Abstract

Energy harvesting has been identified as a key enabling technology for the Internet of Things as it allows a battery-less functioning of electronic devices. While the use of ambient sources of energy is commonly seen as sustainable due to their renewable nature, raw material consumption and recyclability need to be assessed to ensure true sustainability. This is especially relevant in electronics, due to their high complexity stemming from the variety of components and materials in their composition. This work presents the case study of the application of the 12 Principles of Green Engineering to an energy-harvesting platform in the early technology development phase. Specifically, the technological areas of design for disassembly, materials for substitution, fabrication efficiency, and manufacturing processes that enable the use of recycled materials have been evaluated. This has allowed us to identify hazardous raw materials and recommend their substitution. Further recommendations include the adoption of mechanical fixtures to fasten lump components. Additional strategies have been identified but their application has been found out of reach of the technology developers, such as the increase in the manufacturing batch size or the inclusion of solvent recycling, which can only be implemented at larger manufacturing scales. Further strategies, such as the use of recycled Si wafers or dry adhesives as fixtures, represent future solutions for the reduction in the environmental impact which require further R&D efforts from different disciplines. This highlights the need for holistic and multidisciplinary research efforts to fully achieve the circular design.

1. Introduction

The Internet of Things (IoT) is one of the bases of the fourth Industrial Revolution [1], a trend towards automatization and data exchange aimed at increasing operational efficiency. This scenario requires a huge network of connected physical objects (“things”) through the internet. Through remote accessibility and automatization, repeatability and increased efficiency of task performance are achieved [2,3,4,5].

The need for regular battery replacement is hindering the market penetration of many IoT devices by making it economically unviable, unappealing to potential customers, or simply impracticable to undertake battery replacement or recharge due to logistics.

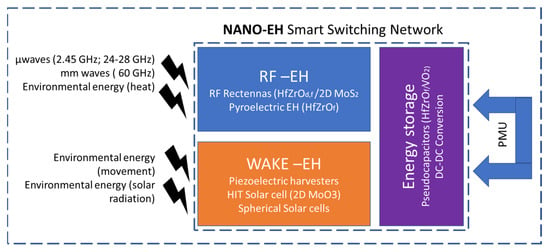

The need for battery-free ultralow-power devices, possibly wearable or implantable, is increasing dramatically in applications such as medical [6,7] and environmental [8] monitoring, industrial automation [9], wireless sensor networks [10,11], intelligent transportation systems [12], and infrastructure monitoring [13,14], among others. Thus, energy harvesting has been identified as a key enabling technology for the green Internet of Things [15]. It could lead to a lower CO2 footprint of future IoT devices by adopting environmentally friendly materials and reducing cabling and battery usage [15]. In this direction, the EU-funded project NANO-EH (Nanomaterials Enabling Smart Energy Harvesting For Next-Generation Internet-Of-Things [16]) has the objective of developing a multi-source energy harvester technological platform by translating forefront knowledge in novel smart nanomaterials such as HfZrO, 2D MoS2, and VO2(B) and their nanomaterial structures into advanced engineering that enables efficient manufacturing processes. The platform integrates radiofrequency energy harvesting at micro- and millimeter waves, piezoelectric energy harvesting, and light harvesting, together with energy storage capabilities through integrated pseudo and supercapacitors. Some of the scientific outcomes on the nanomaterials under study have been published elsewhere [17,18,19,20,21,22,23]. While energy harvesting from ambient sources is renewable and, thus, commonly seen as sustainable, the Paris Agreement [24] and the Sustainable Development Goals [25] broaden the meaning of sustainable energy to resource efficiency, bringing recyclability and the innocuity of materials into play. Indeed, as the first generation of renewable energy infrastructure is reaching its end-of-life phase, their sustainability is being questioned based on their raw material consumption and difficult recyclability or material recovery plans [26,27,28].

Raw material consumption and low or complex recyclability are particularly relevant for electronic devices such as energy harvesters, stemming from the variety of components and materials in their composition and accelerated growth of their waste [29,30].

Indeed, electronic waste is currently the world’s fastest-growing waste stream. The UN Global E-waste Monitor 2020 [31] reports that e-waste (excluding PV waste) reached 53.6 million metric tonnes (Mt) in 2019. The global generation of e-waste will almost double in 16 years, with a growth projection to 74.7 Mt by 2030 [31]. Europe is the continent with the highest documented e-waste collection and recycling rate at 42.5% [31]. Worldwide, collection and recycling sinks to 17.4% of the generated e-waste, and the fate of the remaining 82.6% (44.3 Mt) is uncertain [31].

Discarded electronic and electrical equipment may contain potentially harmful materials that pollute the environment and pose a health and safety hazard for people involved in their informal recycling. These can include phosphor coatings, lead, polychlorinated biphenyls, mercury, and halogenated flame retardants (typically bromine) in plastics [32]. This has triggered EU legislation restricting the use of hazardous substances in electrical and electronic equipment and, in particular, lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls (PBB), and polybrominated diphenyl ethers (PBDE), bis(2-ethylhexyl) phthalate (DEHP), butyl benzyl phthalate (BBP), dibutyl phthalate (DBP), and diisobutyl phthalate (DIBP) [33,34].

Human rights respect is another subject of concern concerning the sourcing of raw materials used in electronics manufacturing, including conflict metals tin, tantalum, tungsten, and gold [35], and EU regulation requires background checks of suppliers [36].

Further, risk of supply is present for a growing number of raw materials used in electronics. The 2020 EU Critical Raw Materials List [37] includes magnesium, germanium, borates, cobalt, natural graphite, vanadium, tungsten, titanium, gallium, silicon metal, and hafnium.

The large amounts of generated e-waste coupled with resource scarcity highlight the need for the adoption of a circular economy approach in the development of electronics and energy-generation devices.

Circular design and the circular economy (CE) are somewhat fluid concepts. A recent paper reviewed 221 definitions of the circular economy in order to assess the consolidation of the concept [38]. It reports that 70–80% of articles recognize “reuse” and “recycle” as the two fundamental principles of CE, and 40% of the definitions mention value maintenance and resource efficiency as an aim of the CE. Despite the variety of interpretation and implementation approaches to the CE, the underlying concepts are not new. It is acknowledged that the schools of thought feeding into the concept include [39] cradle to cradle [40], industrial ecology [41], biomimicry [42], laws of ecology [43], the performance economy [44], regenerative design [45], permaculture [45], natural capitalism [46], and industrial metabolism [47].

The recent literature on circular design focuses on business models [48,49,50] or methods to support or measure circularity [51,52,53,54]. Reports on technical strategies for product development are scarcer [55]. This has been captured in the circular economy conceptualization work by Kirchherr et al., who coded “business models” and “consumers” as circular economy enablers in 2017 [56], whereas they included “technology and innovation” as enablers in their 2023 revision [38]. Thus, technology development fulfilling circular design is still in its infancy. In this paper, the technology developer’s point of view is taken, who undertakes material and manufacturing technique choices or explores replacement possibilities and is confronted with technical barriers and limitations when seeking circular design. It is widely acknowledged that the early development stage is critical for the environmental impact and consequences of technology [57,58,59]. Therefore, recyclability and circular design must be considered from the early technology development phase.

Cradle-to-cradle design methodology is concerned with the design and development of products and processes and, hence, suitable to the technology development at hand. It antagonizes with current recycling in that it starts from the beginning (design for recycling), rather than the current end-of-pipe approach (what to do with waste) [40]. Cradle to cradle sets a vision for product designers towards “what do I do” [60] yet lacks concretion as academic research methodology. Concretion towards “How do I do it?” can be obtained with the 12 Principles of Green Engineering [60]. Thus, these principles [61] are selected in this work as circular design methodology through which the NANO-EH energy-harvesting platform will be benchmarked.

The 12 Principles of Green Engineering are a guideline for scientists and engineers aiming to design new materials, products, processes, and systems that are friendly to human health and the environment [61]. They are conceived for extensive applicability, from the construction of chemical compounds to urban architecture [61]. Some examples include “designers need to strive to ensure that all material and energy inputs and outputs are as inherently nonhazardous as possible” (Principle 1) or “multicomponent products should strive for material unification to promote disassembly and value retention” (Principle 9).

