Uses of Bamboo for Sustainable Construction—A Structural and Durability Perspective—A Review

Abstract

1. Introduction

2. Materials and Methods

2.1. Density

2.2. Moisture Content

3. Mechanical Properties

3.1. Compressive Strength

3.2. Tensile Strength

3.3. Flexural Strength

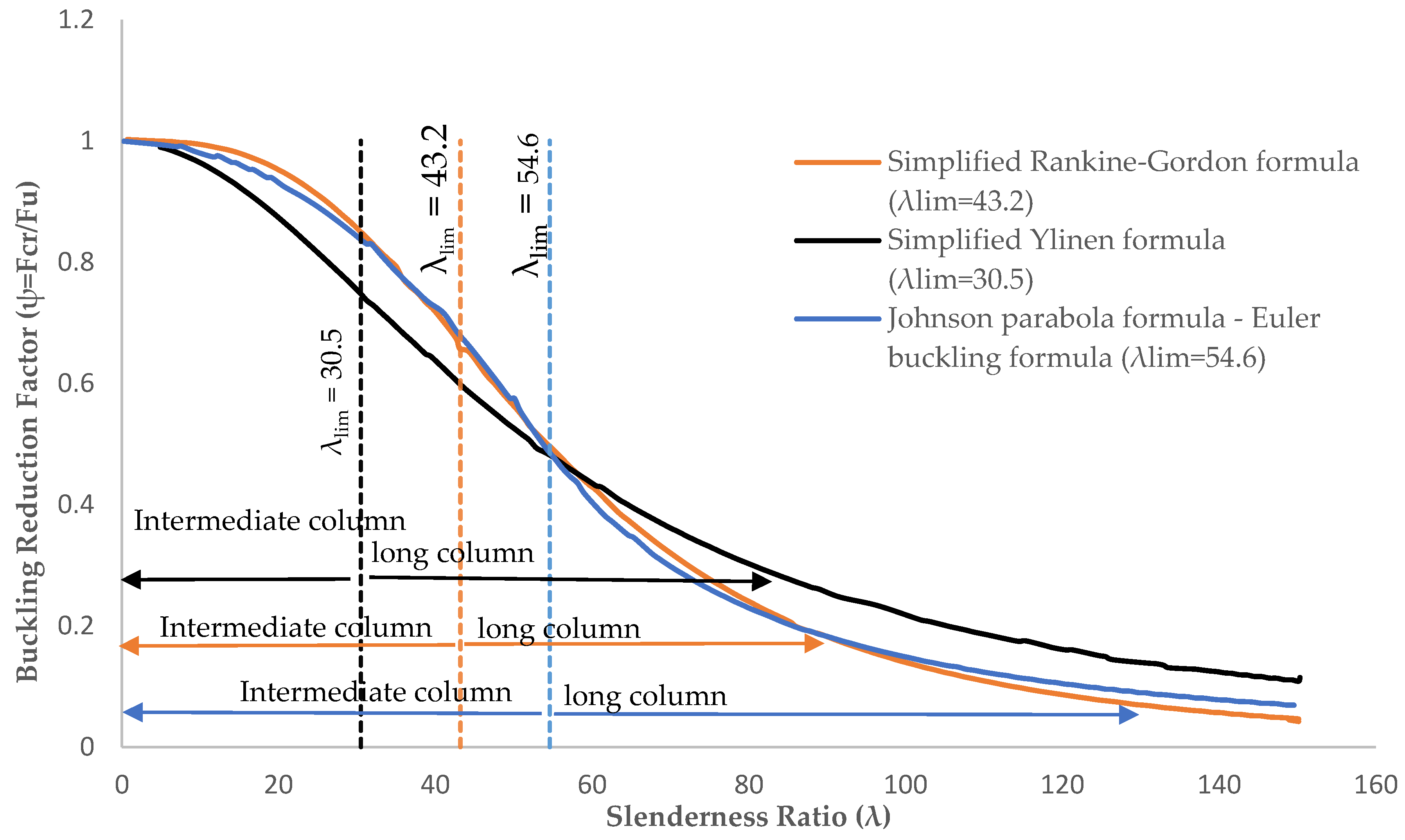

3.4. Buckling

3.5. Shear Strength

4. Cross-Laminated Bamboo

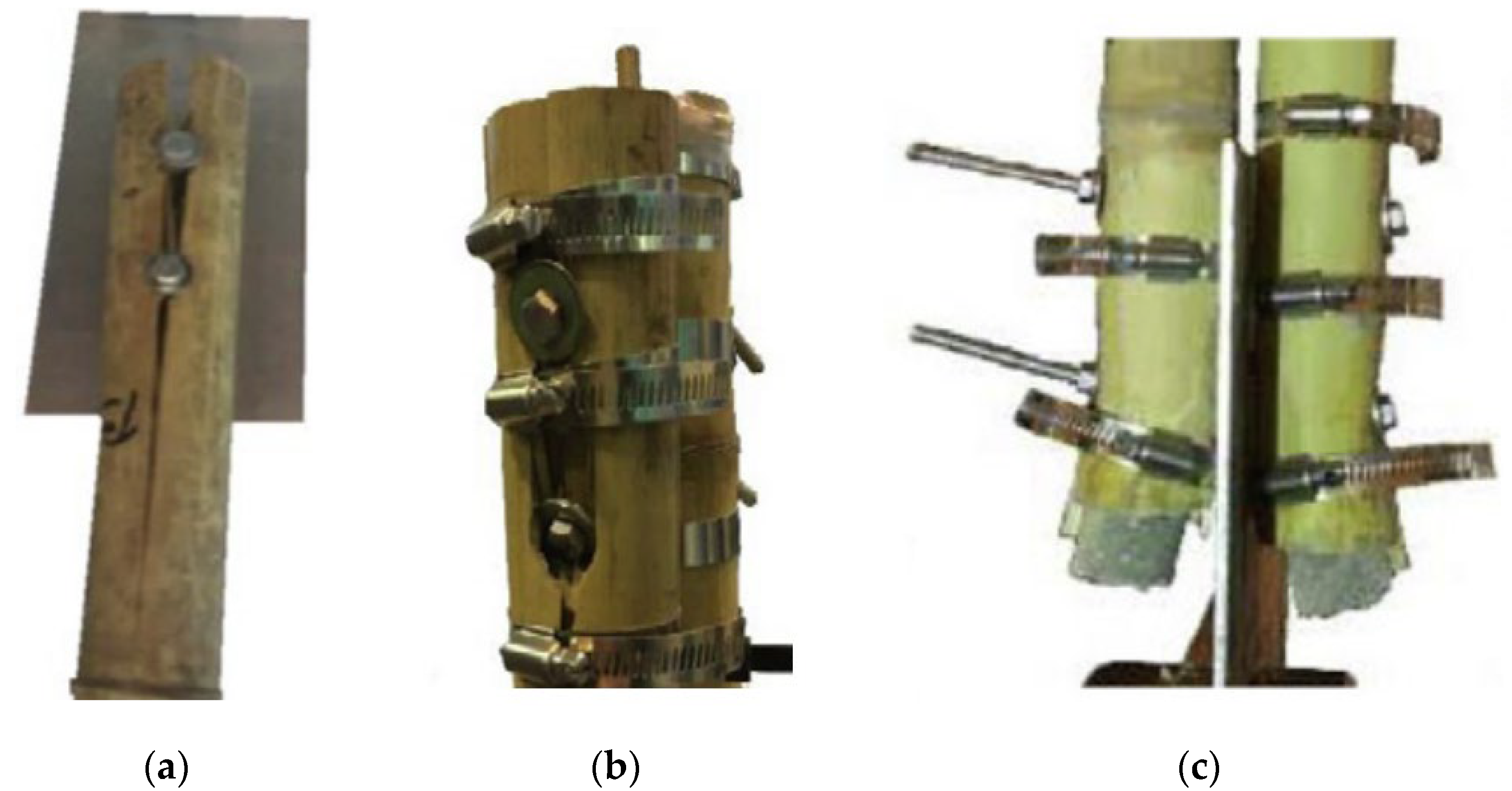

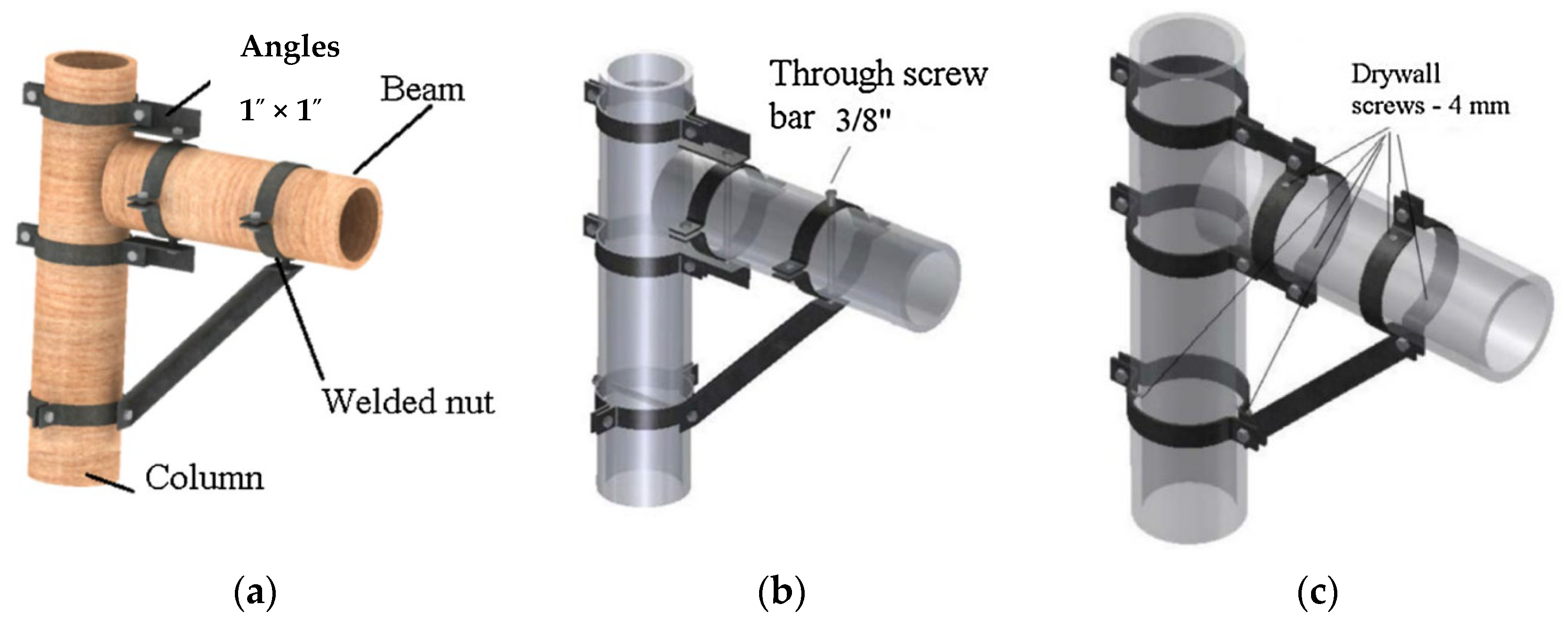

5. Connections

6. Preservation

6.1. Oil-Heated Treatment

6.2. Borax Solution

6.3. Water Soaking

7. Discussion

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chung, K.F.; Yu, W.K. Mechanical Properties of Structural Bamboo for Bamboo Scaffoldings. Eng. Struct. 2002, 24, 429–442. [Google Scholar] [CrossRef]

- Follett, P.; Jayanetti, D. Bamboo in Construction. In Modern Bamboo Structures; Taylor & Francis: London, UK, 2008; pp. 23–32. [Google Scholar]

