Analyzing Interrelationships and Prioritizing Performance Indicators in Global Product Development: Application in the Chinese Renewable Energy Sector

Abstract

1. Introduction

- What are the essential metrics for advancing GPD performance assessment? What is the interrelationship between these performance indicators?

- How does an indicator influence or be influenced by other indicators in the evaluation network?

- What is the importance of each indicator in the evaluation network?

- What measures would be appropriate for developing a practical approach to assessing and improving GPD performance?

- Selecting the appropriate KPIs for assessing GPD projects.

- Assessing the cause-and-effect influences of each indicator and measuring the strengths of those interdependence relationships and interactions.

- Calculating the priority weight of the indicators and recommending appropriate suggestions to improve GPD performance.

2. Literature Review

3. Research Methodology

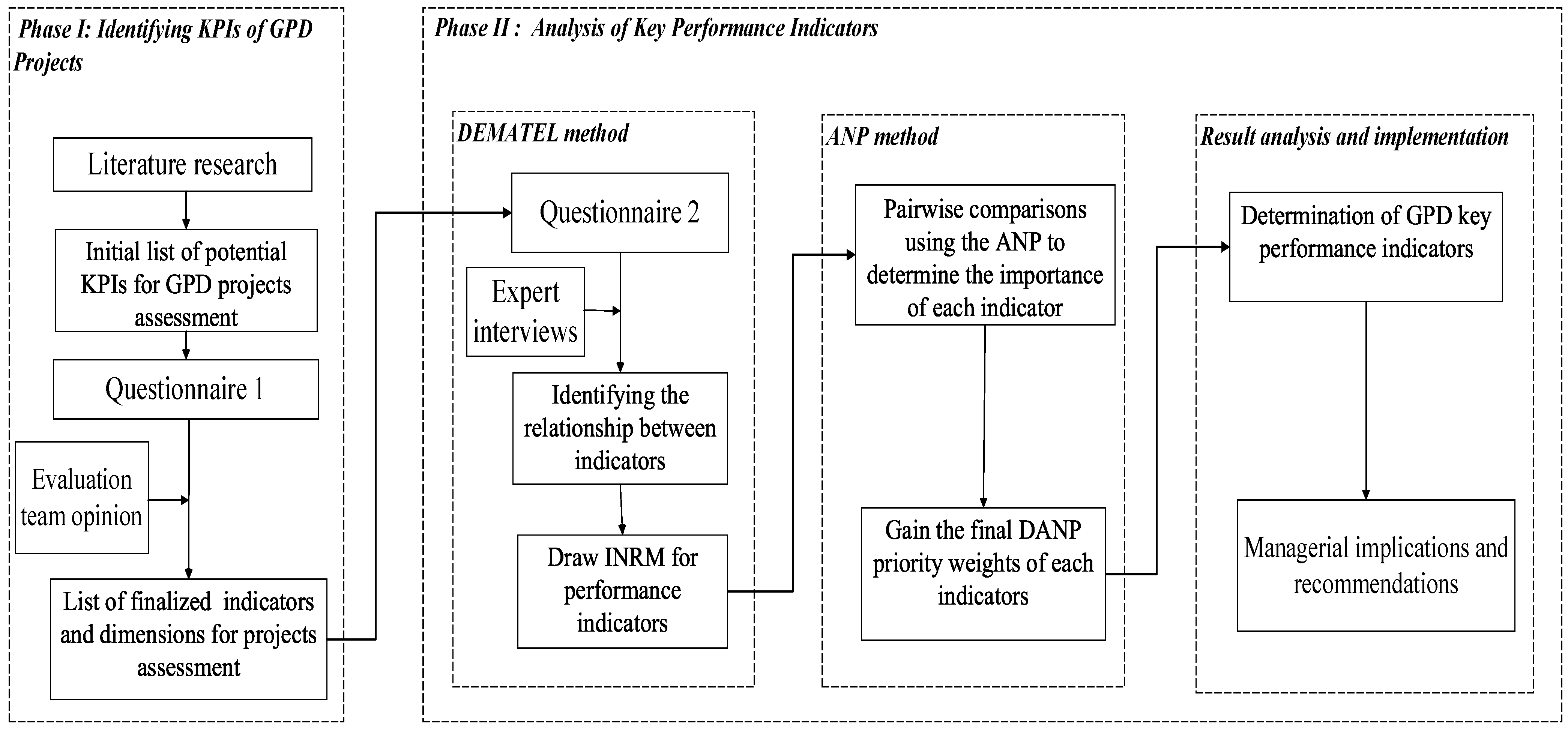

3.1. Proposed Framework for Evaluating GPD Performance

3.2. Using the DANP Approach for GPD

3.2.1. Building the Influential Network Relation Map (INRM) via DEMATEL

3.2.2. Measuring the DANP Weights by Integrating the DEMATEL and ANP

4. Application and Results of the Framework

4.1. Phase I: Identifying KPIs of GPD Projects

4.1.1. Evaluation of the Potential KPIs

4.1.2. KPIs’ Selection and Identification

4.2. Phase II: Analysis of Key Performance Indicators

4.2.1. The Case of Chinese Renewable Energy and Sustainable Technology Development

4.2.2. Respondent Selection, Questionnaire Development, and Data Collection

4.2.3. Determining Interrelationships between KPIs

4.2.4. Determining the DANP Weights

4.3. Indicator Classification According to High and Low Cause-and-Effect Performance

5. Discussion

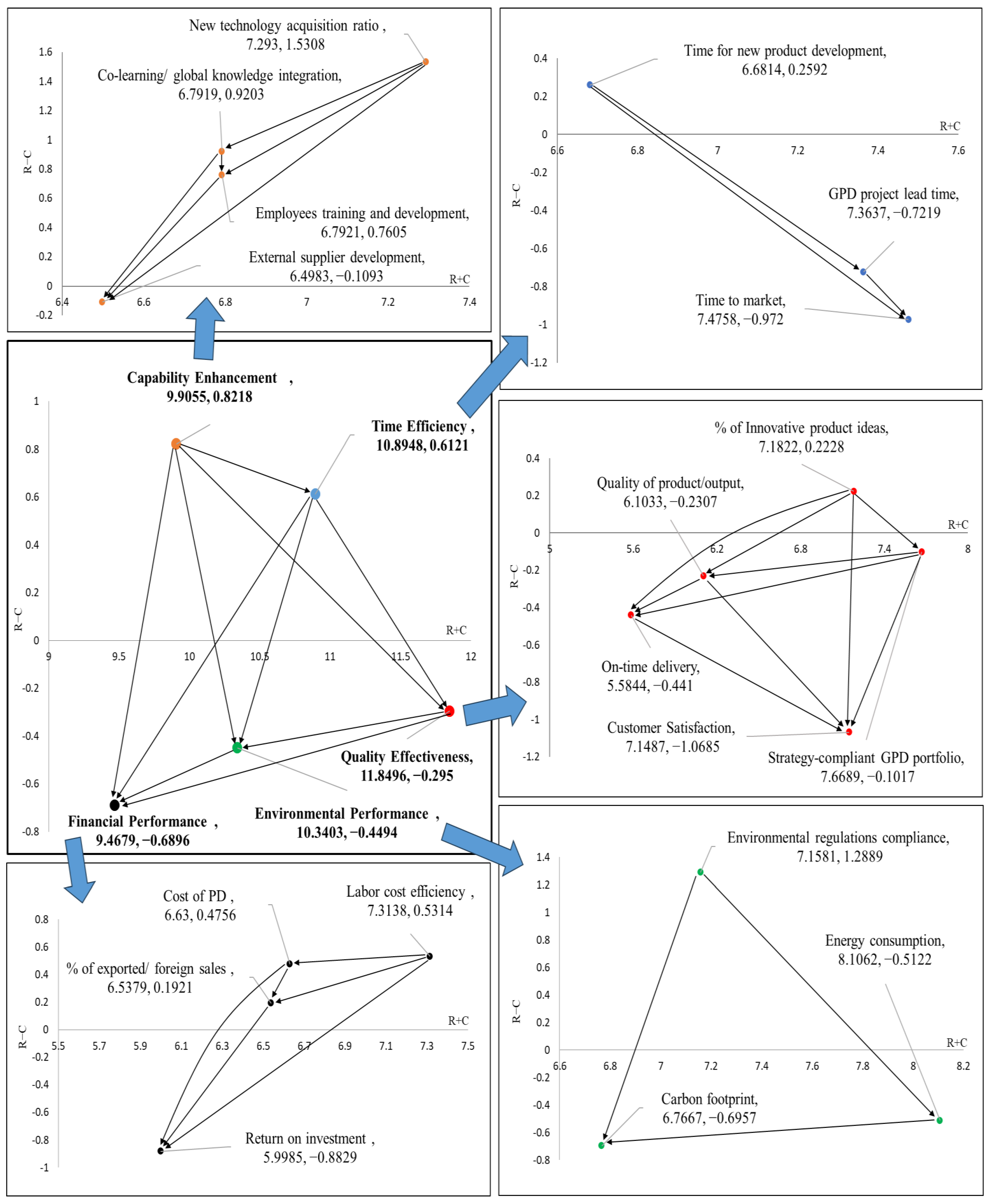

5.1. Analysis of General Cause-and-Effect Relationships

5.2. Cause-and-Effect Analysis for Dimension-Based Indicators

- Financial performance (FP)

- Quality Effectiveness (QE)

- Time Efficiency (TE)

- Environmental performance (EP)

- Capability Enhancement (CE)

5.3. Prioritization of Indicators Based on DANP

5.4. Research Implications and Future Research Directions

- Encourage organizations to invest more in capacity strengthening. Based on research findings, managers are encouraged to prioritize capacity enhancement aspects for evaluating GPD projects due to their significant causal impact in increasing knowledge capacity and identifying areas for improvement to achieve sustainable performance. Active pursuit and adoption of new technologies and leverage of joint learning and training programs significantly drive innovation, improve product quality, increase efficiency, and reduce costs, and these advancements can lead to better market positioning, increased customer satisfaction, and higher overall performance in GPD projects.

