Industry 4.0 Framework Based on Organizational Diagnostics and Plan–Do–Check–Act Cycle for the Saudi Arabian Cement Sector

Abstract

1. Introduction

2. Theoretical Framework

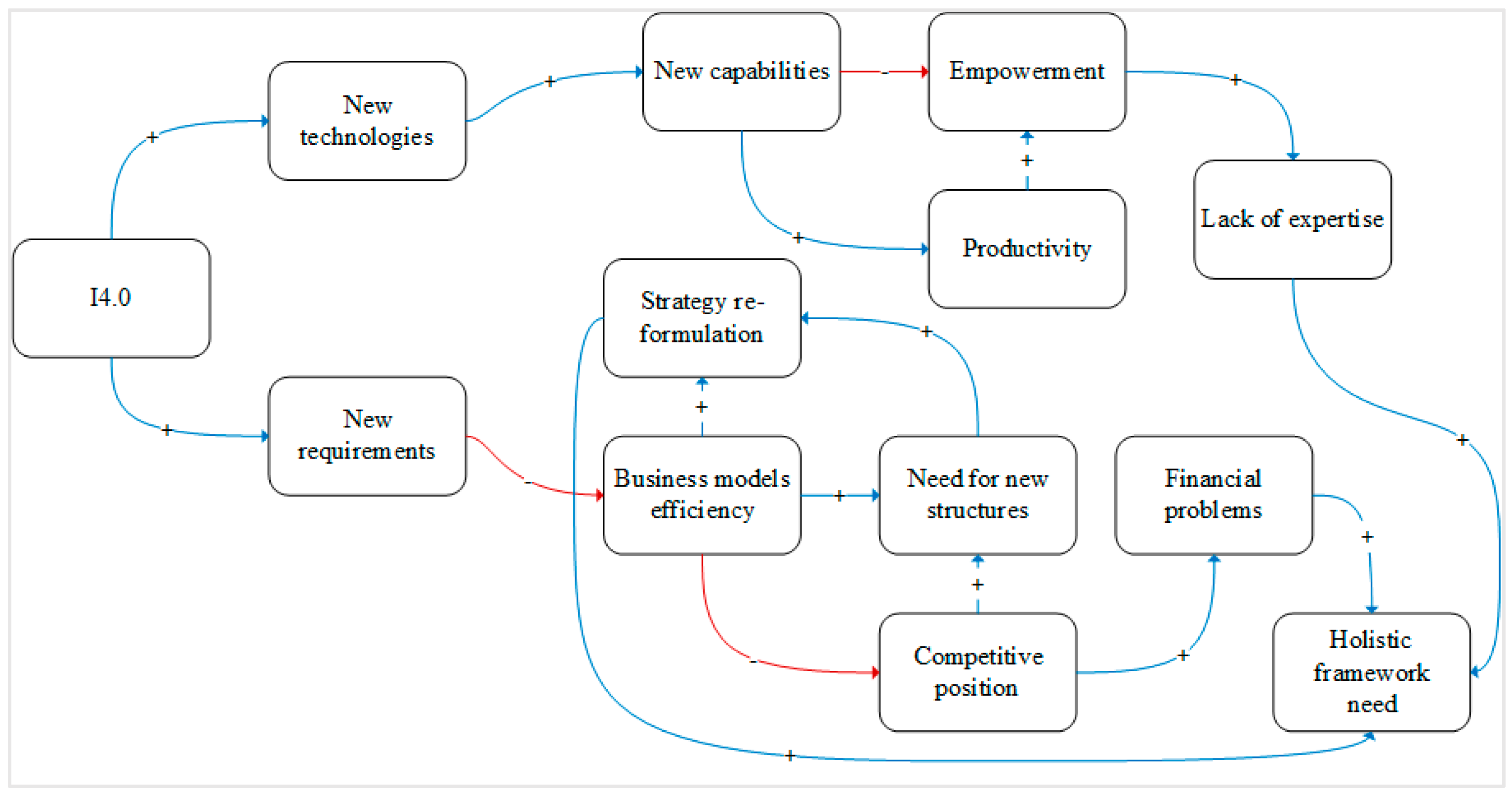

2.1. I4.0 System Disruptions

2.2. Literature Review on Organizational Diagnostics and I4.0 Maturity Models

2.3. Cement Sector within I4.0

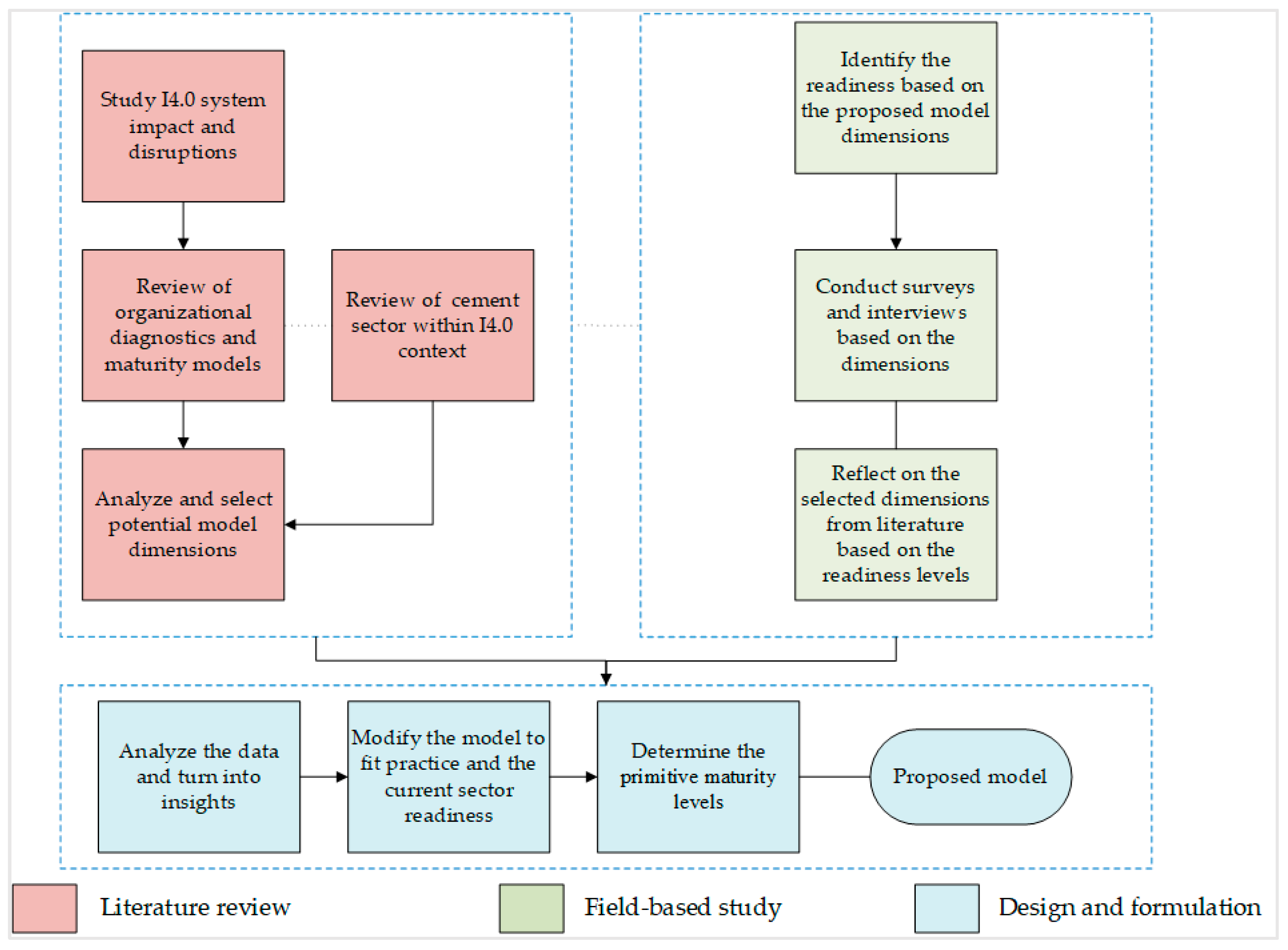

3. Materials and Methods

3.1. Data Collection Procedures

3.2. Sample Profile of the Study

4. Results and Analysis

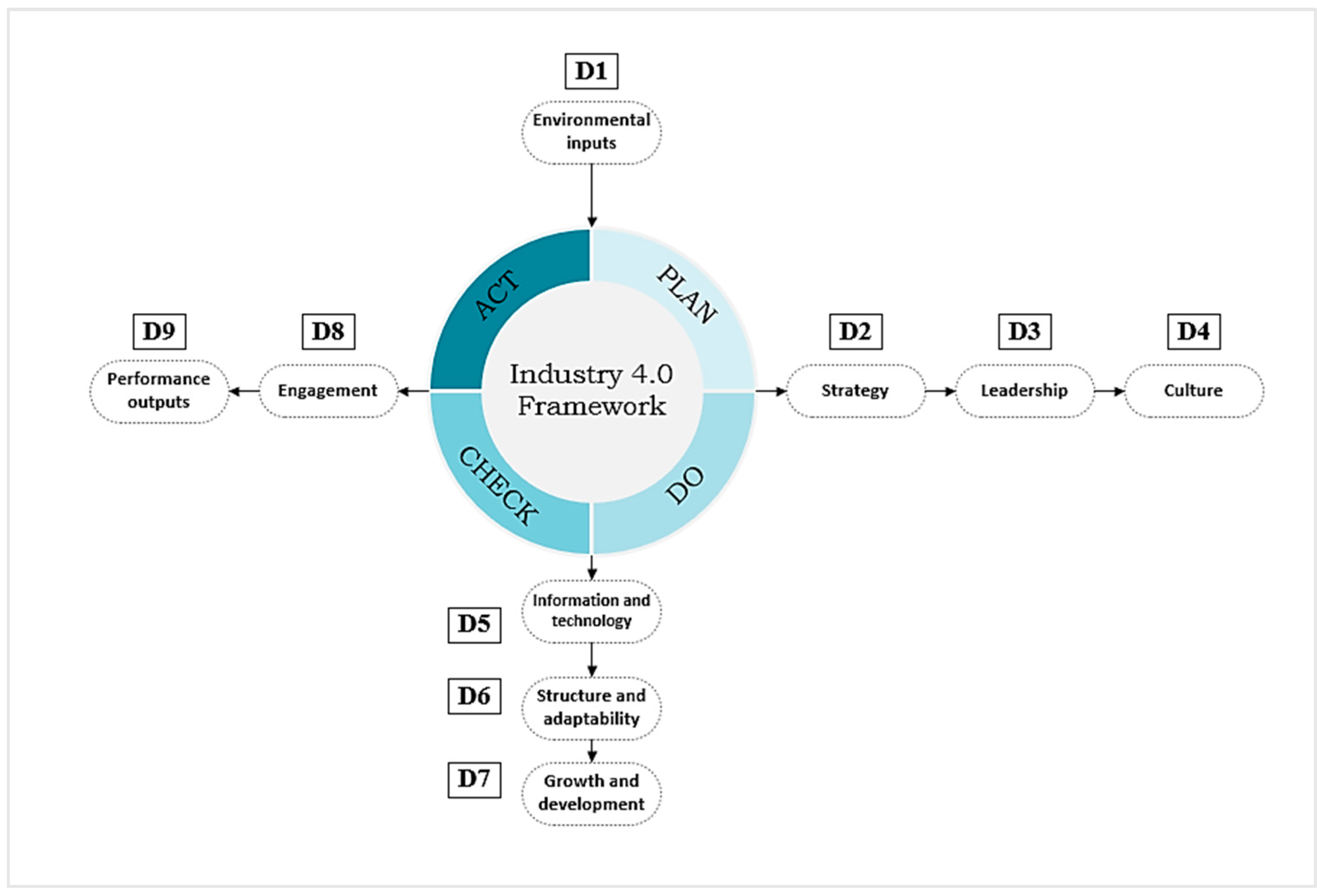

4.1. Proposed Model Diminisnions

- D1—Environmental inputs: Refers to the ability of an organization to understand the outside conditions and situations that affect it. This includes customer needs, the economy, policies, and their competitive position. The arrival of I4.0 will surely influence these inputs and create more organizational prerequisites for adopting I4.0 technologies. Organizations must manage multiple internal and external factors to increase business value and establish a sustainable competitive advantage in order to achieve I4.0 alignment within the organization context. Specific factors include horizontal, vertical, and digital integration, as well as competitive position analysis. Organizational performance in this evolving era necessitates the management of teams of highly specialized technical specialists. In addition, it requires employees trained to operate using I4.0 enablers, with profiles that do not yet exist [31].

- D2—Strategy: This dimension concerns the extent to which strategic measures are adopted to achieve objectives for improvement and innovation initiatives to increase competitive advantage. Organizations should map out an I4.0 strategy with measurable targets to close the gap in their I4.0 readiness. Organizations use strategic planning to define their direction and guide resource allocation decisions [32]. Strategic planning provides an organization with direction, defines measurable objectives, and guides day-to-day decisions. In addition, strategic planning is concerned with the definition of changes that may be influenced by fluctuating market conditions, competitor activity, and technological advancement—elements typically constituting I4.0. Moreover, alignment must be achieved at both enterprise and departmental levels across four domains of decision-making choices, namely digital strategy execution, technology innovation potential, competitive business models, and the level of investments and support for organizations to manage all the multiple internal and external factors described in D1.

- D3—Leadership: Leadership at the senior level must establish a forward-looking, innovative, and technologically advanced organizational culture. Faced with I4.0, leadership has to adapt to the changes; the guidance of teams and organizations toward impactful transformations demands leadership that supports innovative visions. Leadership must adapt to I4.0 to guide teams and organizations toward meaningful transformations. This requires strategic ways to realize new ambitions [33]. Responsive leadership has a special role in fostering an organization’s change in the perspective of a learning and innovation-oriented culture, learning from and managing various situations, while supporting the transition to I4.0. Leader 4.0, however, should not be mistaken for a technological leader; in fact, what transforms a leader into a 4.0 is not just the application of technologies, but also the capacity to foster a novel culture focusing on people, technologies, and innovation while being cognizant of how technologies would affect people and the business line of the organization. Digital leadership should be quick, cross-hierarchical, and team-oriented to digitize operations inside an organization and business ecosystem. A digital leader must implement many business strategies and models, including IT strategies, more adaptable and flexible enterprise platforms, an innovative mentality, skills, and workplaces, to face the challenges of digital transformation. Additionally, leadership needs to exhibit a few qualities to deal with disruptive developments that are continually evolving, including being connected, responsive, collaborative, and network-experienced, as well as encouraging learning toward innovation [34].