This paper presents a case study on the systematic application of the 12 Principles of Green Engineering [61] to the design of an energy-harvesting platform, currently in technology readiness level (TRL) 1–3, in order to obtain recommendations that improve the sustainability and circularity of the design. While energy-harvesting technologies are a vibrant area of research, a literature search combining energy harvesting + circular design, energy harvesting + green engineering, and energy harvesting + cradle to cradle on Google Scholar provided no meaningful results. The search term “recyclable energy harvester” provided some examples where this aspect has been taken into account. Xu et al. [62] report the development of triboelectric nanogenerators using polyvinyl alcohol (PVA) hydrogel as substrate material. The developed energy harvester is labeled as “environmentally friendly” and “recyclable” based on the biodegradability of the PVA hydrogel. However, aspects including raw material health and safety, manufacturing efficiency, disassembly of the different components and material layers, or the definition of “environmentally friendly” are not covered in the work. Ren et al. [63] report a thermoelectric generator based on modular thermoelectric chips, liquid metal as electrical wiring, and dynamic covalent thermoset polyimine as both the substrate and encapsulation for liquid–metal wiring. This design includes different aspects which fit into the selected definition and methodology for circular design (12 Principles of Green Engineering), such as recyclability, modularity, and disassembly. However, the consideration of other aspects such as raw material toxicity or manufacturing efficiency do not appear to be reported. Slabov et al. [64] present a review on “natural” and “eco-friendly” materials for triboelectric energy harvesting. The term “eco-friendly” is not defined. From the text it can be derived that it is considered as bio-based. The review reports advances in triboelectric energy harvesting with bio-based materials, though it acknowledges that, in all reported designs, polymers are used as substrates. The mixing of bio-based and non-bio-based materials in a product is seen as a design flaw towards recycling, as it prevents the biodegradation of the product given the non-bio components, as well as prevents the recycling of the technical materials given the biodegradable content [40]. Thus, to the best knowledge of the authors, a systematic analysis and benchmark of an energy harvester concerning its recyclability and circular design against a defined set of criteria, here selected as the 12 Principles of Green Engineering, has never been presented before. Through this systematic analysis, specific change recommendations for increased circularity will be proposed, which could be also applicable to other electronic devices. This constitutes the first objective of the paper. Further, it seeks to answer the general overreaching question: to what extent can a technology developer fully fulfill the 12 Principles of Green Engineering? This constitutes the second objective of the paper.

2. Materials and Methods

2.1. Description of the Object of Study and Main Materials

The object of study is the NANO-EH energy supply platform. The initial design has considered a general understanding for sustainability and recyclability, without a specific methodology for circular design. It consists of radiofrequency energy harvesters, an energy storage module based on pseudocapacitors, and a wake-up module. This last module aims at overcoming the technological barrier in RH harvesting of the minimum amount of power necessary to make the rectifying diode work efficiently in its nonlinear region to improve the RF-to-DC efficiency by “waking-up” the nonlinear circuitry of the RF harvesting module. The elements comprising each module are summarized in Table 1.

Table 1.

Description of the NANO-EH energy supply platform under study.

The concept is that these different modules will be monolithically integrated on the same Si platform. A schematic of the modules is represented in Figure 1.

Figure 1.

Conceptual schematic of the NANO-EH energy supply platform and included modules.

2.2. Methodology

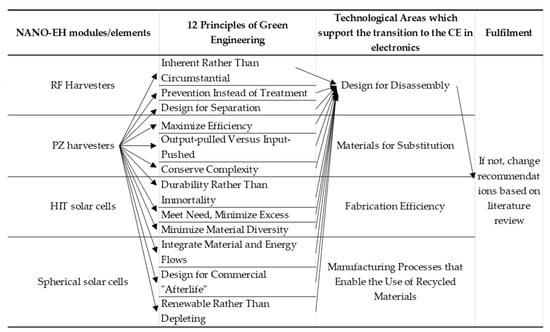

The 12 Principles of Green Engineering [61] will be used as a methodology through which all initially selected raw materials and manufacturing processes will be systematically revised. The nature of advanced electronics is reported to present a challenge in and of itself, since the increased complexity and associated material set required for high-performance product is associated with increased difficulty in its recycling [65]. Strategical R&D needs to transition the electronics sector to the circular economy based on the 12 Principles of Green Engineering have been the object of previous research [65]. Eight technological areas have been identified, as represented in Figure 2. Building on this previous research, in this work, we will focus on the technological areas of design for disassembly, materials for substitution, fabrication efficiency, and manufacturing processes that enable the use of recycled materials, which fall into the scope of the NANO-EH project.

Figure 2.

Technological areas which would support the transition to the circular economy. Reprinted with permission from O’Connor et al. ACS Sustainable Chem. Eng. 2016, 4, 5879–5888 [65]. Copyright 2016 American Chemical Society.

Fulfillment of the 12 Principles of Green Engineering for the mentioned four technological areas and each of the NANO-EH modules will be systematically analyzed. In case of noncompliance, change recommendations will be proposed based on a literature search using Google Scholar and Google Patents as search engines. A schematic representation of the data flow is presented in Figure 3.

Figure 3.

Schematic representation of the data flow in the analysis. For ease of visualization, arrows are drawn for one node only, but the same process is repeated for each node. The full definition of each of the Principles of Green Engineering can be found in Appendix A.

Data collection, screening, and sorting were conducted in the period 2022–2023.

3. Results and Discussion

The results obtained from the analysis of each of the modules is presented below, classified by each of the evaluated technological areas.

3.1. Area of Design for Disassembly

Looking into the NANO-EH energy-harvesting platform, the basis of the concept is the monolithic integration on the same silicon (Si) substrate of the different components as the advanced engineered arrays of rectennas (based on HfZrOd/HfZrOf and 2D MoO3), pyroelectric energy harvesting (based on HfZrOf), and pseudocapacitors (based on HfZrOf). Thus, the concept is not based on the assembly of fully independent modules but on the multifunctional use of hafnium zirconium oxides on an individual platform.

From the recyclability perspective, the multifunctional device would be a single module and the multifunctional use of hafnium zirconium oxides eliminates the need for a higher variety of raw materials, in line with Green Engineering Principle 9 (minimization of material diversity). Therefore, no further module disassembly step is seen as required. Nevertheless, material layers are contained, including Si, Au, and the mentioned hafnium zirconium oxides, which will need separation to recover the elements. Recent reviews have covered the metal recovery processes and technologies from electronic waste [66,67,68], though none of them specifically covers the recovery of hafnium.

The NANO-EH platform still includes some components, such as diodes and surface-mounted devices. The current design involves their die-attach with silver-filled epoxy resins. Removing or decapsulating epoxy resins can be achieved through soaking in dichloromethane, warm sulfuric acid, n-methyl- pyrrolidone toluene, n-methyl-pyrrolidone, or methyl-ethyl-ketone [69]. Immersion in boiling water for an hour has been reported to be successful in most cases, depending on the exact epoxy and surface [69]. Heating above the glass transition temperature (Tg) of the epoxy and prying the components when the epoxy is soft is also reported for debonding, though epoxy residues will remain on the substrate and component. The Tg of epoxies is found between 50 and 250 °C, depending on the formulation [70]. Heating the unit above the degradation temperature of the epoxy (400 °C) would eliminate the bond by decomposition [69]. These techniques would be destructive to the electronic devices and a solution for end-of-life disassembly but would not allow for remanufacturing. Soldering would not be an option, since its removal is energy- and labor-intensive and the potential for metal loss during the treatment is reported as high [66].

For the purpose of nondestructive disassembly, the design of a mechanical clamping of the components would be recommended, which could include solutions such as loaded springs. Copper layers, as needed for the PZ harvester, can be used in the form of adhesive tape, which would allow easy separation from the substrate. An example of copper adhesive tape and a prototype of the PZ harvester can be seen in Figure 4.

Figure 4.

Left: copper adhesive tape. Mosborne01, CC BY-SA 3.0 https://creativecommons.org/licenses/by-sa/3.0, accessed on 5 June 2023, via Wikimedia Commons. Right: prototype of PZ harvester based on PHBV, where the copper layer can be seen. Development and photograph by Luna Geber Engineering, reproduced with permission.

A potential future alternative for allowing disassembly without residues is the use of dry adhesives, which represent a great example of biomimicry [42]. They mimic gecko feet, where the principles of attachment are based on intermolecular van der Waals forces of a surface characterized by arrays of structures. The use of dry adhesives in the area of semiconductors and electronics has been proposed for manufacturing assembly processes, such as the handling of silicon wafers and glass substrates [71] or in micro-masonry [72], but not for permanent die-attach. This would be a future option requiring R&D efforts. For more details on the general principles of gecko adhesion, the reader is referred to [73] and for a recent state-of-the-art review to [74].

3.2. Area of Materials for Substitution

For the assessment of this area, the raw materials inventory used for the manufacturing of the different energy-harvesting modules has been screened to identify further materials for which replacement would be recommended. Specifically, the selection of materials recommended for substitution is based on their toxicity classification by harmonized classification and labeling of the European Union, following Green Engineering Principle 1 (designers need to strive to ensure that all materials and energy inputs and outputs are as inherently nonhazardous as possible). Included in this list will be substances suspected of causing cancer, cancerogenic, and those with long-lasting toxic effects where initiatives for replacement have already been launched. Given the current low TRL, not all designs are final. For those where the evaluation of different candidates is ongoing, preferences according to the principles will be described. Additionally, criticality in terms of the security of supply and greenhouse potential will be considered. Economic sustainability is not covered in this work, though it should be highlighted that the use of hazardous chemicals and solvents also impacts the manufacturing costs by adding the requirement of additional air handling infrastructure, even making commercial deployment not economically feasible [75].

The identified candidates for replacement are listed and described below, module by module.

