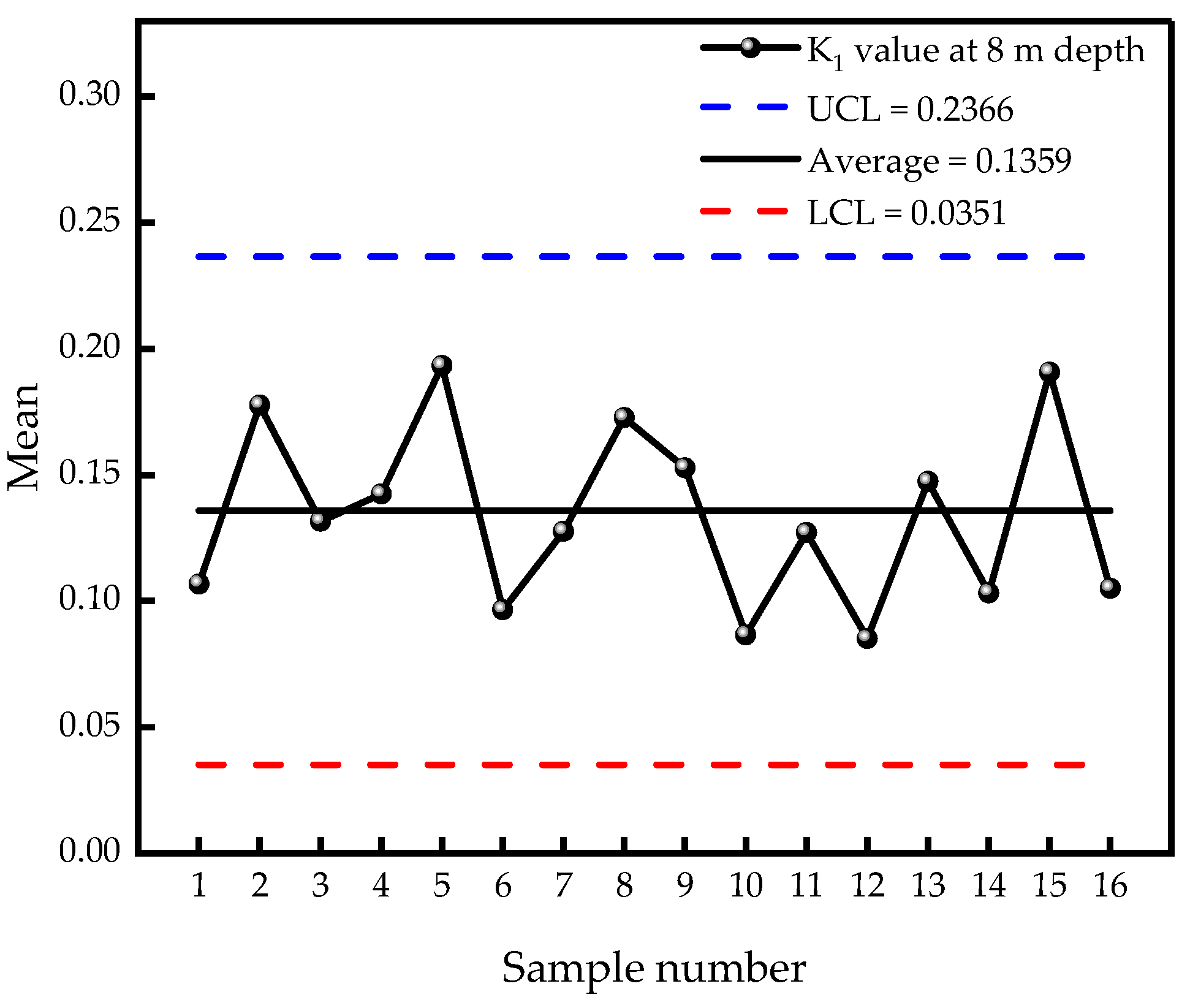

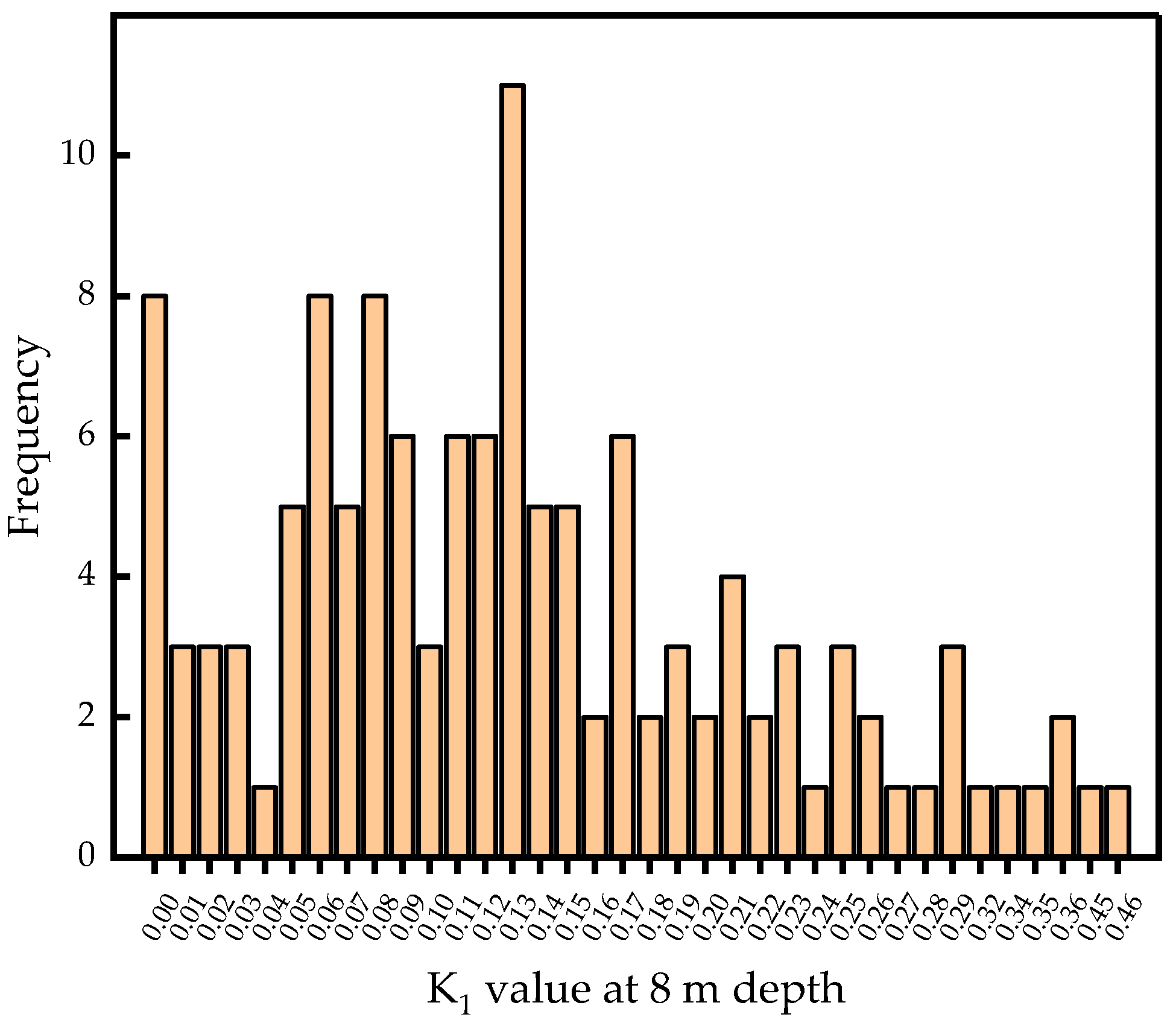

3.1. Statistical Process Control Method for Determining the Critical Value of a Single Index

3.2. Application of Logistic Regression Analysis in Multivariate Information Coupling Prediction

3.2.1. Determination of Investigation Methods

- (1)

- The prediction outburst ratewhere is the predicted outburst rate (%); nt is the number of predicted outburst hazards (times); and N is the total number of predicted outburst hazards (times).