- D4—Culture: Refers to the underlying values, beliefs, and norms that drive the organizational behavior towards I4.0 implementation [35]. This is a critical dimension of our proposed model. This is because, since the proposed model will be applied in Saudi Arabia, it should consider cultural values and other problems related to the region. Regional markets have been significantly impacted by the current shift in trend toward digitization and the extensive application of digital transformation methodologies and strategies. Businesses must now join the I4.0 transformation bandwagon to survive globally. In terms of evolving technologies and ideas infiltrating the workplace, cultural acceptance and willingness to transition are the most significant factors. As the majority of a cement corporate employees in Saudi Arabia, particularly in the GCC countries, are predominantly male, cultural changes would impediment digital transformation. As workplace values and working conditions undergo numerous changes and modifications, passive resistance to new technologies is readily apparent. The digital environment of a company must promote and strengthen digital technology, culture, skills, and talent.

- D5—Information Technology (IT): Refers to the organization systems, IT infrastructure, and communication systems. The organization should facilitate and reinforce its systems and infrastructure to unlock more I4.0 capabilities.

- D6—Structures: Refers to how an organization is designed. There is no doubt that I4.0 design principles will affect an organization’s structure. For instance, the decentralization design principle demands many organizational roles and functional structure changes. The restructuring of facilities in light of I4.0 transformation requirements is very important whereas the main objective is to determine whether the existing administrative organization of the facility accomplishes the requirements of I4.0 or whether this requires a restructuring of the administrative apparatus. And by virtue of the fact that restructuring is a process that requires time, human, and material resources to implement it, this leads us to the need to conduct a study of the economic feasibility of this change, given that preparing a feasibility study reduces risks and increases confidence in the possibility of the restructuring project’s success. The feasibility study usually includes all the information and statistics that help decision makers decide whether to move forward with restructuring or leave the situation as it is, perhaps only re-engineering work procedures or creating digital teams within the organization chart.

- D7—Growth and development: This refers to the level of organization support to the growth projects such as employee skill development and enhancement, including development planning, training and learning, to achieve I4.0 strategic goals. Our capacity to reduce adverse effects on the environment and the economy as a whole will be considerably enhanced by I4.0. Consider carbon emissions—a primary type of undesirable externality. Until recently, the only way for green investing to be profitable was with substantial government subsidies. This is becoming increasingly rare. One of the key worldwide issues now is climate change, and rapid technology advancements in renewable energy, fuel efficiency, and energy storage make investments in these industries increasingly profitable, driving the Gross Domestic Product GDP growth. This dimension is particularly concerned with the extent to which the company exploits modern technologies for expansion and growth, and the extent to which there are plans for continuous development towards I4.0.