- Enable investment in environmental management. Managers must focus on environmental aspects, which are not only aligned with environmental objectives but also have potential economic benefits in GPD projects. Besides reducing carbon emissions and improving energy efficiency, proper management and environmental compliance with regulations can reduce costs, enhance operational efficiency, and demonstrate a commitment to sustainability. Accordingly, GPD managers can achieve environmental goals and reap the associated economic benefits by prioritizing compliance and implementing sustainable practices essential to creating a green image in the market for the company.

- Focus on the effect category of KPIs. The cause category KPIs will drive the effect category KPIs. As a result, managers ought to concentrate on cause group KPIs, including time efficiency and capability enhancement, as foundational elements in driving performance improvements across financial, quality, and environmental dimensions. By enhancing these cause indicators, organizations can create a solid foundation for achieving superior outcomes and overall success in their GPD projects.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tripathy, A.; Eppinger, S.D. Organizing Global Product Development for Complex Engineered Systems. IEEE Trans. Eng. Manag. 2011, 58, 510–529. [Google Scholar] [CrossRef][Green Version]

- Johansson, M.; Olhager, J. Comparing Offshoring and Backshoring: The Role of Manufacturing Site Location Factors and Their Impact on Post-Relocation Performance. Int. J. Prod. Econ. 2018, 205, 37–46. [Google Scholar] [CrossRef]

- Larsen, M.M. Failing to Estimate the Costs of Offshoring: A Study on Process Performance. Int. Bus. Rev. 2016, 25, 307–318. [Google Scholar] [CrossRef]

- O’Leary, M.B.; Cummings, J.N. The Spatial, Temporal, and Configurational Characteristics of Geographic Dispersion in Teams. MIS Q. Manag. Inf. Syst. 2007, 31, 433–452. [Google Scholar] [CrossRef]

- Taylor, T.P.; Ahmed-Kristensen, S. Global Product Development Projects: Measuring Performance and Monitoring the Risks. Prod. Plan. Control 2018, 29, 1290–1302. [Google Scholar] [CrossRef]

- Taylor, T.; Ahmed-Kristensen, S. Global Product Development: KPI Selection Support. In Proceedings of the DESIGN 2016 14th International Design Conference, Dubrovnik, Croatia, 16–19 May 2016. [Google Scholar]

- Henttonen, K.; Ojanen, V.; Puumalainen, K. Searching for Appropriate Performance Measures for Innovation and Development Projects. R&D Manag. 2016, 46, 914–927. [Google Scholar] [CrossRef]

- De Brentani, U.; Kleinschmidt, E.J.; Salomo, S. Success in Global New Product Development: Impact of Strategy and the Behavioral Environment of the Firm. J. Prod. Innov. Manag. 2010, 27, 143–160. [Google Scholar] [CrossRef]