- (2)

- The prediction outburst accuracy ratewhere is the prediction outburst accuracy (%); and nA is the number of times in which there is actually an outburst hazard among the predicted times with outburst risk.

- (3)

- The prediction non-outburst accuracy rate.where is the prediction accuracy rate without outburst (%); nB is the predicted number of times without outburst risk (times); and nC is the number of times in which there is actually no outburst hazard among the predicted times without outburst risk.

3.2.2. Effect Investigation and Analysis

4. Conclusions

- (1)

- When a single index is used to predict the risk of outburst in the coal mine site, the prediction index value of each borehole depth satisfies the law that with the increase of borehole depth, the inspection index first increases, and then decreases after reaching the maximum value. In the field application of the SPC control method to the outburst index of Sihe mine to analyze the upper control limit, the sensitivity value of a single index under each borehole depth is established, which assists the timely discovery of danger warnings.

- (2)

- Through the logistic regression analysis method, taking the measured data of Chongqing Tianfu Mining Group Sanhui 1 mine and Sanhui 3 mine as the inspection and verification indexes, the inspection results show that the accuracy of outburst prediction and non-outburst prediction have been greatly improved, and the accuracy of outburst risk prediction in front of the working face shows a great breakthrough, which has good application value.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luhar, K.A.; Emmerson, M.K.; Reisen, F. Modelling smoke distribution in the vicinity of a large and prolonged fire from an open-cut coal mine. Atmos. Environ. 2020, 229, 117471. [Google Scholar] [CrossRef]

- Bosikov, I.I.; Martyushev, N.V.; Klyuev, R.V.; Savchenko, I.A.; Kukartsev, V.V.; Kukartsev, V.A.; Tynchenko, Y.A. Modeling and Complex Analysis of the Topology Parameters of Ventilation Networks When Ensuring Fire Safety While Developing Coal and Gas Deposits. Fire 2023, 6, 95. [Google Scholar] [CrossRef]

- Gendler, S.G.; Gabov, V.V.; Babyr, N.V.; Prokhorova, E.A. Justification of engineering solutions on reduction of occupational traumatism in coal longwalls. Min. Informational Anal. Bull. 2022, 5–19. [Google Scholar] [CrossRef]

- Młynarczuk, M.; Skiba, M. An Approach to Detect Local Tectonic Dislocations in Coal Seams Based on Roughness Analysis. Arch. Min. Sci. 2022, 67, 743–756. [Google Scholar]

- Kozieł, K.; Janus, J. Force Exerted by Gas on Material Ejected During Gas-geodynamic phenomena Analysis and Experimental Verification of Theory. Arch. Min. Sci. 2022, 66, 491–508. [Google Scholar]

- Black, J.D. Review of coal and gas outburst in Australian underground coal mines. Int. J. Min. Sci. Technol. 2019, 29, 815–824. [Google Scholar] [CrossRef]

- Gabov, V.V.; Zadkov, D.A.; Babyr, N.V.; Xie, F. Nonimpact rock pressure regulation with energy recovery into the hydraulic system of the longwall powered support. Eurasian Min. 2021, 36, 55–59. [Google Scholar] [CrossRef]

- Yan, J.; Zhang, X.; Zhang, Z. Research on geological control mechanism of coal-gas outburst. J. China Coal Soc. 2013, 38, 1174–1178. [Google Scholar]

- Ayruni, A.T. Prediction and Prevention of Gas-Dynamic Phenomena in Coal Mines; Nauka: Moscow, Russia, 1987. [Google Scholar]

- Malyshev, Y.N.; Trubetskoy, K.N.; Airuni, A.T. Fundamental and Applied Methods for the Solution of Coal-Bed Methane Problems; Academy of Mining Sciences Publishing House: Moscow, Russia, 2000. [Google Scholar]

- Rubinsky, A.A.; Mineev, S.P. The Main Patterns of the Manifestation of Powerful Gas-Dynamic Phenomena in Coal Mines; Donetsk National Technical University: Donetsk Oblast, Ukraine, 2009; Volume 10, pp. 129–136. [Google Scholar]