- D8—Engagement: This is for both the customer and employees. The organization should make an effort to meet their requirements and keep them loyal. I4.0 will unlock the potential for a lot of engagement possibilities that must be considered.

- D9—Performance outputs: This dimension covers an important aspect of the proposed model, which is the convergence between I4.0 and measurable outcomes and KPIs. The organization must determine the decision variables that give them the ability to achieve measured goals through I4.0 technologies.

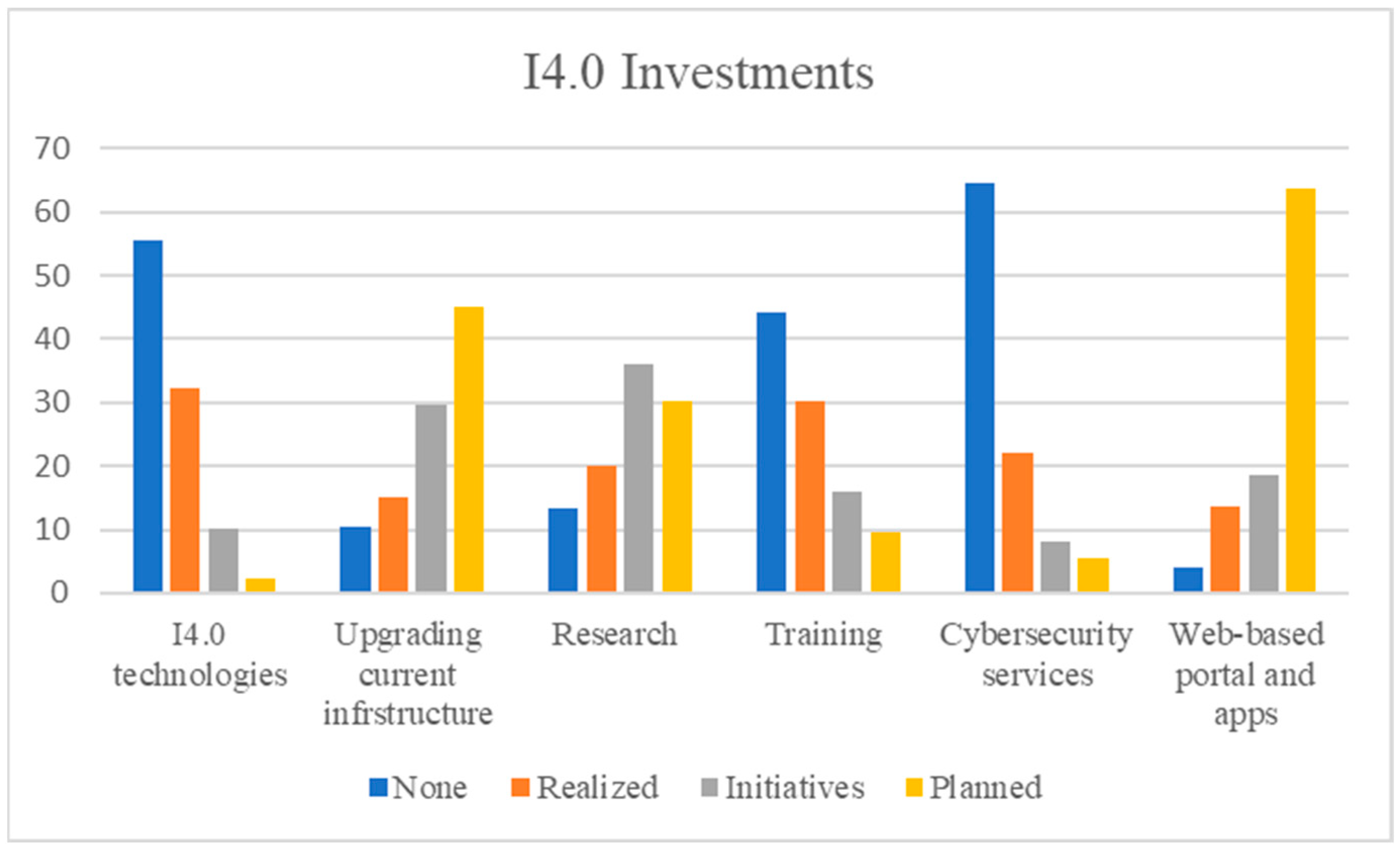

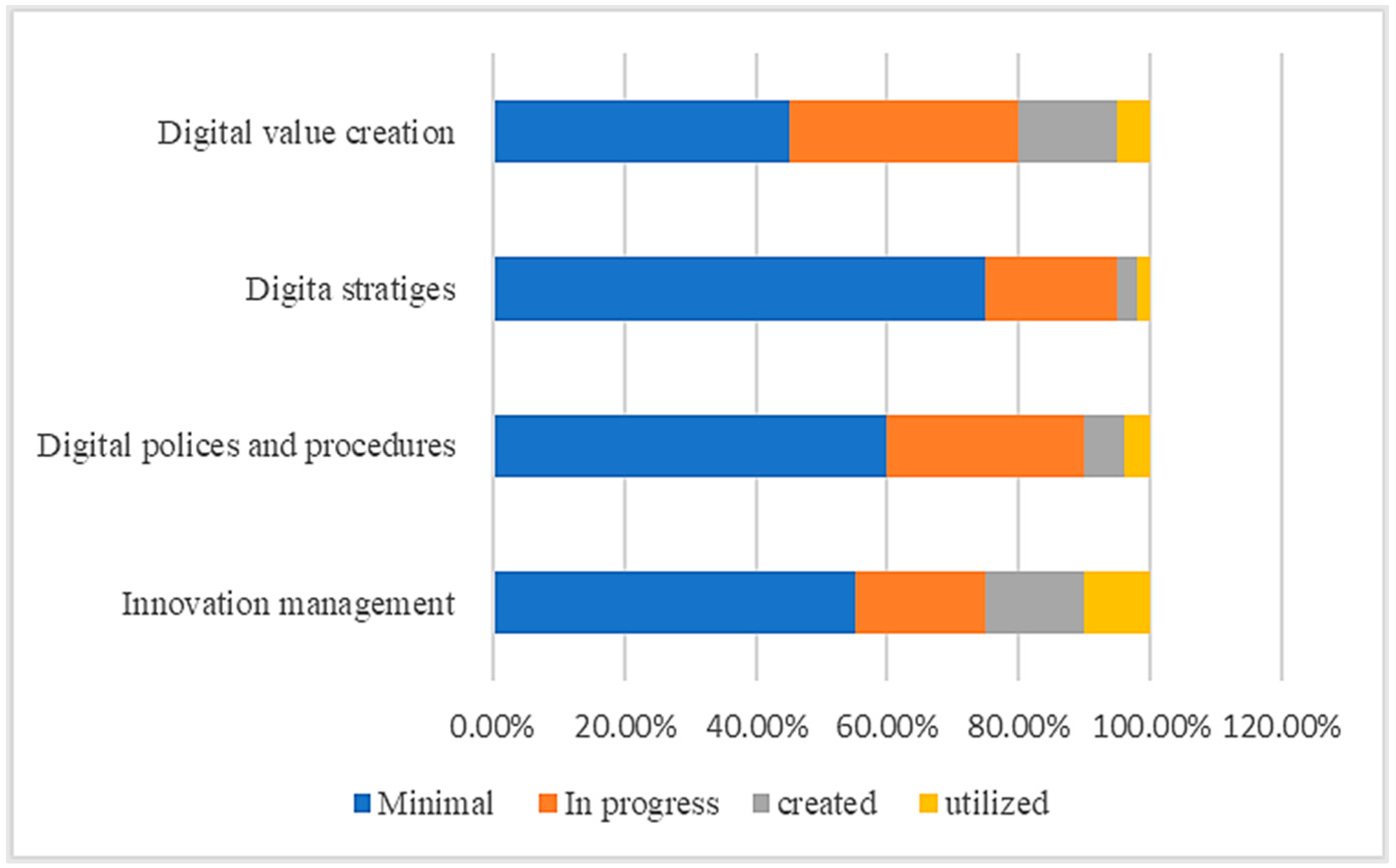

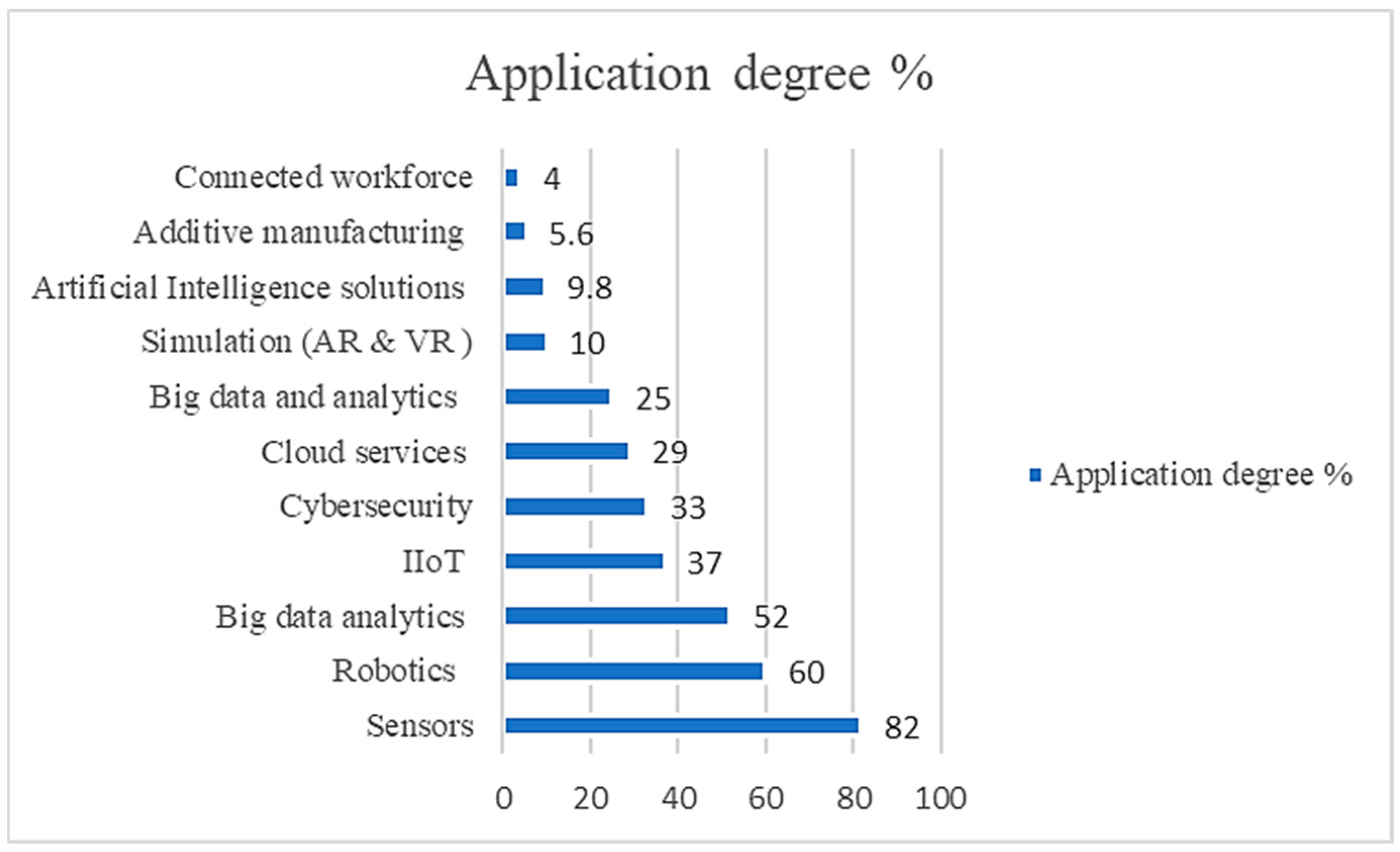

4.2. Survey Analysis and Findings

- The companies have spent a lot of their budgets in the last 5 years updating or expanding their production lines. They have also replaced their old kilns and baghouse filters. This was during the emergence of I4.0. So, cement companies need several more years to invest again in future projects.

