Sustainability Study of a New Solid-State Aluminum Chips Recycling Process: A Life Cycle Assessment Approach

Abstract

1. Introduction

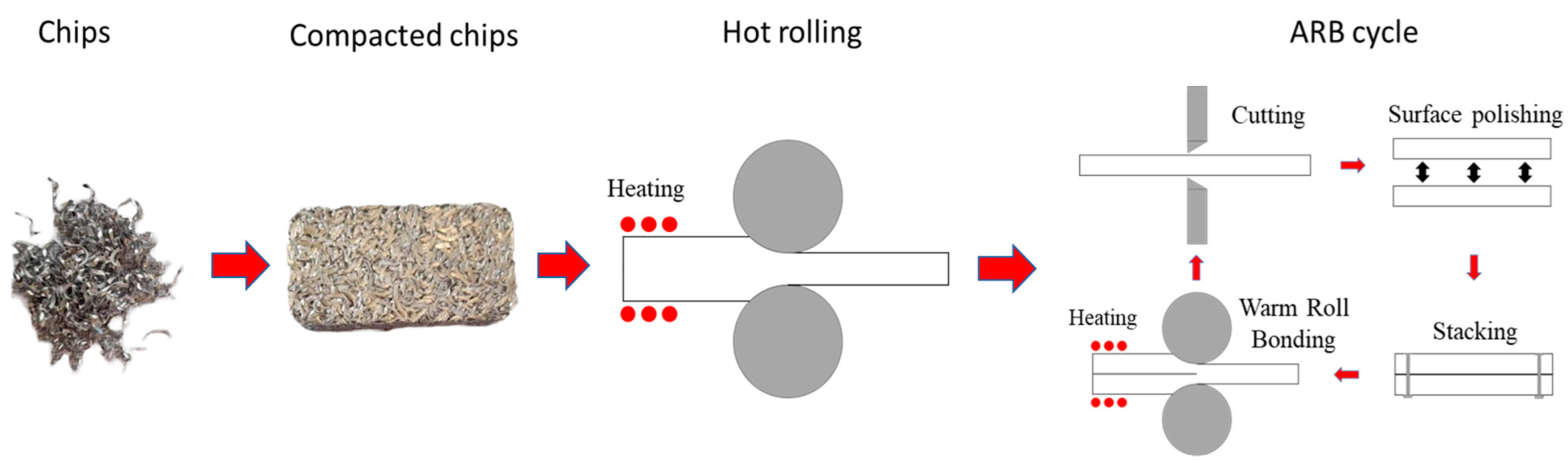

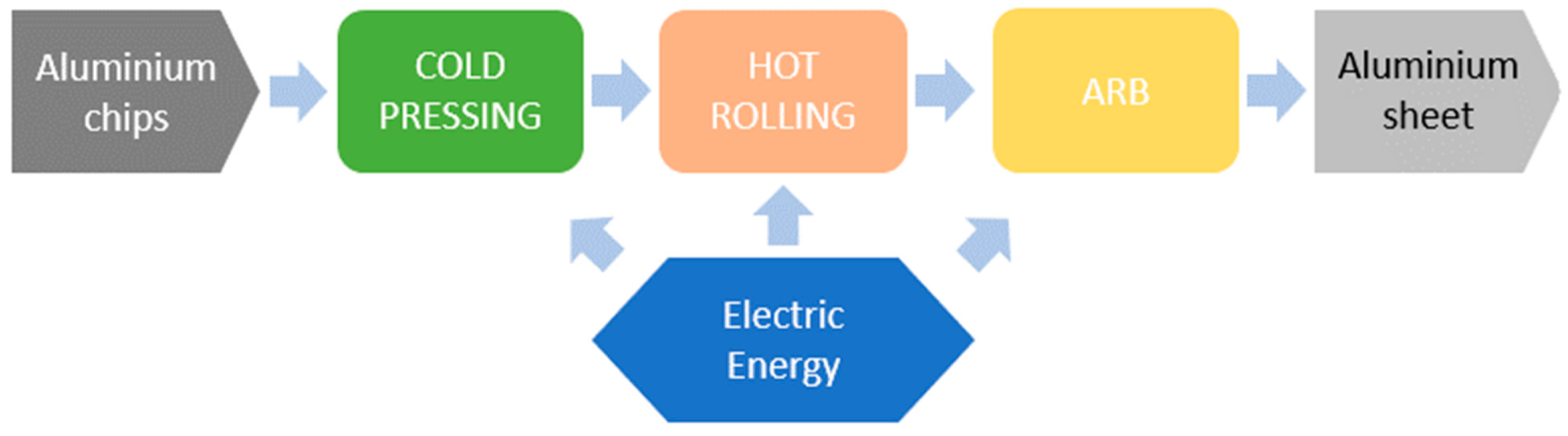

2. DR and ARB Process

3. LCA Analysis

3.1. LCA of Direct Hot Rolling as the SSR Process

- Goal and scope definition.