- Tjader, Y.; May, J.H.; Shang, J.; Vargas, L.G.; Gao, N. Firm-Level Outsourcing Decision Making: A Balanced Scorecard-Based Analytic Network Process Model. Int. J. Prod. Econ. 2014, 147, 614–623. [Google Scholar] [CrossRef]

- Verhaelen, B.; Mayer, F.; Peukert, S.; Lanza, G. A Comprehensive KPI Network for the Performance Measurement and Management in Global Production Networks. Prod. Eng. 2021, 15, 635–650. [Google Scholar] [CrossRef]

- Salimi, N.; Rezaei, J. Evaluating Firms’ R&D Performance Using Best Worst Method. Eval. Program Plan. 2018, 66, 147–155. [Google Scholar] [CrossRef]

- Kumar, A.; Anbanandam, R. Analyzing Interrelationships and Prioritising the Factors Influencing Sustainable Intermodal Freight Transport System: A Grey-DANP Approach. J. Clean. Prod. 2020, 252, 119769. [Google Scholar] [CrossRef]

- Rodríguez Rodríguez, R.; Alfaro Saiz, J.J.; Ortiz Bas, Á.; José, M.; Sáez, V. Identifying Relationships between Key Performance Indicators. In Proceedings of the 4th International Conference on Industrial Engineering and Industrial Management, Donostia-San Sebastián, Spain, 8–10 September 2010. [Google Scholar]

- Yeh, T.M.; Pai, F.Y.; Liao, C.W. Using a Hybrid MCDM Methodology to Identify Critical Factors in New Product Development. Neural Comput. Appl. 2014, 24, 957–971. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Öztürkcan, D. An Integrated Analytic Approach for Six Sigma Project Selection. Expert Syst. Appl. 2010, 37, 5835–5847. [Google Scholar] [CrossRef]

- Govindan, K.; Madan Shankar, K.; Kannan, D. Sustainable Material Selection for Construction Industry—A Hybrid Multi Criteria Decision Making Approach. Renew. Sustain. Energy Rev. 2016, 55, 1274–1288. [Google Scholar] [CrossRef]

- Govindan, K.; Shankar, M.; Kannan, D. Supplier Selection Based on Corporate Social Responsibility Practices. Int. J. Prod. Econ. 2018, 200, 353–379. [Google Scholar] [CrossRef]

- Wu, H.Y. Constructing a Strategy Map for Banking Institutions with Key Performance Indicators of the Balanced Scorecard. Eval. Program Plan. 2012, 35, 303–320. [Google Scholar] [CrossRef]

- Lin, A.J.; Chang, H.Y. Business Sustainability Performance Evaluation for Taiwanese Banks-A Hybrid Multiple-Criteria Decision-Making Approach. Sustainability 2019, 11, 2236. [Google Scholar] [CrossRef]

- Chen, F.H.; Hsu, T.S.; Tzeng, G.H. A Balanced Scorecard Approach to Establish a Performance Evaluation and Relationship Model for Hot Spring Hotels Based on a Hybrid MCDM Model Combining DEMATEL and ANP. Int. J. Hosp. Manag. 2011, 30, 908–932. [Google Scholar] [CrossRef]

- Govindan, K.; Aditi; Dhingra Darbari, J.; Kaul, A.; Jha, P.C. Structural Model for Analysis of Key Performance Indicators for Sustainable Manufacturer–Supplier Collaboration: A Grey-Decision-Making Trial and Evaluation Laboratory-Based Approach. Bus. Strategy Environ. 2021, 30, 1702–1722. [Google Scholar] [CrossRef]

- Wang, L.; Yang, M.; Pathan, Z.H.; Salam, S.; Shahzad, K.; Zeng, J. Analysis of Influencing Factors of Big Data Adoption in Chinese Enterprises Using DANP Technique. Sustainability 2018, 10, 3956. [Google Scholar] [CrossRef]

- Chen, Y.; Jin, Q.; Fang, H.; Lei, H.; Hu, J.; Wu, Y.; Chen, J.; Wang, C.; Wan, Y. Analytic Network Process: Academic Insights and Perspectives Analysis. J. Clean. Prod. 2019, 235, 1276–1294. [Google Scholar] [CrossRef]

- Pero, M.; Rossi, M.; Terzi, S. Evolution of Global Product Development Networks: An Exploratory Study. IEEE Trans. Eng. Manag. 2018, 65, 34–45. [Google Scholar] [CrossRef]

- Sbernini, F.; Granini, N.; Lee Herbert-Hansen, Z.N.; Khalid, W. Contextual Factors Influencing the Success of Global Product Development. Int. J. Prod. Dev. 2018, 22, 464–487. [Google Scholar] [CrossRef]

- Dombrowski, U.; Schmidtchen, K.; Ebentreich, D. Balanced Key Performance Indicators in Product Development. Int. J. Mater. Mech. Manuf. 2013, 1, 27–31. [Google Scholar] [CrossRef]

- Büyükzkan, G.; Arsenyan, J. Collaborative Product Development: A Literature Overview. Prod. Plan. Control 2012, 23, 47–66. [Google Scholar] [CrossRef]

- Chiesa, V.; Frattini, F. Exploring the Differences in Performance Measurement between Research and Development: Evidence from a Multiple Case Study. R&D Manag. 2007, 37, 283–301. [Google Scholar]

- Kaplan, R.S.; Norton, D.P. The Balanced Scorecard-Measures That Drive Performance. Harv. Bus. Rev. 1992, 70, 71–79. [Google Scholar]

- Croom, S.R. The Dyadic Capabilities Concept: Examining the Processes of Key Supplier Involvement in Collaborative Product Development. Eur. J. Purch. Supply Manag. 2001, 7, 29–37. [Google Scholar] [CrossRef]

- Taylor, T.P. Performance Measurement in Global Product Development. In Proceedings of the ICED 2013, International Conference on Engineering Design, Seoul, Republic of Korea, 19–22 August 2013; pp. 207–216. [Google Scholar]

- Kleinschmidt, E.J.; De Brentani, U.; Salomo, S. Performance of Global New Product Development Programs: A Resource-Based View. J. Prod. Innov. Manag. 2007, 24, 419–441. [Google Scholar] [CrossRef]

- Zhang, Y.; Gregory, M.; Shi, Y.J. Global Engineering Networks: The Integrating Framework and Key Patterns. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2007, 221, 1269–1283. [Google Scholar] [CrossRef]