- The cement market is currently experiencing many fluctuations and changes. Some companies cannot spend money on new technologies now.

- Few companies have realized the benefits of the I4.0 implementation; as we can see in the figure, only approximately (30%) have realized they need to allocate a percentage of their budget for future projects related to the I4.0 implementation. Around (5%) have approved targets and objectives for future digital transformation projects that are I4.0-related.

- Under the current market conditions, top managers think that I4.0 is a big change, and spending money on the transformation right now is risky, especially since some companies have spent significant budgets on applying some basic new technologies to storage and laboratory testing operations recently. It is too early to bring in more technologies to reach total transformation.

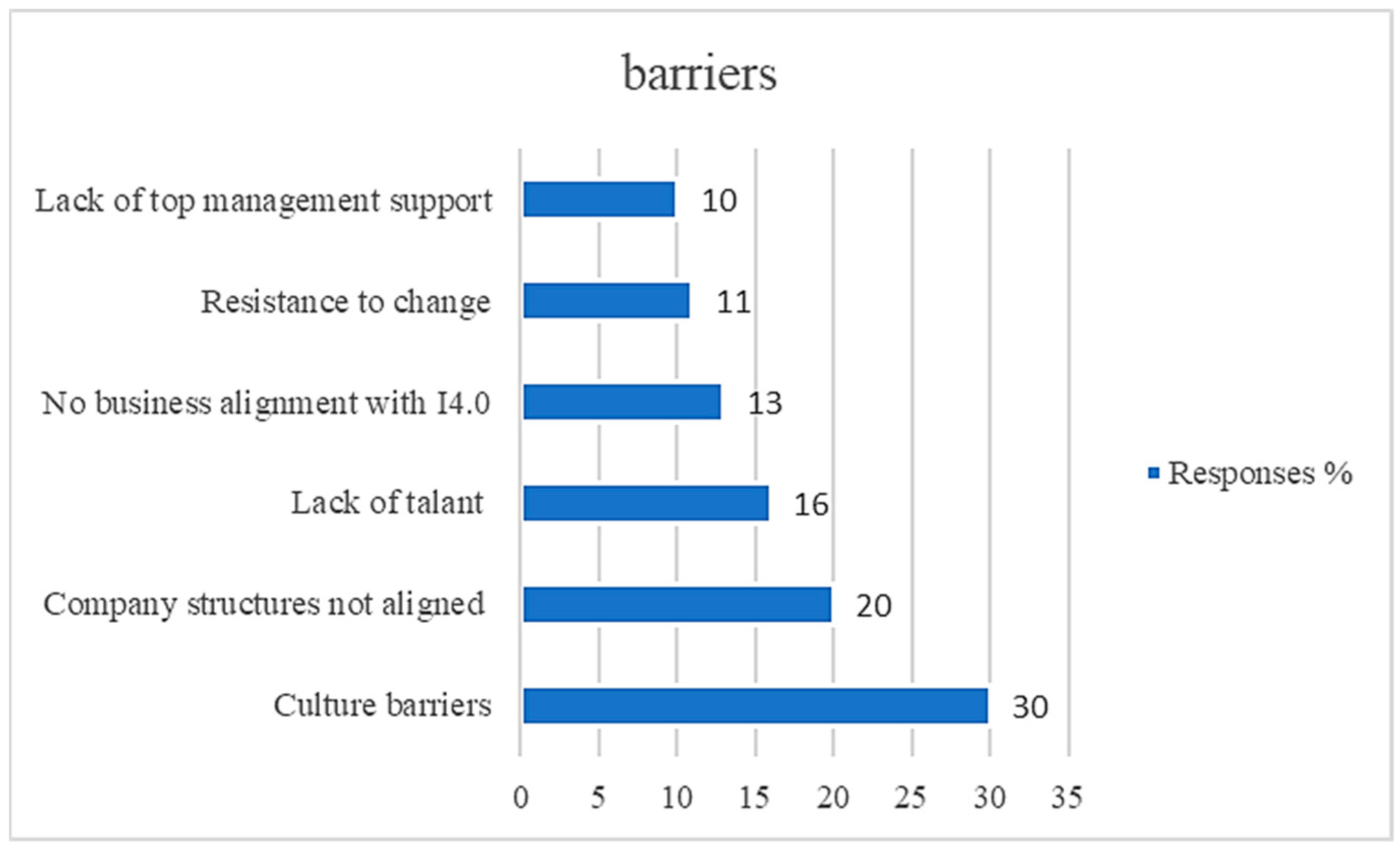

- There is an evident resistance towards new technologies.