3.2.1. Piezoelectric Harvester

State-of-the-art piezoelectric materials are lead zirconate titanate (PZT) and polyvinylidene difluoride (PVDF). Given the toxicity of lead, the search for alternatives to PZT is a research line of the project, fully in line with the sustainability targets and the 12 Principles of Green Engineering (Principle 1). This is a great challenge, as no material has been identified that comprises all the functional properties of PZT required for the broad range of piezoelectric applications as of 2017 [76]. The initial focus has been placed on bio-based and biodegradable materials. As per circular design (cradle to cradle) [40], biodegradable materials are not preferable per se, as long as the chosen technical material is recyclable and nontoxic. Further, the mix of biomaterials and technical materials is discouraged, since the mixture cannot be composted and its recycling becomes more difficult. Thus, a thermoplastic polymer would be more favorable.

The commonly used polyvinylidene difluoride (PVDF) is a stable thermoplastic authorized for medical and food applications and, hence, is nontoxic and recyclable. The PVDF could be remolten and reprocessed at the end of the life of the piezoelectric harvester. Its pyrolysis or incineration, commonly used end-of-life (EoL) treatment for electronic waste [77], should be completely avoided due to the release of toxic hydrogen fluoride [78]. The low solubility of PVDF in common solvents [79] makes the mechanical separation of the PVDF from the other components of the PZ harvester the only sustainable recovery option.

For the use of biopolymers, as PHBV (Poly(3-hydroxybutyrate-co-3-hydroxyvalerate), its mixture with barium titanate (BT)- and/or potassium sodium niobate (KNN)-doped powders is investigated, so as to enhance the piezoelectric properties of the polymer matrix. BT is considered biocompatible and widely considered for tissue engineering applications and bone repair [76] and can be considered nontoxic. The considered synthesis route is the mechanochemical treatment of BaCO3 and TiO2. However, titanium oxide (TiO2) would be a candidate for replacement, as it has been classified as suspected of causing cancer [80] when the content of titanium dioxide particles with an aerodynamic diameter ≤ 10 μm is equal to or greater than 1% w/w [81]. Under this lens, KNN-doped powders appear preferable to BT-doped powders. However, an LCA and supply chain evaluation comparing PZT vs. KNN reports that KNN has a significantly greater environmental impact across the evaluated 16 categories, related to the raw material extraction and processing of niobium [82]. This highlights the need for careful and holistic evaluation of the environmental impacts and the decision challenges faced by technology developers. The use of TiO2 in the synthesis of BT could be circumvented through alternative synthesis routes, such as the preparation of a polymeric precursor with Ba and Ti ions and citric acid and ethylene glycol, followed by a heat treatment in air at 500–900 °C [83] or microwave calcination at 550–700 °C [84].

3.2.2. Spherical Solar Cells

The proposed design by NANOM is a Graetzel-type spherical solar cell [85], manufactured in glass. The advantages of this concept are that it collects and harvests sunlight three-dimensionally, the spherical shape offers good protection for the active layers, they have a simple structure, it is cheap and is suitable for mass production, and dust accumulation is greatly diminished compared with planar solar cells.

In Graetzel-type solar cells, light absorption is realized by a sensitizer, which is attached to the surface of a wide-band semiconductor. Charge separation takes place at the interface via photo-induced electron injection from the dye into the conduction band of the solid. Carriers are transported in the conduction band of the semiconductor to the charge collector. The semiconductor of choice is TiO2. As mentioned in the previous section, its classification as suspected of causing cancer [80] makes it a candidate for replacement based on the principle of precaution. Here, the TiO2 would be delivered as ink, and liquid mixtures containing titanium dioxide are not classified as suspected of causing cancer [81], though the risk may be shifted upstream to the ink manufacturer. Reported alternative wide-band-gap oxides include ZnO [86] and Nb2O5 [87,88]. The previously reported high environmental impact of the raw material extraction and processing of niobium [82] places ZnO as a better candidate from the environmental perspective. Further, it has been reported as a promising alternative to TiO2 because of the similar band structure and relatively high electron mobility (1–5 cm2 V−1 s−1) [89]. Additional replacement candidates are Zn2SNO4 and SnO2, though it is reported that the power conversion efficiencies of these mesoporous electrodes are still lower than that of TiO2 [90].

3.2.3. RF Harvesters

From the inventory of raw materials based on the design of the RF harvesters, the following candidates for replacement have been identified:

- Chlorobenzene: it is used in the metal deposition and patterning manufacturing stages. According to the harmonized classification and labeling (ATP09) approved by the European Union, this substance is toxic to aquatic life, with long-lasting effects [91]; therefore, it would be recommended to replace this solvent. Efforts to identify and replace chlorobenzene with other environmentally friendlier solvents are ongoing in different sectors [92], including semiconductor processing [93]. Larsen et al. [94] have developed a tool for the identification of green solvents for printed electronics. Based on this, more sustainable candidates for the replacement of chlorobenzene include ethoxybenzene, anisole, methyloleate, 2-ethylhexyl acetate, pentyl acetate, and n-Butyl acetate. The experimentally verified dissolution capacity, several relevant physical parameters, detailed category scores, the overall composite score, and the GHS hazard statements can be found in the mentioned reference. By crossing the parameters with the specific requirements for this application, the best candidate can be selected for the NANO-EH case.

- CHF3 is a potent greenhouse gas. A ton of CHF3 in the atmosphere has the same effect as 11,700 tons of carbon dioxide [95]; therefore, it is recommended to substitute it with an inert gas.

The energy-harvesting platform design does not consider any rare earths as raw materials. However, it must be said that hafnium has been included in the 2020 critical raw materials list of the European Union [37]. Therefore, Hf should be used in closed loops only, with a take-back system and R&D efforts placed on the recovery of Hf from the Si substrate.

3.3. Area of Fabrication Efficiency

The currently used manufacturing technologies include atomic layer deposition (ALD), milling, spray coating, and spin coating, among others.

Spray coating is conducted inside the glass cell during the manufacturing of the spherical solar cells, with no raw material loss. The technology expert reports a linear scale-up between small- and larger-scale manufacturing. Therefore, this technique will not be analyzed further.

3.3.1. Atomic Layer Deposition (ALD)

ALD is used for the deposition of hafnium and zirconium oxide layers in the manufacturing of the RH harvesters, pseudocapacitors, and pyroelectric energy harvesters and the deposition of MoO3 in the manufacturing of the HIT solar cells and 60 GHz rectennas. The use of alkylamides of hafnium and zirconium as precursors for ALD of Hf and Zr thin films provided a breakthrough in the production of smooth, pure, and highly conformal films [96]. Compared to solid precursors, this provided further advantages that influence the environmental impact, including the simplification of the synthesis, purification, and handling of the precursors and the formation of less corrosive by-products in comparison to chloride precursors, as well as a significantly lower deposition temperature [96]. ALD allows for precise control of the layer thickness at the atomic level, providing high uniformity of the film growth, thus playing an important role in the miniaturization of nano-scale structures [97,98,99]. This places it as a favorable technology in terms of material efficiency. However, it is reported that precursors typically used in ALD operations are toxic, volatile, and highly reactive [99]. Other aspects, such as low material unitization efficiency (defined as the amount ratio of the materials deposited on the wafer over the total material input, as low as 12%) and significant energy consumption [99], would contribute negatively to its environmental impact.

The literature suggests two routes to reduce the environmental impact of the ALD technology: through improving the deposition efficiency and/or by increasing the batch size [99]. Considering the development of manufacturing technology is not in the scope of the project or the expertise of the project partners, an increase in the batch size could be seen as the most straightforward strategy for reducing the environmental impact. Upscaling involves some technical challenges, such as thickness variations due to macroscale flows inside the reactor, or challenges to purge it entirely.

3.3.2. Milling for Doped BT and KNN Powder Manufacturing

The manufacturing of doped BT and KNN powders considered mainly comprises mixing the raw materials together with a solvent, their milling, followed by a calcination step and further milling to obtain the reactive powder. Within the project, this is carried out in very small batches. For the upscaling to industrial-scale production, the obtention of reproducible powder morphology and microstructure and, consequently, reproducible piezoelectric performance at low production costs are reported as an open issue [100]. A different released cumulative kinetic energy resulting from different jar hindrance factors when upscaling may lead to different products [100]. The use of the planetary milling process vs. slow ball milling allows for reducing both the powder’s production time and calcination temperature, suggesting that mechano-chemical activation synthesis is a promising technology for efficient industrial scale-up [100].

3.3.3. Spin Coating

Spin coating is widely used for the deposition of thin films of photosensitive materials in electronics. The main advantages of this technique are its easy control of the film thickness, through variations in the spin speed and selection of a photoresist based on its viscosity, as well as the maturity of the technology [101]. However, its low material efficiency is an environmental hot spot. It is reported that only 2–5% of the dispensed material is effectively used, while the remaining 95–98% is wasted [101]. Recent interest in spin coating alternatives has emerged, though the motivation is rather related to the limitation on the cell size allowed by this technique [102] than raw material efficiency. Zheng et al. [102] report a blow-drying method as an alternative for spin coating in the manufacturing of perovskite solar cells [102]. Reported advantages include the saving of the antisolvent and sacrificial components, good quality of the layer, scalable process, and simplicity of the equipment. Lee et al. [103] propose brush painting for the roll-to-roll manufacturing of CH3 NH3PbI3/PCBM planar heterojunction perovskite solar cells. This technique presents low material losses, presenting a promising alternative.