- Dossi, A.; Patelli, L. You Learn from What You Measure: Financial and Non-Financial Performance Measures in Multinational Companies. Long Range Plan. 2010, 43, 498–526. [Google Scholar] [CrossRef]

- Koksal, M.H. The Differences between Successful and Unsuccessful New Manufacturing Products in International Markets: Evidence from Turkey. Asia Pac. J. Mark. Logist. 2014, 26, 21–38. [Google Scholar] [CrossRef]

- Abdallah, W.M.; Alnamri, M. Non-Financial Performance Measures and the BSC of Multinational Companies with Multi-Cultural Environment An Empirical Investigation. Cross Cult. Manag. 2015, 22, 594–607. [Google Scholar] [CrossRef]

- Rodrigues, V.P.; Pigosso, D.C.A.; McAloone, T.C. Process-Related Key Performance Indicators for Measuring Sustainability Performance of Ecodesign Implementation into Product Development. J. Clean. Prod. 2016, 139, 416–428. [Google Scholar] [CrossRef]

- Pashaei, S.; Olhager, J. Product Architecture, Global Operations Networks, and Operational Performance: An Exploratory Study. Prod. Plan. Control 2019, 30, 149–162. [Google Scholar] [CrossRef]

- Shao, Q.G.; Liou, J.J.H.; Weng, S.S.; Chuang, Y.C. Improving the Green Building Evaluation System in China Based on the DANP Method. Sustainability 2018, 10, 1173. [Google Scholar] [CrossRef]

- Si, S.L.; You, X.Y.; Liu, H.C.; Zhang, P. DEMATEL Technique: A Systematic Review of the State-of-the-Art Literature on Methodologies and Applications. Math. Probl. Eng. 2018, 2018, 3696457. [Google Scholar] [CrossRef]

- Kadoić, N.; Divjak, B.; Begičević Ređep, N. Integrating the DEMATEL with the Analytic Network Process for Effective Decision-Making. Cent. Eur. J. Oper. Res. 2019, 27, 653–678. [Google Scholar] [CrossRef]

- Zarzycka, E.; Krasodomska, J. Environmental Key Performance Indicators: The Role of Regulations and Stakeholder Influence. Environ. Syst. Decis. 2021, 41, 651–666. [Google Scholar] [CrossRef] [PubMed]

- Büyüközkan, G.; Karabulut, Y. Sustainability Performance Evaluation: Literature Review and Future Directions. J. Environ. Manag. 2018, 217, 253–267. [Google Scholar] [CrossRef] [PubMed]

- Tripathy, A.; Eppinger, S.D. Structuring Work Distribution for Global Product Development Organizations. Prod. Oper. Manag. 2013, 22, 1557–1575. [Google Scholar] [CrossRef]

- Zheng, H.A.; Chanaron, J.J.; You, J.X.; Chen, X.L. Designing a Key Performance Indicator System for Technological Innovation Audit at Firm’s Level: A Framework and an Empirical Study. In Proceedings of the IEEM 2009—IEEE International Conference on Industrial Engineering and Engineering Management, Hong Kong, China, 8–11 December 2009; pp. 1–5. [Google Scholar]

- Deng, P. The Internationalization of Chinese Firms: A Critical Review and Future Research. Int. J. Manag. Rev. 2012, 14, 408–427. [Google Scholar] [CrossRef]

- Haasis, T.I.; Liefner, I. Reviewing the Research on the Internationalization of Chinese Firms: Thematic Expansion, New Impulses and Potential Future Development. Int. J. Emerg. Mark. 2019, 14, 24–50. [Google Scholar] [CrossRef]

- Hristov, I.; Chirico, A. The Role of Sustainability Key Performance Indicators (KPIs) in Implementing Sustainable Strategies. Sustainability 2019, 11, 5742. [Google Scholar] [CrossRef]

- Tsai, C.C. A Research on Selecting Criteria for New Green Product Development Project: Taking Taiwan Consumer Electronics Products as an Example. J. Clean. Prod. 2012, 25, 106–115. [Google Scholar] [CrossRef]

- Tsai, J.F.; Shen, S.P.; Lin, M.H. Applying a Hybrid MCDM Model to Evaluate Green Supply Chain Management Practices. Sustainability 2023, 15, 2148. [Google Scholar] [CrossRef]

- Dong, Z.; Tan, Y.; Wang, L.; Zheng, J.; Hu, S. Green Supply Chain Management and Clean Technology Innovation: An Empirical Analysis of Multinational Enterprises in China. J. Clean. Prod. 2021, 310, 127377. [Google Scholar] [CrossRef]

- Sanchez, O.P.; Terlizzi, M.A.; de Moraes, H.R. Cost and Time Project Management Success Factors for Information Systems Development Projects. Int. J. Proj. Manag. 2017, 35, 1608–1626. [Google Scholar] [CrossRef]

- Li, C.; Wang, S. Digital Optimization, Green R&D Collaboration, and Green Technological Innovation in Manufacturing Enterprises. Sustainability 2022, 14, 12106. [Google Scholar] [CrossRef]

- Bardhan, I.; Krishnan, V.V.; Lin, S. Team Dispersion, Information Technology, and Project Performance. Prod. Oper. Manag. 2013, 22, 1478–1493. [Google Scholar] [CrossRef]

- Mishra, A.; Sinha, K.K. Work Design and Integration Glitches in Globally Distributed Technology Projects. Prod. Oper. Manag. 2016, 25, 347–369. [Google Scholar] [CrossRef]

- Dobrovolskiene, N.; Tamošiuniene, R. Sustainability-Oriented Financial Resource Allocation in a Project Portfolio through Multi-Criteria Decision-Making. Sustainability 2016, 8, 485. [Google Scholar] [CrossRef]

- Madzík, P. Capture and Evaluation of Innovative Ideas in Early Stages of Product Development. TQM J. 2019, 31, 908–927. [Google Scholar] [CrossRef]

- Sun, C.; Xia, Q.; Mei, X. Evaluation of Product Innovation Practice of Chinese Internet Companies Based on DANP Model. Wirel. Commun. Mob. Comput. 2022, 2022, 5744875. [Google Scholar] [CrossRef]

- Xu, L.-J.; Fan, X.-C.; Wang, W.-Q.; Xu, L.; Duan, Y.-L.; Shi, R.-J. Renewable and Sustainable Energy of Xinjiang and Development Strategy of Node Areas in the “Silk Road Economic Belt”. Renew. Sustain. Energy Rev. 2017, 79, 274–285. [Google Scholar] [CrossRef]