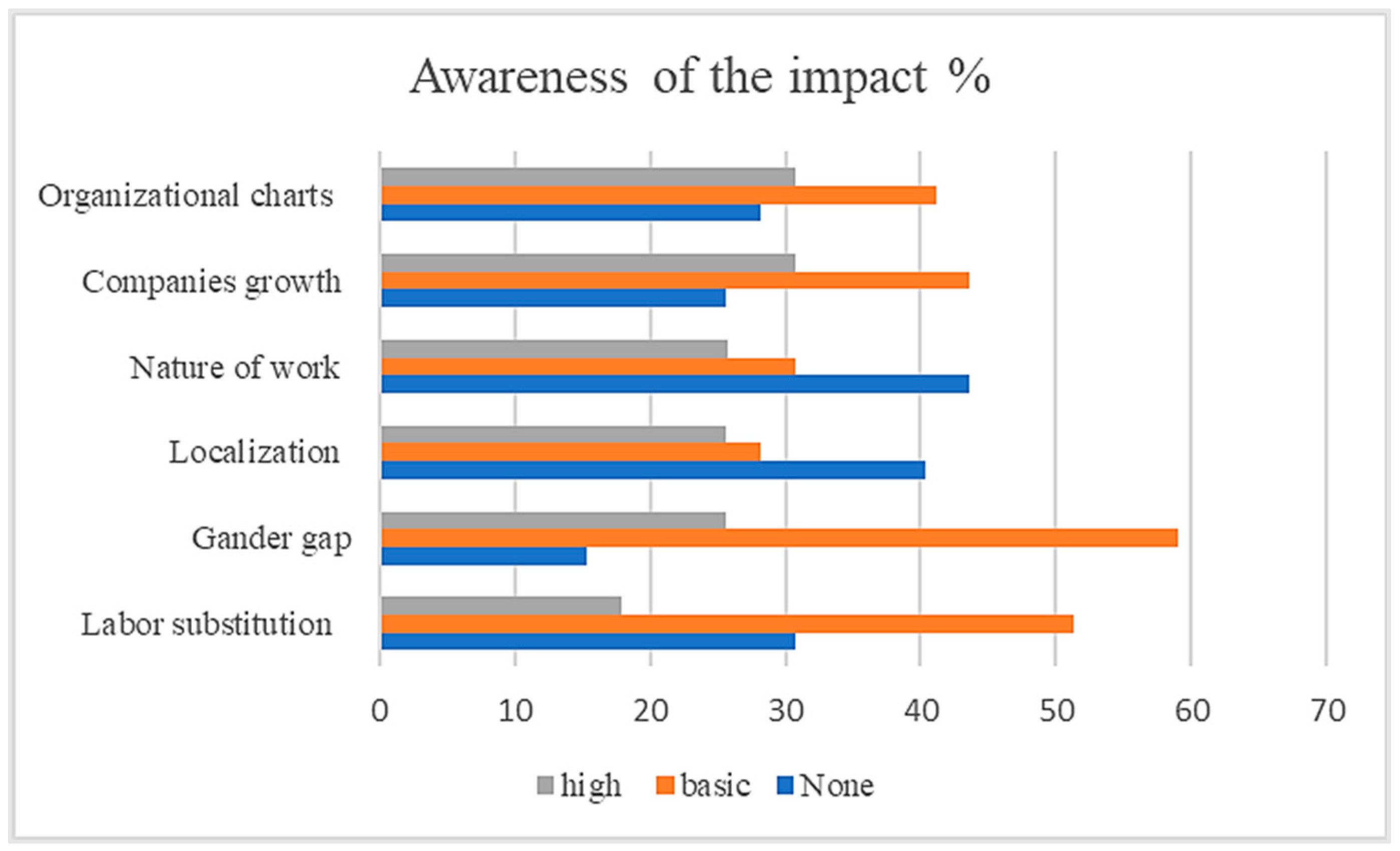

- I4.0 may increase labor inequality and may be limited to a range of advanced and technical skillsets.

- I4.0 may contribute to the empowerment and disempowerment of middle-class jobs as well.

- I4.0 may affect the sense of privacy, both on an organizational level and individual level.

- Language barriers.

- The human versus machine dilemma: there are still fears and untrust of giving some tasks to a machine or AI.

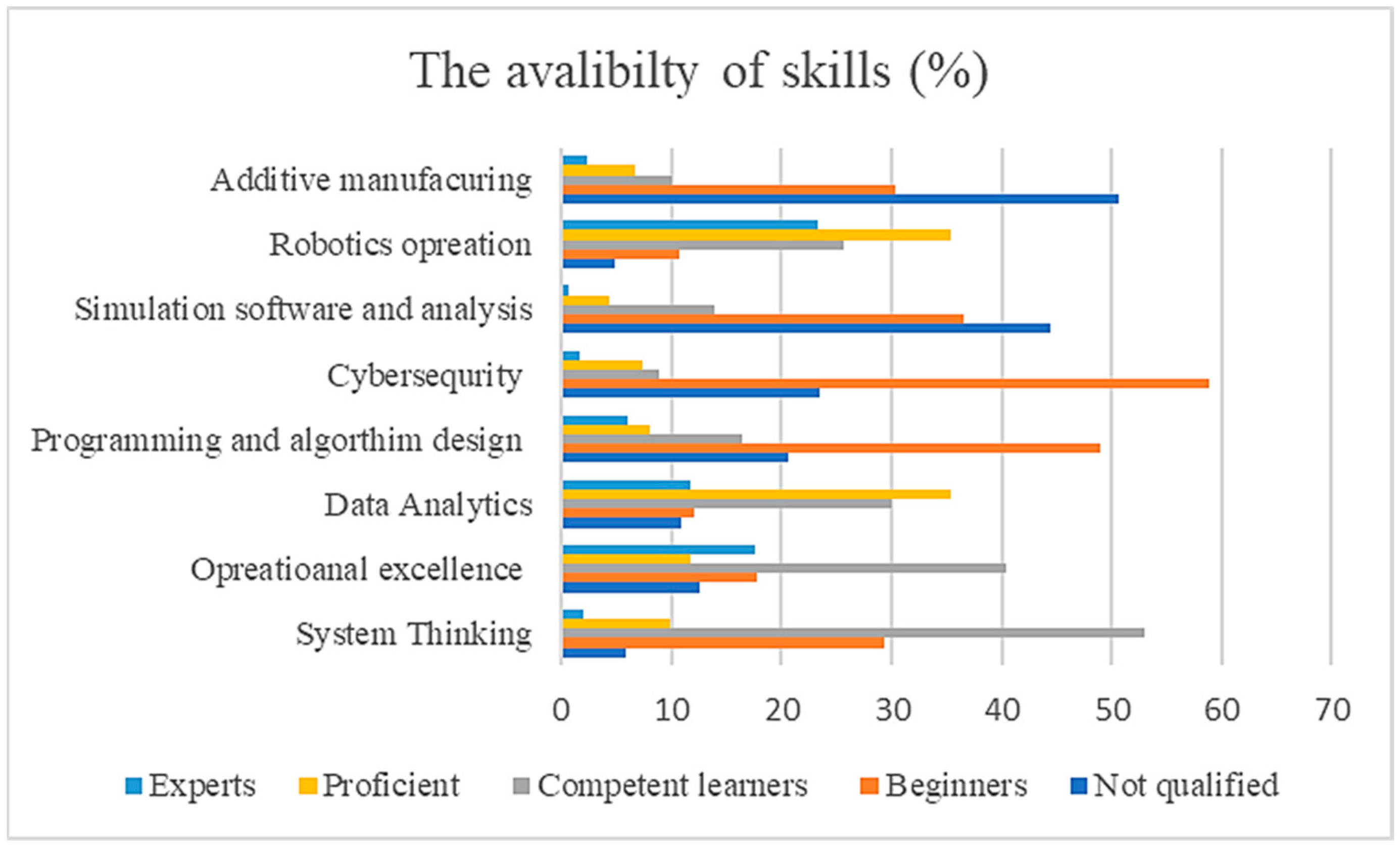

- The test was performed for different departments (job functions) in the companies and showed a p-value = (0.007 < 0.05), indicating a statistical difference between the means.

- A p-value of 0.004 was found when the test was performed based on the level of investments in I4.0 technologies and training plans, indicating a statistical difference between the means of skills and the organizations’ activities towards I4.0.