- Wei, X.; Zhou, H.; Chen, F.; Wang, G. Bending Flexibility of Moso Bamboo (Phyllostachys Edulis) with Functionally Graded Structure. Materials 2019, 12, 2007. [Google Scholar] [CrossRef] [PubMed]

- Moran, R.; García, J.J. Bamboo Joints with Steel Clamps Capable of Transmitting Moment. Constr. Build. Mater. 2019, 216, 249–260. [Google Scholar] [CrossRef]

- Hong, C.; Li, H.; Lorenzo, R.; Wu, G.; Corbi, I.; Corbi, O.; Xiong, Z.; Yang, H.; Zhang, D. Review on Connections for Original Bamboo Structures. J. Renew. Mater. 2019, 7, 713–730. [Google Scholar] [CrossRef]

- Correal, F.F. Bamboo Design and Construction. In Nonconventional and Vernacular Construction Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 521–559. [Google Scholar]

- Nugroho, N.; Bahtiar, E.T. Structural Grading of Gigantochloa Apus Bamboo Based on Its Flexural Properties. Constr. Build. Mater. 2017, 157, 1173–1189. [Google Scholar] [CrossRef]

- Yu, D.; Tan, H.; Ruan, Y. A Future Bamboo-Structure Residential Building Prototype in China: Life Cycle Assessment of Energy Use and Carbon Emission. Energy Build. 2011, 43, 2638–2646. [Google Scholar] [CrossRef]

- Gan, J.; Chen, M.; Semple, K.; Liu, X.; Dai, C.; Tu, Q. Life Cycle Assessment of Bamboo Products: Review and Harmonization. Sci. Total Environ. 2022, 849, 157937. [Google Scholar] [CrossRef]

- Gatóo, A.; Sharma, B.; Bock, M.; Mulligan, H.; Ramage, M.H. Sustainable Structures: Bamboo Standards and Building Codes. Proc. Inst. Civ. Eng. Eng. Sustain. 2014, 167, 189–196. [Google Scholar] [CrossRef]

- Lakkad, S.C.; Patel, J.M. Mechanical Properties of Bamboo, a Natural Composite. Fibre Sci. Technol. 1981, 14, 319–322. [Google Scholar] [CrossRef]