- Wang, E.; Zhang, G.; Zhang, C. Research progress and prospect on theory and technology for coal and gas outburst control and protection in China. J. China Coal Soc. 2022, 47, 297–322. [Google Scholar]

- Cheng, Y.; Zhou, H. Research progress of sensitive index and critical values for coal and gas outburst prediction. Coal Sci. Technol. 2021, 49, 146–154. [Google Scholar]

- Wang, W.; Wang, H.; Zhang, B.; Wang, S.; Xing, W. Coal and gas outburst prediction model based on extension theory and its application. Process Saf. Environ. Prot. 2021, 154, 329–337. [Google Scholar] [CrossRef]

- Wang, C.; Li, X.; Xu, C.; Niu, Y.; Chen, Y.; Yang, S.; Zhou, B.; Jiang, C. Study on factors influencing and the critical value of the drilling cuttings weight: An index for outburst risk prediction. Process Saf. Environ. Prot. 2020, 140, 356–366. [Google Scholar] [CrossRef]

- Sun, Z.; Li, L.; Wang, F.; Zhou, G. Desorption characterization of soft and hard coal and its influence on outburst prediction index. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 2807–2821. [Google Scholar] [CrossRef]

- Tang, J.; Wang, C.; Chen, Y.; Li, X.; Yang, D.; Liu, J. Determination of critical value of an outburst risk prediction index of working face in a coal roadway based on initial gas emission from a borehole and its application: A case study. Fuel 2020, 267, 117229. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, E.; Xu, J.; Peng, S. A new method for coal and gas outburst prediction and prevention based on the fragmentation of ejected coal. Fuel 2021, 287, 11949. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, F.; Luo, Y.; Hu, Q. Desorption characterization of methane and carbon dioxide in coal and its influence on outburst prediction. Adsorpt. Sci. Technol. 2018, 36, 1484–1495. [Google Scholar] [CrossRef]

- Xie, X.; Shu, X.; Fu, G.; Shen, S.; Jia, Q.; Hu, J.; Wu, Z. Accident causes data-driven coal and gas outburst accidents prevention: Application of data mining and machine learning in accident path mining and accident case-based deduction. Process Saf. Environ. Prot. 2022, 162, 891–913. [Google Scholar]

- Li, Z.; Wang, E.; Ou, J.; Liu, Z. Hazard evaluation of coal and gas outbursts in a coal-mine roadway based on logistic regression model. Int. J. Rock Mech. Min. Sci. 2015, 80, 185–195. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, E.; Liu, Z. Study on the comprehensive evaluation model of attributes for coal seam outburst risk. J. Min. Saf. Eng. 2012, 29, 416–420. [Google Scholar]

- Kursunioglu, N.; Onder, M. Application of structural equation modeling to evaluate coal and gas outbursts. Tunn. Undergr. Space Technol. 2019, 88, 63–72. [Google Scholar] [CrossRef]

- Zheng, X.; Lai, W.; Zhang, L.; Xue, S. Quantitative evaluation of the indexes contribution to coal and gas out-burst prediction based on machine learning. Fuel 2023, 338, 127389. [Google Scholar]

- Liu, H.; Dong, Y.; Wang, F. Prediction Model for Gas Outburst Intensity of Coal Mining Face Based on Improved PSO and LSSVM. Energy Eng. 2021, 118, 679–689. [Google Scholar] [CrossRef]

- Wu, Y.; Li, H.; Xu, D. Prediction algorithm of coal and gas outburst based on IPSO-Powell optimized SVM. J. Mine Autom. 2020, 46, 46–53. [Google Scholar]

- Shu, L.; Wang, K.; Liu, Z.; Zhao, W.; Zhu, N.; Lei, Y. A novel physical model of coal and gas outbursts mechanism: Insights into the process and initiation criterion of outbursts. Fuel 2022, 323, 124305. [Google Scholar] [CrossRef]