3.4. Manufacturing Processes That Enable Recycled Materials

The larger amounts of raw materials required in NANO-EH are Si wafers, solvents, including acetone and isopropyl alcohol, and metals, including Al, Au, and Ag. Therefore, a literature search was undertaken to identify strategies and barriers for the use of these materials with recycled origin in the manufacturing of the NANO-EH devices.

3.4.1. Review on Potential and Barriers to the Use of Recycled Si

A literature search in Google Scholar using the terms “Si recycling” and “Si wafer recycling” was conducted in order to evaluate the availability and quality of recycled Si. The references found are related in all cases to the recovery or recycling from PV cells or PV modules.

Recent workers have focused on the recovery of the Si wafers from the solar cells, which would allow the reuse of the wafers avoiding the production of the Si ingot. It is reported that avoiding Si ingot production and wafer cutting could lead to approximately 40% of the cost savings of PV module production [104].

Huang et al. [105] present a method for the recycling and recovery of solar grade Si, Ag, Pb, Sn, and Cu from solar modules. The steps include mechanical removal of the Al frame and junction box, burning of the polymer sheets in a furnace, and removal of glass, which would be recycled. The strings of interconnected cells would be immersed in HNO3 to dissolve the Ag, Pb, Cu, and Sn, which would be recovered one by one through electrowinning. Then, the cells would be immersed in HF to remove the SiNx layer and Al back electrode and, finally, the emitter and back surface would be etched with NaOH to recover the Si. The authors have chosen the chemicals so that they can neutralize each other (NaOH and HNO3 resulting in NaNO3) or have well-established neutralization practices (precipitation of CaF2 by adding Ca(OH)2 to HF [106]) “for a minimum environmental impact”. However, an environmental impact assessment is not included in the paper. This method would recover all the glass, Al frame, junction box, 85–90% of the Si, and 90–95% of the metals, as well as energy recovery of the polymers. Shin et al. [107] propose a similar method for Si cell recovery but use an etching paste (Solartech, containing H3PO4) to remove the SiNx instead of HF, with the advantage placed on the avoidance of the special handling material required for HF due to its corrosive nature [108].

Xu et al. [104] propose the combination of cell recovery with wafer purification, so as to eliminate the conversion efficiency loss typically encountered when using recovered Si wafers. After the Si cell recovery and wafer pre-purification, a one-step ultra-purification and texturing step will take place using metal-assisted chemical etching.

Chen et al. [109] report a method to recover Si with a purity of 99.84% by removing impurities such as Al and Ag through a two-step leaching and dissolving of the impurities.

These works demonstrate the feasibility of using Si wafers of recycled or recovered origin in the manufacturing of the NANO-EH devices. However, none of the above-presented works report the environmental impacts of the proposed recovery processes, which obtain high purities but use significant amounts of chemicals. The LCAs of PV recycling found in the literature correspond to processes where a smaller number of raw materials are recovered or with lower purity.

Latunussa et al. [110] present an LCA of a PV recycling process from which metallurgical-grade silicon scrap can be obtained. The process involves disassembling the junction box, separating the glass, and incineration of the remaining, followed by subsequent acid leaching and electrolysis. In this work, for all the considered impact categories, the main contributions are related to the transport of the PV waste to the recycling site, the incineration processes, and the further metal recovery from the bottom ash. But metallurgical-grade silicon is not valid for microelectronics or solar applications and, hence, this recycled material flow is not valid for NANO-EH.

Despite the recent vibrant research activities on the recovery and recycling of solar-grade Si wafers, no supplier of recovered or recycled Si wafers was identified. The current state-of-the-art recycling (in terms of commercial deployment) of crystalline silicon PV modules involves the recovery of glass, aluminum, and copper, while the cells and other materials such as plastics are incinerated [111]. An LCA commissioned by the IEA revealed that the recovery of glass, aluminum, and copper from c-SI PV modules causes lower environmental impacts than the extraction, refinement, and supply of the respective materials from primary resources, hence providing a net environmental benefit of recycling [111], despite not recovering all materials. Thus, while no technical barrier has been identified which could prevent the use of recycled Si wafers in the future manufacturing of NANO-EH devices, this is not yet possible today. The reported barrier towards commercial deployment is reported to be the costs of recycling [112].

3.4.2. Review on Potential and Barriers to the Use of Recycled Metals

The manufacturing of the different energy-harvesting modules requires Au, Ag, Al, and Cu. Established recycling and recovery of these elements are in place, from electronics waste or from waste streams of other sectors. Thus, barriers towards the sourcing and use of these raw materials from recycled origins are not foreseen.

Since the use of Hf is one of the key breakthroughs of the project and is classified as a critical raw material [37], possibilities of sourcing recycled Hf were evaluated. No use of recycled hafnium has been found reported [67,113]. The contamination of Hf used in the nuclear industry, together with the low content in other super alloys, is reported as the probable reason for the very low end-of-life recycling rate [113].

3.4.3. Review of the Possibilities for Recycling Precursors and Solvents

The reuse and recycling of precursors and solvents could be an effective way of reducing the environmental impact of the manufacturing of NANO-EH devices and electronics in general. Previous studies have found that the amounts of organic solvent consumed during manufacturing can shift the preference when comparing the environmental impacts of different technologies [114].

The search for scientific literature on precursors and solvent recycling was found to be scarce. But some methods for the recycling of different relevant solvents have been found as patents.

Briend et al. [115] present a method for the recycling of silane from and for the deposition of thin Si films. The method recovers 80% of the excess silane injected in the reaction chamber for direct reuse in the same deposition process. The method comprises four consecutive steps, namely (a) the injection of pure silane/pure hydrogen mixture into the reaction chamber for the Si deposition, (b) the extraction of the excess gas mixture (SiH4/H2) from the chamber by pumping a purge gas (N2), and (c) the separation of the SiH4 from the SiH4/H2/N2 mixture.

Ref. [116] discloses a method to recover with high purity the organic solvent used to remove excess photoresist in the manufacturing of semiconductors, in particular, of propylene glycol monomethyl ether acetate (PGMEA). The first step is to separate the photoresist component from the waste liquid by adding an alkali aqueous solution and undertaking an optimized distillation process where the photoresist, metal ions, and fine particles contained in the waste liquid are removed.

These examples highlight how on-site solvent recycling can be integrated into the manufacturing process but, also, that it is only feasible at commercial manufacturing scales. It must be stressed that, while it appears not to be technoeconomically feasible to include solvent recycling in the research and pilot manufacturing scale, commercial manufacturing without solvent recycling may not be technoeconomically feasible either. Solvent disposal has been identified as a major contributor to CapEx in electronics manufacturing [117]. A recent study reports a vendor price reduction of 45% when introducing 50% solvent recycling and of 67% when introducing 90% solvent recycling in the manufacturing of Perovskite quantum Dots PV [117].

3.5. Overreaching Question: To What Extent Can a Technology Developer Fully Fulfill the 12 Principles of Green Engineering?

Having analyzed the fulfillment of the 12 Principles of Green Engineering and proposed recommendations for improvements for each of the four applicable technological areas based on them, we will analyze and discuss the overreaching question of this paper.

Concerning the area of design for disassembly, the selected methodology allowed nonfulfilling aspects of the designs to be identified and draft suggestions for improved dissasembly. Some solutions could be readily implemented in the low TRL prototypes, such as the use of copper tape as substrate in the PZ harvesters. Other identified solutions require further R&D efforts from other disciplines, such as the development of dry adhesives. Thus, while the nonfulfillment can be identified and a solution can be drafted, its implementation cannot always be readily executed by the technology developers. Co-operation is needed from other disciplines and sectors.

As for the area of materials for substitution, the methodology allowed nonfulfillment cases to be clearly identified in the current bill of materials and presented a clear criteria for the selection of replacement candidates. Complying candidates have been identified for all requirements of this case study.

Concerning the area of fabrication efficiency, given that the device’s technology developers are not equipment manufacturers, the most straightforward solution identified to increase efficiency is to increase the batch size. However, the technology developers at this stage can state manufacturing upscaling recommendations but their final adoption is not fully in their hands.

Finally, concerning the area of manufacturing processes that enable recycled materials, a combination of the bottlenecks identified in the design for disassembly and for fabrication efficiency is found. On the one hand, suggestions for on-site recycling of precursors and solvents can be drafted. However, these can only be implemented in an upscaled manufacturing process. On the other hand, the main barrier found for the use of recycled materials is their availability, arising for R&D requirements in recycling processes.