- Life cycle inventory (LCI) analysis.

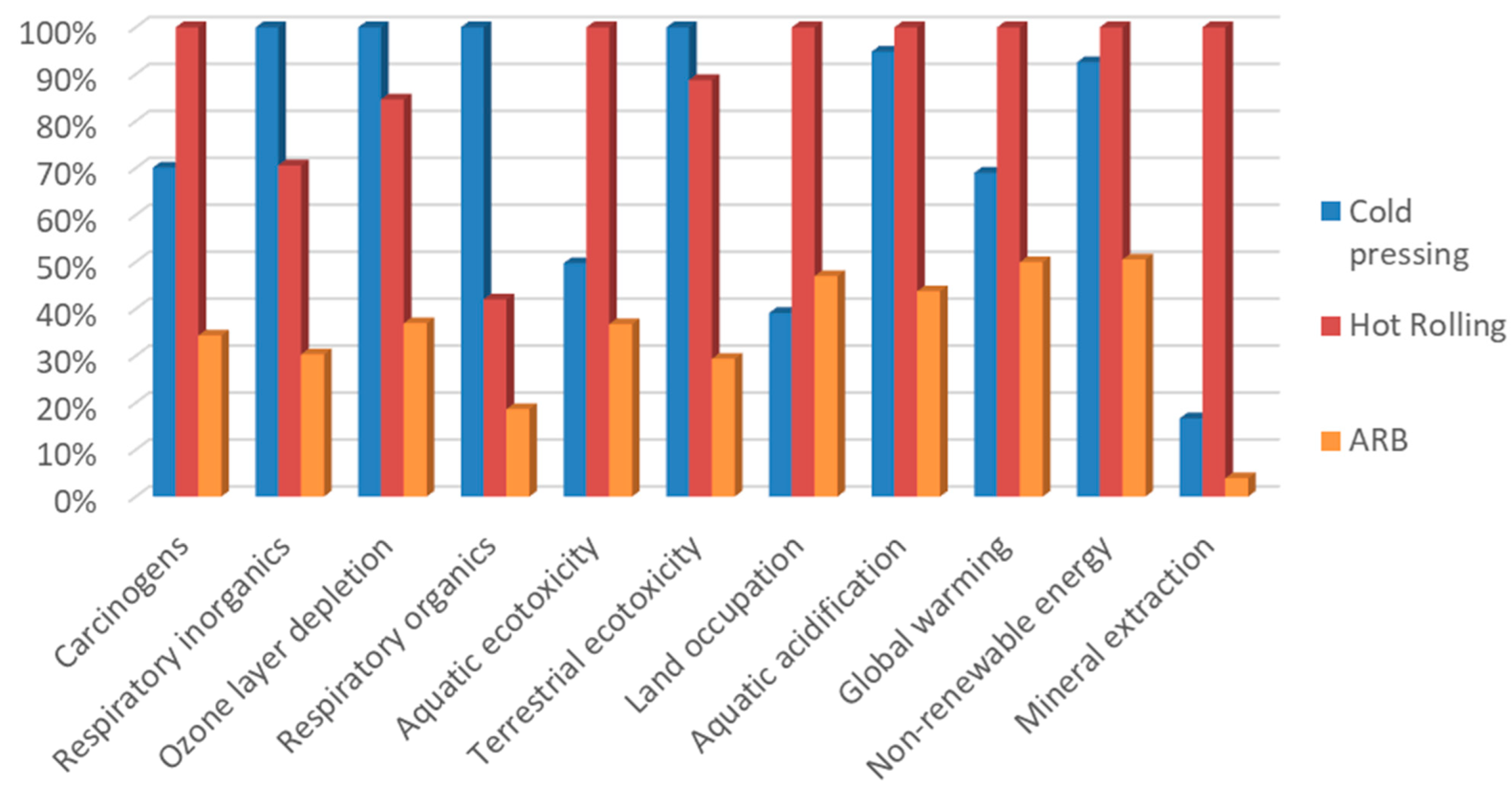