- Zhang, C.; Tang, L.; Zhang, J. Identifying Critical Indicators in Performance Evaluation of Green Supply Chains Using Hybrid Multiple-Criteria Decision-Making. Sustainability 2023, 15, 6095. [Google Scholar] [CrossRef]

- Khan, S.Z.; Yang, Q.; Waheed, A. Investment in Intangible Resources and Capabilities Spurs Sustainable Competitive Advantage and Firm Performance. Corp. Soc. Responsib. Environ. Manag. 2018, 26, 285–295. [Google Scholar] [CrossRef]

| Study Title | Dimensions | No. of KPIs | Source |

|---|---|---|---|

| Performance of Global New Product Development Programs: A Resource-Based View | Financial, windows of opportunity | 6 | [32] |

| Global engineering networks: drivers, evolution, performance, and key pattern | Effectiveness, efficiency | 9 | [33] |

| Success in Global New Product Development: Impact of Strategy and the Behavioral Environment of the Firm | Windows of opportunity, time to market, financial outcomes | 8 | [8] |

| You Learn from What You Measure: Financial and Non-financial Performance Measures in Multinational Companies | Financial, customer, people, internal processes | 35 | [34] |

| Using a hybrid MCDM methodology to identify Critical factors in new product development | Financial, non-financial | 14 | [14] |

| The differences between successful and unsuccessful new manufacturing products in international markets | Export performance | 4 | [35] |

| Firm-Level IT Outsourcing Decision Making: A Balanced Scorecard-Based Analytic Network Process Model | Customer, financial, internal operations, learning and growth | 17 | [9] |

| Non-financial performance measures and the BSC of multinational companies with multi-cultural environment an empirical investigation | Financial, non-financial | 19 | [36] |

| Process-related key performance indicators for measuring sustainability performance of eco-design implementation into product development | Economic, social, environmental | 22 | [37] |

| Global product development projects: measuring performance and monitoring the risks | Development cost, time, product quality, others | 12 | [5] |

| Comparing offshoring and backshoring: The role of manufacturing site location factors and their impact on post-relocation performance | Cost, quality, delivery, flexibility | 9 | [2] |

| Product architecture, global operations networks, and operational performance: an exploratory study | Quality, delivery, flexibility, Cost | 7 | [38] |

| A comprehensive KPI network for the performance measurement and management in global production networks | Quality, efficiency, time, flexibility | 11 | [10] |

| Dimension | KPIs | Description | Sources |

|---|---|---|---|

| Financial Performance (FP) | Cost of PD (FP1) | The cost incurred in the entire product development process, from conception to launch, including research, design, testing, and marketing. | [1,5,31,32,44] |

| Labor cost efficiency (FP2) | The daily performance of each team or individual compared to the benchmarking and GPD site location (changes from one country to another). | [1,2,44,45,46] | |

| % of sales exported/foreign sales (FP3) | The proportion of a company’s total sales generated from international markets and through exports due to GPD projects. | [31,35,46,47] | |

| Return on investment (FP4) | The ratio of profit or return generated to the investment made in offshored PD projects indicates the investment’s efficiency. | [5,9,31,36] | |

| Quality Effectiveness (QE) | On-time delivery (QE1) | The percentage of products or services delivered on time, indicating speed to market and reliability of delivery. | [2,36,45] |

| Quality of product/output (QE2) | The degree to which the developed products and work outputs meet the global market quality standards, reliability, and robustness. | [2,9,14,34] | |

| Customer satisfaction (QE3) | The degree to which customers are satisfied with the quality and usability of the globally developed product and the provided services. | [5,9,36] | |

| % of innovative product ideas (QE4) | The proportion of novelty of the product and the creativity of ideas generated by the virtual teams during the GPD projects. | [7,11,26] | |

| Strategy-compliant GPD portfolio (QE5) | The degree of congruence of the project with the lined visualization measures how much the GPD project portfolio aligns with the organization’s strategic objectives and goals. | [25,26] | |

| Time Efficiency (TE) | Time to market (TE1) | The time it takes to bring a product to market from when it is first conceptualized to when it is finally launched. | [7,8,34,45] |

| Speed for new product development (TE2) | The duration required to develop and introduce “new products” or innovations during GPD projects. | [7,8,31] | |

| GPD project lead time (TE3) | The amount of time it takes to execute a GPD project from project initiation to completion successfully. | [5,6,32] | |

| Environmental Performance (EP) | Carbon footprint (EP1) | The amount of greenhouse gas emissions, particularly carbon dioxide (CO2), produced throughout the lifecycle of the development projects. | [48] |

| Energy consumption (EP2) | The energy resources consumed during various activities involved in developing, producing, and distributing a product on a global project scale. | [48,49,50] | |

| Environmental regulation compliance (EP3) | The degree to which the GPD project aligns with local and international environmental protocols and standards (e.g., adherence to emissions limits and waste disposal regulations). | [37,49,50] | |

| Capability Enhancement (CE) | New technology acquisition ratio (CE1) | The proportion of novel technological tools and approaches gained from overseas projects and applied to recently developed products. | [8,27,32,46,47] |

| Co-learning/global knowledge integration (CE2) | The extent of acquired information and knowledge due to collaboration within GPD projects. | [26,45] | |

| Employee training and development (CE3) | The number of training and development programs provided to employees involved in GPD projects to nurture their skills and knowledge. | [7,36,45] | |

| External supplier development (CE4) | The amount of optimal and trustful cooperation established with external parties, which contributes to enhancing delivery and export. | [26,45,51] |

| FP1 | FP2 | FP3 | FP4 | QE1 | QE2 | QE3 | QE4 | QE5 | TE1 | TE2 | TE3 | EP1 | EP2 | EP3 | CE1 | CE2 | CE3 | CE4 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FP1 | 0.000 | 3.000 | 2.800 | 1.600 | 1.400 | 1.600 | 2.400 | 3.000 | 1.400 | 2.000 | 2.600 | 3.400 | 2.800 | 2.400 | 2.000 | 3.400 | 2.200 | 1.600 | 1.800 |

| FP2 | 1.800 | 0.000 | 3.000 | 2.600 | 1.600 | 1.800 | 2.000 | 2.200 | 3.200 | 3.000 | 2.000 | 3.600 | 3.400 | 3.200 | 3.400 | 2.400 | 2.800 | 2.600 | 1.400 |