- Chandrakeerthy, S.D.S. Design Recommendations for Bamboo Elements in Exposed Temporary Structures; Institution of Engineers Sri Lanka: Colombo, Sri Lanka, 1995; pp. 101–109. [Google Scholar]

- Bahtiar, E.T.; Imanullah, A.P.; Hermawan, D.; Nugroho, N. Abdurachman Structural Grading of Three Sympodial Bamboo Culms (Hitam, Andong, and Tali) Subjected to Axial Compressive Load. Eng. Struct. 2019, 181, 233–245. [Google Scholar] [CrossRef]

- Trujillo, D.J.; López, L.F. Bamboo Material Characterisation. In Nonconventional and Vernacular Construction Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 491–520. [Google Scholar]

- Nugroho, N.; Kartini; Bahtiar, E.T. Cross-Species Bamboo Grading Based on Flexural Properties. IOP Conf. Ser. Earth Environ. Sci. 2021, 891, 012008. [Google Scholar] [CrossRef]

- ISO/TR. 22157-1; Bamboo–Determination of Physical and Mechanical Properties—Part 1: Requirement. International Organization for Standardization: Geneva, Switzerland, 2004.

- Zakikhani, P.; Zahari, R.; Bin Haji Hameed Sultan, M.T.; Abang Abdul Majid, D.L. Morphological, Mechanical, and Physical Properties of Four Bamboo Species. Bioresources 2017, 12, 2479–2495. [Google Scholar] [CrossRef]

- Kamthai, S.; Puthson, P. The Physical Properties, Fiber Morphology and Chemical Compositions of Sweet Bamboo (Dendrocalamus Asper Backer). Agric. Nat. Resour. 2005, 39, 581–587. [Google Scholar]

- Moroz, J.G.; Lissel, S.L.; Hagel, M.D. Performance of Bamboo Reinforced Concrete Masonry Shear Walls. Constr. Build. Mater. 2014, 61, 125–137. [Google Scholar] [CrossRef]

- Bhonde, D.; Nagarnaik, P.B.; Parbat, D.K.; Waghe, U.P. Physical and Mechanical Properties of Bamboo (Dendrocalmus Strictus). Int. J. Sci. Eng. Res. 2014, 5, 455–459. [Google Scholar]

- Fabiani, M. Physical and Mechanical Properties of Italian Bamboo Culms. In Proceedings of the 10th World Bamboo Congress, Damyang, Republic of Korea, 17–22 September 2015. [Google Scholar]

- Shastry, A.; Unnikrishnan, S. Investigation on Elastic Properties of Bamboo and Behavior of Bamboo Reinforced Concrete Beams. Int. J. Earth Sci. Eng. 2017, 10, 304–312. [Google Scholar] [CrossRef]

- Trujillo, D.; Jangra, S.; Gibson, J.M. Flexural Properties as a Basis for Bamboo Strength Grading. Proc. Inst. Civ. Eng.-Struct. Build. 2017, 170, 284–294. [Google Scholar] [CrossRef]

- Parasuram, M.; Baskaran, K. Study on Bamboo and Steel as Hybrid Reinforcement for Concrete Slab. In Proceedings of the Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 28–30 July 2020; IEEE: New York, NY, USA, 2020. [Google Scholar]

- Bahtiar, E.T.; Trujillo, D.; Nugroho, N. Compression Resistance of Short Members as the Basis for Structural Grading of Guadua Angustifolia. Constr. Build. Mater. 2020, 249, 118759. [Google Scholar] [CrossRef]

- Iswanto, A.H.; Madyaratri, E.W.; Hutabarat, N.S.; Zunaedi, E.R.; Darwis, A.; Hidayat, W.; Susilowati, A.; Adi, D.S.; Lubis, M.A.R.; Sucipto, T.; et al. Chemical, Physical, and Mechanical Properties of Belangke Bamboo (Gigantochloa Pruriens) and Its Application as a Reinforcing Material in Particleboard Manufacturing. Polymers 2022, 14, 3111. [Google Scholar] [CrossRef]

- Navaratnam, S.; Christopher, P.B.; Ngo, T.; Le, T.V. Bending and Shear Performance of Australian Radiata Pine Cross-Laminated Timber. Constr. Build. Mater. 2020, 232, 117215. [Google Scholar] [CrossRef]

- Bandara, S.; Rajeev, P.; Gad, E. Structural Health Assessment Techniques for In-Service Timber Poles. Struct. Infrastruct. Eng. 2023, 19, 439–459. [Google Scholar] [CrossRef]

- Autengruber, M.; Lukacevic, M.; Gröstlinger, C.; Eberhardsteiner, J.; Füssl, J. Numerical Assessment of Wood Moisture Content-Based Assignments to Service Classes in EC 5 and a Prediction Concept for Moisture-Induced Stresses Solely Using Relative Humidity Data. Eng. Struct. 2021, 245, 112849. [Google Scholar] [CrossRef]