- Ru, Y.; Lv, X.; Guo, J. Real-Time Prediction Model of Coal and Gas Outburst. Math. Probl. Eng. 2020, 2020, 2432806. [Google Scholar]

- Xu, M.; Wei, P. SPC Evaluation Method and Application on Methane Control Effect of Fully Mechanized Working Face. Coal Technol. 2016, 35, 118–120. [Google Scholar]

| Outburst Dynamic Phenomena | Severe | Moderate | Mild |

|---|---|---|---|

| Coal burst | Firecrackers, cannon bang; the sound of the coal cannon continues. | The interval time between coal guns is longer, and the sound of guns is stronger. | Coal cannon occasionally occurs with a quiet, humming sound. |

| Sloughing slagging | Large area of sloughing accompanied by sound; the side of the sloughing is shifted out; great tremor. | Local sloughing, drop ballast, tremor. | Sloughing, dropping debris phenomenon occurs, with no tremor. |

| Spray roof, drill clamping | Multiple drilling holes and spray holes; the drilling is very serious, and the distance of the jet hole is greater than 5 m; coal spraying phenomenon occurs. | Coal spraying phenomenon occurs, multiple drilling holes, drilling, but relatively gentle; the distance of the hole is less than 5 m. | Individual drilling holes or clip drilling, but within the control range. |

| Structural change of coal | The coal structure is seriously damaged; the coal becomes soft. | Bedding disturbance. | The luster of coal darkens. |

| Gas anomaly | The gas fluctuates, and the maximum concentration exceeds 10%. | The gas fluctuates, and the maximum concentration exceeds 1%. | The gas fluctuates, and the maximum concentration of gas is less than 1%. |

| Name of Index | Value of S | Value of K1 | ||||||

|---|---|---|---|---|---|---|---|---|

| 2 m | 4 m | 6 m | 8 m | 2 m | 4 m | 6 m | 8 m | |

| UCL | 2.10 | 2.29 | 2.52 | 2.61 | 0.23 | 0.24 | 0.26 | 0.24 |

| Fraction of coverage/% | 86 | 86 | 90 | 92 | 88.3 | 92.2 | 91.4 | 86.7 |

| Analysis Item | Unit | Contact Index Point Prediction | Multiple Information Regression Prediction | Actual Outburst Risk | |

|---|---|---|---|---|---|

| K1 | S | ||||

| Total number of predictions (validity checks) | Time | 125 | 125 | 125 | 125 |

| Each index predicts the number of outburst risks | Time | 22 | 3 | 21 | 21 |

| Forecast outburst of each index in the forecast data | % | 17.6 | 2.4 | 16.8 | 16.8 |

| Predicted number of outburst hazards was actually the number of outburst hazards | Time | 17 | 3 | 20 | |

| Prediction accuracy of each index in the forecast data when there is outburst | % | 77.27 | 100 | 94.7 | |

| Number of actual non-outburst times among the predicted non-outburst risk times | Time | 99 | 104 | 103 | 104 |

| Prediction accuracy of each index in the forecast data when there is no outburst | % | 96.12 | 85.25 | 99.04 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Hao, S.; Wu, T.; Zhou, W.; Zhang, J. Data Mining Technology and Its Applications in Coal and Gas Outburst Prediction. Sustainability 2023, 15, 11523. https://doi.org/10.3390/su151511523

Li X, Hao S, Wu T, Zhou W, Zhang J. Data Mining Technology and Its Applications in Coal and Gas Outburst Prediction. Sustainability. 2023; 15(15):11523. https://doi.org/10.3390/su151511523

Chicago/Turabian StyleLi, Xianzhong, Shigang Hao, Tao Wu, Weilong Zhou, and Jinhao Zhang. 2023. "Data Mining Technology and Its Applications in Coal and Gas Outburst Prediction" Sustainability 15, no. 15: 11523. https://doi.org/10.3390/su151511523

APA StyleLi, X., Hao, S., Wu, T., Zhou, W., & Zhang, J. (2023). Data Mining Technology and Its Applications in Coal and Gas Outburst Prediction. Sustainability, 15(15), 11523. https://doi.org/10.3390/su151511523