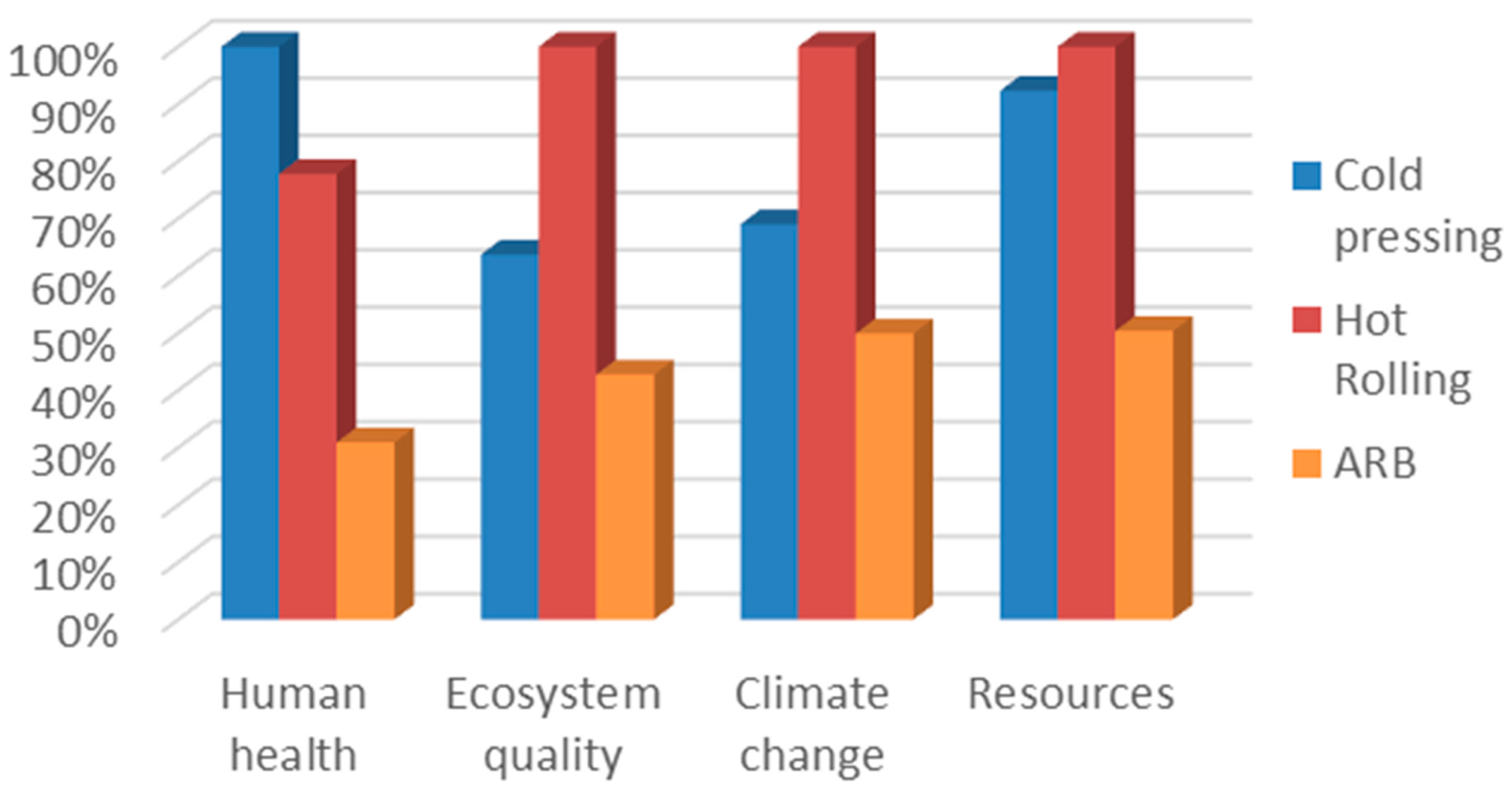

- Life cycle impact assessment (LCIA).

- Interpretation of results.