- Almeida, G.; Hernández, R.E. Changes in Physical Properties of Tropical and Temperate Hardwoods below and above the Fiber Saturation Point. Wood Sci. Technol. 2006, 40, 599–613. [Google Scholar] [CrossRef]

- Liese, W.; Tang, T.K.H. Preservation and Drying of Bamboo. In Bamboo; Springer: Berlin/Heidelberg, Germany, 2015; pp. 257–297. [Google Scholar]

- Jiang, Z.; Wang, H.; Tian, G.; Liu, X.; Yu, Y. Sensitivity of several selected mechanical properties of moso bamboo to moisture content change under the fibre saturation point. Bioresources 2012, 7, 5048–5058. [Google Scholar] [CrossRef]

- Kaminski, S.; Lawrence, A.; Trujillo, D.; Feltham, I.; Felipe López, L. Structural Use of Bamboo. Part 3: Design Values. Struct. Eng. 2016, 94, 42–45. [Google Scholar]

- Harries, K.A.; Sharma, B.; Richard, M. Structural Use of Full Culm Bamboo: The Path to Standardization. Int. J. Archit. Eng. Constr. 2012, 1, 66–75. [Google Scholar] [CrossRef]

- Sakaray, H.; Togati, N.V.V.K.; Reddy, I.R. Investigation on Properties of Bamboo as Reinforcing Material in Concrete. Int. J. Eng. Res. Appl. 2012, 2, 77–83. [Google Scholar]

- Awalluddin, D.; Ariffin, M.A.M.; Osman, M.H.; Hussin, M.W.; Ismail, M.A.; Lee, H.S.; Lim, N.H.A.S. Mechanical Properties of Different Bamboo Species. In Proceedings of the MATEC web of conferences, Sibiu, Romania, 7–9 June 2017; EDP Sciences: Les Ulis, France, 2017. [Google Scholar]

- Mahzuz, H.M.A.; Ahmed, M.; Dutta, J.; Rose, R.H. Determination of Several Properties of a Bamboo of Bangladesh. J. Civ. Eng. Res. 2013, 3, 16–21. [Google Scholar]

- Sabbir, M.A.; Hoq, S.A.; Fancy, S.F. Determination of Tensile Property of Bamboo for Using as Potential Reinforcement in the Concrete. Int. J. Civ. Environ. Eng. IJCEE-IJENS 2011, 11, 47–54. [Google Scholar]

- Nugroho, N.; Bahtiar, E.T. Grading Development of Indonesian Bamboo Culm: Case Study on Tali Bamboo (Gigantochloa Apus). In Proceedings of the 2018 World Conference on Timber Engineering, Seoul, Republic of Korea, 20–23 August 2018. [Google Scholar]

- Molari, L.; García, J.J. On the Radial Variation of the Transverse Mechanical Properties of Bamboo. J. Build. Eng. 2021, 33, 101557. [Google Scholar] [CrossRef]

- Li, X. Physical, Chemical, and Mechanical Properties of Bamboo and Its Utilization Potential for Fiberboard Manufacturing; Louisiana State University and Agricultural & Mechanical College: Baton Rouge, LA, USA, 2004. [Google Scholar]

- Lopez, J. Optimizing the Mechanical Characteristics of Bamboo to Improve the Flexural Behavior for Biocomposite Structural Application; California Polytechnic State University: San Luis Obispo, CA, USA, 2012. [Google Scholar]

- Taylor, D.; Kinane, B.; Sweeney, C.; Sweetnam, D.; O’Reilly, P.; Duan, K. The Biomechanics of Bamboo: Investigating the Role of the Nodes. Wood Sci. Technol. 2015, 49, 345–357. [Google Scholar] [CrossRef]

- Sá Ribeiro, R.A.; Sá Ribeiro, M.G.; Miranda, I.P.A. Bending Strength and Nondestructive Evaluation of Structural Bamboo. Constr. Build. Mater. 2017, 146, 38–42. [Google Scholar] [CrossRef]

- Liu, P.; Zhou, Q.; Fu, F.; Li, W. Bending Strength Design Method of Phyllostachys Edulis Bamboo Based on Classification. Polymers 2022, 14, 1418. [Google Scholar] [CrossRef] [PubMed]

- British Standard BS 5268-2; Structural Use of Timber Part 2: Code of Practice for Permissible Stress Design, Materials and Workmanship. British Standards Institution: London, UK, 2002.