| FP3 | 2.000 | 2.800 | 0.000 | 3.200 | 1.800 | 1.600 | 2.400 | 2.600 | 2.200 | 3.400 | 0.000 | 3.800 | 3.200 | 3.000 | 1.600 | 2.000 | 1.600 | 1.000 | 1.800 |

| FP4 | 2.600 | 1.000 | 1.600 | 0.000 | 0.800 | 1.000 | 2.400 | 1.200 | 2.400 | 2.800 | 1.000 | 2.200 | 2.000 | 2.400 | 0.800 | 1.200 | 1.400 | 1.000 | 2.200 |

| QE1 | 1.600 | 1.000 | 1.400 | 2.000 | 0.000 | 1.800 | 3.000 | 1.600 | 2.400 | 2.600 | 3.200 | 1.400 | 1.800 | 1.000 | 0.800 | 0.600 | 0.000 | 2.200 | 2.400 |

| QE2 | 1.600 | 2.100 | 1.600 | 1.600 | 1.800 | 0.000 | 2.400 | 1.600 | 2.000 | 3.000 | 2.400 | 1.800 | 1.800 | 2.800 | 1.000 | 1.400 | 1.600 | 2.400 | 1.600 |

| QE3 | 1.200 | 2.000 | 2.400 | 1.400 | 1.600 | 2.600 | 0.000 | 2.400 | 2.200 | 2.400 | 1.600 | 2.000 | 1.800 | 2.800 | 2.800 | 1.600 | 2.200 | 1.000 | 1.400 |

| QE4 | 1.800 | 2.200 | 1.600 | 2.000 | 1.600 | 2.200 | 3.400 | 0.000 | 2.400 | 3.200 | 2.400 | 3.200 | 1.800 | 2.800 | 2.600 | 1.600 | 2.400 | 1.600 | 2.200 |

| QE5 | 2.000 | 2.600 | 2.200 | 2.000 | 2.600 | 2.400 | 3.400 | 2.800 | 0.000 | 3.200 | 1.600 | 3.400 | 3.200 | 3.000 | 1.600 | 1.400 | 2.400 | 2.800 | 2.600 |

| TE1 | 2.400 | 2.200 | 1.600 | 1.000 | 2.400 | 2.200 | 3.200 | 3.000 | 2.800 | 0.000 | 1.000 | 2.000 | 2.000 | 3.600 | 1.200 | 1.000 | 1.600 | 2.400 | 2.800 |

| TE2 | 2.000 | 1.800 | 1.600 | 3.200 | 2.800 | 1.800 | 3.400 | 2.800 | 2.400 | 2.800 | 0.000 | 3.000 | 2.200 | 2.600 | 2.200 | 2.400 | 1.400 | 1.000 | 2.000 |

| TE3 | 2.600 | 2.000 | 1.800 | 2.000 | 1.800 | 1.200 | 2.200 | 2.800 | 3.200 | 2.800 | 2.600 | 0.000 | 2.600 | 3.600 | 1.400 | 1.400 | 1.000 | 1.400 | 2.800 |

| EP1 | 2.300 | 1.300 | 1.600 | 3.400 | 1.600 | 2.400 | 2.200 | 1.000 | 2.000 | 2.000 | 1.000 | 1.000 | 0.000 | 3.600 | 1.600 | 1.600 | 2.600 | 2.600 | 2.000 |

| EP2 | 1.800 | 2.400 | 2.600 | 3.000 | 2.600 | 2.400 | 3.000 | 2.600 | 3.200 | 3.000 | 2.400 | 2.200 | 2.000 | 0.000 | 2.000 | 2.800 | 2.400 | 2.600 | 2.000 |

| EP3 | 1.400 | 2.200 | 2.400 | 2.400 | 2.000 | 2.400 | 2.400 | 3.400 | 3.200 | 3.200 | 2.800 | 3.400 | 3.600 | 3.400 | 0.000 | 2.800 | 2.800 | 3.200 | 3.000 |

| CE1 | 3.200 | 3.600 | 3.400 | 2.400 | 2.000 | 2.200 | 3.000 | 3.600 | 2.400 | 3.000 | 3.200 | 3.600 | 3.600 | 2.400 | 2.600 | 0.000 | 2.600 | 2.800 | 2.800 |

| CE2 | 2.400 | 3.000 | 2.400 | 2.600 | 1.600 | 2.300 | 2.600 | 2.000 | 2.600 | 2.800 | 2.600 | 3.600 | 3.200 | 3.400 | 2.400 | 2.200 | 0.000 | 2.200 | 1.600 |

| CE3 | 1.800 | 2.400 | 1.800 | 2.600 | 3.200 | 2.800 | 2.600 | 2.800 | 3.200 | 2.800 | 3.400 | 3.400 | 2.600 | 2.400 | 1.800 | 1.600 | 1.600 | 0.000 | 2.400 |

| CE4 | 1.600 | 2.600 | 1.600 | 1.800 | 2.000 | 2.400 | 2.600 | 2.400 | 2.600 | 2.200 | 2.600 | 1.600 | 1.000 | 2.400 | 2.600 | 2.600 | 1.600 | 1.000 | 0.000 |

| FP1 | FP2 | FP3 | FP4 | QE1 | QE2 | QE3 | QE4 | QE5 | TE1 | TE2 | TE3 | EP1 | EP2 | EP3 | CE1 | CE2 | CE3 | CE4 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FP1 | 0.1316 | 0.1993 | 0.1867 | 0.1769 | 0.1538 | 0.1640 | 0.2182 | 0.2125 | 0.1917 | 0.2166 | 0.1836 | 0.2342 | 0.2104 | 0.2280 | 0.1629 | 0.1847 | 0.1661 | 0.1578 | 0.1737 |

| FP2 | 0.1784 | 0.1592 | 0.2035 | 0.2098 | 0.1714 | 0.1820 | 0.2295 | 0.2145 | 0.2410 | 0.2530 | 0.1864 | 0.2551 | 0.2378 | 0.2617 | 0.1986 | 0.1789 | 0.1895 | 0.1901 | 0.1822 |

| FP3 | 0.1615 | 0.1868 | 0.1279 | 0.1957 | 0.1533 | 0.1566 | 0.2086 | 0.1956 | 0.1972 | 0.2311 | 0.1289 | 0.2297 | 0.2078 | 0.2291 | 0.1473 | 0.1518 | 0.1484 | 0.1409 | 0.1666 |