3.1.1. Goal and Scope Definition

3.1.2. LCI

3.1.3. LCIA

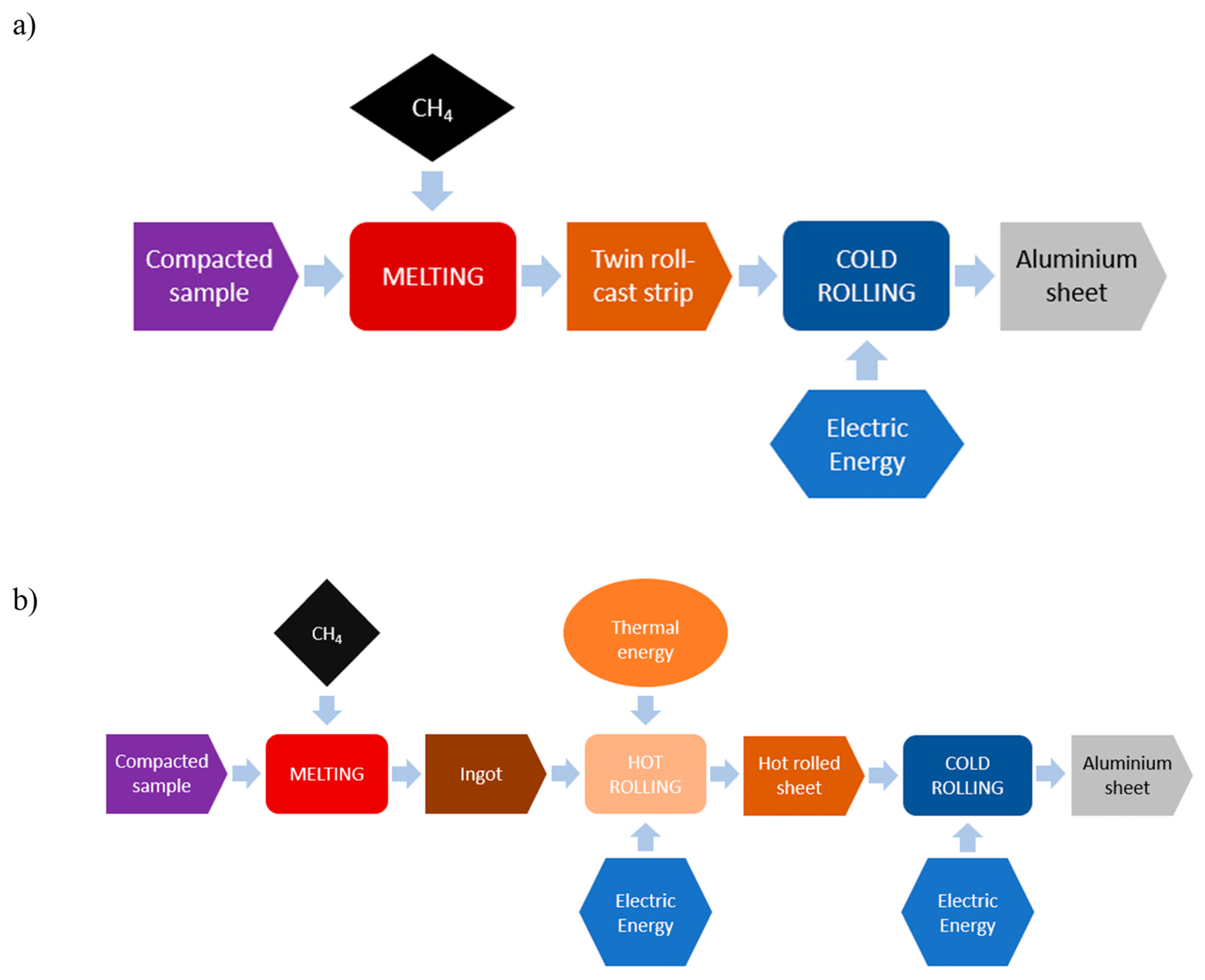

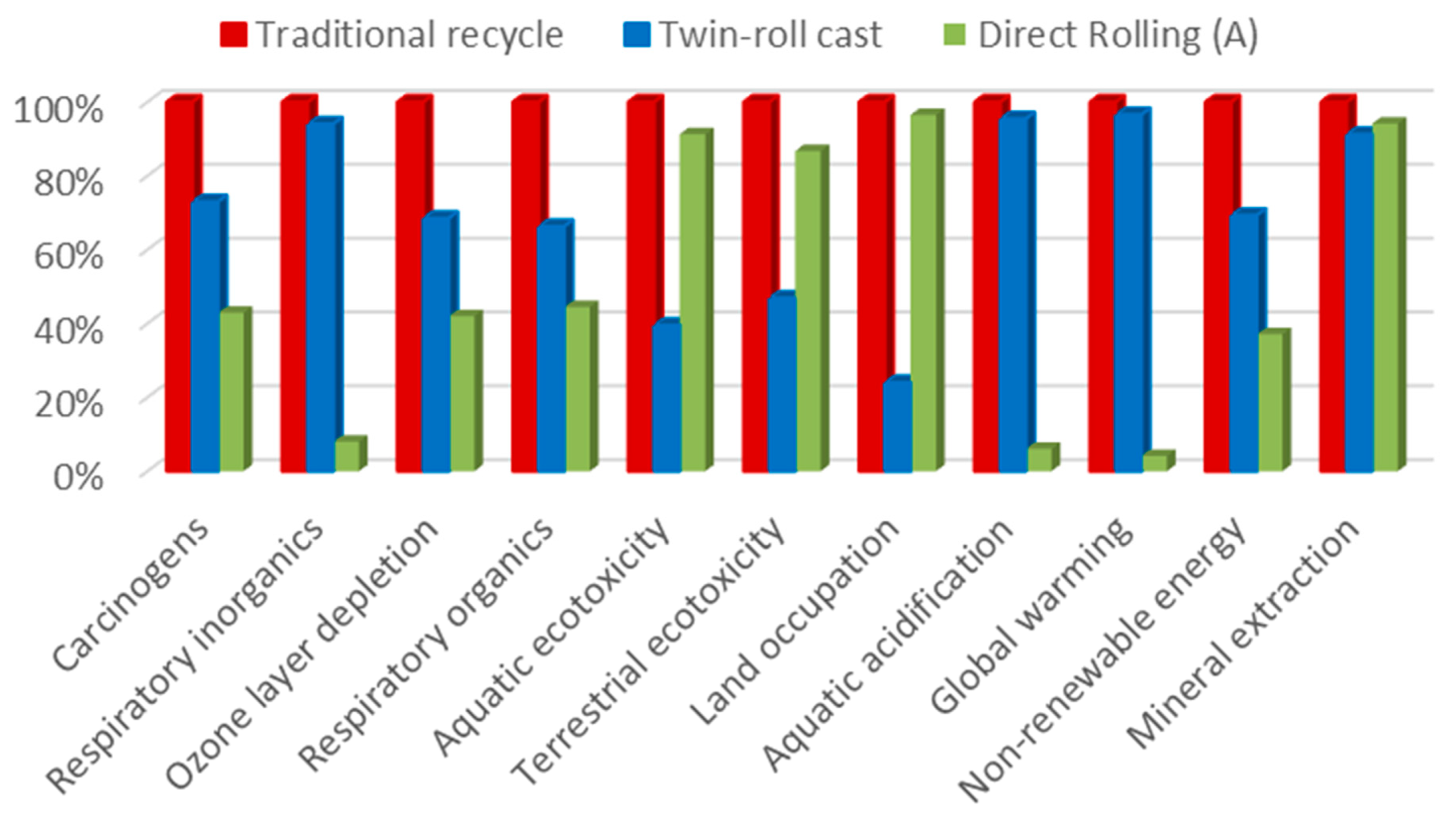