4.3. Intreviews Thematic Analysis

- Theme 1: general awareness

- Theme 2: I4.0 framework and the proposed model

- Theme 3: I4.0 challenges and problems

5. Discussion

5.1. Proposed Model Guidlines

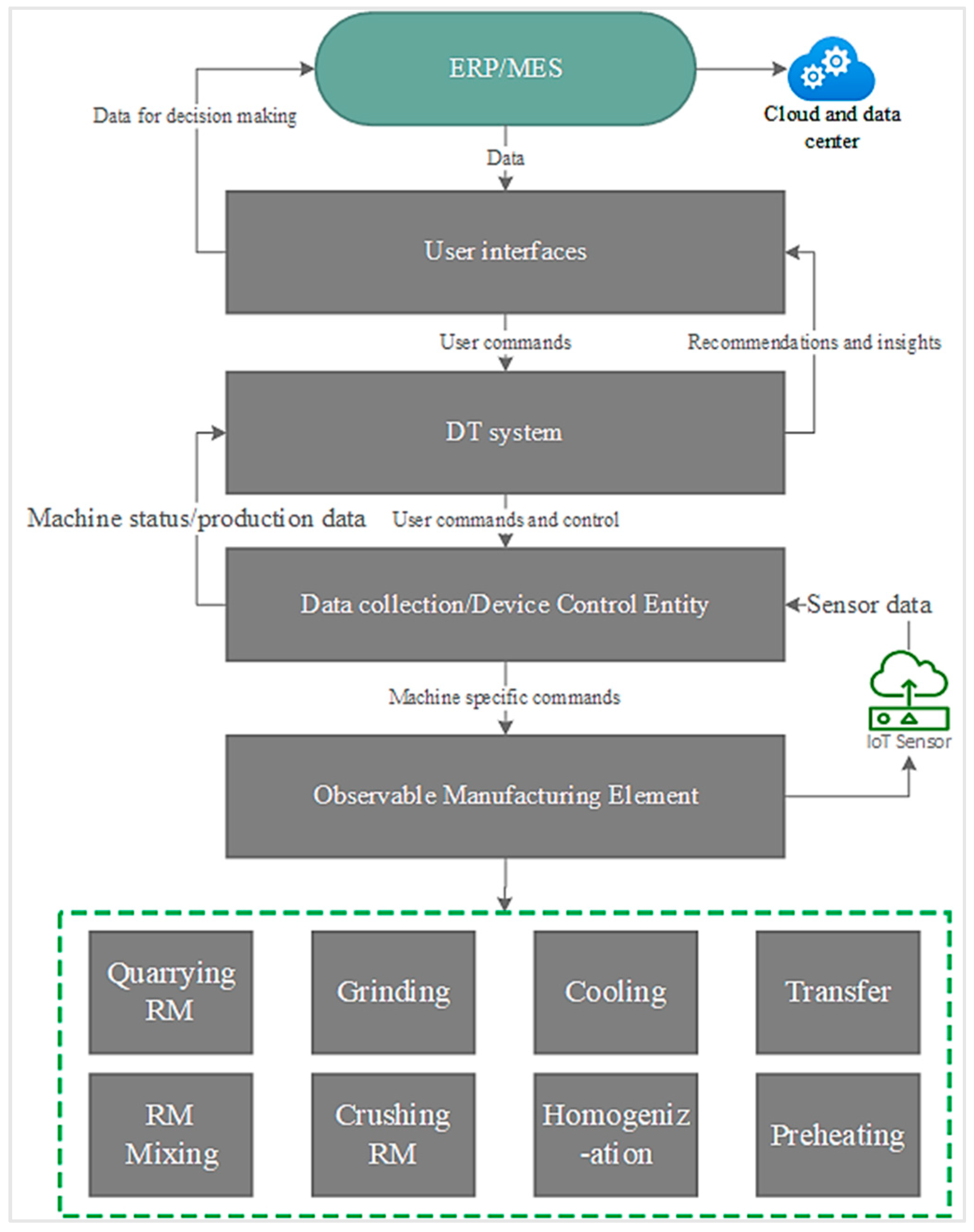

5.2. Case Study

- How many teams must be assembled? For example, the company may feel compelled to create a digital team and invest in their training.

- What are the major DT trends impacting the industry?

- How should the company position itself in the market relative to its rivals when it comes to DT technological progress?

- What policies are needed? Such policies authorize the digital teams to make decisions on behalf of the organization.

- What are the most important goals of using DTs in the company’s unique case (e.g., to make cost-effective use of technology, to improve productivity, to cut labor costs, etc.).

- How is the company’s structure likely to evolve to meet DT standards?

- Can the organization leverage their infrastructure to deploy DT?

- How is the company using their resources?

- What are the possible advantages of using I4.0 technologies, and what are the best DT technologies that suit the organization?

- After implementing the DT project, can the people, customers, and other interested parties absorb the changes and realize the value?

- Is there any resistance to change?

- What goes wrong during the DT implementation process?

- What are the benefits gained from the implementation? Any improvements in the KPIs should be stated.

- Are there any issues or obstacles that prevent the implementation?

6. Conclusions

6.1. Outcomes

6.2. Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rojko, A. Industry 4.0 Concept: Background and Overview. Int. J. Interact. Mob. Technol. 2017, 11, 77–90. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Critical factors for the successful implementation of Industry 4.0: A review and future research direction. Prod. Plan. Control. 2020, 31, 799–815. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W. Ten Years of Industrie 4.0. Sci 2022, 4, 26. [Google Scholar] [CrossRef]

- Sanders, A.; K. Subramanian, K.R.; Redlich, T.; Wulfsberg, J.P. Industry 4.0 and Lean Management—Synergy or Contradiction? In Advances in Production Management Systems The Path to Intelligent, Collaborative and Sustainable Manufacturing, Proceedings of the IFIP WG 5.7 International Conference, APMS 2017, Hamburg, Germany, 3–7 September 2017; Springer: Berlin/Heidelberg, Germany, 2011; p. 341. [Google Scholar] [CrossRef]

- Bongomin, O.; Yemane, A.; Kembabazi, B.; Malanda, C.; Chikonkolo Mwape, M.; Sheron Mpofu, N.; Tigalana, D. Industry 4.0 Disruption and Its Neologisms in Major Industrial Sectors: A State of the Art. J. Eng. 2020, 2020, 8090521. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Sishi, M.; Telukdarie, A. Implementation of Industry 4.0 technologies in the mining industry—A case study. Int. J. Min. Miner. Eng. 2020, 11, 1–22. [Google Scholar] [CrossRef]

- Ghobaei-Arani, M.; Shahidinejad, A. A cost-efficient IoT service placement approach using whale optimization algorithm in fog computing environment. Expert Syst. Appl. 2022, 200, 117012. [Google Scholar] [CrossRef]

- Com, W.A.; Oberer, B.; Erkollar, A. Age Happens. Int. J. Organ. Leadersh. 2018, 7, 404. [Google Scholar] [CrossRef]

- Gajek, A.; Fabiano, B.; Laurent, A.; Jensen, N. Process safety education of future employee 4.0 in Industry 4.0. J. Loss Prev. Process Ind. 2022, 75, 104691. [Google Scholar] [CrossRef]

- Swanson, D.J.; Creed, A.S. Sharpening the Focus of Force Field Analysis. J. Chang. Manag. 2014, 14, 28–47. [Google Scholar] [CrossRef]

- Nograšek, J.; Vintar, M. Technology as the Key Driver of Organizational Transformation in the eGovernment Period: Towards a New Formal Framework. In Electronic Government, Proceedings of the 10th IFIP WG 8.5 International Conference, EGOV 2011, Delft, The Netherlands, 28 Augus–2 September 2011; Springer: Berlin/Heidelberg, Germany, 2011; pp. 453–464. [Google Scholar] [CrossRef]

- Serrat, O. Synergizing the Competing Values Framework and the Six-Box Model. In Leading Solutions; Springer: Singapore, 2021; pp. 173–180. [Google Scholar]

- Kim, S. Strategic orientation, innovation, and the effects of entrepreneurial support mechanism in SMEs in South Korea: An application of subject-mechanism-performance congruence model. Asia Pac. Bus. Rev. 2022, 1–27. [Google Scholar] [CrossRef]

- Cox, A.M.; Pinfield, S.; Rutter, S. Extending McKinsey’s 7S model to understand strategic alignment in academic libraries. Libr. Manag. 2019, 40, 313–326. [Google Scholar] [CrossRef]

- Galbraith, S. Galbraith, Jay R.: Master of organization design–recognizing patterns from living, breathing organizations. In The Palgrave Handbook of Organizational Change Thinkers; Springer: Cham, Switzerland, 2021; pp. 631–650. [Google Scholar]

- Winter, P. Using a High-Performance Planning Model to Increase Levels of Functional Effectiveness Within Professional Development. J. Nurses Prof. Dev. 2016, 32, 33–40. [Google Scholar] [CrossRef] [PubMed]

- Al, A.P.D.H.T. Diagnosis of organizational capabilities according to the (Falletta) Model Survey study at the University of Mosul. Tikrit J. Adm. Econ. Sci. 2021, 17, 395–414. [Google Scholar]

- Steinlechner, M.; Schumacher, A.; Fuchs, B.; Reichsthaler, L.; Schlund, S. A maturity model to assess digital employee competencies in industrial enterprises. Procedia CIRP 2021, 104, 1185–1190. [Google Scholar] [CrossRef]

- Hajoary, P.K.; MA, A.; Garza-Reyes, J.A. Industry 4.0 maturity assessment: A multi-dimensional indicator approach. Int. J. Product. Perform. Manag. 2023; ahead-of-print. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Isniah, S.; Purba, H.H.; Debora, F. Plan do check action (PDCA) method: Literature review and research issues. Jurnal Sistem dan Manajemen Industri 2020, 4, 72–81. [Google Scholar] [CrossRef]

- Hasan, Z.; Hossain, M.S. Improvement of effectiveness by applying PDCA cycle or kaizen: An experimental study on engineering students. J. Sci. Res. 2018, 10, 159–173. [Google Scholar] [CrossRef]

- Investment Opportunity Scorecard. Available online: https://www.investsaudi.sa/en/sectors-opportunities (accessed on 12 June 2023).