All in all, it can be concluded that the 12 Principles of Green Engineering are well suited to identify sustainability hot spots and to draft complying change recommendations. However, the implementation of those recommendations is sometimes out of the hands of the technology developers, since they fall in other stages of the value chain, such as the production of secondary raw materials or upscaled manufacturing. Nevertheless, this should not be seen as discouraging. It is widely accepted that the transition to the circular economy requires a paradigmatic shift across all sectors of the economy, and requesting raw materials that are not yet available (i.e., dry adhesives or recycled Si wafers) or defining upscaling recommendations will catalyze this transition.

4. Conclusions

In this work, the current design and bill of materials and selected manufacturing techniques for the energy-harvesting platform developed in the NANO-EH project have been reviewed and cross-checked with the 12 Principles of Green Engineering to provide first recommendations on sustainability and recyclability improvements. Specifically, the technological areas of design for disassembly, materials for substitution, fabrication efficiency, and manufacturing processes that enable the use of recycled materials have been evaluated.

Concerning the first objective of the paper, it can be seen that some of the research lines followed based on the common understanding of sustainability are already aligned with the principles, such as the minimization of material diversity by the multifunctional use of hafnium zirconium oxides or the substitution of toxic lead zirconate titanate with ceramic-filled polymers. Further recommendations have been suggested, such as the substitution of other hazardous raw materials, such as TiO2 or chlorobenzene, or the adoption of mechanical fixtures to fasten lump components.

Other identified strategies which would improve sustainability, such as the increase in the manufacturing batch size to increase material efficiency or the inclusion of solvent recycling, can only be implemented at larger manufacturing scales and are out of the control of the technology developer.

Further strategies, such as the use of recycled Si wafers or dry adhesives as fixtures, represent future solutions for the reduction in the environmental impact which require further R&D efforts from different disciplines. This highlights the need for holistic and multidisciplinary research efforts to fully achieve the circular design. Thus, the complete fulfillment of the 12 Principles of Green Engineering is not always possible or in the hands of the technology developers in present times. However, suggesting and demanding changes in other stages of the value chain is expected to catalyze the transition to the circular economy.

A life cycle assessment will provide a quantification of the environmental impact of the current designs and is part of upcoming work.

Author Contributions

Conceptualization, L.D. and M.M.; methodology, L.D.; validation, L.D. and M.M.; formal analysis, L.D.; investigation, L.D.; resources, G.C.; writing—original draft preparation, L.D.; writing—review and editing, L.D., G.C. and M.M.; supervision, G.C. and M.M.; project administration, G.C.; funding acquisition, M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research and the APC was funded by the European Union’s Horizon 2020 research and innovation programme, EIC Pathfinder, NANO-EH project, grant number 951761 https://cordis.europa.eu/project/id/951761, accessed on 16 July 2023.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available upon reasonable request with the permission of the project consortium.

Acknowledgments

The authors would like to acknowledge the support, co-operation, and contributions and feedback from all NANO-EH project partners (IMT Bucharest, Universitá di Bologna, Universitá Politecnica delle Marche, INSA-Rennes, Thales, TE-OX, Luna Geber, Nanom Mems in addition to Blue Synergy and Tyndall). Special thanks to Martino Aldrigo, Fabio Gelati, Marin Gheorghe, Ana Borta-Boyon, and Paola Castrillo for the fruitful discussions and insights.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Appendix A. The 12 Principles of Green Engineering. Reprinted with Permission from Environ. Sci. Technol. 2003, 37, 94A–101A [61]. Copyright 2003 American Chemical Society

(1) Designers need to strive to ensure that all materials and energy inputs and outputs are as inherently non-hazardous as possible. (2) It is better to prevent waste than to treat or clean up waste after it is formed. (3) Separation and purification operations should be designed to minimize energy consumption and materials use. (4) Products, processes, and systems should be designed to maximize mass, energy, space, and time efficiency. (5) Products, processes, and systems should be “output pulled” rather than “input pushed” through the use of energy and materials. (6) Embedded entropy and complexity must be viewed as an investment when making design choices on recycling, reuse, or beneficial disposition. (7) Targeted durability, not immortality, should be a design goal. (8) Design for unnecessary capacity or capability (e.g., “one size fits all”) solutions should be considered a design flaw. (9) Material diversity in multicomponent products should be minimized to promote disassembly and value retention. (10) Design of products, processes, and systems must include integration and interconnectivity with available energy and materials flows. (11) Products, processes, and systems should be designed for performance in a commercial “afterlife.” (12) Material and energy inputs should be renewable rather than depleting.

References

- Schwab, K. The Fourth Industrial Revolution; Crown Publishing: New York, NY, USA, 2016; Volume 32, Available online: https://books.google.com/books/about/The_Fourth_Industrial_Revolution.html?id=ST_FDAAAQBAJ (accessed on 27 June 2023).

- Chatterjee, A.; Lobato, C.N.; Zhang, H.; Bergne, A.; Esposito, V.; Yun, S.; Insinga, A.R.; Christensen, D.V.; Imbaquingo, C.; Bjørk, R.; et al. Powering internet-of-things from ambient energy: A review. J. Physics Energy 2023, 5, 022001. [Google Scholar] [CrossRef]

- Logan, M.; Safi, M.; Lens, P.; Visvanathan, C. Investigating the performance of internet of things based anaerobic digestion of food waste. Process. Saf. Environ. Prot. 2019, 127, 277–287. [Google Scholar] [CrossRef]

- Hardin, R.G.; Barnes, E.M.; Delhom, C.D.; Wanjura, J.D.; Ward, J.K. Internet of things: Cotton harvesting and processing. Comput. Electron. Agric. 2022, 202, 107294. [Google Scholar] [CrossRef]

- Chen, E.T. The Internet of Things: Opportunities, Issues, and Challenges. In The Internet of Things in the Modern Business Environment; IGI Global: Hershey, PA, USA, 2017; pp. 167–187. [Google Scholar] [CrossRef]

- Zhang, J.; Das, R.; Zhao, J.; Mirzai, N.; Mercer, J.; Heidari, H. Battery-Free and Wireless Technologies for Cardiovascular Implantable Medical Devices. Adv. Mater. Technol. 2022, 7, 2101086. [Google Scholar] [CrossRef]

- Won, S.M.; Cai, L.; Gutruf, P.; Rogers, J.A. Wireless and battery-free technologies for neuroengineering. Nat. Biomed. Eng. 2021, 7, 405–423. [Google Scholar] [CrossRef]

- Tran, T.V.; Dang, N.T.; Chung, W.-Y. Battery-free smart-sensor system for real-time indoor air quality monitoring. Sens. Actuators B Chem. 2017, 248, 930–939. [Google Scholar] [CrossRef]

- Karunanithy, K.; Velusamy, B. Cluster-tree based energy efficient data gathering protocol for industrial automation using WSNs and IoT. J. Ind. Inf. Integr. 2020, 19, 100156. [Google Scholar] [CrossRef]

- Jameel, F.; Zeb, S.; Khan, W.U.; Hassan, S.A.; Chang, Z.; Liu, J. NOMA-Enabled Backscatter Communications: Toward Battery-Free IoT Networks. IEEE Internet Things Mag. 2020, 3, 95–101. [Google Scholar] [CrossRef]

- Wen, F.; Wang, H.; He, T.; Shi, Q.; Sun, Z.; Zhu, M.; Zhang, Z.; Cao, Z.; Dai, Y.; Zhang, T.; et al. Battery-free short-range self-powered wireless sensor network (SS-WSN) using TENG based direct sensory transmission (TDST) mechanism. Nano Energy 2019, 67, 104266. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, B.; Zhang, L.; Yang, W. Nanogenerator as new energy technology for self-powered intelligent transportation system. Nano Energy 2019, 66, 104086. [Google Scholar] [CrossRef]

- Hester, J.; Sorber, J. The Future of Sensing is Batteryless, Intermittent, and Awesome. In Proceedings of the 15th ACM Conference on Embedded Networked Sensor Systems, SenSys 2017, Delft, The Netherlands, 6–8 November 2017; Association for Computing Machinery, Inc.: New York, NY, USA, 2017; Volume 2017-January. [Google Scholar] [CrossRef]

- La Rosa, R.; Dehollain, C.; Pellitteri, F.; Miceli, R.; Livreri, P. An RF Wireless Power Transfer system to power battery-free devices for asset tracking. In Proceedings of the 2019 26th IEEE International Conference on Electronics, Circuits and Systems, ICECS 2019, Genoa, Italy, 27–29 November 2019; pp. 534–537. [Google Scholar] [CrossRef]

- Becker, T.; Borjesson, V.; Cetinkaya, O.; Baoxing, C.; Colomer-Farrarons, J.; Maeve, D.; Elefsiniotis, A.; Govoni, L.; Hadas, Z.; Hayes, M.; et al. Energy Harvesting for a Green Internet of Things; PSMA: Mendham, NJ, USA, 2021. [Google Scholar]

- European Comission. Nanomaterials Enabling Smart Energy Harvesting for Next-Generation Internet-of-Things|NANO-EH Project|Fact Sheet|H2020|CORDIS|European Commission, CORDIS EU Research Results. 2020. Available online: https://cordis.europa.eu/project/id/951761 (accessed on 23 May 2023).