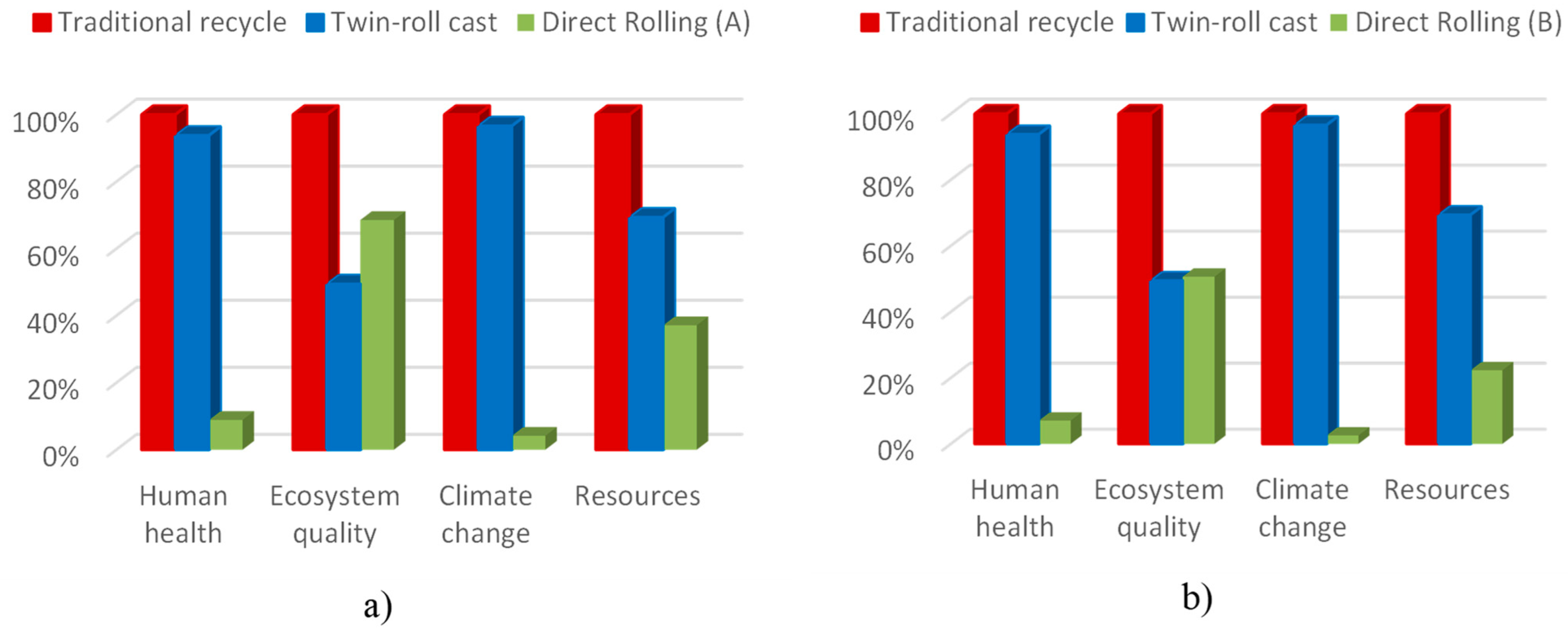

3.2. Comparison between SSR and Industrial Remelting Routes

- Traditional Recycling.