| FP4 | 0.1419 | 0.1233 | 0.1269 | 0.1044 | 0.1075 | 0.1160 | 0.1696 | 0.1362 | 0.1624 | 0.1794 | 0.1159 | 0.1631 | 0.1503 | 0.1764 | 0.1051 | 0.1110 | 0.1163 | 0.1108 | 0.1414 |

| QE1 | 0.1236 | 0.1221 | 0.1222 | 0.1416 | 0.0935 | 0.1309 | 0.1815 | 0.1434 | 0.1628 | 0.1767 | 0.1557 | 0.1488 | 0.1459 | 0.1512 | 0.1051 | 0.0995 | 0.0904 | 0.1314 | 0.1455 |

| QE2 | 0.1376 | 0.1574 | 0.1409 | 0.1504 | 0.1400 | 0.1117 | 0.1886 | 0.1599 | 0.1736 | 0.2026 | 0.1563 | 0.1746 | 0.1636 | 0.2023 | 0.1220 | 0.1269 | 0.1326 | 0.1498 | 0.1456 |

| QE3 | 0.1342 | 0.1603 | 0.1594 | 0.1514 | 0.1393 | 0.1629 | 0.1497 | 0.1787 | 0.1821 | 0.1982 | 0.1458 | 0.1840 | 0.1693 | 0.2085 | 0.1577 | 0.1345 | 0.1478 | 0.1298 | 0.1464 |

| QE4 | 0.1611 | 0.1814 | 0.1618 | 0.1792 | 0.1553 | 0.1724 | 0.2325 | 0.1547 | 0.2062 | 0.2337 | 0.1772 | 0.2256 | 0.1882 | 0.2312 | 0.1699 | 0.1496 | 0.1663 | 0.1552 | 0.1780 |

| QE5 | 0.1757 | 0.2002 | 0.1833 | 0.1920 | 0.1838 | 0.1876 | 0.2471 | 0.2177 | 0.1763 | 0.2486 | 0.1747 | 0.2427 | 0.2255 | 0.2499 | 0.1625 | 0.1557 | 0.1764 | 0.1872 | 0.1966 |

| TE1 | 0.1624 | 0.1724 | 0.1531 | 0.1522 | 0.1616 | 0.1645 | 0.2180 | 0.1983 | 0.2021 | 0.1641 | 0.1446 | 0.1930 | 0.1805 | 0.2321 | 0.1374 | 0.1312 | 0.1442 | 0.1613 | 0.1789 |

| TE2 | 0.1647 | 0.1731 | 0.1612 | 0.1998 | 0.1754 | 0.1643 | 0.2323 | 0.2044 | 0.2051 | 0.2260 | 0.1328 | 0.2208 | 0.1942 | 0.2260 | 0.1617 | 0.1625 | 0.1477 | 0.1438 | 0.1744 |

| TE3 | 0.1694 | 0.1713 | 0.1591 | 0.1734 | 0.1534 | 0.1487 | 0.2044 | 0.1982 | 0.2122 | 0.2183 | 0.1740 | 0.1597 | 0.1944 | 0.2361 | 0.1430 | 0.1411 | 0.1362 | 0.1457 | 0.1823 |

| EP1 | 0.1539 | 0.1476 | 0.1451 | 0.1864 | 0.1390 | 0.1592 | 0.1893 | 0.1528 | 0.1778 | 0.1900 | 0.1355 | 0.1653 | 0.1350 | 0.2210 | 0.1355 | 0.1346 | 0.1542 | 0.1572 | 0.1563 |

| EP2 | 0.1733 | 0.1978 | 0.1914 | 0.2103 | 0.1844 | 0.1878 | 0.2414 | 0.2156 | 0.2344 | 0.2465 | 0.1891 | 0.2241 | 0.2063 | 0.2157 | 0.1699 | 0.1807 | 0.1770 | 0.1843 | 0.1871 |

| EP3 | 0.1822 | 0.2116 | 0.2036 | 0.2182 | 0.1899 | 0.2045 | 0.2520 | 0.2484 | 0.2548 | 0.2714 | 0.2130 | 0.2650 | 0.2529 | 0.2798 | 0.1483 | 0.1959 | 0.1996 | 0.2107 | 0.2219 |

| CE1 | 0.2205 | 0.2439 | 0.2289 | 0.2259 | 0.1955 | 0.2073 | 0.2708 | 0.2604 | 0.2490 | 0.2771 | 0.2264 | 0.2786 | 0.2620 | 0.2723 | 0.2032 | 0.1526 | 0.2030 | 0.2094 | 0.2250 |

| CE2 | 0.1863 | 0.2106 | 0.1906 | 0.2066 | 0.1688 | 0.1879 | 0.2365 | 0.2077 | 0.2271 | 0.2457 | 0.1946 | 0.2512 | 0.2305 | 0.2613 | 0.1792 | 0.1734 | 0.1361 | 0.1799 | 0.1822 |

| CE3 | 0.1721 | 0.1956 | 0.1754 | 0.2023 | 0.1945 | 0.1937 | 0.2335 | 0.2175 | 0.2335 | 0.2426 | 0.2063 | 0.2425 | 0.2146 | 0.2383 | 0.1650 | 0.1586 | 0.1612 | 0.1358 | 0.1934 |

| CE4 | 0.1470 | 0.1773 | 0.1516 | 0.1643 | 0.1521 | 0.1651 | 0.2050 | 0.1862 | 0.1961 | 0.2023 | 0.1704 | 0.1848 | 0.1619 | 0.2084 | 0.1604 | 0.1578 | 0.1426 | 0.1349 | 0.1264 |