- Pelagalli, N.; Aldrigo, M.; Dragoman, M.; Modreanu, M.; Mencarelli, D.; Pierantoni, L. Geometric Diode Modeling for Energy Harvesting Applications. In Proceedings of the 2022 Photonics & Electromagnetics Research Symposium (PIERS), Hangzhou, China, 25–29 April 2022; pp. 517–523. [Google Scholar] [CrossRef]

- Trovarello, S.; Masotti, D.; Aldrigo, M.; Modreanu, M.; Costanzo, A. Design of a 24-GHz dual-polarized rectenna integrated on silicon. In Proceedings of the 2021 51st European Microwave Conference (EuMC), London, UK, 2–7 April 2021; pp. 684–687. [Google Scholar] [CrossRef]

- Laudadio, E.; Aldrigo, M.; Stipa, P.; Pierantoni, L.; Mencarelli, D.; Dragoman, M.; Modreanu, M. A first-principle assessment at atomistic scale of interface phenomena in down-scaling hafnium-based metal-insulator-metal diodes. In Proceedings of the 2022 IEEE MTT-S International Conference on Numerical Electromagnetic and Multiphysics Modeling and Optimization (NEMO), Limoges, France, 6–8 July 2022. [Google Scholar] [CrossRef]

- Zerbo, B.F.; Modreanu, M.; Povey, I.; Lin, J.; Létoublon, A.; Rolland, A.; Pédesseau, L.; Even, J.; Lépine, B.; Turban, P.; et al. Study of MoS2 Deposited by ALD on c-Si, Towards the Development of MoS2/c-Si Heterojunction Photovoltaics. Crystals 2022, 12, 1363. [Google Scholar] [CrossRef]

- Pavoni, E.; Mohebbi, E.; Stipa, P.; Pierantoni, L.; Mencarelli, D.; Dragoman, M.; Aldrigo, M.; Laudadio, E. First-principles investigation of interface phenomena in hafnium-based metal–insulator–metal diodes. Nanoscale Adv. 2023, 5, 2748–2755. [Google Scholar] [CrossRef] [PubMed]

- Mohebbi, E.; Pavoni, E.; Mencarelli, D.; Stipa, P.; Pierantoni, L.; Laudadio, E. PBEsol/HSE functional: A promising candidate for vanadium dioxide (B) characterization. RSC Adv. 2022, 12, 31255–31263. [Google Scholar] [CrossRef] [PubMed]

- Dragoman, M.; Aldrigo, M.; Dinescu, A.; Vasilache, D.; Iordanescu, S.; Dragoman, D. Nanomaterials and Devices for Harvesting Ambient Electromagnetic Waves. Nanomaterials 2023, 13, 595. [Google Scholar] [CrossRef]

- United Nations. The Paris Agreement UNFCCC. In Proceedings of the UN Climate Change Conference (COP21), Paris, France, 30 November–12 December 2015. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement (accessed on 10 May 2023).

- United Nations General Assembly. Transforming Our World: The 2030 Agenda for Sustainable Development. United Nations. 2015. Available online: https://www.unfpa.org/resources/transforming-our-world-2030-agenda-sustainable-development (accessed on 10 May 2023).

- Mulvaney, D.; Richards, R.M.; Bazilian, M.D.; Hensley, E.; Clough, G.; Sridhar, S. Progress towards a circular economy in materials to decarbonize electricity and mobility. Renew. Sustain. Energy Rev. 2020, 137, 110604. [Google Scholar] [CrossRef]

- Kim, H.; Park, H. PV Waste Management at the Crossroads of Circular Economy and Energy Transition: The Case of South Korea. Sustainability 2018, 10, 3565. [Google Scholar] [CrossRef]

- Jensen, P.D.; Purnell, P.; Velenturf, A.P. Highlighting the need to embed circular economy in low carbon infrastructure decommissioning: The case of offshore wind. Sustain. Prod. Consum. 2020, 24, 266–280. [Google Scholar] [CrossRef]

- Cui, J.; Forssberg, E. Mechanical recycling of waste electric and electronic equipment: A review. J. Hazard. Mater. 2003, 99, 243–263. [Google Scholar] [CrossRef]

- Tansel, B. From electronic consumer products to e-wastes: Global outlook, waste quantities, recycling challenges. Environ. Int. 2017, 98, 35–45. [Google Scholar] [CrossRef]

- Forti, V.; Balde, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020. Quantities, Flows, and the Circular Economy Potential; United Nations University (UNU)/United Nations Institute for Training and Research (UNITAR), SCYCLE Programme, International Telecommunication Union (ITU) & International Solid Waste Association (ISWA): Bonn, Germany, 2020; Available online: https://ewastemonitor.info/gem-2020/ (accessed on 27 January 2023).

- Ilankoon, I.; Ghorbani, Y.; Chong, M.N.; Herath, G.; Moyo, T.; Petersen, J. E-waste in the international context—A review of trade flows, regulations, hazards, waste management strategies and technologies for value recovery. Waste Manag. 2018, 82, 258–275. [Google Scholar] [CrossRef]

- European Parliament; Council of the European Union. Directive 2011/65/EU of The European Parliament and of the Council of 8 June 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment. Off. J. Eur. Union 2011, 174, 88–110. [Google Scholar]

- European Parliament; Council of the European Union. Directive 2017/2102/Eu of The European Parliament and of the Council —of 15 November 2017—amending Directive 2011/65/ EU on the restriction of the use of certain hazardous substances in electrical and electronic equipment. Off. J. Eur. Union 2017, 305, 8–11. [Google Scholar]

- United Nations Security Council. Resolution 1896(2009); United Nations: New York, NY, USA, 2009; 5p. [Google Scholar]

- European Parliament; Council of the European Union. Regulation (EU) 2017/821 of the European Parliament and of the Council of the European Union of 17 May 2017 laying down supply chain due diligence obligations for Union importers of tin, tantalum and tungsten, their ores, and gold originating from conflict-affected and high-risk areas. Off. J. Eur. Union 2017, 130, 1–20. [Google Scholar]

- Blengini, G.; Latunussa, C.; Eynard, U.; Matos, C.; Georgitzikis, K.; Pavel, C.; Carrara, S.; Mancini, L.; Unguru, M.; Blagoeva, D.; et al. Study on the EU’s List of Critical Raw Materials (2020) Final Report; Publications Office of the European Union: Louxembourg, 2020.

- Kirchherr, J.; Yang, N.-H.N.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the Circular Economy (Revisited): An Analysis of 221 Definitions. Resour. Conserv. Recycl. 2023, 194, 107001. [Google Scholar] [CrossRef]

- Homrich, A.S.; Galvão, G.; Abadia, L.G.; Carvalho, M.M. The circular economy umbrella: Trends and gaps on integrating pathways. J. Clean. Prod. 2018, 175, 525–543. [Google Scholar] [CrossRef]

- Braungart, M.; McDonough, W. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2002; 193p. [Google Scholar]

- Graedel, T.E.; Allenby, B.R. Industrial Ecology; Prentice Hall: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Benyus, J.M. Biomimicry: Innovation Inspired by Nature; William Morrow & Company: New York, NY, USA, 1997; Available online: https://www.amazon.com/Biomimicry-Innovation-Inspired-Janine-Benyus/dp/0060533226 (accessed on 9 March 2023).

- Commoner, B. The Closing Circle: Nature, Man, and Technology; Alfred A. Knopf: New York, NY, USA, 1971. [Google Scholar]

- Stahel, W.R. The Performance Economy; Palgrave MacMillan: New York, NY, USA, 2006. [Google Scholar]

- Mollison, B.C.; Holmgren, D. Permaculture 1: A Perennial Agricultural System for Human Settlements; Transworld Publishers: London, UK, 1978. [Google Scholar]

- Lovins, A.B.; Lovins, L.H.; Hawken, P. A road map for natural capitalism. Harv. Bus. Rev. 1999, 77, 218–234. [Google Scholar] [CrossRef]

- Ayres, R.U. Industrial metabolism and global change. Int. Soc. Sci. J. 1989, 121, 363–373. [Google Scholar]

- Stål, H.I.; Corvellec, H. A decoupling perspective on circular business model implementation: Illustrations from Swedish apparel. J. Clean. Prod. 2018, 171, 630–643. [Google Scholar] [CrossRef]

- Bocken, N.; Schuit, C.; Kraaijenhagen, C. Experimenting with a circular business model: Lessons from eight cases. Environ. Innov. Soc. Transitions 2018, 28, 79–95. [Google Scholar] [CrossRef]

- Schoden, F.; Schnatmann, A.K.; Blachowicz, T.; Manz-Schumacher, H.; Schwenzfeier-Hellkamp, E. Circular Design Principles Applied on Dye-Sensitized Solar Cells. Sustainability 2022, 14, 15280. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F. How to Assess Product Performance in the Circular Economy? Proposed Requirements for the Design of a Circularity Measurement Framework. Recycling 2017, 2, 6. [Google Scholar] [CrossRef]

- Bovea, M.D.; Pérez-Belis, V. Identifying design guidelines to meet the circular economy principles: A case study on electric and electronic equipment. J. Environ. Manag. 2018, 228, 483–494. [Google Scholar] [CrossRef]

- Crul, M.; Diehl, J.C. Design for Sustainability: Moving from Incremental towards Radical Design Approaches. In Proceedings of the 4th International Conference on Sustainability Engineering and Science, Transitions to Sustainability, Auckland, New Zealand, 30 November–3 December 2010. [Google Scholar]

- Pigosso, D.; McAloone, T. How can design science contribute to a circular economy? ICED23: Design in a complex world. In Proceedings of the 21st International Conference on Engineering Design (IDED 17), Vancouver, BC, Canada, 21–25 August 2017; Volume 5, Design for X, Design to X. pp. 299–307. Available online: https://iced.designsociety.org/publication/3975/How+can+design+science+contribute+to+a+circular+economy%3F (accessed on 27 March 2023).