- Twin Roll Cast.

- DR + ARB.

- Melting: This initial step takes the cold-pressed sample obtained from the aluminum chips as its material input. The process requires additional inputs, such as thermal energy sourced from natural gas, and water used for dross treatment. Considering that in secondary aluminum production, there is a typical metal loss of approximately 20–45%, a total loss of 35% was assumed for this step. To obtain a cast ingot of 1 kg as input for the subsequent rolling process, the mass of compacted chips required was determined to be 1.54 kg. The material output of this step is the aluminum cast ingot, which represents the input for next step, while emissions into the air and water are additional outputs.

- Hot rolling: The cast ingot obtained from the melting stage serves as the primary input for this step. It requires electricity for both the reheating furnace and the rolling machine. The main output is the hot rolled sheet, which is prepared for subsequent cold rolling. Furthermore, considering a 10% material loss during the process, the aluminum residues are also considered as output waste.

- Cold rolling: This final step is carried out to reduce the thickness of the hot rolled sheet to the desired measurement, which, in this analysis, is determined to be 1.6 mm based on experimental procedures conducted in the laboratory. The inputs for this step include the hot rolled sheet, electricity for the rolling machine, and kerosene, which is employed as both a coolant and a lubricant. The output of this step is the cold rolled sheet, with any material loss during this particular process considered negligible.

- Melting: This step is identical to the first stage of traditional recycling, involving the same inputs and outputs. The process begins with the melting of the material, and it shares the same inputs and outputs as the melting step of traditional recycling. Therefore, the datasets and sources utilized for traditional recycling’s melting phase are also applicable to the twin roll cast process.

- Cold rolling: This step is comparable to the third stage of traditional recycling, with the same inputs and outputs. Similar to the cold rolling step in traditional recycling, the inputs and outputs remain unchanged. However, it is important to note that a total material loss of 10% was considered during this step for the twin roll cast process.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| LCA | Life cycle assessment |

| FSE | Friction stir extrusion |

| FSC | Friction stir consolidation |

| ECAP | Equal channel angular pressing |

| SPD | Severe plastic deformation |

| DR | Direct rolling process |

| ARB | Accumulative roll bonding process |

| DR + ARB | Direct rolling process followed by accumulative roll bonding |

| SSR | Solid state recycling |

| LCI | Life cycle inventory |

| LCIA | Life cycle impact assessment |

| UTS | Ultimate tensile strength |

References

- Varshney, D.; Kumar, K. Application and Use of Different Aluminium Alloys with Respect to Workability, Strength and Welding Parameter Optimization. Ain Shams Eng. J. 2021, 12, 1143–1152. [Google Scholar] [CrossRef]

- Cullen, J.M.; Allwood, J.M. Mapping the Global Flow of Aluminum: From Liquid Aluminum to End-Use Goods. Environ. Sci. Technol. 2013, 47, 3057–3064. [Google Scholar] [CrossRef] [PubMed]

- Gutowski, T.G.; Sahni, S.; Allwood, J.M.; Ashby, M.F.; Worrell, E. The Energy Required to Produce Materials: Constraints on Energy-Intensity Improvements, Parameters of Demand. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 2013, 371, 20120003. [Google Scholar] [CrossRef] [PubMed]

- Wagiman, A.; Mustapa, M.S.; Asmawi, R.; Shamsudin, S.; Lajis, M.A.; Mutoh, Y. A Review on Direct Hot Extrusion Technique in Recycling of Aluminium Chips. Int. J. Adv. Manuf. Technol. 2020, 106, 641–653. [Google Scholar] [CrossRef]

- Güley, V.; Ben Khalifa, N.; Tekkaya, A.E. Direct Recycling of 1050 Aluminum Alloy Scrap Material Mixed with 6060 Aluminum Alloy Chips by Hot Extrusion. Int. J. Mater. Form. 2010, 3, 853–856. [Google Scholar] [CrossRef]

- Das, S.K.; Yin, W. The Worldwide Aluminum Economy: The Current State of the Industry. Jom 2007, 59, 57–63. [Google Scholar] [CrossRef]

- Raabe, D.; Ponge, D.; Uggowitzer, P.J.; Roscher, M.; Paolantonio, M.; Liu, C.; Antrekowitsch, H.; Kozeschnik, E.; Seidmann, D.; Gault, B.; et al. Making Sustainable Aluminum by Recycling Scrap: The Science of “Dirty” Alloys. Prog. Mater. Sci. 2022, 128, 100947. [Google Scholar] [CrossRef]