| FP | QE | TE | EP | CE | |

|---|---|---|---|---|---|

| FP | 0.7401 | 1.0322 | 0.9023 | 0.9604 | 0.7541 |

| QE | 1.1020 | 1.1644 | 1.2113 | 1.2185 | 1.0811 |

| TE | 1.1933 | 1.3681 | 0.9824 | 1.1761 | 1.0336 |

| EP | 1.0036 | 1.2386 | 0.9545 | 0.8844 | 0.8644 |

| CE | 1.0396 | 1.2690 | 1.0909 | 1.1556 | 0.8086 |

| Dimension/Indicator | Rank | Nature | ||||

|---|---|---|---|---|---|---|

| FP | 4.3891 | 5.0787 | 9.4679 | 5 | −0.6896 | Effect |

| FP1 | 3.5528 | 3.0772 | 6.6300 | 14 | 0.4756 | Cause |

| FP2 | 3.9226 | 3.3912 | 7.3138 | 5 | 0.5314 | Cause |

| FP3 | 3.3650 | 3.1729 | 6.5379 | 15 | 0.1921 | Cause |

| FP4 | 2.5578 | 3.4407 | 5.9985 | 18 | −0.8829 2 | Effect |

| QE | 5.7773 | 6.0723 | 11.8496 | 1 | −0.2950 | Effect |

| QE1 | 2.5717 | 3.0127 | 5.5844 | 19 | −0.4410 | Effect |

| QE2 | 2.9363 | 3.1670 | 6.1033 | 17 | −0.2307 | Effect |

| QE3 | 3.0401 | 4.1086 | 7.1487 | 9 | −1.0685 2 | Effect |

| QE4 | 3.7025 | 3.4797 | 7.1822 | 7 | 0.2228 | Cause |

| QE5 | 3.7836 | 3.8853 | 7.6689 | 2 | −0.1017 | Effect |

| TE | 5.7535 | 5.1414 | 10.8948 | 2 | 0.6121 | Cause |

| TE1 | 3.2519 | 4.2239 | 7.4758 | 3 | −0.9720 2 | Effect |

| TE2 | 3.4703 | 3.2111 | 6.6814 | 13 | 0.2592 | Cause |

| TE3 | 3.3209 | 4.0428 | 7.3637 | 4 | −0.7219 | Effect |

| EP | 4.9455 | 5.3949 | 10.3403 | 3 | −0.4494 | Effect |

| EP1 | 3.0355 | 3.7312 | 6.7667 | 12 | −0.6957 | Effect |

| EP2 | 3.7970 | 4.3092 | 8.1062 | 1 | −0.5122 | Effect |

| EP3 | 4.2235 | 2.9346 | 7.1581 | 8 | 1.2889 1 | Cause |

| CE | 5.3637 | 4.5418 | 9.9055 | 4 | 0.8218 | Cause |

| CE1 | 4.4119 | 2.8811 | 7.2930 | 6 | 1.5308 1 | Cause |

| CE2 | 3.8561 | 2.9358 | 6.7919 | 11 | 0.9203 1 | Cause |

| CE3 | 3.7763 | 3.0158 | 6.7921 | 10 | 0.7605 | Cause |

| CE4 | 3.1945 | 3.3038 | 6.4983 | 16 | −0.1093 | Effect |

| Dimension/Indicator | Local Weight | Global Weight | Rank |

|---|---|---|---|

| Financial Performance | 0.1928 | 4 | |

| Cost of PD | 0.2448 | 0.0451 | 17 |

| Labor cost efficiency | 0.2676 | 0.0450 | 18 |

| % of sales exported/foreign sales | 0.2516 | 0.0461 | 16 |

| Return on investment | 0.2713 | 0.0508 | 10 |

| Quality Effectiveness | 0.2313 | 1 | |

| On-time delivery | 0.1989 | 0.0463 | 15 |

| Quality of product/output | 0.2093 | 0.0474 | 14 |

| Customer satisfaction | 0.2715 | 0.0599 | 5 |

| % of innovative product ideas | 0.2438 | 0.0650 | 2 |

| Strategy-compliant GPD portfolio | 0.2572 | 0.0488 | 12 |

| Time Efficiency | 0.1967 | 3 | |

| Time to market | 0.3274 | 0.0527 | 8 |

| Speed for new product development | 0.2486 | 0.0522 | 9 |

| GPD project lead time | 0.3111 | 0.0442 | 19 |

| Environmental Performance | 0.2054 | 2 | |

| Carbon footprint | 0.2751 | 0.0487 | 13 |

| Energy consumption | 0.3213 | 0.0567 | 7 |

| Environmental regulation compliance | 0.2186 | 0.0633 | 3 |

| Capability Enhancement | 0.1738 | 5 | |

| New technology acquisition ratio | 0.2532 | 0.0662 | 1 |

| Co-learning/global knowledge integration | 0.2583 | 0.0620 | 4 |

| Employee training and development | 0.2652 | 0.0494 | 11 |

| External supplier development | 0.2911 | 0.0570 | 6 |

| # | Category | Weight | Indicators/Priority | Implications |

|---|---|---|---|---|

| 1 | Cause | High | QE4, TE2, EP3, CE1, CE2 Priority CE1 > QE4 > EP3 > CE2 > TE2 | Indicators in this group are critical. By allocating resources and attention to these indicators, enhancement in these areas can significantly optimize their high causal impact and improve the overall GPD project performance. |

| 2 | Low | FP1, FP2, FP3, CE3 Priority CE3 > FP3 > FP1 > FP2 | The amelioration of this category by considering aligning these indicators with strategic objectives and exploring ways to enhance their influence is beneficial. Although they may not have the highest priority, addressing these indicators can still have a positive impact. | |

| 3 | Effect | High | FP4, QE3, TE1, EP2, CE4 Priority QE3 > CE4 > EP2 > TE1 > FP4 | This group includes the strongly influenced indicators reflecting the outcomes of the GPD projects. Decision-makers should closely monitor these by enhancing their leading “cause” indicators and measuring them regularly to assess project performance accurately. |

| 4 | Low | QE1, QE2, QE5, TE3, EP1 Priority QE5 > EP1 > QE2 > QE1 > TE3 | This group of indicators may not be the primary focus, yet it is necessary to consider monitoring their impact and seeking opportunities for improvement. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malek, R.; Yang, Q. Analyzing Interrelationships and Prioritizing Performance Indicators in Global Product Development: Application in the Chinese Renewable Energy Sector. Sustainability 2023, 15, 11212. https://doi.org/10.3390/su151411212

Malek R, Yang Q. Analyzing Interrelationships and Prioritizing Performance Indicators in Global Product Development: Application in the Chinese Renewable Energy Sector. Sustainability. 2023; 15(14):11212. https://doi.org/10.3390/su151411212

Chicago/Turabian StyleMalek, Razika, and Qing Yang. 2023. "Analyzing Interrelationships and Prioritizing Performance Indicators in Global Product Development: Application in the Chinese Renewable Energy Sector" Sustainability 15, no. 14: 11212. https://doi.org/10.3390/su151411212

APA StyleMalek, R., & Yang, Q. (2023). Analyzing Interrelationships and Prioritizing Performance Indicators in Global Product Development: Application in the Chinese Renewable Energy Sector. Sustainability, 15(14), 11212. https://doi.org/10.3390/su151411212