- Yu, W.K.; Chung, K.F.; Chan, S.L. Column Buckling of Structural Bamboo. Eng. Struct. 2003, 25, 755–768. [Google Scholar] [CrossRef]

- Yu, W.K.; Chung, K.F.; Chan, S.L. Axial Buckling of Bamboo Columns in Bamboo Scaffolds. Eng. Struct. 2005, 27, 61–73. [Google Scholar] [CrossRef]

- Nie, Y.; Wei, Y.; Huang, L.; Liu, Y.; Dong, F. Influence of Slenderness Ratio and Sectional Geometry on the Axial Compression Behavior of Original Bamboo Columns. J. Wood Sci. 2021, 67, 36. [Google Scholar] [CrossRef]

- Bahtiar, E.T.; Malkowska, D.; Trujillo, D.; Nugroho, N. Experimental Study on Buckling Resistance of Guadua Angustifolia Bamboo Column. Eng. Struct. 2021, 228, 111548. [Google Scholar] [CrossRef]

- Porteous, J.; Kermani, A. (Eds.) Structural Timber Design to Eurocode 5; Blackwell Science Ltd: Oxford, UK, 2007; ISBN 9780470697818. [Google Scholar]

- Wang, R.; Shi, J.J.; Xia, M.K.; Li, Z. Rolling Shear Performance of Cross-Laminated Bamboo-Balsa Timber Panels. Constr. Build. Mater. 2021, 299, 123973. [Google Scholar] [CrossRef]

- Yang, S.; Li, H.; Fei, B.; Zhang, X.; Wang, X. Bond Quality and Durability of Cross-Laminated Flattened Bamboo and Timber (CLBT). Forests 2022, 13, 1271. [Google Scholar] [CrossRef]

- Lv, Q.; Wang, W.; Liu, Y. Study on Thermal Insulation Performance of Cross-Laminated Bamboo Wall. J. Renew. Mater. 2019, 7, 1231–1250. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Q.; Huang, D.; Deeks, A.J. Compressive Performance of Laminated Bamboo. Compos. B Eng. 2013, 54, 319–328. [Google Scholar] [CrossRef]

- Li, H.; Wang, L.; Wei, Y.; Wang, B.J. Off-Axis Compressive Behavior of Cross-Laminated Bamboo and Timber Wall Elements. Structures 2022, 35, 452–468. [Google Scholar] [CrossRef]

- Li, H.; Wang, L.; Wang, B.J.; Wei, Y. Study on In-Plane Compressive Performance of Cross-Laminated Bamboo and Timber (CLBT) Wall Elements. Eur. J. Wood Wood Prod. 2023, 81, 343–355. [Google Scholar] [CrossRef]

- Dong, W.; Wang, Z.; Zhou, J.; Gong, M. Experimental Study on Bending Properties of Cross-Laminated Timber-Bamboo Composites. Constr. Build. Mater. 2021, 300, 124313. [Google Scholar] [CrossRef]

- Lv, Q.; Wang, W.; Liu, Y. Flexural Performance of Cross-Laminated Bamboo (CLB) Slabs and CFRP Grid Composite CLB Slabs. Adv. Civ. Eng. 2019, 2019, 1–17. [Google Scholar] [CrossRef]

- Xiao, Y.; Cai, H.; Dong, S.Y. A Pilot Study on Cross-Laminated Bamboo and Timber Beams. J. Struct. Eng. 2021, 147, 06021002. [Google Scholar] [CrossRef]

- Xing, W.; Hao, J.; Sikora, K.S. Shear Performance of Adhesive Bonding of Cross-Laminated Bamboo. J. Mater. Civ. Eng. 2019, 31, 04019201. [Google Scholar] [CrossRef]

- Li, Z.; Xia, M.K.; Shi, J.J.; Wang, R. Shear Properties of Composite Cross-Laminated Bamboo Panels. Eur. J. Wood Wood Prod. 2022, 80, 635–646. [Google Scholar] [CrossRef]

- Awaludin, A.; Andriani, V. Bolted Bamboo Joints Reinforced with Fibers. Procedia Eng. 2014, 95, 15–21. [Google Scholar] [CrossRef]

- Camacho, V.; Páez, I. Estudio de Conexiones En Guadua Solicitadas a Momento Flector; Universidad Nacional de Colombia: Bogotá, Colombia, 2002. [Google Scholar]

- Davies, C. Bamboo Connections; The University of Bath: Bath, UK, 2008. [Google Scholar]

- Moreira, L.E.; Ghavami, K. Limit State Design of Steel Pin Connections for Bamboo Truss Structures. In Proceedings of the 16th International Conference on Non-conventional Materials and Technologies (16th NOCMAT 2015), Winnipeg, MB, Canada, 10–13 August 2015. [Google Scholar]

- Masdar, A.; Suhendro, B.; Siswosukarto, S.; Sulistyo, D. The Study of Wooden Clamps for Strengthening of Connection on Bamboo Truss Structure. J. Teknol. 2015, 72, 97–103. [Google Scholar] [CrossRef]