- Hatayama, H. Evolution of Aluminum Recycling Initiated by the Introduction of Next-Generation Vehicles and Scrap Sorting Technology. Resour. Conserv. Recycl. 2012, 66, 8–14. [Google Scholar] [CrossRef]

- Paraskevas, D.; Kellens, K.; Rinaldi; Dewulf, W.; Duflou, J.R. Resource Efficiency in Manufacturing: Identifying Low Impact Paths. In Proceedings of the 10th Global Conference on Sustainable Manufacturing (GCSM 2012), Istanbul, Turkey, 31 October–2 November 2012; pp. 271–276. [Google Scholar]

- Shamsudin, S.; Lajis, M.; Zhong, Z. Solid-State Recycling of Light Metals: A Review. Adv. Mech. Eng. 2016, 8, 168781401666192. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Forcellese, A.; Mancia, T.; Simoncini, M.; Spigarelli, S. A New Sustainable Direct Solid State Recycling of AA1090 Aluminum Alloy Chips by Means of Friction Stir Back Extrusion Process. Procedia CIRP 2019, 79, 638–643. [Google Scholar] [CrossRef]

- Buffa, G.; Campanella, D.; Micari, F.; Fratini, L. Design and Development of a New Machine Tool for Continuous Friction Stir Extrusion. CIRP J. Manuf. Sci. Technol. 2023, 41, 391–400. [Google Scholar] [CrossRef]

- Baffari, D.; Reynolds, A.P.; Li, X.; Fratini, L. Bonding Prediction in Friction Stir Consolidation of Aluminum Alloys: A Preliminary Study; AIP Publisher: Palermo, Italy, 2018; p. 050002. [Google Scholar]

- Haase, M.; Ben Khalifa, N.; Tekkaya, A.E.; Misiolek, W.Z. Improving Mechanical Properties of Chip-Based Aluminum Extrudates by Integrated Extrusion and Equal Channel Angular Pressing (IECAP). Mater. Sci. Eng. A 2012, 539, 194–204. [Google Scholar] [CrossRef]

- Abd El Aal, M.I.; Yoo Yoon, E.; Seop Kim, H. Recycling of AlSi8Cu3 Alloy Chips via High Pressure Torsion. Mater. Sci. Eng. A 2013, 560, 121–128. [Google Scholar] [CrossRef]

- Ingarao, G.; Baffari, D.; Bracquene, E.; Fratini, L.; Duflou, J. Energy Demand Reduction of Aluminum Alloys Recycling through Friction Stir Extrusion Processes Implementation. Procedia Manuf. 2019, 33, 632–638. [Google Scholar] [CrossRef]

- Duflou, J.R.; Tekkaya, A.E.; Haase, M.; Welo, T.; Vanmeensel, K.; Kellens, K.; Dewulf, W.; Paraskevas, D. Environmental Assessment of Solid State Recycling Routes for Aluminium Alloys: Can Solid State Processes Significantly Reduce the Environmental Impact of Aluminium Recycling? CIRP Ann. 2015, 64, 37–40. [Google Scholar] [CrossRef]

- Buffa, G.; Baffari, D.; Ingarao, G.; Fratini, L. Uncovering Technological and Environmental Potentials of Aluminum Alloy Scraps Recycling Through Friction Stir Consolidation. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 7, 955–964. [Google Scholar] [CrossRef]

- Ingarao, G.; Amato, M.; Latif, A.; La Rosa, A.D.; Di Lorenzo, R.; Fratini, L. Life Cycle Assessment of Aluminum Alloys Chips Recycling through Single and Multi-Step Friction Stir Consolidation Processes. J. Manuf. Syst. 2023, 68, 651–659. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Spigarelli, S.; Gabrielli, F.; Donati, L. Comparison Study of Constitutive Models in Predicting the Hot Deformation Behavior of AA6060 and AA6063 Aluminium Alloys. Mater. Today Proc. 2015, 2, 4732–4739. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel Ultra-High Straining Process for Bulk Materials-Development of the Accumulative Roll-Bonding (ARB) Process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Forcellese, A.; Marconi, M.; Simoncini, M.; Vita, A. Life Cycle Impact Assessment of Different Manufacturing Technologies for Automotive CFRP Components. J. Clean. Prod. 2020, 271, 122677. [Google Scholar] [CrossRef]

- Priarone, P.C.; Ingarao, G.; Settineri, L.; Di Lorenzo, R. On the Impact of Recycling Strategies on Energy Demand and CO2 Emissions When Manufacturing Al-Based Components. Procedia CIRP 2016, 48, 194–199. [Google Scholar] [CrossRef]

- Aluminum Recycling and Processing for Energy Conservation and Sustainability; Green, J.A.S., Ed.; ASM International: Novelty, OH, USA, 2007; ISBN 978-0-87170-859-5. [Google Scholar]