- Doyle, L.; Weidlich, I.; Di Maio, E. Developing Insulating Polymeric Foams: Strategies and Research Needs from a Circular Economy Perspective. Materials 2022, 15, 6212. [Google Scholar] [CrossRef] [PubMed]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Villares, M.; Işıldar, A.; van der Giesen, C.; Guinée, J. Does ex ante application enhance the usefulness of LCA? A case study on an emerging technology for metal recovery from e-waste. Int. J. Life Cycle Assess. 2017, 22, 1618–1633. [Google Scholar] [CrossRef]

- Cucurachi, S.; van der Giesen, C.; Guinée, J. Ex-ante LCA of Emerging Technologies. Procedia CIRP 2018, 69, 463–468. [Google Scholar] [CrossRef]

- Moni, S.M.; Mahmud, R.; High, K.; Carbajales-Dale, M. Life cycle assessment of emerging technologies: A review. J. Ind. Ecol. 2020, 24, 52–63. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M.; Anastas, P.T.; Zimmerman, J.B. Peer Reviewed: Applying the Principles of Green Engineering to Cradle-to-Cradle Design. Environ. Sci. Technol. 2003, 37, 434A–441A. [Google Scholar] [CrossRef] [PubMed]

- Anastas, P.T.; Zimmerman, J.B. Peer Reviewed: Design Through the 12 Principles of Green Engineering. Environ. Sci. Technol. 2003, 37, 94A–101A. [Google Scholar] [CrossRef]

- Xu, W.; Huang, L.-B.; Wong, M.-C.; Chen, L.; Bai, G.; Hao, J. Environmentally Friendly Hydrogel-Based Triboelectric Nanogenerators for Versatile Energy Harvesting and Self-Powered Sensors. Adv. Energy Mater. 2017, 7, 1601529. [Google Scholar] [CrossRef]

- Ren, W.; Sun, Y.; Zhao, D.; Aili, A.; Zhang, S.; Shi, C.; Zhang, J.; Geng, H.; Zhang, J.; Zhang, L.; et al. High-performance wearable thermoelectric generator with self-healing, recycling, and Lego-like reconfiguring capabilities. Sci. Adv. 2021, 7, eabe0586. [Google Scholar] [CrossRef]

- Slabov, V.; Kopyl, S.; dos Santos, M.P.S.; Kholkin, A.L. Natural and Eco-Friendly Materials for Triboelectric Energy Harvesting. Nano-Micro Lett. 2020, 12, 1–18. [Google Scholar] [CrossRef] [PubMed]

- O’connor, M.P.; Zimmerman, J.B.; Anastas, P.T.; Plata, D.L. A Strategy for Material Supply Chain Sustainability: Enabling a Circular Economy in the Electronics Industry through Green Engineering. ACS Sustain. Chem. Eng. 2016, 4, 5879–5888. [Google Scholar] [CrossRef]

- Hsu, E.; Barmak, K.; West, A.C.; Park, A.-H.A. Advancements in the treatment and processing of electronic waste with sustainability: A review of metal extraction and recovery technologies. Green Chem. 2019, 21, 919–936. [Google Scholar] [CrossRef]

- Dodson, J.R.; Hunt, A.J.; Parker, H.L.; Yang, Y.; Clark, J.H. Elemental sustainability: Towards the total recovery of scarce metals. Chem. Eng. Process. Process Intensif. 2012, 51, 69–78. [Google Scholar] [CrossRef]

- Sethurajan, M.; van Hullebusch, E.D.; Fontana, D.; Akcil, A.; Deveci, H.; Batinic, B.; Leal, J.P.; Gasche, T.A.; Kucuker, M.A.; Kuchta, K.; et al. Recent advances on hydrometallurgical recovery of critical and precious elements from end of life electronic wastes—A review. Crit. Rev. Environ. Sci. Technol. 2019, 49, 212–275. [Google Scholar] [CrossRef]

- Epoxy Technology. Reworking, Removing and ‘Decapsulating’ Cured Epoxies 2009. Available online: https://www.tedpella.com/technote_html/Reworking_Cured_Epoxy.pdf (accessed on 17 April 2023).

- Master Bond. How To: Optimizing the Glass Transition Temperature (Tg) MasterBond.com. Available online: https://www.masterbond.com/techtips/how-optimizing-glass-transition-temperature-tg (accessed on 16 March 2023).

- Yi, H.; Hwang, I.; Sung, M.; Lee, D.; Kim, J.-H.; Kang, S.M.; Bae, W.-G. Bio-inspired adhesive systems for next-generation green manufacturing. Int. J. Precis. Engi-Neering Manuf. Green Technol. 2014, 1, 347–351. [Google Scholar] [CrossRef]

- Zhang, Y.; Keum, H.; Park, K.; Bashir, R.; Kim, S. Micro-Masonry of MEMS Sensors and Actuators. J. Microelectromechanical. Syst. 2014, 23, 308–314. [Google Scholar] [CrossRef]

- Mengüç, Y.; Sitti, M. Gecko-Inspired Polymer Adhesives. In Polymer Adhesion, Friction, And Lubrication; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 351–389. [Google Scholar] [CrossRef]

- Eisenhaure, J.; Kim, S. A Review of the State of Dry Adhesives: Biomimetic Structures and the Alternative Designs They Inspire. Micromachines 2017, 8, 125. [Google Scholar] [CrossRef]

- Swartwout, R.; Patidar, R.; Belliveau, E.; Dou, B.; Beynon, D.; Greenwood, P.; Moody, N.; DeQuilettes, D.; Bawendi, M.; Watson, T.; et al. Predicting Low Toxicity and Scalable Solvent Systems for High Speed Roll-to-Roll Perovskite Manufacturing. Solar RRL 2021, 6, 2100567. [Google Scholar] [CrossRef]

- Acosta, M.; Novak, N.; Rojas, V.; Patel, S.; Vaish, R.; Koruza, J.; Rossetti, G.A., Jr.; Rödel, J. BaTiO3-based piezoelectrics: Fundamentals, current status, and perspectives. Appl. Phys. Rev. 2017, 4, 041305. [Google Scholar] [CrossRef]

- Alston, S.M.; Clark, A.D.; Arnold, J.C.; Stein, B.K. Environmental Impact of Pyrolysis of Mixed WEEE Plastics Part 1: Experimental Pyrolysis Data. Environ. Sci. Technol. 2011, 45, 9380–9385. [Google Scholar] [CrossRef] [PubMed]

- Danz, P.; Aryan, V.; Möhle, E.; Nowara, N. Experimental Study on Fluorine Release from Photovoltaic Backsheet Materials Containing PVF and PVDF during Pyrolysis and Incineration in a Technical Lab-Scale Reactor at Various Temperatures. Toxics 2019, 7, 47. [Google Scholar] [CrossRef] [PubMed]

- Marshall, J.E.; Zhenova, A.; Roberts, S.; Petchey, T.; Zhu, P.; Dancer, C.E.J.; McElroy, C.R.; Kendrick, E.; Goodship, V. On the Solubility and Stability of Polyvinylidene Fluoride. Polymers 2021, 13, 1354. [Google Scholar] [CrossRef]

- ECHA. Substance Information—Titanium Dioxide. Available online: https://echa.europa.eu/substance-information/-/substanceinfo/100.033.327 (accessed on 13 March 2023).

- ECHA. Guide on the Classification and Labelling of Titanium Dioxide; ECHA: Helsinki, Finland, 2021.