- Moreira, L.E.; Ghavami, K. Limits States Analysis for Bamboo Pin Connections. Key Eng. Mater. 2012, 517, 3–12. [Google Scholar] [CrossRef]

- Nie, S.; Ran, S.; Wu, D.; Chen, J.; Wang, H.; Wei, Q. Mechanical Properties of Moso Bamboo Connections with External Clamp Steel Plates. J. Renew. Mater. 2022, 10, 487–510. [Google Scholar] [CrossRef]

- Paraskeva, T.; Pradhan, N.P.N.; Stoura, C.D.; Dimitrakopoulos, E.G. Monotonic Loading Testing and Characterization of New Multi-Full-Culm Bamboo to Steel Connections. Constr. Build. Mater. 2019, 201, 473–483. [Google Scholar] [CrossRef]

- Masdar, A.; Suhendro, B.; Siswosukarto, S.; Sulistyo, D. Determinant of Critical Distance of Bolt on Bamboo Connection. J. Teknol. 2014, 69, 3319. [Google Scholar] [CrossRef]

- Paraskeva, T.S.; Grigoropoulos, G.; Dimitrakopoulos, E.G. Design and Experimental Verification of Easily Constructible Bamboo Footbridges for Rural Areas. Eng. Struct. 2017, 143, 540–548. [Google Scholar] [CrossRef]

- Lin, Q.; Huang, Y.; Li, X.; Yu, W. Effects of Shape, Location and Quantity of the Joint on Bending Properties of Laminated Bamboo Lumber. Constr. Build. Mater. 2020, 230, 117023. [Google Scholar] [CrossRef]

- Wang, Z.; Wei, Y.; Jiang, J.; Zhao, K.; Zheng, K. Comparative Study on Mechanical Behavior of Bamboo-Concrete Connections and Wood-Concrete Connections. Front. Mater. 2020, 7, 587580. [Google Scholar] [CrossRef]

- Bui, Q.-B.; Grillet, A.-C.; Tran, H.-D. A Bamboo Treatment Procedure: Effects on the Durability and Mechanical Performance. Sustainability 2017, 9, 1444. [Google Scholar] [CrossRef]

- Kenya Forestry Research Institute Bamboo Harvesting and Preservation Bamboo Training Manual 1. United Nations Industrial Development Organization, 2012. Available online: http://lankaboo.lk/wp-content/uploads/2016/11/1_bamboo_harvesting_and_prese.pdf (accessed on 12 July 2023).

- Singha, B.L.; Borah, R.K. Traditional Methods of Post Harvest Bamboo Treatment for Durability Enhancement. Int. J. Sci. Eng. Res. 2017, 8, 518–522. [Google Scholar]

- Amede, E.A.; Hailemariama, E.K.; Hailemariam, L.M.; Nuramo, D.A. A review of codes and standards for bamboo structural design. Adv. Mater. Sci. Eng. 2021, 2021, 4788381. [Google Scholar] [CrossRef]

- ISO 22156; Bamboo Structures—Bamboo Culms—Structural Design. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 19624; Bamboo Structures—Grading of Bamboo Culms—Basic Principles and Procedures. International Organization for Standardization: Geneva, Switzerland, 2018.

| Reference | Species | Average Specific Gravity |

|---|---|---|

| Chung and Yu [1] | Bambusa pervariabili | 0.708 |

| Phyllostachya pubescens | 0.794 | |

| Kamthai and Puthson [18] | Dendrocalamus asper | 0.725 |

| Moroz et al. [19] | Arundinaria amabilis | 1.100 |

| Nagarnaik et al. [20] | Dendrocalmus strictus | 0.799 |

| Fabiani [21] | Phyllostachys edulis | 0.765 |

| Phyllostachys viridiglaucescens | 0.805 | |

| Unnikrishnan and Shastry [22] | Not mentioned | 0.731 |

| Trujillo et al. [23] | Guadua angustifolia | 0.669 |

| Parasuram and Baskaran [24] | Bambusa vulgaris | 0.700 |

| Bahtiar et al. [25] | Guadua angustifolia | 0.564 |

| Correal [6] | Dendrocalamus strictus | 0.64 |

| Guadua angustifolia | 0.68 | |

| Phyllostachys edulis | 0.79 | |

| Nugroho et al. [15] | Bambusa vulgaris | 0.698 |

| Gigantochloa pseudoarundinaceae | 0.576 | |

| Dendrocalamus asper | 0.640 | |

| Gigantochloa atroviolacea | 0.626 | |

| Gigantochloa apus | 0.642 | |

| Iswanto et al. [26] | Gigantochloa pruriens | 0.593 |

| Study & Country | Species | Type of Preservation | Moisture Content % | Compressive Strength (MPa) | Tensile Strength (MPa) | Flexural Strength (MPa) | Youngs Modulus (GPa) |