- El Mehtedi, M.; Lai, D.; Almehtedi, R.; Carta, M.; Buonadonna, P.; Aymerich, F. Bonding of similar AA3105 aluminum alloy by Accumulative Roll Bonding process. In Proceedings of the 24th International Conference on Material Forming, ESAFORM 2021, Liege, Belgium, 14–16 April 2021; p. 942. [Google Scholar] [CrossRef]

- Mahinroosta, M.; Allahverdi, A. Hazardous Aluminum Dross Characterization and Recycling Strategies: A Critical Review. J. Environ. Manag. 2018, 223, 452–468. [Google Scholar] [CrossRef] [PubMed]

| Cold Pressing | DR | ARB | ||||||

|---|---|---|---|---|---|---|---|---|

| INPUTS | Quantity | Unit | INPUTS | Quantity | Unit | INPUTS | Quantity | Unit |

| Chips | 35 | g | Compacted chips | 35 | g | HR sheet | 31.5 | G |

| Electric energy (press) | 0.0017 | MJ | Electric energy (heat) | 0.032 | MJ | Electric energy (heat) | 0.023 | MJ |

| Electric energy (milling) | 0.006 | MJ | Electric energy (roll) | 0.018 | MJ | Electric energy (roll) | 0.005 | MJ |

| Water (cooling) | 4.73 × 10−5 | m3 | ||||||

| OUTPUTS | Quantity | Unit | OUTPUTS | Quantity | Unit | OUTPUTS | Quantity | Unit |

| Compacted chips | 35 | g | HR sheet | 31.5 | g | ARB sheet | 31.5 | G |

| Steel chips | 405 | g | Aluminum scrap | 3.5 | g | |||

| Melting | Hot Rolling | Cold Rolling | ||||||

|---|---|---|---|---|---|---|---|---|

| INPUTS | Quantity | Unit | INPUTS | Quantity | Unit | INPUTS | Quantity | Unit |

| Compacted chips | 1.538 | kg | Cast ingot | 1 | kg | HR sheet | 0.9 | kg |

| Thermal energy (CH4) | 8.442 | MJ | Electric energy (heat) | 1.08 | MJ | Electric energy (roll) | 0.259 | MJ |

| Water | 1.79 × 10−6 | m3 | Electric energy (roll) | 0.72 | MJ | Kerosene | 0.042 | kg |

| Water (cooling) | 0.0014 | m3 | ||||||

| OUTPUTS | Quantity | Unit | OUTPUTS | Quantity | Unit | OUTPUTS | Quantity | Unit |

| Cast ingot | 1 | kg | HR sheet | 0.9 | kg | CR sheet | 0.9 | kg |

| Emissions to air | Aluminum scrap | 0.1 | kg | |||||

| Emissions to water | ||||||||

| Melting | Cold Rolling | ||||

|---|---|---|---|---|---|

| INPUTS | Quantity | Unit | INPUTS | Quantity | Unit |

| Compacted chips | 1.538 | kg | Twin roll cast | 1 | kg |

| Thermal energy (CH4) | 8.442 | MJ | Electric energy (roll) | 0.288 | MJ |

| Water | 1.79 · 10−6 | m3 | Kerosene | 0.042 | kg |

| OUTPUTS | Quantity | Unit | OUTPUTS | Quantity | Unit |

| Twin roll cast | 1 | kg | CR sheet | 0.9 | kg |

| Emissions to air | Aluminum scrap | 0.1 | kg | ||

| Emissions to water | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Mehtedi, M.; Buonadonna, P.; Carta, M.; El Mohtadi, R.; Mele, A.; Morea, D. Sustainability Study of a New Solid-State Aluminum Chips Recycling Process: A Life Cycle Assessment Approach. Sustainability 2023, 15, 11434. https://doi.org/10.3390/su151411434

El Mehtedi M, Buonadonna P, Carta M, El Mohtadi R, Mele A, Morea D. Sustainability Study of a New Solid-State Aluminum Chips Recycling Process: A Life Cycle Assessment Approach. Sustainability. 2023; 15(14):11434. https://doi.org/10.3390/su151411434

Chicago/Turabian StyleEl Mehtedi, Mohamad, Pasquale Buonadonna, Mauro Carta, Rayane El Mohtadi, Alessandro Mele, and Donato Morea. 2023. "Sustainability Study of a New Solid-State Aluminum Chips Recycling Process: A Life Cycle Assessment Approach" Sustainability 15, no. 14: 11434. https://doi.org/10.3390/su151411434

APA StyleEl Mehtedi, M., Buonadonna, P., Carta, M., El Mohtadi, R., Mele, A., & Morea, D. (2023). Sustainability Study of a New Solid-State Aluminum Chips Recycling Process: A Life Cycle Assessment Approach. Sustainability, 15(14), 11434. https://doi.org/10.3390/su151411434