- Cement Production and Sales | King Abdullah Petroleum Studies and Research Center. Available online: https://datasource.kapsarc.org/explore/dataset/cement-production-and-sales/information// (accessed on 19 May 2022).

- Seshadri, S.; Kandasamy, J.; Rajendran, M. Implementation of Digital Solutions in Cement Process and Plants. In Intelligent and Sustainable Cement Production; CRC Press: Boca Raton, FL, USA, 2021; pp. 347–403. [Google Scholar]

- Dembla, A.; Mersmann, M. Data-Driven Thermal Energy Management Including Alternative Fuels and Raw Materials Use for Sustainable Cement Manufacturing. In Intelligent and Sustainable Cement Production; CRC Press: Boca Raton, FL, USA, 2021; pp. 141–197. [Google Scholar]

- Gupta, S.; Subudhi, S.; Nicorici, I. Why Cement Producers Need to Embrace Industry 4.0. Published by Boston Consulting. Available online: https://www.bcg.com/publications/2018/why-cement-producers-need-embrace-industry-4 (accessed on 18 May 2021).

- Bhattacharya, S.; Saha, J. High level automation to achieve improved productivity, energy efficiency and consistent cement quality. In Proceedings of the 2015 IEEE-IAS/PCA Cement Industry Conference (IAS/PCA CIC), Toronto, ON, Canada, 26–30 April 2015; pp. 1–7. [Google Scholar]

- Bischof, P.; Mata-Falcon, J.; Kaufmann, W. Fostering innovative and sustainable mass-market construction using digital fabrication with concrete. Cem. Concr. Res. 2022, 161, 106948. [Google Scholar] [CrossRef]

- Gamil, Y.; Cwirzen, A. Digital Transformation of Concrete Technology—A Review. Front. Built Environ. 2022, 8, 835236. [Google Scholar] [CrossRef]

- Amrina, E.; Vilsi, A.L. Key Performance Indicators for Sustainable Manufacturing Evaluation in Cement Industry. Procedia CIRP 2015, 26, 19–23. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Stafford, F.N.; Dias, A.C.; Arroja, L.; Labrincha, J.A.; Hotza, D. Life cycle assessment of the production of Portland cement: A Southern Europe case study. J. Clean. Prod. 2016, 126, 159–165. [Google Scholar] [CrossRef]

- Gao, T.; Shen, L.; Shen, M.; Liu, L.; Chen, F. Analysis of material flow and consumption in cement production process. J. Clean. Prod. 2016, 112, 553–565. [Google Scholar] [CrossRef]

- ISO 23247-1:2021; Automation Systems and Integration—Digital Twin Framework for Manufacturing—Part 1: Overview and General Principles. Technical Report. ISO: Geneva, Switzerland, 2021. Available online: https://www.iso.org/standard/75066.html (accessed on 19 May 2023).

- Sjödin, D.R.; Parida, V.; Leksell, M.; Petrovic, A. Smart Factory Implementation and Process Innovation: A Preliminary Maturity Model for Leveraging Digitalization in Manufacturing Moving to smart factories presents specific challenges that can be addressed through a structured approach focused on people, processes, and technologies. Res.-Technol. Manag. 2018, 61, 22–31. [Google Scholar]

- Zeller, V.; Hocken, C.; Stich, V. Acatech Industrie 4.0 maturity index—A multidimensional maturity model, Advances in Production Management Systems. In Advances in Production Management Systems. Smart Manufacturing for Industry 4.0, Proceedings of the IFIP WG 5.7 International Conference, APMS 2018, Seoul, Republic of Korea, 26–30 August 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 105–113. [Google Scholar]

- Asdecker, B.; Felch, V. Development of an Industry 4.0 maturity model for the delivery process in supply chains. J. Model. Manag. 2018, 13, 840–883. [Google Scholar] [CrossRef]

| Model | Focus and Main Dimensions |

|---|---|

| Leavitt’s Model | Strategic tool used to understand what is needed for change in both corporate and personal environments. Considers the driving forces and the restraining forces as a source of management challenge [11]. |

| Weisbord’s Six-Box Model | According to this model, the success factors required for a successful transformation are structure, tasks, people, and technology [12]. |

| Nadler and Tushman’s Congruence Model | This model has an important diagnosis step, which is determining the “gap” current organization status and what it ought to be. Its main dimensions are: purposes, structure, rewards, leadership, helpful mechanisms, and relationships [13]. |

| McKinsey 7S Framework | According to this model, an organization will only be successful if these components work and align with each other: culture, work, people, and structure [14]. |

| Galbraith’s Star Model | The model is to depict how effectiveness can be achieved in an organization through the interactions of seven key elements—structure, strategy, skill, system, shared values, style, and staff [15]. |

| Nelson and Burns’ High-Performance Programming | This model includes five design policies as follows: strategy, structure, and processes, which have to do with the flow of information; rewards and reward systems, which influence the motivation of people to perform and address organizational goals; and lastly, people [16]. |

| Falletta’s Organizational Intelligence Model | This model offers the organization an assessment tool to determine the kind of an organization at four levels: reactive, responsive, proactive, and high-performing [17]. |

| Leavitt’s Model | This is an open systems model depicting 11 variables or factors: environmental inputs; leadership; strategy; culture; structure and decision rights; information and technology; direct manager; measures and rewards; growth and development; employee engagement; and performance outputs [18]. |