|---|---|---|---|---|---|---|---|

| Chandrakeerthy [12] (Sri Lanka) | Bambusa vulgaris | Seasoning | 30 | 29.33 | 89.91 | 53.88 | 18.57 |

| Chung and Yu [1] (China) | Bambusa pervariabili | Air drying | 5–20 | 69 | - | 82 | 9.3 |

| Phyllostachya pubescens | 5–30 | 75 | - | 88 | 9.4 | ||

| Mahzuz et al. [37] (Bangladesh) | Bambusa balcooa | - | - | - | 92.84 | - | 6.26 |

| Sabbir et al. [38] (Bangladesh) | - | Untreated | - | - | 117.1 | - | 51.4 |

| Sakaray et al. [35] (India) | Bambusa vulgaris | Seasoning and applying a waterproof coating | - | 108.2 | 121.0 | - | 15.00 |

| Parasuram and Baskaran [24] (Sri Lanka) | Bambusa vulgaris | Air seasoning and applying wood preservatives | 13.3 | - | 90.0 | - | 9.92 |

| Fabiani [21] (Italy) | Phyllostachys edulis | - | 43.7 | 55.70 | 126.7 | 97.3 | 13.21 |

| Phyllostachys viridiglaucescens | 24.9 | 56.8 | 159.0 | - | - | ||

| Bhonde et al. [20] (India) | Dendrocalmus strictus | Untreated | 6.92 | 78.03 | 95.78 | - | - |

| Awalluddin et al. [36] (Malayasia) | Dendrocalamus asper | Boric acid treatment | 15.9–18.4 | 73.65 | 232.8 | - | 20.00 |

| Bambusa vulgaris | 14.0–19.2 | 78.74 | 231.67 | - | - | ||

| Gigantochloa scortechinii | 15.6–18.1 | 68.62 | 187.67 | - | - | ||

| Schizos tachyum grande | 16.9–19.6 | 40.03 | 149.20 | - | - | ||

| Nugroho et al. [39] (Indonesia) | Gigantochloa apus | Air drying | 16.9 | - | - | 67.3 | 17.95 |

| Nugroho et al. [15] (Indonesia) | Bambusa vulgaris | Conditioning using a fan in an indoor environment | 15.3 | - | - | 40.05 | - |

| Gigantochloa pseudoarundinaceae | 16.7 | - | - | 63.98 | 10.46 | ||

| Dendrocalamus asper | 14.4 | - | - | 99.74 | 18.00 | ||

| Gigantochloa atroviolacea | 15.9 | - | - | 91.87 | - | ||

| Gigantochloa apus | 16.9 | - | - | 76.9 | 15.68 |

| Species | Tensile Strains | Effective Modulus (MPa) | Young’s Modulus (MPa) | Tensile Strength (MPa) | |||

|---|---|---|---|---|---|---|---|

| Inner | Outer | Inner | Outer | Inner | Outer | ||

| Phyllostachys edulis | 0.014–0.035 | 0.008–0.0019 | 1209–2983 | 30% Lower than the outer | 1976–4694 | 39.9 | 14.5 |

| Phyllostachys bambusoides | 796–1694 | 17.6 | 30.5 | ||||

| Phyllostachys iridescens | 16.9 | 23.2 | |||||

| Phyllostachys violascens | 24.1 | 22.6 | |||||

| Guadua angustifolia | 931–1148 | 17.6 | 30.5 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Madhushan, S.; Buddika, S.; Bandara, S.; Navaratnam, S.; Abeysuriya, N. Uses of Bamboo for Sustainable Construction—A Structural and Durability Perspective—A Review. Sustainability 2023, 15, 11137. https://doi.org/10.3390/su151411137

Madhushan S, Buddika S, Bandara S, Navaratnam S, Abeysuriya N. Uses of Bamboo for Sustainable Construction—A Structural and Durability Perspective—A Review. Sustainability. 2023; 15(14):11137. https://doi.org/10.3390/su151411137

Chicago/Turabian StyleMadhushan, Sumeera, Samith Buddika, Sahan Bandara, Satheeskumar Navaratnam, and Nandana Abeysuriya. 2023. "Uses of Bamboo for Sustainable Construction—A Structural and Durability Perspective—A Review" Sustainability 15, no. 14: 11137. https://doi.org/10.3390/su151411137

APA StyleMadhushan, S., Buddika, S., Bandara, S., Navaratnam, S., & Abeysuriya, N. (2023). Uses of Bamboo for Sustainable Construction—A Structural and Durability Perspective—A Review. Sustainability, 15(14), 11137. https://doi.org/10.3390/su151411137