- Ibn-Mohammed, T.; Koh, S.C.L.; Reaney, I.M.; Acquaye, A.; Wang, D.; Taylor, S.; Genovese, A. Integrated hybrid life cycle assessment and supply chain environmental profile evaluations of lead-based (lead zirconate titanate) versus lead-free (potassium sodium niobate) piezoelectric ceramics. Energy Environ. Sci. 2016, 9, 3495–3520. [Google Scholar] [CrossRef]

- Vinothini, V.; Singh, P.; Balasubramanian, M. Synthesis of barium titanate nanopowder using polymeric precursor method. Ceram. Int. 2006, 32, 99–103. [Google Scholar] [CrossRef]

- Vinothini, V.; Vaidhyanathan, B.; Binner, J. Microwave assisted synthesis of barium zirconium titanate nanopowders. J. Mater. Sci. 2011, 46, 2155–2161. [Google Scholar] [CrossRef]

- Grätzel, M. Dye-sensitized solar cells. J. Photochem. Photobiol. C Photochem. Rev. 2003, 4, 145–153. [Google Scholar] [CrossRef]

- Tennakone, K.; Kumara, G.R.R.A.; Kottegoda, I.R.M.; Perera, V.P.S. An efficient dye-sensitized photoelectrochemical solar cell made from oxides of tin and zinc. Chem. Commun. 1999, 1, 15–16. [Google Scholar] [CrossRef]

- Sayama, K.; Sugihara, H.; Arakawa, H. Photoelectrochemical Properties of a Porous Nb2O5 Electrode Sensitized by a Ruthenium Dye. Chem. Mater. 1998, 10, 3825–3832. [Google Scholar] [CrossRef]

- Le Viet, A.; Jose, R.; Reddy, M.V.; Chowdari, B.V.R.; Ramakrishna, S. Nb2O5 photoelectrodes for dye-sensitized solar cells: Choice of the polymorph. J. Phys. Chem. C. 2010, 114, 21795–21800. [Google Scholar] [CrossRef]

- Law, M.; Greene, L.E.; Johnson, J.C.; Saykally, R.; Yang, P. Nanowire dye-sensitized solar cells. Nat. Mater. 2005, 4, 455–459. [Google Scholar] [CrossRef]

- Gong, J.; Liang, J.; Sumathy, K. Review on dye-sensitized solar cells (DSSCs): Fundamental concepts and novel materials. Renew. Sustain. Energy Rev. 2012, 16, 5848–5860. [Google Scholar] [CrossRef]

- European Chemical Agency. Substance Information—Chlorobenzene. Available online: https://echa.europa.eu/substance-information/-/substanceinfo/100.003.299 (accessed on 13 February 2023).

- Dutta, M.; Pathiparampil, A.; Murella, J.; Villacarte, D.; Hamada, D.; Hernandez, J.; Lopez-Linares, F. Determination of base number in lubricants and additives by ASTM D2896: Substitution of chlorinated solvents and alternate electrolyte study. Fuel 2021, 297, 120701. [Google Scholar] [CrossRef]

- Farrell, M.J.; Frey, K.; Mason, J. Corporate Responsibility: A Green Initiative to Reduce Chlorobenzene Based Chemistries in Semiconductor Processing. MRS Adv. 2019, 4, 393–398. [Google Scholar] [CrossRef]

- Larsen, C.; Lundberg, P.; Tang, S.; Ràfols-Ribé, J.; Sandström, A.; Lindh, E.M.; Wang, J.; Edman, L. A tool for identifying green solvents for printed electronics. Nat. Commun. 2021, 12, 1–7. [Google Scholar] [CrossRef]

- Forster, P.; Ramaswamy, V.; Artaxo, P.; Berntsen, T.; Betts, R.; Fahey, D.W.; Haywood, J.; Lean, J.; Lowe, D.C.; Myhre, J.; et al. Changes in Atmospheric Constituents and in Radiative Forcing. In Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Solomon, S., Qin, D., Manning, M., Chen, Z., Marquis, M., Averyt, K.B., Tignor, M., Miller, H.L., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007. [Google Scholar]

- Hausmann, D.M.; Kim, E.; Becker, J.; Gordon, R.G. Atomic Layer Deposition of Hafnium and Zirconium Oxides Using Metal Amide Precursors. Chem. Mater. 2002, 14, 4350–4358. [Google Scholar] [CrossRef]

- Puurunen, R.L. Surface chemistry of atomic layer deposition: A case study for the trimethylaluminum/water process. J. Appl. Phys. 2005, 97, 121301. [Google Scholar] [CrossRef]

- George, S.M. Atomic Layer Deposition: An Overview. Chem. Rev. 2009, 110, 111–131. [Google Scholar] [CrossRef] [PubMed]

- Wang, E.; Yuan, C. A hybrid life cycle assessment of atomic layer deposition process. J. Clean. Prod. 2014, 74, 145–154. [Google Scholar] [CrossRef]

- Beltrami, R.; Mercadelli, E.; Baldisserri, C.; Galassi, C.; Braghin, F.; Lecis, N. Synthesis of KNN powders: Scaling effect of the milling step. Powder Technol. 2020, 375, 101–108. [Google Scholar] [CrossRef]

- Sahu, N.; Parija, B.; Panigrahi, S. Fundamental understanding and modeling of spin coating process: A review. Indian J. Phys. 2009, 83, 493–502. [Google Scholar] [CrossRef]

- Zheng, J.; Zhang, M.; Lau, C.F.J.; Deng, X.; Kim, J.; Ma, Q.; Chen, C.; Green, M.A.; Huang, S.; Ho-Baillie, A.W. Spin-coating free fabrication for highly efficient perovskite solar cells. Sol. Energy Mater. Sol. Cells 2017, 168, 165–171. [Google Scholar] [CrossRef]

- Lee, J.-W.; Na, S.-I.; Kim, S.-S. Efficient spin-coating-free planar heterojunction perovskite solar cells fabricated with successive brush-painting. J. Power Sources 2017, 339, 33–40. [Google Scholar] [CrossRef]

- Xu, X.; Lai, D.; Wang, W.; Wang, Y. A systematically integrated recycling and upgrading technology for waste crystalline silicon photovoltaic module. Resour. Conserv. Recycl. 2022, 182, 106284. [Google Scholar] [CrossRef]

- Huang, W.-H.; Shin, W.J.; Wang, L.; Sun, W.-C.; Tao, M. Strategy and technology to recycle wafer-silicon solar modules. Sol. Energy 2017, 144, 22–31. [Google Scholar] [CrossRef]

- Broeck, K.V.D.; Van Hoornick, N.; Van Hoeymissen, J.; de Boer, R.; Giesen, A.; Wilms, D. Sustainable treatment of HF wastewaters from semiconductor industry with a fluidized bed reactor. IEEE Trans. Semicond. Manuf. 2003, 16, 423–428. [Google Scholar] [CrossRef]

- Shin, J.; Park, J.; Park, N. A method to recycle silicon wafer from end-of-life photovoltaic module and solar panels by using recycled silicon wafers. Sol. Energy Mater. Sol. Cells 2017, 162, 1–6. [Google Scholar] [CrossRef]

- European Chemical Agency. Substance Information—Hydrogen Fluoride. Available online: https://echa.europa.eu/substance-information/-/substanceinfo/100.028.759 (accessed on 28 February 2023).

- Chen, W.-S.; Chen, Y.-J.; Lee, C.-H.; Cheng, Y.-J.; Chen, Y.-A.; Liu, F.-W.; Wang, Y.-C.; Chueh, Y.-L. Recovery of Valuable Materials from the Waste Crystalline-Silicon Photovoltaic Cell and Ribbon. Processes 2021, 9, 712. [Google Scholar] [CrossRef]

- Latunussa, C.E.; Ardente, F.; Blengini, G.A.; Mancini, L. Life Cycle Assessment of an innovative recycling process for crystalline silicon photovoltaic panels. Sol. Energy Mater. Sol. Cells 2016, 156, 101–111. [Google Scholar] [CrossRef]

- Stolz, P.; Frischknecht, R.; Wambach, K.; Sinha, P.; Heath, G. Life Cycle Assessment of Current Photovoltaic Module Recycling; IEA PVPS Task 12, International Energy Agency Power Systems Programme, Report IEA-PVPS T12-13; International Energy Agency: Paris, France, 2018.

- Deng, R.; Chang, N.L.; Ouyang, Z.; Chong, C.M. A techno-economic review of silicon photovoltaic module recycling. Renew. Sustain. Energy Rev. 2019, 109, 532–550. [Google Scholar] [CrossRef]

- Ferro, P.; Bonollo, F. Design for Recycling in a Critical Raw Materials Perspective. Recycling 2019, 4, 44. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, X.; Deng, Y.; Zha, Y.; Yuan, C. Comparison of life cycle environmental impacts of different perovskite solar cell systems. Sol. Energy Mater. Sol. Cells 2017, 166, 9–17. [Google Scholar] [CrossRef]

- Briend, P.; Alban, B.; Chevrel, H.; Jahan, D. Method for Recycling Silane. US20110011129A1, 20 January 2011. [Google Scholar]

- Hong, S.; Cho, S.; Kim, S.; Kwak, S. Recovery Method of Organic Solvent from Photoresist Removal Waste. KR100997743B1, 1 December 2010. [Google Scholar]

- Kirmani, A.R.; Woodhouse, M.; Luther, J.M. Technoeconomic Model Suggests Scaling-Up Perovskite Quantum Dots for Optoelectronics Warrants Improved Synthesis Yield, Solvent Recycling, and Automation. ACS Energy Lett. 2022, 7, 1255–1259. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).