| No | Company | Headcount |

|---|---|---|

| 1 | A | 1670 |

| 2 | B | 800 |

| 3 | C | 686 |

| 4 | D | 268 |

| 5 | E | 910 |

| 6 | F | 650 |

| 7 | G | 123 |

| 8 | H | 208 |

| 9 | I | 550 |

| 10 | J | 758 |

| 11 | K | 520 |

| 13 | L | 361 |

| 14 | M | 498 |

| 15 | N | 95 |

| 16 | O | 123 |

| 17 | P | 410 |

| Frequency (%) | |

|---|---|

| Job functions | |

| Management | 3.5 |

| Finance | 6.29 |

| Engineering | 18.6 |

| Operations | 15.01 |

| IT | 25.07 |

| Other | 31.53 |

| Gander | |

| Male | 80.05 |

| Female | 19.95 |

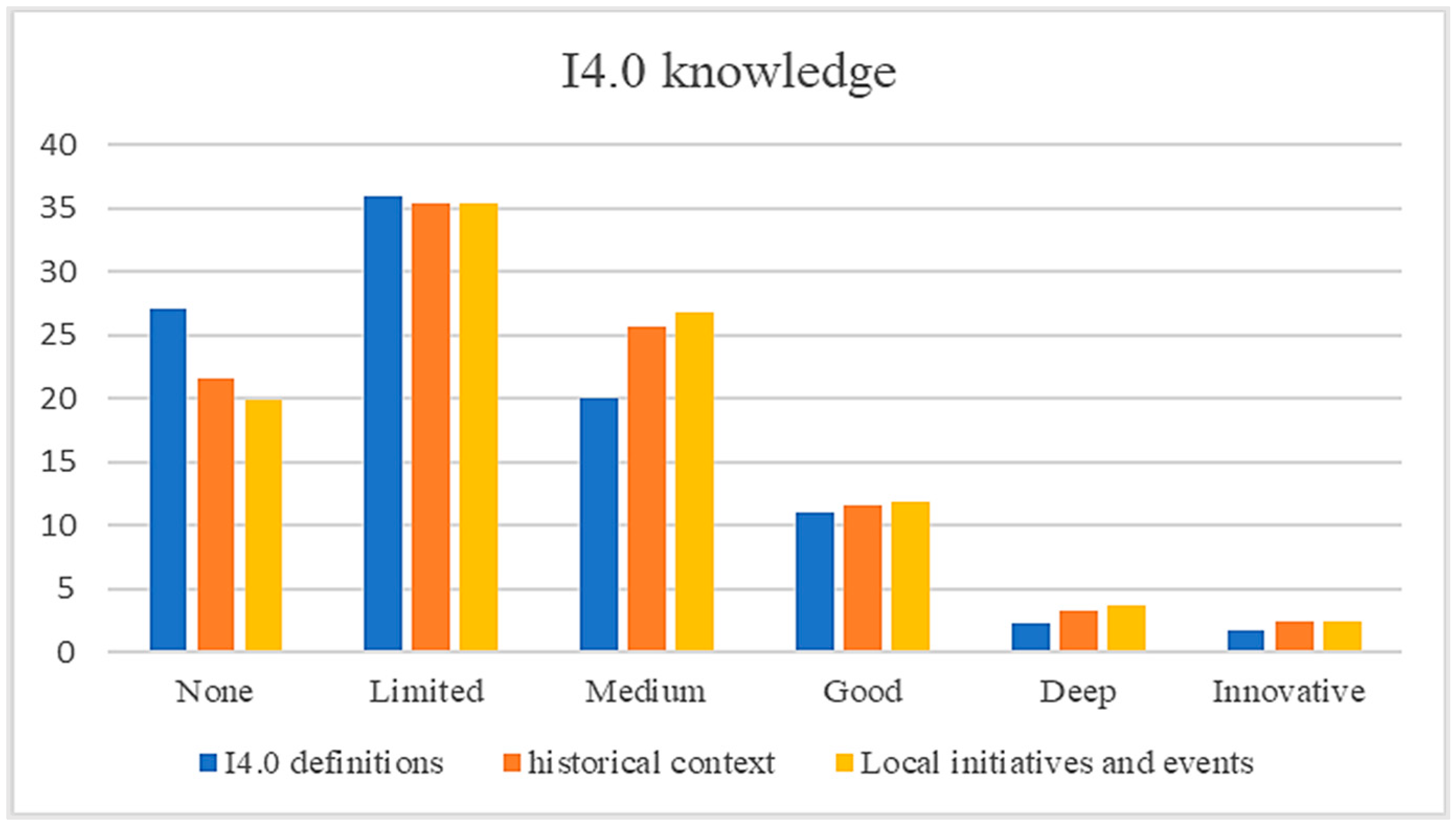

| I4.0 Knowledge Items | Average | Mode | Rank |

|---|---|---|---|

| I4.0 definitions | 1.34 | 1 | 3 |

| I4.0 historical context | 1.48 | 1 | 2 |

| I4.0 events | 1.51 | 1 | 1 |

| I4.0 Skill Items | Average | Mode | Rank |

|---|---|---|---|

| System thinking | 1.72 | 2 | 4 |

| Data analytics | 2.04 | 2 | 3 |

| Operatorial excellence | 2.56 | 3 | 2 |

| Programing | 1.29 | 1 | 5 |

| Cybersecurity | 1.06 | 1 | 7 |

| Simulation (VR and AR) | 1.01 | 1 | 8 |

| Robotics | 3.01 | 3 | 1 |

| Additive manufacturing | 1.10 | 1 | 6 |

| Impact Scope | None | Basic | High | |||

|---|---|---|---|---|---|---|

| Frequency(%) | Count | Frequency(%) | Count | Frequency(%) | Count | |

| Labor substitution | 30.8 | 134 | 51.3 | 80 | 17.9 | 47 |

| Gander parity | 15.4 | 159 | 61 | 40 | 23.6 | 62 |

| Localization | 46.2 | 74 | 28.2 | 121 | 25.6 | 67 |

| Nature of work | 43.6 | 88 | 33.8 | 114 | 22.6 | 59 |

| Companies’ growth | 25.6 | 116 | 44.6 | 67 | 29.8 | 78 |

| Organizational charts | 28.2 | 118 | 45.1 | 74 | 26.7 | 70 |

| Plan | I4.0 Maturity Evaluation Items |

|---|---|

| D1 | Level (1): requirements that may arise due to I4.0 are not specified; I4.0’s major trends are not analyzed. Level (2): I4.0 context studies have been started; market analysis in terms of I4.0 is initiated. Level (3): the organization knows its place in the market in the I4.0 race. Level (4): processes have been aligned with I4.0 technologies; new I4.0 opportunities are being identified. Level (5): dynamic process to study internal and external I4.0 issues. |

| D2 | Level (1): no investments towards I4.0 projects; little buy-in from top management to I4.0 strategies. Level (2): a value proposition of digital strategies is starting to be acknowledged. Level (3): an I4.0 strategy is formulated; funds are allocated; and business model change plans are in place. Level (4): the I4.0 digital strategy is integrated into all of the organization’s strategic objectives. Level (5): the I4.0 digital strategy is embedded in the organizational vision and mission. |

| D3 | Level (1): there is little or no appetite from leaders to adopt I4.0. Level (2): there is on–off collaboration within different departments regarding I4.0 implementation. Level (3): leaders understand the opportunities in I4.0; I4.0 initiatives are being introduced. Level (4): leaders involve team members in I4.0 training projects and provide support. Level (5): leaders understand and fully embrace I4.0 projects. |

| D4 | Level (1): there is a bottom-up drive by staff to embrace a digital culture; there is resistance to change. Level (2): a small number of staff are engaged in I4.0 projects. Level (3): the staff understand the benefits and opportunities, and can introduce creative ideas for I4.0. Level (4): the staff fully embrace the digital strategy and are driving cultural change. Level (5): the staff are digitally savvy and aware of how to utilize I4.0 technologies proactively. |

| Do | I4.0 Maturity Evaluation Items |

|---|---|

| D5 | Level (1): there is no integration of any I4.0 technologies or solutions; legacy systems are still used. Level (2): I4.0 technologies are starting to be utilized. Level (3): the infrastructure for deployment is ready. Level (4): I4.0 technologies are operated and fully integrated within the organization. Level (5): there is full implementation. |

| D6 | Level (1): there is no change in the organizational structure according to I4.0 integration and no I4.0-related roles. Level (2): there is some cross-organization awareness of digital opportunities. Level (3): the digital team is embedded in the organizational structure; the nature and methods of work are changed. Level (4): new types of jobs emerge from the organization. Level (5): the structure is fully oriented around I4.0. |

| D7 | Level (1): no training plans regarding I4.0 are initiated. Level (2): there are I4.0 training initiatives. Level (3): there are training opportunities and projects. Level (4): the staff is constantly being developed. Level (5): I4.0 is in alignment with the core business portfolio for any growth and development programs. |

| Check | I4.0 Maturity Evaluation Items |

|---|---|

| D8 | Level (1): there is minimal knowledge and awareness towards I4.0, and no engagement with interested parties. Level (2): customer engagement solutions have been introduced. Level (3): the staff are qualified and can lead I4.0 projects; there is proactive engagement. Level (4): the organization is service-oriented; the staff are experts. Level (5): all interested parties outside and within the organization can always be connected. |

| D9 | Level (1): there is no realization of I4.0’s benefits to KPIs. Level (2): the potential I4.0 benefits to KPIs are acknowledged. Level (3): the digital team is embedded in the organizational structure; the nature and methods of work are changed. Level (4): KPIs can be advanced with I4.0 implementation. Level (5): the organization can generate innovative solutions to advance KPIs. |

| Model | Focus and Main Dimensions |

|---|---|

| The proposed model | Includes nine dimensions as follows: environmental inputs, strategy, leadership, growth, infrastructure, culture, engagement, and outputs. Embedded with a PDCA iterative cycle. |

| Smart Factory Implementation and Process Innovation [37] | Includes four maturity levels with three organizational dimensions: people, process, and technology. |

| Acatech Industry 4.0 Maturity Index [38] | Includes six levels of maturity with structure, culture, information systems, and resources-related dimensions. |

| Development of an Industry 4.0 maturity model for the delivery process in supply chains [39] | Includes five stages of maturity that focus on supply chain aspects of the organizations. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahnashi, I.; Salah, B.; Ragab, A.E. Industry 4.0 Framework Based on Organizational Diagnostics and Plan–Do–Check–Act Cycle for the Saudi Arabian Cement Sector. Sustainability 2023, 15, 11261. https://doi.org/10.3390/su151411261

Mahnashi I, Salah B, Ragab AE. Industry 4.0 Framework Based on Organizational Diagnostics and Plan–Do–Check–Act Cycle for the Saudi Arabian Cement Sector. Sustainability. 2023; 15(14):11261. https://doi.org/10.3390/su151411261

Chicago/Turabian StyleMahnashi, Ibrahim, Bashir Salah, and Adham E. Ragab. 2023. "Industry 4.0 Framework Based on Organizational Diagnostics and Plan–Do–Check–Act Cycle for the Saudi Arabian Cement Sector" Sustainability 15, no. 14: 11261. https://doi.org/10.3390/su151411261

APA StyleMahnashi, I., Salah, B., & Ragab, A. E. (2023). Industry 4.0 Framework Based on Organizational Diagnostics and Plan–Do–Check–Act Cycle for the Saudi Arabian Cement Sector. Sustainability, 15(14), 11261. https://doi.org/10.3390/su151411261